Abstract

Although tea is the second most consumed beverage in the world, its benefits is not fully achieved because its bioactive compounds are not efficiently extracted from the plant. In this work the extraction of bioactive compounds from a tea blend, composed of 40% green tea, 40% white tea, 10% mint and 10% peppermint, was investigated using a microwave-assisted technique. The effects of ethanol concentration, extraction time, and liquid/solid ratio on the total phenolic content, total flavonoid content and antioxidant potential were quantified. An optimization study was also performed to identify the conditions that enable the maximum extraction of phenolic and flavonoids contents, with a maximum antioxidant capacity. The predicted optimal conditions included a 38.8% ethanol concentration, 3 min of extraction, and a 184.1 mL/g liquid/solid ratio. HPLC analyses were also performed to identify the major antioxidant compounds and the results confirmed the high antioxidant potential of the studied tea blend.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The teas obtained from Camellia sinensis, a plant originating from Asia, are popular all over the world and are widely consumed for their excellent taste and beneficial health effects. These benefits are due to their bioactive compounds, including polyphenols [1], flavonoids, and caffeine, among others. Many studies [2,3,4] have confirmed the high concentration of bioactive compounds in Camellia sinensis leaves and interest in these teas is mainly due to their free radical scavenging activities. The blending of different teas together to produce a final product has been increasingly consumed as a specific product, because it is possible to create a well-balanced flavor using different origins and characters.

The extraction process used in the production of tea can significantly change the composition and bioactivity of the extracts, since most techniques have some drawbacks, including the thermal degradation of some compounds or the excessive extraction time required [5,6,7]. Alternative extraction techniques, including ultrasound and microwave assisted extraction, have been studied due to their high productivity, yield, and selectivity, as well as their short processing times, improved quality, reduced physical and chemical hazards and environmental friendliness [8,9,10,11,12]. In addition to these new extraction techniques, the choice of solvent is also very important [13]. Extractions performed using safe solvents that reduce the amount of energy consumed have often been sought by researchers. Ethanol has been recommended by the US Food and Drug Administration for use as an extraction solvent because of its low toxicity.

Microwave-assisted extraction (MAE) is a green extraction technique that offers an attractive alternative to conventional approaches [14]. MAE involves heating the solvent by the absorption of microwave energy by polar molecules [15]. Microwaves accelerate the energy transfer and promote the disruption of weak hydrogen bonds, facilitating solvent penetration, which results in leaching of the target analyte through rapid extraction solvent entry into the material matrix [16].

This work, for the first time investigated the extraction of bioactive compounds from a tea blend using microwave-assisted extraction (MAE). The blend of teas used in this study was composed of 40% green tea, 40% white tea, 10% mint and 10% peppermint, which has unique and specific characteristics. The effects of the ethanol (solvent) concentration (C), extraction time (t), and liquid/solid ratio (R) on the total phenolic content, total flavonoid content and antioxidant potential were quantified by regression analysis. An optimization study was also performed, for the first time for the extraction process of a blend of tea, using the desirability technique [17] to identify the best extraction conditions. The main bioactive compounds obtained under optimum operating conditions were identified using high-performance liquid chromatography with an ultraviolet detector (HPLC-UV).

Materials and methods

Materials

The tea blend used in the experiments was provided by Provanza, a Brazilian company that manufactures cosmetics and resells teas. By weight, the tea blend is composed of 40% green tea, 40% white tea, 10% mint and 10% peppermint. The blend sheets were crushed, sieved (0.425 mm), and then stored in 500 g metallic packaging, tightly closed. The tea blend had a moisture content of 7.76 ± 0.17 g per 100 g of wet sample.

Sensory analysis was carried out to assemble this blend of teas, since Camellia sinensis teas have an astringent flavor and are not always pleasant to the palate. Mixtures of teas should be capable of deliver a product with a greater amount of bioactive and more pleasant tastes and smells for the consumer. Thus, the bioactive compounds present in individual tea, was considered to choose the blend composition. Some studies of conventional extractions [18,19,20] from the literature show results of bioactive compounds and antioxidant activity of the individual teas used in our blend. Table 1 shows results of Total phenolic content (TPC) and IC50 from the extracts of the each tea of the studied blend.

It can be seen in Table 1 that the white tea and green tea (Camellia sinensis teas) had the highest values of TPC. Therefore these teas were used in the highest and same proportion in the blend. Similarly, mint and peppermint are plants of the same family and have similar bioactive compounds contents. To quantify the proportion of mint and peppermint in this tea, a sensory test was performed, in which the product that most pleased the palate and smell was the mixture with 10% mint and 10% peppermint, consequently the remaining 80% were formed by 40% white tea and 40% green tea.

pH and water activity

The pH of the tea blend was determined using 15 g of crushed sample in 100 mL of distilled water. The mixture was kept in a magnetic stirrer from Fisatom and model 751 for 30 min. Subsequently, the solution was centrifuged, and the supernatant had its pH measured using an ION PH-300 device. The water activity was measured at 25 °C using a Novasina LabSwift equipment.

Extraction procedures

Extraction of the antioxidant compounds from the tea blend was performed in a Panasonic microwave oven model NN-SF560WRUK with a frequency 2450 Hz and 229 W of power. The device operate with a fixed frequency (2450 Hz). The power was chosen based on preliminary tests, in which the power of 229 W led to the best results of the bioactive compounds in the extracts. Table 2 shows an example of these preliminary results. The oven was adapted by connecting it to a condensing system. During the tests, the material was protected from exposure to light. The following independent variables were analyzed: ethanol concentration (C), process time (t), and liquid/solid ratio (R). For the liquid/solid ratio (R), the volume of the hydroethanolic solution was kept constant at 40 mL and for ethanol concentration (C) was considered mass percentage of ethanol in water (grams of ethanol/100g of solution). After extraction, the filtrate was used to determine the content of bioactive compounds, and the filter-retained mass was investigated by scanning electron microscope (SEM) analysis.

Experimental design

The experimental conditions were determined using a central composite design (CCD) [21]. To analyze the three independent variables (C, t, and R), we conducted a total of 17 experiments, with three of them at the center. The response surface technique was used to fit prediction equations for the studied responses and to identify the best extraction conditions. The analyzed responses included the total phenolic and flavonoid compound contents (TPC and TFC) and the antioxidant potential. Table 3 shows the various levels used in the experimental design.

The experimental results were analyzed using regression techniques [22]. We calculated the effects of the independent variables on each dependent variable and determined the significant parameters by an analysis of variance (ANOVA). The adequacies of the fitted equations were evaluated based on the values of the correlation coefficients, F and p. Next, we performed multi-response optimization using the desirability function [17]. To verify the suitability of this methodology, an additional experiment was conducted under the identified optimized conditions and the obtained values were compared with those calculated by the prediction equations.

Bioactive compounds

The extraction responses analyzed in this work included the Total phenolic content (TPC), Total flavonoid content (TFC) and the 2,2-diphenyl-1-picryl-hydrazyl (DPPH) radical scavenging activity.

The TPC was measured using the Folin-Ciocalteu assay [23]. Gallic acid monohydrate (99%) was used as a standard for preparing the calibration curve and the TPC in the extract was presented in terms of milligram gallic acid equivalent (GAE) per 100 grams of dry weight. The aluminum chloride colorimetric assay [24] was used to measure the TFC, with rutin hydrate (94%) as a standard. The TFC was presented in terms of mg of rutin per 100 g of dry weight. In addition to these bioactives compounds determination, the DPPH (radical scavenging activity) analyses were also performed, as an indicative of antioxidant capacity. The DPPH radical scavenging assay, as described by Brand-Williams et al. [25], was used to evaluate the antioxidant potential of the extracts. A solution containing 40 mL of methanol 50%, 40 mL of acetone 70% and 20 mL of distilled water was prepared as standard. The control solution was prepared using the standard solution and DPPH solution without any extract, and methanol was used for the baseline correction. An appropriate dilution of the DPPH solution was used as negative control, i.e., control sample in place of the sample. The IC50 of the tea blend was measured using the spectrophotometric method (at 515 nm). The IC50 is the amount of an antioxidant required to decrease the initial DPPH concentration by 50%, whereby a lower IC50 value indicates a greater overall effectiveness of the antioxidant [26]. This response was presented in terms of µg of DPPH per mL of extract.

HPLC characterization

The extract generated under optimum conditions was analyzed using HPLC-UV to identify the main bioactive compounds. The obtained extract was concentrated by rotary evaporation, and then frozen for 1 h at − 70 °C and subjected to a lyophilization for 24 h [27]. Then, the extract was re-dissolved in methanol, after which it was filtered through a 0.22-µm microporous membrane. The analyses were performed in a Shimadzu HPLC (model LC-20A) equipped with a Discovery HS C18 column.

The compounds were identified using the methodology described by Wang et al. [28]. The run time was 30 min, the mobile phase flow rate was 1.0 mL/min, and the temperature was 30 °C. The mobile phase used comprised methanol/water/orthophosphoric acid in the proportion 20/79.9/0.1 by volume, respectively. The phenolic acids, caffeine and flavonoid compounds were identified by comparing our results with standards for each identified compound based on the retention time.

Microstructure evaluation

To determine the effect of the extraction process on the material, the microstructure of the tea blend was examined using a SEM (Carlzeiss, EVOMA10). The SEM images were recorded at 10 kV and a magnification of 500 ×. Prior to scanning, we fixed the tea blends on specific carbon film holders and coated them with gold [29].

Results and discussion

Experimental results

The tea blend had a pH of 5.52 ± 0.08 and a water activity of 0.583 ± 0.06. Table 4 shows the TPC, TFC and IC50 results for each run of the experimental design. All three responses showed great sensitivity to variations in the operating conditions.

The lowest TPC (354.0 mg GAE/100 g) was obtained in Run 11, which was performed at the lowest liquid/solid ratio (R = 15.9 mL/g), and an intermediate ethanol concentration (C = 50%) and processing time (t = 2 min). The highest TPC (2476.8 mg GAE/100 g) was obtained in run 12, which was also performed at an intermediate extraction time (t = 2 min) and ethanol concentration (C = 50%), but at the highest liquid/solid ratio (R = 184.1 mL/g).

The TFC for all the experimental runs ranged from 5.51 mg of rutin/100 g (run 14) to 2476.8 mg of rutin/100 g (run 7). The highest TFC was obtained in run 7, which was performed with a liquid/solid ratio R = 150 mL/g, an extraction time of 3 min, and a low ethanol concentration (C = 20%). Run 14, which yielded the lowest TFC, was performed at intermediate R (100 mL/g) and t (2 min) levels, but at the highest ethanol concentration (C = 100%). Run 14 also yielded the highest IC50 (2.35 µg/mL) and hence the lowest antioxidant activity. The best antioxidant activity (lowest IC50) was obtained in run 10, which was performed with a liquid/solid ratio R = 150 mL/g, the maximum extraction time (t = 3.7 min), and an intermediate ethanol concentration (C = 50%). According to Reynertson et al. [30], the extracts can be classified into 4 groups according to its IC50 value, as follows: very active extracts with IC50 < 50 µg/mL, moderately active extracts with IC50 between 50 and 100 µg/mL, slightly active extracts with IC50 between 100 and 200 µg/mL and inactive extracts with IC50 > 200 µg/mL. On this basis, for all operating conditions, the extracts from the tea blend studied in this work can be classified as very active.

Due to the nonlinear effects and different behaviors arising from the effects of the independent variables on each response, it is not possible to clearly identify the best operating conditions only by these results. Therefore, we performed an optimization study to identify the best operating conditions, by simultaneously considering all three responses.

Statistical analysis

To quantify the effects of the independent variables on each response, regression equations (Eq. 4) were obtained. In these regressions, the studied variables (t, R and C) were coded using the following equations:

where t is in min, R is in mL/g and C is in %

Where y is the specific dependent variable (either TPC, TFC or IC50), βo is the independent parameter, and βi, βii and βij are the respective coefficients related to the linear, quadratic, and interaction effects.

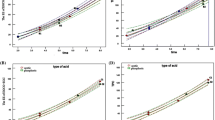

Table 5 shows the regression results for the three responses. The quality of the regression equations was analyzed by ANOVA, R-Squared and residual analyses. We found the fit of all the responses to be adequate, with r2 = 0.927 (TPC), 0.943 (TFC) and 0.957 (IC50). The residual analysis indicated random, independent residuals with normal distribution (mean zero and constant variance). Figure 1 shows the response surfaces obtained by the prediction equations (Equation 4 and Table 5).

The linear effect of the liquid/solid ratio (R) was positive and significant for TPC and TFC and negative for IC50 (positive for antioxidant activity). A high liquid/solid ratio yields less concentrated solutions, which favors the mass transfer process from solute to solvent. The positive effect of R on the extraction of the bioactive compounds can also be observed in Fig. 1a, c, f and g. The parameters (Table 5) related to the extraction time (t) show a strong quadratic effect of this variable, which indicates that a prolonged exposure to elevated temperatures can favor the degradation of the bioactive compounds [31] and that very short processing times may not be sufficient for the extraction of these compounds. This outcome can also be seen in Fig. 1a, b, d and e. Furthermore, it is possible to verify that there are significant interactions between the time variable and the two other independent variables. The parameters related to ethanol concentration (C) indicate that an increase in C reduces the TPC, TFC and the antioxidant activity (increase IC50), but also has a nonlinear effect. This trend also can be observed in Fig. 1a, c and f. Therefore, diluted ethanol is more effective in extracting phenolic compounds than a pure organic solvent because the addition of water in organic solvents creates a more polar medium, which facilitates the extraction of polyphenols. In addition, these compounds occur naturally as glycosides and the presence of sugars makes them more water soluble [32].

Optimization study

An optimization procedure was conducted to simultaneously maximize TPC and TFC and minimize the IC50 (maximize the antioxidant capacity). However, this condition is determined for a multi-response optimization, which means it is not necessarily optimal for each individual response. The multi-response optimization was performed using the desirability function [17]. Figure 2 shows the results of the desirability analysis, in which it can be seen that the optimum conditions (in coded values) were: x1 = 1.0092, x2 = 1.682 and x3 = − 0.3925. Converted to the original units, the optimized independent variables are t = 3.01 min, R = 184.1 mL/g and C = 38.24%.

To validate the results of the optimization study, an additional experiment was performed using the optimal conditions. Table 6 shows the experimental results obtained under optimized conditions and those calculated by the prediction equations (Eq. 4 and Table 5). All experimental measurements were performed in triplicate. We can see that the values obtained in the confirmatory experiment agree well with those predicted by the proposed equations.

Figure 3 shows the TPC, TFC and IC50 results obtained in the 17 CCD experiments, as well as those obtained under optimized conditions, with the horizontal line indicating the responses obtained under the optimized conditions. We can see that the results obtained in the experiment performed using the conditions indicated by the multi-response optimization study led to the highest TFC and lowest IC50 (highest antioxidant capacity), as compared with the results of the experiments performed in the experimental design. With respect to the TPC, the value obtained in the optimal multi-response condition was higher than those obtained in most of the CCD experiments (except for run 12).

SEM results

Figure 4 shows the microstructure of the tea blend observed by SEM, before (a) and after (b) extraction performed at optimal conditions. It can be seen in Fig. 4b that the conditions used in this extraction promoted a breakdown of the cell wall, probably due to cavitation, which facilitated the release of the compounds. Lou et al. [33] emphasized that the use of high temperatures in the extraction process implies a higher vapor pressure, the formation of more bubbles, and therefore greater cell disruption.

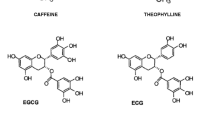

HPLC results

Figure 5 shows the HPLC chromatogram for the tea blend extract obtained at the optimized conditions, in which we can see the presence of the epigallocatechin gallate (EGCG), epicatequin (EC), epigallocatechin (EGC), caffeine and gallic acid (GAE). The tea blend used in this work was composed of 80% leaves of the Camellia sinensis plant and the chromatogram indicates a significant presence of EGCG, as also reported by Saito et al. [34], who investigated the extraction of green tea. Toschi et al. [35] showed that green tea extract is composed mostly of the catechins EGCG and EGC. According to these authors the high concentrations of EGCG and EGC gives green tea extract its great antioxidant capacity. Table 7 shows the concentrations of the main compounds identified by HPLC analysis.

The HPLC results of the tea blend obtained in the present work, under optimized conditions, were compared with those obtained by Wang et al. [28] (considering the concentration of each compound and the mass of tea used), which determined the content of catechins, caffeine and gallic acid present in green tea by HPLC using an isocratic elution system. Table 8 shows both results, in which it can be seen the higher content of GAE, EGC, Caffeine, EGCG and EC in the extracts obtained with the extraction methodology used in the present work.

Conclusions

In this work, the microwave-assisted extraction (MAE) with hydroalcoholic solutions was for the first time used for extraction of bioactive compounds from a tea blend. The results showed that this extraction technique is a good alternative for a tea blend, because it is a green technology and that yields high levels of antioxidant compounds in its extract.

Our statistical analyses showed that the ethanol concentration, liquid/solid ratio and processing time play an important role in the extraction of bioactive compounds from a tea blend, that consists of 40% green tea, 40% white tea, 10% mint, and 10% peppermint by weight. The results indicated that the optimal extraction levels were: 184.1 mL/g liquid/solid ratio, 3 min of microwave extraction and a 38.24% ethanol concentration. These conditions involve a shorter processing time than other extraction techniques, as well as lower processing costs, because 61.76% of the solvent used is water. The optimal conditions led to a TPC of 2164.75 ± 97.61 mg GAE /100 g, a TFC of 12.71 ± 0.18 mg rutin/100 g and an IC50 of 0.773 ± 0.006 μg/mL.

HPLC analyses enabled the identification of important antioxidant compounds, including epigallocatechin gallate, epicatechin, epigallocatechin, caffeine and gallic acid, which are associated with disease prevention.

References

P. Sasikala, A. Chandralekha, R.S. Chaurasiya, J. Chandrasekhar, K.S.M.S. Raghavarao, Ultrasound-assisted extraction and adsorption of polyphenols from Ginger Rhizome (Zingiber officinale). Sep. Sci. Technol. 53(3), 439–448 (2018). https://doi.org/10.1080/01496395.2017.1391290

M.M.M. Bindes, V.L. Cardoso, M.H.M. Reis, D.C. Boffito, Maximisation of the polyphenols extraction yield from green tea leaves and sequential clarification. J. Food. Eng. 241, 97–104 (2019). https://doi.org/10.1016/j.jfoodeng.2018.08.006

L.S. Sousa, B.V. Cabral, G.S. Madrona, V.L. Cardoso, M.H.M. Reis, Purification of polyphenols from green tea leaves by ultrasound assisted ultrafiltration process. Sep. Purif. Technol. 168, 188–198 (2016). https://doi.org/10.1016/j.seppur.2016.05.029

S. Banerjee, J. Chatterjee, Efficient extraction strategies of tea (Camellia sinensis) biomolecules. J. Food Sci. Technol. 52, 3158–3168 (2015). https://doi.org/10.1007/s13197-014-1487-3

S. Franquin-Trinquier, C. Maury, A. Baron, D. Le Meurlay, Optimization of the extraction of apple monomeric based on response surface methodology: comparison of pressurized liquid-solid extraction and manual-liquid extraction. J. Food Comp. Anal. 34, 56–67 (2014). https://doi.org/10.1016/j.jfca.2014.01.005

A. Perva-Uzunalic, M. Skerget, Z. Knez, B. Weinreich, F. Otto, S. Gruner, Extraction of active ingredients from green tea (Camellia sinensis): Extraction efficiency of major catechins and caffeine. Food Chem. 96, 597–605 (2006). https://doi.org/10.1016/j.foodchem.2005.03.015

M.B. Soquetta, F.S. Stefanello, K.M. Huerta, S.S. Monteiro, C.S. Rosa, N.N. Terra, Characterization of physiochemical and microbiological properties, and bioactive compounds, of flour made from the skin and bagasse of kiwi fruit (Actinidia deliciosa). Food Chem. 199, 471–478 (2016). https://doi.org/10.1016/j.foodchem.2015.12.022

M.A.S. Barrozo, K.G. Santos, F.G. Cunha, Mechanical extraction of natural dye from Bixa orellana seeds in spouted bed. Ind. Crops. Prod. 45, 279–282 (2013). https://doi.org/10.1016/j.indcrop.2012.12.052

E. Dorta, M.G. Lobo, M. González, Improving the efficiency of antioxidant extraction from mango peel by using microwave-assisted extraction. Plant Foods Hum. Nutr. 68, 190–199 (2013). https://doi.org/10.1007/s11130-013-0350-4

R.S. Lima, I.L. Nunes, J.M. Block, Ultrasound-assisted extraction for the recovery of carotenoids from guava’s pulp and waste powders. Plant Foods Hum. Nutr. 75, 63–69 (2020). https://doi.org/10.1007/s11130-019-00784-0

X. Pan, G. Niu, H. Liu, Microwave-assisted extraction of tea polyphenols and tea caffeine from green tea leaves. Chem. Eng. Proces. 42, 129–133 (2003). https://doi.org/10.1016/S0255-2701(02)00037-5

T. Taham, F.A. Cabral, M.A.S. Barrozo, Extraction of bixin from annatto seeds using combined technologies. J. Supercrit. Fluids 100, 175–183 (2015). https://doi.org/10.1016/j.supflu.2015.02.006

G. Rusak, D. Komes, S. Likic, D. Horzic, M. Kovac, Phenolic content and antioxidative capacity of green and white tea extracts depending on extraction conditions and the solvent used. Food Chem. 110, 852–858 (2008). https://doi.org/10.1016/j.foodchem.2008.02.072

L.C.B. Reis, L.M. Carneiro, C.R.C. Branco, A. Branco, Comparison of conventional microwave and focused microwave-assisted extraction to enhance the efficiency of the extraction of antioxidant flavonols from jocote pomace (Spondias purpurea L.). Plant Foods Hum. Nutr. 70, 60–169 (2015). https://doi.org/10.1007/s11130-015-0473-x

H.F. Zhang, X.H. Yang, Y. Wang, Microwave assisted extraction of secondary metabolites from plants: current status and future directions. Trends Food Sci Technol 22, 672–688 (2011). https://doi.org/10.1016/j.tifs.2011.07.003

M. Bouras, M. Chadni, F.J. Barba, N. Grimi, O. Bals, E. Vorobiev, Optimization of microwave-assisted extraction of polyphenols from Quercus bark. Ind. Crops Prod. 77, 590–601 (2015). https://doi.org/10.1016/j.indcrop.2015.09.018

G. Derringer, R. Suich, Simultaneous optimization of several response variables. J. Qual. Technol. 12, 214–219 (1980). https://doi.org/10.1080/00224065.1980.11980968

A. Benabdallah, C. Rahmoune, M. Boumendjel, O. Aissi, C. Messaoud, Total phenolic content and antioxidant activity of six wild Mentha species (Lamiaceae) from northeast of Algeria. Asian Pacific J. Tropic. Biomed. 6, 760–766 (2016). https://doi.org/10.1016/j.apjtb.2016.06.016

F. Hajiaghaalipour, J. Sanusi, M.S. Kanthimathi, Temperature and time of steeping affect the antioxidant properties of white, green, and black tea infusions. J. Food Sci. 81, H246–H254 (2016). https://doi.org/10.1111/1750-3841.13149

L.E.A. Camargo, L.S. Pedroso, S.C. Vendrame, R.M. Mainardes, N.M. Khalil, Antioxidant and antifungal activities of Camellia sinensis (L.) Kuntze leaves obtained by different forms of production. Braz. J. Biol. 76, 428–434 (2016). https://doi.org/10.1590/1519-6984.18814

M.A.S. Barrozo, V.V. Murata, S.M. Costa, The drying of soybean seeds in countercurrent and concurrent moving bed dryers. Dry. Technol. 16, 2033–2047 (1998). https://doi.org/10.1080/07373939808917510

M.A.S. Barrozo, A. Mujundar, J.T. Freire, Air-drying of seeds: a review. Dry. Technol. 32(10), 1127–1141 (2014). https://doi.org/10.1080/07373937.2014.915220

V.L. Singleton, J.A. Rossi, Colorimetry of total phenolics with phosphomolibidic phosphotungistic acid reagents. Am. J. Enol. Viticult. 16, 144–158 (1965)

J. Zhishen, T. Mengcheng, W. Jianming, The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 64, 555–559 (1999). https://doi.org/10.1016/S0308-8146(98)00102-2

W. Brand-Williams, M.E. Cuvelier, C. Berset, Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 28, 25–30 (1995). https://doi.org/10.1016/S0023-6438(95)80008-5

A.G. Duzzioni, V.M. Lenton, D.I.S. Silva, M.A.S. Barrozo, Effect of drying kinetics on main bioactive compounds and antioxidant activity of acerola (Malpighia emarginata D.C.) residue. Int. J. Food Sci. Technol. 48, 1041–1047 (2013). https://doi.org/10.1111/ijfs.12060

D.I.S. Silva, G.D.R. Nogueira, A.G. Duzzioni, M.A.S. Barrozo, Changes of antioxidant constituents in pineapple (Ananas comosus) residue during drying process. Ind. Crops Prod. 50, 557–562 (2013). https://doi.org/10.1016/j.indcrop.2013.08.001

H. Wang, K. Helliwell, X. You, Isocratic elution system for the determination of catechins, caffeine and gallic acid in green tea using HPLC. Food Chem 68, 115–121 (2000). https://doi.org/10.1016/S0308-8146(99)00179-X

M.S. Oliveira, G.M. Queiroz, R.C. Guimaraes, C.H. Ataide, M.A.S. Barrozo, Selectivity in phosphate column flotation. Min. Eng. 20, 197–199 (2007). https://doi.org/10.1016/j.mineng.2006.09.004

K.A. eynertson, M.J. Basile, E.J. Kennelly. Antioxidant potential of seven myrtaceous fruits. Ethnobot. Res. Appl. 3, 25-35 (2005). http://ethnobotanyjournal.org/index.php/era/article/view/49.

J. Huang, M. Zhang, B. Adhikari, Z. Yang, Effect of microwave air spouted drying arranged in two and three-stages on the drying uniformity and quality of dehydrated carrot cubes. J. Food Eng. 177, 80–89 (2016). https://doi.org/10.1016/j.jfoodeng.2015.12.023

M. Naczk, F. Shahidi, Extraction and analysis of phenolic in food. J. Chromatogr. A. 1054, 95–111 (2004). https://doi.org/10.1016/j.chroma.2004.08.059

Z. Lou, H. Wang, M. Zhang, Z. Wang, Improved extraction of oil from chickpea under ultrasound in a dynamic system. J. Food Eng. 98, 13–18 (2010). https://doi.org/10.1016/j.jfoodeng.2009.11.015

S.T. Saito, A. Welzel, E.S. Suyenaga, F. Bueno, A method for fast determination of epigallocatechin gallate (EGCG), epicatechin (EC), catechin (C) and caffeine (CAF) in green tea using HPLC. Food Sci. Technol. 26(2), 394–400 (2006). https://doi.org/10.1590/S0101-20612006000200023

T.G. Toschi, A. Bordoni, S. Hrelia, A. Bendini, G. Lercker, P.L. Biagi, The protective role of different green tea extracts after oxidative damage is related to their catechin composition. J. Agr. Food Chem. 48, 3973–3978 (2000). https://doi.org/10.1021/jf000499g

Acknowledgements

We would like to thank the Brazilian research funding agencies CAPES (Federal Agency for the Support and Improvement of Higher Education), CNPq (National Council for Scientific and Technological Development) and FAPEMIG (State of Minas Gerais Research Support Foundation).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rehder, A.P., Silva, P.B., Xavier, A.M.F. et al. Optimization of microwave-assisted extraction of bioactive compounds from a tea blend. Food Measure 15, 1588–1598 (2021). https://doi.org/10.1007/s11694-020-00750-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00750-4