Abstract

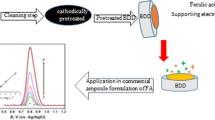

A sensitive voltammetric method for the determination of pyrogallol (PY) was developed employing a boron-doped diamond electrode (BDDE). The composition of the supporting electrolyte was investigated during the development of the methodology. Linear sweep voltammetry (LSV) under the optimized experimental conditions was applied for PY determination with a limit of detection and limit of quantification of 0.85 and 2.82 μmol L−1, respectively. These values are satisfactory for application to real samples. The usability of this method for the quantification of pyrogallol was in range from 2.82 to 296.00 μmol L−1. Finally, the developed method was successfully used for the analysis of real samples of biodiesel produced from rapeseed oil and its blend with diesel fuel. Samples of biodiesel and biodiesel blends were analyzed directly in an electrochemical cell, while samples with very low concentrations of PY in biodiesel were extracted with water using the proposed simple and fast process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global reserves of fossil fuels are limited, and the replacement of these fuels with renewable energy sources is currently an active area of investigation. Biodiesel is produced from raw materials, such as vegetable oils, cooking oils, and animal fats, and can be used to replace diesel fuel. In addition, biodiesel is also used in blends with diesel fuel, in accordance with EN 14214 (standard that describes the requirements and test methods for FAME—the most common type of biodiesel). The main drawback of biodiesel is oxidative degradation, which greatly impairs its properties. This susceptibility to oxidation is beneficial from an environmental perspective, as it renders the fuel biodegradable; however, this is a concern from a fuel quality standpoint, as quality can degrade during storage. Regarding biodiesel blends, it has been found that with an increasing biodiesel content, the stability of the finished blend decreases (Christensen and McCormick 2014; Demirbas 2008; Dwivedi and Sharma 2014; Sarin 2012).

To slow oxidative degradation and improve stability, it is necessary to find appropriate additives and to know the exact amount needed. The most used antioxidants to improve the oxidation stability of biodiesel and its blends with petroleum diesel are pyrogallol (PY), propyl gallate (PG), butylated hydroxytoluene (BHT), butylated hydroxyanisole (BHA), and tert-butyl hydroquinone (TBHQ) (Karavalakis and Stournas 2010; Schober and Mittelbach 2004; Tang et al. 2010). Pyrogallol, the common name for 1,2,3-trihydroxybenzene or 1,2,3-benzenetriol, has been found to be the most effective antioxidant to improve the oxidation stability of biofuels; however, using a large concentration of additives is uneconomical. Antioxidants are usually doped into biodiesel at concentrations of 200, 500, and 1000 ppm (m/m). It is necessary to control stabilization as well as changes during the storage of biofuels. For this purpose, it is important to have a fast, reliable, and cheap analytical method available which may be used in practice (Fattah et al. 2014; Fingueredo et al. 2015).

In the literature, numerous methods, including electrochemiluminescence (Zhang and Zheng 2006), spectrophotometry (Mudasir and Ngatidjo 2002), liquid chromatography (Elzaawely et al. 2005), and gas chromatography (Tor et al. 1996), have been applied for the determination of the antioxidant PY, but these analytical techniques are relatively expensive. Electroanalytical methods represent a cheaper alternative with the possibility of field analysis.

Concerning the voltammetric determination of PY in varied types of samples and using different electrodes, numerous papers have been published. Hung et al. (2014) introduced the determination of PY in real-water samples using conducting poly(3,4-ethylenedioxythiophene) film-modified screen-printed carbon electrodes. The analysis of PY in a similar type of sample has been proposed in other papers. Tashkhourian and Ghaderizadeh (2014) published a voltammetric method using a silica gel modified carbon paste electrode for the analysis of this antioxidant in tap water, green tea, and artificial urine samples. Another technique was developed by Feng et al. (2012), based on the amperometric determination of PY using flow-injection analysis. It is possible to use new electrode materials for the determination of PY, e.g., glassy carbon electrodes (GCE) modified with carbon nanotubes (CNT) (Ziyatdinova et al. 2012), polyaminoanthraquinone modified electrodes (Badawy et al. 2011), and copper-plated screen-printed electrodes (Zen et al. 2002). Boron-doped diamond electrodes have been used only in the paper by Nasr et al. (2009), where the authors studied the electrochemical oxidation of PY at this electrode for the treatment of acidic aqueous wastes containing pyrogallol.

The most published articles report the analysis of PY in water samples, but only one paper has focused on the voltammetric analysis of PY in biodiesels or their blends with petroleum products. These authors described the electroanalysis of PY in biodiesel produced from soybean oil in the presence of the surfactant cetyltrimethylammonium bromide (CTAB). The surfactant in the supporting electrolyte (0.04 mol L−1 in Briton–Robinson buffer) affected the oxidation peak current and increased the solubility of samples. The limit of detection (LOD) and limit of quantification (LOQ) were 4.9 × 10−7 and 1.5 × 10−6 mol L−1, respectively (Araujo et al. 2015).

This study aimed to develop a fast and simple method focusing on the analysis of PY both in biodiesel and its mixture with petroleum diesel (Ekodiesel®) using a boron-doped diamond electrode. The sample matrix of blends with biodiesel differs from biodiesel samples and, for this reason, it should be approached to analyses of this matrix using other method or processes than in the determination of the biodiesel matrix. In this work, we propose the optimal conditions for the voltammetric determination of PY using linear sweep voltammetry without the use of surfactants. Undoubtedly, a major benefit to these analyses lies in the choice of the working electrode, enabling us to perform the oxidative transformation of the analyte of interest at extremely high potentials of about +1.4 V and more, which is of value as the majority of common electrodes suffer from high background. Another advantage is its high stability under given experimental conditions. Due to the low susceptibility to passivation of electrode surface, boron-doped diamond films are ideal electrode material (Chailapakul et al. 2006). In addition, due to its high resistance to adsorption processes (presence of sp3 hybridized diamond carbon atoms), boron-doped diamond differs from other conventional carbon electrodes (Musilová et al. 2009; Yosypchuk et al. 2010). The BDDE provides sufficient sensitivity in the range of analyzed concentration of PY in biodiesel samples.

Experimental

Chemical and reagents

Chemicals used were of analytical reagent grade. A stock solution of PY (4 mg L−1) was prepared by dissolving an appropriate amount of PY (p.a.; PY, Lach-Ner, CZ, CAS: 87-66-1) in distilled water. This solution was stored in the dark at 4 °C. Standard solutions were prepared by diluting this stock solution.

Samples of PY were analyzed in different supporting electrolytes containing: 0.06-0.36 mol L−1 H2SO4 (Penta, CZ, CAS: 7664-93-9), 33% 1,3-propandiol (98%, Sigma-Aldrich, CZ, CAS: 504-63-2), and 6.6-98.7% isopropanol (i-PrOH, Penta, CZ, CAS: 603-117-00-0).

In this work, samples of biofuels, i.e., biodiesel and Ekodiesel®, were analyzed. The biodiesel used was a rapeseed oil methyl ester. Ekodiesel® is the trade name for blended fuel, a high-quality environmentally friendly alternative fuel for compression ignition engines produced by blending petroleum diesel fuel in accordance with EN 590 (standard that describes the physical properties that all automotive diesel fuel must meet if it is to be sold in the European Union and several other European countries) and rapeseed oil methyl ester in accordance with EN 14214 (standard that describes the requirements and test methods for FAME—the most common type of biodiesel), where the content of rapeseed oil methyl ester amounts to at least 31%. Spiked real samples containing 0.24% (w/w) PY were prepared by weighing an appropriate amount of PY and by dissolving it in 25 mL of biodiesel or Ekodiesel® without antioxidant additives. Sodium nitrate (NaNO3 p.a., Penta, CZ, CAS: 7631-99-4) was used for the demulsification of biodiesel in water.

Apparatus and accessories

Linear sweep voltammetry was carried out using an electrochemical analyzer (model “EP 100VA”, HSC Servis Bratislava, Slovak Republic) in a three-electrode cell. A boron-doped diamond electrode (BDDE, boron doping level 1,000 ppm, electrical resistivity of 0.075 Ω cm), purchased in an inert polytetrafluoroethylene (PTFE, Teflon) body with an inner diameter of 3 mm (Windsor Scientific Ltd., UK), was used as the working electrode, Ag|AgCl|saturated KCl as the reference electrode, and a Pt plate (3 × 5 mm) as the counter electrode (both from Monokrystaly, Turnov, CZ).

Procedure

The anodic oxidation of the antioxidant PY was carried out using the linear sweep voltammetric (LSV) method. LSV scanning was performed in the range from the initial potential (E in) of +0.3 V to a final potential (E fin) of +1.5 V, for which the scan rate (v) was 40 mV s−1 and the current range was ±40 μA. Linear sweep voltammograms from supporting electrolytes containing water solutions with 0.06–0.36 mol L−1 H2SO4 and various concentrations of PY were recorded. The total volume of the supporting electrolyte was 10 mL.

To ensure good solubility of the sample matrix, the determination of PY in a supporting electrolyte containing 1,3-propandiol or isopropanol was investigated.

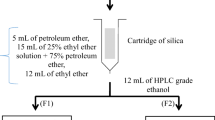

In this study, the antioxidant PY was determined in samples of Ekodiesel® and biodiesel. These samples were analyzed mostly without any treatment. Only in the case of very low concentration of antioxidant in biodiesel, it had to be isolated by extraction using water. For extraction, 12 mL of distilled water and 1 mL of biodiesel were pipetted into the extraction tube. The extraction time was 3 min with intensive shaking. After this time, the tube was fastened in an easel. De-emulsification of the water–biodiesel mixture was performed using 1 g of NaNO3. The mixture was allowed to sediment for 15 min after shaking. Then, the lower aqueous layer was separated using glass wool filtration and transferred into a graduated cylinder; 10 mL of this extract was used for voltammetric analysis.

Results and discussion

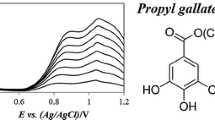

In previously published articles (Chýlková et al. 2012; Tomášková et al. 2014a, b, 2016), it was found that the best results were achieved by anodic oxidation of synthetic phenolic antioxidants in an acidic medium, which is the most suitable for voltammetric determinations of these antioxidants. For this reason, a solution of H2SO4 was used in the present work. First, the voltammetric behavior of PY in a water solution with increasing of amounts of H2SO4 was investigated using LSV at a BDDE. The concentration of H2SO4 in the supporting electrolyte was varied in the range from 0.06 to 0.36 mol L−1. A series of oxidation peaks was recorded in the concentration range of PY from 42.26 to 296.00 μmol L−1. In Fig. 1, typical anodic linear sweep voltammograms are shown, depicting the oxidation signals of PY in the supporting electrolyte with 0.18 mol L−1 H2SO4.

It was found that increasing the concentration of H2SO4 had nearly no effect on E p (peak potential) or the sensitivity of PY determination. This was also confirmed by the results of the statistical evaluation (Jehlička 2015). The limits of detection and quantification, regression equations, and E p are presented in Table 1.

From Table 1, it is evident that E p was not significantly changed, whereas the dependence of the current values on the PY concentration was linear, so these conditions may be used for the quantitative determination of PY. In this work, the supporting electrolyte containing 0.18 mol L−1 H2SO4 was chosen for subsequent experiments, because they were obtained the lowest values of LOD and LOQ for this concentration. The accuracy and precision of the voltammetric determination of PY in the selected supporting electrolyte were tested by means of recovery measurements, where the concentration was quantified via the standard addition method. Determinations of four concentration levels of PY were repeated five times and the obtained results (see Table 2) confirmed the good reproducibility of the determinations using the BDDE.

Due to the character of real samples, it was necessary to use a certain percentage of organic solvents, i.e., 1,3-propandiol and isopropanol, in our case. This study was carried out to ensure matrix dissolution, because the suitable content of organic solvent in the electrolyte allows the direct determination of PY in samples without necessary pretreatment. Therefore, several series of supporting electrolytes with different 1,3-propandiol or isopropanol amounts were assayed. The initial experiments were examined only with the antioxidant in the absence of the sample matrix. On the basis of this series of experiments, it was found that the presence of 1,3-propandiol (for example 40%) into the supporting electrolyte caused a considerable decrease in the PY oxidation signal. Furthermore, it was observed that it was necessary to homogenize the analyzed solution to obtain a reproducible response. An increase in stirring time led to an increase in peak height (I p). This increase was registered until 25 s. After this time, the response was sufficiently reproducible. As depicted in Fig. 2, the peak height was linearly proportional to the concentration in the concentration range from 42.26 to 253.57 μmol L−1 using a supporting electrolyte containing 33.3% 1,3-propandiol.

From Fig. 2, it can be seen that the mentioned peaks were recorded at the half-wave potential E 1/2 1.07 V. No trends in the potential shift could be registered in the tested range of concentrations. In this case, the peaks were clearly distinguishable. From the statistical analysis, the corresponding dependence was as follows: I p = (0.007)c PY + 0.079 (where I p is in μA and c PY is in μmol L−1). The limit of quantification was 8.8 μmol L−1 using the specified conditions.

Furthermore, the effect of the amount of isopropanol on the PY peaks in the supporting electrolyte containing sulfuric acid was examined. The amount of isopropanol was tested in the range from 6.6 to 98.7% in the supporting electrolyte (10 mL). The concentration range of PY was from 105.69 to 846.02 μmol L−1. The results of the calibration measurements and their statistical evaluation from experimentation with i-PrOH-containing solutions are shown in Table 3.

It was found that an increase of i-PrOH in the supporting electrolyte caused a decrease of the PY oxidation signal and E 1/2 shifts to more positive values, i.e., from 1.10 V (for 6.6% i−PrOH) to 1.24 V (for 98.7% i−PrOH). The linear dependences were confirmed using statistical evaluations (see Table 3). In addition, it was demonstrated that an increase of the amount of i−PrOH decreased the sensitivity of determination. The limits of quantification were in the range from 17.92 to 26.17 μmol L−1, and became worse with an increasing amount of i−PrOH. The same behavior was observed for the limit of detection.

Comparison of the sensitivity of PY determination using LSV, SWV, and DPV

For simpler and faster voltammetric analysis of an antioxidant, it is best to ensure a linear relationship between the peak current and the concentration of the determined species. In this part of the study, antioxidant determination was performed using differential pulse voltammetry (DPV) and square-wave voltammetry (SWV), and these results were compared with the method of linear sweep voltammetry (LSV). The supporting electrolyte was an aqueous solution of H2SO4 (0.18 mol L−1) for this voltammetric determination. The concentration of PY varied in the range from 62.08 to 429.43 μmol L−1. The results of the statistical evaluation are summarized in Table 4 together with the results previously obtained using the LSV method.

From Table 4, it can be seen that the sensitivities of DPV and SWV were comparable, but the electroanalytical procedure developed using LSV yielded the best value of the correlation coefficient and sensitivity. For this reason, the LSV method was chosen for subsequent analyses.

Determination of PY in Ekodiesel® samples

For the analysis of Ekodiesel® samples, the selection of the supporting electrolyte depended on the fact that PY is very good soluble in water as opposed to hydrophobic Ekodiesel®. For this reason, the determination of PY was carried out directly in a water solution (according to the proposed supporting electrolyte). Furthermore, analyses of PY were examined in the supporting electrolyte with the addition of isopropanol. The concentrations of isopropanol were 6.7, 32.9, and 98.7%. Figure 3 illustrates typical linear sweep voltammograms obtained by analyzing PY in a model sample of Ekodiesel® with the BDDE and in supporting electrolytes with different amounts of isopropanol. Although it was a heterogeneous mixture, the analyte was transferred into the solution by mixing; the mixture was then stirred for 3–6 min. The analysis was carried out after this period. Regarding the concentration of the antioxidant, it was varied in the range from 105.69 to 422.85 μmol L−1 PY. The content of Ekodiesel® was in the concentration range of 1.7–6.8 mg Ekodiesel®/mL in the analyzed solution. In Fig. 3, it can be seen that increasing the amount of isopropanol caused a shift in the peak potential (E p) to positive potentials. In the case of the determination of PY in the investigated electrolyte containing 98.7% i-PrOH, it was evident that the evaluation could be not performed, as documented in Fig. 3D. The water solution containing 0.18 mol L−1 H2SO4 was chosen for subsequent analyses.

Anodic linear sweep voltammograms of PY in a model sample of Ekodiesel® in supporting electrolytes containing different amount of organic solvent. Exp. con.: method-LSV; electrolyte-0. 18 mol L−1 H2SO4 (a) containing i-PrOH with concentration 6.7% (b), 32.9% (c), and 98.7% (d); E in = +0.3 V; E fin = +1.4 V; v = 40 mV s−1; c PY: from 105.69 to 422.85 μmol L−1, concentration of Ekodiesel®: 1.7–6.8 mg mL−1

The recovery of PY in Ekodiesel® samples was tested by repeatedly analyzing a solution with the antioxidant amount in the range from 0.24 to 0.005%. These amounts levels correspond to real situation, when the initial concentration of PY in sample is about 0.24% and it decreases with time. The obtained results are shown in Table 5.

The volumes of the model samples were dosed in the supporting electrolyte according to the expected concentration range from 0.05 to 1 mL. The recorded peaks were well defined and they were not affected by matrix components. In Table 5, it can be seen that the recovery ranged from 95.8 to 104.2%. The found concentrations of PY were in good agreement with the declared values.

Determination of PY in biodiesel samples

Based on these experiments, it can be stated that the direct determination of PY in biodiesel was associated with the formation of drops in the voltammetric cell. These drops coated the electrode surface with a thin film. From this reason, the measurements were irreproducible. This effect was eliminated using very low volumes of the sample (0.1 and 0.2 mL) and very fast mixing of the solution.

In the case of low concentrations of PY, it was necessary to use a higher amount of the sample, and direct analysis was not possible. For this reason, an extraction process was used to analyze low concentrations of PY (see Experimental part). Water was used for the extraction of PY from biodiesel; 10 mL of this extract was used in the voltammetric cell for analysis. The results of repeated determinations are presented in Table 6.

The error of direct PY determination varied in the range from −3.5% to −4.0 and the error of PY determination using extraction was in the range from −0.2 to +2.7%.

Conclusions

In this study, a simple and fast voltammetric method for the analysis of pyrogallol was proposed and tested on real samples of biodiesel and biodiesel blends with diesel fuel with known concentrations. The boron-doped diamond electrode was successfully applied for the determination of samples containing the studied synthetic antioxidant.

A major benefit to this method lies in the choice of the working electrode, enabling us to perform the oxidative transformation of the analyte of interest at extremely high potentials about +1.4 V and more, which is of value as a majority of common electrodes suffer from high background. Furthermore, a suitable supporting electrolyte was proposed (0.18 mol L−1 H2SO4), which allowed (together with suitable voltammetric procedure) for the direct analysis of PY in most samples. In the next part, an extraction process was developed. Extraction with water was necessary in the case of very low concentrations of PY in biodiesel samples. The higher volume of this matrix was connected with the formation of drops, which led to coating of the electrode surface with a thin film. With this extraction procedure, it was possible to determine very low levels of PY in real samples. The achieved sensitivity is sufficient for analyses of real samples of petroleum products.

In conclusion, the proposed method allows for the determination of the concentration of PY in a difficult matrix, such as biodiesel or its blends, with diesel fuel. Moreover, the method may be used for routine analyses in refinery laboratories and field analyses.

References

Araujo ASA, Caramit RP, Oliveira LCS, Ferreira VS (2015) Electroanalytical method for determining pyrogallol in biodiesel in the presence of a surfactant. Electroanalysis 27:1152–1158. doi:10.1002/elan.201400647

Badawy WA, Ismail KM, Medany SS (2011) Polyaminoanthraquinone modified electrodes as electroanalytical sensors. Int J Electrochem Sci 6:4204–4217. ISSN:1452-3981

Chailapakul O, Siangproh W, Tryk DA (2006) Boron-doped diamond-based sensors: a review. Sens Lett 4:99–119. doi:10.1166/sl.2006.008

Christensen E, McCormick RL (2014) Long-term storage of biodiesel and biodiesel blends. Fuel Process Technol 128:339–348. doi:10.1016/j.fuproc.2014.07.045

Chýlková J, Tomášková M, Mikysek T, Šelešovská R, Jehlička J (2012) Voltammetric determination of BHT antioxidant at gold electrode in biodiesel. Electroanalysis 24:1374–1379. doi:10.1002/elan.201200057

Demirbas A (2008) Biodiesel—a realistic fuel alternative for diesel engine. Springer Verlag, London

Dwivedi G, Sharma MP (2014) Impact of antioxidant and metals on biodiesel stability—a review. J Mater Environ Sci 5:1412–1425. ISSN:2028-2508

Elzaawely AA, Xuan TD, Tawata S (2005) Antioxidant and antibacterial activities of Rumex japonicus HOUTT. Aerial parts Biol Pharm Bull 28:2225–2230. doi:10.1248/bpb.28.2225

Fattah IMR, Masjuki HH, Kalam MA, Hazrat MA, Masum BM, Imtenan S, Ashraful AM (2014) Effect of antioxidants on oxidation stability of biodiesel derived from vegetable and animal based feedstocks. Renew Sustain Energy Rev 30:356–370. doi:10.1016/j.rser.2013.10.026

Feng PS, Wang SM, Su WY, Cheng SH (2012) Electrochemical oxidation and sensitive determination of pyrogallol at preanodized screen-printed carbon electrodes. J Chin Chem Soc 59:231–238. doi:10.1002/jccs.201100384

Fingueredo ES, Vieira EC, D´Elia E (2015) Comparing a novel voltammetric method with a standardized method for quality control of biodiesel. J Ind Eng Chem 23:353–361. doi:10.1016/j.jiec.2014.09.003

Hung CH, Chang WT, Su WY, Cheng SH (2014) Electrochemical determination of Pyrogallol at conducting poly(3,4-ethylenedioxythiophene) film-modified screen-printed carbon electrodes. Electroanalysis 26:2237–2243. doi:10.1002/elan.201400296

Jehlička V (2015) Software for calculating the limit of detection and limit of quantification when using linear regression in analytical chemistry. Media4u Magazine 12:41–45. ISSN:1214-9187

Karavalakis G, Stournas S (2010) Impact of antioxidant additives on the oxidation stability of diesel/biodiesel blends. Energy Fuels 24:3682–3686. doi:10.1021/ef1004623

Mudasir M, Ngatidjo H (2002) Spectrophotometric determination of pyrocathecol and pyrogallol based on their redox reaction with iron(III)/phenanthroline system. Indo J Chem 2:161–163. doi:10.14499/ijc-v2i3p161-166

Musilová O, Barek J, Pecková K (2009) The use of boron-doped diamond film electrodes for detection of organic compounds. Chem Listy 103:469–478. ISSN 1213-7103

Nasr B, Hsen T, Abdellatif G (2009) Electrochemical treatment of aqueous wastes containing pyrogallol by BDD-anodic oxidation. J Environ Manage 90:523–530. doi:10.1016/j.jenvman.2007.12.007

Sarin A (2012) Biodiesel: production and properties. RCS Publishing, Cambridge

Schober S, Mittelbach M (2004) The impact of antioxidants on biodiesel oxidation stability. Eur J Lipid Sci Technol 106:382–389. doi:10.1002/ejlt.200400954

Tang H, Ge Guzman RC, Simon Ng KY, Salley SO (2010) Effect of antioxidants on the storage stability of soybean-oil-based biodiesel. Energy Fuels 24:2028–2033. doi:10.1021/ef9012032

Tashkhourian J, Ghaderizadeh SM (2014) SiO2-modified carbon paste electrode for electrochemical determination of pyrogallol. Russ J Electrochem 50:959–966. doi:10.1134/S1023193514100139

Tomášková M, Chýlková J, Jehlička V, Navrátil T, Švancara I, Šelešovská R (2014a) Simultaneous determination of BHT and BHA in mineral and synthetic oil using linear scan voltammetry with a gold disc electrode. Fuel 123:107–112. doi:10.1016/j.fuel.2014.01.052

Tomášková M, Chýlková J, Navrátil T, Šelešovská R (2014b) Voltammetric determination of antioxidant TBHQ individually and mixed with BHT in petroleum products using gold disc electrode. Energy Fuels 28:4731–4736. doi:10.1021/ef500743t

Tomášková M, Chýlková J, Mikysek T, Jehlička V (2016) Voltammetric determination of antioxidant 4,4´-methylenebis(2,6-di-tert-butylphenol) in lubricating oils using gold disc electrode. Monatsh Chem 147:231–237. doi:10.1007/s00706-015-1562-0

Tor ER, Francis TM, Holstege DM, Galey FD (1996) GC/MS determination of pyrogallol and gallic acid in biological matrices as diagnostic indicators of Oak exposure. J Agric Food Chem 44:1275–1279. doi:10.1021/jf950238k

Yosypchuk O, Barek J, Pecková K (2010) Voltammetric determination of 1-nitropyrene and 1-aminopyrene at a boron-doped diamond film electrode. Chem Listy 104:186–190. ISSN 1213-7103

Zen JM, Chung HH, Kumar AS (2002) Selective detection of o-diphenols on copper-plated screen-printed electrodes. Anal Chem 74:1202–1206. doi:10.1021/ac0110121

Zhang L, Zheng X (2006) A novel electrogenerated chemiluminescence sensor for pyrogallol with core-shell luminolo-doped silica nanoparticles modified electrode by the self-assembled technique. Anal Chim Acta 570:207–213. doi:10.1016/j.aca.2006.04.018

Ziyatdinova G, Gainetdinova A, Morozov M, Budnikov H, Grazhulene S, Redkin A (2012) Voltammetric detection of synthetic water-soluble phenolic antioxidants using carbon nanotube based electrodes. J Solid State Electrochem 16:127–134. doi:10.1007/s10008-011-1295-x

Acknowledgements

Financial support was provided by project No. SGS_2016_002, Czech Republic.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chýlková, J., Tomášková, M., Janíková, L. et al. Sensitive voltammetric method for the fast analysis of the antioxidant pyrogallol using a boron-doped diamond electrode in biofuels. Chem. Pap. 71, 1047–1054 (2017). https://doi.org/10.1007/s11696-016-0025-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-016-0025-3