Abstract

The effects of nano-sepiolite (NS) on fire properties of unheated and heat-treated fir wood were studied using a newly developed apparatus. Separate sets of specimens were prepared to be painted with plain acrylic-latex paint and NS-treated paint as well. Heat treatment of specimens was carried out in a laboratory oven at 185 ºC and under atmospheric air pressure. Six fire properties were measured including times to onset of ignition and glowing, as well as back-darkening and back-holing times. Two properties of mass loss and burnt area were measured once the fire was extinguished and the test on each specimen terminated. Results demonstrated significant improvement in fire properties of NS. The improvement was partially attributed to the mineral nature of sepiolite with low chemical reactivity, acting as an insulating layer towards the penetration of fire to the wood substrate. The improvement in fire properties was also partially attributed to the high thermal conductivity coefficient of sepiolite, delaying the accumulation of heat at the point nearest to the piloted fire to reach ignition point. Heat treatment did not significantly affect fire properties in unpainted specimens. However, fire properties in the painted heat-treated specimens (with both plain paint, and NS-treated paint) tended to decrease, though the values were still significantly higher than those of unpainted heat-treated specimens. FTIR spectra illustrated significant alteration in intensities at wave numbers 3100 cm−1 and 1,00 cm−1, related to the hydroxyl groups of cell-wall polymers (mostly hemicelluloses). These alterations had a negative effect on the adhesion of the water-based paint used in this study. It was concluded that nano-sepiolite has a promising future as a fire retardant. However, as cost is of vital importance for paint manufacturers, further studies on the effects of sepiolite at micron-scale available at a lower price should also be carried out.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wood is a renewable material that has a myriad of applications; therefore, it is vastly studied all over the world and various modification methods were utilized to improve its properties or to achieve new applications (Wang et al. 2019a; Chen et al. 2020). From the very beginning of civilization, ways to preserve solid wood against wood-decaying fungi, insects and termites, and also fire have been examined (Mantanis 2002; Papadopoulos and Gkaraveli 2003; Mantanis and Papadopoulos 2010a, b; Papadopoulos et al. 2010: Papadopoulos 2012; Mantanis et al. 2014; Sandberg et al. 2017; Lykidis et al. 2016, 2018; Taghiyari et al. 2019a, b). Many materials were tested, developed, and finally presented to the industry. Some targeted the pyrolysis of wood polymers, as a convenient method (Östman and Tsantaridis 1995). Some others concentrated on the surface of the wood, to protect it with an insulating layer. Intumescent coatings are listed under this category. Although there are some techniques in which ignitability of wood is decreased and over the past decades, some very effective materials and methods have been developed, the search for environmentally friendly materials and methods is still in progress (Levan and Winandy 1990; White and Sweet 1992; Winandy 2001; Winandy et al. 2008).

Apart from using additive materials to improve some of the drawbacks in wood, there are a number of techniques that deal with modifying cell-wall polymers. Through the modification of these building blocks, some properties can be improved. Heat treatment is considered one of the most popular wood modification techniques that are used worldwide on an industrial scale (Bastani et al. 2016; Sandberg et al. 2017). Therefore, fir wood (Abies alba), a wood species that is used in many parts of the world, was first heat-treated at a mild temperature to find out the impact of heat treatment on its fire properties.

Nanotechnology has been utilized to improve the quality of many materials (Majidi 2012, 2016; Pethig 2017; Suganya et al. 2017; Wang et al. 2019b). In wood and wood-composite panels, nanotechnology was also applied (Tajvidi et al. 2016; Mishra and Ekielski 2019; Papadopoulos and Taghiyari 2019; Papadopoulos et al. 2019; Xu et al. 2019; Taghiyari et al. 2020a). Different nano-materials (metals and minerals) were utilized to increase the thermal conductivity in solid wood species and wood composite mats; they were also used to improve biological resistance against different wood-decaying fungi (Mantanis et al. 2014; Lykidis et al. 2016; Ayata et al. 2017; Humar et al. 2018; Taghiyari et al., 2019ab; Hassani et al. 2019; Zikeli et al. 2019) and finally to decrease duration of hot-pressing which is considered the bottle-neck in most wood-composite manufacturing plants (Taghiyari and Farajpour Bibalan 2013). In this connection, sepiolite is a natural hydrous mineral with unique properties that has been proved effective in improving thermal conductivity in oriented-strand lumber production (Taghiyari et al. 2020b). In the present study and as a second objective, nano-scale sepiolite was used to investigate its effects on fire properties of unheated and heat-treated fir wood.

2 Materials and methods

2.1 Specimen preparation

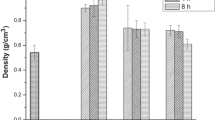

Fir (Abies alba Mill) boards were purchased; they were originally grown in Carpathian zone (Ukraine). The density of the fir specimens was measured to be 0.44 g.cm−3 (at a moisture content of 8%). The boards were kept in the wood workshop for five months before cutting (36–38 °C; relative humidity 27–31%). They were then cut to size, 220 mm in length, 140 mm in width (plain sawn), and 5 mm in thickness. Specimens were free from any fungal or insect attack, checks or cracks, and knots. Twenty specimens were selected and divided into four treatments; for each treatment, five replicate specimens were prepared. Treatments included: control (without any paint or nanomaterial), painted, and NS + painted (nano-sepiolite was mixed with paint and applied on the surface of specimens). A water-based paint was used in this experiment (code number ALCO-6510), purchased from Alvan Paint and Resin Production Co. (Tehran, Iran). The solid content of the paint was 37% ± 1%. Two coats were brushed on each specimen to achieve a 190–200 μm dry paint film on the front and back surfaces of specimens. A 24-h time was given between the two coats to let the first coat dry out. For the nanomaterial-treated specimens, the nano-material was mixed with the paint at 10% based on the wet weight of the paint, before being brushed on specimens. The mixing was done using a magnetic stirrer for 20 min to disperse the nano-sepiolite evenly throughout the paint. However, further studies should be carried out as to the proper method and time to evenly disperse nano-sepiolite in paints. As recommended by the paint manufacturer, the size of the nanoparticles used in this study ranged from 30 to 110 nm. Once painted, all specimens were kept in a conditioning chamber (25 ± 3 °C, 35 ± 3% relative humidity) for two weeks; the moisture content of specimens at the time of fire tests was 8 ± 0.5%.

2.2 Heat treatment process

Once specimens were cut to size, half of them were randomly selected to be heat-treated. The heat treatment was carried out under atmospheric pressure, in a laboratory oven (model Memmert UFE 700). During the process, no water spray or vapor was applied. The target temperature was 185 °C. Once the target temperature was reached, the specimens were heated for 5 h. The specimens were mounted on a wooden holder in vertical position, so that they were not in direct contact with the metal tray of the oven. The oven temperature decreased gradually before removing the specimens. Then, heat-treated specimens were kept along with unheated ones in room conditions (25 ± 3 °C; 35 ± 3% relative humidity) for six weeks to reach a moisture content of 7%.

2.3 Preparation and SEM imaging of nano-sepiolite

As a common hydrated magnesium silicate, sepiolite has a general formula of Mg4Si6O15(OH)2.6H2O. Nano-sepiolite in the present study was originally taken from the geological outcrop of Tanbo Village located in the Senderk region (Minab city located in Senderk region, Iran) (Taghiyari et al. 2020b). The sepiolite macro-fiber crystals were 60 cm in length and the slender ratio (length to width) was more than 1200. The chemical composition of Tanbo sepiolite was determined by XRF analysis (Table 1). Density of sepiolite was 2.3 g.cm−3. After 10 h of heating at 1000 °C, the loss on ignition (L.O.I.) was measured to be 18.9 wt%, indicating a considerable amount of water elimination (H2O) and hydroxyl (OH) from crystal structure during heating (Soltani 2019).

Nano-scale sepiolite was prepared at the geology laboratory of SRTTU University (Tehran, Iran). Sepiolite nanostrands had a mean aspect ratio of 1:15. At least 80% of the nanostrands were below 100 nm. Scanning electron microscope (SEM) imaging was conducted at a specialized laboratory institute in Tehran (Beam Gostar Taban Laboratories) (Fig. 1). For SEM imaging, a field emission scanning electron microscope (FE-SEM) model TESCAN-MIRA III (Manufacturer, Czech Republic) was used. For the preparation, all specimens were first sputter coated with gold. The thickness of the gold coating was about 10 nm.

2.4 Measurement of fire properties

The fire properties were measured using a Fixed Fire Test Apparatus (FFTA), designed and built based on piloted ignition (Fig. 2) (Taghiyari 2012; Haghighi Poshtiri et al. 2014; Soltani et al. 2016; Esmailpour et al. 2018, 2020). As fuel for a Bunsen type burner, a methane-based natural gas was used (90–98%). However, it contained other hydrocarbons as described by Taghiyari et al. (2020b). The flow rate of the gas was 0.097 l/s. The Bunsen burner was held vertically, and specimens under testing were positioned at a 45° angle. Four fire properties were measured based on the time right after the specimens were exposed to the piloted fire, including: time to onset of ignition, time to onset of glowing, back-darkening time, and back-holing time, based on the definition presented by Taghiyari et al. (2020b). Technically, the higher durations for these four properties indicate that an improvement is achieved. The two other fire properties measured included mass loss (measured after termination of the test) and burnt area. A three-wall-compartment protected the whole structure so that air movement could not interfere with the experiment.

Schematic diagram of the Fixed Fire Test Apparatus (FFTA; Iranian Patent No. 67232; approved by Iranian Research Organization for Science and Technology under license No. 3407; USPTO Pub. No.: US 2019/0,212,283 A1; Appl. No. 15/866,752) (Taghiyari 2012; Haghighi Poshtiri et al. 2014; Esmailpour et al. 2018, 2020)

2.5 Analysis of the results

For statistical analysis, the results were assessed using SAS software package (version 9.2; 2010) (Cary, NC, USA). In order to discern differences among the effects of addition of sepiolite or heat treatment on fire properties, one-way analysis of variance was performed. The level of confidence was 95% in all statistical analyses. For grouping purposes among different treatments, Duncan's multiple range test (DMRT) was carried out. Similarities and dissimilarities among the treatments were analyzed by hierarchical cluster analysis, using SPSS software, version 18 (2010) (IBM, USA). Graphical statistics like fitted-line, surface, and contour plots were drawn by Minitab software (2010), version 16.2.2 (Minitab Inc., USA).

3 Results and discussion

The results demonstrated significant increase in time to onset of ignition as a result of the addition of nano-sepiolite (NS) to paint (Fig. 3a). The highest time to onset of ignition was observed in the unheated NS-treated (19.2 s) specimens. Control (unpainted) specimens in both unheated and heat-treated groups had the same lowest time to onset of ignition (8.4 s). Covering specimens with NS-paint resulted in 130% and 58% increase in unheated and heat-treated specimens, respectively. Heat treatment tended to decrease the time to onset of ignition in the painted and NS-treated specimens in comparison to their unheated counterparts, though the values were still significantly higher than those of unpainted heat-treated specimens. The favorable increase in time to onset of ignition in NS-treated specimens was most probably partially attributed to the mineral nature of sepiolite with low reactivity to oxidize. This made sepiolite nanoparticles act as an incombustible layer toward the penetration and transfer of the piloted fire to the substrate. Ultimately, the incombustible layer delayed the woody substrate to ignite, resulting in the significant increase in the time to onset of ignition. Moreover, the thermal conductivity coefficient of sepiolite is 3.9 ± 0.31 (W·m−1·K−1) (Taghiyari et al. 2020b) in comparison to the low coefficient of wood which is reported to be 0.16 and 0.12 (W·m−1·K−1) for hardwoods and softwoods, respectively (Bergman et al. 2011). The increase in time to onset of ignition was also partially attributed to the rather high thermal conductivity of sepiolite. The high thermal conductivity caused easier transfer of heat throughout the specimen under testing, and it prevented accumulation of heat at the point nearest to the piloted fire, eventually a significant increase in the time to onset of ignition was achieved. A scheme is provided to present how a combination of the above mentioned two mechanisms ultimately improved the fire properties in fir wood (Fig. 4). Similar improvement in time to onset of ignition was also achieved by wollastonite and graphene (Esmailpour et al. 2018, 2020). Nearly the same favorable trend was observed for the time to onset of glowing as a result of addition of NS to paint (Fig. 3b). NS-paint increased the time to onset of glowing by 105% and 31% in unheated and heat-treated specimens, respectively.

Painted (with no NS) specimens also showed improvement (favorable increases) in the times to onset of ignition and glowing. A study on beech wood reported that painted specimens with the same acrylic-latex paint, showed a decreasing trend as a result of covering specimens with plain paint, though the decrease was not statistically significant. This difference in decreasing and increasing impact of plain paint on the times to onset of ignition and glowing in the two wood species of beech and fir was mainly attributed to their difference in density. That is, beech wood (with a density of 0.62 g.cm−3) is considered a semi-high density wood species. On the other hand, fir is a medium-density wood species. Specimens in the present study had a density of 0.44 g.cm−3. The low density of wood is a decisive factor on its ignitability. The time to onset of ignition for control beech specimens (that is, unpainted specimens) was reported to be more than 20 s, while that of fir wood was measured to be lower than 10 s. In fact, the paint film covering the low- density wood species of fir had the potential to be effective and to improve the time to onset of ignition, while the inherently longer time to onset of ignition in beech wood did not allow the paint film to reach its maximum efficiency, because before the piloted fire could affect the woody substrate, the film was thermally burnt down by the piloted fire.

Both plain paint (with no NS) and NS-treated paint illustrated significant effect on improving the fire properties of back-darkening and back-holing (Fig. 5a, b). Both properties showed the same trends in unheated and heat-treated fir specimens. The highest and lowest back-darkening times were observed in unheated NS-treated (353.7 s) and heat-treated un-painted (177.1 s) specimens, respectively. NS resulted in 93% and 49% improvement in unheated and heat-treated fir wood, respectively. Nearly the same increasing trends were observed in the back-holing times (Fig. 5b). The highest and lowest back-holing times were observed in NS-treated unheated (1482.8 s) and unpainted unheated (701 s) specimens, respectively.

The weight loss increased significantly as a result of the addition of NS to paint (Fig. 6a). This was attributed to the longer duration of testing time. In the present study with the use of the fixed fire test apparatus, the exposure to the piloted fire discontinued only once back-holing occurred. Therefore, and with regard to Fig. 5b, the duration of testing significantly increased in NS-treated specimens, and consequently the weight loss increased as well. However, the burnt area decreased as a result of covering the specimens with NS-treated paint (Fig. 6b). The significant decrease in the burnt area clearly demonstrated the effectiveness of NS-treated paint in decreasing the chance for fire to spread across planks and timbers. This would provide a longer timespan for firefighters to extinguish the fire, which is translated into saving both lives and property.

Heat treatment of fir specimens tended to decrease the times to onset of ignition and glowing in the painted and NS-treated specimens. The control specimens (unpainted) illustrated statistically the same figures. The decrease in times to onset of ignition and glowing in the heat-treated specimens was partly attributed to the chemical changes in cell-wall polymers of fir wood. Weight measurement of specimens before and after heat treatment revealed that heat treatment resulted in 10.8% weight loss in specimens. Heat treatment in the present study was carried out under mild conditions (185 ºC); therefore, the changes can be assumed to have been mainly occurred in hemicellulose and lignin, as cellulose needs higher temperature to be thermally degraded (Esteves et al. 2008; Bayani et al. 2019a,b). FTIR spectra of the unheated and heat-treated fir specimens demonstrated significantly different intensities at wave numbers of 3300–3100 cm−1 and 1600 cm−1 which are related to O–H stretch (Müller et al. 2009; Lionetto et al. 2012; Bayani et al. 2019b) (Fig. 7). The paint used in the present study was an acrylic-latex paint, which is a water-based paint. Therefore, any alterations in the hydroxyl groups of the substrate would significantly affect the way the paint layer can wet it. The alterations in hydroxyl groups of heat-treated fir wood, and the consequent fluctuations in the above mentioned wave bands in FTIR spectra, resulted in a significant change in the bonds formed between paint layer and woody substrate.

Fitted-line plot between the four fire properties (namely, times to onset of ignition and glowing, back-darkening, and back-holing times) demonstrated significant direct correlation between them. The highest R-squared was found between times to onset of ignition and glowing (86%) (Fig. 8a). Previous studies reported higher R-squared values between fire properties (Esmailpour et al. 2020). The somehow lower R-squared in the present study was as a result of different impact of plain paint and NS-treated paint on unheated and heat-treated fir wood (Figs. 3–5). Contour and surface plots also illustrated direct relationship between times to onset of ignition and glowing with back-darkening (Fig. 8b, c). Weight loss and burnt area did not have high and significant correlation with other properties. This was attributed to the contrasting effects of plain paint and NS-paint on these two properties, and their degrees of effectiveness on unheated and heat-treated specimens as well.

Cluster analysis was conducted based on the six fire properties studied here. The results demonstrated close clustering of the two unpainted treatments (namely, unheated and heat-treated) (Fig. 9). This indicated that heat treatment under mild temperature of 185 ºC did not significantly affect the overall fire properties in fir wood. The two NS-treated groups were clustered rather remotely, indicating that NS-paint had different impact on unheated and heat-treated specimens; this was attributed to the alteration in the hydroxyl groups of cell-wall polymers (mostly hemicellulose) which was discussed earlier.

4 Conclusion

Based on the findings achieved in the present study, it was concluded that sepiolite has a positive effect on fire properties of fir wood and could further be researched as a future fire-retardant in wood. Sepiolite has a positive effect on fire properties based on two main mechanisms. Firstly, the mineral nature of sepiolite with low reactivity to oxidize made it act as an incombustible layer towards the penetration of piloted fire to the substrate. Secondly, the thermal conductivity coefficient of sepiolite is rather high in comparison to wood; therefore, the heat is more easily transferred and distributed throughout the substrate, preventing accumulation of heat at the spot nearest to the piloted fire, and ultimately delaying the process of catching fire. From an industrial point of view, easy mixing procedure with paints, and simple application on surface of wood as well, make it a favorable option for industry sector to use in order to increase the quality of their products for end-users. Still, further studies should be carried out, before officially present it to the market as a practical fire-retardant in paints, like its effect on chemical properties of paints.

References

Ayata U, Akcay C, Esteves B (2017) Determination of decay resistance against Pleurotus ostreatus and Coniophora puteana fungus of heat-treated Scots pine, oak, and beech wood species. Maderas Cienc y Tecnolog 19:309–316

Bastani A, Adamopoulos S, Militz H (2016) Shear strength of furfurylated, N-methylol melamine and thermally modified wood bonded with three conventional adhesives. Wood Mater Sci Eng 12:236–241

Bayani S, Bazyar B, Mirshokraie SA, Taghiyari HR (2019a) Effects of heat treatment on the relative amounts of cellulose in nanosilver-impregnated and untreated poplar wood (Populus alba). Floresta e Ambiente 26:e20160398

Bayani S, Taghiyari HR, Papadopoulos AN (2019b) Physical and mechanical properties of thermally-modified beech wood impregnated with silver nano-suspension and their relationship with the crystallinity of cellulose. Polymers 11:1535

Bergman T, Lavine A, Incropera F, DeWitt D (2011) Fundamentals of heat and mass transfer, 7th edn. Wiley, New York, USA

Chen T, Wu Z, Liu Z, Aladejana JT, Wang X, Niu M, Wei Q, Xie Y (2020) Hierarchical porous aluminophosphate-treated wood for high-efficiency solar steam generation. ACS Appl Mater Interfaced 12(17):19511–19518

Esmailpour A, Taghiyari HR, Nouri P, Jahangiri A (2018) Fire-retarding properties of nano wollastonite in particleboard. Fire Mater 42:306–315

Esmailpour A, Majidi R, Taghiyari HR, Ganjkhani M, Mohseni Armaki SM, Papadopoulos AN (2020) Improving fire retardancy of beech wood by graphene. Polymers 12:303

Esteves B, Graca J, Pereira H (2008) Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 62:344–351

Haghighi Poshtiri A, Taghiyari HR, Karimi AN (2014) Fire-retarding properties of nano-wollastonite in solid wood. Philippine Agric Sci 97:45–52

Hassani V, Taghiyari HR, Schmidt O, Maleki S, Papadopoulos AN (2019) Mechanical and physical properties of oriented strand lumber (OSL): The effect of fortification level of nano wollastonite on UF resin. Polymers 11:1884

Humar M, Lesar B, Thaler N, Krzisnik D, Kregar N, Drnovsek S (2018) Quality of copper impregnated wood in Slovenian hardware stores. Drvna Industrija 69:121–129

Levan S, Winandy JE (1980) Effect of fire retardant treatments on wood strength: a review. Wood Fiber Sci 22:113–131

Lionetto F, Del Sole R, Cannolett D, Vasapollo G, Maffezzoli A (2012) Monitoring wood degradation during weathering by cellulose crystallinity. Materials 5:1910–1922

Lykidis C, Bak M, Mantanis G, Neméth R (2016) Biological resistance of pine wood treated with nano-sized zinc oxide and zinc borate against brown-rot fungi. Eur J Wood Prod 74:909–911

Lykidis C, de Troya T, Conde M, Mantanis GJ, G, (2018) Termite resistance of beech wood treated with zinc oxide and zinc borate nano compounds. Wood Mater Sci Eng 13:45–49

Majidi R (2012) A biosensor for hydrogen peroxide detection based on electronic properties of carbon nanotubes. Mol Phys 111:89–93

Majidi R (2016) Electronic properties of graphyne nanotubes filled with small fullerenes: a density functional theory study. J Comput Electr 15:1263–1268

Mantanis G (2002) Aqueous fire retardant WO 02/102926 A1, World Intellectual Property Organisation.

Mantanis G, Terzi E, Kartal SN, Papadopoulos AN (2014) Evaluation of mold, decay, and termite resistance of pine wood treated with zinc- and copper-based nano compounds. Int Biodet Biodegr 90:140–144

Mantanis G, Papadopoulos AN (2010a) The sorption of water vapour of wood treated with a nanotechnology compound. Wood Sci Technol 44:515–522

Mantanis G, Papadopoulos AN (2010b) Reducing the thickness swelling of wood based panels by applying a nanotechnology compound. Eur J Wood Prod 68:237–239

Mishra PK, Ekielski A (2019) The self-assembly of lignin and its application in nanoparticle synthesis: a short review. Nanomaterials 9:243

Müller G, Schöpper C, Vos H, Kharayipou A, Polle A (2009) FTIR-ATR spectroscopic analyses of changes in wood properties during particle- and fiberboard production of hard- and softwood trees. BioResources 4:49–71

Östman BAL, Tsantaridis LD (1995) Heat release and classification of fire retardant wood products. Fire Mater 19:253–258

Papadopoulos AN, Gkaraveli A (2003) Dimensional stabilisation and strength of particleboard by chemical modification with propionic anhydride. Holz Roh Werkst 61:142–144

Papadopoulos AN, Bikiaris DN, Mitropoulos AC, Kyzas GZ (2019) Nanomaterials and chemical modification technologies for enhanced wood properties: a review. Nanomaterials 9:607

Papadopoulos AN, Militz H, Pfeffer A (2010) The biological behaviours of pine wood modified with linear chain carboxylic acid anhydrides against soft rot decay. Int Biodet Biodegr 64:409–412

Papadopoulos AN (2012) Sorption of acetylated pine wood decayed by brown rot, soft rot and white rot: different fungi – different behaviours. Wood Sci Technol 46:919–926

Papadopoulos AN, Taghiyari HR (2019) Innovative wood surface treatments based on nanotechnology. Coatings 9:866

Pethig R (2017) Review – Where is dielectrophoresis (DEP) going? J Electrochem Soc 164:3049–3055

Sandberg D, Kutnar A. Mantanis G (2017) Wood modification technologies – a review. iForest 10:895 – 908.

Soltani A, Hosseinpourpia R, Adamopoulos S, Taghiyari HR, Ghaffari E (2016) Effects of heat-treatment and nano-wollastonite impregnation on fire properties of solid wood. BioResources 11:8953–8967

Soltani A (2019) Presentation and examination of the occurrence of sepiolite mineral in Tanbo Region, southeastern Minab. Iran Res Earth Sci 10:77–93

Suganya S, Kumar PS, Saravanan A (2017) Construction of active bio-nano composite by inseminated metal nanoparticles onto activated carbon: probing to antimicrobial activity. IET Nanobiotechnol 11:746–753

Taghiyari HR, Bayani S, Miltz H, Papadopoulos AN (2020a) Heat treatment of pine wood: possible effect of impregnation with silver nanosuspension. Forests 11:466

Taghiyari HR (2012) Fire-retarding properties of nano-silver in solid woods. Wood Sci Technol 45:939–952

Taghiyari HR, Farajpour Bibalan O (2013) Effect of copper nanoparticles on permeability, physical, and mechanical properties of particleboard. Eur J Wood Prod 71:69–77

Taghiyari HR, Esmailpour A, Papadopoulos AN (2019a) Paint pull-off strength and permeability in nanosilver-impregnated and heat-treated beech wood. Coatings 9:723

Taghiyari HR, Tajvidi M, Taghiyari HR, Mantanis GI, Esmailpour A, Hosseinpourpia R (2019b) Nanotechnology for wood quality improvement and protection. In: Nanomaterials for agriculture and forestry applications. doi.org/https://doi.org/10.1016/B978-0-12-817852-2.00019-6

Taghiyari HR, Soltani A, Esmailpour A, Hassani V, Gholipour H, Papadopoulos AN (2020) Improving thermal conductivity coefficient in oriented strand lumber (OSL) using sepiolite. Nanomaterials 10:599

Tajvidi M, Gardner DJ, Bousfield DW (2016) Cellulose nanomaterials as binders: laminate and particulate systems. J Renew Mater 4:365–376

Wang Z, Yan Y, Shen X, Jin C, Sun Q, Li H (2019) A wood-polypyrrole composite as a photothermal conversion device for solar evaporation enhancement. J Mater Chem A 7:20706

Wang X, Chen X, Xie X, Yuan Z, Cai S, Li Y (2019) Effect of phenol-formaldehyde resin penetration on the quasi-static and dynamic mechanics of wood cell walls using nanoindentation. Nanomaterials 9:1409

White RH, Sweet MS (1992) Flame retardancy of wood: Present status, recent problems, and future fields. In: Proc. of 3rd Annual BCC Conference of Flame Retardancy pp 250–257

Winandy JE (2001) Thermal degradation of the fire-retardant-treated wood. For Prod J 51:47–54

Winandy JE, Wang Q, White RH (2008) Fire-retardant-treated strandboard: properties and fire performance. Wood Fiber Sci 40:62–71

Xu Q, Ji Y, Sun Q, Fu Y, Xu Y, Jin L (2019) Fabrication of cellulose nanocrystal/chitosan hydrogel for controlled drug release. Nanomaterials 9:253

Zikeli F, Vinciguerra V, D’Annibale A, Capitani D, Romagnoli M, Mugnozza G (2019) Preparation of lignin nanoparticles from wood waste for wood surface treatment. Nanomaterials 9:281

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Taghiyari, H.R., Tajvidi, M., Soltani, A. et al. Improving fire retardancy of unheated and heat-treated fir wood by nano-sepiolite. Eur. J. Wood Prod. 79, 841–849 (2021). https://doi.org/10.1007/s00107-021-01679-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01679-1