Abstract

Fire-retarding properties of 200 ppm nano-silver solution, with a size ranging from 20 to 80 nm, on five woody species were studied and compared with Borax and Celcune®. Blocks of 150 × 130 × 9 mm³ were prepared and divided into four groups of control samples, nano-silver-, Borax-, and Celcune-impregnated specimens. A special apparatus was designed, and six fire-retarding properties of each specimen were measured, namely ignition, glowing, back-darkening and back-holing times, as well as length and width of burning. Results showed that all three kinds of treatments had improving effects on the fire-retarding properties. Celcune showed the best improvement on glowing time. Cluster analysis showed direct relation between density and fire-retardant properties; also, fire-retarding behaviors of the four hardwoods were quite different to those of the one softwood. Furthermore, there are improvements in some fire-retarding properties of nano-silver-impregnated specimens that are in connection with its heat-transfer property.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fire safety is an important concern in all types of construction. Wood is exceptionally important in this regard; it burns when exposed to heat and air. Thermal degradation of wood occurs in stages. The degradation process and the exact products of thermal degradation depend upon the rate of heating as well as the temperatures. The sequence of events for wood combustion is as follows (White and Dietenberger 1999):

-

The wood, responding to heating, decomposes or pyrolyzes into volatiles and char. Char is the dominant product at internal temperatures of less than 300°C, whereas volatiles become much more pronounced at temperatures above 300°C.

-

The volatiles, some of which are flammable, can be ignited if the volatile–air mixture is of the right composition in a temperature range of about 400°–500°C within the mixture. This gas-phase combustion appears as flames.

-

With air ventilation, the char oxidation becomes significant at around 200°C with two peaks in intensity reported at 360°–520°C. This char oxidation is seen as glowing or smoldering combustion until only ash residue remains.

The use of inorganic salts as a treatment to render wood fire-retardant is not a modern development. Indeed, approximately 80 years ago, the wood treating industry developed and later refined a pressure impregnation process where these mineral salts are forced deep into wood cells. This process resulted in a new building component known as fire-retardant-treated (FTR) lumber. Chemicals for FRT lumber are applied to wood building materials such as plywood and structural lumber (including dimensional lumber used to fabricate roof trusses) to reduce the capacity of the wood in contributing to fire. Many FRT chemicals reduce the temperature at which thermal degradation can occur, thereby increasing the amount of char and reducing the amount of flammable volatiles. In this regard, FRT has performed effectively. In the late 1950s and early 1960s, several companies began aggressively marketing formulations of these fire retardants under various trade names. While the formulations of these products were (and still are) proprietary, and no doubt varied to a small degree, these “first generation” products contained inorganic salts, such as monoammonium phosphate and ammonium sulfate. In some cases, zinc chloride and diammonium phosphate were used as well. Other kinds of traditional chemicals, such as lime water (alkaline aqueous solution of calcium hydroxide), have also been studied to find out their fire-retarding properties and compare them with modern ones (Ayrilmis et al. 2007). In the U.S. building codes, fire-retardant-treated wood is required to be a wood product impregnated with the FR chemicals by a pressure process or other means during manufacture, and which shall have a flame spread of not over 25 when tested in accordance with ASTM E 84, show no evidence of progressive combustion when this ten minutes test is extended to an additional 20 min, and not have the flame front progress 3.2 m beyond the centerline of the burner at any time during the test.

Fire-retardant treatments may affect wood in various ways: increased hygroscopicity, reduced strength, dimensional stability changes depending on treatment, wood degradation, corrosion of metal fasteners, adhesion problems, increased abrasiveness, and leaching of treatments (Taghiyari 2006). As evidenced by recent structural problems with fire-retardant-treated plywood, fire-retardant chemicals and high-temperature environments can degrade the strength properties of wood (Winandy et al. 2002). It is suspected that the combination of acidic fire-retardant chemicals and elevated temperatures increases the rate of acid hydrolysis in the wood, thereby causing a loss in strength (LeVan and Winandy 1990). In the meantime, the effects of fire-retardant chemicals is so important that designers intending to use fire-retardant-treated materials in areas of elevated temperatures, such as roof decks, should ask suppliers about the initial effects of fire-retardant formulations on wood strength, stiffness, and fastener corrosion (Winandy 1998).

The problem with using these salts as fire retardants is that, firstly, they are highly hygroscopic. That is, they will absorb moisture from the air when relative humidity becomes high. It has been reported that some products were so hygroscopic that they would actually drip solution at relative humidity of approximately 90%. Initial problems included corrosion of metal fasteners and fittings (such as metal truss plates). Secondly, the smoke and gases produced by fire are toxic and dangerous for the health. The term smoke is frequently used in an all-inclusive sense to mean the mixture of pyrolysis products and air that is present near the fire site. In this context, smoke contains gases, solid particles, and droplets of liquid. Smoke presents potential hazards because it interacts with light to obscure vision and because it contains noxious and toxic substances. Generally, two approaches are used to deal with the smoke problem: limit smoke production and control the smoke that has been produced. The control of smoke flow is most often a factor in the design and construction of large or tall buildings. In these buildings, combustion products may have serious effects in areas remote from the actual fire site (White and Dietenberger 1999).

Based on the above-mentioned literature review, fire-retardant chemicals may be assessed from three main perspectives beyond flammability: reduced strength of wood and corrosion of fasteners, increased hygroscopicity, and production of toxic and smoke gases. Although all these perspectives have been considered over the years and in the new fire-retardant formulations nearly all requirement are met, fire-retarding properties of nano-silver should also be studied as it does not have any acidic chemicals and consequently is not expected to cause reduced strength or corrosion effects on fasteners. The Ag ions may decrease the potential of wood to absorb water as it has the possibility to bond with free hydroxyl sites in the microstructure of wood components (Rassam et al. 2010). In the meantime, its ability to transfer heat is of great importance in wood thermal degradation (Taghiyari 2011a) as it reduces accumulation of heat at one point of wood and consequently may delay thermal degradation, carbonization, and even pyrolysis. Therefore, the idea occurred to consider the possibility of using nano-silver particles as a fire retardant.

Materials and methods

Specimen procurement

Four hardwood and one softwood species were chosen based on their importance in various industrial applications in Iran: hardwoods were beech (Fagus orientalis), poplar (Populus nigra), sycamore (Platanus orientalis), and alder (Alnus spp.). The softwood was silver fir (Abies alba) because of its high import figures. Specimens of each species were divided into four groups of control samples, nano-silver-, Borax-, and Celcune®-impregnated specimens. For every species, ten specimens free from any knots, fissures, and checks were randomly chosen for each group; that is, 40 specimens were prepared for the four treatments of each species, in total 200 specimens. The size of the specimens was 150 (length) × 130 (width) × 9 (thickness) mm³. The length of the specimens was in longitudinal and the width in marginal direction.

Impregnation process

Nano-silver impregnation was performed using 200 ppm solution by an empty-cell process at 3 bar pressure. A 200 ppm aqueous dispersion of silver nanoparticles was made using an electrochemical technique in collaboration with Jafr Sorkhe Fajr Co. (Ltd.). The size range of the silver nanoparticles was measured to be 20–80 nm. The pH of the suspension was 6–7; two kinds of surfactants (anionic and cationic) were used in the suspension as stabilizer; the concentration of the surfactants was three times that of the nano-silver particles. Each specimen was weighted just before and after impregnation to measure the nano-silver solution absorption. The amount of absorption was different for each specimen of every species (Table 1); one possible reason for this is that the concentration of extractives varies in different parts of the tree and therefore, permeability values would consequently vary significantly (Taghiyari and Sarvari 2010). Still, extreme caution was taken in making the sampling process as similar as possible. Borax and Celcune® impregnation was done using full-cell process. Celcune® is a registered trademark for a new combined fire-retardant and preservative chemical patented and produced by Afshar Wood Machinery Manufacturing Company. The amount of Celcune® and Borax retention was reported by the company to be 7–10% based on dry weight basis of solid wood.

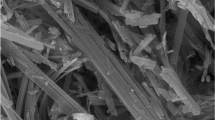

After impregnation, all specimens were sent to a drying kiln to be mildly dried to a moisture content of 10%. Then, they were kept at room temperature (30–35°C and 45–50% relative humidity) for 3 months along with the control specimens. Scanning electron microscope (SEM) micrographs were carried out prior to the fire tests. SEM imaging was done at thin-film laboratory, FE-SEM lab (Field Emission), School of Electrical and Computer Engineering, The University of Tehran.

Fire-retardant testing apparatus

Specimens were mounted on an apparatus (Fig. 1) especially designed and patented by the author using piloted ignition (White and Dietenberger 1999) for testing of the five fire-retarding properties as follows:

Ignition time

The time it takes for each specimen to catch an evident visible flame on the spot nearest to the Bunsen-type burner.

Glowing time

As burning is progressed, at a particular time, the spot nearest to the burner starts glowing; this time is registered as glowing time.

Back-darkening time

Watching the back of specimen, opposite to the spot facing the burner, there comes a time that an increasing dark spot starts to grow.

Back-holing time

As burning continues, a small hole or split appears at the back side of the specimen. The back-holing occurrence terminates the test, and therefore once back-holing has occurred for each specimen, the Bunsen-type burner is turned off and the burning process discontinued.

Length and width of burning

Once back-holing has occurred and the burning process terminated, the area that has been burned is measured in terms of length and width of burning.

The surface of the specimens was subjected to the flame from the Bunsen-type burner at 45 degrees (Fig. 1). The Bunsen-type burner provides a fairly mild and localized fire exposure to the test specimens. The whole structure is put in a glass compartment with a chimney to extract gas and smoke in order to protect the burning flame from wind and air movements.

Statistical analysis

Statistical analysis was conducted using SAS software program, version 9.1. Two-way analysis of variance (ANOVA) was performed on permeability data to conclude significant differences at 99% confidence level. Hierarchical cluster analysis, including dendrogram and the use of Ward methods with squared Euclidean distance intervals, was done by SPSS/14.

Results

Ignition time

Figure 2 shows the results of ignition time for the five species. All three treatments had increasing effects on the ignition time for the five species. This increasing effect is outstanding in Abies alba treated with Celcune®, as well as Populus nigra and Alnus spp. treated with Borax.

Glowing time

Celcune takes the ultimate rank in four of the species; it is only in Alnus spp. that Borax takes the first rank in increasing glowing time (Fig. 3). Although nano-silver-impregnated specimens show an increase in glowing time in all five species, the amount of increase is only significant in Abies alba.

Back-darkening time

Only Borax shows a significant increasing effect on the back-darkening time in all five species (Fig. 4). The other two treatments, nano-silver and Celcune impregnation, do not show a significant increase; back-darkening time has even been reduced in nano-silver-impregnated Abies alba specimens.

Back-holing time

All three kinds of treatments showed an increasing effect on back-holing time (Fig. 5). This increase in time was outstanding in Fagus orientalis, Platanus orientalis, and Alnus spp. (Borax-treated), Abies alba (Celcune-treated), and Platanus orientalis (nano-silver).

Length and width of burning

Nano-silver impregnation has made both length and width of burning to decrease although in most cases not significantly different (Figs. 6, 7). Celcune and Borax-treated specimens, on the other hand, do not follow a regular procedure although they show nearly the same trend when comparing species and the kind of treatment.

Discussion and conclusion

Once the nano-silver-impregnated specimens were seasoned to the same MC level prior to nano-silver impregnation, the weight of all specimens showed a decrease. This indicates that part of the extractive contents of specimens was dissolved in nano-silver solution and was washed out due to the empty-cell process used.

All three treatments increased the ignition time. The amount of increase is outstanding in Abies alba, Populus nigra, and Platanus orientalis (nano-silver-impregnated specimens), as well as in Abies alba (Celcune-treated), Alnus spp. and Populus nigra (Borax-treated). As to Borax and Celcune®, increase in ignition time shows the fire-retarding properties of these two chemicals. As to nano-silver though, an increase in ignition time shows its heat-transfer property (Taghiyari 2011a, b; Taghiyari et al. 2011); that is, due to the transfer of heat from the spot nearest to the burning flame of the Bunsen-type burner, accumulation of heat is delayed at the spot, and therefore, the ignition time is increased. Cluster analysis of ignition time clearly shows that control samples are clustered separately, and Celcune and nano-silver are closely clustered together (Fig. 8); this shows nano-silver is quite comparable with Celcune, and Borax to some extent, for increasing the ignition time.

As to the glowing time, Borax and Celcune® show significant difference with the control samples in all five species (Fig. 3). This property exactly shows fire-retarding property of these two treatments. Although nano-silver-impregnated specimens show an increase, there is little or no significant difference with the control samples except for silver fir. Cluster analysis shows a better scope of the four treatments (Fig. 9). That is, once ignition is occurred, nano-silver-impregnated specimens do not seem much different to normal untreated wood and are therefore clustered with control samples. This proves that nano-silver particles do not tend to alter the nature of wood and may only transfer the heat and therefore delay the process of heat accumulation. Once the surface layer of wood has reached the temperature to be ignited, the further process of glowing does not seem much different to normal untreated woods; still, nano-silver impregnation increases glowing time to a rather noticeable extent (Fig. 3).

The fire-retarding property of Borax, and Celcune® to some extent, is obvious from studying the back-darkening and back-holing times of five species (Figs. 4 and 5). Nano-silver-impregnated specimens, on the other hand, do not show that this kind of treatment has any significant effect on these two properties although it made these two to be increased to some extent. Nano-silver has even slightly decreased the time of back-darkening in Abies alba. Studying the amount of absorption of nano-silver in Abies alba, it was revealed that nano-silver absorption had a great standard deviation. This shows that some of the specimens taken from parts of the tree with low permeability absorbed little amount of solution. Exactly in these specimens, lower times of back-darkening were observed and therefore the decrease in the meantime in comparison with control samples is logical. By eliminating the specimens that had little absorption of nano-silver, an increase in back-darkening time could be seen.

Clustering the four treatments of poplar, based on all the properties measured, again shows that control samples are clustered quite separately (Fig. 10).

Cluster analysis of the five species shows that ignition and glowing properties are very sensitive to the density of wood (Table 1). Poplar and fir with quite similar densities (0.394 and 0.395 g/cm3 respectively) are closely clustered together (Figs. 11, 12). The other three species are also clustered close to each other in ignition cluster (Fig. 11). Glowing cluster shows a better relation with the density; that is, beech and sycamore with very similar densities (0.638 and 0.614 g/cm3, respectively) are clustered together and alder (0.553 g/cm3) is clustered to them with a little bit distance from the base level (Fig. 12).

Cluster analysis of the five species on the basis of back-darkening and back-holing times shows a distinct difference of Abies alba that is clustered fully separately (Figs. 13, 14). This shows that some other factors rather than density may be also involved in these two fire-retarding properties, like the type and kind of wood ingredients and structures. Still, more studies should be done in this regard. As to the four hardwood species studied, it can be seen that back-darkening again shows a great relationship with the density of wood; that is, beech and sycamore that are more or less very similar in density are closely clustered together. At the next stage, alder is clustered to them, and finally, poplar joins them (Fig. 13).

The heat-transfer property of the silver nanoparticles (Taghiyari 2011a, b; Taghiyari et al. 2011) delays accumulation of the heat needed for the burning process in the surrounding parts of flame and therefore, length and width of burning would naturally be decreased in all cases of nano-silver-impregnated specimens. In the other two treatments of Borax and Celcune® though, fire-retarding property of these two compounds makes the flow of heat from the burner not being able to penetrate into the woods and consequently makes it spread to the surrounding parts; therefore, as it happened, an increase in length and width of burning may be seen in some cases.

It may be concluded that nano-silver clearly shows some potential in improving some of the fire-retarding properties in solid woods. It is to be noted that it uses its heat-transferring property in this regard. Therefore, its other aspect as fire retardants should still be studied in detail, such as toxic gases and smoke (Anonymous 1999) as well as hygroscopicity.

Future work

Nano-silver provides some fire retardancy benefits via heat-transferring effects. Future work include the following: (1) combining nano-silver with other fire retardants for synergistic effects, (2) examine other non-fire performance requirements that might benefit from nano-silver treatment such as hygroscopic properties, smoke toxicity, and (3) further evaluate the fire performance of nano-silver treatment using other fire test methods such as those that measure the heat release rate of the burning materials (e.g., cone calorimeter).

References

Anonymous (1999) Wood handbook—wood as an engineering material. Gen. Tech. Rep. FPL—GTR—113. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, p 463

Ayrilmis N, Candan Z, White R (2007) Physical, mechanical, and fire properties of oriented strand board with fire retardant treated veneers. Holz Roh Werkst 65:449–458

LeVan SL, Winandy JE (1990) Effects of fire retardant treatments on wood strength: a review. Wood Fiber Sci 22(1):113–131

Rassam GH, Taghiyari HR, Jamnani B, Khaje MA (2010) Effect of nano-silver treatment on densified wood properties, part one: swelling, recovery set, bending strength, International Research Group on Wood Protection, IRG/WP 10-40533, Section 4

Taghiyari HR (2006) English for special purpose: wood and paper sciences and technology. Karafarinan Publication Organization, p 205. ISBN: 964-7284-50-0

Taghiyari HR (2011a) Study on the effect of nano-silver impregnation on mechanical properties of heat-treated Populus nigra. Wood Sci Technol 45(2):399–404

Taghiyari HR (2011b) Effects of nano-silver on gas and liquid permeability of particleboard. Dig J Nanomater Bioresour 6(4):1509–1517

Taghiyari HR, Sarvari SY (2010) Ultimate length for reporting gas permeability of Carpinus betulus wood; special topics and reviews in porous media, vol 1(4). Begell House Production

Taghiyari HR, Rangavar H, Farajpour Bibalan O (2011) Nano-silver in particleboard. Bio Resour 6(4):4067–4075

White RH, Dietenberger MA (1999) Wood handbook, chapter 17: fire safety; forest products laboratory, Gen. Tech. Rep. FPL—GTR—113. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, p 463

Winandy JE (1998) Techline, properties and use of wood, composites, and fiber products, durability of fire-retardant-treated wood, United States Department of Agriculture, Forest Service, Forest Products Laboratory, VL-5, issued 01/98

Winandy JE, Lebow PK, Murphy JF (2002) Predicting current serviceability and residual service life of plywood roof sheathing using kinetics-based models, the 9th Durability of Building Materials and Components Conference, Brisbane, Australia, p 7

Acknowledgments

The author is grateful to Mr. Mohammad Hossein Nikoonejad, the Dean of The Basije Asatid of Shahid Rajaee Teacher Training University. I appreciate the kind efforts of Mr. Ne’mat Karimi, Mr. Nour-Mohammad Rahmatollahi, and Mr. Yousef Azari, BS graduates at SRTTU, and Mr. Taha Sokhandan and Mr. Abolfazl Rezaii, active members of Wood Industries Scientific Association of SRTTU, as well as Engin. Hadi Gholamiyan (The University of Tehran) for their great cooperation and help in primary wood preparation and tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taghiyari, H.R. Fire-retarding properties of nano-silver in solid woods. Wood Sci Technol 46, 939–952 (2012). https://doi.org/10.1007/s00226-011-0455-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-011-0455-6