Abstract

In this research, optimal conditions for extraction of caffeine and polyphenols were established from Iranian green tea leaves. In the first step, caffeine was extracted with efficacy about 86% versed to 4.5% of EGC + EGCG. The EGCG + EGC was extracted from partially decaffeinated green tea leaves through microwave-assisted extraction (MAE) and ultrasound-assisted extraction (USE) with efficiency levels of 95 and 85%, respectively. The best results for the MAE process were obtained with 7.8 min and three number of extraction cycles and for the USE process were as followed: time 57 min, temperature 65 °C, and the number of extraction cycles 3. The total phenol content values at the best conditions of MAE and the USE processes were 125 ± 5 and 96 ± 6 mg gallic acid/g DW. The 50% inhibition (IC50) on 1,1-diphenyl-2-picrylhydrazyl (DPPH) were 56 and 66 mg/g of phenol for the MAE and USE processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tea (Camellia sinensis), originated in China, dates back several thousand years. In general, fresh green tea leaves contain 30% in dry weight (DW) polyphenols, among which catechins are predominant. Pharmacological features of tea can be seen mainly because of its alkaloids (caffeine) and catechins. These are distinguished into four primary compounds—comprising epicatechin (EC), epicatechin gallate (ECG), epigallocatechin (EGC), and epigallocatechin gallate (EGCG)—and four secondary low-amount compounds—catechin (C), catechin gallate (CG), gallocatechin (GC), and gallocatechin gallate (GCG). The EGCG is 45–55% of tea polyphenol [1]; it is the most potent catechins capable of inhibiting cell proliferation and inducing apoptosis in cancer cells. Green tea and green tea extracts are being applied in several industrial products such as cosmetics, food, and beverages. Anti-inflammatory, antimutagenic, and anticarcinogenic activities, as well as the anti-oxidative activity of catechins, have been established in many studies [2, 3]. Because of the functional properties of catechins, it is considered to develop efficient methods for extraction and purification of its compounds from natural plants such as tea leaves. Previous studies exhibited that a combination of ethyl alcohol and water provide the best condition for extraction of catechins from tea leaves [4]. However, it is desirable to use only water, as it is inexpensive, and the greenest solvent for extracting tea polyphenols (TPs) [5]. Subcritical water extraction has shown a proper potential for extracting TPs from tea leaves and the efficiency was slightly higher than conventional extraction solvents such as methanol and ethanol [6]. Nevertheless, epimerization of catechins and high-cost processing are the main drawbacks of this approach. In conventional green extraction technology, water is the only solvent that was used for leaching of TPs, while some external forces such as stirring, ultrasonication, microwave energy, and rotary shaking should be used to improve the rate of extraction. The microwave assisted extraction (MAE) provides a non-contact heat source, which not only makes heating more efficient and selective but also helps to accelerate energy and mass transfer [7]. The high reproducibility, less solvent and power consumption, more compact procedures, and greater purity of the final product are the advantages of using the MAE. Such extraction can be completed in minutes instead of hours. Ultrasonic-assisted extraction (UAE) is another technique capable of increasing mass transfer in the extraction procedure. The cavitation phenomenon is the principal mechanism of ultrasound [8], which creates micro-channels in the samples and thereby enhances the penetration of the solvent. The extraction of polyphenols by UAE from black tea led to an increase in the content of polyphenols by approx. 15% compared to the conventional method [9]. Response surface methodology (RSM) is an appropriate statistical technique for assessing the effects of multiple factors and their interactions, and it can also be effectively used for finding combinations of these factors to produce the best response [10]. An IV optimal design tends to place fewer runs at the extremes of the experimental region than the D-optimal design; it is a flexible design structure to accommodate the custom model with categorical and numeric factors [11]. The IV-optimally is suitable for RSM method, where prediction is important. Because of ease of calculation, frequency, and importance, the total of (EGCG + EGC) and caffeine were chosen as key compounds for HPLC analysis [12]. With regarded to previous studies, a survey of independent variables in the MAE or USE process with the focus of fewer studies variables can be interested. The effect of tea leave physical conditions, the number of extraction cycles and type of acids was investigated with the aim of experimental design to a better perception of polyphenols extraction from green tea. In point of technical approach, the using of water for all extraction processes increase applicability. The multiple responses such as recovery of main catechins, yield, and TPC were employed to study of a different aspect of extraction parameters. The primary purpose of this research was optimization of variables for extraction of caffeine from tea leaves. The second aim of this investigation was optimization of variables for extracting catechins from decaffeinated tea leaves by the MAE/UAE and comparison of these processes. Only water was used as a solvent that can be a green technology for extracting TPs.

Materials and methods

Material

Fresh green tea leaves were kindly donated from the tea research organization (Iran, Gilan province). The tea leaves were the non-clone type and cropped in May 2016. The cropped tea leaves were immediately divided into two groups. The first group was blanched by domestic microwave at 190 W for 1.5 min and conserved at 4 °C in the refrigerator. The second group instantly was frozen at −20 °C and kept at this temperature before analysis. HPLC-grade methanol, magnesium oxide and sodium carbonate, and ethanol were purchased from Merck (Darmstadt, Germany), while acetic acid was purchased from Acros (Korea). The Folin & Ciocalteu’s phenol reagent, 2,2-diphenyl-1-picryl-hydrazyl-hydrate (DPPH) reagent, and the standards EGC, EGCG, caffeine and gallic acid were obtained from Sigma-Aldrich (St. Louis, MO, USA). Water was purified by using GFL 2014 double distillers.

Decaffeination process

In the laboratory, at first, the moisture of tea leaves was calculated (100 ± 3 °C in 3 h). Proper amounts of tea leaves (Group 1 or 2) with regarded to its moisture were precisely weighed and then transferred to extractor tubes. Acidic water (acetic acid pH 4) was added, and the solid to water ratio were adjusted to 1/20. The extractions process was done according to the experimental design. The extracted solutions were cooled and employed to further analysis for determination of extracted caffeine by HPLC–UV.

The MAE and the USE procedures

For the MAE process, a domestic microwave (DeLonghi MW602) was employed at 190 W. Partially decaffeinated tea leaves 1.03 ± 0.01 g wet based were weighed and crushed (particle size ≤0.0.5 mm), and then placed in a glass container. Next, appropriate amounts of acidic water were added. The solid to water ratio was adjusted 1:40. For the USE extraction, the weight, particle size of samples, type of acids, and solid-to-water ratio were the same as above. The decaffeinated samples were placed in a glass container; the acidic water was added; and extraction was done in an ultrasonic bath with 150 W power (28 kHz, parasonic 11 s, parsnahand ENGG.CO). All experiments were done twice. The infusions of tea leaves yielded from the MAE or USE were submitted for the determination of TPC and EGCG + EGC.

HPLC analysis

HPLC for the analysis of phenolic compounds and caffeine was conducted on an Agilent 1260 infinity series (Agilent Co., Ltd, Santa Clara, CA, USA). A C18 ODS (250 × 4.6 mm, 5 µm) column and a guard column (4 × 3 mm d.i.) with 5 µm nominal particle size were employed. The solvent compositions used were water/acetic acid, 99:1, v/v (solvent A), and HPLC grade methanol (solvent B), with a flow rate of 1 mL/min. The conditions for the HPLC analysis were modified from those described by Zuo et al. [13]. Briefly, the elution started with 100% solvent A and constantly continued up to 5 min and then performed with a gradient elution to reach 35% A at 15 min, and this condition was kept for 4 min. Finally, 100% B was commenced at 19.05 min and was maintained for 8 min. The freshly prepared tea infusion was filtered through a 0.45 mm membrane filter and then was diluted 1:5, 20 µL was injected with a microsyringe and determination was done at 280 nm wavelength of the detector for caffeine, EGCG, and EGC.

TPC analysis

The TPC was determined according to the method defined by ISO 14502-1: 2005 [14]. Briefly, 1.0 mL of the diluted (1:100) extracted sample was added to tubes containing 5.0 mL of a 1/10 dilution of Folin–Ciocalteu’s reagent in water. Then, 4.0 mL of a sodium carbonate solution (7.5% w/v) was added and incubated at room temperature for one hour. The absorbance was measured in a quartz cell at 765 nm with the aim of CECIL 7200. The TPC was exhibited as mg gallic acid equivalents per gram (DW).

Determination of total of caffeine, EGCG + ECG

For calculation of yield and recovery, the extraction of the total amount of caffeine from fresh green tea leaves was carried out according to ISO 10727:2002 [15]. Briefly, dried green tea leaves (0.5 g) were accurately weighed and transferred to glass balloons; next, 150 mL of pure water and 2.25 g of oxide magnesium were added. The flask was heated at the boiling point for 20 min. The supernatant was passed through the 0.45 µm PTFE filter and used for the HPLC analysis. The determination of total EGCG + EGC was performed according to ISO 14502-2:2005 [16]. Briefly, the tea sample (0.2 g) was crushed and extracted twice with 5 mL of 70% methanol at 70 °C with intermittent shaking. The supernatant injected to HPLC-UV.

Calculation of recovery and yield

The extraction efficiency (EE) and yields of two catechins/caffeine were calculated by the formulae:

Free radical scavenging activity assay

The DPPH-free radical-scavenging activity of each sample was measured as described by Fenglin [17]. Briefly, a 0.1 mM solution of the ethanolic DPPH solution was prepared. An aliquot (0.1 mL) of each sample (with appropriate dilution if necessary) was added to 3.0 mL of the ethanolic DPPH solution. Samples were incubated for 30 min at 25 °C in the dark and discolorations were measured at 517 nm. The measurements were performed at least thrice. The percentage of DPPH that scavenged was calculated by using the following formula:

where Acont is the absorbance of the control and Asamp is the absorbance of the sample.

Design of experiments and statistical analysis

To the decaffeination process, three independent variables comprising temperature (20–100 °C, time (1–10 min) both numerical, and type of the tea (frozen or blanched) as categorical factor were optimized by a central composite design (CCD) to reach the maximum value of caffeine’s EE versus minimum value of EE of (EGCG + EGC) as dependent variables. As many as 26 experiments were carried out with five center points. For optimization of the MAE and the USE process, optimal design type IV was chosen [18]. The MAE process was designed with three independent variables comprising the number of extraction cycles (1, 2 or 3 times) and types of acid (phosphoric or acetic acid) as categorical factors and time as numerical variable (2–8 min) total runs were 21. The independent variables of the USE process were the number of extraction cycles (1, 2 or 3), type of acid (phosphoric or acetic acid), temperature (25 or 65 °C) as categorical factors and time as the numerical factor (10–60 min). As many as 26 experiments were carried out. The response variables of the MAE or the USE process were the EE of the total EGCG + EGC and TPC. The pH was set to 4.5 with using of acetic or phosphoric acid. To ensure the accuracy, the experiments were replicated twice. In the present study, Design-Expert 8.0.7.1 Trial version (Stat-Ease Inc., Minneapolis, MN, USA) was applied to the experimental design and regression analysis of experimental data. The MS Excel version 2010 was used for other calculation, and the results were considered as a mean ± standard deviation.

Results and discussion

Decaffeination process

The major bioactive components in green tea leaves are caffeine and catechins. Caffeine content is around 20–40 mg/g. The total amount of caffeine was obtained 12.8 mg/g ± 1 mg and 13.8 mg/g ± 1 mg in blanched and frozen tea leaves, respectively (DW). The yield of caffeine in the best condition was 4.8% (DW). The statistical significance of the regression equation was examined by F-test and ANOVA for the response surface quadratic polynomial model, as revealed in Table 1. The data obtained were fitted to second-order polynomial equations, and the predictive equation is given as:

The Fisher’s F-test had a very high model F-value (1170.79) and a very low P value (P < 0.0001), proving that the model was highly significant and the lack-of-fit was not significant in comparison with the pure error. There is 11.15% chance that a ‘Lack of Fit F-value’ this large could occur due to noise. R2 was increased by adding model terms. Nevertheless, \( {\text{R}}_{\text{adj}}^{2} \) was not increased by adding insignificant variables and could be used to check the adequacy of the model. \( {\text{R}}_{\text{pre}}^{2} \) indicates a regression model that perfectly predicts responses for new observations. The results show the significant effects of temperature and time as well as their interactions on the EE of caffeine (Table 1). The extraction of caffeine shows a great relationship to temperature. The molecular weight of caffeine is lower than catechins, and its solubility is considered in hot water [5]. Also, the kinetic behavior of caffeine extraction shows fast diffusion at the initial time of extraction [19]. The best EE of caffeine was reached about 86% against 6.5% of two catechins. The frozen tea leaves show slightly more EE than blanched tea leaves. The destruction of the cell wall due to thawing may be related to this phenomenon. The extraction parameters regarding the maximum extraction of caffeine and the minimum of catechins were as followed: temperature 88.2 °C, time 8.7 min and type of tea blanched. As constant parameters, the pH of water used for extraction was 4, and the water-to-tea ratio was set 20:1. At these conditions, the desirability about 0.891 was obtained. Our result was almost similar to other studies that used water for extraction of caffeine [20] and was better than some expensive technique. Accelerated solvent extraction system with bio-renewable agrochemical solvent (ethyl lactate) presents recovery about 60% of the caffeine from ground green coffee [21]. The use of supercritical fluid extraction to an extract of caffeine from green tea has exhibited a recovery between 52% to nearly 93% regarding mode and co-solvent [22]. The results obtained by Bermejo and co-workers have exhibited the combination of ethyl lactate and water (25:75) was 1.5 times more effective than only water for extraction of caffeine. The using pressurized liquid extraction with this solvent mixture at 373–423 K removed 53–76% of caffeine and 26–36% of catechins present in the tea leaves [23].

The MAE process

The analysis of variance and quality performance of the response surface quadratic polynomial model were shown in Table 2. The quadratic fitted model of The EE of two catechins was:

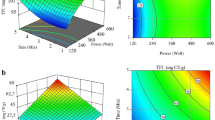

The time, the number of extraction cycles and interaction between them are significant. The type of acid has not a significant effect in the MAE or USE process. It seems that, the efficiency of extraction more affected by pH. The greatest effect is related to time. This result is in agreement with Li and Jiang [24] that have indicated the time of extraction is a primary factor that affects the extraction efficiency of catechins. In the MAE process, the temperature was kept about 65 ± 5 °C by cooled water or stopping the process. The best variables levels were as follows: time 7.8 min, three number of extraction cycles and acetic acid that under these conditions about 95% of two available catechins were extracted. The best yield was 6.25% (DW). Our results was better than Quan and co-workers studies that showed the MAE process at 800 W with ethanol and water mixture (60:40), volume 150 mL, material: solvent ratio 1:6 (g/mL) achieved 82.46% yield of caffeine after 6 min from fresh green tea leave [25]. Multiple extractions are known as an elegant way to increase the extraction efficiency. As shown in Fig. 1(A), with increasing time, the EE of two catechins increased especially by three number of extraction cycles. One possible reason was that with the 7.8 min and microwave intensity at 180 W, the extract solution could get an adequate heating. Also, because of the tea/water ratio of 1:40, the polyphenol degradation, transformation, and mutual reactions do not occur [26]. Figure 1(B) indicates that the influence of the type of acid on extraction efficiency. The TPC was analyzed as second response factor (data of model was not shown). The maximum TPC was 125 ± 5 mg/g. Figure 1(C) shows the effect of time and number of extraction cycles of the TPC. The three number of extraction cycles significantly increases the TPC. However, the effect of one in comparison with 2 number of extraction cycles was not significant. The influence of the type of acid on the TPC was shown in Fig. 1(D). As it is seen, acetic or phosphoric acid partially has same effects on the TPC values. The temperature during the MAE process increased the near boiling point. Xiao and co-workers evaluated the stability of flavonoids during the MAE from Radix Astragali and found out that the extraction performed between 70 and 110 °C did not negatively affect the flavonoid content of the extract, while the temperature above 130 °C degradations of some components occurred [27]. The same trend of the EE of catechins and TPC proved their results.

The USE process

The using of ultrasound as a laboratory-based technique for assisting extraction from plant material is extensively reviewed [28]. The main effects of the factors on the extraction efficiency of catechins were presented in Table 2. The time, the number of extraction cycles, temperature, and their interactions are significant. The type of acid has not a significant effect. The Model F-value of 57.42 implies that the model is significant. There is only a chance of 0.01% that a ‘Model F-Value’ could occur due to noise. The effect of A and D (coded values) are the greatest of all factors. The final EE of the total two catechins (Y) was given by RSM:

The 2-factor interaction (2FI) model type was fitted. As showed by the equation, among the interaction AC2 and AD are significant effects on the EE. At best conditions, time 57 min, temperature 65, phosphoric acid and three number of extraction cycles the EE was 85%. In these circumstances, the yield was 5.91% of EGCG + EGC, and the TPC was obtained 96.26 ± 6 mg/g (DW). The independent variables levels were the same to achieve maximum values of the EE and the TPC. The interaction between times and number of extraction cycles was presented in Fig. 2(A). With increasing of time, the effect of number of extraction cycles on the EE of catechins is clear. The USE increases the content of polyphenols approx. 15% in comparison with the conventional method in black tea [9]. However, application of the USE to the extraction of catechins and caffeine in green tea showed lower efficiency than extraction at room temperature [29]. The result obtained by Hitoshi and Nobuyoshi indicated that extraction of catechins by USE rapidly increase up to 1 h at room temperature. Also, the effect of ultrasonic irradiation is better for green tea leaves than for tea powder, whereas the amount of catechins extracted is smaller for tea leaves than for tea powder [30]. In our study, the EE of this method was about 10% lower than the microwave method. Figure 2(B) indicates that the temperature of 65 °C is more affected than 25 °C on the extraction of catechins. Although, the results obtained by Xia et al. [31] indicated that the better extraction efficiency of the main chemical components was achieved from tea at lower temperatures. The behavior of TPC values was the same as the extraction efficiency of catechins. Figure 2(C, D) show its progress at the point of the level of independent variables. The same trend was obtained for TPC, suggesting that the phenols not to be oxidized during diffusion from the solid into a liquid.

Verification of predictive models

The polynomial regression equations was checked for predicting the typical response values. For this perpous, five additional experiments were performed to test the suggested optimum conditions. Table 3 shows that the models have high potential to predict the results within the range of independent variables.

The DPPH test

The scavenging abilities of the MAE and the USE extracts were evaluated by the DPPH test. Figure 3 shows SC % had a significant increase with the increasing of green tea extracted. According to the TPC test, 100 µL of extracted from the MAE and the USE process (at best conditions) contained 113 and 95 mg/g of phenol (DW) respectively, which gives scavenge radicals about 90% of the MAE and 80% of the USE. The concentration of the extract giving 50% inhibition (IC50) was determined from a dose response curve. IC50 represented the concentration of the extract that inhibited 50% of radicals. For the MAE and the USE process, IC50 was 56 and 66 mg/g of phenol (DW) respectively.

In this work, caffeine and two important catechins EGCG and EGC were extracted by water and application of safe techniques. All steps were optimized with the aim of experimental design. In caffeine extraction, the main variable was temperature. As many as 94.5% of the selected catechins remained intact. However, the best final EE of catechins in two steps included caffeine extraction followed by the MAE process was about 90%. The optimal design was applied for optimization of the MAE and the USE process. The using of the MAE was significantly more efficient for the extraction of catechins, yield, and TPC than the USE. Further, the DPPH results confirmed the performance of the MAE process. The behavior of TPC was the same as the EE of catechins in both methods. As a result, the effects of independent variables were similar on the EE of catechins and TPS either USE or MAE process. However, in point of obtained results, the efficiency of the MAE process was significantly more than the USE process. Consequently, decaffeination by water and using of MAE could be employed as the quick preparation approach to of decaffeinated tea leaf.

References

Hoa C, Chena C, Wanasundara U, Shahidi F. Natural antioxidants from tea. Natural Antioxidants: Chemistry, Health Effects, and Applications: 213–223 (1997)

Finger A, Engelhardt UH, Wray V. Flavonol triglycosides containing galactose in tea. Phytochem. 30: 2057–2060 (1991)

Watson RR, Preedy VR. Bioactive foods and extracts: Cancer treatment and prevention. CRC Press (2010)

Choung MG, Hwang YS, Lee MS, Lee J, Kang ST, Jun TH. Comparison of extraction and isolation efficiency of catechins and caffeine from green tea leaves using different solvent systems. Int. J. Food Sci. Technol. 49: 1572–1578 (2014)

Vuong QV, Roach PD. Caffeine in green tea: its removal and isolation. Sep. Purif. Rev. 43: 155–174 (2014)

Ko M-J, Cheigh C-I, Chung M-S. Optimization of subcritical water extraction of flavanols from green tea leaves. J. Agric. Food. Chem 62: 6828–6833 (2014)

Gujar J, Wagh S, Gaikar V. Experimental and modeling studies on microwave-assisted extraction of thymol from seeds of Trachyspermum ammi (TA). Sep. Purif. Technol. 70: 257–264 (2010)

Knorr D, Zenker M, Heinz V, Lee D-U. Applications and potential of ultrasonics in food processing. Trends Food Sci. Technol 15: 261–266 (2004)

Both S, Chemat F, Strube J. Extraction of polyphenols from black tea–Conventional and ultrasound assisted extraction. Ultrason. Sonochem 21: 1030–1034 (2014)

Yolmeh M, Najafi MBH, Farhoosh R. Optimisation of ultrasound-assisted extraction of natural pigment from annatto seeds by response surface methodology (RSM). Food Chem. 155: 319–324 (2014)

Beringhs AO, Dalmina M, Creczynski-Pasa TB, Sonaglio D. Response Surface Methodology IV-Optimal design applied to the performance improvement of an RP-HPLC-UV method for the quantification of phenolic acids in Cecropia glaziovii products. Rev. bras. Farmacogn. 25: 513–521 (2015)

Labbé D, Tremblay A, Bazinet L. Effect of brewing temperature and duration on green tea catechin solubilization: Basis for production of EGC and EGCG-enriched fractions. Sep. Purif. Technol. 49: 1–9 (2006)

Zuo Y, Chen H, Deng Y. Simultaneous determination of catechins, caffeine and gallic acids in green, Oolong, black and pu-erh teas using HPLC with a photodiode array detector. Talanta 57: 307–316 (2002)

ISO 14502-1:2005. Determination of substances characteristic of green and black tea. Part 1: content of total polyphenols in tea. Colorimetric method using FolineCiocalteu reagent

ISO 10727:2002. Tea and instant tea in solid form - Determination of caffeine content – Method using high-performance liquid chromatography

ISO 14502-2:2005. Determination of substances characteristic of green and black tea—Part 2: Content of catechins in green tea—Method using high-performance liquid chromatography

Fenglin H, Ruili L, Liang M. Free radical scavenging activity of extracts prepared from fresh leaves of selected Chinese medicinal plants. Fitoterapia 75: 14–23 (2004)

Jones B, Goos P. I-optimal versus D-optimal split-plot response surface designs. J. QUAL. TECHNOL. 44: 85 (2012)

Suteerapataranon S, Butsoongnern J, Punturat P, Jorpalit W, Thanomsilp C. Caffeine in Chiang Rai tea infusions: Effects of tea variety, type, leaf form, and infusion conditions. Food Chem. 114: 1335–1338 (2009)

Liang H, Liang Y, Dong J, Lu J, Xu H, Wang H. Decaffeination of fresh green tea leaf (Camellia sinensis) by hot water treatment. Food Chem. 101: 1451–1456 (2007)

Bermejo DV, Luna P, Manic MS, Najdanovic-Visak V, Reglero G, Fornari T. Extraction of caffeine from natural matter using a bio-renewable agrochemical solvent. Food Bioprod. Process. 91: 303–309 (2013)

Sun Q-L, Hua S, Ye J-H, Lu J-L, Zheng X-Q, Liang Y-R. Decaffeination of green tea by supercritical carbon dioxide. J. Med. Plant Res. 4: 1161–1168 (2010)

Bermejo DV, Mendiola JA, Ibáñez E, Reglero G, Fornari T. Pressurized liquid extraction of caffeine and catechins from green tea leaves using ethyl lactate, water and ethyl lactate + water mixtures. Food Bioprod. 96: 106–112 (2015)

Li D-C, Jiang J-G. Optimization of the microwave-assisted extraction conditions of tea polyphenols from green tea. J. Food Sci. Nutr. 61: 837–845 (2010)

Quan PT, Hang T, Hai Ha N, De NX, Tuyen TN. Microwave-assisted extraction of polyphenols from fresh tea shoots. Sci. & Tech. Develop., 9(8), 69–75

Perva-Uzunalić A, Škerget M, Knez Ž, Weinreich B, Otto F, Grüner S. Extraction of active ingredients from green tea (Camellia sinensis): Extraction efficiency of major catechins and caffeine. Food Chem. 96: 597–605 (2006)

Xiao W, Han L, Shi B. Microwave-assisted extraction of flavonoids from Radix Astragali. Sep. Purif. Technol. 62: 614–618 (2008)

Chemat F, Rombaut N, Sicaire A-G, Meullemiestre A, Fabiano-Tixier A-S, Abert-Vian M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34: 540–560 (2017)

Choung M-G, Lee M-S. Optimal extraction conditions for simultaneous determination of catechins and caffeine in green tea leaves. Food Sci. Biotechnol. 20: 327–333 (2011)

Hitoshi K, Nobuyoshi M. Extraction of Catechins from Green Tea Using Ultrasound. Jpn. J. Appl. Phys. 46: 4936 (2007)

Xia T, Shi S, Wan X. Impact of ultrasonic-assisted extraction on the chemical and sensory quality of tea infusion. J. Food Eng. 74: 557–560 (2006)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ghasemzadeh-mohammadi, V., Zamani, B., Afsharpour, M. et al. Extraction of caffeine and catechins using microwave-assisted and ultrasonic extraction from green tea leaves: an optimization study by the IV-optimal design. Food Sci Biotechnol 26, 1281–1290 (2017). https://doi.org/10.1007/s10068-017-0182-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0182-3