Abstract

The aim of this study was to evaluate the combined effect of initial nitrogen content on the production of hydrogen sulphide and other volatile compounds during alcoholic fermentation. For that propose, three commercial wine strains of Saccharomyces cerevisiae were used to ferment synthetic grape juice media under different nitrogen concentrations. H2S was measured throughout fermentations and other aroma compounds were analyzed at the end of the experiments. The trigger levels at which an inverse relationship between the initial nitrogen present in media and total H2S production varied among the three strains tested. For UCD522 and PYCC4072, the highest H2S levels were produced in media with 267 mg N l−1 of initial nitrogen, whereas the lowest levels were detected with nitrogen limitation/starvation conditions (66 mg N l−1). Moreover, 21 other aroma compounds belonging to different chemical classes were identified and quantified by solid phase micro-extraction (SPME) coupled to gas chromatography–mass spectrometry (GC–MS). The initial nitrogen concentration more than yeast strain had a decisive effect on the final aroma composition, suggesting that modulation of nutrients emerges as a useful tool for producing desired flavour and odour compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogen sulphide (H2S) production is of major concern in winemaking, since it has a profound negative effect on the sensory quality of wines due to its rotten egg odour detectable at very low concentrations. In Saccharomyces cerevisiae, H2S is the product of the sulphate reduction sequence (SRS) pathway and acts as an intermediate in the biosynthesis of sulphur-containing amino acids [35]. The biosynthesis of sulphur amino acids requires nitrogen-containing carbon precursors derived from the intracellular nitrogen pool and sulphide from the sulphate reduction pathway. Thus, the rate of H2S formation seems to be regulated by cellular demands for sulphur amino acids and maintenance of intracellular nitrogen pools [12]. Several environmental and nutritional factors have been associated with H2S production under winemaking conditions, namely (1) levels of elemental sulphur [29, 34] naturally available as sulphate at an average concentration of 200 mg l−1 [24], (2) presence of sulphur dioxide [1, 32] commonly added (50–200 mg l−1) to grape must prior to wine fermentation, (3) presence of organic compounds containing sulphur [2], and (4) vitamin deficiency [5, 36, 42, 43]. Yet, poor correlations between H2S formation and assimilable nitrogen have been reported [30, 41]. Nevertheless, the effects of nitrogen as well as those factors mentioned before are highly dependent on yeast genetic background [12, 16, 31], making it difficult to devise strategies to prevent H2S formation during winemaking.

It is widely accepted that the nature and the availability of yeast assimilable nitrogen play a significant role in wine sensorial traits. Organic acids, higher alcohols, aldehydes, ketones, and sulphur-compounds have been considered the most significant sensorial components of wine and constitute the main group of compounds that form the ‘‘fermentation bouquet’’ [23]. A few organic acids are volatile enough to contribute to its odour, acetic (vinegary), propanoic (goaty) and butanoic acid (spoiled butter). In wine, only acetic acid can appear in concentrations above its perception threshold [23], and its production seems to be inversely correlated with initial nitrogen levels [3, 4, 37]. Higher alcohols such as isoamyl alcohol, amyl alcohol, and isobutyl alcohol are produced during fermentation by similar biochemical reactions as a result of decarboxylation of α-keto acids derived by either transamination of amino acids (α-ketoisocaproic acid from leucine, α-ketoisovaleric acid from valine, and α-keto-β-methylvaleric acid from isoleucine) via the Ehrlich pathway [44] or through sugar catabolism [8]. These alcohols, together with acids form esters such as ethyl acetate, hexyl acetate, isoamyl acetate (banana-like aroma) ethyl caproate, ethyl caprylate (apple-like aroma), and 2-phenylethyl acetate (fruity and flowery like aroma) during fermentation, which significantly contribute to the pleasant fruity aroma of wines, beer, and other alcoholic beverages. At low levels, all these compounds contribute to perceived wine aroma complexity. However they have also been considered as responsible for off-flavours when present in too high amounts [26]. Among other factors, nitrogen content affects the pattern of both higher alcohols and esters formed during fermentation, via regulation of the Erhlich, fatty acid, and ester synthesis pathways [33]. Furthermore, the quantities of these various compounds that are produced during fermentation have been shown to vary significantly within wine yeast species and strain [26]. Only recently a few studies have been conducted for determining the effect of nitrogen on aroma compounds formation in wine [7, 40]. Therefore, the aim of the present work was to assess H2S production and to determine the potential differences in volatile aroma compounds formation by three wine yeast strains during high sugar alcoholic fermentations under different nitrogen conditions. In this way, we studied three widely used commercial S. cerevisiae strains grown in synthetic grape juice media and batch culture, mimicking winemaking conditions, under different initial nitrogen concentration 66, 267 and 402 mg N l−1. The knowledge of growth and fermentative behaviour, volatile compound production and other oenological characteristics which impact wine properties could be useful for selecting the most appropriate strain to produce a wine with the desired flavour and odour qualities.

Materials and methods

Strains and maintenance conditions

Three strains of S. cerevisiae were used in this study. S. cerevisiae UCD522 was kindly supplied by the Enology Culture Collection, Department of Viticulture and Enology, University of California, Davis, USA. S. cerevisiae PYCC4072 was originally isolated from a sample of Fermivin, industrial wine yeast distributed by Rapidase, which was obtained from the Portuguese Yeast Culture Collection (PYCC), New University of Lisbon, Portugal, and the commercial strains S. cerevisiae EC1118 was obtained from the market as active dried yeast. The strains tested were chosen based on their potential ability to produce H2S in solid media [18]: (1) UCD522 (a high producer), (2) PYCC4072 (an average producer) and (3) EC1118 (a poor producer). The yeast cultures were maintained at 4°C on slants of yeast peptone dextrose agar (YPD), containing: glucose 20 g l−1, peptone 10 g l−1, yeast extract 5 g l−1 and agar 20 g l−1. Before use, it was transferred to a new slant of YPD for 24 h at 25°C.

Culture media

A chemically defined grape juice medium (GJM) similar in composition to typical grape juice, as previously described by Henschke and Jiranek [12] of the Australian Wine Research Institute, was used with minor modifications. Glucose (200 g l−1) was used as the only carbon and energy source, and nitrogen was added at different concentrations (66, 267, and 402 mg N l−1) supplied as diammonium phosphate (DAP), to facilitate monitoring nitrogen consumption profile. Moreover, ammonium, as ammonium phosphate or sulphate salts, up to the legal limit of 1,000 mg l−1 are widely used by winemakers to increase nitrogen content of grape musts according to OIV regulation. The pH was adjusted to 3.7 with NaOH prior to sterile filtration of the media.

Inocula and fermentation conditions

For all experiments, starter cultures were prepared by pre-growing the yeast overnight in 100 ml shake flasks, containing 70 ml of the same medium with the same composition used in all assays. Incubation was done at 25°C in an orbital shaker at 150 rpm. This pre-culture was used to inoculate experimental cultures with an initial population of 5 × 105 CFU ml−1.

Fermentations were done in 250 ml flasks filled to 2/3 of their volume, fitted with a side-arm port sealed with a rubber septum for anaerobic sampling and maintained at 20°C in an orbital shaker at 120 rpm. Fermentations were monitored using weight loss as an estimate of CO2 production. Aseptic sampling was accomplished using a syringe-type system. To avoid medium accumulation in the system, a stylet was inserted in the needle holder. Each flask was closed with a rubber stopper, allowing fermentation gasses to escape through a glass tube connected to a two-way valve by Teflon tubing; the other end of the tubing was connected to a tube with 10 ml of trapping solution to create a fermentation lock and a trap for H2S. Every 24 h, each flask was removed from the shaker, disconnected from the trap, weighed, and connected to a new trap. Samples were collected daily for assessing fermentation and growth parameters.

Prior to sampling, the flasks were stirred for homogeneity. The end of alcoholic fermentation was confirmed using Clinitest tablets (Roche). At that time, samples were taken from different fermented media to be screened for aroma compounds production by solid phase micro-extraction (SPME) coupled to gas chromatography–mass spectrometry (GC–MS). Additionally, viable cell number, culture dry weight and residual glucose and nitrogen levels were determined in all experiments.

All experiments were repeated at least three times and all reported data are mean values.

Determination of viable cell number and culture dry weight

Optical density (660 nm) of appropriately diluted culture samples was used as an estimate of yeast cell growth. Samples of 2 × 50 and/or 3 × 15 ml were centrifuged in pre-weighed tubes for 10 min at 2,300g, washed twice with deionised water, dried for 24 h at 100°C, and stored in a desiccator before weighing. Duplicate and triplicate determinations varied by less than 1%.

Determination of sugar concentration

Glucose was quantified by the 2,4-dinitrosalicylic acid (DNS) method [21].

Determination of ammonium

Ammonium calculations were done using a continuous-flow analysis system (sampler, pump, dialysis unit, ammonium unit, photometer, and recorder). Ammonium calculations were based on the Berthelot reaction as previously described [19].

Determination of oenological parameters

Total SO2, volatile acidity and ethanol production were determined as reported by the Office International de la Vigne et du Vin [22].

Hydrogen sulphide determination

The amount of H2S liberated by yeast cultures was determined colorimetrically following selective collection of fermentation gases with a modified fermentation lock and sulphide-trapping system as described by Jiranek et al. [16]. A suspension of cadmium hydroxide was used as trapping solution, containing 5.59 mmol l−1 3CdSO4 8H2O and 15 mmol l−1 NaOH. Amine reagent contained 37.5 mmol l−1 N,N-diethyl-p-phenylene diamine. HCl (Sigma, St. Louis, USA) in 9.12 mmol l−1 H2SO4, and FeCl3 solution (60% w/w) was added immediately prior to use. This mixture (325 μl) was added to 10 ml of trapping solution in 30 ml screw-cap bottles, which were immediately closed and shaken vigorously for 30 s. After 1 h of incubation at room temperature, absorbance of samples was measured at 672 nm. H2S content was calculated using a calibration curve prepared with known amounts of sulphide in the range of 0–12 μg, according to the methodology described by Acree et al. [1] and Rees et al. [25].

SPME procedure and GC–MS analysis

SPME fibers

The fibers used in this study were coated with polydimethylsiloxane (PDMS), 100 μm and were supplied by Supelco (Bellefonte, PA, USA). Also the holder used for manual injection was from the same supplier (Supelco, Bellefonte, PA, USA).

Chromatographic conditions

Chromatographic analyses were performed using an Agilent 6890 N gas chromatograph equipped with a 5973 N mass spectrometer. The target analytes were separated using a Innowax capillary column, 30 m × 0.25 mm with 0.5 μm film thickness (Agilent, Santa Clara, CA, USA). The column was maintained at 40°C for 5 min after desorption, ramped at 4°C min−1 up to 200°C, and then ramped at 10°C min−1 up to 240°C, where it was held for 15 min Helium was used as the carrier gas at 34 cm s−1 average linear velocity. A 0.75-mm liner was used and analysis performed in the splitless mode. All mass spectra were acquired in electron impact (EI) mode at 70 eV, using full scan with a scan range of 26–250 atomic mass units, at a rate of 6.12 scans s−1. Identification of all compounds were confirmed by comparing mass spectra and retention indices with those of authentic standards. Ethyl propionate (99%), ethyl 2-methylbutyrate (95%), isoamyl alcohol (98.5%), ethyl hexanoate (99%), linalool (97%), 1-octanol (99.5%), butyric acid (99%), ethyl decanoate (99%), isovaleric acid (98%), diethyl succinate (99%), hexanoic acid (98%), octanoic acid (98%), decanoic acid (99.5%), and 2-octanol (99.5%) were supplied by Fluka (Sigma-Aldrich Chemie GmbH, Steinheim, Germany). Ethyl acetate (99.5%), ethyl butyrate (98%), isoamyl acetate (98%), ethyl octanoate (98%), 2-phenylethyl acetate (99%), and 2-phenylethanol (99%) were from Merck (Merck, Damstadt, Germany). Ethyl isobutyrate (99%) and ethyl isovalerate (98%) were from Aldrich (Sigma-Aldrich Chemie GmbH, Steinheim, Germany).

The compounds were quantified in selected ion monitoring (SIM) mode, by selecting for each compound their most characteristic ions as follows: ethyl acetate (43), ethyl propionate (57), ethyl isobutyrate (43 + 71), ethyl butyrate (71), ethyl 2-methylbutyrate (57 + 102), ethyl isovalerate (88), isoamyl acetate (43), isoamyl alcohol (55), ethyl hexanoate (88), ethyl octanoate (88), linalool (71 + 93), 1-octanol (55 + 56), butyric acid (60), ethyl decanoate (88), isovaleric acid (60), diethyl succinate (101), 2-phenylethyl acetate (104), hexanoic acid (60), 2-phenylethanol (91), octanoic acid (60), and decanoic acid (73). In order to eliminate variations in extraction efficiency caused by small differences in the sample matrix (particularly ethanol content), internal standardization using 2-octanol as the internal standard was applied to quantify the analytes.

SPME extraction procedure

SPME extraction was performed according to the methodology previously described [17], with minor modifications. For sample preparation, to 10 ml of sample (synthetic wine solution), 10 ml of internal standard solution (2-octanol, 200 μg l−1) plus 4 g of NaCl were transferred to 40 ml vials (Supelco P/N 27181) and hermetically sealed with PTFE-faced silicone septum. Before the extraction step, samples were equilibrated for 10 min at 20 ± 1°C. Then the PDMS fibre was inserted through the vial septum and exposed to sample headspace for 60 min under constant temperature and permanent magnetic stirring (300 rpm) to perform the extraction, under the same conditions of temperature and agitation. Then the fibre was removed from the sample headspace and inserted into the injection port of the gas chromatograph, for thermal desorption (splitless mode) at 270°C for 10 min and subsequent chromatographic analysis was performed.

Preparation of standards and SPME fiber calibration

Single standard stock solutions (1% v/v) of the volatile compounds were prepared by spiking each compound in pure ethanol (Merck LiChrosolv). Working solutions, prepared just before use, were made from the stock solutions by spiking and mixing them with a hydro-alcoholic solution (11.5% v), containing tartaric acid (3 g l−1) and potassium hydrogen tartrate (3 g l−1), and adjusted to pH 3.2 with 6 M NaOH. The concentrations of the analytes in the working solution was as follows: ethyl acetate (50 mg l−1), ethyl propionate (500 μg l−1), ethyl isobutyrate (200 μg l−1), ethyl butyrate (350 μg l−1), ethyl 2-methylbutyrate (25 μg l−1), ethyl isovalerate (25 μg l−1), isoamyl acetate (3.5 mg l−1), isoamyl alcohol (400 mg l−1), ethyl hexanoate (400 μg l−1), ethyl octanoate (300 μg l−1), linalool (50 μg l−1), 1-octanol (50 μg l−1), butyric acid (500 μg l−1), ethyl decanoate (200 μg l−1), isovaleric acid (2 mg l−1), diethyl succinate (50 μg l−1), 2-phenylethyl acetate (2 mg l−1), hexanoic acid (5 mg l−1), 2-phenylethanol (150 mg l−1), octanoic acid (6 mg l−1), and decanoic acid (5 mg l−1). This solution was used as the higher concentration calibration standard, and six more calibration solutions were prepared by serially diluting the working solution by twofold with the hydro-alcoholic solution. For fiber calibration, all calibration solutions were analyzed in triplicate by GC–MS using the same SPME extraction procedure as for the fermented GJM samples.

Statistical analysis

Factorial design experiments were used to analyze the influence of grape juice initial nitrogen concentration (three levels) and yeast strain (three strains) on aroma compounds formation. Statistical analyses were done using Statistica 7.0 software (StatSoft Inc., 2004). For paired comparisons, the Tukey honestly significant difference (HSD) test was used.

Results

Effects of nitrogen concentration on hydrogen sulphide production and its relation to growth and fermentation profiles

The formation of H2S was evaluated during alcoholic fermentation in three wine yeast strains of S. cerevisiae grown in batch cultures, in synthetic grape juice medium, mimicking the conditions of natural wine fermentation. The amounts of assimilable nitrogen added into the media were selected according to previous data obtained in our laboratory to determine limiting nitrogen concentrations in growth and fermentation pattern using S. cerevisiae PYCC4072 [19]. Accordingly, three fermentation conditions have been established by manipulating nitrogen concentration in the media: (1) 66 mg l−1 is a N-limiting concentration that leads to sluggish fermentation (as complete dryness has been obtained after 28–29 days), (2) 267 mg l−1 is the concentration of nitrogen required for completion of alcoholic fermentation, in a reasonable time, and (3) 402 mg l−1 is an excess nitrogen concentration, since some nitrogen remains in the fermented media at the end of alcoholic fermentation. To correctly analyze the effect of nitrogen availability on H2S liberation, sulphur level was maintained constant in all media as MgSO4 7H2O (1.23 g l−1) and no sulphite was added prior to fermentation.

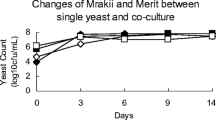

A global view of the fermentation, growth profiles and hydrogen sulphide production of each of the strains associated to the three test conditions are presented in Figs. 1, 2, 3 and in Table 1. The results show that in media containing 66 mg l−1 (limiting nitrogen concentration that leads to sluggish fermentation), the strain UCD522 was able to complete alcoholic fermentation after 576 h (Fig. 1a), while PYCC4072 and EC1118 (Figs. 2a, 3a) failed to attain total sugar degradation, leaving at 696 h (Table 1), approximately 13 and 11 g of residual glucose, respectively. Nitrogen was exhausted from the medium in the first 24 h, except for the strain EC1118, and glucose consumption followed for nearly 24–29 days, even in the absence of nitrogen in the medium (Figs. 1a, 2a, 3a). In addition, cell viability remained high (around 97%) until the end of the fermentation (data not shown). In media with 267 mg N l−1, the strains UCD522 and PYCC4072 behaved similarly (Figs. 1b, 2b). All nitrogen available was consumed after 48 h and the values obtained for growth and fermentation parameters were approximately the same in both strains (Table 1). The EC1118 strain behaved quite differently, consuming nitrogen more slowly than the two others, which was correlated with the extent of fermentation (Fig. 3b; Table 1). Elevating initial nitrogen levels from 267 to 402 mg l−1 had no significant effect on UCD522 and PYCC4072 growth and fermentation patterns (Figs. 1b, c, 2b, c), yet for yeast strain EC1118 an increase in growth and fermentation rates was observed (Table 1). The fermentative patterns of all the yeasts tested were very similar, despite the differences in final biomass formation particularly lower for EC1118 (Figs. 1c, 2c, 3c). All fermentations were completed within 144 h without depleting nitrogen from the media, and no significant differences in the amount of nitrogen used by the three strains were observed.

Fermentation profiles and hydrogen sulphide liberation (histograms) in synthetic grape juice medium at 20°C, containing an initial nitrogen concentration of 66 (a), 267 (b) and 402 mg N l−1 (c) of yeast strain UCD522. Data points are the mean from triplicate fermentations ± SD (smaller error bars are hidden behind the data symbols)

Fermentation profiles and hydrogen sulphide liberation (histograms) in synthetic grape juice medium at 20°C, containing an initial nitrogen concentration of 66 (a), 267 (b) and 402 mg N l−1 (c) of yeast strain PYCC4072 Data points are the mean from triplicate fermentations ± SD (smaller error bars are hidden behind the data symbols)

Fermentation profiles and hydrogen sulphide liberation (histograms) in synthetic grape juice medium at 20°C, containing an initial nitrogen concentration of 66 (a), 267 (b) and 402 mg N l−1 (c) of yeast strain EC1118. Data points are the mean from triplicate fermentations ± SD (smaller error bars are hidden behind the data symbols)

With regards to the H2S evolution during the fermentation, the results show that a strain-dependent variation in the H2S formation in response to nitrogen availability occurs (Figs. 1, 2, 3). In opposition to what has been seen for wine yeast strains UCD522 and PYCC4072, for the strain EC1118 (poor H2S producer) it was possible to observe an inverse relationship between the amounts of initial nitrogen present in the media and total H2S production (Table 1). Nevertheless, for all the concentrations studied, the levels of sulphide produced by this strain were almost negligible (Fig. 3a–c). Regarding PYCC4072 (Fig. 2a–c) in the fermentations conducted with low and sufficient nitrogen levels, 66 and 267 mg l−1, respectively, the peak of sulphide liberation occurred after nitrogen depletion. In media supplemented with 402 mg l−1, where approximately 70 mg N l−1 remained in the medium (Table 1), there was not a notable H2S production (Fig. 2c). On the contrary, for UCD522 even when nitrogen was in excess (Fig. 1c) a noteworthy H2S release was detected. As for PYCC4072 in the media with initial nitrogen levels of 66 and 267 mg l−1, sulphide production was induced following complete nitrogen consumption by yeast cells, after 24 and 48 h, respectively (Fig. 1a, b).

Effect of yeast strain and initial nitrogen concentration on aroma compounds formation

To evaluate how nitrogen concentration in media affected aroma formation, samples were taken for GC–MS analysis of volatile compounds at the end of fermentations. The results of volatile compounds produced by the tested strains under different nitrogen conditions are presented in Figs. 4, 5, 6 and the results of a two-way ANOVA are presented in Table 2. Global analyses of results revealed that yeast strains differed only quantitatively, but not qualitatively with regard to the 21 aroma compounds analyzed in this study. The wine strain EC1118 produced significantly higher levels of total organic acids, specifically hexanoic, octanoic, and decanoic acids, whereas no significant differences between UCD522 and PYCC4072 were detected; only isovaleric acid was produced at higher levels by these two strains. However, the amounts of each one of the acids analyzed was significantly (p < 0.001) affected by nitrogen concentration. As the nitrogen concentration increased up to 267 mg l–1, higher hexanoic acid production was observed for the three strains, being particularly evident in EC1118 strain. In high nitrogen media (402 mg l−1), hexanoic acid concentrations significantly decreased in EC1118 and UCD522 and increased in PYCC4072. In contrast, the amounts of isovaleric acid decreased with increasing nitrogen concentration, mainly in UCD522 and PYCC4072.

Concentrations of acids produced by Saccharomyces cerevisiae UCD522, PYCC4072 and EC1118 grown in synthetic grape juice medium with 200 gl−1 of glucose and different nitrogen concentrations (66, 267, and 402 mg N l−1) supplied as diammonium phosphate (DAP). Data are the mean from triplicate fermentations ± SD

Concentrations of alcohols produced by Saccharomyces cerevisiae UCD522, PYCC4072 and EC1118 grown in synthetic grape juice medium with 200 gl−1 of glucose and different nitrogen concentrations (66, 267, and 402 mg N l−1) supplied as diammonium phosphate (DAP). Data are the mean from triplicate fermentations ± SD

Concentrations of esters produced by Saccharomyces cerevisiae UCD522, PYCC4072 and EC1118 grown in synthetic grape juice medium with 200 gl−1 of glucose and different nitrogen concentrations (66, 267, and 402 mg N l−1) supplied as diammonium phosphate (DAP). Concentrations of ethyl acetate are divided by 100. Data are the mean from triplicate fermentations ± SD

In respect to ethyl acetate formation, the tested strains responded differently to nitrogen variation (Table 2). The strain PYCC4072 produced less ethyl acetate at high levels of nitrogen, while the strains EC1118 and UCD522, in less extent, produced high ethyl acetate at high levels of nitrogen.

The amounts of ethyl butyrate, ethyl hexanoate, ethyl octanoate, and ethyl decanoate were significantly (p < 0.001) variable within the strains and their highest concentrations were found in the media with 402 mg N l−1, except for UCD522 for ethyl hexanoate and ethyl octanoate. Conversely, the amounts of diethyl succinate, ethyl isovalerate, ethyl propionate, ethyl isobutyrate, and ethyl 2-methylbutyrate were significantly found in the media with 66 mg N l−1. In respect to the alcohols, there were significant differences in their final concentrations due to nitrogen (p < 0.001) as well as to the yeast strain, except for isoamyl alcohol as shown in Table 2. The strains PYCC4072 and in particular UCD522 were found to produce more 2-phenylethanol and linalool than EC1118. All strains produced high levels of isoamyl alcohol and 2-phenylethanol in low nitrogen media. Increasing nitrogen in the media resulted in a decrease in fusel alcohols produced by the three wine strains. A similar trend was observed for 2-phenylethyl acetate levels in all strains, while isoamyl acetate increased at high nitrogen concentrations. All strains were found to produce more linalool and 1-octanol in high nitrogen media. Nevertheless, the amounts of linalool produced by EC1118 almost doubled from low to high nitrogen concentration, while in the other two strains small (PYCC4072) or no variation was found (UCD522).

Oenological parameters

At the end of all fermentations, other parameters that could have an impact on wine character, such as alcohol production, volatile acidity, total sulphite (SO2) and residual sugar were determined and the results are presented in Table 3. For all strains tested, the acetic acid content of final media, represented by volatile acidity, was lower in media with 66 mg l−1 of initial nitrogen. There were no major differences in the final ethanol concentration though being somewhat higher under 402 mg N l−1 in the strain EC1118.

The pH value fell from its initial value of 3.7 during fermentation in all cases with an inverse correlation with initial nitrogen content of the media. There was a rapid decrease in pH in fermentation course during the two initial days, but after this time, remained almost constant (results not shown). The yeast strains UCD522 and PYCC4072 produced more sulphite than EC1118, except under low nitrogen fermentation.

Discussion

In the present study, the influence of nitrogen levels on growth and fermentation kinetics as well as on the production of important yeast-derived wine aroma compounds was assessed. The initial nitrogen concentration affected fermentation length, maximum fermentation rate and final biomass which are consistent with previous findings [10, 12, 19, 39]. From the analysis of the yeast performance challenged by nitrogen deficiency, it can be highlighted that all three yeast strains tested were able to consume glucose for nearly a month in a nitrogen depleted media, suggesting that cells are able to sustain basal glucose uptake capacity during long periods of nitrogen deprivation. Using a transposon mutagenesis approach, Gardner et al. [11] have identified two genes NGR1 and GID7, whose disruption improved sugar catabolism throughout nitrogen limited fermentations. The authors suggested that the absence of these genes could prevent deactivation of Hxt7p enhancing the ability to maintain its catabolic activity under conditions of nitrogen starvation. This result could explain why high numbers of nitrogen starved cells from sluggish cultures are able to reduce the time it takes to complete a nitrogen problematic fermentation, as observed by Varela et al. [39].

The association between a shortage of assimilable nitrogen and H2S production during wine fermentations was first reported by Vos and Gray [41]. In this report, a strain-dependent variation in the H2S formation in response to nitrogen availability was found, in agreement with previous findings [10, 12, 16, 31]. The wine strain EC1118 seems to be a poor-nitrogen responder in a range of 66–402 mg N l−1, as no remarkable H2S was detected under all experimental conditions. This strain has shown the ability to produce higher amounts of H2S in response to nitrogen status during alcoholic fermentation using synthetic grape juice media [5, 43]. The discrepancy between H2S liberation observed in this work compared with earlier studies could have various explanations. The nitrogen sources differed between the studies: a mixture of amino acids in the earlier studies as opposed to ammonium in the present work. Additionally, the former studies were performed under vitamin deficiency conditions [5, 43]. The amounts of pantothenic acid (10, 50 and 250 μg l−1) [43] and biotin (0, 1 and 10 μg l−1) [5] used in those studies could have stimulated H2S liberation. These effects were overlooked in the current study as the initial levels of these vitamins (125 μg l−1 of biotin and 1,000 μg l−1 of pantothenic acid) in all media were largely in excess [12]. Taken together ours and theirs results, it seems that for wine strain EC1118, nitrogen source and vitamin deficiency could have a greater impact on H2S liberation than nitrogen content.

For yeast strains UCD522 and PYCC4072, nitrogen depletion triggered H2S liberation in the media with initial 66 and 267 mg N l−1, although to different extents. Surprisingly, it was in the media with 66 mg N l−1, that lower sulphide liberation was observed, being restricted to the first 48 h of fermentation. As far as we know, this is the first time that such behaviour has been pinpointed. It should be underlined that the inferior amounts of sulphide detected in the low nitrogen fermentations (66 mg N l−1) could not be due to the reduced fermentation rate observed as in our experiments, anaerobic conditions were established in the first hours of fermentation and every 24 h, the CO2 was forced to be released into the sulphide trap by vigorous agitation. This finding could be accounted for by the fact that sulphide production constitute a very energy-demanding process and under nitrogen starvation conditions, yeast cells must slow down some metabolic pathways to enable cell survival. These unexpected results are in line with those previously obtained for the strain PYCC4072 in which genes involved in the SRS, and thus in H2S formation, are among the list of genes that are specifically down-regulated (unpublished results) under conditions of nitrogen deficiency (66 mg l−1) [20], where in this study was found a lower level of H2S liberated.

For both wine strains, UCD522 and PYCC4072, an inverse relationship between the amounts of initial nitrogen present in culture media and total H2S production was seen with the higher levels of nitrogen (267 and 402 mg l−1), where cells displayed higher fermentative activity. However, in this study under conditions of nitrogen excess (402 mg l−1), H2S liberation was almost undetectable in the strain PYCC4072, whereas UCD522 still produced considerable amounts of this off-flavour. This finding as already been seen by Gardner et al. [10] with the low nitrogen-requiring strain AWRI 835, which produced H2S even when nitrogen remained in the medium. These observations suggest a complex regulation of yeast sulphur and nitrogen metabolism highly dependent on the yeast strain genetic background and could be either due to differences in activity level of enzymes involved in incorporating sulphide into amino acids [31] or to differences in the ability to retain a greater amount of H2S within the yeast cells [28].

Although, in the last 20 years, extensive research have been made on the effect of grape juice nitrogen status on H2S production [10, 12, 16, 31], only recently, studies have focus on the impact of nitrogen on the formation of aroma compounds by yeast. In this study, a variety of volatile aroma compounds were found at the end of fermentations, confirming the contribution of yeast to the diversity of wine “bouquet”. Moreover, this study provides good evidence that nitrogen concentration in grape juice strongly influences volatile compounds formed by the yeasts eliciting sensorial differences in the final product. Our results combined with those obtained in other laboratories conducted in natural grape juice [14, 38] or in model solutions [6, 40] show that, aside quantitative variation for each aroma compound found within different studies, most of them displayed the same trend in response to nitrogen level at the beginning of fermentation. That is at increasing nitrogen levels, a set of aroma compounds are elevated, including ethyl butyrate, isoamyl acetate, as well as the medium chain fatty acids, hexanoic, octanoic and decanoic, and their respective ethyl esters—ethyl hexanoate, ethyl octanoate, and ethyl decanoate. On the contrary, 2-phenylethanol, isoamyl alcohol, ethyl 2-methylbutyrate, and isovaleric acid are more produced under lower nitrogen concentrations, irrespective of the nitrogen source, yeast strain, or the fermentations conditions (static batch fermentation or mild agitation) used. A few compounds such as ethyl acetate, linalool and 2-phenyl-acetate seem to be more dependent on yeast strain. In fact, the levels of linalool reported in this study for UCD522 are of a similar order of magnitude of those obtained by Carrau et al. [6] for the same strain grown under different vinification conditions. Up to now, the role of yeasts in terpene formation in wines has been considered irrelevant or even ignored, since the increase of terpenoid compounds found in the must during fermentation has only been attributed to β-glucosidase activity, which releases free monoterpenes from glycosidically bound precursors [9, 13, 27]. Recently, Herrero et al. [15] were able to achieve the production of free linalool at a concentration above its aroma threshold (4–10 ppb) by engineering the pathway for monoterpene production in wine yeasts. However, the authors underline the fact that the commercial application of genetically modified industrial microorganisms is problematic due to public concern. Thus modulation of linalool formation by nitrogen concentration could be of sensory interest for winemakers.

In conclusion, the results obtained within the present work demonstrated that a complex interaction between initial nitrogen concentration and yeast strain exist in respect to H2S and other aroma compounds formation. From the findings here reported, the wine strains respond to nitrogen limitation/starvation conditions by producing (1) less sulphide, (2) less sulphite, (3) less acetic acid, (4) less medium chain fatty acids, and (5) more isoamyl alcohol, ethyl-2-methyl-butyrate and 2-phenylethanol. These results are particularly relevant, considering that in winemaking is simultaneously desirable to achieve high levels of compounds that impart pleasant fruity and floral aromas, low levels of off-flavours and low levels of toxic compounds that could compromise yeast fermentative activity. It is worthwhile pointing out that while this is an interesting new observation, it might be difficult to achieve under industrial conditions and might have the disadvantage of leading to sluggish or stuck fermentation.

The results in this study also indicate that nutrient management in growth media could be an interesting option for producing wines with specific characters and styles. Further studies are underway in our laboratory to identify and understand how nitrogen levels affect the expression of genes involved on aroma compounds formation.

References

Acree TE, Sonoff EP, Splittstoesser DF (1971) Determination of hydrogen sulfide in fermentation broths containing SO2. Appl Microbiol 22:110–112

Acree TE, Sonoff EP, Splittstoesser DF (1972) Effect of yeast strain and type of sulphur compound on hydrogen sulphide production. Am J Enol Vitic 23:6–9

Agenbach W (1977) A study of must nitrogen content in relation to incomplete fermentations, yeast production and fermentation activity. In: Beukman EF (ed) Proceedings of the South African Society for Enology and Viticulture. South Africa, Stellenbosch, pp 66–87

Bely M, Rinaldi A, Dubourdieu D (2003) Influence of assimilable nitrogen on volatile acidity production by Saccharomyces cerevisiae during high sugar fermentation. J Biosci Bioeng 96:507–512. doi:10.1016/S1389-1723(04)70141-3

Bohlscheid JC, Fellman JK, Wang XD, Ansen D, Edwards CG (2007) The influence of nitrogen and biotin interaction on the performance of Saccharomyces in alcoholic fermentation. J Appl Microbiol 102:390–400. doi:10.1111/j.1365-2672.2006.03180.x

Carrau FM, Medina K, Boido E, Farina L, Gaggero C, Dellacassa E, Versini G, Henschke PA (2005) De novo synthesis of monoterpenes by Saccharomyces cerevisiae wine yeasts. FEMS Microbiol Lett 243:107–115. doi:10.1016/j.femsle.2004.11.050

Carrau FM, Medina K, Farina L, Boido E, Henschke PA, Dellacassa E (2008) Production of fermentation aroma compounds by Saccharomyces cerevisiae wine yeasts: effects of yeast assimilable nitrogen on two model strains. FEMS Yeast Res 8:1196–1207. doi:10.1111/j.1567-1364.2008.00412.x

Crowell EA, Guymon JF, Ingraham JL (1961) Techniques for Studying the Mechanism of Higher Alcohol Formation by Yeasts. Am J Enol Vitic 12:111–116

Fia G, Giovani G, Rosi I (2005) Study of beta-glucosidase production by wine-related yeasts during alcoholic fermentation. A new rapid fluorimetric method to determine enzymatic activity. J Appl Microbiol 99:509–517. doi:10.1111/j.1365-2672.2005.02657.x

Gardner JM, Poole K, Jiranek V (2002) Practical significance of relative assimilable nitrogen requirements of yeast: a preliminary study of fermentation performance and liberation of H2S. Aust J Grape Wine Res 8:175–179. doi:10.1111/j.1755-0238.2002.tb00253.x

Gardner JM, McBryde C, Vystavelova A, De Barros Lopes M, Jiranek V (2005) Identification of genes affecting glucose catabolism in nitrogen-limited fermentation. FEMS Yeast Res 5:791–800. doi:10.1016/j.femsyr.2005.02.008

Henschke PA, Jiranek V (1993) Yeasts—metabolism of nitrogen compounds. In: Fleet GH (ed) Wine microbiology and biotechnology. Harwood, Switzerland, pp 77–164

Hernández LF, Espinosa JC, Fernández-González M, Briones A (2003) Beta-glucosidase activity in a Saccharomyces cerevisiae wine strain. Int J Food Microbiol 80:171–176. doi:10.1016/S0168-1605(02)00149-6

Hernández-Orte P, Ibarz MJ, Cacho J, Ferreira V (2005) Effect of the addition of ammonium and amino acids to musts of Airen variety on aromatic composition and sensory properties of the obtained wine. Food Chem 89:163–174. doi:10.1016/j.foodchem.2004.02.021

Herrero O, Ramón D, Orejas M (2008) Engineering the Saccharomyces cerevisiae isoprenoid pathway for de novo production of aromatic monoterpenes in wine. Metab Eng 10:78–86. doi:10.1016/j.ymben.2007.11.001

Jiranek V, Langridge P, Henschke PA (1995) Regulation of hydrogen sulphide liberation in wine producing S. cerevisiae strains by assimilable nitrogen. Appl Environ Microbiol 61:461–467

Martorell N, Martí MP, Mestres M, Busto O, Guasch J (2002) Determination of 4-ethylguaiacol and 4-ethylphenol in red wines using headspace-solid-phase microextraction-gas chromatography. J Chromatogr A 975:349–354. doi:10.1016/S0021-9673(02)01277-3

Mendes-Ferreira A, Mendes-Faia A, Leão C (2002) Survey of hydrogen sulphide production by wine yeasts. J Food Prot 65:1033–1037

Mendes-Ferreira A, Mendes-Faia A, Leão C (2004) Growth and fermentation patterns of Saccharomyces cerevisiae under different ammonium concentrations and its implications in winemaking industry. J Appl Microbiol 97:540–545. doi:10.1111/j.1365-2672.2004.02331.x

Mendes-Ferreira A, del Olmo M, Garcia-Martinez J, Jiménez-Martí E, Leão C, Mendes-Faia A, Perez-Ortin JE (2007) Saccharomyces cerevisiae signature genes for predicting nitrogen deficiency during alcoholic fermentation. Appl Environ Microbiol 73:5363–5369. doi:10.1128/AEM.01029-07

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428. doi:10.1021/ac60147a030

Office International de la Vigne et du Vin (1990) Recueil des méthodes internationales d’analyse des vins et des moûts. OIV, Paris

Rapp A, Versini G (1991) Influence of nitrogen compounds in grapes on aroma compounds of wine. In: Rantz (ed.) Proceedings of the international symposium on nitrogen in grapes and wines. American Society for Enology and Viticulture, Davis, CA, pp 156–164

Rauhut D (1993) Yeasts—production of sulfur compounds. In: Fleet GH (ed) Wine microbiology and biotechnology. Harwood, Switzerland, pp 183–223

Rees TD, Gyllenspetz AB, Docherty AC (1971) The determination of trace amounts of sulphide in condensed steam with NN-diethyl-p-phenylenediamine. Analyst (Lond) 96:201–208. doi:10.1039/an9719600201

Romano P, Fiore C, Paraggio M, Caruso M, Capece A (2003) Function of yeast species and strains in wine flavour. Int J Food Microbiol 86:169–180. doi:10.1016/S0168-1605(03)00290-3

Rosi I, Vinella M, Domizio P (1994) Characterization of β-glucosidase activity in yeasts of oenological origin. J Appl Bact 77:519–527

Rupela OP, Tauro P (1985) Genetic control of hydrogen sulfide retention in Saccharomyces cerevisiae. Biotechnol Lett 7:279–282. doi:10.1007/BF01042378

Schutz M, Kunkee RE (1977) Formation of hydrogen sulfide from elemental sulfur during fermentation by wine yeast. Am J Enol Vitic 28:137–144

Sea K, Butzke C, Boulton RB (1998) Seasonal variation in the production of hydrogen sulfide during wine fermentations. In: Waterhouse AL, Ebeler SE (eds) Chemistry of wine flavor. American Chemical Society, Washington DC, pp 81–95

Spiropoulos A, Tanaka J, Flerianos Y, Bisson LF (2000) Characterization of hydrogen sulfide in commercial and natural wine isolates of Saccharomyces. Am J Enol Vitic 51:233–248

Stratford M, Rose AH (1985) Hydrogen sulphide production from sulphite by Saccharomyces cerevisiae. J Gen Microbiol 131:1417–1424

Swiegers JH, Pretorius IS (2005) Yeast modulation of wine flavor. Adv Appl Microbiol 57:131–175. doi:10.1016/S0065-2164(05)57005-9

Thomas CS, Boulton RB, Silacci MW, Gubler WD (1993) The effect of elemental sulfur, yeast strain and fermentation medium on hydrogen sulfide production during fermentation. Am J Enol Vitic 44:211–216

Thomas D, Surdin-Kerjan Y (1997) Metabolism of sulfur amino acids in Saccharomyces cerevisiae. Microbiol Mol Biol Rev 61:503–532

Tokuyamai T, Kuraishi H, Aida K, Uemura T (1973) Hydrogen sulfide evolution due to pantothenic acid deficiency in the yeast requiring this vitamin, with special reference to the effect of adenosine triphosphate on yeast cysteine desulfhydrase. Gen Appl Microbiol 19:439–466. doi:10.2323/jgam.19.439

Tromp A (1984) the effect of yeast strain, grape solids, nitrogen and temperature on fermentation rate and wine quality. S Afr J Enol Vitic 5:1–6

Ugliano M, Siebert T, Mercurio M, Capone D, Henschke PA (2008) Volatile and color composition of young and model-aged Shiraz wines as affected by diammonium phosphate supplementation before alcoholic fermentation. J Agric Food Chem 56:9175–9182. doi:10.1021/jf801273k

Varela C, Pizarro F, Agosin E (2004) Biomass content governs fermentation rate in nitrogen-deficient wine musts. Appl Environ Microbiol 70:3392–3400. doi:10.1128/AEM.70.6.3392-3400.2004

Vilanova M, Ugliano M, Varela C, Siebert T, Pretorius IS, Henschke PA (2007) Assimilable nitrogen utilisation and production of volatile and non-volatile compounds in chemically defined medium by Saccharomyces cerevisiae wine yeasts. Appl Microbiol Biotechnol 77:145–157. doi:10.1007/s00253-007-1145-z

Vos PJA, Gray RS (1979) The origin and control of H2S during fermentation of grape must. Am J Enol Vitic 30:187–197

Wainwright T (1971) Production of H2S by yeasts: role of nutrients. J Appl Bact 34:161–171

Wang XD, Bohlscheid JC, Edwards CG (2003) Fermentative activity and production of volatile compounds by Saccharomyces grown in synthetic grape juice media deficient in assimilable nitrogen and/or pantothenic acid. J Appl Microbiol 94:1–11. doi:10.1046/j.1365-2672.2003.01827.x

Webb AD, Ingraham JL (1963) Fusel oil. Adv Appl Microbiol 5:317–353. doi:10.1016/S0065-2164(08)70014-5

Acknowledgments

This work was done as part of the FCT project PTDC/AGR-ALI/71460/2006. The authors thank Dr. J. Coutinho for the ammonium determination and Dr. R.N. Bennett for English revision of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mendes-Ferreira, A., Barbosa, C., Falco, V. et al. The production of hydrogen sulphide and other aroma compounds by wine strains of Saccharomyces cerevisiae in synthetic media with different nitrogen concentrations. J Ind Microbiol Biotechnol 36, 571–583 (2009). https://doi.org/10.1007/s10295-009-0527-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-009-0527-x