Abstract

In this study, we attempted to enhance angiotensin I converting enzyme (ACE) inhibitory activity using an ultrafiltration (UF) membrane and to improve the emulsifying and foaming properties of fractions. ACE inhibitory activities of the corn gluten hydrolysate prepared by Flavourzyme had the same trend as protein contents and the IC50 value was 0.18 mg solid after 8 h hydrolysis. The hydrolysate was separated by using two kinds of UF membrane (10 and 5 kDa cut-off membranes) and three fractions, >10 kDa, 5–10 kDa, and <5 kDa, were obtained. The yields of these three fractions were 58.3%, 27.2% and 14.5% as dry matter, respectively. The IC50 value (the concentration of ACE inhibitor required to inhibit 50% of the ACE activity under specific conditions) of the <5 kDa fraction was 0.05 mg solid and was approximately fourfold that of the original, 5–10, and >10 kDa fractions. The average hydrophobicity of the <5 kDa fraction was slightly lower than that of the others according to the hydrophobicity index of Nozaki and Tanford, but according to the Krigbaum and Meirovitch index, that of the <5 kDa fraction was slightly higher than those of the others, showing there might be no significant differences among the fractions. The emulsifying activity and emulsion stability in the <5 kDa fraction was higher than those in the other fractions. Two fractions, <5 kDa and >10 kDa, showed poor foaming capacity at below pH 6.0. The foam stabilities of two fractions (<5 kDa and >10 kDa) increased with increasing pH, but that of 5–10 kDa decreased with increasing pH. The UF treatment was an effective method for the enhancement of ACE inhibitory activity with improvement of functional properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Technological processes used in food manufacture affect the functional, nutritional and biological properties of food proteins. On the other hand, proteins may be added as functional ingredients to foods to emulsify, bind water or fat, form foams or gels, and alter flavor, appearance, and texture [1]. In recent years, the role of proteins in the diet as physiologically active components has been increasingly acknowledged. Such proteins or their precursors may occur naturally in raw food materials exerting their physiological action directly or upon enzymatic hydrolysis in vitro and in vivo.

Much scientific interest has focused on physiologically active peptides derived from food proteins. These peptides are inactive within the sequence of the precursor protein and can be released by enzymatic proteolysis.

Angiotensin I converting enzyme (ACE) acts on blood pressure regulation, and inhibition of this enzyme can exert an antihypertensive effect. ACE-inhibitory peptides have been isolated from enzymatic digest of food proteins. Oshima et al. [2] reported that collagen and gelation digests contain ACE-inhibitory peptides. Enzymatic digestion of casein produces ACE-inhibitory peptides, as does the cultivation of Flammulina velutipes [3, 4]. Some of these identified ACE-inhibitory peptides have also been shown to have an antihypertensive effect in vivo [3].

Protein hydrolysates often have to be fractionated to obtain the peptides with a higher functionality or higher nutritional value in a more purified form. Since the differences in physicochemical properties of these peptides are often small, a separation technology which can discriminate small differences in charge, size and hydrophobicity of species is necessary. The molecular weight of the hydrolyzed protein is one of the most important factors in producing protein hydrolysates with the desired functional properties to use as functional materials [5]. In order to obtain a hydrolysate or peptide fraction with both a desired molecular size and a functional property, one method is to use an ultrafiltration (UF) membrane system. This system has the major advantage that the molecular weight distribution of the desired hydrolysates can be controlled by adoption of an appropriate UF membrane [6, 7].

A potential method for large-scale fractionation and enrichment of ACE inhibitor is a UF membrane with different cut-off values. In the present study, the large-scale fractionation and enrichment of the ACE inhibitor from corn gluten hydrolysate using UF membranes is carried out. The characterization of the separated fractions having functional properties such as emulsifying property, foaming property, and inhibitory activity against ACE was carried out.

Materials and methods

Materials

Flavourzyme was purchased from Novo Korea (Seoul, Korea). Corn gluten was a gift from Doosan (Suwon, Korea). Hippuryl-L-histidyl-L-leucine (Hip-His-Leu) and ACE from rabbit lung were obtained from Sigma (St. Louis, Mo.).

Preparation of corn gluten hydrolysate with Flavourzyme and fractionation of the hydrolysate

Corn gluten treated with enzymatic digestion and thermal denaturation was suspended in distilled water (5% w/v). Corn gluten suspensions were adjusted to pH 6.0 with 2 N NaOH and incubated with Termamyl 120 L (Novo, Copenhagen, Denmark) at 80 °C for 3 h. The reaction mixture was filtered to remove the starch digests, then washed three times with the same amount of water. To increase the degree of hydrolysis, corn gluten suspensions from which starch had been removed by the enzymatic digestion and washing process were heated at 100 °C for 45 min.

After enzymatic digestion and thermal denaturation, the pH of the suspension was adjusted to pH 7.0. The corn gluten suspension was incubated with Flavourzyme (enzyme-substrate ratio=100 leucine amino peptidase units) at 50 °C for 8 h in a pH stat. After the hydrolysis, the reaction was terminated by boiling for 15 min. The protein hydrolysate was then centrifuged at 3,000×g for 20 min. The supernatant was first passed through a 10 kDa molecular weight cut-off membrane (Satocon cassette, Sartorius, Germany). A portion of the solution was removed immediately and the filtrate was then pumped through a 5 kDa molecular weight cut-off membrane. The respective permeates passed through each membrane and the fractions with >10 kDa, with 5–10 kDa, and with <5 kDa molecular weight peptides were freeze-dried. The protein content was measured by the procedure of Bradford [8] using bovine serum albumin as standard material during the hydrolysis.

Assay of ACE inhibitory activity

The ACE inhibitory activity was measured by a modification of the method of Cushman and Cheung [9]. A mixture (300 μl) containing a 100 mM sodium borate buffer (pH 8.3), 300 mM NaCl, 8 mU ACE from rabbit lung, and an appropriate amount of the inhibitor solution was pre-incubated at 37 °C for 10 min. The reaction was initiated by adding 0.15 ml of Hip-His-Leu at a final concentration of 5 mM, and terminated by adding 0.5 ml of 1 M HCl after 30 min of incubation. The hippuric acid liberated was extracted with 1.5 ml of ethyl acetate, and then 1.0 ml of the extract was evaporated to the dryness by a Speed back concentrator (Savant, USA). The residue was then dissolved in 1.0 ml of deionized water. The absorbance at 228 nm was measured to evaluate the degree of ACE inhibitory activity. The concentration of ACE inhibitor required to inhibit 50% of the ACE activity under the above conditions was defined as IC50.

Hydrophobicity of fraction

The hydrophobicity of the fraction of hydrolysate was evaluated by the hydrophobicity indices of Nozaki and Tanford [10], Krigbaum and Komoriya [11], and Meirovitch [12]. The average hydrophobicity (Q) is calculated using the following equation:

in which I i is the hydrophobicity index of the amino acid, and A i indicates the molar concentration of amino acid.

Emulsifying properties

The emulsifying activity index (EAI) at various pHs was measured by the turbidimetric method of Pearce and Kinsella [13]. To form an emulsion, a 0.5% (w/v) sample was dispersed and adjusted to pH 3.0–8.0 in increments of 1.0 with 1.0 N HCl or 1.0 N NaOH. Dispersed sample (12 ml) and corn oil (4 ml) were homogenized in a blender (IKA, T25B, Germany) at 12,000 rpm for 1 min. A 50 μl sample of the emulsion was taken from the bottom container at time intervals, and diluted with 5 ml of 0.1% sodium dodecyl sulfate. The absorbance of the dilute emulsion was the determined at 500 nm. All the experiments were conducted at room temperature. The EAI was calculated according to the following equation:

where T is the turbidity, D is the dilution factor, φ is the volume fraction of the dispersed phase (oil), C is the weight of protein per unit volume of aqueous phase before the emulsion is formed, A is the observed absorbance, and L is the pathlength of the cuvette. Emulsion stability was determined by measuring the half-life of the turbidity measured immediately after the emulsion had formed.

Foaming properties

Foaming capacity and stability of the samples were studied according to the method of Sathe and Salunkhe [14]. A 0.5% (w/v) sample dispersion (20 ml) was adjusted to pH 3.0–8.0, and then stirred for 2 min at 10,000 rpm with a blender (IKA). The whipped sample was immediately transferred into a cylinder and the total volume was measured after 30 s. The foaming capacity was calculated according to the following equation:

The whipped sample was allowed to stand at 20 °C for 3 min, and then the volume of whipped sample was recorded for foam stability and was calculated as follows:

Results and discussion

ACE inhibitory activity of corn gluten hydrolysate with Flavourzyme

Various ACE inhibitory peptides have been isolated from the hydrolysates of food materials. However, enzymic treatment of food proteins results in a bitter taste due to the formation of low molecular weight peptides composed mainly of hydrophobic amino acids. Thus, the formation of peptides with bitterness is the most serious problem in the practical use of food protein hydrolysates. We attempted to produce a hydrolysate with low bitterness from corn gluten containing powerful ACE inhibitory activity. Flavourzyme can produce the lowest bitterness of the hydrolysate [15]. Flavourzyme is a fungal endo-protease and exo-protease complex and is recommended for the production of the debittered hydrolysate. It was evaluated as effective enzyme for the production of corn hydrolysate with slight bitterness in our previous studies [15].

Flavourzyme was used in order to prepare the hydrolysate of corn gluten (Fig. 1). Protein contents of the hydrolysate with Flavourzyme increased greatly as the hydrolysis time increased. ACE-inhibitory activities of the hydrolysate showed the same trends as protein contents, in that the inhibitory activity increased with protein content. With Flavourzyme hydrolysate, IC50 decreased as hydrolysis time increased. The IC50 value (IC50: 0.18 mg) of Flavourzyme was the lowest when incubated for 8 h, but after that there was a slight increase. After 4 h hydrolysis, protein contents were slightly increased, but the IC50 value decreased until 8 h hydrolysis. Therefore, further hydrolysis after 4 h increased ACE inhibitor rather than protein hydrolysis.

Changes of protein contents and angiotensin I converting enzyme (ACE) inhibitory activities in corn gluten hydrolysate with Flavourzyme. The protein content was measured by the procedure of Bradford [8] using bovine serum albumin as standard material

Molecular weight distribution of the fraction of hydrolysate

For the separation and enrichment of ACE inhibitor, the large-scale fractionation of the ACE inhibitor from corn gluten hydrolysate using UF membranes was carried out. After the hydrolysis, the hydrolysate was separated by using two kinds of UF membranes (10 and 5 kDa cut-offs ) according to molecular size, and three fractions were obtained after filtration: >10 kDa, 5–10 kDa, and <5 kDa. The yields of these fractions were 58.3%, 27.2% and 14.5% (dry basis) respectively. Figure 2 shows the molecular weight distribution of each fraction. The <5 kDa fraction had a size distribution of less than 10 kDa and three major peaks showed 5,500, 4,100, and 3,000 of molecular weight. The pattern of the molecular weight distribution of the 5–10 kDa fraction was similar to that of the <5 kDa fraction, but the size distribution was more than 5 kDa and major peaks showed 9,500, 7,000 and 4,700 of molecular weight. However, the >10 kDa fraction had four peaks, and the molecular weights of major peaks were 25,000, 15,000, 11,000, and 7,000. Mannheim and Cheryan [16] reported the molecular weight distribution of enzymatic hydrolysate of zein. The zein hydrolysate showed two major peaks at 3,700 and 27,700 Da, and several minor peaks in the 1,000–15,000 and 82,000–105,000 Da ranges. They also reported the presence of a small amount of the high molecular weight fraction in UF permeates. This could be due to post filtration aggregation of peptides. Wilson [17], using sodium-dodecyl sulfate-polyacrylamide gel electrophoresis, found two major fractions of 24,000–27,000. Paulis and Bietz [18] suggested that the disulfide bonds cause oligomer formation in zein. Using HPLC, they found that these oligomers were composed of 22,000–24,000 Da fractions. These oligomers were apparently involved in extensive noncovalent bonding that facilitates formation of oligomers. This phenomenon might be the reason for the appearance of the high molecular weight first peak after UF (Fig. 2).

Molecular weight distribution profiles of corn gluten hydrolysate fractionated depending on the molecular weights of peptides with ultrafiltration (UF) membranes of 10 kDa and 5 kDa. The resultant hydrolysates (<5 kDa, 5–10 kDa, and >10 kDa) were chromatographed on high performance gel permeation with GPC column (Ultrahydrogel 250, 7.8×300 mm, Waters)

ACE inhibitory activity and hydrophobicity of fraction

Recently, many ACE-inhibitory peptides have been isolated from food sources. ACE-inhibitory peptides were composed of many components of foods and also composed of hydrophobic and/or aromatic amino acid residues. Therefore, it is necessary to fortify the ACE-inhibitory activity and to produce the ACE inhibitor with only slight bitterness. After the fractionation of ACE inhibitor, UF was carried out and three fractions were obtained. The IC50 value of the <5 kDa fraction was 0.05 mg solid and was approximately fourfold higher than that of the original, 5–10, and >10 kDa fractions (Table 1). Oshima et al. [2] reported that large peptides from gelatin had no inhibitory effect on the ACE activity. Kinoshita et al. [19] revealed that two major fractions of high and low molecular weight were fractionated from soy sauce by gel filtration chromatography. The high molecular weight fraction reduced the blood pressure in hypertensive rats while the low one did not. Matsui et al. [20] reported that, with respect to alkaline protease hydrolysates derived from sardine muscle, ACE inhibitory activity markedly increased with increasing proteolysis.

The oral intake of protein hydrolysates is limited by their often very bitter taste. Bitterness is due to peptides with neutral amino acids of large alkyl or aromatic side chains. Therefore, the hydrophobicity of the fraction of Flavourzyme hydrolysate was measured to evaluate the bitterness of the hydrolysate (Table 2). Average hydrophobicity of the <5 kDa fraction was slightly lower than that of the others according to the hydrophobicity index of Nozaki and Tanford [10], but according to those of Krigbaum and Komoriya [11] and Meirovitch [12], that of the <5 kDa fraction was slightly higher than those of the others, showing there might be no significant differences among the fractions.

According to the hypothesis of Ney [21], bitterness is related to the average hydrophobicity of the peptide. A peptide is certainly bitter when its Q value exceeds 1,400 cal/mol [22, 23]. The bitterness of peptide is caused by the hydrophobic action of its amino acid residues, but is limited by its molecular weight. Proteins with high Q values such as casein (1,650 cal/mol) and soybean protein (1,540 cal/mol) could produce bitter peptides. The Q values of the fractions in this study according to the hydrophobicity index of Nozaki and Tanford [10], and Krigbaum [11] were to be less than 1,400 cal/mol.

Emulsifying and foaming properties of the fractions

Functional properties of proteins are those physicochemical attributes that lend desirable physical characteristics to foods and are responsible, in part, for certain textural and sensory properties of foods. These functional properties include solubility, water and fat absorption, gelation, emulsion stability, whippability, and foaming and sensory properties. The peptides produced by enzymic hydrolysis have smaller molecular sizes and fewer secondary structures than those of the original proteins. They may be expected to have increased solubility, decreased viscosity, and changed foaming, gelling, and emulsifying properties [24].

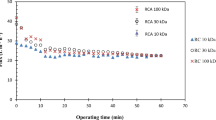

Emulsifying and foaming properties of the fractions were measured in the pH range 3–8 (Fig. 3, Fig. 4). The emulsifying activities of the fractions decreased to a low level at acidic pH, but increased in alkaline conditions. The emulsifying activity in the <5 kDa fraction was higher than those in the other fractions. In acidic and neutral pH, the fraction with small peptides (<5 kDa) was higher in emulsifying activity than that with large peptides (>10 kDa). Lee et al. [25] reported that there might be an optimum molecular size for a protein to have good emulsion properties. The poor emulsifying activity probably corresponds to the solubility of the fraction [26]. Since the >10 kDa fraction was composed of high molecular weight peptides, the solubility of the >10 kDa fraction might be lower than those of the <5 kDa and 5–10 kDa fractions. Meanwhile, other reports have indicated that the emulsion activity of pancreatic casein hydrolysate decreases linearly with the degree of hydrolysis [27].

The patterns of the emulsion stabilities for fractions were increased at neutral pH. Emulsion stabilities of <5 kDa fraction showed the highest values in pH 3–8, but the values of emulsion stabilities were superior in the >10 kDa fraction than in the 5–10 kDa fraction at above pH 5.0.

Two fractions, <5 kDa, and >10 kDa, showed poor foaming capacity at below pH 6.0 (Fig. 4). However, the 5–10 kDa fraction showed a similar foaming capacity throughout the pH range tested. Foaming capacity might be affected by the fractionation of the hydrolysate with the UF membrane, except for the 5–10 kDa fraction, and increased with increasing molecular weight of the fraction. The foam stabilities of two fractions (<5 kDa and >10 kDa) increased with increasing pH, but that of 5–10 kDa decreased with increasing pH. According to these results, the physicochemical properties were affected by the separation of the hydrolysates depending on the molecular weight of the peptides. Jeon et al. [28] also reported that whippability and foam stability of hydrolysate increased with increasing molecular weight of hydrolysate. As shown in the above, UF treatment of hydrolysate improved the emulsifying and foaming properties of the original hydrolysate.

In conclusion, the <5 kDa fraction showed the greatest enhancement of ACE inhibitory activity by UF treatment. This fraction also showed a slight increase in hydrophobicity, but the hydrophobicity of the other fractions might not be significantly different. The emulsifying properties of the <5 kDa fraction were higher than those of the others, even though it had slightly low foaming properties.

In this study, the ACE inhibitory activities of the hydrolysates were distinctly different among fractions. It indicates that separation of hydrolysates based on molecular weight distinctly enhanced the ACE inhibitory activity. The fractionation with UF treatment did not increase the bitterness according to the hydrophobicity index, but improved functional properties. The UF treatment was an effective method for the enhancement of ACE inhibitory activity without increasing bitterness and with improvement of functional properties, such as emulsifying and foaming properties.

References

Anantharaman K, Finot PA (1993) Food Rev Int 9:629–655

Oshima G, Shimabukuro H, Nagasava K (1979) Biochim Biophys Acta 566:128–137

Nakamura Y, Yamamoto N, Sakai K, Okubo A, Yamazaki S, Takano T (1995) J Dairy Sci 78:777–783

Kim JM, Ra KS, Noh DO, Suh HJ (2002) J Ind Microbiol Biotechnol 29:292–295

Deeslie WD, Cheryan M (1991) J Food Sci 57:411–413

Cheryan M, Mehaia MA (1990) Biotechnology and food process engineering. Dekker, New York

Cheryan M (1986) Ultrafiltration handbook. Technomic, Lancaster, Pa.

Bradford M (1976) Anal Biochem 72:248–254

Cushman DW, Cheung HS (1981) Biochem Pharmacol 20:1637–1648

Nozaki Y, Tanford C (1971) J Biol Chem 246:2211–2217

Krigbaum WR, Komoriya A (1979) Biochem Biophys Acta 576:204–206

Meirovitch H, Rackvosky S (1980) Macromolecules 13:1398–1403

Pearce KN, Kinsella JE (1978) J Agric Food Chem 26:716–723

Sathe SK, Salunkhe DK (1981) J Food Sci 46:71–74, 81

Suh HJ, Whang JH, Kim YS, Bae SH, Noh DO (2003) Process Biochem 38:1239–1244

Mannheim A, Cheryan M (1993) Cereal Chem 70:115–121

Wilson CM (1988) Cereal Chem 65:72–73

Paulis JW, Bietz JA (1988) Cereal Chem 65:215–222

Kinoshita E, Yamakoshi J, Kikuchi M (1993) Biosci Biotechnol Biochem 57:1107–1110

Matsui T, Matsufuji H, Seki E, Osajima K, Nakashima M, Osajima Y (1993) Biosci Biotechnol Biochem 57:922–925

Ney KH (1979) Food taste chemistry. American Chemical Society, Washington D.C.

Fukui H, Kanahisa N, Ishibashi I, Miyake I, Okai H (1983) Bull Chem Soc Jpn 56:766–778

Otagiri K, Miyake H, Ishibashi H, Fukui H, Kanehisa OH (1983) Bull Chem Soc Jpn 56:1118–1129

Chobert JM, Sitohy MS, Whitaker JR (1988) J Agric Food Chem 36:220–224

Lee SW, Shimuzu M, Kaminogawa S, Yamauchi K (1987) Agric Biol Chem 51:161–166

Ochiai K, Kamata Y, Shibsaki K (1982) Agric Biol Chem 46:91–96

Mahmoud MI, Malone WT, Cordle CT (1992) J Food Sci 57:1223–1229

Jeon YJ, Byun HG, Kim SK (1999) Process Biochem 35:471–478

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.M., Whang, J.H. & Suh, H.J. Enhancement of angiotensin I converting enzyme inhibitory activity and improvement of the emulsifying and foaming properties of corn gluten hydrolysate using ultrafiltration membranes. Eur Food Res Technol 218, 133–138 (2004). https://doi.org/10.1007/s00217-003-0825-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-003-0825-x