Abstract

A series of one-dimensional compression tests up to 60 MPa were conducted to study the compression behavior and particle breakage for carbonate sand and quartz sand in different locations. The results show that at high stress, particle breakage is the main factor of compression, and the carbonate sand from South China Sea is the most compressible and easily crushed for its angular particle shape, smaller single particle strength, and higher calcium carbonate content. A relationship between applied stress and plastic work considering particle breakage was established by taking Hardin’s relative breakage index Br as an intermediate variable, and a compression model is developed which could describe the compression deformation caused by crushing. At the same time, the proposed model is also applicable to the whole compression process, and it could well describe the results of test in this paper and in previous studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbonate sand is a sediment composed of calcium carbonate or other insoluble substances. It is primarily distributed in tropical continental shelves and coastlines or sub-tropical regions (Holmes 1978). In recent years, the carbonate sand is widely used as foundation of buildings and roads or construction materials. Due to carbonate sand presents characteristics of high void ratio, irregular particle shape and high crushability (Semple 1988; Brandes 2011; Zhou et al. 2019), particle breakage significantly affects the deformation characteristics of carbonate sand which gives rise to a series of problems to foundation stability and engineering safety. Therefore, the compression caused by crushability of carbonate sand has been under active investigations by many researchers and engineers (McDowell 2002; Kikumoto et al. 2010; Al Hattamleh et al. 2013; Xiao et al. 2017; Lin et al. 2020).

In one dimensional compression, particle breakage is the main internal factor contributing to the reduction of volume. In order to investigate the influence of particle breakage on one dimensional compression, De Souza and Roberts (1958) first defined a yield point and stated that beyond which the particle breakage becomes significant through loading a high stress of 138 MPa. Later studies confirmed that the compression mechanism before and after the yield point could be considered as particle rearrangement and particle crushing, respectively (Roberts 1965; Hardin 1985; Coop 1990; Hagerty et al. 1993; McDowell and Bolton 1998; Chuhan et al. 2003; Wils et al. 2015). Moreover, Nakata et al. (2001) related the statistics of individual particle crushing with the compression line curvature, providing a more convincible understanding about the nature of compression for crushable soils. Xiao et al. (2017) established the empirical correlations between the Hardin’s relative breakage index Br with the changes in stress, strain, and input energy based on one-dimensional compression tests.

For crushable sand, such as carbonate sand, it is fundamental to have an understanding of the impact of particle breakage on soil compression behavior, which is expected to evaluate the foundation settlement accurately, especially when the soils are subjected to high stresses. Some of the existing compression models could be used to simulate the compressibility at high stress levels.

Hardin (1987) defined a model of “\(\frac{1}{e}=\frac{1}{{e}_{0}}+\frac{1}{{S}_{1D}}{(\frac{{\sigma }_{v}^{'}}{{p}_{a}})}^{p}\)”, inspired by the linear relationship between \(\frac{1}{e}\) and \({(\frac{{\sigma }_{v}^{'}}{{p}_{a}})}^{p}\) before yielding and \({S}_{1D}\) is a constant at this stage; after yielding, \({S}_{1D}\) varies with stress and should be determined by extra six parameters pertaining to soil crushability.

Pestana and Whittle (1995) developed an elaborated elasto-plastic model with four parameters through assuming that the tangent bulk modulus as the function of current void ratio (e) and effective stress (\({\sigma }_{v}^{'}\)), which successfully predicted the loading and unloading compression behavior.

Meidani et al. (2017) made an assumption of active and inactive void ratios whose decrease are induced by particle rearrangement and crushing respectively, and proposed a two-parameter model based on the linear relation between “de/dσ'v” and “e,” the model performs well when \({\sigma }_{\mathrm{v}}^{\mathrm{'}}\) < 8 MPa for calcareous sands. Nevertheless, it is still a problem worth studying to consider the impact of particle crushing on soil compression, especially under high pressure.

In this paper, based on one-dimensional compression tests under 60 MPa for the carbonate sand and quartz sand, the yield stress “σb” at yield point (De Souza and Roberts 1958) of different sand is determined. For the post-yield loading stage, i.e., σ′v > σb, taking Br as the intermediate variable, a compression model considering particle breakage is established. Experimental results show that the model is also applicable to the case where σ′v < σb.

Materials and test procedure

Sample preparation

The carbonate sands tested in this paper are from South China Sea (SC) and Arabian Gulf (AG). In addition, a type of quartz sand (QZ) obtained from Tianjin, China is prepared for contrast. Figure 1 shows the scanning electron micrograph (SEM) of these sands. It can be seen that the sand particles of SC are most angular and contain a large amount of intraparticle voids. By contrast, the particles of AG are sub-angular with smooth surfaces, and the shape of the particles of QZ are similar to that of SC.

The chemical components of the sands are studied by energy-dispersive X-ray spectrometry (EDS), as shown in Table 1, the calcium carbonate content (CaCO3) for sample SC, AG, QZ are 91.85%, 80.93%, and 4.73%, respectively. The predominant chemical compositions in the quartz sand are silica (SiO2), with the value of 86.6%.

Five kinds of oven-dried specimens were prepared and tested, and the particle size distributions (PSD) are shown in Fig. 2. According to ASTM (2017), the tested specimens are all poorly graded. SC1 and SC2 were carbonate sands from South China Sea with different medium grain sizes of 0.4, 0.15 mm; AG4 represented the carbonate sand from Arabian Gulf; SC3, which was graded identically with AG4, was made of the carbonate sand from South China Sea; QZ5, the quartz sand with the same PSD as that of SC1, was prepared for contrast with SC1.

The physical and single particle mechanical properties indexes of the tested materials are reported in Table 2 (ASTM 2014; ASTM 2016a; ASTM 2016b; ASTM C136 2019). Single particle crushing tests were carried out for 1–2-mm diameter selected from three kinds of sand. For each kind of sand, 30 particles are investigated, with reference to Nakata et al. (1999), McDowell and Amon (2000) and Xiao et al. (2020). The single particle strength σ is obtained according to the method proposed by Jaeger (1967),

where F is the value of the maximum peak loading measured in the single particle crushing test. d is the distance between the platens at the start of the single particle crushing test. Taking the average value of 30 particles as the single particle strength σ.

As seen in Table 2, the largest single particle strength is quartz sand, followed by Arabian Gulf sand, and South China Sea carbonate sand. In addition, the values of Mohs hardness are cited from Mohs (1825).

Since this test mainly studies the impact of particle crushing on compression, the tested sands in this study were air dried sands. The tested specimens were 61.8 mm in diameter and 20 mm in height. Each specimen was designed to compress at Dr = 45%, 60%, and 75% prepared by the tapping method of Ladd (1978). Air dried sand was divided into two layers, the solid mass for each layer mL at a given relative density Dr is calculated as:

where ρd is the dry density of specimen at given relative density; ρdmax , ρdmin are the maximum and minimum dry density, respectively; V is the volume of specimen.

Then, each layer was placed into the mold lined with 0.3-mm-thick rubber membrane through a zero-drop-height funnel. To ensure the uniformity of specimen, the first layer is compacted to a lower density, of which the height is designed as 10 ~ 11.5 mm, then the second layer is placed and compacted to the height of 20 mm. The target height of each layer was achieved by tapping the mold with a rubber hammer. The actual relative densities used in tests and following analyses are illustrated in Table 3.

Test procedure

A series of one-dimensional compression tests were carried out by the high pressure oedometer located in the Institute of Geotechnical Engineering, Tianjin University and performed according to ASTM (1996). The tests were conducted on the specimens of SC1, SC2, SC3, AG4, and QZ5 at three initial relative densities about 45%, 60%, and 75% to the target vertical effective stress of 60 MPa to get the compression properties of soils.

To investigate the particle crushing with increasing stress, additional tests were conducted on the specimens with the initial relative density of 60%. In these tests, six terminated stress levels of 2.0, 4.0, 6.0, 10, 20, and 40 MPa were applied, whose test series number are SC1-2, SC2-2, SC3-2, AG4-2, and QZ5-2. After each test, specimens were poured out carefully and followed by particle sieving for the analysis of PSD. Table 3 presents a summary of all the tests conducted.

Results and discussion

One-dimensional compression behavior

The experimental \({\sigma }_{v}^{'}-{\varepsilon }_{v}\) curves for tested specimens with different relative densities, subjected to the elevated vertical effective stress of 60 MPa, are shown in Fig. 3a, c, and e. All the trend lines represent that volumetric strain increases with an increase of \({\sigma }_{v}^{'}\), and at a given stress, the volumetric strain is less for each specimen with higher initial relative density. The corresponding \(e-log{{\sigma }^{'}}_{v}\) curves are plotted in Fig. 3b, d, and f. Notably, it could be found that the \(e-log{{\sigma }^{'}}_{v}\) curves for each specimen with different initial relative densities converge into a unique line, which is called the limiting compression curve (LCC) by Pestana and Whittle (1995), indicating that the effect of initial relative density on compression is eliminated at relatively high stresses.

Different characteristics of sands from different locations

Figure 3a and b compare the compression behavior for specimens SC1 and SC2, of which the medium grain sizes are 0.4 mm and 0.15 mm, respectively. From \({\sigma }_{v}^{'}-{\varepsilon }_{v}\) curves, the produced volumetric strain of SC2 is less than that of SC1 at a given \({{\sigma }^{'}}_{v}\) no matter what the initial relative density is. This phenomenon could be explained by more preexisting fissures and crystal imperfections in larger grain size particles, so it could be easily crushed (Zhang et al. 1990; Chuhan et al. 2003).

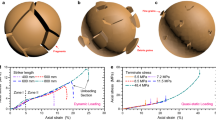

Comparisons are made between specimens SC3 and AG4 with the same grading curve (Fig. 3c, d), which are both the carbonate sand based on the classification system in Clark and Walker (1977), but located in different marine areas of South China Sea and Arabian Gulf, respectively. It was obvious that during the whole loading process, the volumetric strain of SC3 is larger than that of AG4 no matter what the initial relative density is. When the stress increases to 60 MPa, the highest total volumetric strain of SC3 compressed at three initial relative densities up to 40%, and that of AG4 is 27%, indicating that the carbonate sand of South China Sea would experience more deformation and be easily compressed than the carbonate sand of Arabian Gulf. The differences may come from different calcium carbonate content, different particle angularity, and single particle strength.

In addition, comparisons between SC1 and QZ5 are showed in Fig. 3e and f. It could be found that the increasing of εv with \({{\sigma }^{'}}_{v}\) is obviously faster in carbonate sand than in quartz sand, and the maximum final volumetric strain of QZ5 is 27%, which is much smaller than that of SC1 up to 44%. Moreover, from the \(e-log{{\sigma }^{'}}_{v}\) curves, the void ratio of QZ5 decreases much slowly before 10 MPa than that of SC1, which further validates that carbonate sand has higher compressibility than that of quartz sand due to the large amount of particle breakage, which is validated later in this paper.

Yield stress determined from the \(e-{{log\sigma }^{'}}_{v}\) plot

The “yield point” defined by De Souza and Roberts (1958) was determined as the point of maximum curvature in the \(e-log{{\sigma }^{'}}_{v}\) curves. The yield points in tests are shown in Fig. 3 (marked as red star symbols), and the corresponding yield stresses \({\sigma }_{b}\) are listed in Table 3.

Figure 4 shows the relationship between the yield stress \({\sigma }_{b}\) with respect to the initial relative density for each sand specimen. Apparently, a strong positive linear relation could be observed between the two variables, that is, the particle crushing initiates at a much lower stress in loose sand than in dense sand. This can be explained by the fact that the coordination number increases with increasing relative densities. Particles are imposed on smaller average contact stress for the large amount of particle contacts in a denser configuration, which results in the ability of resisting particle crushing intensifies (Hendron Jr 1963; Coop and Lee 1992; Mesri and Vardhanabhuti 2009).

Moreover, the figure shows that the carbonate sands from South China Sea have the lower yield stresses, and the yield stresses of QZ5 and AG4 are obviously higher than those of carbonate sand specimens SC1 and SC3, though they have the same PSDs. Combining the analysis of compression behavior in Fig. 3, it could be found that a low yield stress is significative of high compressibility.

Particle size distributions and particle crushing

After tests, the PSD curves are plotted in Fig. 5 to determine the particle breakage. In this study, the relatively breakage index Br proposed by Hardin (1985) was used to assess particle breakage. Br is defined as,

where Bp is the breakage potential, which is determined by the area between the initial gradation curve, and the vertical line representing the lower limit of particle size d = 0.074 mm; Bt is the total breakage, equal to the area between the initial and final gradation curves (Fig. 6).

Definition of relative breakage index Br (Hardin 1985)

The relative breakage index Br determined from the grading curves in Fig. 5 is listed in Table 3. Figure 5a (1–5) shows the PSD before and after 60 MPa applied under different initial relative density. It could be found that the initial relative density has almost no effect on the amount of broken particles at the end of the test, which is different with that at low stress levels proposed by Xiao et al. (2017). This fact demonstrates that the effect of initial relative density on compression will be reduced and eventually eliminated when subjected to high stresses. In addition, at 60 MPa, the relative breakage index Br of SC1 is the largest, reaching 36%, significantly higher than that of SC2 (Br = 18%) and SC3 (Br = 21%), which are both carbonate sand from South China sea but with smaller medium grain size; the relative breakage index Br of AG4 is 16.5%, smaller than that of same graded specimen SC3 (Br = 21%). For the relative breakage index Br of QZ5, it is much smaller (Br = 14%) than that of the same graded specimen SC1(Br = 36%). It is because that carbonate sand has more angular particle shape, smaller single particle strength, and higher calcium carbonate content, which are recognized as the internal factors that lead to the high crushability of carbonate sand (Nakata et al. 2001; Wang et al. 2021).

The evolutions of PSD for test series of SC1-2, SC2-2, SC3-2, AG4-2, and QZ5-2 with the relative density about 60% are shown in Fig. 5b (1–5). For each given specimen, the PSD curves appear a gradual change deviating from the initial grading curve, indicating that particle breakage extent intensifies as the stress increases.

The relationship between Br and vertical effective stress \({\sigma }_{v}^{'}\) is shown in Fig. 7. It could be found that the curve of specimen SC1 lies high alone departing from other curves since its Br is much larger than that of other specimens at each given stress, implying the great particle crushability of SC1. From the enlarged graph, it can be seen that at low stress levels, the trend lines of SC1, SC2, and SC3 are convex upward which are different from that of AG4 and QZ5, this might be due to that the carbonate sand from South China Sea would experience significant particle crushing even at the low stress compared to the Arabian Gulf’s sand and quartz sand.

Many people have studied the evolution of Br with the changes in applied stress subjected to one-dimensional compression or isotropic compression, the fitting form including power-law, inverse-exponential law, and hyperbolical function (Yan and Shi 2014; Mun and McCartney 2017; Xiao et al. 2017). The inverse-exponential form is used in this paper:

where \(\alpha\) and \(\beta\) are material coefficients As \({\sigma }_{v}^{'}\rightarrow\infty\), then \(B_r\rightarrow\alpha\). It means that a limit state of particle breakage exists, which is consistent with the discussion of breakage mechanics in Einav (2007). For the parameter \(\beta\), when \(\beta\rightarrow0\), then \(B_r\rightarrow0\). It means that when particles do not break, the Br of soil tends to 0. The fitting curves (dashed lines) for each specimen are plotted in Fig. 7, and the values of \(\alpha\) and \(\beta\) are listed in Table 4 with good R2 value varying from 0.9759 to 0.9987.

From Figs. 3 and 7, it could be found that the more particle breakage is subjected, the greater the compressibility of soil, which can be explained by the fact that the initially compression in sand is limited due to grain-scale frictional slip, rotation, and sliding. But if the effective stress is high enough, crushing of the particles becomes prominent, which could generate large relative motions between sand particles, consequently result in large deformation (e.g., De Souza and Roberts 1958; Hagerty et al. 1993; Chuhan et al. 2003; Al Hattamleh et al. 2010).

A compression model for crushable sand

Derivation of the compression model for post-yield stage

The plastic work is considered as a comprehensive index that incorporates the material characteristics including grain size distribution, grain strength, and particle shape, as well as the stress level (Yu 2017). The relationship between the plastic work and particle breakage is concerned by many people. Miura and Sukeo (1979) proposed an S-type model to describe the increasing trend of surface area with the plastic work per unit volume for triaxial test; Lade et al. (1996) derived a new crushing parameter B10 and correlated it with the total input energy per unit volume in a hyperbolic model; Wu et al.(1997) discovered a unique correlation between the relative breakage index Br and the plastic work based on the triaxial tests for artificial calcareous sands, regardless of the test conditions and stress paths; moreover, Xiao and Liu (2017) defined a breakage factor pertain to d50 for rockfill materials during triaxial loading and made a correlation with the plastic work in an exponential function.

During one dimensional compression, the incremental plastic work per unit volume is defined as:

where \({\varepsilon }_{v}\) and \({\varepsilon }_{ve}\) are the total volumetric strain and elastic volumetric strain and \({\sigma }_{v}^{'}\) is the vertical effective stress. In general, the magnitude of elastic volumetric strain is so small compared to the total volumetric strain that can be neglected for dry granular soils, especially when subjected to significant particle crushing. Therefore, Eq. (6) can be simplified as:

The total volumetric strain \({\varepsilon }_{\nu }\) could be divided into two components, termed as \({\varepsilon }_{\nu 1}\) and \({\varepsilon }_{\nu 2}\), which are produced before and after yielding mainly resulted from particle movements to adjust particles position and particle breakage, respectively. It means,

Combining the terms \({\varepsilon }_{\nu 1}\) and \({\varepsilon }_{\nu 2}\) with Eq. (7), the corresponding plastic work \({W}_{p1}\) and \({W}_{p2}\) can be obtained, which represent the plastic works inputted before and after the yield stress, see Fig. 8. It could be expressed as,

in which \({\varepsilon }_{b}\) is the volumetric strain at the yield stress \({\sigma }_{b}\).

Because \({W}_{p2}\) is the plastic work mainly for particle breakage, there could be a relationship between the particle breakage \({B}_{r}\) and \({W}_{p2}\). In this paper, the model proposed by Wu et al. (1997) is used,

It could be written as

where \(\kappa\), \(\lambda\) are parameters.

Figure 9 shows the relationship between the relative breakage index \({B}_{r}\) and the corresponding plastic work \({W}_{p2}\) for five specimens whose relative density is about 60%. From the figure it could be found that the proposed model can better express the relationship between them. The value of \(\kappa\), \(\lambda\) are listed in Table 4. The coefficient \(\lambda\) reflects the rate of increase and therefore represents the crushability of tested specimens, that is, the more crushable the specimen is, the larger value of \(\lambda\) would be obtained.

Substitute Eq. (5) into Eq. (13), the relationship between \({\text{W}}_{{\text{p}}{2}}\) and \({\sigma }_{v}^{'}\) can be induced through making the relative breakage index \({B}_{r}\) as the transitional variable.

where A \(={\left(\frac{\alpha }{\kappa }\right)}^{\frac{1}{\lambda }}\), \(B=\beta\), \(\Gamma=\frac1\lambda\), the values of A, B, Γ are listed in Table 4. Although Br does not show up, this equation reflects the energy used for particle breakage at a given vertical effective stress.

Figure 10 shows the evolution of the plastic work \({W}_{p2}\) with the vertical effective stress \({\sigma }_{v}^{'}\) at three initial relative densities for five specimens. All the regression parameters R2 exceed 0.99, illustrating that Eq. (14) gives an excellent fitting to the experimental results.

Meanwhile, for one dimensional compression, the incremental volumetric strain \(d\varepsilon\) is expressed by the incremental void space as

in which \({e}_{0}\) is the initial void ratio. At the same time, the void ratio e for loading can be written as a function of the vertical effective stress \({\sigma }_{v}^{'}\)

then the incremental volumetric strain can be given by

Introducing Eqs. (14) and (17) into Eq. (11) yields

then taking the derivative of the vertical effective stress on both sizes of the equation, follows:

\({e}_{0}\) is the initial void ratio. A, B, Γ are model parameters. To this end, Eq. (19) can well describe the change of void ratio by particle breakage.

Taking SC2 (Dr = 60%) as an example, Fig. 11 shows the relationship between the total plastic work \({W}_{p}\) and \({\sigma }_{v}^{'}\), the red star in this figure represents the yield point. The dashed line in the figure uses the model of Eq. (14) (the same as that in Fig. 10b). A, B, Γ are consistent with the values listed in Table 4. It can be seen that when \({\sigma }_{v}^{'}>{\sigma }_{b}\), a good match can be obtained. But in the range of \({\sigma }_{v}^{'}\le {\sigma }_{b}\), the fitted value is significantly higher than the tested value, for the reason that the effect of crushing is taken into account in Eq. (14), which overestimates the plastic work without crushing.

The compression model for whole stage

It can be seen from the above analysis that the compression deformation caused by particle crushing can be better described by plastic work using \({B}_{r}\) as an intermediate variable. Considering that the compression deformation caused by particle position adjustment can also be expressed by plastic work (\({W}_{p1}\)), therefore the form of Eq. (14) is also used to describe the \({W}_{p}-{\sigma }_{v}^{'}\) curve in the whole range of stress, and the parameters are obtained by data fitting method. The fitting results are shown in Fig. 12. As can be seen from the figure, a good fitting can be obtained with all the coefficients R2 exceed 0.999 (Table 5).

Herein, the three parameters are rewritten as At, Bt, Γt from data fitting for \({W}_{p}-{\sigma }_{v}^{'}\) to distinguish from the corresponding parameters A, B, Γ from breakage evaluation for \({W}_{p2}-{\sigma }_{v}^{'}\) curves. To this end, it could be convincible to give the compression model for the whole stress range of validity, as

From which, it has only three parameters pertaining to sand properties and can be numerically integrated from the initial loading condition (\({\sigma}_v^{'}\rightarrow0\), \({e}_{0}\)), eluding the extra procedure to identify the yielding point on each compression curves. In addition, it could be observed that as \({\sigma }_{v}^{'}\rightarrow \infty\), the extreme condition induce the same result of \(\frac{de}{d{\sigma }_{v}^{'}}\rightarrow 0\), implicitly reflecting the existence of asymptotic void ratios at extremely high stresses.

The one dimensional compression lines described by Eq. (20) with the three model parameters listed in Table 5 are compared to experimental results for the five tested specimens at three initial relative densities in semi-logarithmic space. As can be seen in Fig. 13, the model lines agree very well with the experimental data.

Predicted one-dimensional compression lines using Eq. (20) and the experimental data for five specimens at three initial relative densities: (a) SC1; (b) SC2; (c) SC3; (d) AG4; (e) QZ5

In addition, 8 groups of sands presented in previous literatures are used to verify the proposed model, see Fig. 14. It could be found that all the model curves have a good match with the data points, regardless of the mineral, grain size, gradation, initial density, single particle strength, showing a flexibility of the proposed model in capturing the compression behavior for a wide range of sands. The physical characteristics of sands used and model parameters are summarized in Table 6.

Predicted compression lines using Eq. (20) and experimental data for different types of crushable sand

Discussion of the model parameters

In this paper, Br is used as an intermediate variable to establish a compression model considering particle breakage, i.e., Eq. (19) for post-yield stage. In this equation, the three parameters A, B, Γ can be derived from the breakage behavior of soil directly, i.e., the parameters are from the relationship of Br-\({\sigma }_{v}^{'}\) and Br-Wp2.

Figure 15 illustrates the rationality of this method by taking SC1-2 as an example. The blue line represents the relationship between e and \({log\sigma }_{v}^{'}\) obtained by the proposed method with the data from \({\sigma }_{\mathrm{v}}^{\mathrm{'}}<20 \;\mathrm{MPa}\). The red line shows the relationship between e and \({log\sigma }_{v}^{'}\) obtained by data fitting method with the data from \({\sigma }_{\mathrm{v}}^{\mathrm{'}}<20 \;\mathrm{MPa}\). It can be seen that the compression behavior of \({\sigma }_{\mathrm{v}}^{\mathrm{'}}<20 \;\mathrm{MPa}\) can be well described by the proposed method and the data fitting method. But there is a big gap between the predicted results and the test results when \({\sigma }_{\mathrm{v}}^{\mathrm{'}}>20 \;\mathrm{MPa}\) for data fitting method when the test data were absent for fitting. However, the relationship between e and \({log\sigma }_{v}^{'}\) obtained from the evaluation of particle breakage behavior have a good performance to predict the compression behavior of soil when \({\sigma }_{v}^{'}\) > 20 MPa.

At the same time, the form of the compression model (Eq. 19) can also be extended to the whole loading range (0–60 MPa in this study) whose model parameters (At, Bt, Γt) need to be obtained by data fitting. To this end, the model proposed (Eq. 20) in this study can better describe the test results, but its accuracy in predicting the compressibility of soil beyond the test range needs to be further confirmed.

Conclusions

This paper investigates the compression behavior and particle breakage for carbonate sands from South China Sea, Arabian Gulf, and quartz sand from Tianjin, China by conducting a series of one dimensional compression tests. The following conclusions could be inferred from the results:

-

1.

At high stress levels, the effect of initial relative densities on compression and particle breakage decreased and eventually eliminated, which can be verified by the converging \(e-{{log}^{'}}_{v}\) curves and roughly the same particle breakage extent of each specimen with three initial relative densities.

-

2.

Compared to the quartz sand, carbonate sand is more compressible and easier to crush, which could be attributed to its angular particle shape, lower single particle strength and higher calcium carbonate content. At the same time, the more particle breakage are subjected, the greater the compressibility of the sand, because of large relative motions between sand particles resulting in large deformation.

-

3.

The yield points for five specimens at each given relative density show that the relation between the yield stress with respect to the relative density is positively linear. In addition, the results show that the low yield stress is significative of high compressibility.

-

4.

In order to consider the effect of particle breakage on soil compression, the relationship between \({W}_{p2}\) and \({\sigma }_{\nu }^{'}\) was established by taking \({B}_{r}\) as an intermediate variable, then the relationship between void ratio e and \({\sigma }_{\nu }^{'}\) was further obtained. This model has a good performance in predicting the compression deformation caused by crushing. It also shows that there is a close relationship between the compression deformation of sand and the plastic work.

-

5.

For the compression deformation caused by the adjustment of particle position can also be characterized by plastic work, thus the above model further be extended to the whole compression process, that is, the same model form is adopted to describe the soil deformation in the whole compression process. By obtaining the model parameters with data fitting method, satisfying results are obtained for the available experimental data in this paper and from other literatures. But its accuracy in predicting the compressibility of soil beyond the test range needs to be further confirmed.

References

ASTM (1996) ASTM D243–04. Standard test methods for one-dimensional consolidation properties of soils, annual book of ASTM Standards. ASTM, Philadelphia

ASTM D854 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. West Conshohocken, PA, USA

ASTM D4253 (2016a) Standard test method for maximum index density and unit weight of soils using vibratory table. West Conshohocken, PA, USA

ASTM D4254 (2016b) Standard test method for minimum index density and unit weight of soils and calculation of relative density. West Conshohocken, PA, USA

ASTM D2487–17 (2017) Standard practice for classification of soils for engineering purposes (unified soil classification system). West Conshohocken, PA, USA

ASTM C136 (2019) Standard test method for sieve analysis of fine and coarse aggre-gates. West Conshohocken, PA, USA

Altuhafi FN, Coop MR (2011) Changes to particle characteristics ass-ociated with the compression of sands. Géotechnique 61(6):459–471. https://doi.org/10.1680/geot.9.P.114

Al Hattamleh O, AlShalabi F, Al Qablan H et al (2010) Effect of grain crushing and bedding plane inclination on Aqaba sand behavior. Bull Eng Geol Environ 69:41–49. https://doi.org/10.1007/s10064-009-0238-6

Al Hattamleh OH, Al-Deeky HH, Akhtar MN (2013) The consequence of particle crushing in engineering properties of granular materials. Int J Geosci 4(7):1055–1060. https://doi.org/10.4236/ijg.2013.47099

Brandes HG (2011) Simple shear behavior of calcareous and quartz sands. Geotech Geol Eng 29(1):113–1126. https://doi.org/10.1007/s10706-010-9357-x

Chuhan FA, Kjeldstad A, Bjørlykke K, Høeg K (2003) Experimental compression of loose sands: Relevance to porosity reduction during burial in sedimentary basins. Can Geotech J 40(5):995–1011. https://doi.org/10.1139/T03-050

Clark AR, Walker BF (1977) A proposed scheme for the classification and nomenclature for use in the engineering description of middle eastern sedimentary rocks. Geotechnique 27(1):93–99, 366. https://doi.org/10.1680/geot.1977.27.1.93

Coop M (1990) The mechanics of uncemented carbonate sands. Géotechnique 40(4):607–626. https://doi.org/10.1680/geot.1990.40.4.607

Coop M, Lee I (1992) The behaviour of granular soils at elevated stresses. In: Predictive soil mechanics: Proceedings of the Wroth Memorial Symposium held at St Catherine’s College, Oxford. p 186–198

De Souza JM, Roberts JE (1958) The compressibility of sands. Proc ASTM 58:1269–1277

Einav I (2007) Breakage mechanics – part I: theory. J Mech Phys Solids 55(6):1274–1297. https://doi.org/10.1016/j.jmps.2006.11.003

Hagerty M, Hite D, Ullrich C, Hagerty D (1993) One-dimensional high-pressure compression of granular media. J Geotech Geoenviron Eng 119(1):1–18. https://doi.org/10.1061/(ASCE)0733-9410(1993)119:1(1)

Hardin BO (1985) Crushing of soil particles. J Geotech Geoenviron Eng 111(10):1177–1192. https://doi.org/10.1061/(ASCE)0733-9410(1985)111:10(1177)

Hardin BO (1987) 1-d strain in normally consolidated cohesionless soils. J Geotech Geoenviron Eng 113(12):1449–1467. https://doi.org/10.1061/(ASCE)0733-9410(1987)113:12(1449)

Hendron Jr A (1963) The behavior of sand in one-dimensional compression. Ph.D. thesis, University of Illinois, Urbana, Ill. Johnson, K.L. 1985. Contact mechanics. Cambridge University Press, London, UK

Holmes A (1978) Principles of physical geology. Nelson, London: Sunbury-on-Thames, p 730

Jaeger JC (1967) Failure of rocks under tensile conditions. Int J of Rock and Mining Science 4:219–227

Kikumoto M, Wood DM, Russell A (2010) Particle crushing and deformation behaviour. Soils Found 50(5):767–767. https://doi.org/10.3208/sandf.50.547

Ladd R (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23. https://doi.org/10.1520/GTJ10364J

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Geoenviron Eng 122(4):309–316. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:4(309)

Lin L, Li S, Sun L, Liu X, Chen W (2020) Evolution of particle size distribution for carbonate sand under impact load. Powder Technol 376:549–564. https://doi.org/10.1016/j.powtec.2020.08.046

McDowell G, Bolton M (1998) On the micromechanics of crushable aggregates. Géotechnique 48(5):667–679. https://doi.org/10.1680/geot.1998.48.5.667

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40(5):133–141

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42(1):139–145. https://doi.org/10.3208/sandf.42.139

Mehta AA, Patel A (2018) An investigation on the particle breakage of indian river sands. Eng Geol 233:23–37. https://doi.org/10.1016/j.enggeo.2017.12.001

Meidani M, Chang CS, Deng Y (2017) On active and inactive voids and a compression model for granular soils. Eng Geol 222:156–167. https://doi.org/10.1016/j.enggeo2017.03.006

Mesri G, Vardhanabhuti B (2009) Compression of granular materials. Can Geotech J 46(4):369–392. https://doi.org/10.1139/T08-123

Miura N, Sukeo O (1979) Particle-crushing of a decomposed granite soil under shear stresses. Soils Found 19(3):1–14. https://doi.org/10.3208/sandf1972.19.3_1

Mohs F (1825) Treatise on mineralogy. Mercury Press, Edinburgh

Mun W, Mc Cartney JS (2017) Roles of particle breakage and drainage in the isotropic compression of sand to high pressures. J Geotech Geoenviron Eng 143(10):04017071. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001770

Nakata Y, Hyde AFL, Hyodo M, Murata H (1999) A probabilistic approach to sand particle crushing in the triaxial test. Geotechnique 49(5):567–583

Nakata Y, Kato Y, Hyodo M, Hyde AF, Murata H (2001) One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found 41(2):39–51. https://doi.org/10.3208/sandf.41.2_39

Pestana JM, Whittle A (1995) Compression Model for Cohesionless Soils Géotechnique 45(4):611–631. https://doi.org/10.1680/geot.1995.45.4.611

Roberts JE (1965) Sand compression as a factor in oil field subsidence. Ph.D. thesis, Massachusetts Institute of Technology, Cambridge, Mass

Semple RM (1988) The mechanical properties of carbonate soils. International conference on calcareous sediments. Rotterdam, Perth, WA: Balkema, p 807–836

Wang C, Ding X, Yin ZY et al (2021) Mechanical characteristics and particle breakage of coral sand under one-dimensional repeated loading. Acta Geotech. https://doi.org/10.1007/s11440-021-01381-9

Wils L, Van Impe P, Haegeman W (2015) One-dimensional compression of a crushable sand in dry and wet conditions. Proc., 3rd International Symposium on Geomechanics from Micro to Macro, Taylor and Francis Group-London, p 1403–1408

Wu JP, Chu Y, Lou ZG (1997) Influence of particle breakage on deformation and strength properties of calcareous sands [in Chinese]. Chinese J Geotech Eng 19(5):49–55

Xiao Y, Liu H (2017) Elastoplastic constitutive model for rockfill materials considering particle breakage. Int J Geomech 17(1):04016041. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000681

Xiao Y, Liu H, Chen Q, Ma Q, Xiang Y, Zheng Y (2017) Particle breakage and deformation of carbonate sands with wide range of densities during compression loading process. Acta Geotech 12(5):1177–1184. https://doi.org/10.1007/s11440-017-0580-y

Xiao Y, Meng M, Daouadji A, Chen Q, Wu Z, Jiang X (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11(2):375–388. https://doi.org/10.1016/j.gsf.2018.10.010

Yan W, Shi Y (2014) Evolution of grain grading and characteristics in repeatedly reconstituted assemblages subject to one-dimensional compression. Géotech Lett 4(3):223–229. https://doi.org/10.1680/geolett.14.00039

Yu FW (2017) Characteristics of particle breakage of sand in triaxial shear. Powder Technol 320:656–667. https://doi.org/10.1016/j.powtec.2017.08.001

Zhang J, Wong TF, Davies DM (1990) Micromechanics of pressure-induced grain crushing in porous rocks. J Geophys Res 95(B1):341–352. https://doi.org/10.1029/jb095ib01p00341

Zhou XZ, Chen YM, Liu HL, Zhang XL (2019) Experimental study on the cyclic behavior of loose calcareous sand under linear stress paths. Mar Georesources Geotechnol 1–14. https://doi.org/10.1080/1064119X.2019.1567631

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 42072294 and 51890911).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, X., Li, S., Li, Y. et al. Study of the influence of particle breakage on compression properties for carbonate sand. Bull Eng Geol Environ 81, 89 (2022). https://doi.org/10.1007/s10064-022-02579-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-02579-1