Abstract

Grape pomace is a high potential by-product due to its content of valuable compounds, such as pectin. It is highly perishable and requires pretreatment for its conservation. Therefore, this work aims to evaluate the effect of four drying methods: convective drying, freeze-drying, infrared-radiation drying, and solar drying, on the properties of pectin fractions obtained from pisco grape pomace. Freeze-drying and convection drying reported the highest extraction yields. The drying of grape pomace by all the methods evaluated decreased the degree of esterification on the pectins. The highest reducing sugar content (19.8%) and antioxidant capacity (7238 µmol TE/100 g d.m.) were obtained from freeze-drying pretreatment. The highest galacturonic acid content (28.4%) and molecular weight (63.3 kDa) were found in the pectin obtained from the convective drying pretreatment. Thus, each drying method evaluated affects the pectin’s physicochemical properties differently. Also, pectin fractions with a high degree of methoxylation and a high antioxidant capacity were obtained from pisco grape pomace. This study provides information about the effect of drying as a pretreatment of pisco grape pomace on the properties of the pectin obtained from it.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of novelty

Grape pomace is the main by-product of the pisco and wine industry. Despite its high content of valuable compounds, such as pectin, it is mainly used to produce compost. On the other hand, large quantities of this by-product are produced in a short period. So a strategy of revaluation and conservation of pisco grape pomace is needed. The novelty of this work focuses on using this by-product to obtain pectin, considering that the processes applied for its conservation could influence the properties of pectin. In addition, the pectin obtained from grape pomace has different physicochemical properties from those found in citric pectin, which could favor the obtaining of pectin oligosaccharides, which are compounds with prebiotic potential.

Introduction

In recent years, the interest in reducing food waste increased for environmental and sustainable development reasons [1]. Food waste is a valuable source of high added-value compounds like polysaccharides, polyphenols, essential oils, pigments, proteins, flavorings, enzymes, dietary fiber, among others, and there is an increasing interest in research food waste valorization from different industries [2]. Grape pomace is the principal solid by-product generated during winemaking by the winery industry. It is constituted by skin, seed, and stalks grape represents approximately 20% of the total volume of grape processed [3]. Also, grape pomace is a by-product with a high potential for its content of unfermented sugars, alcohol, polyphenols, tannins, pigments, and other valuable products, according to be the grape variety [4, 5].

While so many studies have focused on this by-product, few talk about pomace from white varieties. Industries that use the white grape to produce white wine or pisco (a distilled alcohol made from grapes) need to find revaluation options that are not only considered for compost and animal feed [6]. By-products of the wine industry were widely used for their polyphenol and oil content, but in recent years it has been taking attention for its fiber content, specifically pectin [4, 7]. Pectin is a heterogeneous polysaccharide located in the middle lamella and the cell wall of plants. It is widely used in the food industry as a gelling agent, stabilizing, and thickening agent [8].

The pectin content in grape pomace could depend on the grape variety and the state of maturity of the grape [9, 10], the industrial process, and the addition of pectolytic enzymes in the winemaking process [11]. A few authors have explored the use of pomace as a source for obtaining pectin [12, 13]. An analysis of carbohydrates in pomace from ten grape varieties as raw material to produce fiber concentrates would show that pectic substances are the main component of the cell wall (40 to 54% of the total cell wall) [14]. Minjares-Fuentes et al. [12] studied the optimization of pectin extraction from grape pomace of Cabernet Sauvignon with a yield of 32, 3%, and Colodel et al. [13] obtained pectin from Chardonnay grape pomace with a yield of 11.1%. The previous shows that grape pomace is a very interesting source of pectin; even so, no studies were found on the effect of a grape pomace pretreatment on the properties of pectin, nor the use of grape pomace from the pisco industry as a source of pectin.

On the other hand, the harvest of grapes occurs only for 2–3 months per year. For this reason, it is necessary to apply conservation strategies to avoid contamination of the raw material until the extraction of different compounds. Furthermore, the grape pomace is highly perishable due to its high moisture content (60–80%) [14]. Therefore, drying pomace could be necessary before being processed to extract biocompounds [15]. Also, drying produces ruptures and destruction of the cell wall and, consequently, larger pores that could improve the extraction of pectin [16]. Monsoor [17] studied the effect of the drying method on the functional properties of soy hull pectin, and the highest extraction yield was achieved when drying was carried out by convective drying and freeze-drying. Therefore, the dehydration of the grape pomace could have a double purpose: stabilization against deterioration and the increase in the extraction of pectin, and also these results could be influenced by the dehydration method used.

According to the International Organization of Vine and Wine, Chile is the sixth major producer and the fourth exporter of wine in the world [18]. In 2019, vineyard surface area in Chile exceeded 136 thousand ha, of which 26.4% correspond to white varieties. The Chilean pisco industry covers 9812 hectares of grape cultivation, of which 89% belong to the Coquimbo Region [19]. The grape variety Pedro Jimenez (Vitis vinifera l.) is the most cultivated for Pisco production in Chile, corresponding to 48% of the total strains cultivated for this purpose. The main residue of the pisco industry as the winery industry is grape pomace. Approximately 13,000 tons of grape pomace are generated per year in Chile (approximate calculation based on the grape harvested per hectare). It is principally used for compost and animal feed production. Also, the final disposal of grape pomace implies an additional cost for the pisco and wine industry; additionally, its revaluation is minimal.

The literature shows that grape pomace could be an interesting source of pectin, the little information on the effect of drying methods on the properties of pectin and, the need to revalue the by-products of the wine and pisco industry through the exploration of new alternatives. Therefore, the objective of this study was to evaluate the effect of four drying methods on the extraction yield, the physical–chemical properties, and the composition of the obtained pectin of pisco grape pomace.

Materials and methods

Raw material and reagents

Pisco grape pomace (PGP) was collected from the Pisco CCU S.A. processing plant in Ovalle city, Region Coquimbo, Chile (latitude 30° 39′ 02.87′′ S and longitude 71° 19′ 19.40′′ W, 215 m altitude). It was composed of 95% Pedro Jimenez (Vitis vinifera L.) variety, 4.65% Muscat Rose (Vitis vinifera L.) variety, and 0.35% Muscat of Alexandria (Vitis vinifera L.) variety, harvested in autumn early. It was recently pressed in the moment of collection. On the collection day, grape pomace was packed in bags of 3 kg approx. and stored at − 20 °C for further processing.

Commercial pectin from citrus peel (Sigma-Aldrich, Co. (St. Louis, MO, USA)) with galacturonic ≥ 74.0% (dry basis) was used as reference. Galacturonic acid was purchased from Sigma-Aldrich, Co. (St. Louis, MO, USA). All other chemicals used in this study were analytical grade.

Drying methods

Frozen PGP was thawed in a cold room at 4 °C for 15 h before drying by four different methods. Convective drying (CD) was carried out for 8 h until constant weight in a convective dryer designed and built at the Food Engineering Department of Universidad de La Serena, Chile [20]. The air velocity was set at 1.5 m/s and the temperature at 50 °C. The pomace samples, around 400 g per tray, were spread homogeneously on two drying trays. The energy consumption of the CD method was 126.94 kWh/kg.

Infrared radiation drying (IR) was carried out in an electric dryer oven with two infrared incandescent lamps of 175 W (Philips, PAR38 IR 175 W E27 240 V CL 1CT/12, Amsterdam, Netherlands) designed and built in the Food Engineering Department of Universidad de La Serena [21]. The drying temperature was 50 °C. The tray was positioned at 0.25 m from infrared lamps. Batches of 150 g of grape pomace per tray were dried. The drying time was 5.5 h. The energy consumption of the IR method was 66.96 kWh/kg.

Freeze-drying (FD) was carried out in a freeze-dryer (VirTis Wizard 2.0 Advantage Plus XL-70, Gardiner, NY, USA.) for 65 h in two stages: primary drying with six ramps temperatures from -20 to 15 °C and the secondary drying at 20 °C. The condenser temperature and chamber vacuum pressure were fixed at − 55 °C and 0.027 kPa, respectively. The sample (400 g) was frozen at − 80 °C a day before the freeze-drying process. The energy consumption of the FD method was 357.5 kWh/kg.

Solar drying (SD) was carried out in a solar dryer designed and built in the Food Engineering Department of Universidad de La Serena and installed in Elqui Valley [21]. The solar drying has a copper plate as a collector to absorb incident solar radiation and a cover of a transparent glass sheet. The pomace sample (4 kg) was dried for 72 h.

Dried pomace was milled and sieved (< 0.75 mm) in a Cross Knives mill (Retch Cross SK 100 comfort, Hann, Germany) to obtain powder of PGP.

Proximate composition analysis

Moisture content was determined by gravimetry with AOAC method No. 934.06. Crude protein content was determined using the Kjeldahl method with a conversion factor of 6.25 (AOAC No. 960.52). Lipid content was analyzed by gravimetry using Soxhlet extraction (AOAC No. 960.39). Crude ash content was estimated by incineration in a muffle furnace at 550 °C (AOAC No. 923.03). Carbohydrate was calculated by difference. All methodologies followed the methodology of the Association of Official Analytical Chemists (AOAC 1990). The water activity (aw) was measured at 25 °C using AQUA LAB equipment (4TE, Pullman, WA, USA). All measurements were done in triplicate. The moisture content was expressed over a wet basis (w.b.). The result of protein, lipid, ash, and carbohydrate content was expressed over a dry matter basis (d.m.).

Pectin extraction

Pectin was extracted using a hot-acid extraction method modified from Geerkens et al. [22]. Distilled water adjusted with HCl to reach pH 1.5 was mixed with PGP powder (50 g in 300 mL). Hydrolysis was carried out at 50 °C with constant stirring for 4 h using a magnetic stirrer MS-H280-Pro (Dragon Lab, Beijing, China). The solution first was filtered and pressed manually using a cloth strainer and then centrifugated at 3220 g for 20 min in centrifuge 5810R (Eppendorf, Hamburg, Germany). The pH of the supernatant was adjusted at pH > 3 with NaOH, and then this solution was added to 300 mL of ethanol precooling at − 20 °C to precipitate pectin. It was left to stand overnight at − 20 °C and centrifuged at 3220 g for 20 min. The resulting pellet was lyophilized to obtain pectin of PGP. The pectin yield was calculated according to Eq. (1).

Response surface methodology (RSM) was used to maximize the yield of pectin extraction from grape pomace. A central composite design (CCD) with two independent variables was employed. The variables studied were extraction time (A) in a range of 1 to 4 h and pH extraction (B) in a range of 1.5 to 4. The response variable to be optimized was the extraction yield (R1). The design consisted of 13 experiments with five replicates of the central point (2.5 h and pH 2.5) (Online Resource 1). A quadratic polynomial model was used to process the results. For data processing, the Design Expert 11 software was used.

Pectin characterization

Fourier transform infrared (FTIR) spectrometry

Pectin samples resulting from yield maximization by response surface were analyzed by FTIR to observe the effect of the evaluated conditions on the degree of esterification (DE). FTIR analysis was performed on an infrared spectrophotometer SPECTRUM TWO (PerkinElmer, Massachusetts, USA). The spectra obtained adjusted the wavenumber between 4000 and 400 cm−1, 16 sweeps per sample, and the output was reported in percentage of transmittance vs. wave number. The effect on the DE was observed by comparing the intensity of the bands between 1740 and 1630 cm−1 corresponding to methyl-esterified and non-methyl-esterified carboxyl groups, respectively [23].

Degree of esterification (DE)

The degree of esterification (DE) was determined by a titrimetric method as Bochek et al. [24] with modification. First, a pectin solution (0.5 g/100 mL) was titrated with NaOH 0.1 N until pH 8.5; this volume was registered as V1. Then 25 mL of NaOH 0.1 N was added, left to stand for 30 min, and neutralized with 25 ml of HCl 0.25 N. Finally, the solution was titrated with NaOH 0.1 N until pH 7.5. This second volume was registered as V2. The DE was calculated using Eq. (2).

Composition of pectin

Humidity and ash of pectin were determined by the same method of the proximate composition described in section “Proximate composition analysis”. The protein content of pectin was determined using a Bradford method assay with bovine serum albumin as the standard [25]. Reducing ends of pectin was determined by the 3,5-dinitrosalicylic acid (DNS) assay for reducing sugar using galacturonic acid as standard. The galacturonic acid content was determined using the m-hydroxydiphenyl method [26].

Molecular weight distribution

The molecular weight distribution of pectin samples was measured by high-performance size exclusion chromatography (HPSEC) using a JASCO LC-4000 HPLC System equipped with a refractive index detector (RID). The system was run at 0.2 mL/min with an Acclaim SEC-1000 (150 × 7.8 mm) analytical column (Thermo Scientific, USA) thermostated at 55 °C. The mobile phase was phosphate buffer (0.0177 M KH2P04 and 0.0079 M K2HP04) [27]. Kit Pullulan standards from Mp 342 Da to 708 kDa (PSS GmbH, Japan) were used as calibration standards. Each pectin sample was dissolved (20 mg/mL) in 100 mM acetate buffer, pH 4.5 at 50 °C. Before being injected, each sample was diluted (1:20) in the mobile phase and filtered (0.2 µm).

DPPH free radical scavenging assay

The antioxidant capacity of pectin samples was determined by the DPPH method described by Sun et al. [28], adapted to microplate assay. Each pectin sample was dissolved (5 mg/mL) in distilled water at 50 °C overnight. Then dilutions were made (0.05; 0.15; 0.25; 0.5; 1.0; 1.5; 2.0; 3.0; 4.0 and 5.0 mg/mL) in distilled water. 100 µL of ten different concentrations (0.05 to 5 mg/mL) of pectin solution was added to 100 µL of DPPH methanol solution (120 µM). The mixture was kept in a dark place for 30 min, and then the absorbance was determined at 517 nm in a Multilabel Plate Reader. The DPPH scavenging activity was calculated according to Eq. (3):

where Ablank is the absorbance of distilled water instead of pectin sample, Asample is the absorbance of the sample, and Acontrol is the absorbance of methanol instead of DPPH solution.

Oxygen radical absorbance capacity (ORAC) assay

The ORAC assay was carried out according to Zhang et al. [29] in an Infinite 200 PRO multimode reader (Tecan, Austria) using Trolox as an antioxidant standard. Pectin solution (20 mg/ml) was diluted 1:20. In a 96 well plate was added 40 µl of each sample of pectin and 200 µl of fluorescein (100 nmol/L, prepared in phosphate buffer pH 7.4) and incubated for 20 min at 37 °C. Then, 30 µl of 2,2′-azobis-2-amidinopropane (AAPH) 0.36 mol/L were added to start the reaction. Fluorescence was measured every minute until the reading had declined to less than 5% of the initial reading with an excitation wavelength of 485 nm and an emission wavelength of 535 nm. Antioxidant activity was expressed as Trolox equivalents (µmol TE/g d.m.) and was quantified by the areas under the kinetic fluorescein decay curve and a calibration curve of Trolox (0–150 µM). Standards and samples were run in triplicate.

Statistical analysis

All experimental measurements were carried out in triplicate, and the results were expressed as mean value ± standard deviation. Statistical analysis was performed using the analysis of variance (ANOVA) technique with a significance level (α) of 0.05 using the R language version 4.0.5 (https://cran.r-project.org/).

Results and discussion

Fresh and dehydrated grape pomace composition

The dehydration of grape pomace could be an important process for its preservation and following processing since the total of the pomace is produced in a short period, so it would be difficult to process the total of this by-product before its decomposition. Therefore, pisco grape pomace (PGP) was dehydrated by four drying methods, convective drying (CD), infrared radiation drying (IR), freeze-drying (FD), and solar drying (SD). Each method has specific drying conditions according to the physicochemical principles that govern it [30]. Therefore, ideal drying conditions were established for each method that would allow reaching equilibrium moisture in the shortest time without further compromising the properties of the grape pomace. In this way, the intention is to compare the complete drying strategy.

Fresh grape and dehydrated pomace samples were characterized by proximate analysis, including moisture content, lipids, ash, protein, carbohydrate, and crude fiber (Table 1). The values comparison allows us to observe the effect of the different drying methods on these components.

PGP composed principally for Pedro Jimenez (Vitis vinifera L.) variety (95%) had a moisture content of 54.43 g/100 g fresh weight and water activity of 0.969, this moisture content is lower than reported by González-Centeno et al. [14] for pomace of four white grape varieties (62.80–72.20 g/100 g fresh pomace). The high humidity and water activity in the pomace contribute to the acceleration of its microbial decomposition. Furthermore, the production of a large volume of this by-product in a short time makes it necessary to seek stabilization strategies such as dehydration before extracting the compounds of interest [15]. The moisture content of PGP dehydrated by different methods is 3.30 g/100 g fresh weight (average value), and the water activity of all dried PGP is less than 0.400, which ensures they are microbiologically stable. SD reported the lowest moisture content (1.59 g/100 g w. b. and IR the highest (4.67 g/100 g w. b).

Total carbohydrate, calculated by difference with the other components and probably formed by cell wall polysaccharides, is the principal component excepting the water content (78.62 g/100 g d.m. on average). Among the dried grape pomace samples, IR reports the lowest content (77.50 g/100 g d.m.) and SD the highest content (79.11 g/100 g d.m.), which is the closest to the fresh sample (79.60 g/100 g d.m.). Despite the above, there are no statistically significant differences between PGP samples. Therefore, the grape pomace can be stabilized without damaging the sugar content to be extracted. The high amount of carbohydrates in the pomace makes it an interesting source of sugars with high added value. Corbin et al. [10] reported that of the total carbohydrate content found in white grape pomace (Sauvignon Blanc), 70% are soluble carbohydrates in an aqueous medium, and of the total of this aqueous fraction, 4% are soluble pectin.

The lipid content of dried samples (mean 7.92 g/100 g d.m.) was almost three times higher than the content in the fresh sample (2.74 g/100 g d.m.). The above was expected because seeds increase their contact surface during grinding of the dehydrated samples, which helps to release a higher lipid content during soxhlet extraction. The protein content in the dry pomace samples (average 8.08 g/100 g d.m) decreases compared to the fresh pomace (10.06 g/100 g d.m.). This decrease occurred probably because, during drying, degradation reactions such as Maillard reactions occur with increased temperature, so reducing sugars react with amino groups reducing protein content. The ash content decreased compared to the control, and there was no significant difference between the different drying methods. Grape pomace is a complex matrix composed of skin, seed, and stalks of grape. Therefore, the proportion composition of the sample could cause variability in ash determination. As the drying and ground process helps to homogenate the sample, the variability in ash content of drying samples reduce. In general, the values reported in this work for the composition of grape pomace are within the range of values reported by González-Centeno et al. [14] for the pomace of four varieties of white grape (Chardonnay, Macabeu, Parellada, and Premsal B).

Determination of the extraction conditions of pectin from fresh grape pomace

Response surface methodology (RMS) and central composite design (CCD) were used to maximize the yield extraction of pectin from fresh grape pomace. Therefore, the effects of extraction time (A) and pH (B) on yield extraction of pectin were studied. The results of 13 runs, including design, observed, and predicted response, are shown in Online Resource 1. The analysis of variance ANOVA of the second-order polynomial model is shown in Online Resource 2. High F-value and p-value lower (α < 0.05) indicate that the model is significant, and the terms with significant influence over yield are the relation between pH and time (AB) and quadratic term of time (B2). The R2 (coefficient of determination) value was 0.7609, and the adequate precision was above 4, indicating that the model could be used to navigate the design space. The model with significant terms is shown in Eq. (4).

The result showed that the yield of extracted pectin ranged from 1.23 to 3.05%, reaching the maximum value (3.05%) at pH 1.5 and 4 h. The relationship between dependent and independent variables is represented in 3D plots of response surfaces (Fig. 1). As can be seen, when extracting at pH 2.5 and 1.5, increasing extraction time results in increased yield extraction. Still, when extracting at pH 4, the rise of time extraction decreases yield extraction. For its part, pH has a quadratic effect on pectin extraction yield. For example, when extracting for 2 h and varying pH from 4 to 2.5, yield extraction decreased from 2.24 to 1.80%; but while pH continued decreasing to 1.5, the yield extraction increased to 2.49. Therefore, the extraction yield depends on the interaction between extraction time and pH. Besides, it was observed that the highest extraction yield was achieved with long times and low extraction pH. Colodel et al. [13] studied the effect of extraction time, pH, and the solid–liquid ratio on the acid extraction yield of pectin from white grape pomace (Chardonnay). They reported that low pH and long extraction times increase the extraction yield. Minjares-Fuentes et al. [12] also investigated the effect of pH and time extraction on the ultrasound-assisted extraction of pectin from red grape pomace (Cabernet Sauvignon). They observed that the yield increases with the time extraction and decreases when pH decreases from 2 to 1.5 but then increases when pH decreases from 1.5 to 1. It is possible that other variables such as extraction temperature also influence performance, but at temperatures above 50 °C other PGP compounds, such as starch, could be extracted [5]. Therefore, in this work, the temperature of 50 °C was used to improve the selectivity of the extraction. The differences in extraction yield obtained in this work, compared to other reports [13], can be explained by differences in cultivar variation, harvest time, production procedures, and extraction method [9,10,11].

The degree of esterification (DE) is an important parameter to classify pectin due to its commercial use as a gelling agent. The DE of pectin is defined as the percentage of esterified galacturonic acid units of the total number of units of the molecule, which defines the classification of pectin as high methoxy when the DE > 50% or of low methoxy if DE < 50% [31]. The FTIR analysis was applied to pectin extracted from fresh grape pomace to estimate the effect of the variation of time and pH extraction on the DE (Fig. 2). According to Monsoor [17], the region between 2000 and 1000 cm−1 represents the most important functional groups in pectin, so this region is used to compare the degree of esterification. The peaks at 1740 and 1630 cm−1 or in nearby wavenumbers could represent the esterified and free carboxyl groups, respectively. Therefore, the DE could be estimated by a relationship of intensity from these peaks [17, 23, 32, 33]. Two types of behavior were observed in the different pectin samples analyzed, one where the band at 1630 is the smaller and another where the band at 1740 is the smaller (Fig. 2), which could be interpreted as pectin with a greater and lesser degree of esterification, respectively. Figure 2a shows the infrared spectrum of two pectin samples extracted at the same pH and different times, 2.5 and 4 h. As can be seen, the intensity of the peak at 1630 cm−1 is bigger than 1740 cm−1 of two spectrums in a similar proportion; therefore, probably the time extraction cannot influence DE. On the other hand, Fig. 2b shows the infrared spectrum of three pectin samples extracted at the same extraction time and different pH, 1.5, 2.5, and 4.0. The spectrum of pectin extracted at pH 2.5 and 4.0 are too similar; the peaks at 1630 are bigger than 1740 in similar proportions, but the spectrum of pectin extracted at pH 1.5 showed that the peak at 1740 is bigger than 1630. Therefore, pH less than two probably influences on DE of pectin from grape pomace [12].

As the extraction yield and DE increased at a longer time and low pH, the condition selected for extracted pectin from pisco grape pomace was at pH 1.5 for four h at 50 °C with stirring.

Influence of dehydration methods on pectin extraction

Pectin was extracted from dry grape pomace to evaluate the effect of the dehydration methods applied as pretreatment on the characteristics of pectin. The extraction method optimized previously was used. Pectin extracted from fresh matter (PF) and commercial pectin from the citrus peel (CP) were used as a control to compare the pectin extracted from PGP dried by convective drying (PCD), infrared drying (PIR), freeze-drying (PFD), and solar drying (PSD).

The yield of pectin extraction from pisco grape pomace varied between 2.58% and 3.02% (Table 2). The yields of PF, PFD, and PCD were significantly higher than PIR and PSD. The low yield for PIR and PSD could be attributed to the drying mechanism (radiation). Since the radiant energy is absorbed directly by the food, the surface layers dry faster than the rest of the food. It could produce a contraction of a fiber of the surface layer and difficult pectin extraction. As freeze-drying conserves the matrix structure, the extraction yield of PFD was the same as PF (there is no statistically significant difference). In this way, drying by radiation could affect pectin extraction.

Although PFD yield is slightly bigger than PCD yield, there is no statistically significant difference between them. Monsoor (2005) reported something similar; they obtain higher pectin extraction yields from freeze-dried and oven-dried soybean hulls than spray-drying [17]. Therefore, CD and FD could contribute to extending the useful life of the pomace without significantly impairing the efficiency in the extraction of pectin.

Degree of esterification (DE) of pectin fractions

As was mentioned before, the degree of esterification influences the functional properties of pectin. High methoxy pectin (HMP) forms gels under high sugar concentration and low pH (≤ 3.5) conditions, whereas low methoxy pectin (LMP) forms gels in the presence of calcium [31]. All the pectins obtained from PGP are high methoxy pectin. The DE of pectin extracted from fresh grape pomace is 85.41%, similar to that measured for citrus pectin (Table 2). On the other hand, when the pisco grape pomace is dried, the DE significantly decreases, varying between 63.66 and 68.21% (Table 2). It has been reported that the enzyme pectin methylesterase has more significant activity when the raw material is damaged by heating processes, bruising, chill or freeze [34]. Pectin methylesterase is present in most plant tissues and is responsible for releasing the methoxyl groups of the galacturonic acid chain of pectins. Thus, drying methods involving heating or freezing could promote pectin methylesterase activity and reduce DE in pectins.

The PFD and PCD were the pectins with higher DE, 68.21% and 67.16%, respectively. On the other hand, PSD (63.66%) and PIR (64.37%) were the lower DE pectins. Qin et al. reported something similar on pectin extracted from Chinese quince fruit, where it is seen that pectin obtained from sun-dried fruit has a lower DE than when freeze-drying is used [35].

Pectin composition

Moisture, ash, protein, and reducing sugar of pectin samples are shown in Table 2. Lipids were not detectable. In general, the moisture content of pectin extracted from dried PGP is lower than PF (6.63 g/100 g) and CP (6.77 g/100 g), probably because pectins with a higher DE tend to be more hygroscopic [36]. The average ash content of pectin extracted from dried PGP is 24.4 g/100 g d.m. and 4.7 times greater than CP (5.13 g/100 g d.m.). The difference could be due to the use of NaOH to adjust pH before precipitation with ethanol during pectin extraction, as described in the methodology. This adjusted forming NaCl, which probably increases the ash content. The average protein content of pectin obtained from PGP (0.85 g/100 g d.m.) is lower than CP protein content (1.48 g/100 g d.m.). There is no significant difference between the protein content of PF and PFD (1.19 and 1.06 g/100 g d.m., respectively). The freeze-dried method has a lower loss of soluble protein, probably because freeze-dried occurs at low temperatures, and the denaturation of protein occurs at high temperatures, affecting the solubility of dried matter [37]. PSD showed the lowest protein content (0.51 g/100 g d.m.) probably because of the largest exposure to solar-dried (72 h) and low humidity, which means the high contractions of fiber because of water evaporation. Thus, drying methods that involve heating for a prolonged time, such as SD, could produce protein denaturation and reduce the protein content in pectins.

Estimating the reducing sugar content, by the DNS method, in unhydrolyzed pectin samples could be interesting since it would only consider the sugars at the ends of the pectin and the branches. It could give us an idea of how branched the pectin is. The results show a higher reducing sugar content at the ends of the pectins obtained from PGP (17.808 g/100 g d.m.) than CP (6.15 g/100 g d.m.). This difference may be due to different raw materials sources, their composition, and their structure [31]. In this case, the pectin obtained from grape pomace could have more side chains of different sugars. Pectin obtained from dried PGP has a lower reducing sugar content than PF, perhaps because while drying, the reaction between reducing sugars with an amine, the Maillard reaction, is accelerated by temperature. PCD and PIR reported the lowest values of the reducing sugar content, probably because these drying methods were developed at a high temperature (50 °C) which accelerated the Maillard reaction. On the other hand, PFD reported the content of reducing sugars closer to PF, probably because freeze-drying was developed at low temperatures, so Maillar reactions are less likely to occur. Therefore, drying methods involving high heating temperatures, such as CD and IR, could accelerate the Maillard reaction, reducing protein and sugar content in pectins.

Galacturonic acid content

The galacturonic acid content (GalA) of pectin fractions was measured by a colorimetric method after total hydrolysis with H2SO4 (m-hydroxydiphenyl method). The result varied between 22.9 and 37.3% (Table 2). The GalA of pectin from fresh PGP (37.3%) is lower than CP (77.3%). This difference may be due to the source from which the pectin was obtained [38]. Also, the extraction method could affect the GalA content. Colodel et al. [13] reported that time, pH extraction, and the liquid–solid ratio could affect the content of uronic acids in pectins obtained from grape pomace of the Chardonnay strain. They optimized the pectin extraction method and obtained pectins with GalA content from 14.8 to 62.3%. Another factor affecting galacturonic acid content is the different processes the raw material undergoes before being a by-product. In this work, grape pomace from the Pisco industry was used, where pectinases are used during grape fermentation to increase carbohydrates’ availability, which could fractionate the pectins before their extraction. Although the galacturonic acid content of the pectins obtained is less than that required for their commercial use, other authors reported that pectins with a low galacturonic acid content still have valuable rheological properties in gel additives [38] and interesting bioactive properties, such as antioxidant capacities [39].

The GalA of the pectins from dry pomace is lower than PF, and this is contrary to that reported by Qin et al. [35], where the pectin extracted from Chinese quince fruits dehydrated by lyophilization had a higher GalA (76.41%) than the pectin obtained from fresh fruit (37.07%). Qin et al. [35] mention that the pectin extracted from the lyophilized fruit presents a lower proportion of the Ramnogalacturonan-I region (chains of galacturonic acid interspersed with branched rhamnoses with galactose and arabinose chains) compared to the pectin obtained from fresh pomace, 23.14% and 46.12%, respectively. Therefore, the pectins obtained from dry grape pomace may be composed of a more significant proportion of the branched region, which would affect the content of galacturonic acid. In this sense, PCD was the highest galacturonic acid content among the pectins obtained from pretreated pomace but the lowest sugar reducing content. On the contrary, PFD was the lowest GalA content and the highest sugar reducing content.

Therefore, GalA content in pectins obtained could be principally affected by the source of raw matter and the conditions of extraction methods. Nevertheless, drying as a pretreatment of the raw matter could affect the GalA content. As mentioned before, drying methods that involve high temperatures, such as CD, could decrease sugar reducing content and, indirectly, increase the available GalA content when measured.

Molecular weight

The molecular weight distribution of pectin samples was measured by Size Exclusion Chromatographic (SEC) (Table 3). All pectin samples from PGP present four peaks, and CP two peaks. The common peak between PGP pectins and CP (< 342 Da) represents the acetate present in the dilution buffer. The high molecular weight peak (peak 1) of PF (58.9 KDa) was lower than CP (110.9 KDa). The difference between PGP pectin with CP could be attributed to the different sources of raw material, the different extraction conditions, and the effect of the pectinolytic enzymes added during the elaboration of pisco, which hydrolyze the pectin on grape pomace. However, the size of PGP pectins was in the range of commercial pectin size, which varies from 50 to 150 KDa [40]. Qin et al. [35] also obtained pectin with lower molecular weight than citrus and apple pectin, 70.4 KDa and 54.1 KDa for pectins obtained from freeze-dried and solar dried Chinese quince fruit, respectively. PCD reported the highest molecular weight (63.3 KDa), followed by PIR (60.2 KDa), and there is no statistically significant difference between both.

In the same way, there is no statistically significant difference between PSD and PFD, which reported the lowest molecular weight, 50.6 and 49.1 KDa, respectively. In pisco production, pectinases are added to grape pomace to hydrolyze pectin and improve sugar availability. In this sense, drying methods could affect the activity of residual pectinases and, therefore, the pectin size. The convective and infrared radiation dryings took less time than the other drying methods, so residual pectinases in pomace might have had less time to hydrolyze pectin, thus obtaining pectin fractions with higher molecular weight in PCD and PIR. Convective drying was the method that allowed us to get the pectin with the highest molecular weight and freeze-drying the pectin with the lowest molecular weight from pisco grape pomace.

Pectin antioxidant activity

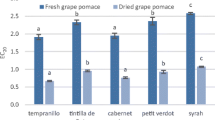

All pectin samples were analyzed using DPPH radical scavenging assay (Fig. 3a) and ORAC assay (Fig. 3b). The DPPH method is an electron transfer-based assay that measures the antioxidant capacity, and ORAC is a hydrogen atom transfer-based assay that determines the antioxidant activity [41].

Antioxidant activity of pectin extracted from pisco grape pomace drying by different methods. a DPPH radical scavenging activity. b ORAC radical absorbance capacity. CP is commercial pectin, and PF is pectin obtained from fresh pisco grape pomace. The drying methods are convective drying (CD), infrared radiation drying (IR), freeze-drying (FD), and solar drying (SD). Different letters indicate a statistically significant difference (p < 0.05) (Color figure online)

For the DPPH assay, ten concentrations of each pectin sample between 0.05 and 5 mg/ml were evaluated to find the half-maximal inhibitory concentration (IC50). The highest DPPH radical scavenging (> 90%) was reached at 3 mg/ml for almost all pectin from PGP samples. As shown in Fig. 3a, most PGP pectins reached 50% of DPPH radical scavenging (IC50) with a concentration lower than 0,5 mg/ml, except PCD. The IC50 values (mg/mL) were 0.337 ± 0.05 for PF, 0.372 ± 0.01 for PFD, 0.436 ± 0.02 for PIR, 0.496 ± 0.02 for PSD, and 0.616 ± 0.04 for PCD. In general, the IC50 values of the grape pomace pectins reported in the present work are lower than the citrus pectin sample, which reached a maximum of DPPH scavenging activity of 46% at a concentration of 4 mg/ml, and other studies [28, 42]. PF and PFD report the lowest IC50values, and there is no statistically significant difference (p < 0.05) between them. Qin et al. [35] studied the effect of different drying methods on the antioxidant capacity of pectin obtained from Chinese quince fruit. They found that the pectin obtained from a fresh sample has the highest IC50 value and that the pectin obtained from the freeze-dried fruit has the lowest value, followed by the pectin obtained from the fruit dehydrated by solar drying. The previously could mean the effect of drying methods on the IC50 varies according to the source of pectin.

As mentioned before, pectin′s antioxidant activity from PGP was measured using the ORAC assay (Fig. 3b). High antioxidant activity was found in PF of 9413 µmol TE/100 g dm. A similar value was reported in the Chilean grape variety Black Seedless (9832 µmol TE/100 g dm) in the Portal Antioxidante database (www.portalantioxidantes.com; consulted on October 3, 2020). The antioxidant capacity of pectin decreases in the same way as reducing sugars under different drying methods, as shown in the figure in Online Resource 3. In this sense, this work found a high correlation (R = 0.98) between total antioxidant capacity and reducing sugar. This correlation could mean that reducing sugars at the ends and branches of pectin reduces free radical molecules, which is probably the cause of the antioxidant activity in pectin [43]. As mentioned above, the drying methods evaluated as pretreatment affect the reducing sugar content in the pectin, possibly by the Maillard reaction; this probably also indirectly affects the total antioxidant capacity. Among the pectins obtained from dehydrated PGP, PCD reported the lowest antioxidant activity (4171 µmol TE/100 g dm) and PFD the highest (7238 µmol TE/100 g dm). In this sense, freeze-drying could be the appropriate pretreatment to obtain pectins with greater antioxidant capacity from pisco grape pomace.

Conclusion

In this work, pectin samples obtained from pisco grape pomace (PGP) dehydrated by different methods: PCD (convective drying), PIR (infrared drying), PFD (freeze-drying), and PSD (solar drying), were analyzed to evaluate the effect of pretreatment on the extraction yield, physicochemical properties, and antioxidant activity. Also, acid extraction of pectin from fresh pisco grape (PF) was optimized to obtain a higher extraction yield. The results showed that the pectin obtained from grape pomace of the Pedro Jimenez (Vitis vinifera L.) variety has different physical–chemical characteristics to those found in citric pectin and reported for grape pomace of other grape varieties. In addition, the different drying methods used for pretreatment of the grape pomace and the acid extraction conditions also influenced the properties and characteristics of the pectin. The degree of esterification (DE) of the pectins showed a noticeable decrease due to the dehydration of the raw material. Despite this, all pectins obtained from grape pomace were high methoxyl pectins. Also, PFD had the highest DPPH radical scavenging activity and ORAC radical absorbance capacity among pectin samples obtained from dehydrated PGP. Furthermore, all drying methods reduced the antioxidant capacity of pectin in the same way that they reduced the content of reducing sugars, finding a high correlation (R = 0.98) between antioxidant capacity and reducing sugars. It is possible that the pectins obtained in this work present a more branched structure than citrus pectins. Future studies are needed to characterize the structure and composition of pisco grape pomace pectin. Finally, this work presents an interesting option for the revaluation of pisco grape pomace, which is currently used to elaborate compost and as animal feed, sub-products of low added value.

References

FAO. (2019). The State of Food and Agriculture. In Moving forward on food loss and waste reduction. Licence: CC BY-NC-SA 3.0 IGO

K.L. Ong, G. Kaur, N. Pensupa et al., Trends in food waste valorization for the production of chemicals, materials and fuels: Case study South and Southeast Asia. Bioresour Technol 248, 100–112 (2018). https://doi.org/10.1016/j.biortech.2017.06.076

S. Djilas, J. Čanadanović-Brunet, G. Ćetković, By-products of fruits processing as a source of phytochemicals. Chem Ind Chem Eng Q 15, 191–202 (2009). https://doi.org/10.2298/CICEQ0904191D

C. Beres, G.N.S. Costa, I. Cabezudo et al., Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag 68, 581–594 (2017). https://doi.org/10.1016/j.wasman.2017.07.017

R.A. Muhlack, R. Potumarthi, D.W. Jeffery, Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag 72, 99–118 (2018). https://doi.org/10.1016/j.wasman.2017.11.011

G. Spigno, L. Marinoni, G.D. Garrido, 1—State of the Art in Grape Processing By-Products, in Handbook of Grape Processing By-Products. ed. by C.M. Galanakis (Academic Press, Cambridge, 2017), pp. 1–27

R.G. Maroun, H.N. Rajha, E. Vorobiev, N. Louka, 7—Emerging Technologies for the Recovery of Valuable Compounds From Grape Processing By-Products, in Handbook of Grape Processing By-Products. ed. by C.M. Galanakis (Academic Press, Cambridge, 2017), pp. 155–181

L. Flutto, PECTIN | Food Use, in Encyclopedia of Food Sciences and Nutrition, 2nd edn., ed. by B. Caballero (Academic Press, Oxford, 2003), pp. 4449–4456

K.J. Nunan, I.M. Sims, A. Bacic et al., Changes in cell wall composition during ripening of grape berries. Plant Physiol 118, 783–792 (1998). https://doi.org/10.1104/pp.118.3.783

K.R. Corbin, Y.S.Y. Hsieh, N.S. Betts et al., Grape marc as a source of carbohydrates for bioethanol: Chemical composition, pre-treatment and saccharification. Bioresour Technol 193, 76–83 (2015). https://doi.org/10.1016/j.biortech.2015.06.030

R. Apolinar-Valiente, I. Romero-Cascales, E. Gómez-Plaza et al., Cell wall compounds of red grapes skins and their grape marcs from three different winemaking techniques. Food Chem 187, 89–97 (2015). https://doi.org/10.1016/j.foodchem.2015.04.042

R. Minjares-Fuentes, A. Femenia, M.C. Garau, J.A. Meza-Velázquez, Ultrasound-assisted extraction of pectins from grape pomace using citric acid: A response surface methodology approach. Carbohydr Polym 106, 179–189 (2014). https://doi.org/10.1016/j.carbpol.2014.02.013

C. Colodel, L.C. Vriesmann, R.F. Teófilo, C.L. de Oliveira Petkowicz, Optimization of acid-extraction of pectic fraction from grape (Vitis vinifera cv. Chardonnay) pomace, a Winery Waste. Int J Biol Macromol 161, 204–213 (2020). https://doi.org/10.1016/j.ijbiomac.2020.05.272

M.R. González-Centeno, C. Rosselló, S. Simal et al., Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: grape pomaces and stems. LWT—Food Sci Technol 43, 1580–1586 (2010). https://doi.org/10.1016/j.lwt.2010.06.024

A.M. Goula, K. Thymiatis, K. Kaderides, Food and Bioproducts Processing Valorization of grape pomace : Drying behavior and ultrasound extraction of phenolics. Food Bioprod Process 100, 132–144 (2016). https://doi.org/10.1016/j.fbp.2016.06.016

C. Drosou, K. Kyriakopoulou, A. Bimpilas, M. Krokida, A comparative study on different extraction techniques to recover red grape pomace polyphenols from vinification prets. Ind Crop Prod 75, 141–149 (2015). https://doi.org/10.1016/j.indcrop.2015.05.063

M.A. Monsoor, Effect of drying methods on the functional properties of soy hull pectin. Carbohydr Polym 61, 362–367 (2005). https://doi.org/10.1016/j.carbpol.2005.06.009

OIV (2019) Statistical Report on World Vitiviniculture (pp. 1–23). International Organisation of Vine and Wine. https://www.oiv.int/en/oiv-life/oiv-2019-report-on-the-world-vitivinicultural-situation

SAG (2020) Catastro Vitícola Nacional 2018. Servicio Agricola Ganadero, División de Protección Agrícola y Forestal, Subdepartamento de Viñas y Vinos, Chile. http://www.sag.cl/ambitos-de-accion/catastro-viticola-nacional/1490/publicaciones

A. Vega-Gálvez, M. Miranda, C. Bilbao-Sáinz et al., Empirical modeling of drying process for apple (cv. Granny Smith) slices at different air temperatures. J Food Process Preserv 32, 972–986 (2008). https://doi.org/10.1111/j.1745-4549.2008.00227.x

A. Vega-Gálvez, J. Poblete, I. Quispe-Fuentes et al., Chemical and bioactive characterization of papaya (Vasconcellea pubescens) under different drying technologies: evaluation of antioxidant and antidiabetic potential. J Food Meas Charact 13, 1980–1990 (2019). https://doi.org/10.1007/s11694-019-00117-4

C.H. Geerkens, A. Nagel, K.M. Just et al., Mango pectin quality as influenced by cultivar, ripeness, peel particle size, blanching, drying, and irradiation. Food Hydrocoll 51, 241–251 (2015). https://doi.org/10.1016/j.foodhyd.2015.05.022

A. Ninčević Grassino, M. Brnčić, D. Vikić-Topić et al., Ultrasound assisted extraction and characterization of pectin from tomato waste. Food Chem 198, 93–100 (2016). https://doi.org/10.1016/j.foodchem.2015.11.095

A.M. Bochek, N.M. Zabivalova, G.A. Petropavlovskii, Determination of the esterification degree of polygalacturonic Acid. Russ J Appl Chem 74, 796–799 (2001). https://doi.org/10.1023/A:1012701219447

M.M. Bradford, A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72, 248–254 (1976). https://doi.org/10.1016/0003-2697(76)90527-3

N. Blumenkrantz, G. Asboe-Hansen, New method for quantitative determination of uronic acids. Anal Biochem 54, 484–489 (1973). https://doi.org/10.1016/0003-2697(73)90377-1

P. Li, J. Xia, Z. Nie, Y. Shan, Pectic oligosaccharides hydrolyzed from orange peel by fungal multi- enzyme complexes and their prebiotic and antibacterial potentials. LWT—Food Sci Technol 69, 203–210 (2016). https://doi.org/10.1016/j.lwt.2016.01.042

D. Sun, X. Chen, C. Zhu, Physicochemical properties and antioxidant activity of pectin from hawthorn wine pomace: A comparison of different extraction methods. Int J Biol Macromol 158, 1239–1247 (2020). https://doi.org/10.1016/j.ijbiomac.2020.05.052

L. Zhang, J. Li, S. Hogan et al., Inhibitory effect of raspberries on starch digestive enzyme and their antioxidant properties and phenolic composition. Food Chem 119, 592–599 (2010). https://doi.org/10.1016/j.foodchem.2009.06.063

J.A. Moses, T. Norton, K. Alagusundaram, B.K. Tiwari, Novel drying techniques for the food industry. Food Eng Rev 6(3), 43–55 (2014). https://doi.org/10.1007/S12393-014-9078-7

F. Dranca, M. Oroian, Extraction, purification and characterization of pectin from alternative sources with potential technological applications. Food Res Int 113, 327–350 (2018). https://doi.org/10.1016/j.foodres.2018.06.065

M. Güzel, Ö. Akpınar, Food and Bioproducts Processing Valorisation of fruit by-products : Production characterization of pectins from fruit peels. Food Bioprod Process 115, 126–133 (2019). https://doi.org/10.1016/j.fbp.2019.03.009

B. Muhoza, S. Xia, J. Cai et al., Food Hydrocolloids Gelatin and pectin complex coacervates as carriers for cinnamaldehyde: Effect of pectin esteri fi cation degree on coacervate formation, and enhanced thermal stability. Food Hydrocolloids 87, 712–722 (2019). https://doi.org/10.1016/j.foodhyd.2018.08.051

J.P. Van Buren, CHAPTER 1 - Function of Pectin in Plant Tissue Structure and Firmness, in The Chemistry and Technology of Pectin. ed. by R.H. Walter (Academic Press, San Diego, 1991), pp. 1–22

Z. Qin, H.-M. Liu, X.-C. Cheng, X.-D. Wang, Effect of drying pretreatment methods on structure and properties of pectins extracted from Chinese quince fruit. Int J Biol Macromol 137, 801–808 (2019). https://doi.org/10.1016/j.ijbiomac.2019.06.209

E. Tsami, G.K. Vagenas, D. Marinos-Kouris, Moisture sorption isotherms of pectins. J Food Process Preserv 16, 151–161 (1992). https://doi.org/10.1111/j.1745-4549.1992.tb00197.x

D. Dehnad, S.M. Jafari, M. Afrasiabi, Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci Technol 57, 116–131 (2016). https://doi.org/10.1016/j.tifs.2016.09.002

J. Mierczyńska, J. Cybulska, A. Zdunek, Rheological and chemical properties of pectin enriched fractions from different sources extracted with citric acid. Carbohydr Polym 156, 443–451 (2017). https://doi.org/10.1016/j.carbpol.2016.09.042

V.V. Smirnov, V.V. Golovchenko, F.V. Vityazev et al., The antioxidant properties of pectin fractions isolated from vegetables using a simulated gastric fluid. J Chem (2017). https://doi.org/10.1155/2017/5898594

A.A. Sundar-Raj, S. Rubila, R. Jayabalan, thottiam Vasudevan R, A review on pectin: Chemistry due to general properties of pectin and its pharmaceutical uses. Sci Rep 1, 550–553 (2012)

R. Apak, S. Gorinstein, V. Böhm et al., Methods of measurement and evaluation of natural antioxidant capacity/activity (IUPAC Technical Report). Pure Appl Chem 85, 957–998 (2013). https://doi.org/10.1351/PAC-REP-12-07-15

X. Wang, Q. Chen, X. Lü, Pectin extracted from apple pomace and citrus peel by subcritical water. Food Hydrocoll 38, 129–137 (2014). https://doi.org/10.1016/j.foodhyd.2013.12.003

K. Nara, A. Yamaguchi, N. Maeda, H. Koga, Antioxidative activity of water soluble polysaccharide in pumpkin fruits (Cucurbita maxima Duchesne). Biosci Biotechnol Biochem 73, 1416–1418 (2009). https://doi.org/10.1271/bbb.80529

Acknowledgements

The authors wish to acknowledge ANID doctoral scholarship N° 21181191 and ANID Fondecyt Regular research Grant No. 1190260.

Funding

Agencia Nacional de Investigación y Desarrollo de Chile (ANID),doctoral scholarship no 21181191, Pamela Vásquez, Fondecyt research Grant No. 1190260, Claudia Bernal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vásquez, P., Vega-Gálvez, A. & Bernal, C. Production of antioxidant pectin fractions, drying pretreatment methods and physicochemical properties: towards pisco grape pomace revalue. Food Measure 16, 3722–3734 (2022). https://doi.org/10.1007/s11694-022-01482-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01482-3