Abstract

In this study, a procedure for optimization of an LED lens module design based on 3 LED light sources was divided into two phases. For preliminary optimization of the dimensions of the LED lens module in Stage I, an optical analysis with orthogonal arrays and TracePro (an optical design package) combined with analysis of variance was conducted to investigate relationships between the multiple optical quality characteristics (viewing angle and average illuminance) and dimension parameters and find the initial optimal parameter combination of the LED lens module. In Stage II, the initial optimal parameter combination determined in Stage I was employed to develop an orthogonal array L25(56) for optical simulation. The experimental data of the orthogonal array were used to train and test the back-propagation neural network to develop an optical quality predictor, which was integrated into the genetic algorithms and the particle swarm optimization in order to find the optimal parameter combination that conformed to optical quality. From the experimental results, the proposed optimization procedure contributes to a precise viewing angle to achieve the goal of optical quality and improved the average illuminance in development of the product. The procedure to optimize the optical design developed in this study can be applied to design all types of LED lens modules and improve the optical design and technology of the LED lens industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

From the view of green technology becoming increasingly important in this era of global climate change and constant energy resource price rises, light-emitting diode (LED) lighting has gradually merged into our surroundings and is increasingly significant and extensively used to replace conventional light sources as a result of the advances in manufacturing technology and reduced costs in recent years. The procedure of optical design consists of (1) primary optics for which the LED emission angle, magnitude of the flux, distribution of the luminous intensity, and extent and distribution of color temperature are determined prior to an LED lens module becoming a lighting product; (2) secondary optics for which the optical performance of light is improved by optical lenses when the primary optical design is completed; and (3) tertiary optics for which luminescence is delivered with a combination of LED lighting modules. Accordingly, determining how to construct a complete system to develop LED lens modules will substantially contribute to the lighting industry and improve the competitiveness of the LED industry.

To design an LED lens, one must change the lens’ shape and dimensions for refracted or reflected light, the path of the traveling light, and other types of luminescent sources based on fundamental optical theories. To further concentrate light via a concentrator LED lens and improve the viewing angle, the direction of the traveling light has to be adjusted with custom-designed accessories. In this regard, studies of applications of indoor lighting with LEDs emphasize the design of LED lenses mostly for required light sources. In one instance, a changed viewing angle of the LED with a lens designed by Parkyn and Pelka [1] for Candela distribution of LED redistributed and further concentrated the light via this lens. To design the required viewing angle for an improved uniform illuminance LED array system and substantially reduce costs for LED lighting module manufacturers, Moreno and Tzonchev [2] referred to both the Sparrow rule for configurations of different types of LED arrays and various transfer functions of parameters to design a uniform illuminance LED array system.

By virtue of the improved high-operational speeds of computers and recent popular optical analysis packages, accelerated computer-aided optical analyses for LEDs, including the liquid crystal display (LCD) light guide plate (LGP), optical film, and optical lenses, have saved considerable time, manpower, and expense. Still, designers must develop a model to design an LED lens with analytical software, perform experimental analyses by trial-and-error, and empirically adjust the dimension parameters by which they construct a new model for further analyses and checks. Because modifying parameters and dimensions relies solely on a designer’s personal experience, the accumulated time spent analyzing each model and modifying the parameters by trial and error can be considerable. In view of the repeated corrections and incalculable time needed to design an optimal lens, it was our intention in this study to develop a procedure to optimize comprehensive optical design.

As a commonly used method to design good-quality lenses within default parameters, the Taguchi method has been adopted by many scholars to contribute to the design and adjustment of parameters of optical systems. The signal-to-noise (S/N) ratios are employed for finding the optimal level of parameters. As indicated by experimental results, issues of lens design and manufacturing errors can substantially be moderated by a robust design. Based on the Taguchi method, Fang [3] divided parameters of lens design into different levels based on each parameter’s response to the quality characteristics (such as luminance and uniformity) and obtained experimental results that indicated a better quality design within the default parameters. Chen et al. [4] integrated TracePro (an optical analysis package) with the Taguchi method to explore the effects of a parameter (the bore diameter of the microstructure of the LGP) on optical qualities (luminance and uniformity of the LGP) for a side-emitting backlight module. Despite the modest frequency, cost, and time associated with experimental designs using the Taguchi method, global optimal parameter combinations are still not available.

To resolve this problem, many scholars use artificial neural networks and relevant optimization theories to obtain continuous, global optimal parameter combinations based on the learning capabilities of artificial neural networks (ANNs) in which the product quality in a complicated or nonlinear problem is exactly predicted and an optimal parameter combination is obtained with an integrated optimization theory [5, 6]. Su and Wong [7] integrated the particle swarm optimization and a BPNN to construct a multi-input and multi-output controller in the CMP process and demonstrated quality characteristics that more accurately converged toward the target with substantially reduced errors. Li et al. [8] investigated optimized dot patterns on an LCD LGP by employing an ANN and a genetic algorithm to acquire optimized results, and achieved 90 % uniformity. Chen et al. [9] proposed an optimization system of an LED lens cap design based on one LED light source. Optical design software (TracePro) and the orthogonal table of the Taguchi method were used in simulation experiments. The viewing angle and the luminance uniformity were employed as the optical quality objective. The genetic algorithm with the quality predictor was used to ascertain the optimum parameter combination of overall size.

This study proposed a two-stage LED lens module design system based on 3 LED light sources. The system can predict the viewing angle and average illuminance and combine optical quality predictor with GA and PSO to get the optical solution of design parameters for the geometric shape of the lens module. Though optimization of optical design functions has been established in commercial software like TracePro, LightTools, and ASAP, users can only utilize the design function with limited available variables from the software.

2 The proposed two-stage optimization system

The objective of this study was to develop a completely optimized optical design system that delivers an expected viewing angle of 20° and an average illuminance with an optimal light concentration effect. The procedure for optimization of an LED lens module design based on 3 LED light sources was divided into two phases. In Stage I, we optimized the pattern distribution by conducting simulation experiments with TracePro and orthogonal arrays of Taguchi method. Analysis of variance (ANOVA) was employed to investigate relationships between the quality characteristics and dimensions of the lens module and to discover important factors that affected the pattern distribution and uniformity. In Stage II, the dimensions of the lens module were optimized by defining the second Taguchi experiment according to important factors obtained in Stage I for a more uniform pattern distribution. BPNN was used to train and test the experimental data to develop an optical quality predictor of the lens module, which was used to predict the viewing angle and the average illuminance with different dimensions and shapes. Finally, the optical quality predictor was integrated with GA and PSO to find out the optical solution of design parameters for the geometric shape of the lens module. The flowchart for the proposed two-stage optimization system is shown in Fig. 1, and the procedure is as follows:

-

I.

Identify experimental factors and quality characteristics and plan the experiments

By relying on the preliminary dimensions for the design, we set the dimension parameters to adjust the design with an expected viewing angle and uniform average illuminance. The procedure is described as follows:

-

a.

Determine correlations among dimensional parameters of an LED lens module, select quality characteristics, and decide on the extent of signal factors and important noise factors.

-

b.

Identify all control factors and choose important control factors and levels.

-

c.

Select an adequate orthogonal array and designate control factors into an array for experiments and data collection.

-

II.

Preliminary optimization of the shape of an LED lens module

An orthogonal array of Taguchi method was used for experiments. The LED lens module size parameter combination was adopted to set up a L25(56) orthogonal table. ANOVA was employed to investigate relationships between the quality characteristics and dimensions of the lens module and to find out important factors that affected the pattern distribution and uniformity. When significant factors were decided and critical factors were defined via contrasts among the illuminance diagrams, a secondary optimization analysis was performed to acquire the expected optical quality.

-

III.

Secondary optimization and development of an optical quality predictor

In Stage II, the experimental parameters were redesigned, and a secondary Taguchi experiment was constructed. The experimental data of the orthogonal array L25(56) were used to train the back-propagation neural network to develop an optical quality predictor. In addition, the experimental data of five new combinations randomly generated within the levels of the orthogonal array were used to test the optical quality predictor.

-

IV.

Optimization model of an LED lens module

The second stage is to optimize the viewing angle and average illuminance. The optical quality predictor was then integrated into GA and PSO to find the optimal parameter combinations. The fitness function for both PSO and GA is defined as follows:

(where \( {\text{UCL}}_{j} = \bar{y}_{j} + S_{j} \) and \( {\text{LCL}}_{j} = \bar{y}_{j} - S_{j} \));

where X is the dimension parameters, y NT oi is the predicted value of i response that is a nominal of the best type response and has a certain target value y NT ti , a is the total number of responses, which is the nominal-the-best type and has a certain target. y Noj is the predicted value of j response that is the nominal-the-best type of responses and does not have a certain target value, b is the total number of responses, which is the nominal-the-best type and does not have certain target, UCL j is the upper control limit of j response, LCL j is the lower control limit of j response, the j response’s mean and standard deviation are obtained by using all of the Taguchi experiment data and are presented as \( \bar{y}_{j} \) and S j , respectively. y L ok is the predicted value of k response that is a larger-the-better type response and has a lower specification S lk , c is the total number of responses, which is a larger-the-better type. y S ol is the predicted value of l response that is a smaller-the-better type response, which has a upper specification S ul , d is the total number of responses, which is smaller-the-better type. P m is the notation of parameter m, e is the total number of parameters, LSR m and USR m are the lower and upper search ranges of parameter m, respectively. The setting method of LSR m and USR m is listed as follows:

where PS nm is the parameter setting value of parameter m, which lets the S/N ratio of response n be highest, D m is the factor level’s equal range of parameter m in the Taguchi experiment.

3 Case study

3.1 Preliminary analyses based on the Taguchi method

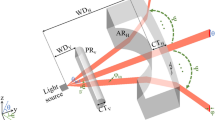

In view of the considerably complicated analyses and calculations for the optical paths of an LED optical lens module with multiple light sources and the analyses of distinct angles of beams emitted by the LED dies, the shape and dimensions of the LED lens module with multiple light sources is very critical to the illuminance properties of an LED lens. Because of the restricted shape and dimensions of the preliminary LED lens module design and lens design concepts shown in Figs. 2 and 3, the dimensions of G and R in the preliminary module design derived from several optical simulations and analyses had little effect on the viewing angle or average illuminance. For the lens module parameters (A, B, C, D, E, and F), the six lens-related control factors and dimensions corresponding to five levels in Table 1 and default values were assigned to L25(56) orthogonal arrays for experiments on the Taguchi orthogonal arrays conducted with TracePro (a package for optical simulations). As shown in Table 2, the experiment results (No. 1–25) are data on the viewing angle and average illuminance. The parameter settings of TracePro for optical simulations are shown in Table 3.

3.2 ANOVA for quality characteristics

In this study, the light distribution and average illuminance based on the experiments of L25(56) orthogonal arrays for optical analyses were generally classified into four types, a, b, c, and d in Table 4, as shown in Figs. 4, 5, 6, and 7. On the basis of the saturated orthogonal array, some factors that had smaller sums of squares should be merged to estimate error variance. ANOVA for the viewing angle and average illuminance is shown in Tables 5 and 6, respectively. The following analytical results were found: (1) A certain positive correlation was observed between factor D and the average illuminance, that is, the better average illuminance for factor D between 18 and 20 mm was based on experimental data using the Taguchi method. (2) Factor D significantly affected the viewing angle and average illuminance according to the ANOVA and was highlighted as a significant factor for these two quality characteristics. Factor E was critical in comparing both the viewing angle and the average illuminance. To ensure that the viewing angle effectively delivered both light concentration and quality characteristics of an LED lens module with multiple light sources (a viewing angle of 20°), we further analyzed category c (groups 3, 4, 5, 6, 7, 14, 18, 21, and 25) with a better light concentration in the pattern distribution and determined that the concentrated pattern distribution for factor E was 4.4–5.6 mm. Accordingly, D and E were adjusted, while the others remained unchanged in the second Taguchi experiment.

3.3 The second Taguchi experiment

The purpose of adjusting dimensions of critical factors D and E was to develop factor levels in the Taguchi method. Factor levels in the second Taguchi method are shown in Table 7, which was assigned to L25(56) for more effective experimental data. As shown in Table 8 for L25(56), data from nos. 1–25 are experiment results generated by using the second Taguchi method; the data for nos. 26–30 are experimental results randomly generated within the Taguchi factor levels and taken as data tested in the BPNN.

With analyses of the experimental results by the second Taguchi method, the parameter combination of group 5 as the optimal parameter combination contributed to the distribution of the average illuminance as shown in Fig. 8, and the viewing angle conformed to the comparative quality objective of this study. Despite the parameter combination using group 11 facilitating a viewing angle of close to 20° and the average illuminance being better than that of group 5, the parameter combination of group 5 was still selected as the optimal parameter combination owing to the corresponding pattern distribution being superior to that of group 11 (Fig. 9) based on analyses of the illuminance.

3.4 Development of the optical quality predictor and trends of optical characteristics in critical factors

Through 3488-generation training of the BPNN in which the optical quality predictor was developed with experimental data used in two Taguchi methods, the training RMSE was 0.007, and the testing RMSE was 0.012, which was within an acceptable range for errors generated in the design of parameters of an LED lens module. By considering interactions between factors and one factor not being determined by changes in another single factor, the trends of the viewing angle and the average illuminance changed could be clearly understood. Critical factors were (factors D and E) through development of the BPNN optical quality predictor, as shown in Figs. 10 and 11. From distributions of 3D viewing angles and average illuminance, the following analytical results were found: (1) E was characteristic of larger-the-better and D was characteristic of smaller-the-better. (2) The average illuminance was optimal with D and E equal to approximately 19.5 and 5 mm, respectively.

3.5 Optimization model

3.5.1 GA integrated with the optical quality predictor

To optimize parameters of the LED lens module with multiple light sources, we integrated the GA with the quality predictor and defined the optimal parameter combination (from the second Taguchi method) as the parameter combination in the GA with the search range of the optimal parameter combination (quality characteristics in group 5) ± 1/2 the Taguchi level, as shown in Table 9. According to the ANOVA of quality characteristics, significance was observed between factor D (or E) and the viewing angle (or the average illuminance) so that the factors that were adjusted were D and E, while factors A, B, C, and F remained unchanged. The fitness function for the parameter search in the GA is

where y o1 is the quality characteristic (viewing angle) predicted by the BPNN; 20 is the viewing angle; y o1 is the output of average illuminance predicted by the BPNN; and the threshold of average illuminance is 84.4 according to the Taguchi method (group 5); x m is the notation of parameter m, LSR m and USR m are the lower and upper search range of parameter m. Integrating the GA with the quality search predictor, we obtained the optimal parameter combination, D = 19.83 and E = 5.51, for a lens viewing angle of 20° and plotted the illuminance distribution (Fig. 12) with the optical simulations completed.

3.5.2 PSO integrated with the quality predictor

To optimize parameters of the LED lens module with multiple light sources, we integrated the PSO with the quality predictors and defined the optimal parameter combination (from the second Taguchi method) as the initial value for the PSO of parameter variables X (0), since both the hybrid BPNN-PSO search approach and the hybrid BPNN-GA search approach were the preliminary initial process parameter settings obtained from the Taguchi method. Therefore, the initial values of parameter variables X (0) were A of 85, B of 62, C of 4, D of 20, E of 5.6, F of 3.6 (group 5). The search ranges of process parameters in the PSO method can be obtained as shown in Table 10. The target function for the parameter search in PSO is

where y o1 is the quality characteristic (viewing angle) predicted by the BPNN; y t1 is a viewing angle of 20°; y o2 is the output of the average illuminance predicted by the BPNN; and the threshold of average illuminance is 84.4; x m is the notation of parameter m, LSR m and USR m are the lower and upper search range of parameter m. Integrating PSO with the optical quality predictor for the search, we obtained the optimal parameter combination, D = 19.75 and E = 5.45, for a lens viewing angle of 20° and plotted the illuminance distribution (Fig. 13) when the optical simulations were completed.

4 Results and discussion

In this study, GA or PSO with integration of the optical quality predictor was used to search for the optimal parameter combination. It was compared with other methods and often used to search for optimal parameters such as trial-and-error and the Taguchi method, which is a method for discontinuous optimization to obtain a locally discontinuous optimal solution rather than a global optimal solution based on default parameter levels. From the numerical results, the frequency of calculations with PSO was 5 times less than that with the GA owing to the initial values (the optimal combination from the Taguchi method) assigned to PSO compared to no initial values assigned to the GA. For the overall pattern distribution, PSO was better than the GA. This can be attributed to the optimal solution for an individual particle considered in the calculations and the optimal solution for the particle swarm gradually converging to the global optimal solution after iterations and corrections.

The optimal parameter combination can be quickly and effectively searched for in the BPNN with integration of the optical quality predictor and GA (or PSO), and the BPNN delivered better optical quality through simulations using TracePro (such as improved average illuminance), which was superior to that of the parameter combination in the Taguchi method. Comparisons of the optical quality are shown in Table 11.

5 Conclusions

A conventional optical analysis to simulate and to analyze a light-emitting diode (LED) lens module along with the Taguchi method and trial-and-error method is normally applied to experimental design. The optimal parameter combination derived from the Taguchi method is the best parameter solution applicable to the discontinuous region, but is unfavorable for the optimal optical design due to excessive time consumed in the analyses. In addition, the Taguchi method is still not available for global optimal parameter combinations. In this study, a procedure and a brand new systematic method was proposed for optimizing the optical design of an LED lens module. In the first Taguchi method for two quality characteristics, viewing angle and average illuminance, the factors critical to the pattern distribution were discovered through applying ANOVA to the collected data. Next, the pattern distribution was significantly improved in the second Taguchi method. Then, the optimal parameter combination detected the integration of the developed optical quality predictor and GA or PSO contributed to both the viewing angle converging to the target value and improved illuminance. The experimental results demonstrated that the viewing angle converged to the target value and the illuminance improved; moreover, the pattern distribution was more uniform. Therefore, the proposed system can be applied to the optical design of various LED lens modules, so as to help the LED industry by improving the design technology and increasing the development performance.

References

Parkyn WA, Pelka DG (2005) Illuminance-mapping linear lenses for LEDs. Int Soc Opt Eng Conf SPIE 5942:1–12

Moreno I, Tzonchev RI (2004) Effects on illumination uniformity due to dilution on arrays of LEDs. Int Soc Opt Eng Conf SPIE 5529:268–275

Fang YC, Tzeng YF, Li SX (2008) Multi-objective design and extended optimization for developing a miniature light emitting diode pocket-sized projection display. Opt Rev 15(5):241–250

Chen WC, Wang MW, Chen CT, Fu GL (2009) An integrated parameter optimization system for MISO plastic injection molding. Int J Adv Manuf Technol 44(5–6):501–511

Smrelar J, Pandit D, Fast M, Assadi M, De S (2010) Prediction of power output of a coal-fired power plant by artificial neural network. Neural Comput Appl 19(5):725–740

Gandomi AH, Alavi AH (2012) A new multi-gene genetic programming approach to nonlinear system modeling. Part I: materials and structural engineering problems. Neural Comput Appl 21(1):171–187

Su CT, Wong JT (2007) Designing MIMO controller by neuro-traveling particle swarm optimizer approach. Exp Syst Appl 32(3):848–855

Li CJ, Fang YC, Cheng MC (2009) Study of optimization of an LCD light guide plate with neural network and genetic algorithm. Opt Exp 17(12):10177–10188

Chen WC, Lai TT, Wang MW, Hung HW (2011) An optimization system for LED lens design. Exp Syst Appl 38:11976–11983

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, WC., Liu, KP., Liu, B. et al. Optimization of optical design for developing an LED lens module. Neural Comput & Applic 22, 811–823 (2013). https://doi.org/10.1007/s00521-012-0990-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-0990-6