Abstract

Hordeum vulgare L. is a highly valuable cereal crop worldwide. However, its yield is decreasing due to increasing abiotic stresses. The prolonged action of oxidants creates an imbalance in the functioning of antioxidant systems. One important way to stabilize the redox homeostasis of plants is through the use of microbial preparations that enhance the synthesis of antioxidant compounds. At inoculation of seeds of the barley varieties (Burkhant, Virazh, and Copeland) with the nanocomposite complex bacterial preparation Azogran in plants, the levels of the most identified phenolic acids and flavonoids in the free and bound fractions were increased. Whereas in plants whose seeds were stressed with hydrogen peroxide (H2O2) and inoculated with Azogran, phenolic compounds (Ph-OH) with a high ability to inactivate the harmful effects of H2O2 dominated. In particular, in the plants of the Burkhant barley variety, the concentration-free chlorogenic (by 33.1%), syringic, benzoic, p-coumaric acids, rutin and bound chlorogenic, benzoic and trans-ferulic acids increased. In the plants of the Virazh barley variety, the levels of free caffeic, syringic acids, quercetin and bound 4-hydroxyphenylacetic (4-HPA), trans-ferulic, sinapic, trans-cinnamic acids, quercetin, and kaempferol increased. In plants of the Copeland barley variety, only the content of 4-HPA and trans-ferulic (by 79.9%) acids in the free fraction and syringic acid in the bound fraction was raised. Thus, despite the unequal response of different varieties of barley to the action of the bacterial preparation Azogran, the synthesis of those Ph-OH, which are an effective buffer against peroxide stress, increased in their plants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the important tasks of modern crop production is to increase the resistance of valuable agricultural crops to the influence of abiotic stress factors (soil drought, frost, salinity, heavy metals, UV radiation, herbicides, and flooding) and biotic stress factors (phytopathogens, phytoviruses) [1, 2]. The increase in their intensity leads to an increase in the level of reactive oxygen species (ROS), which are aggressive stress agents. Exceeding the generation of oxidants over the cell’s ability to eliminate them leads to hyperoxidation—oxidative stress [3]. Oxidative stress determines the state in which the “prooxidant-antioxidant” balance is disturbed in the cell, which leads to hydroxylation of nucleic acids, protein denaturation, lipid peroxidation, and apoptosis [4].

Among the members of the Poaceae family, barley (Hordeum vulgare L.) is one of the most economically important grain crops [5], since this cereal is grown in countries whose climatic conditions differ dramatically [6].

In recent years, the increase of anomalies in the environment leads to the accumulation of oxidants in the organism of plants. The high damaging capacity of ROS, the initiators of phytostress, poses a threat to important biomolecules (DNA, proteins, enzymes, lipids, etc.) of plant cells. The redox-homeostasis of phytoobjects is supported by a complex of antioxidants (AN). The balanced operation of high- and low-molecular protectors during different phases of oxidative stress plays an important role in maintaining the viability of plants. However, prolonged exposure to oxidants disrupts redox cycles [7].

Thus, the functioning of the plant organism’s defense system largely depends on the concentration of oxidants. First, high levels of ROS damage protective enzymes (catalase, peroxidase, superoxide dismutase), which leads to a decrease in their activity. Second, the action of stress agents depletes the pool of low-molecular-weight antioxidants. As a result, these disturbances in the normal work of AN lead to the death of plant cells [8].

One of the stabilization ways of redox homeostasis in the plant organism is their mutually beneficial relationships with rhizosphere microorganisms [9]. Such microbes include representatives of the genera Bacillus, Pseudomonas, Azospirillum, Azotobacter, Klebsiella, Enterobacter, Alcaligenes, Arthrobacter, Burkholderia, Serratia, and others [10, 11]. Plant growth-promoting rhizobacteria (PGPR) are of interest in the creation of biological plant protection agents, as they are characterized by the formation of long-term protection of the macroorganism against various stress factors [12]. PGPR contribute to the development of stress tolerance in phytoobjects through various mechanisms [13]. One of which is the activation of the synthesis of various antioxidant compounds in the plant organism [14].

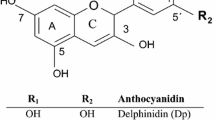

Among them, compounds of phenolic nature (Ph-OH), in particular phenolcarboxylic acids and flavonoids, are of particular interest. These secondary metabolites play an important role in plant metabolism. However, their main mechanisms are related to direct and indirect antioxidant action. That is, Ph-OH acts as electron donors for oxidants, inactivate free radicals, and chelate metal ions that initiate ROS formation reactions [15]. And they can also indirectly activate antioxidant enzymes and inhibit enzymes that induce pro-oxidant effects [16].

In the crop sector of Ukraine, Mongolia, and Canada, barley is one of the dominant cereal crops. The most promising varieties in these countries include Virazh (Ukraine), Burkhant (Mongolia), and Copeland (Canada). They are widely used in production and consumption, and therefore have a high research value.

Accordingly, the main goal of the presented work was to compare the differences that were founded in the composition and content of free and bound phenolic compounds in different barley varieties, the seeds of which were exposed to the action of hydrogen peroxide and post-treatment with the nanocomposite complex bacterial preparation Azogran. This study is important in understanding the role of complex microbial preparations in modern agricultural biotechnologies.

Materials and methods

Research objects

Bacterial strains

-

Bacillus subtilis IMV B-7023 was isolated from black soil (Cherkasy region, Ukraine). The strain is supported at the Depositary of the Zabolotny Institute of Microbiology and Virology, NAS of Ukraine. This strain is a component of the nanocomposite complex bacterial preparation Azogran for crop production [17].

-

Azotobacter vinelandii IMV B-7076 was isolated from the rhizosphere of sugar beet in the Department of Microbiological processes on solid surfaces, Zabolotny Institute of Microbiology and Virology, NAS of Ukraine. This strain is a component of the nanocomposite complex bacterial preparation Azogran for crop production [18].

-

Nanostructured mineral bentonite is a variety of minerals of the montmorillonite group. We used bentonite from the Dashukovsky deposit (Cherkasy region). The size of bentonite nanoparticles was 28.92–99.21 nm;

-

Grain seeds of spring barley: Virazh (Ukraine), Burkhant (Mongolia), Copeland (Canada) varieties;

-

Nanocomposite complex bacterial preparation Azogran. The bacteria that make up the biological product are active producers of amino acids, enzymes, organic acids, antibiotics, phytohormones, vitamins, phenolic compounds, and other biologically active components [19].

-

The cultivation conditions of bacteria

B. subtilis IMV B-7023 was cultivated in modified glucose-mineral liquid nutrient medium [20], g L−1: (NH4)2SO4—0.5; MgSO4 × 7H2O—0.3; NaCl—0.3; KCl—0.3; CaCO3—5.0; MnSO4 × 7H2O—0.001; FeSO4 × 7H2O—0.001; glucose—10.0; sodium glycerophosphate—2.0; distilled water—1.0 L; pH 7.0–7.2.

The number of viable cells (colony-forming units (CFU)) was determined by the method of seeding a suspension of bacteria on a potato agar medium from serial tenfold dilutions. The composition of potato agar medium [21], g L−1: peeled potatoes—200.0; CaCO3—0.2; MgSO4 × 7H2O—0.2; agar–agar—15.0; tap water—1 L; pH 6.8–7.2.

A. vinelandii IMV B-7076 was cultivated in liquid Burke’s medium [22], g L−1: K2HPO4 × 3H2O—0.64; KH2PO4—0.16; NaCl—0.2; MgSO4 × 7H2O—0.2; CaSO4 × 2H2O—0.05; Fe2(SO4)3—0.005; FeSO4 × 7H2O—0.003; Na2MoO4 × 2H2O—0.001; sucrose—20.0; distilled water—1.0 L; pH 7.0–7.2.

The number of viable cells (colony-forming units (CFU)) was determined by the method of seeding a suspension of bacteria on an Ashby’s solid nutrient medium [22], g L−1: sucrose—20.0; K2HPO4 × 3H2O—0.2; MgSO4 × 7H2O—0.2; NaCl—0.2; K2SO4—0.1; CaCO3—5.0; distilled water—1.0 L. In this medium was added the 1 mL of microelement solution (according to Fedorov) of the following composition: H3BO3—5.0; (NH4) 2MoO4 × 2H2O—5.0; ZnSO4 × 7H2O—0.2; KJ—0.5; NaBr—0.54; Al2(SO4)3 × 18H2O—0.3; distilled water—1.0 L; pH 7.2–7.3.

Cultivation of the studied bacterial strains in liquid nutrient media was carried out on rotary shakers (n = 240 rpm) in Erlenmeyer flasks with a volume of 750 mL (100 mL of medium) or in microbiological test tubes into which 20 mL of the medium was added. A daily culture of bacteria was used as an inoculum. The number of viable cells was determined by seeding bacterial suspensions from serial tenfold dilutions onto agar media. After cultivating the inoculations at a temperature of + 28 ± 1 °C, the colonies (colony-forming units, CFU) were counted on the surface of the agar medium in the dilution where their number ranged from 30 to 300.

The design of peroxide stress

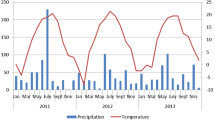

Plants of three barley cultivars were grown under greenhouse conditions (the temperatures around 18 °C during day and 14 °C at night, a photoperiod of 12 h and 50–70% humidity). The seed material previously was subjected to different treatment options:

-

Seeds were soaked in sterile distilled water (H2O) during 1 h;

-

Seeds were bacterized with 3 ml of nanocomposite complex bacterial preparation Azogran for 1 h (Nano-CP);

-

Seeds were treated with 33% hydrogen peroxide for 30 min. (H2O2);

-

Seeds were exposed to 33% hydrogen peroxide (30 min.) and bacterized with 3 ml of nanocomposite complex bacterial preparation Azogran for 1 h (H2O2 + Nano-CP).

The seeds of each barley variety were sowed in 4 replications, 50 seeds per row.

Extraction of free and bound phenolic compounds from different varieties of barley

Plants were selected in phase of stem elongation and dried at room temperature (22 °C) without access to direct light to constant weight. The samples were ground to a powder-like state by a SaturnST-CM1031 electric coffee grinder (220–240 V, 50 Hz, China). A sample (1 g) was took from each variant and divided into two parts of 0.5 g each:

-

First part (extraction of the free phenolic compounds): a sample (0.5 g) of each of the samples of barley plants was placed in round-bottom flasks under reflux and extracted twice with methanol (CH3OH) (50 mL per sample) at a water bath (67.4 °C) during 2 h. The total volume of the extract (100 mL) was filtered through No. 1 filter paper in the Buchner funnel. The resulting filtrate was evaporated to dryness on an IR-1M2 rotary evaporator (Production Association Khimlaborpribor, USSR). The dry residue was redissolved in 2 mL of methanol and analyzed by HPLC;

-

Second part (extraction of the hydrolysis fraction of phenolic compounds): a weighed portion (0.5 g) of each of the samples of barley plants was introduced into round-bottom flasks under reflux and was subjected to acid hydrolysis by adding 30 mL of a mixture of 2 M HCl:CH3OH (1:1). The presence of methanol prevents the destruction of some phenolic acids [23].

Hydrolysis was carried out at 90 °C for 2 h. The hydrolysates were filtered through No. 1 filter paper in the Buchner funnel. The extraction was repeated three times by ethyl acetate (CH3COOC2H5) (30 mL per sample) during 30 min. The extracts were evaporated to dryness on an IR-1M2 rotary evaporator (Production Association Khimlaborpribor, USSR). The dry residue was redissolved in 2 mL of methanol and analyzed by HPLC. The content of bound phenolic compounds was determined from the difference between the amount of total and free polyphenols in the hydrolysis fraction.

HPLC analysis of phenolic acids

High-performance liquid chromatography (HPLC) (Agilent 1200, USA) was used to assess the composition of phenolic acids extracted from the barley samples. Methanol (CH3OH) (A) and 0.1% formic acid (H-COOH) in water (B) were used as the mobile phase. The settings for the elution gradient were as follows: 0 min—A (25%): B (75%); 25 min—A (75%): B (25%); 27 min—A (100%): B (0%); 35 min—A (100%): B (0%). Separation was carried out on a Zorbax SB-Aq column (4.6 mm × 150 mm, 3.5 µm) (Agilent Technologies, USA), flow rate was 0.5 mL/min, thermostat temperature was 30 °C, injection volume was 4 µL. Detection was carried out using a diode array detector with signal registration at 250 nm and 275 nm and fixation of absorption spectra in the range of 210–700 nm [24]. Identification and quantitative analyses were carried out using standard solutions of phenolic compounds: gallic acid, 4-hydroxyphenylacetic acid (4-HPAA), chlorogenic acid, caffeic acid, syringic acid, p-coumaric acid, trans-ferulic acid, sinapic acid, trans-cinnamic acid. The values are expressed as µg g−1 DW (dry weight).

HPLC analysis of flavonoids

High-performance liquid chromatography (HPLC) (Agilent 1200, USA) was used to assess the composition of flavonoids extracted from the barley samples. Acetonitrile (A) and 0.1% formic acid in water (B) were used as the mobile phase. The settings for the elution gradient were as follows: 0 min—A (30%): B (70%); 20 min—A (70%): B (30%); 22 min—A (100%): B (0%); 30 min—A (100%): B (0%). Separation was carried out on a Zorbax SB-C18 column (4.6 mm × 150 mm, 3.5 µm) (Agilent Technologies, USA), flow rate was 0.25 mL/min, thermostat temperature was 30 °C, injection volume was 4 µL. Detection was carried out using a diode array detector with signal registration at 280 nm and 365 nm and fixation of absorption spectra in the range of 210–700 nm [25,26,27]. Identification and quantitative analyses were carried out using standard solutions of flavonoids: rutin, quercetin-3-b-glucoside, naringin, neohesperidin, quercetin, naringenin, kaempferol, luteolin, apigenin. The values are expressed as µg g−1 DW.

Statistical analysis

Microsoft Excel (Microsoft Corporation, USA) was used to analyze the data on the average of the three replicates (± SE) obtained from the three independent experiments. Differences were compared with the statistical significance at a P level less than 0.05 (P < 0.05) [28]. Tukey’s test was used to determine significant (P < 0.05) differences between the samples.

Results and discussion

Composition and content of the free phenolic acids of different barley varieties

Modern agricultural biotechnologies are closely related to microbial biopreparations for crop production, in particular those of complex action. They are one of the important components of ecological agriculture [29, 30]. The mechanism of formation of plants stress tolerance with the help of biological preparations is closely related to the metabolites of bacteria included in their composition. A number of these compounds are considered as triggers that start a cascade of plant-specific biosynthetic processes that increase resistance to the damaging effects of oxidants [31, 32]. One of these processes can be the activation of the production of phenolic compounds in the organism of phytoobjects [14].

We established significant differences in the qualitative and quantitative composition of phenolic compounds in the plants of the studied varieties of barley, the seeds of which were subjected to hydrogen peroxide (H2O2) treatment and post-treatment with Azogran.

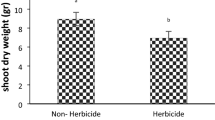

The 4-hydroxyphenylacetic, chlorogenic, caffeic, syringic, benzoic, p-coumaric, trans-ferulic, sinapic and trans-cinnamic acids were identified in the variant with the treatment of seeds of different varieties of barley with distilled sterile water (dH2O). Their highest content was observed in the free fraction of phenolic compounds obtained from Copeland variety barley plants—1488 µg g−1 DW (Fig. 1, Table 1). No significant differences in the quantitative composition were found in the extracts obtained from plants of two other varieties of barley (Table 1).

Whereas, the content of phenolic acids in the free fraction obtained from Virazh variety barley plants increased significantly when seeds were treated with the nanocomposite complex bacterial preparation Azogran. Accordingly, the concentration of sinapic acid increased by 97.9%, trans-cinnamic acid by 106.9%, syringic acid by 116.4%, caffeic acid by 117.9%, benzoic acid by 123.9%, 4-HPAA by 124.6%, chlorogenic acid by 158.8%, p-coumaric acid by 230.2%, compared to the sample where the seeds were treated with sterile distilled water (Table 1).

As for the other varieties, only in the Copeland variety plants, the content of sinapic acid was increased by 1.6%, syringic acid by 8.8%, caffeic acid by 13.9%, and trans-ferulic acid by 104.2%, compared to the variant where barley seeds were treated with dH2O (Table 1). The concentration of phenolic acids in Burkhant variety plants practically did not differ from this sample where seeds were treated with dH2O. No changes in the qualitative composition of these compounds in the plants of the studied barley varieties were recorded (Table 1).

The results obtained on the effect of PGPR on the levels of phenolic acids in plants were consistent with a number of other studies. In particular, the content of these compounds in the Piper betle L. after inoculation with Serratia marcescens NBRI1213 bacteria [33] and in the Tagetes minuta after inoculation with Pseudomonas fluorescens WCS417r and Azospirillum brasilense [34] was increased. Singh et al. [35] reported that mono- or complex inoculation of chickpea seeds with Ps. fluorescens Pf4 and Ps. aeruginosa Pag strains activated the synthesis of gallic, ferulic, and chlorogenic acids in plants.

Under the influence of an aggressive stress agent (H2O2) on barley seeds, the total content of phenolic acids in the free fraction obtained from Copeland variety and Burkhant variety plants decreased by 15.4% and 78.9%, compared to the variant where the seeds were treated with sterile distilled water. In particular, in the Burkhant variety plants, the concentration of chlorogenic acid decreased by 138.71 µg g−1 DW, caffeic acid by 175.52 µg g−1 DW, benzoic acid by 139.00 µg g−1 DW, trans-ferulic acid by 41.34 µg g−1 DW, and sinapic acid by 132.74 µg g−1 DW, respectively. And in the Copeland variety plants, the level of chlorogenic acid decreased by 39.04 µg g−1 DW, caffeic acid by 45.50 µg g−1 DW, benzoic acid by 116.54 µg g−1 DW, and sinapic acid by 57.80 µg g−1 DW, respectively. It was also found that syringic acid was not identified in methanol extracts obtained from plants of these barley varieties (Fig. 2, Table 1).

Elguera et al. [36] found that at growing of Lepidium sativum in the presence of cadmium chloride [Cd(II)], the content of chlorogenic, ferulic, and caffeic acids in the free fraction of phenolic acids obtained from plant leaves decreased. Increased levels of ROS can lead to disruption of the secondary-metabolite biosynthesis (in particular phenolic compounds) whose structural skeleton consists of carbon atoms [37].

However, the treatment of seeds of the barley Virazh variety with hydrogen peroxide increased the level of phenolic acids (free fraction) by two times in plants compared to the variant (dH2O) (Table 1). Stress tolerance and biological activity of cereal crops significantly depend on their variety [38,39,40].

At post-treatment with Azogran for seeds of the tested cereal varieties, the concentration of phenolic acids (free fraction) increased only in plants of barley Burkhant variety by 27.24 µg g−1 DW, compared to stressed plants of the same variety. Especially the level of sinapic acid increased by 34.1%. This phenolic compound is a powerful antioxidant. Its antiradical activity (ARA) is significantly higher than that of ferulic acid [41, 42]. Chiappero et al. [43] found that inoculated with Ps. fluorescens WCS417 r and B. amyloliquefaciens GB03 drought-stressed Mentha piperita plants activated the synthesis of phenolic compounds. Post-treatment of stressed seeds of two other barley varieties with biological preparation Azogran did not have a pronounced stimulating effect on the content of phenolic carboxylic acids of the free fraction in their plants. Thus, for barley Virazh variety, an increase in caffeic acid by 5.7% was observed, and in plants of Copeland variety, the content of 4-HPAA increased by 15.0% and trans-ferulic acid by 79.9%, compared to the stressed variant (Table 1). These phenolic compounds effectively inactivate such stress agents as hydrogen peroxide and hydroxyl radical [44, 45]. Their high antioxidant activity depends on the presence of hydroxyl and methoxy groups in the chemical structure [46]. All phenolic carboxylic acids, including syringic acid (SA), were identified in the qualitative composition (Table 1). The antioxidant potentials of SA and caffeic acid are very similar [47]. And the high ARA of this phenolic compound is due to the presence of two methoxy groups attached to the aromatic ring at positions 3 and 5 [48, 49]. Thus, post-treatment with the nanocomposite complex bacterial preparation Azogran of hydrogen peroxide-stressed seeds of different barley varieties activated the synthesis of phenolic acids with powerful antioxidant and antiradical properties in plants.

Composition and content of the bound phenolic acids of different barley varieties

The qualitative and quantitative content of phenolic acids in the hydrolysis fraction obtained from plants of different barley varieties differed significantly from their presence in the free fraction and depended on the variant of seed treatment.

It was found that the hydrolyzed fraction of phenolic compounds obtained from plants of the Burkhant barley variety, whose seeds were soaked in sterile distilled water, contains syringic, benzoic, p-coumaric, trans-ferulic, sinapic, and trans-cinnamic acids (Table 2). In addition to these phenolic acids, 4-HPAA and caffeic acids were found in the plants of Virazh barley variety, but syringic acid was absent. The quantitative content of each of the phenolic acids in the bound fraction was the highest compared to the other two varieties (Fig. 3B, Table 2). In the hydrolyzed fraction of phenolic acids from plants of Copeland barley variety, all phenolic acids were present, except for gallic acid (Fig. 3C, Table 2).

At inoculation of seeds of the Burkhant barley variety with the nanocomposite complex bacterial preparation Azogran, in the bound fraction of phenolic acids obtained from plants, a high level of caffeic acid (3,4-dihydroxycinnamic acid) was found—89.88 µg g−1 DW (Table 2). This compound is an ortho-dihydroxyphenol with a powerful antioxidant potential and can inactivate the highly aggressive hydroxyl radical [50]. The product of the methylation reaction of caffeic acid is ferulic acid, which, together with p-coumaric acid, initiates the synthesis of lignin [51, 52]. This natural polymer provides plant resistance to various abiotic stressors [53].

In the bound fraction obtained from plants of Virazh barley variety, after inoculation seeds with Azogran, high content of caffeic acid (239.82 µg g−1 DW) and benzoic acid (264.40 µg g−1 DW) was detected (Table 2).

The treatment of seeds with 33% H2O2 negatively affected both on qualitative and on quantitative composition of phenolic acids in the bound fraction obtained from plants of the three tested barley varieties. In particular, in plants of Burkhant barley variety, the concentration of benzoic acid decreased by 145.40 µg g−1 DW, p-coumaric acid by 3.14 µg g−1 DW, trans-ferulic acid by 55.90 µg g−1 DW, sinapic acid by 6.60 µg g−1 DW, and trans-cinnamic acid by 9.88 µg g−1 DW, compared to plants of the same variety grown from seeds soaked in sterile distilled water (Table 2).

In plants of the Virazh barley variety, only the content of sinapic acid decreased by 55.60 µg g−1 DW compared to the sample which seeds were soaked in the sterile distilled water (Table 2).

Hydrogen peroxide had the most negative effect on the content of phenolic acids in the bound fraction in plants of Copeland barley variety. Accordingly, the concentration of caffeic acid decreased by 76.18 µg g−1 DW, benzoic acid by 64.70 µg g−1 DW, p-coumaric acid by 32.08 µg g−1 DW, trans-ferulic acid by 13.60 µg g−1 DW, sinapic acid by 92.44 µg g−1 DW, and trans-cinnamic acid by 7.78 µg g−1 DW, compared to the variant which seeds were soaked only in sterile distilled water. Also, 4-HPAA, chlorogenic, and syringic acids were not identified for this variety (Fig. 4, Table 2).

Thus, the effect of peroxide stress on phenolic acids in the bound fraction of all three tested barley varieties differed significantly. However, the concentration of caffeic, benzoic, trans-ferulic, and sinapic acids decreased most sharply (Table 2).

Similar results were obtained by different groups of scientists in the study of the profile of phenolic compounds in different plant species under abiotic stress. In scientific papers [54, 55], it was showed that Vitis vinifera plants grown under cold stress conditions had decreased levels of esters and glycosides of the caffeic, ferulic, and p-coumaric acids compared to the control. According to a study by Kovacik et al. [56], among the 14 identified phenolic acids in the leaf rosette of Matricaria chamomilla, the content of chlorogenic and caffeic acids decreased sharply under NaCl stress. The decrease in the content of phenolic acids may be the result of inhibition by stress agents of the activity of enzymes involved in their biosynthesis [57].

Post-treatment of seeds of the different barley varieties with nanocomposite complex bacterial preparation Azogran caused an increase in the content of only some phenolic acids in stressed plants. Accordingly, in the bound fraction obtained from barley plants of the Burkhant variety, the concentration of chlorogenic acid increased by 14.22 µg g−1 DW and benzoic acid by 50.76 µg g−1 DW, compared to plant varieties where seeds were treated only with hydrogen peroxide (Table 2). Chlorogenic acid (CGA) is a phenolic derivative with a unique chemical structure that is a combination of caffeic and quinic acids. This allows CGA to effectively neutralize R in plant cells [58, 59]. Benzoic acid, in turn, ensures the resistance of phytoobjects to various abiotic and biotic stresses: drought, cold [60], phytopathogenic fungi [61].

In the same fraction from plants of the Virazh barley variety, the concentration of 4-HPAA increased by 32.58 µg g−1 DW, trans-ferulic acid by 3.36 µg g−1 DW, and sinapic acid by 4.40 µg g−1 DW compared to the variant where seeds are treated with a stress agent only (Table 2). 4-Hydroxyphenylacetic acid, in addition to being an antioxidant [62], effectively inhibits the development of some phytopathogenic microbes: Fusarium culmorum 50536, Fusarium solani 50666, Alternaria alternate 16765 [63]. The mechanism of antioxidant action of the ferulic acid is difficult and is aimed at inhibiting the surge of ROS and neutralizing free radicals in living cells. Also, this phenolic compound is responsible for chelation of protonated metal ions (Cu (II) and Fe (II)), the initiators of the Fenton reaction [64, 65], the product of which is a highly reactive hydroxyl radical. Ferulic acid not only converts free radicals (R·) into neutral molecules, but also inhibits enzymes that catalyze R· generation [66]. No significant changes were found in the content of phenolic acids in the bound fraction obtained from plants of Copeland barley variety. In addition, syringic acid was identified, which was absent in barley plants that developed from stressed seeds (Table 2). Tiwari et al. [67] reported that inoculation of wheat (Triticum aestivum) seeds with Bacillus pumilus under salt stress conditions promoted the accumulation of syringic acid in plants.

Composition and content of the free flavonoids of different barley varieties

In plants of barley varieties, whose seeds were subjected to different treatments, the content of flavonoids in free and bound fractions was determined. As a result, significant differences were found.

The free fraction of flavonoids extracted from plants Burkhant barley variety, whose seeds were treated with sterile distilled water, contained rutin, quercetin-3-β-glycoside, quercetin, and luteolin (Fig. 5A, Table 3). The pronounced antioxidant, anti-inflammatory, and antitumor properties of quercetin and luteolin are due to the high similarity of their chemical structure. Only the presence of a hydroxyl group in the quercetin molecule at position 3 distinguishes these two flavonoids [68].

In the same fraction obtained from plants Virazh barley variety, in addition to the above flavonoids, neohesperidin was identified. The total content of these compounds was the highest and amounted to 30.72 µg g−1 DW (Fig. 5B, Table 3). Only two flavonoids were detected in Copeland plants—quercetin-3-β-glycoside and quercetin (Fig. 5C, Table 3). The flavonoid content is an important indicator of the antioxidant potential of plants and also determines the health benefits of functional foods [69].

The treatment of seeds of different barley varieties with the nanocomposite complex bacterial preparation Azogran increased the concentration of flavonoids in the free fraction obtained from plants of Burkhant and Virazh varieties by 9.52 µg g−1 DW and 11.64 µg g−1 DW, respectively, compared to the previous variant. The study [70] showed that inoculation of the roots of two broccoli varieties with Paraburkholderia graminis PHS1, P. hospita mHSR1, and P. terricola mHS1 strains contributed to the accumulation of secondary metabolites, including flavonoids, in plants.

In addition, naringin was identified in Burkhant plants (Fig. 6, Table 3). This flavanone is a glycoside of naringenin and is able to effectively inactivate hydroxyl and superoxide radicals, thus protecting DNA from oxidative stress [71, 72].

Under the action of 33% hydrogen peroxide on barley seeds, the synthesis of flavonoids in the free fraction in barley plants of the Burkhant variety was significantly reduced. Among the previously detected flavonoid compounds, only quercetin-3-β-glycoside was identified—4.30 µg g−1 DW. Glycosylated flavonoids with a catechol group at the 3′–4′ position are characterized by a high antioxidant potential [73]. A number of experimental studies [74,75,76] have shown that the concentration of quercetin glycosides in different plant species remained high in response to various abiotic stresses.

While for barley variety Virazh, an increase in the concentration of some flavonoids in the free fraction was observed. In particular, the content of quercetin increased by 6.13 μg/g DW and luteolin by 9.15 μg/g DW, compared to plants of the same variety, whose seeds were treated with sterile distilled water (Fig. 7, Table 3). On the one hand, the impact of stress factors on plants can impair their ontogeny and productivity in general, and on the other hand, it can activate the metabolism of important biologically active compounds [40].

No significant changes in the quantitative and qualitative content of flavonoids in the free fraction of the barley variety Copeland were found.

Post-treatment of the stressed seed material of the studied cereal crop with the biological product Azogran had no significant effect on the level of flavonoids in the free fraction in plants of all three barley varieties (Table 3).

Composition and content of the bound flavonoids of different barley varieties

In barley samples, the content of flavonoids in the bound fraction was checked and significant differences between varieties were found. The concentration of flavonoids in the bound fraction was higher than in the free fraction. It should be noted that in plants of different varieties of blue Highland barley, the content of flavonoids in the free fraction significantly exceeded the content of bound flavonoids [77]. While, in buckwheat, wheat, rice, corn, and oats, flavonoids prevailed in the bound fraction [78]. At treatment seeds with sterile distilled water, the total content of these compounds in plants of Burkhant variety was 190.52 µg g−1 DW, Virazh variety was 47.76 µg g−1 DW, and Copeland variety was 20.55 µg g−1 DW. Differences were also found in the qualitative composition. Rutin, quercetin-3-β-glycoside, quercetin were identified in barley plants of Burkhant variety; quercetin, kaempferol in Virazh variety; quercetin-3-β-glycoside, quercetin in Copeland variety (Fig. 8; Table 4). This difference is related to the genotype of each of the barley varieties under study. For example, Xi-Juan with co-authors [77] found that in blue Highland barley plants, naringenin and hesperidin predominated in the bound fraction of flavonoids. While Kim with co-authors [79] showed that in colored barley, the main flavonoid was myricetin.

Treatment of seeds with nanocomposite complex bacterial preparation was accompanied by an increase in the concentration of flavonoids only in plants of the Virazh variety to 125.27 µg g−1 DW (Table 4). Ali et al. [80] found that the treatment of Arabidopsis thaliana with the microbial preparation Soil Builder™-AF increased the induction of the transcriptional profile of genes of the phenylpropanoid pathway, which contributed to the accumulation of flavonoids in the leaves of plants.

The stimulating effect of Azogran on the qualitative and quantitative composition of flavonoids in the bound fraction in plants of the other two varieties was not detected. In particular, for Burkhant variety, a decrease in flavonoid content by 170.69 µg g−1 DW was recorded compared to the variant in which the seeds were treated with sterile distilled water (Table 4). This may be due to the specifics of the development of each of the studied cereal varieties, when their seeds were treated with the nanocomposite complex bacterial preparation Azogran. The effect of PGPR on phenylpropanoid pathways is associated with the stimulation or inhibition of plant growth at a certain phase of their development. That is, if rhizobacteria activate growth, then the biosynthesis of flavonoids is inhibited and, conversely, with a decrease in growth, the level of these phenolic compounds in plants increases [81]. We conducted our research with barley plants in the tube stage. This is one of the most critical periods in the ontogeny of cereal spiked crops. This phase is characterized by the formation of flowers in the spikelets and active growth of the spikelet. That is, this is the transition from the vegetative to the generative phase of cereal crop development [82]. In barley plants of Burkhant and Copeland varieties, whose seeds were inoculated with Azogran, this transition was very slow. They were still growing quite actively, which may have influenced the decrease in flavonoid levels.

Under the action of hydrogen peroxide on the seed of the Virazh variety, the content of flavonoids in the bound fraction decreased by 29.36 µg g−1 DW, compared to plants whose seeds were treated with the nanocomposite complex bacterial preparation Azogran. Treatment of barley grain of Burkhant variety with this stress agent stimulated the synthesis of naringin in plants, its concentration was 19.66 µg g−1 DW, while the content of other flavonoids in the bound fraction decreased (Table 4). Hydrogen peroxide had a stimulating effect only on the flavonoid complex of Copeland plants. In addition, neohesperidin was identified. The increase in the flavonoid content may be due to the ability of H2O2 to regulate the expression of the genes of phenylalanine ammonia lyase, chalcone synthase, and stilbene synthase, which are involved in the synthesis of plant flavonoids [83, 84].

Post-treatment of stressed barley seeds with Azogran had the most positive effect on the flavonoid complex of the bound fraction of plants of the Virazh variety. Accordingly, a high content of quercetin-3-β-glycoside—36.78 µg g−1 DW and quercetin—42.63 µg g−1 DW was found (Table 4). For the other two varieties, this effect was not observed. Ayuso-Calles with co-authors [85] showed that in lettuce inoculated with Rhizobium laguerreae bacteria, which developed under salt stress, the content of flavonoids was slightly reduced compared to inoculated plants growing under normal conditions. Such effects may have different causes. First, it is the type of microorganisms-inoculants. Zapata-Sufientes et al. [86], at studying the effect of Pseudomonas paralactis, Sinorhizobium meliloti, and Acinetobacter radioresistens on the flavonoid content of cucumbers, found that S. meliloti bacteria contribute to the greatest accumulation of these compounds in the fruits of these plants. Secondly, it is the plant variety. According to a study by Jeon et al. [81], treatment of two broccoli varieties, Malibu and Coronado, with the epiphytic rhizobacterium Paraburkholderia led to a greater accumulation of flavonoid glycosides only in Malibu plants. Whereas Zaferanchi et al. [87] pointed out an insignificant concentration difference of flavonoids in marigold plants of Isfahan double flower and Isfahan single flower varieties, the seeds of which were inoculated with PGPR (Azotobacter sp.145PI and Azospirillum sp.AC49I). And third, it is the level of influence of the stressor on the plant, the higher it is, the greater the imbalance of redox homeostasis and other biochemical processes in the cells.

Conclusion

The large amplitude of variation of phenolic carboxylic acids and flavonoids indicates the specificity of the interaction of different barley varieties with the bacteria components of Azogran and their different responses to the effect of the preparation under conditions of peroxide stress. For barley variety Virazh, higher results were obtained in studying the effect of the stress agent and nanocomposite complex bacterial preparation Azogran on the qualitative and quantitative content of phenolic compounds in its plants. Since the selection of this variety and its agricultural technology is carried out in Ukraine, it is more adapted to the climatic conditions and soil microbial community of this country. At that time, the Burkhant (Mongolia) and Copeland (Canada) barley varieties were first grown in Ukraine. However, the proposed treatment of native and post-treatment of stressed seeds of these barley varieties with a nanocomposite complex bacterial preparation helped to activate the synthesis of a complex of phenolic compounds in their plants.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Cramer GR, Urano K, Delrot S, Pezzotti M, Shinozaki K (2011) Effects of abiotic stress on plants: a systems biology perspective. BMC Plant Biol 11(1):163. https://doi.org/10.1186/1471-2229-11-163

Vanlerberghe G (2013) Alternative oxidase: a mitochondrial respiratory pathway to maintain metabolic and signaling homeostasis during abiotic and biotic stress in plants. Int J Mol Sci 14:6805–6847. https://doi.org/10.3390/ijms14046805

Le Gal K, Schmidt EE, Sayin VI (2021) Cellular redox homeostasis. Antioxidants 10:1331–1337. https://doi.org/10.3390/antiox10091377

Genestra M (2007) Oxyl radicals, redox-sensitive signaling cascades and antioxidants. Cell Signal 19(9):1807–1819. https://doi.org/10.1016/j.cellsig.2007.04.009

Distelfeld A, Avni R, Fischer AM (2014) Senescence, nutrient remobilization, and yield in wheat and barley. J Exp Bot 65:3783–3798. https://doi.org/10.1093/jxb/ert477

Adrian CN, Andrew JF, Timothy SG, Philip LB, Luke R, Cesar R, Joanne R, Brian JS, Stuart S, William TB, Robbie W, Philip JW, Ian JB (2011) Barley: a resilient crop? Strengths and weaknesses in the context of food security. Food Sec 3:141–178. https://doi.org/10.1007/s12571-011-0126-3

Foyer CH, Trebst A, Noctor G (2005) Protective and signaling functions of ascorbate, glutathione and tocopherol in chloroplasts. In: Demming-Adams B, Adams WW (eds) Advances in photosynthesis and respiration: photoprotection, photoinhibition, gene regulation, and environment. Kluwer Academic, Dordrecht, pp 241–268

Chaki M, Begara-Morales JC, Barroso JB (2020) Oxidative stress in plants. Antioxidants 9(6):481–488. https://doi.org/10.3390/antiox9060481

Abdelaal K, AlKahtani M, Attia K, Hafez Y, Kiraly L, Künstler A (2021) The role of plant growth-promoting bacteria in alleviating the adverse effects of drought on plants. Biology 10:520–523. https://doi.org/10.3390/biology10060520

Bhattacharyya PN, Jha DK (2012) Plant growth-promoting rhizobacteria (PGPR): emergence in agriculture. World J Microbiol Biotechnol 28:1327–1350. https://doi.org/10.1007/s11274-011-0979-9

Kumari P, Meena M, Upadhyay RS (2018) Characterization of plant growth promoting rhizobacteria (PGPR) isolated from the rhizosphere of Vigna radiata (mung bean). Biocatal Agric Biotechnol 16:155–162. https://doi.org/10.1016/j.bcab.2018.07.029

Rosenblueth M, Martinez-Romero E (2006) Bacterial endophytes and their interactions with hosts. Mol Plant-Microbe Interact 19:827–837. https://doi.org/10.1094/MPMI-19-0827

Kumar A, Patel JS, Meena VS, Ramteke PW (2019) Plant growth-promoting rhizobacteria: strategies to improve abiotic stresses under sustainable agriculture. J Plant Nutr 42:1402–1415. https://doi.org/10.1080/01904167.2019.1616757

Chandran H, Meena M, Swapnil P (2021) Plant growth-promoting rhizobacteria as a green alternative for sustainable agriculture. Sustainability 13(19):10986. https://doi.org/10.3390/su131910986

Cosme P, Rodriguez AB, Espino J, Garrido M (2020) Plant phenolics: bioavailability as a key determinant of their potential health-promoting applications. Antioxidants (Basel) 9(12):1263. https://doi.org/10.3390/antiox9121263

Ballard CR, Maróstica MR (2018) Health benefits of flavonoids. In: Segura-Campos MR (ed) Bioactive compounds: health benefits and potential applications. Elsevier Inc., Amsterdam, pp 185–201

Kurdish IK, Roy AO (2003) Strain of bacteria Bacillus subtilis for bacterial fertilizer obtaining for plant-growing. Patent of Ukraine No. 54923A, 17 March 2003 (in Ukraine)

Kurdish IK, Bega ZT (2006) Strain of bacteria Azotobacter vinelandii for bacterial fertilizer obtaining for plant-growing. Patent of Ukraine No. 72856, 15 July 2006 (in Ukraine)

Kurdish I, Roy A, Hryshchenko R (2019) Method for obtaining a nanocomposite complex bacterial preparation for crop production. Patent for utility model No. 135362 Ukraine, 24 Oct 2019 (in Ukraine)

Menkina RA (1950) Bacteria which mineralize organic phosphorus compounds. Microbiology 19(4):308–315

Dobrovolskaya TG, Skvortsova IN, Lysak LV (1989) Methods of isolation and identification of soil bacteria. Lomonosov Moscow State University, Moscow (Book in Russian)

Rubenchik LI (1960) Azotobacter and its application in agriculture. USSR Academy of Science publishers, Kyiv

Babbar N, Oberoi HS, Sandhu SK, Bhargav VK (2014) Influence of different solvents in extraction of phenolic compounds from vegetable residues and their evaluation as natural sources of antioxidants. J Food Sci Technol 51(10):2568–2575. https://doi.org/10.1007/s13197-012-0754-4

Pereira GA, Arruda HS, de Morais DR, Peixoto Araujo NM, Pastore GM (20202) Mutamba (Guazuma ulmifolia Lam) fruit as a novel source of dietary fiber and phenolic compounds. Food Chem 310:125857. https://doi.org/10.1016/j.foodchem.2019.125857

Seo ON, Kim GS, Kim YH, Park S, Jeong SW, Lee SJ, Jin JS, Shin SC (2013) Determination of polyphenol components of Korean Scutellaria baicalensis Georgi using liquid chromatography-tandem mass spectrometry: contribution to overall antioxidant activity. J Funct Foods 5:1741–1750. https://doi.org/10.1016/j.jff.2013.07.020

Tao W, Zhou Z, Zhao B, Wei T (2016) Simultaneous determination of eight catechins and four theaflavins in green, black and oolong tea using new HPLC–MS–MS method. J Pharm Biomed Anal 131:140–145. https://doi.org/10.1016/j.jpba.2016.08.020

Tótha G, Barabás C, Tóth A, Kéry Á, Béni S, Boldizsár I, Varga E, Noszál B (2016) Characterization of antioxidant phenolics in Syringa vulgaris L. flowers and fruits by HPLC-DAD-ESI-MS. Biomed Chromatogr 30:923–932. https://doi.org/10.1002/bmc.3630

Lakin GF (1990) Biometrics. Higher School, Moscow (Book in Russian)

Singh R (2019) Microbial biotechnology: a promising implement for sustainable agriculture. In: Sing JS, Singh DP (eds) New and future developments in microbial biotechnology and bioengineering. Elsevier, B. V, pp 107–114

Davranov K, Shurigin V, Samadiy S, Djalolova B (2021) The conception of microbial preparations development for crop production. Microbiol J 83(1):87–100. https://doi.org/10.15407/microbiolj83.01.087

van Loon LC (2007) Plant responses to plant growth promoting rhizobacteria. Eur J Plant Pathol 119:243–254. https://doi.org/10.1007/s10658-007-9165-1

Kumar A, Verma JP (2018) Does plant—microbe interaction confer stress tolerance in plants: a review? Microbiol Res 207:41–52. https://doi.org/10.1016/j.micres.2017.11.004

Lavania M, Chauhan PS, Chauhan SVS, Singh HB, Nautiyal CS (2006) Induction of plant defense enzymes and phenolics by treatment with plant growth-promoting rhizobacteria Serratia marcescens NBRI1213. Curr Microbiol 52:363–368. https://doi.org/10.1007/s00284-005-5578-2

Cappellari L, Santoro MV, Nievas F, Giordano W, Banchio E (2013) Increase of secondary metabolite content in marigold by inoculation with plant growth-promoting rhizobacteria. Appl Soil Ecol 70:16–22. https://doi.org/10.1016/j.apsoil.2013.04.001

Singh UP, Sarma BK, Singh DP (2003) Effect of plant growth-promoting rhizobacteria and culture filtrate of Sclerotium rolfsii on phenolic and salicylic acid contents in chickpea (Cicer arietinum L.). Curr Microbiol 46:131–140. https://doi.org/10.1007/s00284-002-3834-2

Elguera JCT, Barrientos EY, Wrobel K, Wrobel K (2013) Effect of cadmium (Cd(II)), selenium (Se(IV)) and their mixtures on phenolic compounds and antioxidant capacity in Lepidium sativum. Acta Physiol Plant 35:431–441. https://doi.org/10.1007/s11738-012-1086-8

Radi AA, Farghaly FA, Hamada AF (2013) Physiological and biochemical responses of salt-tolerant and salt-sensitive wheat and bean cultivars to salinity. J Biol Earth Sci 3(1):B72–B88

Chakraborty U, Pradhan B (2012) Oxidative stress in five wheat varieties (Triticum aestivum L.) exposed to water stress and study of their antioxidant enzyme defense system, water stress responsive metabolites and H2O2 accumulation. Braz J Plant Physiol 24(2):117–130. https://doi.org/10.1590/S1677-04202012000200005

Caverzan A, Casassola A, Brammer SP (2016) Antioxidant responses of wheat plants under stress. Genet Mol Biol 39:1–6. https://doi.org/10.1590/1678-4685-GMB-2015-0109

Kowalczewski PŁ, Radzikowska D, Ivanišová E, Szwengiel A, Kačániová M, Sawinska Z (2020) Influence of abiotic stress factors on the antioxidant properties and polyphenols profile composition of green barley (Hordeum vulgare L.). Int J Mol Sci 21(2):397. https://doi.org/10.3390/ijms21020397

Jin XL, Yang RT, Shang YJ, Dai F, Qian YP, Cheng LX, Zhou B, Liu ZL (2010) Oxidative coupling of cinnamic acid derivatives and their radical-scavenging activities. Chin Sci Bull 55:2885–2890. https://doi.org/10.1007/s11434-010-3064-0

Nićiforović N, Abramovič H (2014) Sinapic acid and its derivatives: natural sources and bioactivity. Compr Rev Food Sci Food Saf 13(1):34–51. https://doi.org/10.1111/1541-4337.12041

Chiappero J, Cappellari LR, Sosa Alderete LG, Palermo TB, Banchio E (2019) Plant growth promoting rhizobacteria improve the antioxidant status in Mentha piperita grown under drought stress leading to an enhancement of plant growth and total phenolic content. Ind Crops Prod 139:111553. https://doi.org/10.1016/j.indcrop.2019.111553

Adjimani JP, Asare P (2015) Antioxidant and free radical scavenging activity of iron chelators. Toxicol Rep 2:721–728. https://doi.org/10.1016/j.indcrop.2019.111553

Lu Y, Wang W, Wang D, Bian X, Zhang H, Shi P (2022) Reaction mechanism of ferulic acid scavenging OH and NO2 radicals: a theoretical study. Struct Chem 33:641–647. https://doi.org/10.1007/s11224-021-01855-2

Aguilar-Hernández I, Afseth NK, López-Luke T, Contreras-Torres F, Wold JP, Ornelas-Soto N (2017) Surface enhanced Raman spectroscopy of phenolic antioxidants: a systematic evaluation of ferulic acid, p-coumaric acid, caffeic acid and sinapic acid. Vib Spectrosc 89:113–122. https://doi.org/10.1016/j.vibspec.2017.02.002

Marinova EM, Yanishlieva NV (2003) Antioxidant activity and mechanism of action of some phenolic acids at ambient and high temperature. Food Chem 81:189–197. https://doi.org/10.1016/S0308-8146(02)00411-9

Karamaæ M, Kosinska A, Pegg RB (2005) Comparison of radical–scavenging activities of selected phenolic acids. Pol J Food Nutr Sci 14:165–170

Srinivasulu C, Ramgopal M, Ramanjaneyulu G, Anuradha CM, Suresh KC (2018) Syringic acid (SA)—a review of its occurrence, biosynthesis, pharmacological and industrial importance. Biomed Pharmacother 108:547–557. https://doi.org/10.1016/j.biopha.2018.09.069

Dai J, Mumper RJ (2010) Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15(10):7313–7352. https://doi.org/10.3390/molecules15107313

Goleniowski ME, Bonfill M, Cusido R, Palazon J (2013) Phenolic acids. In: Ramawat KG, Merillon JM (eds) Natural products. Springer, Berlin, pp 1951–1973

Šamec D, Karalija E, Šola I, Bok VV, Salopek-Sondi B (2021) The role of polyphenols in abiotic stress response: the influence of molecular structure. Plants 10:118. https://doi.org/10.3390/plants10010118

Klein A, Keyster M, Ludidi N (2015) Response of soybean nodules to exogenously applied caffeic acid during NaCl-induced salinity. S Afr J Bot 96:13–18. https://doi.org/10.1016/j.sajb.2014.10.016

Weidner S, Kordala E, Brosowska-Arendt W, Karamać M, Kosińska A, Amarowicz R (2009) Phenolic compounds and properties of antioxidants in grapevine roots followed by recovery. Acta Soc Bot Pol 78:279–286. https://doi.org/10.5586/asbp.2009.036

Król A, Amarowicz R, Weidner S (2014) Changes in the composition of phenolic compounds and antioxidant properties of grapevine roots and leaves (Vitis vinifera L.) under continuous of long-term drought stress. Acta Physiol Plant 36:1491–1499. https://doi.org/10.1007/s11738-014-1526-8

Kováčik J, Klejdus B, Hedbavny J, Bačkor M (2009) Salicylic acid alleviates NaCl-induced changes in the metabolism of Matricaria chamomilla plants. Ecotoxicology 18:544–554. https://doi.org/10.1007/s10646-009-0312-7

André CM, Schafleitner R, Legay S, Lefèvre I, Aliaga CA, Nomberto G, Hoffmann L, Hausman JF, Larondelle Y, Evers D (2009) Gene expression changes related to the production of phenolic compounds in potato tubers grown under drought stress. Phytochemistry 70:1107–1116. https://doi.org/10.1016/j.phytochem.2009.07.008

Lallemand LA, Zubieta C, Lee SG, Wang Y, Acajjaoui S, Timmins J, McSweeney S, Jez JM, McCarthy JG, McCarthy AA (2012) A structural basis for the biosynthesis of the major chlorogenic acids found in coffee. Plant Physiol 160(1):249–260. https://doi.org/10.1104/pp.112.202051

Gramazio P, Prohens J, Plazas M, Andújar I, Herraiz F, Castillo E, Knapp S, Meyer RS, Vilanova S (2014) Location of chlorogenic acid biosynthesis pathway and polyphenol oxidase genes in a new interspecific anchored linkage map of eggplant. BMC Plant Biol 14(1):350. https://doi.org/10.1186/s12870-014-0350-z

Senaratna T, Merritt D, Dixon K, Bunn E, Touchell D, Sivasithamparam K (2003) Benzoic acid may act as the functional group in salicylic acid and derivatives in the induction of multiple stress tolerance in plants. Plant Growth Regul 39:77–81. https://doi.org/10.1023/A:1021865029762

Nehela Y, Taha NA, Elzaawely AA, Xuan TD, Amin M, Ahmed ME, El-Nagar A (2021) Benzoic acid and its hydroxylated derivatives suppress early blight of tomato (Alternaria solani) via the induction of salicylic acid biosynthesis and enzymatic and nonenzymatic antioxidant defense machinery. J Fungi 7(8):663. https://doi.org/10.3390/jof7080663

Eliseu R, Naira P, Ismael IR, Luciano VG, Camila RM, Roseane F (2011) Phenolic compounds and antioxidant activity of blueberry cultivars grown in Brazil. Food Sci Technol 31(4):911–917. https://doi.org/10.1590/S0101-20612011000400013

Tserkovniak LS (2011) Biologically active compounds of Azotobacter vinelandii IMV V-7076 and Bacillus subtilis IMV V-7023 and their influence on plants. Dissertation, Zabolotny Institute of Microbiology and Virology of National Academy of Sciences of Ukraine

Sharma A, Shahzad B, Rehman A, Bhardwaj R, Landi M, Zheng B (2019) Response of phenylpropanoid pathway and the role of polyphenols in plants under abiotic stress. Molecules 24:2452. https://doi.org/10.3390/molecules24132452

Stompor-Goracy M, Machaczka M (2021) Recent advances in biological activity, new formulations and prodrugs of ferulic acid. Int J Mol Sci 22(23):12889. https://doi.org/10.3390/ijms222312889

Kumar N, Pruthi V (2014) Potential applications of ferulic acid from natural sources. Biotechnol Rep 4:86–93. https://doi.org/10.1016/j.btre.2014.09.002

Tiwari S, Singh P, Tiwari R, Meena KK, Yandigeri M, Singh DP, Arora DK (2011) Salt-tolerant rhizobacteria-mediated induced tolerance in wheat (Triticum aestivum) and chemical diversity in rhizosphere enhance plant growth. Biol Fertil Soils 47(8):907–916. https://doi.org/10.1007/s00374-011-0598-5

Rajhard S, Hladnik L, Vicente FA, Srčič S, Grilc M, Likozar B (2021) Characterization of flavonoids and polyphenolic compounds and solubility determination of luteolin in water, nonpolar, polar aprotic and protic solvents. Processes 9:1952. https://doi.org/10.3390/pr9111952

Lahouar L, El Arem A, Ghrairi F, Chahdoura H, Ben Salem H, El Felah M, Achour L (2014) Phytochemical content and antioxidant properties of diverse varieties of whole barley (Hordeum vulgare L.) grown in Tunisia. Food Chem 145:578–583. https://doi.org/10.1016/j.foodchem.2013.08.102

Jeon J-S, Carreno-Quintero N, van Eekelen HDLM, De Vos RCH, Raaijmakers JM, Etalo DW (2021) Impact of root-associated strains of three Paraburkholderia species on primary and secondary metabolism of Brassica oleracea. Sci Rep 11:2781. https://doi.org/10.1038/s41598-021-82238-9

Busto MD, Meza V, Ortega N, Perez-Mateos M (2007) Immobilization of ´ naringinase from Aspergillus niger CECT 2088 in poly(vinyl alcohol) cryogels for the debittering of juices. Food Chem 104(3):1177–1182. https://doi.org/10.1016/j.foodchem.2007.01.033

Cavia-Saiz M, Busto MD, Pilar-Izquierdo MC, Ortega N, Perez-Mateos M, Muñiz P (2010) Antioxidant properties, radical scavenging activity and biomolecule protection capacity of flavonoid naringenin and its glycoside naringin: a comparative study. J Sci Food Agric 90(7):1238–1244. https://doi.org/10.1002/jsfa.3959

Tattini M, Galardi C, Pinelli P, Massai R, Remorini D, Agati G (2004) Differential accumulation of flavonoids and hydroxycinnamates in leaves of Ligustrum vulgare under excess light and drought stress. New Phytol 163:547–561. https://doi.org/10.1111/j.1469-8137.2004.01126.x

Lillo C, Lea US, Ruoff P (2008) Nutrient depletion as a key factor for manipulating gene expression and product formation in different branches of the flavonoid pathway. Plant Cell Environ 31:587–601. https://doi.org/10.1111/j.1365-3040.2007.01748.x

Olsen KM, Slimestad R, Lea US, Brede C, Løvdal T, Ruoff P, Verheul M, Lillo C (2009) Temperature and nitrogen effects on regulators and products of the flavonoid pathway: experimental and kinetic model studies. Plant Cell Environ 32:286–299. https://doi.org/10.1111/j.1365-3040.2008.01920.x

Bathia C, Pandey A, Gaddam SR, Hoecker U, Trivedi PK (2018) Low temperature-enhanced flavonol synthesis requires light-associated regulatory components in Arabidopsis thaliana. Plant Cell Physiol 59:2099–2112. https://doi.org/10.1093/pcp/pcy132

Xi-Juan Y, Bin D, Ming-Tao F (2018) Free and bound phenolic compound content and antioxidant activity of different cultivated blue highland barley varieties from the Qinghai-Tibet Plateau. Molecules 23(4):879. https://doi.org/10.3390/molecules23040879

Adom KK, Liu RH (2002) Antioxidant activity of grains. J Agric Food Chem 50:6182–6187. https://doi.org/10.1021/jf0205099

Kim MJ, Hyun JN, Kim JA, Park JC, Kim MY, Kim JG, Lee SJ, Chun SC, Chung IM (2007) Relationship between phenolic compounds, anthocyanins content and antioxidant activity in colored barley germplasm. J Agric Food Chem 55:4802–4809. https://doi.org/10.1021/jf0701943

Ali MB, McNear DH (2014) Induced transcriptional profiling of phenylpropanoid pathway genes increased flavonoid and lignin content in Arabidopsis leaves in response to microbial products. BMC Plant Biol 14:84. https://doi.org/10.1186/1471-2229-14-84

Jeon J-S, Rybka D, Carreno-Quintero N, de Vos R, Raaijmakers J, Etalo D (2022) Metabolic signatures of rhizobacteria-induced plant growth promotion. Plant Cell Environ 45(10):3086–3099. https://doi.org/10.1111/pce.14385

Mamiedova EI (2017) Effect of hydrothermal conditions and agrotechnological practices of growing on peculiarities of growth and development of spring barley plants in Northern Steppe. Grain Crops 1(2):300–306

Nyathi Y, Baker A (2006) Plant peroxisomes as a source of signalling molecules. Biochim Biophys Acta 1763:1478–1495. https://doi.org/10.1016/j.bbamcr.2006.08.031

Jamaludin R, Mat N, Mohd KS, Badaluddin NA, Mahmud K, Sajili MH, Khandaker MM (2020) Influence of exogenous hydrogen peroxide on plant physiology, leaf anatomy and rubisco gene expression of the Ficus deltoidea Jack var. Deltoidea. Agronomy 10(4):497. https://doi.org/10.3390/agronomy10040497

Ayuso-Calles M, Garcia-Estevez I, Jimenez-Gomez A, Flores-Felix JD, Escribano-Bailon MT, Rivas R (2020) Rhizobium laguerreae improves productivity and phenolic compound content of lettuce (Lactuca sativa L.) under saline stress conditions. Foods 9(9):1166. https://doi.org/10.3390/foods9091166

Zapata-Sifuentes G, Hernandez-Montiel LG, Saenz-Mata J, Fortis-Hernandez M, Blanco-Contreras E, Chiquito-Contreras RG, Preciado-Rangel P (2022) Plant growth-promoting rhizobacteria improve growth and fruit quality of cucumber under greenhouse conditions. Plants 11:1612. https://doi.org/10.3390/plants11121612

Zaferanchi S, Salmasi SZ, Lisar SYS, Sarichami MR (2019) Influence of organics and bio fertilizers on biochemical properties of Calendula officinalis L. Int J Hort Sci Technol 6(1):125–136. https://doi.org/10.22059/ijhst.2019.266831.258

Acknowledgements

We thank the members of the Department of Microbiological Processes on Solid Surfaces, Zabolotny Institute of Microbiology and Virology, National Academy of Sciences of Ukraine for useful advice in experimental work with plants under greenhouse conditions.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

IS designed experiments, performed extraction of phenolic compounds from plant material, analyzed data and wrote manuscript. UE participated in designing the experiments, experiment analysis, and interpretation of data. BD provided seeds of two barley varieties Burkhant (Mongolia) and Copeland (Canada). MK performed HPLC analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethics requirements

The authors declare this study was conducted in accordance with ethical guidelines and principles.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Skorochod, I., Erdenetsogt, U., Dondov, B. et al. Phenolic compounds profiles of different barley varieties under the action of nanocomposite complex bacterial preparation Azogran in conditions of abiotic stress. Eur Food Res Technol 250, 1307–1325 (2024). https://doi.org/10.1007/s00217-023-04460-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04460-1