Abstract

The research was conducted to determine the effects of pretreatment solutions on drying yield, raisin weight, drying time, soluble solids content (SSC), titratable acidity, pH, total phenolics, total flavonoids, and antioxidant activity (2,2-diphenyl-1-picrylhydrazyl [DPPH] and ferric reducing-antioxidant power [FRAP] assays) of the local grape varieties (‘Bilbizeki’, ‘Raşe kewnar’, ‘Kerküş’) grown in Şırnak province in Türkiye. The study determined three different applications for grape drying: drying in sun (control), dipping in water with wood ash + 2.5% olive oil (AWI), and dipping in 5% potassium carbonate + 1.5% olive oil (PSI). It was determined that the raisin belonging to the control application had higher raisin weight than the raisin undergoing AWI application. Significantly, the control application had higher drying yield and drying rate in all grape varieties compared to PSI application. SSC and pH values of drying applications were found to be similar in all grape varieties. However, significantly higher acidity was obtained from the raisin of AWI only in ‘Bilbizeki’ and from the raisin of AWI and PSI in ‘Raşe kewnar’ compared to the raisin of the control application. In ‘Raşe kewnar’ and ‘Kerküş’ grapes, raisin undergoing PSI application showed significantly higher total phenolics, flavonoids, and antioxidant activity (according to FRAP) than raisin undergoing both control and AWI applications. It was determined that the total flavonoids and DPPH antioxidant activity of ‘Bilbizeki’ raisin obtained from the PSI and AWI applications were significantly higher than those dried by the control application. As a result, the effects of pretreatment solutions on drying time, drying yield, and bioactive compounds have been revealed by research. In conclusion, PSI can be recommended as a pretreatment solution to preserve bioactive compounds that are important for human health and accelerate drying time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Anatolia ranks first in the production output of some fruit species, including grape. Türkiye is the sixth-largest country in total grape production in the world and the second-largest country in raisin production after the USA (Keskin et al. 2022). Grape production in Türkiye is focused on meeting fresh grape, raisin, and wine/must grape needs (Unal et al. 2019, 2020). Grapes are produced in almost every region of Türkiye. It is produced in many local products such as vinegar, molasses, and pickled leaves from grapes in Türkiye (Celik 2014). Consumer preferences may differ from region to region. Türkiye produces 3.67 million tons of fresh grape and has 3.9 million decares of vineyard area. Table grape, raisin, as well as traditional products and wine are consumed at a rate of 50.6%, 38.9, and 10.5% of total fresh grape production, respectively (TURKSTAT 2021).

Grape increases the human body’s resistance to diseases with its rich resveratrol, fiber, vitamins, amino acids, phenolics, mineral elements, and antioxidant activity, in addition to its unique taste, flavor, and smell (Perestrelo et al. 2014; Keskin et al. 2022). Many studies have reported that grapes have a high phenol content, thus being a good source of antioxidants (Kammerer et al. 2004; Hollecker et al. 2009; Saglam and Saglam 2018). Recent findings have found that grape reduces the incidence of chronic diseases such as aging, annoying diseases, cardiovascular diseases, and cancer (Kovacic et al. 2005; Hassan and Al-Rawi 2013; Teixeira et al. 2014; Bakhshabadi et al. 2017; Kaya 2021).

Raisins are generally obtained after pre-drying, drying, and post-drying processes. These processes are highly effective on raisin quality due to enzyme activities, sugar content, and drying time (Sério et al. 2014; Keskin et al. 2022). During the drying process, there is a significant concentration difference in total antioxidant activity, volatile compounds, vitamins, minerals, and fiber content compared to fresh grapes (Franco et al. 2004). Fresh grapes can be dried in the sunlight/shade by immersing them in potash or water with ash or by modern methods such as vacuum or microwave drying and hot air drying (Panagopoulou et al. 2019). Grapes are dried in different ways according to consumer taste in Türkiye. Grapes can be dried directly in the sun as well as in the shade. In sunlight drying, the grapes are dried for 2–3 weeks by laying them on soil, concrete floors, or shelves. In shade drying, the grapes are dried for 2 or 4 weeks without being exposed to direct sunlight. Before drying, pretreatment can be done to remove water from the grapes (Esmaiili et al. 2007). In Asia Minor, the immersion solution is used to increase the drying rate of the berries in the cluster. In ancient times, solutions were prepared with wood ash or olive oil, but today, especially olive oil, wood ash, or potassium carbonate is used. Potash solution, a combination of potassium carbonate and fatty acids, is still preferred in commercial cold dips. Water wood ash is also still used as an organic dipping solution. Grapes dried without dipping have a gray-blackish color, tough skin, a dry and oil-free surface, and the sugar content is less than those dried by dipping (Guler and Candemir 2013).

The main aim of this study was to determine the effects of wood ash and potassium carbonate pretreatment solutions on drying yield and bioactive compounds of raisins.

Material and Methods

Plant Materials

In the study, local grape varieties (‘Bilbizeki’, ‘Kerküş’, and ‘Raşe kawner’) (Vitis vinifera L) grown in producer vineyards in the İdil district of Şırnak Province of Türkiye (37°20′30″ N, 41°53′25″ E and altitude 778 m) were used as plant material (Fig. 1). Some berry and cluster characteristics of varieties are shown in Table 1.

Each grape variety was hand-harvested and soluble solids content (SSC) (22–24% for each variety) was used as the harvest criterion. In the study, clusters with uniform berry sizes were selected. Before drying, the average moisture content of the cultivars ranged from 70 to 80%.

Experimental Design and Preparation of Pretreatment Solutions

In a first step, enough grape was taken from each variety. The grapes of each variety were then divided into three groups for each pretreatment solution. The preparation of pretreatment solutions is presented below.

Preparation of water with ash: after adding 7% of oak wood ash to the water, boiling was carried out. The mixture was removed from the fire and cooled, leaving it to rest. After the ash had settled to the bottom, the water was removed and boiled again, and approximately 2.5% olive oil was added.

Preparation of potassium carbonate: 5 kg potassium carbonate was dissolved in 100 L water. Then, 1.5 L olive oil with high acidity (2–4%) was added to this solution (Akdeniz 2011). Subsequently, the bunches were immersed in the prepared solutions for about 5 s. Then, all samples were placed on the white cloth laid on soil to prevent contamination and dried in the sun. The clusters left to dry were controlled at regular intervals to ensure homogeneous drying. The drying process continued until the moisture content of the samples was 17% (Unal et al. 2019, 2020). During the drying process, the average temperature in the province was 31.6 °C, relative air humidity was 16%, precipitation was 0%, and wind speed was 0.6 m/s.

Applications in which no pretreatment solution was used were referred to as control, while immersion in potassium carbonate and water with ash solutions were referred to as PSI and AWI applications, respectively.

Berry Weight, Drying Yield, and Drying Time

The drying yield was determined by weighing berry weights using digital scales with a precision of 0.01 g (WL-6002) before and after drying, and the change was expressed as a percentage. Raisin weight was determined by measuring with digital scales of 50 raisin in each replication and the results were expressed as grams. Drying time was calculated as the number of days from the day the grapes began to dry to the day when drying ended.

Soluble Solids Content (SSC), Titratable Acidity, and pH

First, 10‑g raisin samples were taken from each replication and their seeds were removed. The samples were crushed with an electric blender and 100 ml of distilled water was poured on them; they were then kept at room condition for 6 h. Finally, they were filtered with cheesecloth and a sufficient amount of the filtrate obtained was taken; SSC was measured with a digital refractometer (RA-600), and the values were expressed as percentages (Uzun et al. 2020). For titratable acidity, a sufficient amount of the filtrate obtained was taken and determined by titration with 0.1 N NaOH, and the results were given as g tartaric acid L−1 (Uzun et al. 2020). The pH of the filtrate was determined with a pH meter (7D 1000 pH/mV, Adwa).

Total Phenolics, Total Flavonoids, and Antioxidant Activity

Enough raisins were taken in each replication, and the seeds were first separated from the fruit flesh. Then, raisin samples were homogenized by shredding in an electric shredder (Waring, Torrington, CT, USA). Subsequently, a 2‑g raisin sample from each replication of each variety was taken into a 15-ml falcon tube and 8 ml methanol was added to this. The samples were kept at 4 °C for 2 days and then centrifuged for 5 min at 12,000 rpm (Hettich-Zentrifugen, Universal 320‑R, Germany). Total phenolics, flavonoids, and antioxidant activity (2,2-diphenyl-1-picrylhydrazyl [DPPH] and ferric reducing-antioxidant power [FRAP] assays) were analyzed by taking a sufficient amount of extract from the tube. Readings were carried out on a UV-vis 1280 spectrophotometer (Shimadzu, Japan).

Total Phenolics

Total phenolics were determined using the Folin-Ciocalteu’s reagent according to the method reported by Ozturk et al. (2019). First, 600 μL raisin extract was taken and 4.0 mL distilled water was added. Then, 100 μL Folin-Ciocalteu’s reagent and 300 μL sodium carbonate (Na2CO3) at 2% concentration were added and incubated for 2 h at room conditions. After incubation, the solution, which turned greenish, was read in a UV-vis spectrophotometer (Shimadzu, Japan) at 760 nm wavelength and the results were calculated as gallic acid equivalent. Results were expressed as g GAE kg−1 dry weight (dw).

Total Flavonoids

Total flavonoids were determined according to the method reported by Zhishen et al. (1999). A total of 600 µL of the extractant was taken and 3.7 mL methanol was added to make up to 4.3 mL. Then, 100 µL 10% aluminum nitrate (Al[NO3]3) and 0.1 M ammonium acetate (NH4CH3CO2) were added to this, and the solution was completed to 4.5 mL and kept in the dark at room conditions for 40 min. In the samples, readings were done at 415 nm wavelength in a UV-vis spectrophotometer. Results were presented as g quercetin equivalent (QE) kg–1 dw.

DPPH Antioxidant Activity

DPPH free radical scavenging activity of the extract obtained from the samples was determined according to the method presented by (Blois 1958). In the study, DPPH solution was chosen as the free radical, 500 µL of the extract was first taken, and 2.5 mL of ethanol was added to make up to 3.0 mL. The total volumes of 0.5 ml of 0.1 mM ethanol solution of DPPH free radical, sample extract, and standard antioxidant solution (50–500 µg/mL) were made up to 4 ml. The resulting solution was mixed with vortex for 1 min and placed for 30 min at room conditions. The absorbance of the solution was then read at 517 nm wavelength in a UV-vis spectrophotometer. Results were presented as mmol Trolox equivalent (TE) kg−1 dw.

Ferric ions (Fe+3) Reducing Antioxidant Power (FRAP)

For FRAP analysis (Ozturk et al. 2019), phosphate buffer (1.15 mL, 0.2 M, pH 6.7) was first prepared, and 100 µL of raisin extract sample was coated with potassium ferricyanide (K3Fe (CN)6) (1.25 mL, 1%) and added together. Then, the reaction mixture was kept at 50 °C for 20 min and cooled to room temperature. Subsequently, trichloroacetic acid (TCA, [1.25 mL, 10%]) and iron chloride (FeCl3 [0.25 mL, 0.1%]) were added and mixed with vortex for 1 min. Finally, the absorbance of the solution was read at 700 nm in a UV-vis spectrophotometer. Results are presented as mmol Trolox equivalent (TE) kg−1 dw.

Statistical Analysis

The experiment was designed according to a completely randomized parcels design with three replications. Whether the data were homogeneously distributed was checked by Kolmogorov-Smirnov Test. Levene’s test confirmed homogeneity control of the group variances. Tukey’s multiple-comparison test was used to compare treatments and the statistical significance level was set at P < 0.05. Statistical analyses were performed using the SPSS 17 software (IBM Corp., Chicago, USA).

Results

Raisin Weight, Drying Yield, and Drying Time

There was no effect of pretreatment solutions on raisin weight in ‘Bilbizeki’ and ‘Raşe kawner’ varieties. However, in the ‘Kerküş’ variety, the raisin weight of the control treatment was significantly higher (P < 0.05) than that of the AWI treatment. In terms of drying yield, the control treatment was significantly higher in ‘Bilbizeki’ variety compared to other treatments. However, the drying yield of both control and AWI-treated raisin in ‘Raşe kawner’ and ‘Kerküş’ varieties was significantly higher than that of PSI-treated raisin. Considering the drying time (speed) values, it was determined that the drying time (speed) of the raisin belonging to the control treatment in all varieties was significantly higher than that of both AWI and PSI treatments. Drying times (speed) were close to each other in AWI- and PSI-treated raisin (Table 2).

Soluble Solids Content (SSC), Titratable Acidity, and pH

It was observed that pretreatment solutions had no effect on SSC and pH in all grape varieties. On the other hand, the effect of pretreatment solutions on titratable acidity was not determined in the ‘Kerküş’ grape variety. However, the effect of the pretreatment solutions was significant in ‘Bilbizeki’ and ‘Raşe kawner’ grape varieties. In ‘Bilbizeki’ variety, raisin that received AWI and PSI treatments had higher titratable acidity than control raisin. It was also observed that the titratable acidity content of both AWI and PSI treatments in the ‘Raşe kawner’ variety was significantly higher than control treatment (Table 3).

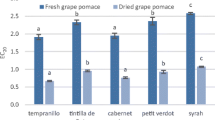

Total Phenolics, Total Flavonoids, and Antioxidant Activity

There was no effect for pretreatment solutions on total phenolics and antioxidant activity (in FRAP assay) in the ‘Bilbizeki’ grape variety. However, it was determined that the total flavonoid content and antioxidant activity (in DPPH) of AWI- and PSI-treated raisin were significantly higher than control raisin. Total phenolics, flavonoids, and antioxidant activity (in FRAP assay) of raisin receiving PSI treatment were significantly higher than the content of raisin receiving both control and AWI treatment in ‘Raşe kawner’ and ‘Kerküş’ grape varieties. On the other hand, in ‘Raşe kawner’ variety, it was observed that antioxidant activities according to the FRAP test were significantly different from all other treatments. The highest and lowest antioxidant activity were obtained from raisin receiving PSI and AWI treatments, respectively (Table 4).

Discussion

Raisin Weight, Drying Yield, and Drying Time

Drying time and yield are essential parameters in fruit drying (Mazlum and Nizamlioğlu 2021; Keskin et al. 2022). In the study, the effect of pretreatment solutions on drying yield and drying time was determined in general. However, the effect of pretreatment solutions on raisin weight was significant in ‘Kerküş’ grape variety. Indeed, Jadhav et al. (2010) determined that the solutions obtained from potassium carbonate + olive oil mixtures in different concentrations in ‘Thompson seedless’ grape variety affected the raisin weight. Zemni et al. (2017) found that the raisin weight in the ‘Italia Muscat’ grape variety was 1.45 g in the sun-drying application, 1.75 g in those dried by dipping in 6% K2CO3 + 0.5 olive oil solution, and 1.06 g in those dried by dipping in 1.0% NaOH solution. Generally, 1 kg raisin can be obtained from 3–5 kg of fresh grapes, and the drying yield can vary between 20 and 35% (Guler and Candemir 2013). The drying yield in our study varied between 19.17 and 34.97%. Our study observed that pretreatment solutions had a significant effect on drying yield in all varieties. It was determined that the raisin samples dipped in potash solution had a lower drying yield. Celik (2019) reported that the drying yield was 21, 20.65, and 18.76% in ‘Razakı’, ‘Osmanca’, and ‘Gelin’ varieties, respectively, and the difference between control and other treatments (wood ash and potash solution) was statistically significant in terms of drying yield. On the other hand, Kapuci (2021) reported that the drying yield differs depending on the applied solutions, varying between 24.31 and 26.54% in the ‘Bineteti’ variety and between 18.63 and 20.20% in the ‘Zeyti’ variety. Pretreatment solutions had a significant effect on drying time. During the dipping process, the solutions cause the wax layer on the berry to break down (Matteo et al. 2000; Esmaiili et al. 2007; Dev et al. 2008). It was observed in the study that raisin receiving AWI and PSI treatments (dipped in the melt) dried in a shorter time than raisin receiving control treatment. Similarly, Tulasidas et al. (1996) reported on grapes dipped in 0.5% NaCO3, 0.5% NaOH + 2% ethyl oleate, 0.5% NaOH + 3% ethyl oleate, and 2.5% K2CO3 + 3% ethyl oleate solution and dried at 11.07, 8.7, and 11.0 h, respectively. In the ‘Rubi’ grape variety, the drying times were determined as 204.6 h in control and 95.0 and 93.3 h in the grapes dipped in 6.0% K2CO3 + 0.5% olive oil and 6.0% K2CO3 + 2.5% olive oil solutions for 2 min, respectively (Telis et al. 2006). It is stated that a variety of characteristics such as cluster size and density, berry size, skin thickness, the water content of grapes and sugar content of grapes, drying technique, harvest time, climatic conditions during the harvesting period, and environmental conditions during the drying process affect drying yield and duration (Jalili Marandi 1996; Christensen and Peacock 2000; Ramming 2009).

Soluble Solids Content (SSC), Titratable Acidity, and pH

Compared to fresh grapes, raisin have higher SSC. While the sugar rate in fresh grapes is around 20% at the beginning of drying, this rate can increase up to 85% after drying (Akdeniz 2011). However, it has also been reported that the drying method can affect this rate (Yalcinkaya 2016). Having said that, in this study, an effect for drying methods on SSC and pH was not observed. However, it was noticed that titratable acidity caused differences in ‘Bilbizeki’ and ‘Raşe kawner’ varieties. Jadhav et al. (2010) reported that the SSC content of raisins dipped in potassium carbonate + olive oil solution in the ‘Thompson seedless’ grape variety ranged from 70.71 to 82.97%, and the titratable acidity content ranged from 0.25 to 0.32%. The acidity of raisins, which were also obtained according to different dipping solutions and drying techniques, ranged from 0.46 to 0.51% in the ‘Thompson seedless’ variety and from 0.54 to 0.63% in ‘Perlette’ variety (Mandal and Thakur 2015). The researchers’ findings showed that the SSC contents obtained in the study were at a similar level and the acidity content was higher. The difference in acidity may be due to the drying technique, the grape’s ecology, and the variety (Foshanji et al. 2018). In line with our findings, Yalcinkaya (2016) reported that the pH values of raisins varied between 4.29 and 4.52, acidity values between 0.77 and 1.05%, and SSC between 81.74 and 87.13% with different drying applications.

Total Phenolics, Total Flavonoids, and Antioxidant Activity

Due to the desire of consumers to consume foods with rich phenol content and their high antioxidant activity, different techniques are used both before and after harvest in fruit and vegetable production. Today, reducing the loss of nutrient content in the product processing process is one of the most central issues for food manufacturers (Mazlum and Nizamlioğlu 2021; Keskin et al. 2022). In this study carried out in this context, the effects of pretreatment solutions on bioactive compounds of raisin were examined and differences were observed in bioactive compounds depending on the pretreatment solutions. In general, it was determined that raisin dipped in potash solution (PSI) had higher total phenolics, flavonoids, and antioxidant activity. It was reported in previous studies that there are differences in bioactive compounds depending on drying methods (Breksa et al. 2010; Zemni et al. 2017; Foshanji et al. 2018). In a study conducted on the ‘Thompson Seedless’ grape variety, Yeung et al. (2003) reported that the total phenolic content of raisin dipped in sulfur dioxide was higher than those dipped in hot water and those dried in the sun.

Similarly, it was stated that the phenol content of the ‘Italia Muscat’ variety changes depending on the drying technique (Zemni et al. 2017). Similar to our findings, Celik (2019) and Kapuci (2021) reported that bioactive compounds differ according to pretreatment solutions, and dipped raisins contain higher total phenolics and antioxidant activity than sun-dried ones. In contrast, Yalcinkaya (2016) stated that lower bioactive compounds were obtained from the application of 3% K2CO3 + 1.5% olive oil compared to sun drying. The diversity of varieties and ecology may have caused the difference between the findings. Many factors such as drying time, drying conditions, grape variety, ecology, and maturity can affect bioactive compounds (Mazlum and Nizamlioğlu 2021).

Conclusion

The effects of pretreatment solutions on grape drying time, drying yield, and bioactive compounds have thus been revealed by research. Finally, 5% potassium carbonate + 1.5% olive oil solution (PSI) can be recommended as a pretreatment solution to preserve bioactive compounds that are important for human health and to accelerate the drying time.

References

Akdeniz B (2011) Geleneksel usullerde Sultani Çekirdeksiz üzüm çeşidinin kurutulması. Gıda Teknol Elektron Derg 6(1):13–22

Bakhshabadi H, Mirzaei H, Ghodsvali A, Jafari SM, Ziaiifar AM, Farzaneh V (2017) The effect of microwave pretreatment on some physico-chemical properties and bioactivity of black cumin seeds. Ind Crops Prod 97:1–9

Blois MS (1958) Antioxidant determinations by the use of a stable free radical. Nature 181(4617):1199–1200

Breksa AP III, Takeoka GR, Hidalgo MB, Vilches A, Vasse J, Ramming DW (2010) Antioxidant activity and phenolic content of 16 raisin grape (Vitis vinifera L.) cultivars and selections. Food Chem 121(3):740–745

Celik H (2014) Üzümün Besin Değeri. TÜRKTOB (Türkiye Tohumcular Birliği Dergisi)

Celik M (2019) The effects of some local cultivars and pretreatment solutions on drying period and raisin grape quality. Erwerbs-Obstbau 61:67–74

Christensen LP, Peacock WL (2000) The raisin drying process. In: Christensen LP (ed) Raisin production manual university of California, 1st edn., pp 207–216

Dev SRS, Padmini T, Adedeji A, Gariépy Y, Raghavan GSV (2008) A comparative study on the effect of chemical, microwave, and pulsed electric pretreatments on convective drying and quality of raisins. Dry Technol 26(10):1238–1243

Esmaiili M, Sotudeh-Gharebagh R, Cronin K, Mousavi MAE, Rezazadeh G (2007) Grape drying: a review. Food Rev Int 23:257–280

Foshanji AS, Krishna HC, Vasudeva KR, Ramegowda GK, Shankarappa TH, Bhuvaneswar S, Sahel NA (2018) Effects of pretreatments and drying methods on nutritional and sensory quality of raisin. J Pharmacogn Phytochem 7(4):3079–3083

Franco M, Peinado RA, Medina M, Moreno J (2004) Off-vine grape drying effect on volatile compounds and aromatic series in must from Pedro Ximénez grape variety. J Agric Food Chem 52(12):3905–3910

Guler A, Candemir A (2013) Çekirdeksiz Kuru Üzüm Üretiminde Alternatif Çeşitler ve Kuru Üzüm Karakteristiklerinin Belirlenmesi. Selcuk Tarım Gıda Biliml Derg A 27:348–358 (Türkiye 8. Bağcılık ve Teknolojileri Sempozyumu, 47 (Özel Sayısı)

Hassan HA, Al-Rawi MM (2013) Grape seeds proanthocyanidin extract as a hepatic-reno-protective agent against gibberellic acid induced oxidative stress and cellular alterations. Cytotechnology 65:567–576

Hollecker L, Pinna M, Filippino G, Scrugli S, Pinna B, Argiolas F (2009) Simultaneous determination of polyphenolic compounds in red and White grapes grown in Sardinia by high performance liquid chromatography–electron spray ionization–mass spectrometry. J Chromatogr A 1215:3402–3408

Jadhav PD, Kakade DK, Suryawanshı GB, Ruggue VC, Chavan ND, Kumar VVS (2010) Effect of different pretreatments on physico-chemical parameters of raisins prepared from variety Thompson Seedless. TAJH 5(1):237–239

Jalili Marandi R (1996) Study on the different kind of raisin processing. Zeitone 32:124–126

Kammerer D, Claus A, Carle R, Schieber A (2004) Polyphenol screening of pomace from red and white grape varieties (Vitis vinifera L.) by HPLC-DAD-MS/MS. J Agric Food Chem 52:4360–4367

Kapuci F (2021) Gercüş (Batman) Yöresinde Yetiştirilen Bazı Çekirdekli Yerel Üzüm Çeşitlerinin Kurutulması Üzerine Araştırmalar (yüksek lisans tezi). Van Yüzüncü Yıl Üniversitesi, Fen Bilimleri Enstitüsü, Van

Kaya O (2021) Antioxidant and total phenolic contents of some native grape cultivars grown in adıyaman province. Karadeniz Zirvesi 5. Uluslararası Uygulamalı Bilimler Kongresi, Ordu, 24 Feb 2021

Keskin N, Kaya O, Ates F, Turan M, Gamboa GG (2022) Drying grapes after the application of different dipping solutions: effects on hormones, minerals, vitamins, and antioxidant enzymes in Gök Üzüm (Vitis vinifera L.) raisins. Plants 11(4):529

Kovacic P, Pozos RS, Somanathan R, Shangari N, O’Brien PJ (2005) Mechanism of mitochondrial uncouplers, inhibitors, and toxins: focus on electron transfer, free radicals, and structure-activity relationships. CMC 12(22):2601–2623

Mandal G, Thakur AK (2015) Preparation of raisin from grapes varieties grown in Punjab with different processing treatments. Int J Bio-res Env Agril Sci 1(1):25–31

Matteo DM, Cinquanta L, Galiero G, Crescitelli S (2000) Effect of povel physical pretreatment process on the drying kinetics of seedless grapes. J Food Eng 46:83–89

Mazlum I, Nizamlioğlu NM (2021) The effects of different drying methods on some physical and chemical properties of ‘Eksikara’ grape cultivar grown in Karaman region. J Berry Res 11(3):395–418

Ozturk A, Yıldız K, Ozturk B, Karakaya O, Gun S, Uzun S, Gundogdu M (2019) Maintaining postharvest quality of medlar (Mespilus germanica) fruit using modified atmosphere packsging and methyl jasmonate. LWT 111:117–124

Panagopoulou EA, Chiou A, Karathanos VT (2019) Water-soluble vitamin content of sun-dried Corinthian raisins (Vitis vinifera L., var. Apyrena). J Sci Food Agric 99:5327–5333 (CrossRef)

Perestrelo R, Silva C, Pereira J, Câmara JS (2014) Healthy effects of bioactive metabolites from Vitis vinifera L. grapes: a review. In: Grapes: Production, phenolic composition and potential biomedical effects, pp 305–338

Ramming DW (2009) Water loss from fresh berries of raisin cultivars under controlled drying conditions. Am J Enol Vitic 60:208–214

Saglam ÖC, Saglam H (2018) İnsanlık Tarihinde Üzümün Önemi. J Agric 1(2):1–10 (Review article)

Sério S, Rivero-Pérez MD, Correia AC, Jordão AM, González-San JML (2014) Analysis of commercial grape raisins: Phenolic content, antioxidant capacity and radical scavenger activity. Cienc Tec Vitivin 29:1–8

Teixeira A, Baenas N, Dominguez-Perles R, Barros A, Rosa E, Moreno DA, Garcia-Viguera C (2014) Natural bioactive compounds from winery by-products as health promoters: a review. Int J Mol Sci 15:15638–15678

Telis VRN, Lourençon VA, Gabas AL, Telis-Romero J (2006) Drying rates of Rubi grapes submitted to chemical pretreatments for raisin production. Pesq Agropec Bras 41(3):503–509

Tulasidas TN, Raghavan GSV, Norris ER (1996) Effects of dipping and washing pretreatments on microwave drying of grapes. J Food Process Engineering 19:15–25

TURKSTAT (2021) https://data.tuik.gov. Accessed: 30.05.2022

Unal MS, Saglam H, Kirkaya H (2019) Şırnak ili İdil ilçesinde yetiştirilen mahalli üzüm çeşitlerinin değerlendirilme şekilleri. Bahri Dagdas Bitkisel Arastırma Derg 8(1):159–162

Unal MS, Ucas C, Sezgin H (2020) Midyat/Mardin İlçesinde Yöresel Üzüm Çeşitlerini Değerlendirilme Şekilleri. Bahri Dagdas Bitkisel Arastırma Derg 9(2):268–279

Uzun T, Hallac B, Altin A, Kaya G (2020) Midyat/Mardin ve Beşiri/Batman İlçelerinde Satışa Sunulan Bazı Kuru Üzüm Çeşitlerinin Fizikokimyasal Özelliklerinin Karşılaştırılması. Turk J Agr Eng Res 1(2):404–414

Yalcinkaya E (2016) Kuru Besni Üzümünde Bandırma Eriyiğinin (Potasa Çözeltisi) Aroma Profili Üzerine Etkileri (yüksek lisans tezi, basılmamış). İnönü Üniversitesi, Fen Bilimleri Enstitüsü, Malatya

Yeung CK, Glahn RP, Wu X, Liu RH, Miller DD (2003) In Vitro iron bioavailability and antioxidant activity of raisins. J Food Science 68(2):701–705

Zemni H, Sghaier A, Khiari R, Chebil S, Ismail HB, Nefzaoui R, Hamdi Z, Lasram S (2017) Physicochemical, phytochemical and mycological characteristics of Italia Muscat raisins obtained using different pretreatments and drying techniques. Food Bioprocess Technol 10:479–490

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64(4):555–559

Acknowledgements

The author would like to thank the Scientific Research Unit of Şırnak University for the financial support (project number: 2022.FNAP. 13.01.02).

Author information

Authors and Affiliations

Contributions

Mehmet Settar Unal: methodology, investigation, conceptualization, validation, writing—original draft.

Corresponding author

Ethics declarations

Conflict of interest

M.S. Unal declares that he has no competing interests.

Rights and permissions

Springer Nature oder sein Lizenzgeber hält die ausschließlichen Nutzungsrechte an diesem Artikel kraft eines Verlagsvertrags mit dem/den Autor*in(nen) oder anderen Rechteinhaber*in(nen); die Selbstarchivierung der akzeptierten Manuskriptversion dieses Artikels durch Autor*in(nen) unterliegt ausschließlich den Bedingungen dieses Verlagsvertrags und dem geltenden Recht.

About this article

Cite this article

Unal, M.S. Effects of Pretreatment Solutions on Drying Yield and Bioactive Compounds of Local Grape Raisin. Erwerbs-Obstbau 65, 1881–1887 (2023). https://doi.org/10.1007/s10341-022-00757-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-022-00757-9