Abstract

The purpose of this study is to summarize the current knowledge of the enzymes which are involved in the hydrolysis of cyanide, i.e., cyanide hydratases (CHTs; EC 4.2.1.66) and cyanide dihydratases (CynD; EC 3.5.5.1). CHTs are probably exclusively produced by filamentous fungi and widely occur in these organisms; in contrast, CynDs were only found in a few bacterial genera. CHTs differ from CynDs in their reaction products (formamide vs. formic acid and ammonia, respectively). Several CHTs were also found to transform nitriles but with lower relative activities compared to HCN. Mutants of CynDs and CHTs were constructed to study the structure-activity relationships in these enzymes or to improve their catalytic properties. The effect of the C-terminal part of the protein on the enzyme activity was determined by constructing the corresponding deletion mutants. CynDs are less active at alkaline pH than CHTs. To improve its bioremediation potential, CynD from Bacillus pumilus was engineered by directed evolution combined with site-directed mutagenesis, and its operation at pH 10 was thus enabled. Some of the enzymes have been tested for their potential to eliminate cyanide from cyanide-containing wastewaters. CynDs were also used to construct cyanide biosensors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Reducing environmental pollution by cyanide compounds, which represent serious health hazards for humans and cause damage to ecosystems, is a global challenge. Cyanides are released in the wastes from various industrial activities such as metal plating, coal gasification, coal coking, gold and silver ore leaching and the production of some pharmaceuticals, synthetic fibers, plastics, dyes, or agrochemicals. Both chemical methods and active sludge are generally applied to eliminate cyanide from wastewaters, but each of these methods has its drawbacks such as high costs, long reaction times, use of toxic chemicals, or generation of toxic wastes.

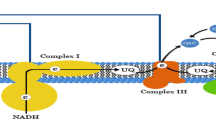

The use of enzymes is a promising way to eliminate these problems. There are diverse metabolic pathways of the microbial breakdown of cyanide, which involve, e.g., anaerobic assimilation, reaction with thiosulfate (catalyzed by rhodanese), and hydrolytic reactions, which are catalyzed by a cyanide hydratase (CHT; EC 4.2.1.66) or a cyanide dihydratase (CynD; EC 3.5.5.1) (Basile et al. 2008). The reaction product is formamide in CHTs but formic acid and ammonia in CynDs (Fig. 1). The hydrolytic pathway seems to be the most attractive for biotechnology: the products are of low toxicity and can be converted further, the enzymes do not require any cofactors, and their specific activities are high.

The current knowledge of nitrile- and cyanide-hydrolyzing enzyme as a whole was previously summarized (O’Reilly and Turner 2003; Thuku et al. 2009, Martínková et al. 2009). Various pathways of cyanide biodegradation were reviewed by Ebbs (2004), Baxter and Cummings (2006), Dash et al. (2009), and Gupta et al. (2010). However, there has been no review specializing in CHTs and CynDs, and the recent literature on this topic has not been summarized at all. Therefore, this work will aim to fill this gap, focusing on the state of the art in the production, biochemical characterization, structure-activity relationships, and potential environmental uses of these enzymes.

Enzyme production

The first CHTs were characterized, and their genes cloned in phytopathogenic fungi (Stemphylium loti; Gloeocercospora sorghi, Leptosphaeria maculans, genus Fusarium; O’Reilly and Turner 2003). The sequences of experimentally confirmed CHTs were used to search databases for further members of this enzyme group (Basile et al. 2008; Kaplan et al. 2013; Veselá et al. 2015). These analyses indicated that cht genes occur in a wide range of filamentous fungi. In contrast to CHTs, CynDs seem to occur rarely in nature and were only characterized in Alcaligenes xylosoxidans subsp. denitrificans, Bacillus pumilus, and Pseudomonas stutzeri (O’Reilly and Turner 2003).

E. coli proved to be a suitable host for the production of both CynDs and CHTs (Jandhyala et al. 2005; Basile et al. 2008; Kaplan et al. 2013; Rinágelová et al. 2014). The wild-type strains of fungi with significant CHT activities (Fusarium oxysporum, G. sorghi) seemed to occur rarely. Therefore, the heterologous production was the method of choice to obtain other CHTs for characterization. In this way, new CHTs were produced from the genes found in Gibberella zeae, Aspergillus nidulans, Neurospora crassa (Basile et al. 2008), Aspergillus niger (Kaplan et al. 2013; Rinágelová et al. 2014), Penicillium chrysogenum (Kaplan et al. 2013), Botryotinia fuckeliana and Pyrenophora teres f. teres (Veselá et al. 2015).

The ability to degrade cyanide was also found in a few members of Basidiomycota (Cabuk et al. 2006; Özel et al. 2010). It is unclear which enzyme(s) catalyzed this degradation—the products were not detected except for a slight production of ammonia. It was postulated that the biodegradation could proceed via an oxidative pathway but a participation of rhodanese was also not excluded (Cabuk et al. 2006).

A strain of Klebsiella oxytoca was also able to utilize cyanide (Kao et al. 2003; Chen et al. 2008), tetracyanonickelate (Chen et al. 2009), and some nitriles (Kao et al. 2006; Chen et al. 2010). The key enzyme of the biodegradation of cyanide was postulated to be nitrogenase (Kao et al. 2003) but this enzyme was not detected among the proteins whose production was enhanced in the presence of cyanide (Tang et al. 2010). Recently, however, a cyanide-hydrolyzing enzyme was obtained from a strain of Klebsiella sp. grown on cyanide and used to construct a cyanide sensor (Mak et al. 2005a; see below). The properties of the enzyme are unclear, as it was only partially purified and its amino acid (aa) sequence was not determined.

Catalytic properties and structure-activity relationships

Substrate specificity and reaction products

The purified CHTs generally exhibited high specific activities (102–103 U mg−1) for cyanide (Jandhyala et al. 2005; Rinágelová et al. 2014). Their V max values achieved up to 6.8.103 U mg−1 of protein in A. niger. However, their K m values were also high (typically ca. 100 mM). The V max and K m values of the CynDs were significantly lower, i.e., 88–100 U mg−1 of protein and 1.7–7.3 mM, respectively (Table 1).

A number of CHTs were found to transform nitriles (Table 1). In the CHTs from Fusarium lateritium (Nolan et al. 2003) and F. oxysporum (Yanase et al. 2000), the relative activities for the saturated and unsaturated aliphatic nitriles or benzonitrile were only ca. 0.01–0.04 % compared to cyanide. However, the nitrilase activities examined with fumaronitrile and 2-cyanopyridine (2-CP) as the substrates of CHTs from A. niger (Rinágelová et al. 2014), P. chrysogenum (Kaplan et al. 2013), and B. fuckeliana and P. teres (Veselá et al. 2015) were higher (ca. 0.8–3.7 % compared to cyanide). In the CHT from A. niger, the V max and K m values for fumaronitrile and 2-CP as substrates have been found to be one to two orders of magnitude lower than that for HCN (Table 1). Therefore, 2-CP was used as the substrate in a CHT assay (Rinágelová et al. 2014). The nitriles examined as potential substrates of CynDs were not transformed by these enzymes except for cyanoacetic acid, which was hydrolyzed by CynD in P. stutzeri (Table 1).

In some nitrilases, vice versa, the ability to accept HCN as substrate was demonstrated. These were, e.g., some fungal arylacetonitrilases which transformed HCN into formamide with ≤2.5 % relative activities compared to phenylacetonitrile (Veselá et al. 2013; Kaplan et al. 2013).

The reaction product of cyanide depends both on the enzyme and the substrate (Table 1). The product of the CHT-catalyzed conversion of HCN is formamide. However, the CHTs from A. niger, P. teres, or B. fuckeliana gave at least partly acids from their nitrile substrates (Rinágelová et al. 2014; Veselá et al. 2015). In contrast, amides were found to be the products of the CHT from F. oxysporum (Yanase et al. 2000).

Properties of enzyme mutants

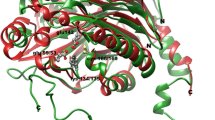

Some variants of CHTs and CynDs were prepared in order to study the structure-activity relationships in these enzymes, especially the role of the C-terminal part. According to CynD and nitrilase models, this part is involved in the interactions between the subunits. These interactions seem to be essential for their correct assembly and, hence, for enzyme activity (Sewell et al. 2005; Thuku et al. 2009). The activity was actually decreased or abolished by deletions in this part, depending on the extent of the deletion and the enzyme (Table 2).

Other structural motifs which are likely to participate in the interactions between the subunits are two insertions typical for nitrilases and cyanide (di)hydratases. One of these insertions (15 aa residues) was deleted in the CynDs from P. stutzeri and B. pumilus, and its impact on the enzyme activity was confirmed (Table 2). The residues which may participate in the formation of salt bridges (Y201 and A204 in B. subtilis, Y200 and C203 in P. stutzeri) were also found to be important for enzyme activity (Sewell et al. 2005).

In the N-terminal part of the CHT from F. lateritium, residues T12 and S13 were found to be important for the enzyme function, as the corresponding point mutations led to the loss of or a decrease in enzyme activity (Table 2). The impact of a further five conserved residues was examined in a similar way, and negative effects on activity were generally observed (Table 2). Directed evolution combined with site-directed mutagenesis proved to be an efficient way to extend the pH operating range of CynD. The wild-type enzyme exhibited the optimum activity at pH 8 and was not able to hydrolyze HCN at pH higher than 9. However, cyanide wastes should be maintained at alkaline pH to prevent HCN release. Therefore, the CynD from B. pumilus was engineered for an increased activity under these conditions (pH 9–10), and several mutants were shown to meet this requirement (Table 2). At the same time, the improved variants were more thermostable than the wild-type enzyme (Wang et al. 2012).

Applications

Bioremediation of wastewaters

Whole cells or crude, purified, or immobilized enzymes have been examined as tools for cyanide biodegradation at the laboratory scale (Table 3). A CynD enzyme preparation with industrial potential was introduced by Novo-Nordisk. This catalyst (Cyanidase®) consisted of whole cells of A. denitrificans cross-linked with glutaraldehyde (Ingvorsen et al. 1992). Due to its high affinity for cyanide, it was able to reduce high cyanide concentrations (up to 26,000 mg L−1) to trace levels in buffers at pH 7–7.6.

The CHT preparation “Cyclear” (Imperial Chemical Industries, England) consisted of the dried mycelium of F. lateritium (Cluness et al. 1993). The product exhibited a long half-life of 100–200 days but its disadvantage was its sensitivity to heavy metals (Basheer et al. 1992).

Recently, several heterologously produced CHTs and CynDs were examined as catalysts (Jandhyala et al. 2005; Basile et al. 2008; Rinágelová et al. 2014). A whole-cell catalyst consisting of E. coli producing the CHT from A. niger was also used and examined in a continuous membrane reactor (Rinágelová et al. 2014). This reactor could be operated for at least 3 days with no decrease in the efficiency of cyanide removal, which was almost complete. Formamide was detected as the only product (Rinágelová et al. 2014).

To decrease the toxicity of the effluent further, formamide may be converted into formic acid using an amidase (Campos et al. 2006). In this experiment, the cyanide-converting catalyst was whole cells of F. oxysporum immobilized in calcium alginate. The product of this catalyst, formamide, was hydrolyzed by whole cells of Methylobacterium sp. immobilized in the same way. The system consisted either of a single reactor containing both catalysts or of a cascade of two connected reactors (Fig. 2).

Two-stage transformation of cyanide into formate and ammonia (Campos et al. 2006)

The whole cells of A. denitrificans were effective at treating zinc electroplating baths or wastewater from marzipan production, in which cyanide concentrations (62 and 95 mg L−1, respectively) were decreased to trace levels (Ingvorsen et al. 1992). The high content of cyanide in some Cu- and Ag-plating baths (ca. 1 M, 26,000 mg L−1 of cyanide; Basile et al. 2008) required the samples to be diluted tenfold before adding the CHTs. Four different purified CHTs were examined for this purpose and the one from N. crassa exhibited the highest effectiveness. For instance, it removed ca. 90 % of the cyanide content (initial concentration 2600 mg L−1) from the Ag-plating bath within 1 h. In the presence of Cu residues, the degradation of cyanide was less effective (maximum ca. 70 %).

The CHT from A. niger was also examined, as a crude enzyme, for its ability to remove cyanide from coke plant wastewaters. The enzyme was found to be only slightly deactivated by typical components of these wastewaters (phenol, sulfide, ammonium, thiocyanate). Thus, the elimination of cyanide in a wastewater sample spiked with up to 520 mg of cyanide per liter was almost complete (Chmátal et al. 2013).

Biosensors

The general disadvantages of many chemical and physicochemical methods developed for cyanide detection is their high costs, time consumption, use of toxic chemicals, numerous interferences, or complex pre-treatment of the samples (Mak et al. 2005b, Ma and Dasgupta 2010). As a result, a great deal of attention has been paid to biological methods which, potentially, may be a more convenient alternative. Some of them were based on the inhibition of the enzyme activity or cell respiration by cyanide (Mak et al. 2005b). However, these methods also exhibited some disadvantages such as the need for regular enzyme replacement or the effect of readily utilizable compounds on the respiration of the cells (Mak et al. 2005b).

Using biosensors based on the enzymatic degradation of cyanide by, e.g., rhodanese (Mak et al. 2005a, b) or CynD (Mak et al. 2005a; Fig. 3), should eliminate these problems. CynD immobilized on NHS-Sepharose™ was first used in combination with an ammonia electrode (Keusgen et al. 2004; Turek et al. 2007). In order to reduce the biosensor size, the ammonia electrode was replaced with a pH-sensitive electrolyte/insulator/semiconductor (EIS) layer made of Al/p-Si/SiO2/Si3N4 (Keusgen et al. 2004). The pH-sensitive Si3N4 layer was used to detect the medium acidification caused by the conversion of cyanide (Ketterer and Keusgen 2010).

Another biosensor was based on the cascade reaction catalyzed by three enzymes—CynD, formate dehydrogenase (FDH) and salicylate hydroxylase (SHL). Cyanide was hydrolyzed into formate which was utilized by FDH to form CO2, while NAD was reduced to NADH. SHL recycled NADH, while forming catechol and CO2 from salicylate and oxygen. Finally, a Clark electrode was used to record the consumption of oxygen (Mak et al. 2005a).

Alternatively, CynD and a commercial FDH were combined with an amperometric sensor in a flow injection analysis (Ketterer and Keusgen 2010). Here, NADH produced in the reaction catalyzed by FDH was detected by amperometry. The enzymes immobilized in cartridges were integrated into a flow-through apparatus. This sensor exhibited a high long-term stability and was suitable for the analysis of complex samples such as the plant extracts. A strong interference of the sensor with formate (reaction product) can be expected. Of some other potential interferences, only that with thiocyanate (0.1–0.5 mM) was confirmed, whereas sulfide or nitriles did not affect the results at the same concentrations.

Conclusions and recommendations for future work

A number of cyanide-converting enzymes from bacteria and fungi were demonstrated to be applicable to cyanide biodegradation or detection. Compared to the chemical processes and the use of active sludge or other microbial cultures, this approach is the least explored but most promising because it uses simple, stable, and environmental-friendly systems with predictable responses to changing reaction conditions. Enzymatic processes do not require any additives; the reaction products are less toxic and can be further degraded by enzymes. The processes may be cost effective provided the price of the enzymes is acceptable. To this end, overproduction of the enzymes in heterologous hosts and their repeated use will probably be essential. The spectrum of characterized CHTs has been recently broadened which should enable suitable enzymes to be selected for each specific application. Database mining and the construction of artificial variants may be useful to obtain catalysts with better operational properties. It will be necessary to investigate how the enzyme works in wastewaters, primarily to analyze the effects of potential enzyme inhibitors in these samples. Examining this factor will also be important for the development of cyanide biosensors.

References

Basile LJ, Willson RC, Sewell BT, Benedik MJ (2008) Genome mining of cyanide degrading nitrilases from filamentous fungi. Appl Microbiol Biotechnol 80:427–435. doi:10.1007/s00253-008-1559-2

Basheer S, Kut OM, Prenosil JE, Bourne JR (1992) Kinetics of enzymatic degradation of cyanide. Biotechnol Bioeng 39:629–634. doi:10.1002/bit.260390607

Baxter J, Cummings SP (2006) The current and future applications of microorganisms in the bioremediation of cyanide contamination. Antonie Van Leeuwenhoek 90:1–17. doi:10.1007/s10482-006-9057-y

Cabuk A, Unal AT, Kolankaya N (2006) Biodegradation of cyanide by a white rot fungus, Trametes versicolor. Biotechnol Lett 28:1313–1317. doi:10.1007/s10529-006-9090-y

Campos MG, Pereira P, Roseiro JC (2006) Packed-bed reactor for the integrated biodegradation of cyanide and formamide by immobilised Fusarium oxysporum CCMI 876 and Methylobacterium sp. RXM CCMI 908. Enzym Microb Technol 38:848–854. doi:10.1016/j.enzmictec.2005.08.008

Chen CY, Kao CM, Chen SC (2008) Application of Klebsiella oxytoca immobilized cells on the treatment of cyanide wastewater. Chemosphere 71:133–139. doi:10.1016/j.chemosphere.2007.10.058

Chen CY, Kao CM, Chen SC, Chen TY (2009) Biodegradation of tetracyanonickelate by Klebsiella oxytoca under anaerobic conditions. Desalination 249:1212–1216. doi:10.1016/j.desal.2009.06.036

Chen CY, Chen SC, Fingas M, Kao CM (2010) Biodegradation of propionitrile by Klebsiella oxytoca immobilized in alginate and cellulose triacetate gel. J Hazard Chem 177:856–863. doi:10.1016/j.jhazmat.2009.12.112

Cluness MJ, Turner PD, Clements E, Brown DT, O’Reilly C (1993) Purification and properties of cyanide hydratase from Fusarium lateritium and analysis of the corresponding chy1 gene. J Gen Microbiol 139:1807–1815

Chmátal M, Rinágelová A, Veselá AB, Kaplan O, Martínková L (2013) A recombinant cyanide hydratase from Aspergillus niger K10 and its use for the degradation of cyanide from synthetic wastewaters. International Conference on Chemical Technology (Mikulov, Czech Republic, 8.-10.4.2013), Book of Abstracts, p. 14

Dash RR, Gaur A, Balomajumder C (2009) Cyanide in industrial wastewaters and its removal: a review on biotreatment. J Hazard Mat 163:1–11. doi:10.1016/j.jhazmat.2008.06.051

Ebbs S (2004) Biological degradation of cyanide compounds. Curr Opin Biotechnol 15:231–236. doi:10.1016/j.copbio.2004.03.006

Gupta N, Balomajumder C, Agarwal VK (2010) Enzymatic mechanism and biochemistry for cyanide degradation: a review. J Hazard Mater 176:1–13. doi:10.1016/j.jhazmat.2009.11.038

Ingvorsen K, Godtfredsen SE, Højer-Pedersen B, Novo-Nordisk (1992) Microbial cyanide converting enzymes, their production and use. US Patent 5:116,744

Jandhyala DM, Willson RC, Sewell BT, Benedik MJ (2005) Comparison of cyanide-degrading nitrilases. Appl Microbiol Biotechnol 68:327–335. doi:10.1007/s00253-005-1903-8

Kaplan O, Veselá AB, Petříčková A, Pasquarelli F, Pičmanová M, Rinágelová A, Bhalla TC, Pátek M, Martínková L (2013) A comparative study of nitrilases identified by genome mining. Mol Biotechnol 54:996–1003. doi:10.1007/s12033-013-9656-6

Kao CM, Liu JK, Lou HR, Lin CS, Chen SC (2003) Biotransformation of cyanide to methane and ammonia by Klebsiella oxytoca. Chemosphere 50:1055–1061. Doi: 10.1016/S0045-6535(02)00624-0

Kao CM, Chen KF, Liu JK, Chou SM, Chen SC (2006) Enzymatic degradation of nitriles by Klebsiella oxytoca. Appl Microbiol Biotechnol 71:228–233. doi:10.1007/s00253-005-0129-0

Ketterer L, Keusgen M (2010) Amperometric sensor for cyanide utilizing cyanidase and formate dehydrogenase. Anal Chim Acta 673:54–59. doi:10.1016/j.aca.2010.04.058

Keusgen M, Kloock JP, Knobbe D-T, Jünger M, Krest I, Goldbach M, Klein W, Schöning MJ (2004) Direct determination of cyanides by potentiometric biosensors. Sensor Actuat B—Chem 103:380–385. doi:10.1016/j.snb.2004.04.067

Ma J, Dasgupta PK (2010) Recent developments in cyanide detection: a review. Anal Chim Acta 673:117–125. doi:10.1016/j.aca.2010.05.042

Mak KKW, Law AWC, Tokuda S, Yanase H, Renneberg R (2005a) Application of cyanide hydrolase from Klebsiella sp. in a biosensor system for the detection of low-level cyanide. Appl Microbiol Biotechnol 67:631–636

Mak KKW, Yanase H, Renneberg R (2005b) Cyanide fishing and cyanide detection in coral reef fish using chemical tests and biosensors. Biosens Bioelectron 20:2581–2593. doi:10.1016/j.bios.2004.09.015

Martínková L, Vejvoda V, Kaplan O, Kubáč D, Malandra A, Cantarella M, Bezouška K, Křen V (2009) Fungal nitrilases as biocatalysts: recent developments. Biotechnol Adv 27:661–670. doi:10.1016/j.biotechadv.2009.04.027

Nolan LM, Harnedy PA, Turner P, Hearne AB, O’Reilly C (2003) The cyanide hydratase enzyme of Fusarium lateritium also has nitrilase activity. FEMS Microbiol Lett 221:161–165. doi:10.1016/S0378-1097(03)00170-8

O’Reilly C, Turner PD (2003) The nitrilase family of CN hydrolysing enzymes—a comparative study. J Appl Microbiol 95:1161–1174. doi:10.1046/j.1365-2672.2003.02123.x

Özel YK, Gedikli S, Aytar P, Ünal A, Yamac M, Cabuk A, Kolankaya N (2010) New fungal biomasses for cyanide biodegradation. J Biosci Bioeng 110:431–435. doi:10.1016/j.jbiosc.2010.04.011

Rinágelová A, Kaplan O, Veselá AB, Chmátal M, Křenková A, Plíhal O, Pasquarelli F, Cantarella M, Martínková L (2014) Cyanide hydratase from Aspergillus niger K10: overproduction in Escherichia coli, purification, characterization and use in continuous cyanide degradation. Proc Biochem 49:445–450. doi:10.1016/j.procbio.2013.12.008

Sewell BT, Thuku RN, Zhang X, Benedik MJ (2005) Oligomeric structure of nitrilases. Effect of mutating interfacial residues on activity. Ann N Y Acad Sci 1056:153–159. doi:10.1196/annals.1352.025

Tang P, Hseu YC, Chou HH, Huang, KY, Chen SC (2010) Proteomic analysis of the effect of cyanide on Klebsiella oxytoca. Curr Microbiol 60:224-228. doi:10.1007/s00284-009-9529-1

Thuku RN, Brady D, Benedik MJ, Sewell BT (2009) Microbial nitrilases: versatile, spiral forming, industrial enzymes. J Appl Microbiol 106:703–727. doi:10.1111/j.1365-2672.2008.03941.x

Turek M, Ketterer L, Classen M, Berndt HK, Elbers G, Kruger P, Keusgen M, Schoning MJ (2007) Development and electrochemical investigations of an EIS (electrolyte-insulator-semiconductor) based biosensor for cyanide detection. Sensors 7:1415–1426. doi:10.3390/s7081415

Veselá AB, Petříčková A, Weyrauch P, Martínková L (2013) Heterologous expression, purification and characterization of arylacetonitrilases from Nectria haematococca and Arthroderma benhamiae. Biocat Biotrans 31:49–56. doi:10.3109/10242422.2012.758117

Veselá AB, Rucká L, Kaplan O, Pelantová H, Nešvera J, Pátek M, Martínková L (2015) Bringing nitrilase sequences from databases to life: the search for novel substrate specificities with a focus on dinitriles. Appl Microbiol Biotechnol, submitted

Wang L, Watermeyer JM, Mulelu AE, Sewell BT, Benedik MJ (2012) Engineering pH-tolerant mutants of a cyanide dihydratase. Appl Microbiol Biotechnol 94:131–140. doi:10.1007/s00253-011-3620-9

Yanase H, Sakamoto A, Okamoto K, Kita K, Sato Y (2000) Degradation of the metal-cyano complex tetracyanonickelate (II) by Fusarium oxysporum N-10. Appl Microbiol Biotechnol 53:328–334

Acknowledgements

This study was funded by the Technology Agency of the Czech Republic (grant no. TA01021368), the Czech Science Foundation (grant no. P504/11/0394), and the Institute of Microbiology of the Academy of Sciences of the Czech Republic, v.v.i. (grant no. RVO61388971).

Conflict of interest

The authors declare that they have co competing interest.

Ethical statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martínková, L., Veselá, A.B., Rinágelová, A. et al. Cyanide hydratases and cyanide dihydratases: emerging tools in the biodegradation and biodetection of cyanide. Appl Microbiol Biotechnol 99, 8875–8882 (2015). https://doi.org/10.1007/s00253-015-6899-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-6899-0