Abstract

A novel pH–temperature-sensitive elastomer was made from maleate poly(vinyl alcohol)-graft-isopropylacrylamide (PVAM-graft-PNIPAM), namely PVNI and deproteinized natural rubber (DPNR) in a water-based system. The swelling ratio in water of PVNI/DPNR hydrogel enhanced as a function of PVNI portion in hydrogel due to increasing of hydrophilic group in the hydrogel. Surprisingly, the percentage of swelling in water of PVNI/DPNR hydrogel 7:3 is 24 times based on pristine DPNR. In addition, the highest tensile strength of PVNI/DPNR hydrogel was found at 7:3 PVNI/DPNR. The highest elongation at break of PVNI/DPNR hydrogel was improved after the addition of DPNR. Moreover, the resulting smart hydrogel showed a good pH–temperature sensitivity. In addition, it yielded a good polymer membrane for encapsulating capsaicin (CSC) in different media. After its use, it also easily decomposed in the natural environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Smart or intelligent polymers for matrix of drug delivery have been major areas of research over the past few decades [1, 2]. The advantages of smart polymer are maximizing drug effectiveness, avoiding side effects and decreasing the frequency of administration. Poly(N-isopropylacrylamide) (PNIPAM) polymer is one of a popular smart polymers [3]. When PNIPAM was immersed into aqueous solution at over 32 °C, PNPAM solution instantaneously converts a clear solution into a milky suspension. Generally, PNIPAM is soluble in organic solvents, such as chloroform, acetone, methanol, and various other alcohols. Moreover, PNIPAM is also soluble in water, as long as the solution is kept reasonably cold. Therefore, it is used in controlled drug-release carriers [4], recyclable absorbents [5], enzyme immobilization networks [6] and membranes [7] for chemical separation and biomaterials [8] because of the sharpness of the transition, a transition temperature that is close to body temperature, the robustness of the polymer itself, and the availability of information on the polymer and its phase transition. In earlier works, many researches have reported the modification of PNIPAM [9–11]. For example, N-(2-hydroxy-tert-butyl) acrylamide (HTBAM)-graft-N-hydroxyethylacrylamide copolymer (P (HTBAM-co-HEAM)) was synthesized from N-(2-hydroxy-tert-butyl) acrylamide (HTBAM) and N-hydroxyethylacrylamide (HEAM) monomer [9]. Results showed that the polyN-(2-hydroxy-tert-butyl) acrylamide displays a highly sensitive lower critical solution temperature (LCST) transition caused by cooperative dehydration upon heating comparable to PNIPAM. N-isopropyl acrylamide-graft-graphene oxide (PNIPAM-graft-GO) was synthesized from NIPAM and graphene oxide (GO) in aqueous solution at ambient temperature to use selective adsorptions with different phenol pollutants [9], because of the different interactions of hydrogen bonds and the molecule structure of the adsorbates [9, 10]. The GO-PNIPAM adsorbate shows good phenol adsorption with temperature sensitivity because of its thermoresponsive transition of the hydrogen bond. Moreover, GO-PNIPAM is also recyclable in the potential water remediation. Here, PNIPAM was grafted with maleate poly(vinyl alcohol) (PVAM) and then blended with natural rubber (NR) which have not yet been reported. Our previous work studied the preparation of PVAM without initiator in aqueous phase [12]. PVAM responds to changes in pH with deswelling at strongly acidic pH 2.0 and also mildly acidic pH 5. The hydrogels of hydrophobic polymer (NR) are sensitive to the condition of the surrounding environment [13] and this property has been exploited in many fields such as pharmacy [14] and biotechnology [15]. In case of NR, the hydrophilic behavior and biodegradation of NR was improved by grafting with starch (St) [16]. The water resistance, toluene resistance and elongation at break of natural rubber-graft-cassava starch (NR-graft-CSt) were improved after the addition of the maleated epoxidized natural rubber (MENR) compared to pristine NR-graft-CSt [17]. The novel films demonstrated good biodegradability in soil. Moreover, NR was used as raw material to produce a novel hydrogel. Before preparing the hydrogel, the chemical structure of NR was altered by epoxidation reaction to synthesize the epoxidized natural rubber (ENR) [18]. Then, the ENR was blended with St and poly(vinyl alcohol) (PVA) in the presence of glutaraldehyde (GA) as a crosslinking reagent. The swelling ratio of novel hydrogel decreased as a function of the GA content, ENR content, PVA content. The tensile strength of the polymer hydrogel can be improved by adding silver. In addition, prevulcanized natural rubber was used to prepare the hydrogel [19]. The reduction in the contact angle and the increase in water absorption after the addition of the prevulcanized natural rubber film and irradiation are due to the production of the hydrogel layer. The objective of the present study was to develop the preparation of pH–temperature-sensitive hydrogel based on the PVNI and DPNR without a crosslinker. The effect of PVNI/DPNR ratio on the properties including swelling ratio, contact angle value, tensile strength, elongation at break and biodegradation in natural soil. After preparing hydrogel, it was used to polymer matrix for loading of capsaicin (CSC). CSC has been selected as a model drug for loading and its released behavior has been studied in simulated gastric and intestinal fluids.

Experimental materials

Natural rubber latex with an average molecular weight of ~1 × 106 g/mol (Chana Latex Co., Ltd., Songkhla, Thailand) was used for the present study. CSC was received from our own laboratory and Sigma-Aldrich Co., Castle Hill, Australia. PVNI was synthesized by our laboratory. Triton™ X-100 was purchased from Sigma-Aldrich. The CSC from chili was prepared by extraction method. Chili was mashed in grinder (Sharp company, Japan). The mashed chili was immersed in 50:50 water–ethanol for 14 days. Then the mixed chili was filtered to get capsaicin solution. The CSC solution was then evaporated to get a 1000 ppm of CSC in pepper extraction which was evaluated by UV spectroscopy.

Preparation of PVNI/DPNR hydrogel

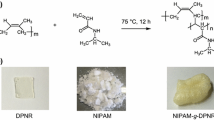

Triton™ X-100 (Sigma-Aldrich, Germany) 10 % solution was added to NR latex and it was stirred for 30 min at room temperature. After that, urea 10 % solution was added into NR latex/Triton™ X-100 and was stirred for 60 min. NR latex/urea (Sigma-Aldrich, Germany) was incubated at room temperature for 7 days. After 7 days, incubated NR was centrifuged at 10,000 rpm, 25 °C for 30 min and two times. The cream of low-protein NR was diluted with distilled water to obtain 30 % DRC. The nitrogen content (N-content) of DPNR was about 0.012 % which was estimated from Nitrogen analyzer (Thermo-Scientific-Model 42i-HL, USA). 10 % wt Triton™ X-100 solution was added into the low-protein NR latex, namely DPNR and was stirred for 5 min at room temperature. PVNI was synthesized according to our previous work [20]. Firstly, PVAM was prepared by adding 3 g MA in distilled water of 20 ml into 70 g of 10 % PVA solution and the mixture solution was stirred at 70 °C for 2 h. After 2 h, 90 g of 11 % w/w PVAM (7:3 PVA:MA) solution was cooled at room temperature. After that, KPS was added into the PVAM solution at 70 °C and then stirred it for 5 min. NIPAM monomer was added into mixture solution at 70 °C. The mixture solution was stirred at 70 °C for 1 h. After 1 h, the PVNI solution was cooled at room temperature. Then, PVNI is blended with low-protein NR (2:8, 3:7, 4:6, 5:5, 6:4 and 7:3) and stirred for 30 min at room temperature to get the PVNI/DPNR hydrogel, namely PVNI/DPNR hydrogel given in Fig. 1. The PVNI/DPNR hydrogel mixtures were poured in a mold and deposited for 7 days at room temperature. After 7 days, PVNI/DPNR hydrogel sheets were immersed in distilled water for 3 days at room temperature to remove impurities. After that, the PVNI/DPNR hydrogel sheets were dried at room temperature for 2 days.

FTIR and XRD

The PVNI/DPNR sample was analyzed by attenuated total reflection Fourier transform infrared (ATR-FTIR) (Bruker EQUINOK 55, USA) in the range of 4000–500 cm−1. X-ray diffractograms of the graft copolymer samples were obtained using an X-ray diffractometer (X’Pert MPD, PHILIPS, Netherlands) with a Cu–NF filter and Cu Ka radiation (XRD).

Hydrophilic testing

The samples used to determine the swelling ratio in distilled water were 2 × 2 cm cut pieces. The samples were weighed before swelling in distilled water. For the swelling ratio, samples were immersed in 25 mL of distilled water at room temperature (28 °C) for 7 h. After that, the samples were reweighed after removing excess water from the hydrogel surface with tissue paper. The swelling ratio was calculated by Eq. (1).

where W 1 is the initial dry weight of the sample (g) and W 2 is the weight of the swollen sample (g).

The sessile drop method and a contact angle goniometer (KRÜSS model G10, Germany), with an optical subsystem to capture the profile of a liquid on a solid substrate were used to measure the contact angle. The angle was formed between the liquid and the solid interface. Sample pieces were cut for the dumbbell-shaped test. Tensile testing was performed using an Instron (IX3366, Japan) machine at a crosshead speed of 100 mm/min according to ISO 37. The tensile strength and elongation at break (Eb) were obtained from the tests in dried state.

pH-thermo sensitive testing

The smart PVNI/DPNR hydrogel was measured in terms of its swelling and deswelling abilities in a solution at pH of 5.5 and 8.0. The swelling capacity of the smart polymer hydrogel at each pH was measured according to Eq. (1) at consecutive time intervals (60 min).

The equilibrium swelling studies were performed in buffer solutions of different temperatures (29 and 39 °C) at pH 7.0 buffer solutions.

Loading of capsaicin (CSC)

After that, the ratio of PVNI/DPNR hydrogel was equal to 4:6 which was selected to use a polymer membrane for encapsulation of capsaicin (CSC). 0.1 % CSC was added into 100 g of 4:6 PVNI/DPNR hydrogel solution during stirring. The 4:6 PVNI/DPNR mixture in the presence of the capsaicin (CSC) was poured into a mold and allowed to deposit for 7 days at ambient temperature. The efficiency for the entrapment of CSC in the hydrogel matrix was calculated from the ratio between the initial mass of CSC to be encapsulated, and its mass in the final product. In this case, a known amount of CSC (ca. 12 mg) loaded hydrogel matrix was dispersed in a pH 5.5 and pH 8.0 buffer solution medium and stirred for 2 days at room temperature. Subsequently, the suspension (swollen hydrogel) was filtered, and the content of dissolved CSC in the distilled water medium solution was determined using a UV spectrometry (Shimadzu UV-1601, Japan) at 206 nm (λ max). The resulting CSC-loaded hydrogels were allowed to release in 100 mL of pH 5.5 and pH 8.0 buffer solutions and at different temperatures (29 and 39 °C) as a function of time, respectively. At definite intervals of time, an aliquot (5 mL) was taken for analysis of the CSC in the hydrogel. At scheduled time, the solution was replaced by 5 mL fresh buffer solution and the released CSC was measured and calculated by absorption of light at 206 nm using a UV spectrometry (Shimadzu UV-1601, Japan. Experiments were performed thrice for every sample and the average values were used to plot profiles.

The release results were evaluated using an empirical equation to estimate the value of n as follows (Eq. (2)).

where M t /M ∞ is the released fraction at time t, n is the release exponent, and K is the release factor. From the slope and intercept of the plot of log (M t /M ∞) against log (t), the kinetic parameter n was calculated.

% Biodegradation

To examine the biodegradation, dried hydrogel samples (3 cm × 3 cm) of a known weight were buried 5 cm deep in 100 g of top soil collected in Hat Yai, Songkhla, Thailand, and water was added every week for 30 days. Each week, the samples were carefully removed, rinsed with distilled water to remove the soil and dried in a desiccator at 40 °C for 24 h before being reweighed. The biodegradation of the samples in soil was obtained according to Eq. (3).

where W 3 is the initial dry weight of the samples (g) while W 4 is the dry residual weight of the samples after biodegradation in soil (g).

Results and discussion

Synthesis of PVNI and ATR-FTIR result

The possible chemical reaction of PVAM-graft-PNIPAM made from PVAM and NIPAM is represented in Fig. 2. After MA was immersed in the water medium, it altered to form a succinic anhydride acid. Then, succinic anhydride acid reacted with the hydroxyl group of PVA to the PVAM. The CH2 groups of PNIPAM reacted with CH2 free radical of PVAM to form the graft copolymer as shown in Fig. 2. When K2S2O8 was received by heat and it alters into K2S2O8 free radical. Then, it reacted with PNIPAM molecule. The PNIPAM radical attached to methylene carbon of PVAM, which was activated by K2S2O8 leading to the PVNI.

FTIR spectra of DPNR, PVNI and PVNI/DPNR hydrogel are shown in Fig. 3. The FTIR peaks of the PVNI were found at 3077 and 3299 cm−1 due to NH stretching broad bands for secondary amide group and its H-bonded complex. The CH stretching in CH3 was located at 2967 and 2875 cm−1, C=O amide I band was found at 1658 cm−1, NH amide II band was at 1554 cm−1, CH3 deformation in isopropyl group was found at 1457 and 1407 cm−1, NH–C=O trans-amide III band was found at 1245 cm−1, C–N stretching was located at 1170 cm−1. After the addition of the DPNR into the PVNI, the main FTIR band of the PVNI appeared at 1658, 3299, 1457 and 1245 cm−1. The main FTIR peaks of DPNR were located at 1446 and 1375 cm−1. The FTIR peak of PVNI overlapped with spectrum of DPNR at 1664 cm−1. The intensity of the FTIR peak at 1375 cm−1 from CH3 of the DPNR was proportional to the content of the DPNR in the hydrogel as given in Fig. 3.

XRD result

The XRD patterns of PVNI, DPNR and 6:4 PVNI/DPNR hydrogel are shown in Fig. 4. The XRD studies for these specimens were carried out to understand the changes in the crystallinity of the PVNI, before and after the fabrication of hydrogel. The pristine DPNR and PVNI did not record sharp peaks, as it is an amorphous polymer. Hence, one broad peak of the DPNR was observed at 2θ of 19° while two broad peaks including 10° and 21° were found in the PVNI sample. When DPNR was mixed with PVNI, the XRD of the 6:4 PVNI/DPNR hydrogel showed one broad peak at the same angles with PVNI. The reason for this is that during the process of hydrogel, the polymer was unable to rearrange polymer chains in a regular order due to limited time [21].

Swelling ratio and contact angle results

The effect of DPNR content on the swelling ratio of the PVNI/DPNR hydrogel is presented in Fig. 5a, b. The swelling ratio of the PVNI/DPNR hydrogel increased as the increase of the PVNI content because the hydrophilicity of the PVNI was higher than the DPNR as shown in Fig. 5a, b. The PVNI consists of two groups of hydrophilic amide and carboxylic groups which would bring the balance between hydrophilic and hydrophobic groups. When the outside temperature was below the LCST of the hydrogel, the hydrogen bonding formed between a hydrophilic group of polymer chains and the water molecule, leading to the swelling of hydrogel and increasing of its volume. As the temperature increased (higher than the LCST), the hydrogen bonding interaction was weakened and the interaction was strengthened between hydrophobic groups of polymer chain due to the bound water in the hydrogel transform into free water and diffused outwards [22]. The phase separation of hydrogel occurred with its internal structure collapse, severe volume contraction, and the swelling ratio fell sharply. As the temperature continues to rise, the affinity between intermolecular and intra-molecular in the hydrogel was strengthened. Finally, the hydrogel became dense because of the loss of the internal water, so the swelling ratio had no obvious change. This might be due to that the PVNI contains amide group in the graft copolymer therefore hydrogen bridging between H2O and amino groups, resulting a higher swelling ratio in water studied the swelling behavior of temperature- and solvent-sensitive hydrogels in buffer solution. The effect of PVNI/DPNR ratio on the water contact angle value of the hydrogel is shown in Fig. 6. The results showed that the contact angel reduced with enhancing of the PVNI content owing to the hydrophilic group of the PVNI. For example, the water contact angle of the PVNI/DPNR hydrogel at 2:8, 3:7, 4:6 and 5:5 PVNI:DPNR was 96.79°, 94.99°, 93.43° and 83.49°, respectively.

SEM images

The adhesion between PVNI and DPNR phase in the PVNI/DPNR hydrogel with different PVNI:DPNR ratios were confirmed by SEM images. Their results are reported in Fig. 7. It was clear that good adhesion between them of all PVNI/DPNR hydrogels was observed. The morphology of 2:8 PVNI/DPNR appeared as mostly smooth. PVNI was easily dispersed in the DPNR phase observed from its morphology (Fig. 7a). However, when the portion of the PVNI in the PVNI/DPNR hydrogel increased from 2:8 PVNR: DPNR ratio to 5:5 PVNR:DPNR ratio, the morphology of 5:5 PVNI/DPNR hydrogel showed more roughness on their surface (Fig. 7b). Moreover, the occurrence of many domains was found. When the portion of the PVNI in the PVNI/DPNR hydrogel continued to increase from 5:5 PVNR:DPNR to 7:3 PVNR:DPNR, many droplets formed on its morphology surface (Fig. 7c). In addition, the morphology of 7:3 PVNI/DPNR hydrogel exhibits most roughness compared to other samples. This phenomenon [23–26] is referred that the slightly phase separation was occurred due to difference in polar between DPNR and PVNI.

pH and temperature sensitivity result

The pH sensitivity of the PVNI/DPNR hydrogel was investigated using medium at 5.5 and 8.0 pH and its result is reported in Fig. 8a. It is clear that both 4:6 PVNI/DPNR hydrogel and 3:7 PVNI/DPNR hydrogel significantly responded to change in pH. The phase transition process of hydrogel was reversible. There was a reversible swelling–de-swelling behavior which changed in pH medium at 5.5 and 8.0. The hydrogel dehydrated and de-swelling occurred when the pH of the medium was 5.5 and the hydrogel swelled at pH 8.0, the distance between the polymer chains was relatively close. The COOH groups from PVNI/DPNR hydrogel dissociate at pH 8.0, and the repulsion between COO– groups led to the expansion of the chains and swelling of the hydrogels. Penetration of water molecule into the hydrogel decreased due to increasing hydrophobic portion [24]. The polymer chain segment of hydrogel was stretched due to the effect of the water molecule, the collapsed structure of hole restored gradually and the swelling rate of hydrogel increased significantly. There was a reversible swelling–de-swelling behavior which was changed in pH medium at 5.5 and 8.0. After that, the graft copolymer sample was immersed in pH 5.5 medium. It attributed to the presence of carboxylate functional groups on the backbone of the hydrogel. It was found that the swelling ratio of the graft copolymer sample decreased because H+ ions diffused into the PVNI/DPNR hydrogel matrix and neutralized negatively charged –COO− groups. As a result, neutral layer of de-swelled polymer can form around the inner portion of the matrix, which is still ionized and swollen [24–26].

The effect of different temperatures (29 and 39 °C) of PVNI/DPNR hydrogel film on the oscillatory swelling behavior is shown in Fig. 8b. At temperature 29 °C, the swelling of PVNI/DPNR hydrogel film increased while the swelling of the PVNI/DPNR hydrogel at 39 °C decreased due to disruption of their hydrogel bonding with water and the increasing hydrophobic interaction among propyl groups [27] which resulted in increase of shrinkage and pressure inside polymer matrix. This might be due to the balance of hydrophilic (–CONH–) group and hydrophobic [–CH(CH3)2–] group. Thus, below LCST the hydrogel is swollen, hydrated, and hydrophilic. However, above LCST it is collapsed and dehydrated [28].

Tensile strength and elongation at break results

The effect of DPNR on the tensile strength and the elongation at break of the PVNI/DPNR hydrogel with different hydrogel ratios is depicted in Fig. 9a, b, respectively. The tensile strength of the DPNR was 1.2 MPa while the tensile strength of 2:8 PVNI/DPNR hydrogel was 4.2 MPa. The tensile strength continually increased as a function of the PVNI content. The influence of the DPNR content on the elongation at break of the PVNI/DPNR hydrogel is illustrated in Fig. 9b. It was revealed that after incorporation of DPNR in the PVNI, the elongation at break of PVNI was improved. The data showed the opposite trend with the tensile strength. The highest elongation at break of the PVNI/DPNR hydrogel was observed at 2:8 PVNI:DPNR. Poor elongation at break was found with high proportion of PVNI content, because of a brittleness of PNIPAM and phase separation. These results were agreement with previous work [29]. This could attribute the relative decrease in mechanical properties of the graft copolymer [29].

Capsaicin release

The CSC release of PVNI/DPNR hydrogel film at pH 5.5 and pH 8.0 medium is shown in Fig. 10a. It was found that the CSC release of PVNI/DPNR hydrogel film at pH 5.5 was higher than PVNI/DPNR hydrogel film at pH 8.0. The capsaicin release behavior of the PVNI/DPNR hydrogel did not correspond with swelling ratio results. In pH 5.5 medium, H+ ions from water medium attracted with COO− ions from PVNI/DPNR hydrogel film which led to the collapse of matrix of PVNI/DPNR hydrogel film as shown in Fig. 10a, it occurred osmotic pressure inside the polymer matrix which resulted to increase of CSC release in pH 5.5 medium [28]. However, in pH 8.0 medium, OH− ions diffused into the polymer matrix and pushed between OH− ion and –COO− ion. This repulsive force might occur with the expansion of polymer film. This result might lead to decrease of capsaicin release in pH 8.0 medium. The PVNI/DPNR hydrogel film can also be applied in plaster for attaching of wound on skin. From the plot of log (M t /M α) with log (t), release exponent (n) was estimated as shown in Fig. 10b. The n value of 6:4 PVNI/DPNR hydrogel at pH 5.5 and pH 8.0 was 0.4609 and 0.4229, respectively, at a regression of 0.98 and 0.99, respectively, indicating that these systems show almost Fickian diffusion. On the basis of the diffusion exponent, an n value of 0.5 indicates the drug-release mechanism approaches a Fickian diffusion controlled release [29].

The effect of different temperatures (29 and 39 °C) of PVNI/DPNR film on the capsaicin release is shown in Fig. 11a. This result increased CSC release at 39 °C and was faster than that of hydrogel at 29 °C, as shown in Fig. 11b. These results are in agreement with increasing shrinkage behavior of hydrogel. The CSC cumulative release from capsules at 39 °C exposed for 0.5, 5, 10, 24, 48 and 72 h in aqueous medium was 20, 50, 70, 90, 95 and 100 %, respectively. When the PVNI/DPNR hydrogel was immersed in aqueous medium for 0.5, 5, 10, 24, 48 and 72 h at 29 °C, the CSC release was 7, 30, 44, 60, 70 and 78 %, respectively. The n value of PVNI/DPNR hydrogel is reported in Fig. 11b. The n value of PVNI/DPNR hydrogel after the immersion in water medium at 29 and 39 °C was 0.4604 and 0.3691 with a regression of 0.99 and 0.97 respectively. These values indicated that a Fickian diffusion controlled release was found.

The n value of this study was an agreement with our previous work [24]. We studied the encapsulation of neem using sodium alginate, poly(vinyl alcohol) as a matrix.

% Biodegradation

The effect of PVNI portion in the PVNI/DPNR hydrogel on the biodegradation in soil is presented in Fig. 12. The change in weight of pristine PVNI/DPNR hydrogels was evaluated after immersion in natural soil for 30 days. The % biodegradation of PVNI/DPNR hydrogel increased with increasing PVNI. Since PVNI possessed amide, hydroxyl and carboxyl groups in chemical structure, it can be degraded by hydrolytic biodegradation. For example, the % biodegradation of 2:8, 6:4, 5:5 and 7:3 PVNI:DPNR hydrogel were 6, 13, 15 and 16 %, respectively. When the portion of PVNI was increased from 5:5 PVNI:DPNR to 7:3 PVNI:DPNR, the % weight loss was 16 %. DPNR can be slowly degraded by bacteria and fungi in soil which are activated by moisture and heat. In our previous work, we studied the biodegradation of NR-graft-CSt [16]. The rate of biodegradation of the NR-graft-CSt increased with increasing CSt content. The higher molecular weight of NR is around (∼106 g/mol) which results in it being more difficult to biodegrade [17]. The evidence for biodegradation of the PVNI:DPNR was again confirmed by SEM. The SEM images of biodegradation in soil of PVNI/DPNR hydrogel at (a) 400×, (b) 1000× and (c) 2000× are illustrated in Fig. 13. It can be seen that the image of SEM showed a hole on its surface sample due to enzyme adsorption [26].

These data indicated that the fungus growth attaches firstly on their surface. These results agreed well with the results of the % weight loss findings.

Conclusions

The novel pH–temperature sensitivity of hydrogel from the PVNI and DPNR was successfully prepared in a water-based system. With increasing PVNI portion, the swelling ratio in water of PVNI/DPNR hydrogel was improved due to increasing of hydrophilic group in the hydrogel. The percentage of swelling in water of 7:3 PVNI/DPNR hydrogel was 24 times based on pristine DPNR. The highest tensile strength of PVNI/DPNR hydrogel was found at 7:3 PVNI/DPNR hydrogel and its value was 17 MPa. The highest elongation at break of PVNI/DPNR hydrogel was improved after the addition of DPNR. Moreover, the resulting smart hydrogel showed a good pH–temperature sensitivity. After that, it was used as a polymer membrane for encapsulating capsaicin in different media. After its use, it also easily decomposed in the natural environment.

References

Kwon SS, Kong BJ, Park SN (2015) Physicochemical properties of pH-sensitive hydrogels based on hydroxyethyl cellulose–hyaluronic acid and for applications as transdermal delivery systems for skin lesions. Eur J Pharm Biopharm 92:146

Hui B, Ye L (2016) Structure of polyvinyl alcohol-g-acrylic acid-2-acrylamido-2-methyl-1-propanesulfonic acid hydrogel and adsorption mechanism for advanced Pb(II) removal. J Ind Eng Chem 35:309

Yang J, Dong X, Gao Y, Zhang W (2015) One-step synthesis of methacrylated POSS cross-linked poly(N-isopropylacrylamide) hydrogels by γ-irradiation. Mater Lett 157:81

Dhanya S, Bahadur D, Kundu GC, Srivastava R (2013) Maleic acid incorporated poly-(N-isopropylacrylamide) polymer nanogels for dual-responsive delivery of doxorubicin hydrochloride. Eur Polym J 49:22

Nur H, Snowden MJ, Cornelius VJ, Mitchell JC, Harvey PJ, Benée LS (2009) Colloidal microgel in removal of water from biodiesel. Colloid Surf A 335:133

Yin Y, Dong Z, Luo Q, Liu J (2012) Biomimetic catalysts designed on macromolecular scaffolds. Prog Polym Sci 37:1476

Yang HC, Luo J, Lv Y, Shen P, Xu ZK (2015) Surface engineering of polymer membranes via mussel-inspired chemistry. J Membr Sci 483:42

Nguyen MK, Alsberg E (2014) Bioactive factor delivery strategies from engineered polymer hydrogels for therapeutic medicine. Prog Polym Sci 39:1235

Cui Q, Wang Y, Wu F, Erjian Wang E (2013) Novel temperature-responsive functional polymers based on poly(N-(2-hydroxy-tert-butyl) acrylamide). Polymer 54:4521

Gong Z, Li S, Han W, Wang J, Ma J, Zhang X (2016) Recyclable graphene oxide grafted with poly(N-isopropylacrylamide) and its enhanced selective adsorption for phenols. Appl Surf Sci 362:459

Kwok MH, Ngai T (2016) A confocal microscopy study of micron-sized poly(N-isopropylacrylamide) microgel particles at the oil–water interface and anisotopic flattening of highly swollen microgel. J Colloid Interf Sci 461:409

Sukhlaaied W, Riyajan S (2014) Green synthesis and physical properties of poly(vinyl alcohol) maleated in an aqueous solutions. J Polym Environ 22:350

Yang B, Xu D, Wu X, Li Z, Lei L, Zhang X (2015) Efficient removal of pentachlorophenol from wastewater by novel hydrophobically modified thermo-sensitive hydrogels. J Ind Eng Chem 25:67–72

Gao C, Ren J, Zhao C, Kong W, Dai Q, Chen Q, Liu C, Sun R (2016) Xylan-based temperature/pH sensitive hydrogels for drug controlled release. Carbohydr Polym 151:189–197

Gupta P, Vermani K, Garg S (2002) Hydrogels: from controlled release to pH-responsive drug delivery. Drug Discov Today 7:569–579

Riyajan S, Sasithornsonti Y, Phinyocheep P (2012) Green natural rubber-g-modified starch for controlling urea release. Carbohydr Polym 89:251

Riyajan S (2015) Robust and biodegradable polymer of cassava starch and modified natural rubber. Carbohydr Polym 134:267

Riyajan S, Jitdaphon W, Leejarkpai T, Luang K (2014) Effect of additives on the physical properties of a biopolymer hydrogel from epoxidized natural rubber, poly(vinyl alcohol), and starch. KGK Kaut Gummi Kunst 67:34

Ratnam CT, Yoshii F, Makuuchi K, Zaman K (1999) Hydrogel coating of RVNRL film by electron-beam irradiation. J Appl Polym Sci 72:1421

Sukhlaaied W, Riyajan S (2015) Synthesis and properties of a maleated poly (vinyl alcohol) (PVAM) grafted with poly-N-isopropylacrylamide) (PVAM-g-PNIPAM). 25th International Conference of Thaksin University “Thailand Research: A Vision of Futurity” at Thaksin University (Songkhla Campus) Songkhla, Thailand, 10–12 June

Pawar MD, Rathna GVN, Agrawal S, Kuchekar BS (2015) Bioactive thermoresponsive polyhydrogel nanofiber formulations for wound healing. Mater Sci Eng C 48:126

Wei W, Hu X, Qi X, Yu H, Liu Y, Li J, Zhang J, Dong W (2015) A novel thermo-responsive hydrogel based on salecan and poly(N-isopropylacrylamide): synthesis and characterization. Colloid Surf B 125:1

Ismail H, Shaari SM, Othman N (2011) The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene–butadiene rubber (SBR) compounds. Polym Test 30:784

Kulkarni RV, Boppana R, Krishna Mohan G, Mutalik S, Kalyane NV (2012) pH-responsive interpenetrating network hydrogel beads of poly(acrylamide)-g-carrageenan and sodium alginate for intestinal targeted drug delivery: synthesis, in vitro and in vivo evaluation. J Colloid Inter Sci 367:509

Yang J, Hu DD, Zhang H (2012) Preparation and thermally induced adhesion properties of a poly(vinyl alcohol)-g-N-isopropylacrylamide copolymer membrane. React Funct Polym 72:438

Ishihara M, Nakanishi K, Ono K, Sato M, Kikuchi M, Saito Y, Yura H, Matsui T, Hattori H, Uenoyama M, Kurita A (2002) Photocrosslinkable chitosan as a dressing for wound occlusion and accelerator in healing process. Biomaterial 23:833

Don TM, Chen HR (2005) Synthesis and characterization of AB-crosslinked graft copolymers based on maleilated chitosan and N-isopropylacrylamide. Carbohydr Polym 61:334

Sukhlaaied W, Riyajan SA (2016) Preparation and properties of a novel environmentally friendly film from maleated poly(vinyl alcohol) grafted with chitosan in solution form: the effect of different production factors. Polym Bull 73:791

Riyajan S, Sakdakdapiphanich J (2010) Characterization of biodegradable semi- interpenetrating polymer based on poly (vinyl alcohol) and sodium alginate containing natural neem for its natural neem control release application. Polym Inter 59:1130

Acknowledgments

The authors thank the Department of Materials Science and Technology, Prince of Songkla University, The Thailand Research Fund/Prince of Songkla University/Thammasat University, for financial support (RSA5780018) and The Royal Golden Jubilee Ph.D. Program (2.L.PS/53/C.1.N.XX).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sukhlaaied, W., Riyajan, SA. A novel pH and temperature-sensitive maleate poly(vinyl alcohol)-graft-isopropylacrylamide/natural rubber blend: preparation and properties. Polym. Bull. 74, 803–821 (2017). https://doi.org/10.1007/s00289-016-1746-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1746-8