Abstract

The monotonic and cyclic simple shear behavior of several loose skeletal calcareous sands is investigated and compared to that of common Nevada and Ottawa quartz sands in order to draw contrasts between these types of materials and to develop stiffness and modulus degradation curves for quasi-nonlinear ground response analysis. Mobilized frictional resistance and cyclic strength are generally higher for the calcareous sands, whereas shear modulus and damping are larger for quartz sand at strain levels between 0.05 and 1%. Degradation properties do not appear to be very sensitive to the initial cyclic stress ratio. Differences in behavior between the calcareous and quartz sands are presumably due to contrasts in grain geometry, hardness, gradation and the amount of intraparticle voids.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Calcareous sediments cover approximately 40% of the ocean floor (Holmes 1978). They are especially widespread in tropical and subtropical shallow waters of the Pacific Ocean where seismic hazards are often very high. The potential for damages caused by strong shaking of calcareous sediments has been made painfully clear by numerous catastrophic earthquakes such as the Guam earthquake of 1993, the Hawaii earthquake of 2006, the Haiti earthquake of 2010 and many others. In each of these cases, calcareous sediments were observed to liquefy and spread, causing extensive damage to port facilities and other offshore structures. It is well known that calcareous sediments pose a challenge to offshore construction, particularly the installation of driven piles and their response to dynamic loads (McClelland 1988).

The character of biogenic calcareous sands is quite different from that of quartz sands, yet our understanding of the dynamic behavior of granular soils comes primarily from studies conducted on quartz sands of terrigenous origin. Calcareous sands typically have lower grain hardness, larger intragranular porosity, a wider range of grain shapes, and more complex structural arrangements that reflect unique post-depositional processes of cementation, dissolution, recrystallization, and other diagenetic changes. It is not surprising then that there are significant differences in mechanical behavior among various types of calcareous sands, and with respect to quartz sands (Celestino and Mitchell 1983). Field and laboratory investigations have highlighted differences in terms of compressibility, volume changes and grain crushing during shearing, yielding, friction, and water permeation (Datta et al. 1979; Semple 1988; Al-Douri and Poulos 1991; Jewell 1993; Kwag et al. 1999; Ong et al. 1999; Coop and Airey 2003). Although there have been a few studies that have addressed the dynamic behavior of calcareous sediments (Lo Presti et al. 1993; Kwag et al. 1999; Sharma and Fahey 2003a, b; Mao and Fahey 2003; Seidman 2007; Porcino et al. 2008), most of them have not sought to draw particular distinctions with the corresponding behavior of terrigenous soils. What evidence exists is limited and sometimes contradictory. Some laboratory studies indicate that the cyclic strength of loose calcareous sands is higher than that of quartz sands at equivalent densities and stress conditions (Chen 1985; Morioka and Nicholson 2000; Nicholson 2006). Rollins et al. (2004) suggest that liquefaction is triggered at different stress levels in reefoidal calcareous sand deposits compared to quartz sand deposits, again suggesting that cyclic strengths are different. On the other hand, Mejia and Yeung (1995) report similar liquefaction behavior for both classes of sands based on observations of field liquefaction.

This study evaluates the monotonic and cyclic strength characteristics of several shallow water loose calcareous sands and compares the response to that of clean granular quartz sands. The paper also provides stiffness degradation and damping curves necessary for dynamic site response analyses. Cyclic characteristics are presented for two calcareous sands from Hawaii that are similar in many respects to reefoidal sediments found throughout many areas of the Pacific Basin, the Caribbean Ocean, Australia and the Arabian Peninsula. The findings are of special significance to Hawaii, where most of the major port facilities incorporate loose dredged calcareous sediments of this type as fill material. The 2006 M6.7 earthquake caused heavy liquefaction damages at Kawaihae Harbor and forced its closure for a period of time. Of concern is the fact that the same type of loose calcareous dredge material is found at most other major ports in Hawaii and in other earthquake prone areas in the world. A reassessment of seismic performance of ports, pipelines and other seafloor structures requires better characterization of the mechanical properties of shallow-water calcareous sediments. Here we provide some of the information that is lacking for proper engineering analysis and design involving these unique materials.

2 Physical Properties

The study focused on a subclass of loose calcareous sands found in the littoral zone surrounding the Hawaiian Islands (Maui Dune, Kawaihae Harbor and East Island; Table 1). The calcareous sediments are composed of detrital skeletal grains derived from the breakdown of coral reef structures, mollusks, algae, echinoderms and sponges. The grains have been further broken, rounded and sorted by waves and currents. They are of Holocene age and reflect a mineralogy dominated by aragonite and magnesium-rich calcite typical of very young sediments. There is no evidence of cementation or other diagenetic processes, although calcarenite, calcirudite and limestone are found at depth and on shore. The Maui dune sand was collected in Wailuku, Maui, where it has been exposed above water for a few thousand years. Kawaihae Harbor sand was obtained from areas that liquefied during the 2006 earthquake. East Island is located along the Hawaii island chain and sediments there are very similar to those found elsewhere in coastal areas of Hawaii.

Standard commercial Nevada and Ottawa quartz sands were selected for comparison. They represent quarried materials that are widely used for geotechnical testing purposes. The Nevada sand is commonly used in centrifuge and cyclic testing studies. The Tampa Bay sand was obtained from shallow waters near the entrance to Tampa Bay, Florida, where the sediments constitute a mix of quartz sands transported down from the Florida Panhandle and local reefoidal detritus similar to that in the Hawaiian sands. It only contains 11% carbonate grains and therefore is quite similar in many regards to the Nevada and Ottawa quartz sands. Specific gravity is slightly higher for the calcareous sands, which reflects the difference in unit weights of calcite and quartz.

Grain size distributions are shown in Fig. 1. According to the Unified Soil Classification System (USCS), the soils all classify as poorly sorted sands or silty sands. Fines content (particles smaller than 0.075 mm) is limited, although it rises to as much as 13.9% for the Kawaihae Harbor sand. The fine fraction is generally referred to as micrite. The gradations indicated in Fig. 1 suggest that all soils are coarse enough and contain insufficient amounts of plastic fines to be susceptible to liquefaction (Xenaki and Athanasopoulos 2003; Andrews and Martin 2000). Of course, whether liquefaction develops depends also on confining stress and void ratio (Polito and Martin 2001; Cubrinovski and Ishihara 2002; Thevanayagam 1998), as well as dynamic load and drainage characteristics. Angularity of the sand grains increases somewhat in proceeding from the quartz sands to the calcareous sands (Table 1, Fig. 2). The descriptive terms used in Table 1 follow the guidelines contained in ASTM D2488.

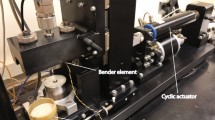

The monotonic strength program involved all but one of the materials listed in Table 1, whereas cyclic testing and shear wave velocity measurements were limited to the Nevada, Maui Dune and Kawaihae Harbor sands. Since it is nearly impossible to collect representative undisturbed sand samples that lack cementation or cohesion, sample preparation involved laboratory reconstitution of bulk field samples to specific densities or void ratios. All testing was conducted using an NGI-type simple shear apparatus with the specimen contained in a flexible wire reinforced membrane that prevents lateral strains and therefore imposes Ko lateral stress conditions. Vertical stresses were applied with a vertical loading ram prior to static shearing, cyclic loading or shear wave velocity measurement. A new batch of material was used for each test. Samples were 35 cm2 in area and 16 mm in height. Maximum grain sizes and sample dimensions all met standard requirements set by ASTM D6528.

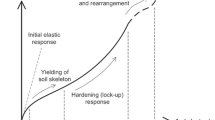

3 Monotonic Strength

Direct simple shear (DSS) tests were conducted on the Ottawa, Tampa Bay, East Island, Maui Dune, and Kawaihae Harbor sands. DSS tests were carried out on dry samples under constant vertical stress conditions (i.e. drained conditions). Each test consisted of applying a predetermined vertical stress, followed by shearing to failure in the horizontal direction. The data was analyzed to examine the stress–strain response and the Mohr–Coulomb strength parameters. An example of shear and volume response is shown in Fig. 3 for the Tampa Bay (quartz) and Kawaihae Harbor (carbonate) sands. In all cases, shear stresses increase uniformly with no indication of peaking or softening. This is, of course, indicative of loose granular behavior. There are, however, significant differences in terms of volume changes between the quartz and carbonate tests. Whereas the quartz sands show consistent compression during shearing, the carbonate tests show some compression early on, but then dilation during the later stages. This is true despite roughly similar void ratios and overlapping normal stresses in the two sets of tests. This is thought to be due to the slightly more elongated and angular nature of the carbonate grains, which need to undergo more normal displacements, i.e. dilation, as they shear past each other, when compared to the more rounded quartz grains (Seidman 2007; Brandes and Seidman 2008).

As a result of greater dilation, the calcareous sediments are able to mobilize a higher level of frictional resistance. This was clearly evident in terms of maximum friction angles, as shown in Table 2. The quartz sands (Ottawa and Tampa Bay) yielded familiar friction angles for standard quartz sands in the range of 28–29° (Mitchell and Soga 2005). In contrast, the calcareous sands indicate values well above 30°. This agrees with previous studies on coastal and continental shelf calcareous sands, which indicate friction angles mostly in the 38–50° range (Datta et al. 1979; Hull et al. 1988; Brandes et al. 2000). It should be pointed out that these previous tests focused on skeletal and debris sands that in some cases were quite angular. The values determined in this study are slightly lower than the range reported in many previous studies, with friction angles closer to 35°, due in part to a somewhat more rounded grain shape resulting from vigorous agitation in very dynamic shallow-water environments. According to this view, frictional resistance above that of round hard quartz sands, i.e. the Ottawa and Tampa Bay sands, is due to dilation during shearing as a result of the more elongated and angular grain structures of the skeletal calcareous sands.

It should be pointed out that the friction angles reported herein might not represent steady-state values. Instead, they are the largest values that could be measured given the limitations of the test equipment, typically corresponding to end-of-test shear strains of 20%. Ring shear tests conducted on carbonate sands by Coop et al. (2004) suggest that stable friction values may require shear strains on the order of 30% or more. Depending on normal stress, even this level of strain may not be sufficient to achieve critical state conditions.

Another factor that affects frictional resistance is particle breakage. Given the lower hardness of calcareous grains, these types of sands tend to undergo more breakage during shearing than quartz sands. This is especially true for skeletal calcareous sands with significant intraparticle voids (Datta et al. 1979; Semple 1988; Joer et al. 1997). Crushing reduces dilatant, brittle behavior in favor of more contractive, plastic shear response. The result is a reduction in mobilized friction. Of course, the degree of crushing depends on void ratio and confining stress. Crushing leads to curved failure envelopes. This is illustrated in Fig. 4 for the Kawaihae Harbor and Ottawa sands. Changes in friction angle over a normalized vertical stress range of 1–10 were calculated for all the sands and are listed in Table 2. Clearly, the reduction in frictional resistance with increase in normal stress is larger for the calcareous sands compared to the quartz sands. The degree of particle breakage can be quantified in terms of grain size distribution parameters before and after shearing (Hardin 1985). However, there was little observable change in gradation in any of the tests. It would appear that particle degradation was limited to the rounding of sharp edges, without necessarily causing major grain breakage. The expectation is that calcareous sands with more angular and elongated grains, typically found in less dynamic environments, would yield higher peak fiction values at low normal stresses, but would also undergo more pronounced particle breakage and corresponding reduction in mobilized friction at larger normal stresses and strains.

4 Cyclic Strength

If stress–strain and mobilized friction behavior of calcareous sands under monotonic conditions is different from that of quartz sands, it is reasonable to ask whether this is also the case under dynamic conditions. To examine this possibility, a total of 28 cyclic simple shear (CSS) tests were conducted on the Maui Dune sand, the Kawaiahae Harbor sand, and the Nevada quartz sand (Table 3). The Maui Dune and Kawaihae Harbor sands were tested at two different relative densities, identified as HD (high density) and LD (low density). Sample preparation was similar to that of the static tests, but different amounts of tamping and vibration were needed in order to achieve the desired initial void ratios. In the case of the LD samples, sand was placed into the wire-reinforced membrane using dry pluviation with little, if any, need for further densification. The HD samples required different amounts of densification after pluviation. Following specimen preparation, samples were first loaded vertically, allowed to consolidate for a short period of time until no further vertical displacements were observed, and then subjected to sinusoidal constant shear stress amplitude loading at a frequency of 0.5 Hz. The two-way loading was symmetric about the initial vertical condition. Tests were continued until they reached 20% (one-way) shear strain. The cyclic phase was conducted at constant height (constant volume). This means that the system monitored the height of the specimen and changed vertical loading as needed to maintain the initial height of the sample. Given the lateral constraint imposed by the wire-reinforced membrane, this also implies that the volume of the specimen remained the same during the cyclic phase. In other words, tests were conducted in an undrained fashion. Initial stress conditions are given in terms of the cyclic stress ratio:

where τ cyc is the shear stress amplitude and σ n is the applied normal stress. Multiple tests were conducted on each sand type, with overlapping CSRs as indicated in Table 3.

Typical results are shown in Fig. 5a for the Nevada sand and in Fig. 5b for the Kawaihae Harbor sand. Constant height implies that as the specimen is cycled, the normal stress decreases, with the reduction equivalent to the rise in pore pressure under undrained conditions. Pore pressure is given in terms of the normalized pore pressure ratio. This is calculated as the ratio of normal stress to initial normal stress. Liquefaction is assumed to occur at a shear strain of 3.75%. The number of cycles to liquefaction, NL, is indicated in Fig. 5a, b. Liquefaction here is defined at a specific value of shear strain during cyclic loading, as opposed to a given stress-based condition, and this reflects a particular serviceability limit in the field (Kramer 1996). It was found that this level of shear strain yielded the most consistent evaluation for the onset of liquefaction given the test conditions and soil types investigated.

A difference in behavior between the calcareous and quartz sands is apparent in Fig. 5a, b. These particular tests were conducted at similar relative densities, although the initial void ratio for the Kawaihae sand is slightly larger. Despite the lower void ratio and CSR for the Nevada sand test, it liquefied after only 14 cycles, compared to 22 cycles for the Kawaihae sand. Thus the Nevada sand appears to be more susceptible to liquefaction. This becomes more evident when all the tests for these two materials are combined in terms of standard cyclic liquefaction resistance curves, as shown in Fig. 6a. For the range of densities and void ratios investigated, the Nevada sand trend line is located below the ones for the calcareous sand. This is also true when the trends for the Maui Dune sand tests are added (Fig. 6b). Clearly, the cyclic strength of the calcareous sands is larger than that for the quartz sand. This general observation is true even when one considers the effects of the initial stress and void ratios (or densities). Thus the results agree with those of Chen (1985) and Morioka and Nicholson (2000).

The reason for the difference in cyclic strength is attributed to differences in grain geometry and gradation. The Kawaihae and Maui calcareous sands are somewhat more elongated and angular than the Nevada sand, requiring more work to accommodate cyclic loading. Hence a larger number of cycles are necessary to achieve liquefaction for the calcareous sands. However, it is also necessary to consider gradation characteristics and the potential for particle breakage. Presumably particle breakage may result in a reduction in strength, similar to that noted under monotonic loading conditions. However, there was virtually no evidence of particle breakage when examining the samples after testing. This effect may be more critical at confining stresses higher than the ones used in this study. On the other hand, the grain size distribution of the Nevada sand is narrower than that of the two calcareous sands (Fig. 1) and it is well known that sands with uniform grain sizes are more susceptible to liquefaction than well-graded ones. This is thought to be a more important factor here than particle breakage.

5 Shear Wave Velocity

Each of the sediment types listed in Table 3 was subjected to bender element testing using the same setup as for the monotonic and cyclic tests. The intention was to examine the small-strain response of the sands used in the cyclic strength testing program. Samples prepared to the densities and void ratios indicated in Table 3 were loaded vertically and shear wave velocities were measured with a set of bender elements at various vertical stresses. The results are summarized in Fig. 7a. Maximum shear modulus (Fig. 7b) was calculated based on measured shear wave velocities assuming elastic response:

where ρ is density and V s is shear wave velocity.

The range of shear wave velocities and small-strain shear stiffnesses are similar to those expected for loose granular sands (Lee and Santamarina 2005; Hanchar 2006), although few measurements have been reported for calcareous sands or for normal stresses beyond 200 kPa. As expected, velocity and stiffness are very much dependent on confining stress. Shear wave velocities for the calcareous sands are significantly higher than for the Nevada quartz sand, despite generally lower relative densities and higher void ratios. This is attributed to larger grain-to-grain contact areas that develop as interparticle stresses cause some grinding and refitting of the interfaces. The result is tighter and better grain contacts that are able to transmit acoustic energy faster and more effectively. Velocities are highest for the Maui dune sand, and for the HD tests when compared to the LD ones.

The discrepancy in velocities between the calcareous and quartz sands is problematic for assessment of field liquefaction based on shear wave velocity measurements. Standard cyclic resistance ratio (CRR) curves that rely on shear wave velocities have been developed based mainly on terrigenous quartz sands (Andrus and Stokoe 2000). They may need to be modified for calcareous sands. Such a possibility was also suggested by Rollins et al. (2004) based on blast-induced liquefaction field tests conducted on Maui on similar materials as the ones used in this study.

6 Shear Modulus and Damping Ratio

The stress–strain behavior leading up to liquefaction can be evaluated in terms of shear stiffness and damping ratio. Secant stiffness values were calculated for each cycle with reference to the point of load reversal. Damping ratio was computed as the ratio of peak energy during the cycle to the total energy dissipated (Kramer 1996). Standard modulus reduction curves are usually presented by normalizing secant stiffness to maximum stiffness determined from small-strain tests. The normalized values presented in Figs. 8 through 10 are based on the shear wave velocities in Fig. 7 and were determined from Eq. (2).

An example of shear modulus and damping ratio values calculated for one of the Maui LD tests, along with the corresponding trend lines, is presented in Fig. 8. Results obtained with the NGI-type simple shear device span from about 0.05% to nearly 15% strain. This represents the practical limits for this particular test apparatus. These strains are above elastic and no-volume thresholds for sands, which are typically about 0.01–0.02% for quartz sands, depending on confining stress (Hsu and Vucetic 2004). Above these levels, irrecoverable strains begin to accumulate. This means that the normalized modulus reduction curves are expected to trend upward and approach a stiffness ratio of 1.0 at about 0.01% strain. However, accurate values of volumetric and elastic threshold strains for calcareous sands remain to be determined. Given differences in mineralogy, grain hardness, intraparticle voids and structure between quartz and calcareous sands, it would not be surprising if threshold strains for calcareous sands were to be lower than for quartz sands.

Figure 8c shows a damping ratio of about 5% at a shear strain of 0.1%. Theoretically, there is no hysteretic dissipation of energy at strains below the cyclic shear strain threshold. Therefore, the trend line in Fig. 8c would be expected to approach a 0% damping ratio at strains on the order of 0.01% or so. At the other end, damping ratios at strains much above 1% are difficult to determine accurately. This is certainly true for the sands tested in this study, which tended to drift toward liquefaction at strains above about 1% (Fig. 5a, b). At that point, energy dissipation increases dramatically, equipment compliance becomes problematic, and computed damping values are fraught with inaccuracies. This explains why the decrease in damping ratio seen above 1% strain disagrees with trends observed by Vucetic and Dobry (1991) and others, which indicate a leveling off or continued increase in damping at higher strains. Thus from here on, results are only shown up to 1% shear strain.

Trend lines similar to those shown in Fig. 8 were developed for all the cyclic tests. The effect of stress level on these curves, in terms of CSR, is shown in Fig. 9 for the 4 Maui LD tests. The stiffness reduction curves are all nearly the same, with a small difference becoming apparent when normalizing with respect to maximum shear modulus. Similar observations apply to the other soil types as well. In general, modulus reduction curves appear to be rather independent of CSR. Damping ratios in Fig. 9 increase somewhat with CSR. This was also the case for the other calcareous sands, whether LD or HD, but not so for the Nevada quartz sand, for which no discernable trend was apparent. The dependence is most evident at CSR values above 0.1%, but it is almost nonexistent below that. In any case, the dependence on CSR is not strong and for practical purposes it may be neglected.

If the influence of stress level on the stiffness and damping curves is ignored, a single trend line can be inferred for each material type. Average trend lines for the five sets of tests are shown in Fig. 10. The stiffness reduction curves for the four calcareous test sets are almost identical. The corresponding curves for the Nevada quartz sand are somewhat higher. In other words, shear modulus values are larger for the quartz sand, especially at low shear strains well before the onset of liquefaction. Degradation differences between the calcareous sands are more pronounced in terms of damping ratio. Whereas the HD and LD trends for each sand type are similar, the Kawaihae Harbor sand indicates significantly lower damping than the Maui sand, which in turn shows less damping than the Nevada quartz sand. This is true for shear strain above about 0.2%, whereas the trends reverse at shear strains less than that. The relatively low amount of damping for the Kawaihae Harbor sand is attributed to a larger amount of fines (Table 1). In general, the presence of fines is thought to decrease damping, particularly if the fines are of a plastic nature (Vucetic and Dobry 1991).

Despite any differences in stiffness and damping between the two classes of soils, the values shown in Fig. 10 generally agree with those reported for granular soils in previous studies such as those by Seed and Idriss (1970); Laird and Stokoe (1993) and Assimaki et al. (2000). In the case of the calcareous soils, measured stiffnesses plot near the bottom range of values typically associated with quartz sands, at least for strain levels less than 0.1%. On the other hand, damping ratios for the Maui sand (and also the Nevada sand) are quite comparable to those reported in previous studies for typical quartz sands, although those of the Kawaihae Harbor sand are somewhat lower.

7 Summary

Monotonic and cyclic simple shear tests results have been presented for a series of skeletal calcareous sands from shallow-water areas, primarily surrounding the islands of Hawaii, as well as for two commercial quartz sands. The objectives were to compare the response of loose skeletal calcareous and detrital quartz sands and to provide strength and cyclic degradation characteristics for these sediments, especially for the calcareous sands. The modulus reduction and damping curves can be used for quasi-nonlinear ground response analysis based on the equivalent linear material model. This approach represents a common compromise between linear and fully non-linear modeling approaches. The results can be incorporated into modern commercial codes with little difficulty. With regard to overall behavior, a number of observations can be made.

Peak mobilized friction angles are larger for the calcareous sands than for the quartz sands, which is due to contrasting volume change tendencies resulting from mineralogical and textural differences. Measured friction angles for the calcareous sands are not as high as reported in other studies because of significant particle fracturing and rounding caused by the high-energy, shallow-water environment where they were formed.

Particle breakage and rounding during shearing can cause a substantial decrease in friction angle at higher normal stresses. This decrease is more severe in the calcareous sands due to lower grain hardness and more prevalent intraparticle voids.

Cyclic liquefaction resistance is higher for the calcareous sands than for the quartz sand. This is attributed to differences in grain geometryand gradation. As expected, cyclic resistance increases with increasing density (or decreasing void ratio).

Shear wave velocities at comparable normal stresses are higher for the calcareous sands, with the difference substantial enough to merit a reevaluation of standard shear wave velocity CRR curves for use with calcareous sands.

Reasonable degradation properties for the type of sands used in this study are limited to the range of 0.05–1% shear strain for the NGI-type simple shear device commonly used for laboratory testing. Within this range, sands behave non-linearly and experience stiffness reduction and hysteretic damping.

Stiffness and damping ratio are not very dependent on CSR, although it could be argued that there is a small increase in both properties with CSR, particularly for CSR values above 0.1. Average stiffness and damping ratio trend curves are lower for the calcareous sands in comparison to the quartz sand. Among the calcareous sands, stiffness values are nearly the same for the two types of sands and for the range of densities investigated. On the other hand, the Kawaihae Harbor sand, with significantly more fines, reveals substantially less damping than the Maui dune sand at shear strains above 0.2%.

References

Al-Douri RH, Poulos HG (1991) Static and cyclic direct shear tests on carbonate sands. Geotech Test J 15(2):138–157

Andrews DCA, Martin GR (2000) Criteria for liquefaction of silty soils. In: Proceedings of the 12th world conference on earthquake engineering. Auckland, New Zealand, pp 110–116

Andrus RD, Stokoe KH II (2000) Liquefaction resistance of soils from shear-wave velocity. J Geotech Geoenviron Eng 126(11):1015–1025

Assimaki D, Kausel E, Whittle A (2000) Model for dynamic shear modulus and damping for granular soils. J Geotechn Geoenviron Eng 126(10):859–1869

Brandes HG, Seidman J (2008) Dynamic and static behavior of calcareous sands. In: Proceedings of the 18th international offshore and polar engineering conference, vol 2. Vancouver, Canada, pp 573–578

Brandes HG, Khadge NH, Nakayama DD (2000) Consolidation and strength properties of calcareous sediments from Kaneohe and Kailua Bays, Hawaii. In: Proceedings of the 10th international offshore and polar engineering conference, vol 2. Seattle, Washington, pp 470–476

Celestino TB, Mitchell JK (1983) Behavior of carbonate sands for foundations of offshore structures. In: Proceedings, Brazil offshore ’83. Rio de Janeiro, pp 85–102

Chen YP (1985) Liquefaction potential of coral sand. M.S. Thesis, Department of Civil Engineering, Colorado State University, Fort Collins, Colorado

Coop MR, Airey DW (2003) Carbonate sands. In: Tan TS, Phoon KK, Hight DW, Leroueil S (eds) Characterization and engineering properties of natural soils, pp 1049–1086

Coop MR, Sorensen KK, Bodas Freitas T, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Geotechnique 54(3):157–163

Cubrinovski M, Ishihara K (2002) Maximum and minimum void ratio characteristics of sands. Soils Found 42(6):65–78

Datta M, Gulhati SK, Rao GV (1979) Crushing of calcareous sands during shear. In: Proceedings, offshore technology conference, Houston, vol 3. pp 1459–1467

Hanchar S (2006) A comparison of bender elements and torsional shear wave transducers. M.S. Thesis, Department of Civil Engineering, University of Rhode Island, Kingston, Rhode Island, 76 p

Hardin BO (1985) Crushing of soil particles. J Geotech Eng 111(10):1177–1191

Holmes A (1978) Principles of physical geology. Sunbury-on-Thames, Nelson, London, p 730

Hsu C-C, Vucetic M (2004) Volumetric threshold shear strain for cyclic settlement. J Geotech Geoenviron Eng 130(1):58–70

Hull TS, Poulos HG, Alehossein H (1988) The static behavior of various calcareous sediments. In: Jewell RJ, Khorshid MS(eds) Engineering for calcareous sediments, proceedings of the international conference on calcareous sediments, Perth, vol 1. pp 87–96

Jewell RJ (1993) An introduction to calcareous sediments. Research Report No. G1075. Department of Civil Engineering, The University of Western Australia, 45 p

Joer HA, Ismail M, Randolph MF (1997) Compressibility and crushability of calcareous soils. Research Report No. G1263. Department of Civil Engineering, The University of Western Australia, 11 p

Kramer SL (1996) Geotechnical earthquake engineering. Prentice Hall, Upper Saddle River, p 653

Kwag JM, Ochiai H, Yasufuku N (1999) Yielding stress characteristics of carbonate sand in relation to individual particle fragmentation strength. In: Al-Shafei KA (ed) Engineering for calcareous sediments, proceedings of the 2nd international conference on engineering for calcareous sediments, Bahrain, vol 1, pp 79–86

Laird JP, Stokoe KH (1993) Dynamic properties of remolded and undisturbed soil samples tested at high confining pressures. Geotechnical Engineering Report GR93-6. Electrical Power Research Institute, Palo Alto, California

Lee J-S, Santamarina JC (2005) Bender elements: performance and signal interpretation. J Geotech Geoenviron Eng 131(9):1063–1070

Lo Presti DCF, Pallara O, Lancellota R, Armandi M, Maniscalco R (1993) Monotonic and cyclic loading behavior of two sands at small strains. Geotech Test J 16(4):409–424

Mao X, Fahey M (2003) Behaviour of calcareous soils in undrained cyclic simple shear. Geotechnique 53(8):715–727

McClelland B (1988) Calcareous sediments: an engineering enigma. In: Jewell RJ, Khorshid MS (eds) Engineering for calcareous sediments, proceedings of the international conference on calcareous sediments, Perth, vol 2, pp 777–784

Mejia LH, Yeung MR (1995) Liquefaction of coralline soilsduring the 1993 guam earthquake. earthquake-induced movements and seismic remediation of existing foundations and abutments. Geotechnical special publication No. 55, ASCE, pp 33–48

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. Wiley, Hoboken 577 p

Morioka BT, Nicholson PG (2000) Evaluation of the liquefaction potential of calcareous sand. In: Proceedings of the 10th international offshore and polar engineering conference, Brest, France, vol II, pp 494–500

Nicholson PG (2006) Liquefaction evaluation discrepancies in tropical lagoonal soils. J Geotech Geol Eng 24(5):1259–1269

Ong SE, Joer HA, Randolph MF (1999) Frictional behavior in calcareous soils. In: Al-Shafei KA (ed) Engineering for calcareous sediments, proceedings of the 2nd international conference on engineering for calcareous sediments, Bahrain, vol 1, pp 219–228

Polito CP, Martin JR II (2001) Effect of nonplastic fines on the liquefaction resistance of sands. J Geotech Geoenviron Eng 127(5):408–415

Porcino D, Caridi G, Ghionna VN (2008) Undrained monotonic and cyclic simple shear behaviour of carbonate sand. Geotechnique 58(8):635–644

Rollins KM, Nicholson P, Lane JD, Rollins RE (2004) Liquefaction hazard assessment using controlled-blasting techniques. In: Proceedings, 11th international conference on soil dynamics and earthquake engineering and 3rd international conference on earthquake geotechnical engineering, vol 2, pp 630–637

Seed HB, Idriss IM (1970) Soil moduli and damping factors for dynamic response analyses. Report EERC 70-10. Earthquake Engineering Research Center, University of California, Berkeley, Berkeley, California

Seidman J (2007) Static and dynamic properties of various sands using a direct simple shear apparatus. M.S. Thesis. Department of Civil and Environmental Engineering, University of Hawaii, 115 p

Semple RM (1988) The mechanical properties of carbonate soils. In: Jewell RJ, Khorshid MS (eds) Engineering for calcareous sediments, proceedings of the international conference on calcareous sediments, Perth, vol 2, pp 807–836

Sharma SS, Fahey M (2003a) Evaluation of cyclic shear strength of two cemeneted calcareous soils. J Geotech Geoenviron Eng 129(7):608–618

Sharma SS, Fahey M (2003b) Degradation of stiffness of cemented calcareous soil in cyclic triaxial tests. J Geotech Geoenviron Eng 129(7):619–629

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenviron Eng 124(6):479–491

Vucetic M, Dobry R (1991) Effect of soil plasticity on cyclic response. J Geotech Eng 117(1):89–107

Xenaki VC, Athanasopoulos GA (2003) Liquefaction resistance of sand-silt mixtures: an experimental investigation of the effect of fines. Soil Dyn Earthq Eng 23:183–194

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brandes, H.G. Simple Shear Behavior of Calcareous and Quartz Sands. Geotech Geol Eng 29, 113–126 (2011). https://doi.org/10.1007/s10706-010-9357-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-010-9357-x