Abstract

A significant problem of biofuels is their low oxidative stability, which could be improved by addition of synthetic antioxidants. Therefore, the monitoring of antioxidant content plays a crucial role in using of biofuels. In this work, the new method of voltammetric determination of synthetic antioxidant propyl gallate (propyl 3,4,5-trihydroxybenzoate) in biofuels using linear sweep voltammetry with a gold disc electrode as the working electrode was developed. In comparison with other published papers dealing with the determination of propyl gallate in food samples, voltammetric analysis of antioxidant under study in biofuels requires a completely different approach of determination due to the composition of these samples. The proposed method enables the determination of antioxidant in model samples with excellent results. Its applicability was verified by analysis of practical biofuel samples. Limit of detection 0.39 µg cm−3 and limit of quantification 1.31 µg cm−3 were obtained. The proposed method can be used to control of the quality of biofuels.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The drive to reduce dependency on fossil fuels has focused attention over recent years on the use of alternative fuels for transport. With rapid depletion of fossil fuel resources and rising levels of greenhouse gases, it has become imperative that these are replaced by alternative fuels. These fuels are less hazardous to the environment and also have the same efficiency as that of the conventional fuels. There are several alternatives, like biodiesel, ethanol or biogas, that can be used as transportation fuels in the place of conventional fuels being used today [1, 2].

Biodiesels, the fatty acid methyl ester (FAME) or fatty acid ethyl ester, are created through cracking of oils or greases and then converting with methanol or ethanol. The quality of biodiesel deviates markedly from that of petroleum diesel, since biodiesel consists of a narrow spectrum of products which are polar and chemically reactive. From an engine viewpoint, it is more favorable to use biodiesel in a blend with petroleum diesel, which improves oxidation stability. In this work, one of the used real samples was Ekodiesel®, which is a trade name for high-quality “environmental friendly” alternative fuel for compression ignition engines produced by mixing of standard diesel fuel in accordance with EN 590 and fatty acid methyl esters (rapeseed oil methyl ester) in accordance with EN 14214, where the content of rapeseed oil methyl ester amounts to at least 31% [3–5].

The instability of biodiesel compared to petroleum diesel leads to many questions and concerns about storing fuel that may contain even low concentrations of biodiesel. Several approaches exist to either prevent undesirable oxidation as far as possible or decelerate its rate. One of them is obviously to prevent contact of the fatty material with air and pro-oxidants or to avoid elevated temperatures or the presence of light. Oxidation cannot be entirely prevented but can be significantly slowed down by employing of antioxidants, which are chemicals that inhibit the oxidation process. In literature, authors published some articles [6–8] focusing on the oxidation stability and the effect of antioxidants in biodiesel produced from various oils (e.g. Calophyllum inophyllum seed oil or Karanja oil).

Antioxidants added to biodiesel or Ekodiesel® may occur naturally, like α-tocopherol, or may be synthesized as the commonly used tert-butylated hydroxytoluene (BHT), tert-butylhydroquinone (TBHQ), pyrogallol (PY), and propyl gallate (PG) [9, 10]. In order to monitor and control the content of antioxidants, there is an increasing demand for reliable, sufficiently sensitive, and accessible analytical methods with the respective procedures. Also electrochemical methods with typically inexpensive instrumentation are potentially applicable to the determination of various antioxidants in petroleum products [11–13], offering a very good analytical performance in relatively simple procedures.

This paper deals with voltammetric determination of PG, which is an antioxidant used mainly in biodiesel or commercial food. Due to the fact, that PG is an electrochemically active compound, some papers dealing with its voltammetric determination in different samples have been already introduced. Authors in paper [14] used for electrochemical measurements differential pulse voltammetry (DPV) and a carbon paste electrode (CPE) in supporting electrolyte containing 20% methanol (v/v) and Briton–Robinson buffer (pH 5). The applicability of the method was tested on the determination of PG in edible oil after extraction to methanol. A low limit of detection (LOD) of 2.4 × 10−7 mol dm−3 was obtained. In the paper [15], the authors investigated oxidative properties of PG antioxidant in surfactant solutions and microemulsions using cyclic voltammetry (CV) and glassy carbon electrode (GCE). Another study [16], in which the authors described a cylindrical carbon fiber microelectrodes modified with poly(3-methylthiophene) and voltammetric behavior of PG in aquatic solutions, proved low LOD (4.0 × 10−7 mol dm−3) using DPV.

Other papers deal with electrochemical determination of PG in mixture with different antioxidants using a number of processes to differentiate these mixtures. Authors in [17] developed the new approach for analysis of TBHQ, BHA, and PG using chemometrics. The mixture of antioxidants was analyzed in the samples of sea-buckthorn and linseed oils using CV and GCE. Also in the paper [18], authors investigated the voltammetric behavior of four antioxidants (BHA, BHT, TBHQ, and PG) using linear sweep voltammetry (LSV) at a GCE with the aid of chemometric approaches. The proposed method applied for analysis of the antioxidants in commercial food samples employed 0.1 mol dm−3 perchloric acid and 1% methanol as a supporting electrolyte. Robledo et al. [19] proposed method for analysis of different synthetic antioxidant mixtures in edible oils using square wave voltammetry (SWV) and Pt band ultramicroelectrode. The methodology was based on the different acid–base properties of antioxidants in acetonitrile solutions + 0.1 mol dm−3 (C4H9)4NPF6 with those recorded in the same reaction medium when different aliquots of (C4H9)4NOH were added to allow a qualitative differentiation between antioxidants. Another method was described by Ceballos et al. [20], reporting the determination of BHT, BHA, and PG in samples of vegetable oils or lard. Authors applied LSV and CV in combination with a carbon fiber disc working electrode.

In the present paper, the gold disc electrode was used for examination of voltammetric behavior of PG and analysis of practical samples. This electrode material provides a simple and interesting alternative to the above-mentioned electrodes. Moreover, successful use of this electrode was possible without any mechanical cleaning and the obtained signal was stable and scanning could be repeated as required in the case of serial analyses for a long time. Voltammetric analysis of propyl gallate in biofuels requires a completely different approach of determination due to the composition of these samples.

Results and discussion

In our recently published articles [11–13], which are interested in analysis of the most commonly used synthetic antioxidants, was found that an acidic medium is the most suitable for their voltammetric determination. For this reason, the solution of H2SO4 was used also in the present paper.

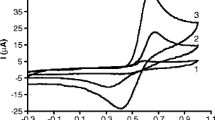

The influence of H2SO4 concentration on voltammetric signals of PG was studied in more detail. The concentration of H2SO4 was varied from 0.06 to 0.36 mol dm−3. Peak potentials, corresponding to the anodic oxidation of PG with concentration 29.49 µg cm−3, increase with decreasing pH of supporting electrolyte. They are shifted from 0.70 V for H2SO4 concentration 0.06 mol dm−3 to 0.74 V for H2SO4 concentration 0.36 mol dm−3. The registered voltammetric signals (I p —peak current) of PG are illustrated in Fig. 1.

Due to the highest registered voltammetric signals of PG (Fig. 1), the concentration range 0.12–0.18 mol dm−3 can be used for the determination of antioxidant under study. For this purpose, we chose the H2SO4 with concentration 0.18 mol dm−3 as the supporting electrolyte for the following experiments.

For most of analytical methods, the followed response should be directly proportional to the concentrations of the analyte in wide range of concentration. In this case, the evaluation is easier and faster. Figure 2 illustrates voltammograms obtained after addition of various amounts of PG recorded on the gold disc electrode in 0.18 mol dm−3 H2SO4 (water solution).

Anodic linear sweep voltammograms of PG in 0.18 mol dm−3 H2SO4 after subtraction of the baseline. Experimental conditions: LSV method; E in +0.4 V, E fin +1.2 V; v = 40 mV s−1; c PG curve 1 21.03 μg cm−3; curve 2 41.89 μg cm−3; curve 3 62.60 μg cm−3; curve 4 83.12 μg cm−3; curve 5 103.33 μg cm−3; curve 6 123.39 μg cm−3; curve 7 143.18 μg cm−3; curve 8 162.72 μg cm−3

The concentration of PG was chosen in range from 21.03 to 162.72 μg cm−3. As can be seen from this figure, the PG provides two oxidation peaks at E p 0.88 and 1.05 V, respectively, which coincides with results in the paper of Gunckel et al. [21]. When the height of the second peak was used for evaluation, the linear dependence could be described by following equation: I p = −(0.02 ± 1.91 × 10−2) + (0.08 ± 7.39 × 10−4)c PG , where I p is in μA and c PG is in μg cm−3. According to statistical evaluation, LOD 0.69 μg cm−3 and LOQ 2.31 μg cm−3 were obtained.

Then, the possibility of increasing sensitivity of the method by addition of some organic solvent was examined. For this purpose, ethanol (EtOH) was chosen as the appropriate solvent. It was found that with increasing amount of EtOH the peak height decreases and obtained LOD varied in the range 0.39–1.42 μg cm−3 (Table 1). It can be seen from Table 1, it is obvious that the best results were obtained in the supporting electrolyte containing 10% EtOH. Thus, this electrolyte was used in all further measurements.

The accuracy and reliability of the analysis of PG under proposed experimental conditions were tested using model solution with c PG 1.97 μg cm−3. The determination was repeated six times and the average concentration of 2.01 μg cm−3 was found. This value was within the 95% interval of reliability (lower limit, 1.88 μg cm−3; upper limit, 2.14 μg cm−3) and differed by +2% from the spiked value. The standard deviation was 0.124 μg cm−3, which proved excellent results.

Determination of PG in model samples of Ekodiesel®

The analysis of model samples of Ekodiesel® containing 0.24 and 0.047% PG, respectively, could be performed directly without necessary treatment, despite the fact that the matrix of Ekodiesel® is insoluble in water but the analyte is water soluble. The volume 20 mm3 of Ekodiesel® was dosed in case of model sample with higher concentration. Then, the mixture was intensively stirred for 1 min followed by the anodic oxidation. The content of PG was determined by standard addition method and at least two standard additions of known concentration were added into the mixture. By repeated analyses of five model samples with identical concentration of 0.24% PG, the average value of 0.242% was found within an interval 0.22–0.26%, thus yielding a recovery of 95.8–108.3%, which could be regarded as a satisfactory result. The standard deviation was 0.016%.

The volume of 100 mm3 was dosed in the analysis of model sample with concentration of 0.047% PG as described above. In this case, the average value 0.045 % coincides with spiked value and differs by only −3.4%. The standard deviation was 0.002%. 95% interval of reliability was obtained with followed values: lower limit 0.043% and upper limit 0.047%. No matrix effect of Ekodiesel® was observed on the obtained voltammetric curves of PG.

Determination of PG in model samples of biodiesel

It was found that due to many analyses of this matrix, the direct determination of PG was not possible. The active surface of a gold disc electrode was coated with the hydrophobic matrix of biodiesel. For this reason, the sample was pretreated. The samples of biodiesel were extracted with distilled water, and then 1 cm3 of the water layer was analyzed. Linear sweep voltammograms performed in the medium of the extract and after the baseline (curve of supporting electrolyte) subtraction are illustrated in Fig. 3. This approach served for better quantitative evaluation of the proposed method. The standard addition method was also used for the determination. Five replicated determinations gave an average value of 0.134% (95% interval of reliability with lower limit 0.12% and upper limit 0.15%) with standard deviation 0.011% and differed by −4.3% from the spiked value (0.14%).

Anodic linear sweep voltammograms of PG in biodiesel after subtraction of baseline. Experimental conditions: LSV method; supporting electrolyte: 0.18 mol dm−3 H2SO4 + 10% EtOH; E in +0.6 V, E fin +1.4 V; v = 40 mV s−1; curve 1 0.14% PG in biodiesel; curves 2, 3 standard additions of PG (V PG = 20 mm3, c PG = 8.12 μg dm−3)

Conclusion

In this paper, new, sensitive, and rapid voltammetric method for determination of the widely used antioxidant propyl gallate was developed. Monitoring of this antioxidant can be employed to estimate oxidative stability of biofuels. It can be useful to monitor biofuels stability during storage. Preventing the oxidative degradation of biofuels is a major concern to producers, sellers, and consumers of biodiesel in neat form and in mixtures with diesel as well. For purposes of monitoring the effects on fuel quality caused by oxidative degradation, the proposed LSV method in combination with gold working electrode offers reproducible response. Analysis of PG in biofuels can be performed directly without necessity of pretreatment sample, when Ekodiesel® is analyzed, and after extraction using distilled water in case of biodiesel. In spite of this separation step, the determination is very rapid and simple. The proposed method should be applicable in laboratories that deal with quality of fuels.

Experimental

Chemical and reagents

Stock solution of PG (4 g dm−3) was prepared by dissolving of the appropriate amount of PG powder (p.a., Sigma Aldrich) in ethanol (EtOH, Penta, CZ). This solution was stored in a refrigerator at 4 °C. Analyzed solutions were prepared by dilution of this stock solution. 0.18 mol dm−3 H2SO4 prepared by dilution of 96 % H2SO4 (Penta, CZ) was used as a supporting electrolyte. In some measurements, this supporting electrolyte contained 10 and 20% (v/v), respectively, of ethanol (EtOH, Penta, CZ).

Different samples were analyzed: model sample of Ekodiesel® containing 0.24 or 0.047% (w/w) PG was prepared by weighing of appropriate amount of PG and by dissolving in 25 cm3 of Ekodiesel®. The solution was homogenized using ultrasound. The model sample of biodiesel (rapeseed oil methyl ester, FAME) containing 0.23% (w/w) PG was prepared by weighing 0.05 g PG and dissolving in 25 cm3 of biodiesel. The model sample with concentration 0.14% was prepared by diluting of this mixture.

Apparatus and accessories

Voltammetric measurements were performed using an electrochemical analyzer (model “EP 100VA”, HSC Servis Bratislava, SK) in three-electrode setup which was composed of the gold disc (AuDE, diameter 2 mm, HSC Servis Bratislava, SK) as the working electrode, Ag|AgCl|3 mol dm−3 KCl as the reference, and the Pt plate (3 × 5 mm) as the counter electrode (both from Monokrystaly, Turnov, CZ).

Procedure

The anodic oxidation of antioxidant PG was carried out using the LSV method, with instrumental setting: current range ±40 μA, initial potential (E in ) +0.4 V, final potential (E fin ) +1.3 V, and scan rate (v) 40 mV s−1. 10 cm3 of the supporting electrolyte (0.18 mol dm−3 H2SO4) was used for all measurements. Analyte concentrations were found using the standard addition method. The concentration was evaluated based on the wave height.

References

Salvi BL, Subramanian KA, Panwar NL (2013) Renew Sustain Energy Rev 25:404

Moka S, Pande M, Rani M, Gakhar R, Sharma M, Rani J, Bhaskarwar AN (2014) Renew Sustain Energy Rev 32:697

Allgeier T, Ullman J (2014) Fuels, Alternative fuels. In: Reif K (ed) Diesel engine management: Systems and components. Springer Vieweg, Germany, p 34

Preol (2010) Product sheet. Products of Preol, a. s. Company. DIALOG. http://www.preol.cz/products/fuel/ekodiesel/. Accessed 1 Jan 2010

Sarin A (2012) Biodiesel (production and properties). The Royal Society of Chemistry, UK

Fattah IMR, Masjuki HH, Kalam MA, Masum BM (2014) Mater Res Innov 18:90

Rawat DS, Joshi G, Lamba BY, Tiwari AK, Mallick S (2014) Fuel 120:30

Yang ZY, Hollebone BP, Wang ZD, Yang C, Landriault M (2013) Fuel Process Technol 106:366

Karavalakis G, Hilari D, Givalou L, Karonis D, Stournas S (2011) Energy 36:369

Nivetha S, Roy DV (2013) J Energy Chem 22:935

Chýlková J, Tomášková M, Mikysek T, Šelešovská R, Jehlička J (2012) Electroanalysis 24:1374

Tomášková M, Chýlková J, Navrátil T, Šelešovská R (2014) Energy Fuels 28:4731

Tomášková M, Chýlková J, Mikysek T, Jehlicka V (2016) Monatsh Chem 147:231

Dejmková H, Vysoká M, Zavázalová J, Zima J, Barek J (2010) Electrochemical determination of propyl gallate on carbon paste electrode. In: Navrátil T, Fojta M, Schwarzová K (eds) XXXth modern electrochemical methods. Best Servis Ústí nad Labem, Jetřichovice, p 26

Szymula M, Narkiewicz-Michalek J (2006) J Appl Electrochem 36:455

Agui L, Lopez-Huertas MA, Yanez-Sedeno P, Pingarron JM (1996) J Electrochem 414:141

Ziyatdinova GK, Savaliev AA, Evtugyn GA, Budnikov HC (2014) Electrochim Acta 137:114

Ni Y, Wang L, Kokot S (2000) Anal Chim Acta 412:185

Robledo SN, Zon MA, Ceballos CD, Fernández H (2011) Food Chem 127:1361

Ceballos C, Fernández H (2000) Food Res Int 33:357

Gunckel S, Santander P, Cordano G, Ferreira J, Munoz S, Nunez-Vergara LJ, Squella JA (1998) Chem Biol Interact 114:45

Acknowledgements

Financial support was provided by The Ministry of Education, Youth and Sports of the Czech Republic (Project No. CZ.1.07/2.3.00/30.0021 “Strengthening of Research and Development Teams at the University of Pardubice”).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomášková, M., Chýlková, J., Šelešovská, R. et al. Voltammetric method for rapid determination of propyl gallate and its application for monitoring of biofuels quality. Monatsh Chem 148, 457–461 (2017). https://doi.org/10.1007/s00706-016-1860-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-016-1860-1