Abstract

A variety of fungal species are known to degrade cyanide through the action of cyanide hydratases, a specialized subset of nitrilases which hydrolyze cyanide to formamide. In this paper, we report on two previously unknown and uncharacterized cyanide hydratases from Neurospora crassa and Aspergillus nidulans. Recombinant forms of four cyanide hydratases from N. crassa, A. nidulans, Gibberella zeae, and Gloeocercospora sorghi were prepared after their genes were cloned with N-terminal hexahistidine purification tags, expressed in Escherichia coli, and purified using immobilized metal affinity chromatography. These enzymes were compared according to their relative specific activity, pH activity profiles, thermal stability, and ability to remediate cyanide contaminated waste water from silver and copper electroplating baths. Although all four were similar, the N. crassa cyanide hydratase (CHT) has the greatest thermal stability and widest pH range of >50% activity. N. crassa also demonstrated the highest rate of cyanide degradation in the presence of both heavy metals. The CHT of A. nidulans has the highest reaction rate of the four fungal nitrilases evaluated in this work. These data will help determine optimization procedures for the possible use of these enzymes in the bioremediation of cyanide-containing waste. Similar to known plant pathogenic fungi, both N. crassa and A. nidulans were induced to express CHT by growth in the presence of KCN.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cyanide waste is becoming an increasingly prevalent problem in today’s society. An estimated 18 billion liters of cyanide-containing waste are generated annually in the USA (Baxter and Cummings 2006). With such uses as gold and silver mining, electroplating, steel manufacturing, polymer synthesis, pharmaceutical production, and other specialized applications including dyes and agricultural products, it is difficult to avoid its use. Remediation of cyanide-containing waste is necessary due to the ability of cyanide to poison the respiratory system by inhibiting the final transport of electrons from cytochrome C oxidase to oxygen. Currently, the most widely used methods of detoxification are chemical oxidation of cyanide to less toxic compounds or stabilization using reagents and cement in soil to reduce permeability (Baxter and Cummings 2006).

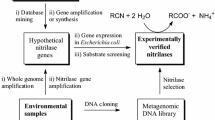

A variety of biological approaches to cyanide waste remediation have been proposed over many decades (Akcil and Mudder 2003). There are enzymes that convert cyanide to non-toxic products, but special conditions are required for this conversion. Nitrogenases, found in nitrogen-fixing prokaryotes, require strictly anaerobic conditions (Hardy and Knight 1967; Li et al. 1982). Rhodanese, an enzyme found in all animals, some plants, fungi, and prokaryotes, requires thiosulfate to function (Westley 1987). Nitrilases do not have these drawbacks; they convert cyanide using a simple hydrolytic pathway which involves nucleophilic attack by a conserved cysteine (Kobayashi et al. 1998). This cysteine, along with a lysine and a glutamic acid, is conserved throughout the nitrilase superfamily and forms the catalytic triad necessary for catalytic activity (Brenner 2002; Kobayashi et al. 1998; Pace and Brenner 2001). Banerjee et al. (2002) observed that there are a number of reactions catalyzed by nitrile-metabolizing enzymes that are either already used in large scale or have the potential to become so. This has been demonstrated by the successful commercial use of such organisms as Pseudomonas chlororaphis B23 (Banerjee et al. 2002) and Rhodococcus rhodochrous J1 to convert another nitrile, 3-cyanopyridine, to nicotinic acid (Mathew et al. 1988).

Microbial nitrilases are a family of enzymes that convert nitriles, such as cyanide, to less harmful compounds through a hydration reaction (Kobayashi and Shimizu 1994). Cyanide hydratases (CHT), which are found in numerous plant pathogenic fungi such as Fusarium solani (Barclay et al. 1998a) and Gloeocercospora sorghi (Wang et al. 1992) convert cyanide to formamide (Cluness et al. 1993). Other cyanide hydratases are found in Fusarium lateritium (Cluness et al. 1993; Nolan et al. 2003) and Leptosphaeria maculans (Sexton and Howlett 2000). The related cyanide dihydratases convert cyanide to formate and ammonia (Watanabe et al. 1998a) and are found in Alcaligenes xylosoxidans subsp. dentrificans (Ingvorsen et al. 1991), Bacillus pumilus (Meyers et al. 1993), and Pseudomonas stutzeri AK61 (Watanabe et al. 1998b). It has been proposed that subtle differences in the active site dictate the leaving group and hence distinguish the cyanide dihydratases from the hydratases (Jandhyala et al. 2005; Wang et al. 1992; Wang and VanEtten 1992). Both groups of enzymes have many qualities that make them promising candidates for remediation. They have stability over long periods, require no co-factors, are readily expressed at high levels, and can function as purified enzyme, crude extracts, or within cells (Jandhyala et al. 2005).

The many uses of cyanide produce a wide variety of waste products with varying qualities, such as pH and concentration of other contaminants; therefore, having nitrilases better suited for these conditions would be of value. Genome searching revealed that a variety of non-plant pathogenic fungi, including human pathogens such as Aspergillus fumigatus, carry related genes. We have cloned the genes from lab strains of the saprophytic fungi Aspergillus nidulans and Neurospora crassa as well as a plant pathogenic fungi Gibberella zeae and compared them to the previously characterized nitrilase from G. sorghi (Jandhyala et al. 2005; Wang et al. 1992; Wang and VanEtten 1992). This work compares these four cyanide hydratases with respect to their relative stabilities, rate of cyanide degradation, and ability to work under pH conditions expected for cyanide containing waste.

Materials and methods

Bacterial strains and plasmids

The plasmids and strains used are described in Table 1. The N. crassa knockouts were provided by the Fungal Genetics Stock Center as part of their comprehensive gene knockout project (McCluskey 2003).

Culture media and reagents

Escherichia coli strains were grown in L-broth containing 0.05% glucose and 0.5% glycerol (0.2% lactose added to induce protein expression), which is essentially the autoinduction media of Studier (2005). Antibiotics were added to concentrations of 100 μg ml−1 ampicillin, 25 μg ml−1 chloramphenicol, or 25 μg ml−1 kanamycin for selection in E. coli strains. N. crassa strains were grown in 1X Vogel’s medium (Vogel 1956), whereas A. nidulans was grown in complete medium (Kaminskyj 2001).

DNA manipulations

The cyanide hydratase gene was amplified from A. nidulans and G. zeae genomic DNA and complementary DNA (cDNA) from N. crassa using PfuTurbo® Hotstart polymerase chain reaction (PCR) Master Mix (Stratagene, La Jolla, CA, USA). The primers used introduced an NdeI site at the ATG codon and a unique site in the downstream primer (beyond the stop codon) for cloning into p2160. These clones were sequenced and later moved by subcloning into pET26b to produce untagged protein and pET28a to generate N-terminal His-tagged proteins.

Removal of introns was necessary for the genomic A. nidulans and G. zeae clones. The A. nidulans gene contained three introns and G. zeae contained two. The QuikChange® site-directed mutagenesis kit (Stratagene) was used to create deletions of the intron segments, producing the predicted proteins shown in Fig. 1. All constructs were transformed into MB3436 for routine cloning, and the E. coli B strain BL21(DE3)pLysS was used for expression from the T7 promoter.

CHT multiple sequence alignment. Alignment of our sequences of the four fungal cyanide-degrading nitrilases. Identical residues noted by line, similar amino acids by colon, and less similar by a dot. Non-conservative charges are left blank below the alignment. The catalytic triad residues are marked by a gray box

Expression and purification of CHT from E. coli

Protein production from strains MB3487, MB3643, MB3644, and MB3653 was achieved in 50 ml cultures of autoinduction medium containing 25 μg ml−1 kanamycin and grown overnight at 30°C. The cells were collected by centrifugation, and the cell pellets were resuspended in 20 ml of 20 mM sodium phosphate (pH 7.4), 100 mM NaCl, 12.5 mM imidazole (pH 7.4), and 1 mg ml−1 lysozyme. After incubation on ice for 15 min, cells were lysed by freezing at −80°C and thawing for five cycles. Viscous DNA was removed by the addition of a crude preparation of Serratia nuclease (Miller et al. 1991) before centrifugation at 3,750 rpm for 15 min. The supernatant was then clarified with a 0.45-μm filter.

The hexahistidine-tagged cyanide hydratase enzymes were purified from crude cell lysates by immobilized metal affinity chromatography using a 1-ml precharged HisTrap™ Ni Sepharaose™ high performance column (Amersham Biosciences, Piscataway, NJ, USA). The column was washed with five column volumes of water and ten column volumes of buffer B (25 mM imidazole, 1 mM NaCl, and 20 mM sodium phosphate) before passing the filtered lysate through the column. The column was then washed with ten column volumes of buffer B with 100 mM imidazole. Enzyme was eluted using ten column volumes of buffer B with 500 mM imidazole. Peak fractions having cyanide-degrading activity were pooled and stored at 4°C.

pH activity profiles

The pH profiles for the purified cyanide hydratases of G. sorghi, G. zeae, N. crassa, and A. nidulans were determined using sodium phosphate buffers between pH 4.5 to pH 11. A 1 M stock solution of KCN was diluted in 100 mM 3-(N-morpholino)propanesulfonic acid (MOPS), pH 7.6, to yield a final KCN concentration of 100 mM. Reactions were run in duplicate at room temperature in a final volume of 300 μl consisting of 100 mM buffer, enzyme diluted in the same pH buffer, and 10 mM KCN. Enzyme concentrations used for rate measurements were: 1.8 μg ml−1 for N. crassa, 3.5 μg ml−1 for G. sorghi (tenfold more for pH 11), 2.2 μg ml−1 for A. nidulans (tenfold more for pH 10.5 and 11), and 6.9 μg ml−1 for G. zeae (tenfold more for pH 4.5 and 11). Reactions were run for up to 61 min with the baseline sample taken at 1 min and at subsequent time points where a measurable amount of cyanide still remained. The picric acid method for determining cyanide concentration was used to determine the rate of degradation (Fisher and Brown 1952). To each 0.1-ml sample, 0.2 ml of 0.5% picric acid in 0.25 M sodium carbonate was added and heated to 100°C for 6 min. The absorbance at 520 nm was measured to determine the change in OD per minute between the 1-min baseline and the subsequent time point. Controls containing cyanide without enzyme were run at each pH.

Determination of thermal stability

To determine their thermal stability, each enzyme was incubated at temperatures of 27°C, 37°C, 43°C, and 50°C, and samples were taken at time points ranging from 30 min to 48 h. The remaining activity of each enzyme sample was then measured at room temperature in 0.1 M MOPS, pH 7.4, with 10 mM KCN. All assays were performed in duplicate. Enzyme concentrations initially were the same as for the pH profiles, but were increased as needed due to loss of activity upon prolonged incubation at the higher temperatures. Assays were otherwise performed as described for the pH profiles.

Enzyme parameters

Enzyme was diluted in 1 ml 0.1 M MOPS, pH 7.6, and 1 M KCN, pH 7.6, was added to final concentrations of 20, 40, 60, 80, 100, 120, and 140 mM. Upon the addition of cyanide, each reaction was divided into three tubes of 300 μl each. Reactions were run for 61 min at room temperature with samples being taken at 1, 6, 11, 31, and 61 min. Enzyme concentrations used for rate analysis were 0.61 μg ml−1 for N. crassa, 1.36 μg ml−1 for G. sorghi, 0.98 μg ml−1 for A. nidulans, and 1.20 μg ml−1 for G. zeae. The picric acid assay loses linearity above ~12 mM; therefore, all cyanide concentrations above 10 mM were diluted 1:10 before adding picric acid and 120 and 140 mM samples were diluted 1:20. After boiling for 6 min, 700 μl of water was added to the reaction. The reactions were further diluted twofold into 1-ml cuvettes, and the OD520 was measured. The change in OD was calculated using the same method as with the pH profiles.

Cyanide induction of fungal cultures

Overnight A. nidulans cultures were prepared in 2 ml of complete medium (Kaminskyj 2001) inoculated 1:100 with A. nidulans spores. After growing overnight, the culture was diluted fivefold at a final volume of 1 ml in two separate tubes. To one tube, KCN was added to 0.1 mM for induction. The cultures were grown overnight.

N. crassa cultures of the wild-type (FGSC #2489) and a cht knockout strain (FGSC #11825) of the same mating type, provided by the Fungal Genetics Stock Center, were similarly grown overnight at 30°C in 1X Vogel’s + 1.5% glucose. The cultures were harvested, washed, and each resuspended in two tubes 1X Vogel’s + 1.5% glucose and two tubes 1X Vogel’s + 1.5% glucose containing no nitrogen source. KCN (2 mM) was added to one tube of each set. After growing for 3 h at 30°C, the cultures were washed and resuspended in 4 ml 0.1 M MOPS.

Both A. nidulans and N. crassa were harvested, washed, and sonicated. Each lysate was assayed with 5 mM KCN.

Enzyme activity on industrial water samples

Water samples were obtained from an electroplating plant in Houston, Texas; these are samples from silver and copper electroplating baths. They have cyanide concentrations of approximately 1 M and are at a pH in excess of 11. They also contain the residual silver or copper normally present in such electroplating bathwater. Each water sample was diluted to ~100 mM in 1 M MOPS. This also lowered the pH to ~8 so that pH would have no influence on activity. For use as a control, laboratory stocks of KCN were also diluted to 100 mM in 1 M MOPS. For use as a measurement of total cyanide per sample, 100 mM copper, silver, and KCN samples were set up with no enzyme present. For each cyanide sample, enzyme was added and incubated at room temperature for 24 h. Total volume for each reaction was 100 μl. Enzyme concentrations used were 7.19 μg ml−1 for N. crassa, 7.01 μg ml−1 for G. sorghi, 8.86 μg ml−1 for A. nidulans, and 13.71 μg ml−1 for G. zeae for the KCN and silver assays. Tenfold more enzyme was used for the copper assays. After 24 h, the picric acid endpoint method was used and OD520 measured to determine the percent cyanide degraded.

Results

Cloning for expression in E. coli

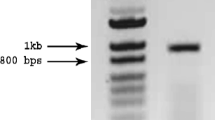

The cht gene of N. crassa, A. nidulans, and G. zeae were PCR-amplified from a cDNA library of N. crassa or the genomic DNA of A. nidulans and G. zeae. The resulting products were then subcloned into p2160 and transformed into MB3436 to allow for blue-white screening. Introns were deleted from the A. nidulans and G. zeae clones by site-directed mutagenesis using the Quick-change protocol. When the introns were deleted from the A. nidulans gene to match the NCBI entry (AN8773.2) nitrilase open reading frame, no activity could be observed. Upon comparison with other nitrilases, it was obviously larger, and the intron assignment was likely not to be correct. A more likely sequence was then deduced from this comparison, especially the highly homologous one from A. fumigatus. This new open reading frame, shown in Fig. 1, was active against cyanide. The DNA of each final clone was verified. The cDNA clone for G. sorghi was already in our collection (Jandhyala et al. 2005).

All four were then subcloned using the NdeI site of pET28a to create N-terminal His-tagged constructs and likewise to pET26b to generated untagged proteins. The final confirmed constructs were transformed into BL21 (DE3) pLysS. All strains expressed cyanide-degrading activity shown by measuring loss of cyanide. High level expression of nitrilase was easily visualized using sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE). Expression levels and enzyme activity was comparable from both the His-tagged and untagged versions of these enzymes. Purified enzymes were therefore prepared using the His-tagged proteins.

Purification of CHT enzymes

CHT was purified from MB3487, MB3643, MB3644, and MB3653 using immobilized metal affinity chromatography as described in “Materials and methods”, and SDS-PAGE was used to analyze the purity and relative concentration of the protein preparations. Protein preparations were stored at 4°C because storage at −80°C resulted in precipitation and loss of activity. The enzymes were stable for many months at 4°C.

pH activity profile of CHT enzymes

The pH activity profiles of purified G. sorghi, G. zeae, N. crassa, and A. nidulans CHT were measured at pH’s ranging from 4.5 to 11 (Fig. 2). All of these displayed maximum activity between pH 6 and 7, with an abrupt decrease in activity above pH 10 and below their individual maxima. CHT from G. sorghi and G. zeae displayed greater than 50% of their maximal activity throughout the range of pH 6–8.5, the narrowest range of activity. N. crassa CHT had greater than 50% maximal activity over the widest range, which was between pH 5 and 9. A. nidulans CHT also had a relatively wide range of activity, but at all points, the activity was generally lower than N. crassa except at pH values below 5.5.

Thermal stability

To determine the stability of each enzyme, they were incubated at 27°C, 37°C, 43°C, and 50°C and the activity measured at time points ranging between 0 and 48 h (Fig. 3). All four enzymes retained greater than 70% of their relative activity after 48 h at 27°C; however, at 50°C, their activity dropped below 5% by 48 h. When comparing activity at 37°C and 43°C, the CHT from N. crassa was most stable with no loss of activity after 48 h at 37°C and about 40% of activity remaining after 48 h at 43°C. G. zeae CHT showed an initial increase in activity at lower temperatures, but the subsequent stability was similar to N. crassa CHT. Both of these enzymes showed a gradual decrease in activity at 50°C. The CHT of A. nidulans and G. sorghi quickly lost activity at the two highest temperatures, and 50% of activity was lost after 48 h at 37°C.

Thermal stabilities of CHT. AG. sorghi, BN. crassa, CG. zeae, and DA. nidulans. Shown is the activity remaining after incubation at the noted temperatures for periods between 0 and 48 h. Enzyme samples taken at each time point were assayed using 10 mM KCN. The picric acid endpoint method was used to determine the rate of degradation. Each point is calculated as the percentage of the 0 time point which is set as 100%. The average of two trials is plotted, and the error bars represent the value range of these experiments

Enzyme parameters

We observed that the rate of the reaction decreases at high substrate concentrations in the case of all the enzymes, which is indicative of substrate inhibition. The reaction rates of the purified recombinant CHT enzymes are listed in Table 2. When comparing rates at a substrate concentration of 20 mM KCN, the A. nidulans and N. crassa CHT had the highest rates at 0.22 and 0.21 ΔOD min−1 μg−1 enzyme, respectively. The G. sorghi CHT had the lowest activity of the group by over threefold. The reaction rate of the G. zeae enzyme did not show a significantly lower rate when compared to A. nidulans and N. crassa. With the exception of G. sorghi, all of the enzymes reached their maximal rate around 60 mM KCN and had relatively similar maximum rates, with N. crassa having the highest rate. G. sorghi did not reach maximum activity until 80 mM KCN and had a much lower maximum rate than the other three enzymes.

Regulation of cyanide hydratase expression

Cultures of N. crassa wild-type strains of both mating types (FGSC #2489) as well as a knockout mutant at the cht gene locus, generated by the Fungal Genetics Stock Center (FGSC #11825), were grown in minimal medium as described. The effect of cyanide on CHT expression was tested by adding 2 mM KCN to one set of cultures. The effect of exogenous ammonia was also tested with N. crassa because the breakdown of cyanide leads to the release of ammonia. Shown in Table 3 is the change in OD per minute that was calculated from the average of three reactions. It appears that the presence or absence of nitrogen had no effect on induction of activity, but the presence of cyanide during growth clearly caused induction of cht gene expression. The cht knockout strains had no detectable activity under any conditions (not shown).

A. nidulans grown with or without KCN showed similar KCN induction of nitrilase expression (not shown), but these assays were not analyzed quantitatively.

Activity on electroplating bath samples

The ability of each enzyme to degrade cyanide from silver or copper electroplating bath waters was measured over a 48-h period (Fig. 4). As a control, assays were run using KCN alone (Fig. 4A). All of the cyanide was degraded from these samples by 48 h, with N. crassa showing the fastest rate of cyanide degradation. Silver plating bath samples were assayed and are plotted in Fig. 4B. These assays were run using the same enzyme concentration as the KCN control assay. A. nidulans showed the lowest level cyanide degradation with ~30% of the cyanide remaining after 48 h. The other three CHT enzymes degraded approximately 90% of the cyanide in the silver sample by 48 h, with N. crassa degrading this amount after less than 5 h.

Enzymatic treatment of electroplating bath samples. Ability of N. crassa, G. sorghi, G. zeae, and A. nidulans to degrade KCN (A) and cyanide in wastewater samples from silver (B) or copper (C) electroplating baths as described in “Materials and methods”. Shown is the percent of cyanide remaining after assaying for periods between 0 and 48 h. Each point is calculated relative to that at time point zero. C showing cyanide degraded in the presence of copper was assayed using tenfold more enzyme than A and B. Each panel shows a representative experiment

When the same amount of enzyme was used for the copper wastewater sample, very little degradation was observed (not shown). Shown in Fig. 4C is the percent cyanide degraded from the copper plating bath sample when tenfold more enzyme was added. For all four cyanide hydratases, 30% or more cyanide remained in the sample after 48 h. This could be caused by the copper forming a complex with either the cyanide or the enzyme, preventing degradation or by some other contaminant in the sample. Supplementing with additional enzyme had no significant effect. As with the other wastewater sample, the N. crassa CHT has the highest activity and degraded the most cyanide, and A. nidulans showed the least activity, with greater than 60% of the cyanide remaining after 48 h.

Discussion

The cht gene of N. crassa, A. nidulans, G. zeae, and G. sorghi was expressed in E. coli with and without an amino terminal 6-His purification tag. The tagged enzymes were purified and used for comparison with respect to their pH profiles, thermal stability, and enzyme parameters.

The pH profiles of the four recombinant fungal nitrilases (Fig. 2) showed that N. crassa had the widest range of activity (at least half-maximal activity between pH 5.2 and pH 9) and G. zeae and G. sorghi displayed the narrowest range, with at least half-maximal activity between approximately pH 6 and pH 8.5. A. nidulans displayed a relatively wide range of >50% activity relative to its maximal rate, but this was >80% at only two pH values. Jandhyala et al. (2005) showed that the CHT of G. sorghi was more tolerant of higher pH values than were the CynDs of B. pumilus and P. stutzeri, but the two CynD enzymes appear to be more tolerant of lower pH. These differences in pH tolerance are significant; applications generating cyanide wastewater are routinely conducted at alkaline pH to reduce the formation of hydrogen cyanide gas, often above pH 10.

When comparing the thermal stabilities (Fig. 3), there was a clear difference in the effect of higher temperatures on each cyanide hydratase. This is best shown by the activity remaining after 48 h at 43°C. The CHT of N. crassa and G. zeae had greater remaining activity after 48 h than did G. sorghi and A. nidulans. The high stability of these enzymes at expected operating temperatures (37°C or below) suggests that small quantities of enzyme can be used for treatment over 48 h or longer. Given there is so little loss of activity by 48 h, one might expect the enzymes to continue working well beyond that time period. This result is similar to that we found previously (Jandhyala et al. 2005).

With all these enzymes, we observed significant substrate inhibition at high concentrations of KCN. Substrate inhibition is not uncommon among the nitrilase group of enzymes (Ingvorsen et al. 1991; Pertsovich et al. 2005; Piotrowski et al. 2001). There is no evidence that this is due to allosteric effects or changes in substrate association (Jandhyala 2002; Pertsovich et al. 2005); it may be caused by blocking access to the active site by excessive substrate binding. Because of this inhibition, we were unable to compare kinetic values, but instead compared relative reaction rates. A. nidulans and N. crassa enzymes had similar reaction rates at 20 mM KCN, only slightly higher than G. zeae; however, that of G. sorghi was approximately threefold less. This was also true when comparing each enzyme’s maximum reaction rate. G. sorghi, however, had its maximal rate around 80 mM cyanide, whereas the others were around 60 mM.

When comparing the ability to degrade cyanide in industrial electroplating bath samples (Fig. 4), N. crassa performed more efficiently than the other enzymes and degraded more cyanide at a faster rate. The CHT of A. nidulans had the lowest activity relative to the others when assayed with these samples. In Jandhyala et al. (2005), we showed that other nitrilases were tolerant to many heavy metals other than mercury, not a metal used in electroplating. While the electroplating bath samples needed to be diluted and its pH adjusted closer to neutral from its original pH >11, these will not add significant costs to a treatment process, and enzymatic treatment is likely to be highly cost-competitive because it can be done on site and not require shipping of the wastewater to a treatment facility.

Other fungal nitrilases have previously been studied such as those of F. lateritium, F. solani, F. oxysporum, and L. maculans. Cyanide hydratase activity in all four of these organisms had been shown to be inducible by cyanide (Barclay et al. 1998a; Cluness et al. 1993; Sexton and Howlett 2000; Yanase et al. 2000). This work demonstrates that enzymes with similar activity and regulation are found in saprophytic strains of N. crassa and A. nidulans and not just the plant pathogenic fungi as previously thought. The amino acid sequence encoded by the cht of N. crassa is 72% and 82% identical to the sequences of G. sorghi and F. lateritium, respectively, and that of A. nidulans is the most distant of the group with about 60% identity to the other members. F. solani has been shown to degrade cyanide under acidic conditions (Barclay et al. 1998a), while the enzymes in this study are more active in the useful alkaline pH range.

Comparisons of the many fungal nitrilases will help determine the best candidate for the remediation of cyanide-containing industrial wastewater. Based on our results, the CHT from N. crassa is our most promising candidate for this purpose. It showed high activity over a wide range of pH values, stability for at least 48 h when incubated at temperatures ranging from 27°C to 43°C, and a high rate of cyanide degradation. In the near future, we hope to genetically optimize this enzyme for use in detoxification of cyanide-containing waste.

References

Akcil A, Mudder T (2003) Microbial destruction of cyanide wastes in gold mining: process review. Biotechnol Lett 25:445–450

Banerjee A, Sharma R, Banerjee UC (2002) The nitrile-degrading enzymes: current status and future prospects. Appl Microbiol Biotechnol 60:33–44

Barclay M, Tett VA, Knowles CJ (1998a) Metabolism and enzymology of cyanide/metallocyanide biodegradation by Fusarium solani under neutral and acidic conditions. Enzyme Microb Technol 23:321–330

Baxter J, Cummings SP (2006) The current and future applications of microorganism in the bioremediation of cyanide contamination. Antonie Van Leeuwenhoek 90:1–17

Brenner C (2002) Catalysis in the nitrilase superfamily. Curr Opin Struct Biol 12:775–782

Cluness MJ, Turner PD, Clements E, Brown DT, O'Reilly C (1993) Purification and properties of cyanide hydratase from Fusarium lateritium and analysis of the corresponding chy1 gene. J Gen Microbiol 139:1807–1815

Fisher FB, Brown JS (1952) Colorimetric determination of cyanide in stack gas and waste water. Analyt Chem 24:1440–1444

Hardy RW, Knight E Jr. (1967) ATP-dependent reduction of azide and HCN by N2-fixing enzymes of Azotobacter vinelandii and Clostridium pasteurianum. Biochim Biophys Acta 139:69–90

Ingvorsen K, Hojer-Pedersen B, Godtfredsen SE (1991) Novel cyanide-hydrolyzing enzyme from Alcaligenes xylosoxidans subsp. denitrificans.. Appl Environ Microbiol 57:1783–1789

Jandhyala D (2002) Cyanide degrading nitrilases for detoxification of cyanide containing waste watersBiology and Biochemistry. University of Houston, Houston, p 130

Jandhyala DM, Willson RC, Sewell BT, Benedik MJ (2005) Comparison of cyanide-degrading nitrilases. Appl Microbiol Biotechnol 68:327–335

Kaminskyj SGW (2001) Fundamentals of growth, storage, genetics, and microscopy of Aspergillus nidulans. Fungal Genet Newsl 48:25–31

Kobayashi M, Shimizu S (1994) Versatile nitrilases: nitrile-hydrolysing enzymes. FEMS Microbiol Lett 120:217–224

Kobayashi M, Goda M, Shimizu S (1998) Nitrilase catalyzes amide hydrolysis as well as nitrile hydrolysis. Biochem Biophys Res Commun 253:662–666

Li J, Burgess BK, Corbin JL (1982) Nitrogenase reactivity: cyanide as substrate and inhibitor. Biochem 21:4393–4402

Mathew CD, Nagasawa T, Kobayashi M, Yamada H (1988) Nitrilase-catalyzed production of nicotinic acid from 3-cyanopyridine in Rhodococcus rhodochrous J1. Appl Environ Microbiol 54:1030–1032

McCluskey K (2003) The Fungal Genetics Stock Center: from molds to molecules. Adv Appl Microbiol 52:245–262

Meyers PR, Rawlings DE, Woods DR, Lindsey GG (1993) Isolation and characterization of a cyanide dihydratase from Bacillus pumilus C1. J Bacteriol 175:6105–6112

Miller MD, Benedik MJ, Sullivan MC, Shipley NS, Krause KL (1991) Crystallization and preliminary crystallographic analysis of a novel nuclease from Serratia marcescens. J Mol Biol 222:27–30

Nolan LM, Harnedy PA, Turner P, Hearne AB, O'Reilly C (2003) The cyanide hydratase enzyme of Fusarium lateritium also has nitrilase activity. FEMS Microbiol Lett 221:161–165

Pace HC, Brenner C (2001) The nitrilase superfamily: classification, structure and function. Genome Biol 2:REVIEWS0001

Pertsovich SI, Guranda DT, Podchernyaev DA, Yanenko AS, Svedas VK (2005) Aliphatic amidase from Rhodococcus rhodochrous M8 is related to the nitrilase/cyanide hydratase family. Biochem 70:1280–1287

Piotrowski M, Schonfelder S, Weiler EW (2001) The Arabidopsis thaliana isogene NIT4 and its orthologs in tobacco encode beta-cyano-l-alanine hydratase/nitrilase. J Biol Chem 276:2616–2621

Sexton AC, Howlett BJ (2000) Characterisation of a cyanide hydratase gene in the phytopathogenic fungus Leptosphaeria maculans. Mol Gen Genet 263:463–470

Studier FW (2005) Protein production by auto-induction in high density shaking cultures. Protein Expr Purif 41:207–234

Vogel HJ (1956) A convenient growth medium for Neurospora (medium N). Microbiol Genet Bull 13:42–43

Wang P, VanEtten HD (1992) Cloning and properties of a cyanide hydratase gene from the phytopathogenic fungus Gloeocercospora sorghi. Biochem Biophys Res Commun 187:1048–1054

Wang P, Matthews DE, VanEtten HD (1992) Purification and characterization of cyanide hydratase from the phytopathogenic fungus Gloeocercospora sorghi. Arch Biochem Biophys 298:569–575

Watanabe A, Yano K, Ikebukuro K, Karube I (1998a) Cloning and expression of a gene encoding cyanidase from Pseudomonas stutzeri AK61. Appl Microbiol Biotechnol 50:93–97

Watanabe A, Yano K, Ikebukuro K, Karube I (1998b) Cyanide hydrolysis in a cyanide-degrading bacterium, Pseudomonas stutzeri AK61, by cyanidase. Microbiology 144(Pt 6):1677–1682

Westley J (1987) Thiosulfate: cyanide sulfurtransferase (rhodanese). Methods Enzymol 77:285–291

Yanase H, Sakamoto A, Okamoto K, Kita K, Sato Y (2000) Degradation of the metal-cyano complex tetracyanonickelate (II) by Fusarium oxysporum N-10. Appl Microbiol Biotechnol 53:328–334

Acknowledgments

The financial support of the Robert A. Welch Society (Grants E-1263 and A-1310) and the Texas Hazardous Substance Research Center are gratefully acknowledged. The Fungal Genetic Stock Center created the locus disruptions promptly upon our request, and Dr. Wayne Versaw was instrumental in assisting us with the growth and characterization of the fungal strains.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Basile, L.J., Willson, R.C., Sewell, B.T. et al. Genome mining of cyanide-degrading nitrilases from filamentous fungi. Appl Microbiol Biotechnol 80, 427–435 (2008). https://doi.org/10.1007/s00253-008-1559-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1559-2