Abstract

Traditional measurements of block size (or degree of jointing), such as the rock quality designation (RQD), are questionable due to certain theoretical limitations, including orientation bias and their weakness in considering the joint persistence and three-dimensional shapes of block sizes. This may lead to inaccurate characterizations of rock mass structures and unreliable classification of rock mass qualities. The modified blockiness index (MBi) is a three-dimensional measurement of block size which was developed to overcome these problems. In this study, correlations between MBi and several traditional block size measurements were assessed; based on the MBi, the rock mass rating (RMR) system was modified, and this version was termed RMRmbi. In the first part of this work, multiple simulated experiments were conducted using the GeneralBlock software program and 3DEC (three-dimensional distinct element code), and a large volume of MBi, RQD, joint frequency (JF) and volumetric joint count (Jv) values (artificial data sets) were obtained; subsequently, the correlations between MBi and RQD, JF and Jv were assessed. In the second part, the combined use of RQD and JF in the RMR system was replaced with MBi, and hence, the RMRmbi system was developed; based on the artificial data sets, the viability of RMRmbi was preliminarily supported. At the end of this study, the correlations between MBi and RQD, JF and Jv were verified based on actual data; the RMRmbi was applied to real cases, and a comparison between RMRmbi and RMR was conducted. The results showed that (i) the MBi can capture the influence of joint persistence; (ii) the RMRmbi system can overcome the theoretical limitations caused by RQD and JF; and (iii) simulated experiments showed that the RMRmbi values are more reliable, thus validating the accuracy of RMRmbi and revealing its great potential for future application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rock mass is a type of discontinuous material that often contains a variety of joints, which discretize the rock mass into blocks of various sizes and shapes (Palmstrom 2005; Xia et al. 2016; Yarahmadi et al. 2018). The quantity and sizes of blocks within rock mass (or degree of blockiness) have a major controlling influence on the quality and stability of rock masses. Accurate measurement of block size is a basic task in rock mass characterization and classification, and can also provide robust data for designing rock engineering structures (Celada et al. 2014).

Over the past several decades, a large number of block size measurements have been proposed. Some existing measurements are listed in Table 1. In this table, all the three-dimensional measurements are indirect, because rock mass structure cannot be directly examined in three dimensions (Shang et al. 2018), and these three-dimensional measurements are basically performed from the joint data acquired from rock exposure. In addition, joint frequency (JF) is essentially identical to joint spacing (JS), and the same is true for volumetric joint count (Jv) and P30.

Actually, only a few of these measurements have been widely accepted, including the RQD, JF, and Jv. The RQD has gained wide acceptance and application compared to the other two indices. In civil and mining engineering worldwide, borehole penetrations occur every day, and professionals always record the degree of rock mass jointing in the form of RQD (Zhang 2016). Also, many rock mass quality classification systems include RQD as a basic input parameter, for example, the geomechanics classification system/rock mass rating system (RMR) (Bieniawski 1989), tunneling quality index (Q-system) (Barton et al. 1974) and the quantified version of the Geological Strength Index chart (GSI) (Hoek and Diederichs 2013). The use of JF and Jv is also popular. In the RMR system, JF has a weighting “score” of 20 points, which is used together with RQD to quantify the degree of rock mass jointing; notably, in the updated version of the RMR system (Celada et al. 2014), the combined use of RQD and JF was replaced by the sole use of JF, but this version is controversial (Koutsoftas 2017). The Jv is often used in conjunction with the Rock Mass index (RMi) (Palmstrom 1996), and in some Chinese geotechnical codes (PRC Ministry of Construction 1995), the intactness index of rock mass (Kv) (Liu et al. 2017) can be estimated using Jv. It should be noted that the previous findings are reviewed only from the perspective of the essential concepts of these indices; some works in which certain techniques such as three-dimensional point cloud (Riquelme et al. 2016) and discrete fracture network (Zhang et al. 2013) were employed to determine the RQD, JF or Jv value are not discussed in this study.

However, various researchers (Palmstrom 2005; Zhang et al. 2012; Chen et al. 2019) have noted that the three measurements (i.e., RQD, JF and Jv) are limited. For example, two major criticisms of RQD are that RQD values are very sensitive to the scanline or borehole direction, and that RQD counts only the core pieces longer than 100 mm and therefore cannot effectively differentiate rock masses with various structures. These two shortfalls have become the basis for arguments against the use of the RQD in rock mass classification systems (Pells et al. 2017). The other two indices also suffer from limitations: JF is also orientation-dependent, and joint persistence is ignored in the Jv method (Lin 2008). Actually, many block size measurements and rock mass quality classification systems fail to consider joint persistence (Kim et al. 2007). In addition, Hoek and Diederichs (2013) reported that some traditional measurements of the degree of rock mass jointing, including RQD, JF and Jv, cannot capture the effect of block scale.

Other measurements of block size were not mentioned, such as the weighted joint density (WJD) (Terzaghi 1965), RQD/JN (Barton et al. 1974) (RQD/JN denotes the RQD value divided by the joint set number) and block volume (Vb) (Palmstrom 2005). This is due to the following: (i) the WJD is, in fact, a correct approach for joint data, which is mainly used to remedy the one-dimensional joint density for borehole orientation bias (Terzaghi 1965); (ii) the RQD/JN is slightly unreliable, because the determination of the JN is often subjective in nature (Grenon and Hadjigeorgiou 2003); and (iii) the Vb is an interpretation of Jv (Palmstrom 2005).

Inaccurate measurement of block size (or degree of rock mass jointing) may result in unreliable classification of rock mass quality (Palmstrom 2005; Aydan et al. 2014). Therefore, in this study, the modified blockiness index (MBi) is introduced (for details, see Section 2), and an attempt has been made to incorporate the MBi into the RMR system. The study consists of two main parts: (i) correlations of MBi with RQD, JF and Jv are evaluated; and (ii) a modified RMR system (RMRmbi) with a great application potential is developed and its viability analyzed. To consider all possible cases, the study was carried out based on multiple simulated experiments and some real engineering projects. In addition, multiple simulated experiments were conducted using the GeneralBlock program (a 3DJN model generator) (Xia et al. 2016) and 3DEC (three-dimensional distinct element code) (Itasca 2013) together.

Outline of the modified blockiness index (MBi)

Joints intersect rock mass in complicated three-dimensional patterns; however, traditional measurements of block size are often performed in one or two dimensions, and they are also unable to consider the influence of joint persistence and block scale. The modified blockiness index (MBi), proposed by Xia et al. (2015) and revised by Chen et al. (2018), is capable of overcoming these difficulties. The MBi is a three-dimensional measurement that enables the quantification of the block size distribution of a given rock mass, and its calculation is based on the three-dimensional join network model (3DJN model) generated by stochastic and/or deterministic joints. MBi value can be calculated by

where B1, B2, B3, B4 and B5 are the ratios of blocks in the ranges of 0–0.008 m3, 0.008–0.03 m3, 0.03–0.2 m3, 0.2–1.0 m3, and > 1.0 m3, respectively, to the total rock mass volume, and the fractions (i.e., 1, 1/2, 1/3, 1/4 and 1/5) are the empirical scale effect coefficients, which are determined based on engineering practice (Wang et al. 2010; Chen et al. 2018). When the MBi value is close to 1, it suggests that the rock mass is very fractured; when the MBi value is close to 0, it indicates a very low degree of rock mass jointing. The suggested jointing classes based on MBi are presented in Table 2.

In fieldwork, the MBi associated with a given rock mass can be determined based on the following steps: (i) obtaining joint measurement data, including joint orientation, trace length and joint density; (ii) demarcating statistically homogeneous structural domains: generally, the domains can be identified using joint orientation data, together with various statistical methods, e.g., Chi-square test (Miller 1983; Martin and Tannant 2004; Li et al. 2014); (iii) establishing a three-dimensional joint network model; (iv) identifying the sizes of all blocks inside the rock mass model; and (v) calculating the MBi value using Eq. (1). Steps (iii) and (iv) can be carried out using GeneralBlock.

In essence, the MBi concept can be treated approximately as an extension of RQD and Vb, namely, all the MBi, RQD and Vb are direct representations of the blockiness of rock mass, which are different from JF and Jv. In other words, MBi, RQD and Vb all consider block size: MBi and Vb count blocks of all sizes in three dimensions, and RQD counts rock pieces greater than 100 mm in one dimension; however, JF and Jv quantify rock mass blockiness from the perspective of one- and three-dimensional joint density. In addition, although both MBi and Vb are indirect measurements, their determination methods differ: Vb is estimated mainly by Jv, and MBi is determined by certain techniques including three-dimensional joint network representation and rock block identification.

Compared to the RQD and JF, the MBi index can take into account the joint persistence, because the three-dimensional block size corresponds well with various joint geometries (Kim et al. 2007). However, the RQD is controlled primarily by the one-dimensional joint density (their theoretical correlation is presented in Eq. (7), Section 3), which cannot capture the effect of joint persistence. Therefore, in the following sections, we attempt to replace the RQD and JF with MBi in the RMR system in order to fully consider the rock mass jointing degree in three dimensions.

Correlations of MBi with RQD, JF and Jv

To consider all possible cases, multiple simulated experiments were conducted to obtain a large volume of artificial data sets. Under such ideal conditions, the correlations of MBi with RQD, JF and Jv were evaluated. Validations are presented in Section 5, using a number of real data.

Design of simulated experiment

When the JN value is fixed, the joint density (or frequency, or spacing) has the greatest effect on the degree of rock mass jointing, followed by joint persistence (Bieniawski 1989; Shang et al. 2018), whereas the other joint geometrical parameters, such as joint orientation (JO) and distribution type, have negligible effects (Zhang et al. 2009). If all joint geometrical parameters are considered, the workload is too heavy. Therefore, the joint data in Xia et al. (2015) are employed (Table 3), including the average joint orientation, joint trace standard deviation and distribution type of joint traces. In this section, the joint parameters in Table 3 are fixed, and the JS and JP values are changed. In addition, 3DJN models are constructed using the GeneralBlock program, and the block sizes are identified and recorded; these models are passed on to 3DEC, and a specific code is developed and executed in 3DEC, where RQD, JF and Jv values are determined.

Pairs of “JS-JP”

Since the degree of jointing is mainly affected by joint spacing (JS) and joint persistence (JP), the schemes of simulated experiments were developed by means of the following steps: (i) select a range of JS and JP values, and two groups of samples (i.e., JS and JP) can be obtained; and (ii) develop pairs of “JS-JP” by the cross joins of JS and JP values, respectively, from the two groups of samples, while other joint geometrical parameters remain fixed.

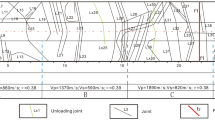

The joint spacing and persistence can be classified into seven and five intervals, respectively (ISRM 1978), as shown in Table 4. A total of 18 joint spacing values and 10 joint persistence values were selected, and two groups of samples (i.e., JS and JP) were obtained; therefore, 180 pairs of “JS-JP” were developed by the cross join method. It can be observed from Table 4 that most of the selected joint spacing values are in the range of 0.02 to 2 m, which reflects those commonly found in engineering practice (ISRM 1978; Bejari and Khademi Hamidi 2013; Riquelme et al. 2015; Buyer and Schubert 2017; Wong et al. 2018). The other joint geometrical parameters are fixed, as shown in Table 3. Based on these 180 pairs, 180 schemes are established, and 180 3DJN models with different structures are created. Some 3DJN models (established using GeneralBlock) are presented in Fig. 1. It is noted that the distribution types of joint persistence values are in agreement with Table 3, and the joint spacing values are derived for three-dimensional joint densities (Xia et al. 2016):

where d3 is three-dimensional joint density. This is because in many 3DJN model generators, including GeneralBlock, the input parameters with regard to joint density are of three-dimensions.

The geometrical and mechanical properties are controlled predominantly by the size of the “sample” or “specimen” under investigation, i.e., the effect of the representative elementary volume (REV). Also, the geometrical REV is not the same as the mechanical REV, and geometrical and mechanical REV represent the geometrical and mechanical properties that have reached a constant behavior, respectively. In this study, all the parameters (e.g., RQD) are related to the structural and geometrical features of models. Thus, all of the 3DJN models have met the size requirement for geometrical REV and are also greater than the joint persistence value. An example of REV determination is presented in Fig. 2. In this figure, the REV of a 3DJN model (JP = 0.5 m and JS = 0.13 m), which is also shown in Fig. 1, was determined: when the model size is greater than 4 m, the coefficients of variation (COV) for RQD, JF, Jv and MBi (the procedures for determining them are presented in Section 3.1.2) are all within the range of 0 to 0.5, and therefore the REV of this 3DJN model is determined as 4 m. Additionally, in order to reasonably measure RQD values, the sizes of the 3DJN models are all larger than 1.5 m.

Data acquisition

Data acquisition was carried out using 3DEC, with exception of the MBi values. RQD and JF values were determined by setting scanlines in the 3DJN models. To minimize the directional bias, the scanline and model boundary were fixed, and the joint network was rotated. In this way, the RQD and JF values in different directions could be measured, and the scanline length remained unaltered, as shown in Fig. 3. The scanline is perpendicular to XY plane (in a Cartesian coordinate system), and the intersection point is the model’s center (0, 0, 0). Therefore, the scanline can be described as

The joint in a model (Fig. 4) can be represented as

where A, B and C are the components of a normal vector of a joint, respectively, x0, y0 and z0 are the central coordinate values of a joint, and r is the joint radius. From Eqs. (3) and (4), an equation of the intersection of the joint and scanline can be established; if the solution of this equation is a real number, an intersection point exists between the joint and scanline, and vice versa. After the coordinates of the intersection points are obtained, the RQD and JF values can be easily calculated.

The rotation of a joint network can be achieved by the rotation matrix A (Zheng et al. 2014):

where α1 is the rotation angle of the joint network in the dip direction, and β1 is the rotation angle of the joint network in the dip angle. Therefore, the joint central coordinates after rotation (x′, y′, z′) can be obtained by

Additionally, joint orientation will also change after the rotation of the joint network. Similarly, the joint orientation after rotation can be calculated using A; the detailed processes are not repeated in this section.

Overall, a large number of RQD and JF values can be determined from a 3DJN model (an example is shown in Fig. 5), and their averages are defined as unique representative RQD and JF values. The means and standard deviations of the RQD and JF values for all 3DJN models are shown in Figs. 6 and 7. The two figures indicate that the RQD values fall mainly within the interval of 90–100, and the JF values fall mainly within the interval of 0–20.

Other unsettled questions involve the determination of Jv and MBi. In fieldwork, the Jv is often measured by the average spacing for well-defined joint sets (Palmstrom 2005), but obviously, this approach is inapplicable in this study, because it leads to identical results produced by various 3DJN models. With regard to the essence of the Jv concept, i.e., the number of joints per unit volume of rock mass, the Jv is found to be equivalent to the P30 (fracture/m3) (Dershowitz et al. 2003). In this work, the P30 values for all 3DJN models were determined using the built-in codes in 3DEC. Additionally, the sizes of blocks inside the 3DJN models were identified using GeneralBlock, as shown in Fig. 8, and the MBi values were determined according to Eq. (1). The Jv and MBi values for all 3DJN models are shown in Figs. 9 and 10. It can be seen that the Jv values fall mainly in the interval of 0–200, and the standard deviation is very large (231.37), because several 3DJN models contain very small and dense joints. For example, the Jv of the 3DJN model (JP = 0.5 m and JS = 0.01 m) is 2784.59. The MBi values fall mainly within the interval of 0–30.

Validating the effectiveness of artificial data

In Section 3.1, 180 3DJN models were established, and a substantial amount of artificial data was obtained. Before assessing the correlations between MBi and RQD/JF/Jv, it is necessary to check the validity of the artificial data, i.e., whether these artificial data reflect the objective trend.

The relation between RQD and JF (Priest and Hudson 1976) is

For the JF values ranging from 6 to 16, the linear relation between RQD and JF is

Therefore, a scatter plot of artificial RQD and JF values was created, and regression analysis was carried out, which is presented in Fig. 11. The figure shows that the data points are fitted using Eqs. (7) and (8), and the coefficients of determination are 0.99 and 0.93, respectively. Additionally, F tests were carried out, and the F and p values suggested that the null hypotheses were rejected, and that the two regression models, i.e., Eqs. (7) and (8), were significant. This means that the results of the simulation experiment are effective and reliable, and moreover that the artificial data sets produced by the theoretical 3DJN models are in line with the objective trends.

Correlation between MBi and RQD

In the field of rock mechanics and rock engineering, RQD has received much attention over the past few decades. It was found that RQD is closely related to JF, Jv, P-wave velocity, deformation modulus and unconfined compressive strength (Feng and Jimenez 2015; Zhang 2016). Since the MBi is a direct representation of block size, similar to RQD, the MBi may correlate well with the RQD.

Based on Figs. 6 and 10, a scatter plot of MBi and RQD was created (note that some data points were deleted because too many RQD values were close to 100%, which can lead to invalid curve-fitting). Linear and nonlinear regression analyses were conducted (Fig. 12), which yielded

Figure 12 shows that the two coefficients of determination are 0.72 and 0.77, respectively, and the F and p values indicate than the null hypotheses are rejected and the regression models are significant.

Considering that the block sizes are controlled mainly by joint spacing and joint persistence (Kim et al. 2007), and that the RQD concept takes into account only the core pieces longer than 100 mm, joint persistence was involved in the assessment of the correlation between MBi and RQD. Therefore, multiple linear and nonlinear regression analyses were performed (Figs. 13 and 14), which yielded

Correlation between MBi and RQD and JP (artificial data), corresponding to Eq. (11)

Correlation between MBi and RQD and JP (artificial data), corresponding to Eq. (12)

Figures 13 and 14 show that the coefficients of determination are 0.85 and 0.92, respectively, and the F and p values indicate that the null hypotheses are rejected and the two regression models are significant. Additionally, Eq. (11) is a multiple linear model, and hence, the collinearity statistics was carried out, which is presented in Table 5. A review of Table 5 indicates that all VIF values for each variable are less than 10, indicating that no strong correlation exists between the two independent parameters.

From Eqs. (9)–(12), four inverse relations between MBi and RQD were found, namely, the larger the MBi, the smaller the RQD. Figure 12 also shows that when the RQD is 0, the MBi values vary from 60 to 100; when the RQD is 100, the range of MBi values is approximately 0–30. This may be attributed to the conceptual difference between MBi and RQD, i.e., (i) the RQD counts only the core pieces longer than 100 mm, while the MBi consider all blocks; and (ii) joint persistence is neglected with the RQD method.

Correlation between MBi and JF

Based on Figs. 7 and 10, the MBi values were plotted with JF, as shown in Fig. 15. The nonlinear regression analysis yields

The coefficient of determination is 0.76, and the F and p values are 551.45 and 0.00, respectively, which suggests that the null hypothesis is rejected, and the regression model is significant. For JF values less than 30, a linear relation is found

The coefficient of determination is 0.70, and the F and p values are 536.73 and 0.00, respectively. Additionally, when the JF is greater than 30, the MBi shows a poor relation with JF.

By incorporating the JP into the assessment, multiple linear and nonlinear analyses were conducted (Figs. 16 and 17), which yielded

Correlations between MBi and JF (artificial data), corresponding to Eq. (15)

Correlations between MBi and JF (artificial data), corresponding to Eq. (16)

The corresponding coefficients of determination are 0.84 and 0.91. F tests were carried out, and the F and p values indicate that the null hypotheses were rejected, and the regression models are significant.

Correlation between MBi and Jv

Based on Figs. 9 and 10, the scatter plot of MBi vs. Jv is delineated in Fig. 18. Note that the difference in orders of magnitude between various Jv values is too large, so the ln(Jv) is employed, and the data points with different colors denote various joint persistence. It is observed from Fig. 18 that the data points are very discrete, for which regression analysis cannot be properly performed; however, when the color (i.e., the joint persistence) is identical, the MBi values increase with the increase in Jv. Therefore, it is better to take into consideration the joint persistence.

Multiple nonlinear regression analysis (Fig. 19) yields

Correlations between MBi and Jv (artificial data), corresponding to Eq. (17)

Additionally, the coefficient of determination is 0.89, and the F and p values are 603.96 and 0.00, respectively, suggesting that the null hypothesis is rejected, and the regression model is significant.

A comparison between measured MBi values and estimated values was performed using Eq. (17), which is presented in Fig. 20. Although the coefficient of determination is rather high, the fitted curve is below the 1:1 line, meaning that the measured values are greater than the estimated values.

Comparison between measured MBi values (artificial data) and estimated MBi values using Eq. (17)

RMRmbi and its preliminary validation

Development of RMRmbi

Inaccurate measurements of block size may lead to unreliable rock mass classification results (Palmstrom 2005; Aydan et al. 2014). The combined use of RQD and JF in the RMR system is limited, because (i) both RQD and JF values are orientation-dependent; (ii) the RQD method counts only core pieces greater than 100 mm, which is sometimes unreasonable (Harrison 1999); (iii) both the RQD and JF methods neglect joint persistence; and (iv) the ratings of RQD plus JF are a repetition of joint density, resulting in the doubling of the influence of joint density on the final RMR rating. Although some researchers (Koutsoftas 2017) have maintained that these limitations would not reduce the applicability of the RMR system, these theoretical limitations do exist in reality, and thus improvement of the subsystem (i.e., the ratings of RQD plus JF) of the RMR is desired.

Motivated by the need to improve the RMR system, an attempt was made to substitute the combined use of RQD and JF with MBi, while keeping the other input parameters unchanged; this version is referred to as RMRmbi. As shown in Sections 2 and 3, the main advantages of using MBi to replace RQD and JF are as follows: (i) the MBi is a three-dimensional measurement and is not orientation-dependent; (ii) the MBi counts blocks of all sizes; (iii) joint persistence is considered, as shown in Section 3; and (iv) the MBi does not repeatedly calculate the joint density. The rating of MBi (RM) can be determined using a continuous function, as described by Eq. (18).

The greater the value of the MBi, the smaller the degree of rock mass jointing, and the poorer the rock mass quality, and vice versa. Table 6 can be used to determine the RM value. Therefore, RM is inversely proportional to MBi. The other input parameters, including, intact rock uniaxial compressive strength, are kept unchanged.

Preliminary validation of the viability of RMRmbi

Since the RMRmbi and traditional RMR systems are different from the characterization of rock mass structure, only the RM and RRQD + JF were compared. RRQD + JF (Warren et al. 2016) can be calculated by

Therefore, RRQD + JF = RRQD + RJF.

Actually, the application of RMRmbi in real cases is inadequate, because it is a new modification with regard to RMR. To confirm its viability, the results of simulated experiments considering many circumstances were used. The RM and RRQD + JF were applied to the artificial data sets (Figs. 6, 7 and 10), and the results are presented in Fig. 21, which shows that most of the RM and RRQD + JF values fall within the interval 30–40. The cumulative frequency curves are delineated in Fig. 22. The figure shows that for the interval of 8–40, the two curves are very smooth and have extremely similar trends, meaning that the two subsystems (i.e., RM and RRQD + JF) share an ability to distinguish the rock masses of various structures.

Figure 22 also indicates that for the interval of 0–8, the RRQD + JF shows poor “performance”, because the cumulative frequency curve of RRQD + JF does not start from the origin; however, in this interval, the curve of RM grows from the origin and shows a more natural transition, which means that the RM is more sensitive to rock masses with a high degree of jointing and can properly distinguish them. If one classification system is able to differentiate objects with a greater degree of refinement than another system, then it can be said that this system is better (Warren et al. 2016). Therefore, the RM is viable.

The correlation between RM and RRQD + JF values was evaluated based on the 1:1 line, which is presented in Fig. 23. It is found that although the MBi can be treated as an extension of RQD, the RM and RRQD + JF yield slightly different results. As shown in Fig. 23, when the RRQD + JF is close to 0, the RM values vary from 0 to 15; when the RRQD + JF is near 40, the RM values vary in the range of 35–40. However, the best-fitted curve is very close to the 1:1 line, with a rather high coefficient of determination.

Additionally, for the RQD and JF values determined in the simulated experiments, the directional bias has been the removed (i.e., they properly reflect the degrees of rock mass jointing), but in fieldwork, it is very difficult to guarantee that the RQD and JF values will not be biased by direction. This is why the substitution was performed. This problem is completely overcome in the RMRmbi system, which is a particular advantage of this RMRmbi.

Validations based on actual data

Validating the correlations of MBi with RQD, JF and Jv based on actual data

Validation studies were performed based on real case histories (Guangxi University and Huaxi Group 2013; Central South University et al. 2011; Wang 2011; Pan 2012). The MBi values were plotted with the RQD, JF and Jv values in Fig. 24. Based on these real data (Fig. 24), the assessed correlations (i.e., Eqs. (9)–(17)) were verified:

- (i)

The fitting analyses were applied to the actual MBi values and estimated MBi values using Eqs. (9)–(12), and the fitted curves are presented in Fig. 25. The figure shows that all fitted curves are very close to the 1:1 line, indicating that the four correlation equations (i.e., Eqs. (9)–(12)) properly reflect the relationship of MBi and RQD. Considering the coefficients of determination and the proximity degree of the 1:1 line and fitted curves, it can be concluded that Eq. (9) estimates the MBi value more accurately.

- (ii)

According to the actual JF values presented in Fig. 24, the estimated MBi values were produced using Eqs. (13)–(16). Fitting analyses were carried out based on the actual MBi values and estimated MBi values by JF, which are illustrated in Fig. 26. It can be seen from Fig. 26 that almost all the actual MBi values are less than the estimated values. Additionally, the coefficient of determination of the red curve is larger, but the associated curve is far from the 1:1 line; the blue and brown curves are closer to the 1:1 line, with lower coefficients of determination. Considering the coefficients of determination and the proximity degree of the 1:1 line and fitted curves, it can be concluded that Eq. (15) estimates the MBi value more accurately.

- (iii)

From Eq. (17), the estimated MBi values were obtained by the Jv values (Fig. 24). Fitting analysis was performed, and the fitted curve is presented in Fig. 27. It is observed that the fitted curve is very close to the 1:1 line, with a coefficient of determination of 0.60, which is not very high. Also, the mean absolute percentage error (MAPE) and root-mean-square error (RMSE) of the measured and estimated values are 39.31% and 15.97, respectively. The lower coefficient of determination and larger errors can be explained by the relatively weak reliability of Eq. (17) or the lack of enough real data.

Comparison of measured MBi values (real cases) and estimated MBi values using Eq. (17)

Figures 25, 26 and 27 show that none of the fitted curves are too far away from the 1:1 line, and in fact, some curves are very close to the line. Moreover, the corresponding coefficients of determination are rather high, with the smallest being 0.60. It can be concluded that the correlations of MBi with RQD, JF and Jv, which were obtained from the artificial data sets, are capable of being applied to the real data and are extremely sound.

Application of RMRmbi and its comparison with RMR

Comparative analysis of RMRmbi and RMR

In Section 4, the viability of RMRmbi was preliminarily verified based on the artificial data sets, which confirm that the ability of RMRmbi to differentiate rock masses with various structures is better than that of RMR (Fig. 22). In this section, the real data values (presented in Fig. 24) and the other input parameters (i.e., intact rock uniaxial compressive strength, joint condition and groundwater condition) are used to determine the final RMRmbi and RMR values, and a comparison between RMRmbi and RMR is subsequently carried out, as shown in Fig. 28. As seen in Fig. 28, the fitted curve is fairly close to the 1:1 line, suggesting that in some cases they have similar a ability to differentiate the rock mass quality.

Figure 28 shows few data, which means that at times, RMRmbi is the same as RMR. Actually, because the real application of RMRmbi is inadequate, simulated experiments were conducted in this study. Figure 22 indicates that RM is better from the perspective of assessing rock mass structures with a rating of < 8 (Section 4.2). Therefore, the RM and RMRmbi are viable, because RMRmbi is just different from RMR in evaluating rock mass jointing degree.

Some typical case studies of RMRmbi

The Tongkeng Mine project was launched by a subsidiary corporation of the Huaxi Group Co., Ltd., Guangxi, China, which is owned by the Chinese government, and has a yearly capacity of 2 million tons or more. Three large ore bodies occur in this mine, i.e., Ximaidai, and no. 91 and 92 ore bodies. The exploitation of ore body no. 91 has been completed, and ore body no. 92 is under production, with probable mineral reserves of 30 million tons.

The no. 92 ore body occurs in silicalite and limestone, and is a large, thick ore body with a gentle dip angle. The minerals vary, and mainly include cassiterite, pyrite, marmatite, pyrrhotite and arsenopyrite, and quartz is the typical gangue mineral. When the caving method is used, instabilities (e.g., ground fall, sidewall spalling and roof collapse) frequently appear due to the incipient joint swarm, high ground stress and blasting disturbance, and some installed supports always fail.

Four study sites were selected in which to perform rock mass quality classification. Study site 1 is in the T214 stope at the 494 level, which is the intersection between the no. 14 production drift and ventilation gallery; study site 2 is in the T201 panel at the 434 level; study site 3 is in the no. 2 panel at the 405 level, whose center is the intersection between the no. 3 drill access and ventilation drift; and study site 4 is in the undercut chamber at the 355 level. The locations and ground conditions of these sites are illustrated in Fig. 29. Additionally, joint mapping and core drilling were carried out, which is shown in Fig. 30. The joint orientation data are presented in Fig. 31.

Based on the joint information collected, the joint network models of the four study sites were established, and are shown in Fig. 32. The values of all input parameters of RMRmbi and RMR were measured, and the projected features were also considered, as shown in Table 7. In addition, the MBi values were calculated by identifying the blocks inside the cubic sub-joint network models to arrive at the REV sizes (Fig. 33), which are extracted from the models presented in Fig. 32.

Joint network models of the four sites. a Study site 1 (with drift length of 20 m and height of 2.8 m); b study site 2 (with drift length of 10 m and height of 3.2 m); c study site 3 (with drift length of 10 m and height of 3.2 m); and d study site 4 (with drift length of 10 m and height of 3.2 m). Note that only the large-scale joints are exhibited, and the small-scale joints are unobservable

Table 7 shows that with exception of study site 1, the RMRmbi and RMR ratings are divergent. To compare the two systems, the field situations are presented in Table 5. The rock mass classes by stand-up span time are shown in Table 9. From Tables 7, 8 and 9, it can be observed that the RMRmbi is more reliable; for example, for study site 3, the RMR rating is IV, and in Table 9, the rock mass stand-up time is expected to be approximately 10 h for a span of 2.5 m. However, with respect to the field situation, when the gallery is formed, a large-scale collapse occurs immediately; very long and dense rock bolts are systematically installed, with wire mesh and shotcrete of high thickness. Obviously, the RMRmbi rating (V) is more reasonable. In short, therefore, based on the field situation, the following can be concluded: for study site 1, both the RMRmbi and RMR ratings are rational; for study sites 2 and 3, the RMR ratings are overestimated, because the field situations are worse, and the expected stand-up time derived by RMRmbi ratings are in keeping with the actual conditions. For study site 4, the RMR rating is conservative, and the RMRmbi rating is appropriate.

A review of Table 7 also shows that the discrepancy between the RRQD + JF and RM values for the study sites (aside from study site 1) are very significant. Palmstrom (2005) found that when one-dimensional measurements of rock mass jointing degree (e.g., RQD) were applied to a blocky rock mass, various results could be experienced owing to different directions of the core drillings and scanlines, as shown in Fig. 34. Zheng et al. (2018) also used an example to demonstrate that for a stratified rock mass, the RQD values rely heavily on borehole direction. Therefore, differences between RRQD + JF and RM are inevitable. However, three-dimensional measurements of rock mass jointing degree are not orientation-dependent (Palmstrom 2005). The MBi is indeed a three-dimensional index, which is also a critical advantage of RMRmbi compared to RMR.

Different RQD values with various directions (Palmstrom 2005). Note that S1, S2 and S3 are the average spacing of joint sets 1, 2 and 3, respectively

Conclusions

Traditional measurements of block size or degree of jointing (e.g., RQD, JF and Jv) have been questioned and criticized, due to their inherent limitations, and the same is true for rock mass classification systems. Therefore, in this study, the MBi was introduced, and correlations of MBi with RQD, JF and Jv were evaluated; the combined use of RQD and JF was replaced with MBi in the RMR system, and this version was termed RMRmbi. From the results, the following conclusions can be drawn:

- (i)

Close correlations were found between MBi and RQD, JF and Jv, and when joint persistence was considered, the correlations were more significant, which shows that the MBi can fully capture the influence of joint persistence. Based on these correlations, the reasonableness and advantages of MBi are highlighted.

- (ii)

Because of the lack of sufficient real applications of RMRmbi (which is also a limitation of this study), simulated experiments were conducted to confirm the viability of RMRmbi, and the experimental results were in line with the objective trends (Section 3.2). Experimental simulation results suggest that the sensibility of RM and RRQD + JF is similar, but RM is better because it can properly distinguish rock masses whose jointing ratings are lower than 8 (Fig. 22). Comparative analysis of RMRmbi and RMR shows that in some cases, RMRmbi is the same as RMR. The typical applications of RMRmbi and RMR show that the RMRmbi ratings are more in line with common practice, based on observations of field situations. For the relatively fractured rock masses, the RMRmbi may be more reliable. Undoubtedly, the theoretical limitations of the combined use of RQD and JF are addressed, and the three-dimensional rock block sizes and joint persistence can be considered; therefore, the RMRmbi system has strong application potential.

- (iii)

Compared to the RMR system, the RMRmbi is simplified, because the RQD and JF are replaced with MBi. To determine MBi, the joint data and computer technology (presented in Section 2) are needed. However, in the short term, it is necessary to take time to complete the simulation of the joint system and calculation of block sizes, and the amount of time spent will be entirely dependent on the complexity of the joint system.

Additionally, the RMRmbi developed in this study is a new offering. In future work, significant effort should be made to further justify it, including (1) relations between RMRmbi and various rock mass properties (e.g., rock mass strength); (2) stability assessment of different rock engineering properties (e.g., slope and tunnel) by supplementing the RMRmbi; (3) determining how to select proper supporting schemes based on RMRmbi; and (4) determining how to rapidly simulate the rock joint system and calculate the rock block sizes for determining an RMRmbi value within a short period of time.

Abbreviations

- 3DEC:

-

Three-dimensional distinct element code

- 3DJN :

-

Three-dimensional joint network model

- A :

-

Rotation matrix

- COV :

-

Coefficient of variation

- d 3 :

-

Three-dimensional joint density

- JF :

-

Joint frequency

- JN :

-

Joint set number

- JO :

-

Joint orientation

- JP :

-

Joint persistence

- JS :

-

Joint spacing

- J v :

-

Volumetric joint count

- MAPE:

-

Mean absolute percentage error

- MB i :

-

Modified blockiness index

- REV:

-

Representative elementary volume

- R M :

-

The rating of MBi in the RMRmbi system

- RMR :

-

Rock mass rating system

- RMR mbi :

-

A modified RMR system based on the MBi

- RMSE:

-

Root-mean-square error

- RQD :

-

Rock quality designation

- R RQD+JF :

-

The ratings of RQD plus JF in the RMR system

- VIF:

-

Variance inflation factor

References

Aksoy CO (2008) Review of rock mass rating classification: historical developments, applications, and restrictions. J Min Sci 44:51–63. https://doi.org/10.1007/s10913-008-0005-2

Aydan Ö, Ulusay R, Tokashiki N (2014) A new rock mass quality rating system: rock mass quality rating (RMQR) and its application to the estimation of geomechanical. Rock Mech Rock Eng 47:1255–1276. https://doi.org/10.1007/s00603-013-0462-z

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech Felsmechanik Mécanique des Roches 6:189–236. https://doi.org/10.1007/BF01239496

Bejari H, Khademi Hamidi J (2013) Simultaneous effects of joint spacing and orientation on TBM cutting efficiency in jointed rock masses. Rock Mech Rock Eng 46:897–907. https://doi.org/10.1007/s00603-012-0314-2

Bieniawski ZT (1989) Geomechanics classification: engineering rock mass classifications. Wiley, New York

Buyer A, Schubert W (2017) Calculation the spacing of discontinuities from 3D point clouds. Procedia Eng 191:270–278. https://doi.org/10.1016/j.proeng.2017.05.181

Celada B, Tardáguila I, Varona P, Bieniawski ZT (2014) Innovating tunnel design by an improved experience-based RMR system. In: Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil, vol 3, pp 1–9

Central South University, Huaxi Group, Liuzhou Huaxi Nonferrous Designing Institute (2011) Assessment of the engineering rock mass quality in Xintongkuang mine (a concluding report)

Chen Q, Niu W, Zheng W et al (2018) Correction of some problems in blockiness evaluation method in fractured rock mass. Rock Soil Mech 39(10):3727–3734 (in Chinese with English abstract)

Chen Q, Yin T, Jia H (2019) Selection of optimal threshold of generalised rock quality designation based on modified blockiness index. Advances in Civil Engineering 2019:1340549

Deere DU, Hendron AJ, Patton FD et al (1967) Design of Surface and Near-Surface Construction in rock. In: Fairhurst C (ed) Failure and breakage of rock. Society of Mining Engineers of AIME, New York, pp 237–302

Dershowitz W, Doe T, Uchida M et al (2003) Correlations between fracture size, transmissivity, and aperture. Soil and rock America. In: Proceedings of the 12th Panamerican Conference on Soil Mechanics and Geotechnical Engineering, 39th US Rock Mechanics Symposium, Cambridge, 22-26 June, pp 887–891

Feng X, Jimenez R (2015) Estimation of deformation modulus of rock masses based on Bayesian model selection and Bayesian updating approach. Eng Geol 199:19–27. https://doi.org/10.1016/j.enggeo.2015.10.002

Grenon M, Hadjigeorgiou J (2003) Evaluating discontinuity network characterization tools through mining case studies. Soil Rock America 2003, Boston, 1, 137–142

Guangxi University, Huaxi Group (2013) Classification for the jointed rock masses and optimization of the mining technology in Tongkeng mine (a concluding report)

Harrison JP (1999) Selection of the threshold value in RQD assessments. Int J Rock Mech Min Sci 36:673–685

Hoek E, Diederichs MS (2013) Quantification of the geological strength index chart. Presented at the 47th US Rock Mechanics/Geomechanics Symposium, ARMA 13-672, San Francisco CA, June 23-26, 2013

ISRM (1978) Suggested methods for the quantitative description of discontinuities in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15:319–368. https://doi.org/10.1016/0148-9062(79)91476-1

Itasca (2013) 3DEC: three-dimensional distinct element code. Ver. 5.0. Itasca Consulting Group Inc, Minneapolis

Kim BH, Cai M, Kaiser PK, Yang HS (2007) Estimation of block sizes for rock masses with non-persistent joints. Rock Mech Rock Eng 40:169–192. https://doi.org/10.1007/s00603-006-0093-8

Koutsoftas DC (2017) Discussion of “rock quality designation (RQD): time to rest in peace”. Can Geotech J 55:584–592. https://doi.org/10.1139/cgj-2017-0497

Li Y, Wang Q, Chen J et al (2014) Determination of structural domain boundaries in jointed rock masses: an example from the Songta dam site, China. J Struct Geol 69:179–188

Lin F (2008) Evaluation of in-situ measurement methods for counting volumetric joints of rock mass. J Eng Geol 16:663–666 (in Chinese with English abstract)

Liu Q, Liu J, Pan Y et al (2017) A case study of TBM performance prediction using a Chinese rock mass classification system – hydropower classification (HC) method. Tunn Undergr Sp Technol 65:140–154. https://doi.org/10.1016/j.tust.2017.03.002

Martin MW, Tannant DD (2004) A technique for identifying structural domain boundaries at the EKATI diamond mine. Eng Geol 74:247–264. https://doi.org/10.1016/j.enggeo.2004.04.001

Miller SM (1983) A statistical method to evaluate homogeneity of structural populations. Math Geol 15:317–328

Palmstrom A (1982) The volumetric joint count: a useful and simple measure of the degree of rock mass jointing. Proc 4th Congr Int Assoc, Engng Geol, vol 2, pp 221–228

Palmstrom A (1996) Characterizing rock masses by the RMi for use in practical rock engineering: part 1: the development of the rock mass index (RMi). Tunn Undergr Sp Technol 11:175–188. https://doi.org/10.1016/0886-7798(96)00015-6

Palmstrom A (2005) Measurements of and correlations between block size and rock quality designation (RQD). Tunn Undergr Sp Technol 20:362–377. https://doi.org/10.1016/j.tust.2005.01.005

Pan H (2012) Research on grouting uplifting mechanism of plinth of concrete facing dam. Xihua University, Chengdu

Pells PJ, Bieniawski ZT, Hencher SR, Pells SE (2017) Rock quality designation (RQD): time to rest in peace. Can Geotech J 54:825–834. https://doi.org/10.1139/cgj-2016-0012

PRC Ministry of Construction (1995) Standard for engineering classification of rock masses. China planning press, China (in Chinese)

Priest SD, Hudson JA (1976) Discontinuity spacings in rock. Int J Rock Mech Min Sci 13:135–148. https://doi.org/10.1016/0148-9062(76)90818-4

Riquelme AJ, Abellán A, Tomás R (2015) Discontinuity spacing analysis in rock masses using 3D point clouds. Eng Geol 195:185–195. https://doi.org/10.1016/j.enggeo.2015.06.009

Riquelme AJ, Tomás R, Abellán A (2016) Characterization of rock slopes through slope mass rating using 3D point clouds. Int J Rock Mech Min Sci 84:165–176. https://doi.org/10.1016/j.ijrmms.2015.12.008

Shang J, West LJ, Hencher SR, Zhao Z (2018) Geological discontinuity persistence: implications and quantification. Eng Geol 241:41–54. https://doi.org/10.1016/j.enggeo.2018.05.010

Terzaghi RD (1965) Sources of error in joint surveys. Géotechnique 15:287–304. https://doi.org/10.1680/geot.1965.15.3.287

Wang X (2011) Analysis and simulation of fractured character in layer rockmass based on probabilistic: a case study of the dam of Jinping I hydropower station. China University of Geoscience, Wuhan

Wang C, Hu P, Sun W (2010) Method for evaluating rock mass integrity based on borehole camera technology. Rock Soil Mech 31:1326–1330. (in Chinese with English abstract). https://doi.org/10.16285/j.rsm.2010.04.008

Warren SN, Kallu RR, Barnard CK (2016) Correlation of the rock mass rating (RMR) system with the unified soil classification system (USCS): introduction of the weak rock mass rating system (W-RMR). Rock Mech Rock Eng 49:4507–4518. https://doi.org/10.1007/s00603-016-1090-1

Wong LNY, Lai VSK, Tam TPY (2018) Joint spacing distribution of granites in Hong Kong. Eng Geol 245:120–129. https://doi.org/10.1016/j.enggeo.2018.08.009

Xia L, Li M, Chen Y et al (2015) Blockiness level of rock mass around underground powerhouse of three gorges project. Tunn Undergr Sp Technol 48:67–76. https://doi.org/10.1016/j.tust.2015.02.002

Xia L, Zheng Y, Yu Q (2016) Estimation of the REV size for blockiness of fractured rock masses. Comput Geotech 76:83–92. https://doi.org/10.1016/j.compgeo.2016.02.016

Yarahmadi R, Bagherpour R, Taherian SG, Sousa LMO (2018) Discontinuity modelling and rock block geometry identification to optimize production in dimension stone quarries. Eng Geol 232:22–33. https://doi.org/10.1016/j.enggeo.2017.11.006

Zhang L (2016) Determination and applications of rock quality designation (RQD). J Rock Mech Geotech Eng 8:389–397. https://doi.org/10.1016/j.jrmge.2015.11.008

Zhang Q, Bian Z, Yu M (2009) Preliminary research on rockmass integrity using spatial block identification technique. Yanshilixue Yu Gongcheng Xuebao/Chinese J Rock Mech Eng 28(3):507–515 (in Chinese with English abstract)

Zhang W, Wang Q, Chen J et al (2012) Determination of the optimal threshold and length measurements for RQD calculations. Int J Rock Mech Min Sci 51:1–12

Zhang W, Chen J, Cao Z, Wang R (2013) Size effect of RQD and generalized representative volume elements: a case study on an underground excavation in Baihetan dam, Southwest China. Tunn Undergr Sp Technol 35:89–98. https://doi.org/10.1016/j.tust.2012.12.007

Zheng J, Deng J, Yang X et al (2014) An improved Monte Carlo simulation method for discontinuity orientations based on fisher distribution and its program implementation. Comput Geotech 61:266–276

Zheng J, Yang X, Lü Q et al (2018) A new perspective for the directivity of rock quality designation (RQD) and an anisotropy index of jointing degree for rock masses. Eng Geol 240:81–94. https://doi.org/10.1016/j.enggeo.2018.04.013

Acknowledgements

This work was funded by the National Key R&D Program of China (no. 2018YFC0808402).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, Q., Yin, T. Modification of the rock mass rating system (RMRmbi) considering three-dimensional rock block size. Bull Eng Geol Environ 79, 789–810 (2020). https://doi.org/10.1007/s10064-019-01596-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-019-01596-x