Abstract

Transglutaminase (TG), which is an important enzyme for food processing, can enhance the firmness, viscosity and water binding capacity of food products by catalyzing the cross-linking reaction of proteins. Since preservation of the enzyme activity is essential, the production of microencapsulated powder form of TG can be a great challenge to maintain its initial activity. In this study, TG was microencapsulated using a freeze drying technique and the effects of homogenization conditions and coating material ratios on the enzyme activity were investigated using D-optimal combined design. Mannitol, gum arabic and casein were chosen as coating materials and different homogenization times (1–5 min) and homogenization rates (11,200–20,000 rpm) were applied. The optimum conditions which ensure the maximum enzyme activity have been determined as 11,200 rpm of homogenization rate, 1.27 min of homogenization time, and in addition a mixture of mannitol, gum arabic and casein with ratios 38.2, 40.2, and 21.6%, respectively. Most of the activity loss occurred in the homogenization stage and the coating materials preserved enzyme activity during freeze drying. At the optimum point, the remaining activity of the microencapsulated TG was 93% while that of the crude (without coating materials) TG was 64% at the same drying conditions. Moreover, the effects of the microencapsulation conditions on the physical properties of powder such as moisture content, color, particle, bulk and tapped densities, porosity and flowability were determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Transglutaminase (EC 2.3.2.13, protein-glutamine \( \gamma \)-glutamyltransferase) is an enzyme that can create significant changes in food proteins via acyl transfer reactions, deamidation and crosslinking reactions (Kuraishi et al. 2001). These changes in protein structure are one of the main subjects of enhancing the functional properties of food macromolecules and producing new compounds. Transglutaminase (TG) can increase the hardness of final products, lead to enhanced texture and stability by reducing syneresis, and can increase emulsifying properties, gelation ability and water-binding capacity. Increases in the hardness values of the samples are due to the basic function of transglutaminase, which consists of cross-linking milk proteins covalently. Consequently, the formation of new covalent bonds results in gels with different structures constructed by the stabilization of 3D networks (Gaspar and Góes-Favoni 2015). Moreover, the addition of some essential amino acids in the form of lysine-methionine and lysine-arginine peptides to the modification process can make the food products more valuable in terms of nutrition (Motoki and Seguro 1998; Kieliszek and Misiewicz 2014). TG is widely used for the reconstruction of meat products through cross-linking. TG usage can reduce losses during cooking and improve the textural properties of meat products (Kuraishi et al. 2001; Gaspar and Góes-Favoni 2015). Lower grade meat products such as deboned meat and collagens can be converted into more valuable products by TG. The pale, soft and exudative meats’ gelling ability and textural properties can be enhanced by the crosslinking of myofibrillar proteins, which is affected by TG (Katayama et al. 2006). TG is used in the dairy industry for obtaining a better texture in cheese and preventing whey separation in yoghurt production (Motoki and Seguro 1998; Kuraishi et al. 2001; Yokoyama et al. 2004) Also, the deamidation of gliadin in pasta produced with wheat flour by TG can reduce the prevalence rate of celiac disease (Gharibzahedi et al. 2019). TG is naturally and abundantly found in animal tissues, as well as in blood and plant tissues and it can be produced by microbial strains such as Streptomyces mobaraensis, S. cinnamoneum, S. ladakanum, S. lividans, S. platensis, S. sioyaensis, S. hygroscopicus, Bacillus substilis, Pseudomonas putida and Zygomonas mobilis (Zhu et al. 1998; Taguchi et al. 2002; Lin et al. 2006; Cui et al. 2007; Bourneow et al. 2012; Kieliszek and Misiewicz 2014). Microbial TG can be produced with high productivity and purity without any requirement for difficult separation techniques compared to other transglutaminases which are extracted from plant and animal sources (Macedo et al. 2011).

When enzymes are isolated from their natural environments, it is hard to maintain their stability and they generally lose their activity during storage in water solutions. Encapsulation is a successful technique to overcome these instability issues compared to the free enzymes in solution, and encapsulated enzymes are easily separated and reusable over several cycles with little loss of activity (Vikartovska et al. 2007). Although spray drying is frequently used in the encapsulation of flavors, lipids and pigments, this process is limited to use for materials with low thermal resistance biomaterials such as microorganisms, essential oils, protein-based components and enzymes (Gharsallaoui 2007). The spray drying process can damage temperature-sensitive components such as enzymes or probiotic bacteria when compared to freeze drying (Knorr 1998). Freeze drying is one of the best preservation techniques for heat-labile materials such as enzymes (Adamiec et al. 2006). Although freeze drying is commonly used for preparing stable enzyme powders, it can cause different types of stresses such as low temperature stress, dehydration stress and ice crystal formation which can deactivate and destabilize the enzymes (Ramos et al. 1997). When considered from this point of view, microencapsulation of the enzyme by freeze drying can be a challenge to avoid these kinds of problems (Kawai and Suzuki 2007). There have been several studies in the literature relating to microencapsulation of enzymes using freeze drying (Izutsu et al. 1994; Desai and Park 2005; Anjani et al. 2007; Liu et al. 2011; Zhang and Zhong 2018). Different coating materials have been used to prevent the activity of enzymes during microencapsulation by freeze drying (Arakawa et al. 2001). The most commonly used coating materials are gum arabic, maltodextrin, emulsifying starches, whey protein, etc. (Ray et al. 2016). Mannitol is a widely used bulking agent for freeze drying as the crystallization results in a good cake structure; however, its protection ability for proteins is less than other amorphous sugars and sugar alcohols (Debulis and Klibanov 1993; Izutsu et al. 1994; do Vale Morais et al. 2016). Gum arabic, with its low viscosity, high solubility and surface-active qualities, is very useful for the encapsulation of enzymes (Amid et al. 2014; Andrea et al. 2016). Furthermore, some milk proteins such as sodium caseinate are reported as suitable coating materials for bioactive materials (Heidebach et al. 2010; Vinceković et al. 2017). Although these materials have many of the desirable properties of an encapsulating agent, no single wall material supplies all the properties required of an ideal encapsulating agent (Desai and Park 2005). Therefore, approaches for improving encapsulating properties have focused on blends of these materials for microencapsulation. The objective of this study was to examine the effects of homogenization time, homogenization rate and coating material compositions on TG activity during microencapsulation by freeze drying. Moreover, the physical properties of the enzyme powder such as moisture content, color, particle, bulk and tapped densities, porosity and flowability were determined under different microencapsulation conditions.

Materials and methods

Materials

A commercial microbial transglutaminase (Benosen, Tegen 20X, Turkey) powder was used to prepare a crude enzyme solution. To remove the impurities, the enzyme dispersion (20%, w/w) was subjected to a dialysis using dialysis tubing cellulose membrane (Sigma-Aldrich, 14,000 MW cut-off, USA) at 4 °C until a constant dry matter content (10%) was reached. After the dialysing process, the obtained crude enzyme solution with 10% dry matter was used for all microencapsulation processes. Commercial powder forms of mannitol, gum arabic, and casein were chosen as coating materials, and stock solutions of these materials were prepared with dry matter content of 15, 15 and 10%, respectively. These stock solutions were prepared one night before the microencapsulation processes and kept at 4 °C for rehydration.

Activity assay

The enzymatic activity of TG was determined using the colorimetric hydroxamate method with the specific substrate of N-carbobenzoxy-l-glutaminylglycine (Z-Gln-Gly). For this purpose, 200 µl of 200 mM Tris–HCl, 25 µl of 12.5 mM glutathione, 25 µl of 125 mM hydroxylamine and 75 µl of 37.5 mM of Z-Gln-Gly solutions were added to 100 µl of enzyme solution and incubated for 1 h at 37 °C. At the end of the incubation, 425 µl of solution (15% TCA-5% FeCl3) was added to the reaction medium to stop the reaction, and centrifuged at 11,000 rpm for 5 min. Then, the absorbance of the supernatant phase was determined at 525 nm. The calibration of the absorbance-hydroxamate curve was carried out using l-glutamic acid γ-monohydroxamate as a standard. One unit of TG activity in a one ml of sample (U/ml) was described as the amount of enzyme which caused the formation of 1.0 µmole of hydroxamate per minute by catalyzing the reaction between Z-Gln-Gly and hydroxylamine at pH 6.0 and 37 °C (Bourneow et al. 2012). The initial activity of the crude enzyme solution was found to be 7.45 ± 0.04 U/ml.

Microencapsulation processes

A laboratory scale homogenizer (IKA-Works, Ultra Turrax T-18 Basic, Germany) was used for homogenization of the enzyme solution and coating materials with different compositions. Three different homogenization times (1, 3 and 5 min) and three different homogenization rates (11,200, 15,600 and 20,000 rpm) were applied as the homogenization process conditions. The crude enzyme solution dry matter to coating material ratio was kept constant at 1:1 and the final dry matter of the mixtures (coating material + crude enzyme solution) were adjusted to 10% for all conditions. The coating material compositions and homogenization process conditions are given in Table 1. The homogenized mixtures (30 ml) at different conditions were transferred to metal plates and frozen for 3 h at − 80 °C. After freezing, the freeze drying process was carried out for 18 h in a freeze dryer (CHRIST, Alpha 1–4 LSC, Germany). The main drying was conducted for 16 h at 1 mbar and secondary drying was applied subsequently for 2 h with a shelf temperature at 30 °C under a vacuum of 0.01 mbar.

The effect of the total process (homogenization + freeze drying) on the TG activity was defined as ‘remaining activity (%)’ and calculated by using Eq. 1. The activity of the final product was determined by rehydrating the final product to the same dry matter content as the initial mixture. Moreover, to determine the individual effects of the homogenization and freeze drying steps on enzyme activity, the ‘remaining activity after homogenization’ and ‘remaining activity after drying’ were defined. The ‘remaining activity after homogenization’ was calculated by dividing the activity after homogenization to the activity of the crude enzyme solution and the ‘remaining activity after drying’ was calculated by dividing the activity of the final product by the activity after homogenization.

Moisture content

The moisture content of the microencapsulated enzyme powder was determined by an infrared moisture analyzer (Shimadzu, MOC63u, Japan) at 90 °C and correlated previously by the air drying method at the same temperature.

Particle, bulk and tapped densities

Particle density (\( \rho_{p} \)) of the powder sample was analyzed according to the liquid pycnometer method using toluene. The bulk density (\( \rho_{b} \)) of the samples were determined by measuring the weight of the powder and the corresponding volume. Approximately 2 g of powder sample was placed in a 10 ml graduated cylinder. The bulk density was calculated by dividing the mass of the powder by the volume occupied in the cylinder. For the tapped density (\( \rho_{t} \)), the cylinder was tapped vigorously by hand until no further change in volume occurred (Jinapong et al. 2008).

Porosity

The porosity (\( \varepsilon \)) of the powder samples were calculated using the relationship between the tapped (\( \rho_{t} \)) and particle (\( \rho_{p} \)) densities of the powders as calculated using Eq. 2 (Jinapong et al. 2008).

Flowability

The flowability of powder was evaluated using the Carr’s Index (CI, percent compressibility) (Eq. 3) and the Hausner Ratio (HR) (Eq. 4) (Carr 1965; Hausner 1967).

Color

The color of the TG powder samples (CIE L, a, and b values) was measured with a colorimeter (3NH Colorimeter NR-200, China).

Experimental design and statistical analysis

To investigate the effects of the independent variables namely the coating materials ratio [mannitol (C1), gum arabic (C2) and casein (C3)] and homogenization conditions [homogenization time (X1) and homogenization rate (X2)] on the enzyme activity during the microencapsulation process a ‘D-optimal combined design’ was performed which included 59 experiments (Table 1). The remaining activity data of the runs was selected as a dependent variable. The optimum process conditions providing the maximum remaining activity were estimated using the desirability function method. All experimental data was fitted to a second-order polynomial model. Significant terms in the models were found through the analysis of variance (ANOVA) by using Design Expert-version 7.0 software at a confidence level of 95% and the model adequacies were checked by R2, adj-R2, adequate precision and coefficient of variation (C.V.%). At the estimated optimum microencapsulation conditions that provided the maximum remaining activity, three experiments were conducted and one sample T test was performed to verify the optimization.

Results and discussions

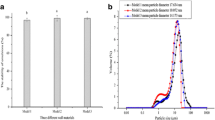

The experimental design and the remaining activity values after the homogenization and freeze drying processes are given in Table 1. Experimental results showed that the remaining activity on completion of the entire process, which is the key parameter of microencapsulation efficiency, ranged between ~ 74 and 92%. To determine the individual effect of the homogenization conditions, the TG activity after homogenization was compared to the crude enzyme activity. It was observed that when both the homogenization time and homogenization rate were increased, the remaining activity after homogenization decreased dramatically (Table 1). The low remaining activity after the homogenization values were obtained when the homogenization time was 5 min and the homogenization rate was 20,000 rpm (75.38–82.64%). On the other hand, when homogenization was applied for 1 min at 11,200 rpm, the initial crude enzyme activities were substantially preserved (90.78–98.29%). The increasing shear effects due to the high homogenization rate and time might cause damage to protein by changing their secondary and/or tertiary structures through unfolding or by disruption of the quaternary structure of a multi-subunit protein and this damage may have caused a loss of enzyme activity (Ghadge et al. 2005; Thomas and Geer 2011). Because of the loss of enzyme activity through the homogenization process, it is necessary to pay attention to the use of the enzyme in dairy products where the homogenization process is frequently applied.

To observe the individual effects of the freeze drying stage on TG activity, the activity after the homogenization process was compared to the activity of the final powder product. The remaining activity after freeze drying values ranged between 86.61 and 97.65%, which indicated that the proportion of the different coating materials affected the final enzyme activity. When the coating material ratios were equal, the highest remaining activity after drying was determined at 3 min of homogenization time and 15,600 rpm of homogenization rate. However, the lowest remaining activity was obtained at homogenization conditions of 11,200 rpm for 1 min when the same coating material compositions were used (Table 1). This phenomenon can be explained by inadequate homogenization which was not enough to bring together the coating materials and enzyme molecules. Hence, the remaining activity after drying that indicates microencapsulation efficiency was affected by not only the coating material composition, but also the homogenization conditions. In the experiment where three different coating materials were used in equal proportions, the materials protected the enzyme more effectively because of the different physicochemical effects of the coating materials and the remaining activity values were found to be higher. Coating materials such as casein, mannitol and gum arabic have different effects on the protection of biological materials against oxidation, as well as mechanical, cold and drying stresses. This can minimize the loss of enzyme activity (Amid et al. 2014; Shiga et al. 2014; Glab and Boratyński 2017).

Optimization of the microencapsulation process was carried out using experimental remaining activity values which describe the effects of the entire process on TG activity. The experimental data arranged according to D-optimal combined design was evaluated to determine the optimum composition of the coating materials and the homogenization conditions that ensure maximum enzyme activity. To perform this operation, Design Expert-version 7.0 software (Stat-Ease Inc., MN, USA) was utilized for numerical optimization. The statistical significance of all effects and regression equation coefficients calculated for the remaining activity are given in Table 2. The calculated special cubic × quadratic models of the remaining activity were statistically significant at p < 0.01 level whereas the lack of fit of the models was not significant (Table 2). Regression analysis and ANOVA were conducted for fitting the model and to examine the statistical significance of the model terms. The effects that were not significant (p > 0.05) were stepped down from the models without damaging the model hierarchy. The equation representing the descriptive model for the remaining activity is shown using Eq. 5. Moreover, R2, R2-adj and coefficient of variation (C.V.) were calculated to check the adequacy of the model. The coefficient of determination (R2) value is quite high (> 0.983), indicating that a high proportion of variability was explained by the data and the RSM models were adequate. Table 2 shows that R2 and adj-R2 did not differ clearly, which indicates that the insignificant terms have not been included in the model. The relative dispersion of the experimental points from the predictions of the model which is defined as the C.V.% was calculated as 1.70%.

Analyzing the results, coating material composition (mannitol to gum arabic ratio) and homogenization time interactions were the most effective independent variables affecting the remaining activity. Perturbation plots (Fig. 1a) showed that the remaining activity was increased with the increase in mannitol, gum arabic and casein; however, a saddle system was identified because of the interaction of the composition of the coating materials and process condition (Fig. 1b). This was explained by the remaining activity which had the lowest value at the maximum and minimum levels of homogenization time (at the central point of homogenization rate). Sun-Waterhouse et al. (2013) also stated that the type of coating materials had a significant impact on the encapsulation efficiency of the microcapsules. The effect of the composition of the coating material on the remaining activity is further revealed in Fig. 2 which made it clear that the increase in the gum arabic to mannitol and casein ratio led to an increase in the remaining activity of the enzyme.

The counter plots and 3-D graphs of the predicted model for TG activity are illustrated in Fig. 2. According to Fig. 2, TG activity was significantly influenced by the composition of the coating materials and the interactions between MA–GA, MA–HT, MA–HR, GA–HT, GA–HR, CS–HT and CS–HR (p < 0.01). The remaining activity decreased with an increase in the homogenization rate and time when the highest ratios of mannitol to gum arabic were applied or vice versa (Fig. 2). These findings were consistent with the results of the ANOVA and perturbation plots (Table 2 and Fig. 1).

Numerical optimization was performed for the mixture and the process parameters of the microencapsulation process to obtain the highest remaining activity. To perform this operation, Design Expert-Version 7.0 software (Stat-Ease Inc., MN, USA) was utilized. According to the desirability function, optimum point conditions were chosen as 11,200 rpm for the homogenization rate, 1.27 min of homogenization time, and the mixture of mannitol, gum arabic and casein with ratios 38.2, 40.2 and 21.6%, respectively. The predicted remaining activity was determined to be 91.82%. Validation of the optimum point response prediction was carried out by the freeze drying of TG at the selected optimum conditions with three repetitions. According to the experimental results at optimum point conditions, the experimental (93.04 ± 0.04%) and predicted remaining activity values did not differ statistically (p > 0.05). The crude TG solution without coating materials was also freeze dried under the same drying conditions. The remaining activity value was found to be 63.86 ± 0.04%, which was significantly lower when compared to that of the microencapsulated TG at the optimum point (p < 0.05).

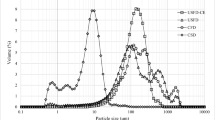

The physical properties of the microencapsulated TG powder were determined for every single run of the experimental design. The physical characteristics of different TG powders in terms of moisture content, color values, particle density, bulk and tapped densities, porosity and flowability values are given in Table 3 and the ANOVA results have been previously represented in Table 2. The moisture content of the samples varied in the range of 4.74–7.42% (wet basis) which was within the limits for moisture specification of dried powders in the food industry (Koç et al. 2014). The results showed that when gum arabic and casein mixture were used as coating materials, the moisture values increased while lower moisture values were obtained when mannitol was the only coating material. The larger ice crystal formation during freezing with mannitol may lead to better sublimation during freeze drying (Debulis and Klibanov 1993). On the other hand, when casein was used as coating material, higher moisture content values were observed which may be related to the high water binding capability of casein micelles (Kneifel and Seiler 1993). The ANOVA results for moisture content showed that the model was statistically significant (p < 0.01) whereas the lack of fit was not significant (p > 0.05). The effect of linear mixture, GA–CS interaction and MA–GA–CS interaction was statistically significant at the level of a 99% confidence interval (p < 0.01). The color of the different samples was determined in terms of CIE L, a and b values. The L, a and b values were in the range of 78.79–99.33, 0.53–8.12 and 5.80–22.30, respectively. The current study showed that the L values of the powder increased with an increase in the mannitol ratio whereas the b values of the samples increased with an increase in the gum arabic ratio. All color values were statistically significant in respect of the model (p < 0.05). The differentiation of L, a and b values could be due to the composition of the coating materials, which can be supported by the ANOVA results. It was observed that the linear mixture had a significant effect for L, a and b values (p < 0.05). The L values were also affected by the interactions of GA–HT–HR and GA–HT2. The interaction of MA–GA had also significant effect on the a and b values (Table 2). The particle density results ranged between 1206 and 1476 kg/m3 and the coating material composition or process variables had no significant affect on the particle density (p > 0.05). However, MA–CS, GA–HT, MA–GA–HT, MA–GA–CS–HR and GA–CS–HT–HR interactions had a significant effect on the particle density values of microencapsulated TG powders. The bulk and tapped densities of the samples varied from 50.15–288.5 kg/m3 and 71.71–250.7 kg/m3, respectively. In dried food products, bulk density can be related to moisture content and this mostly correlated with the drying method (Koç et al. 2008). Accordingly, the low bulk density values of a sample may increase the risk of oxidation during storage because of the fact that there is more air within the powder particles (Fitzpatrick 2005). The differences in bulk and tapped density can arise from the proportion of MA or GA to CS. When mannitol was used as the coating material, the bulk density was increased, while GA–CS decreased the bulk density of the samples. The ANOVA table showed that the model was significant (p < 0.05), while lack of fit was not significant (p > 0.05) for the bulk and tapped densities (Table 2). The interactions of MA–CS, MA–CS–HT, MA–HT2 and MA–GA–CS–HT–HR had a significant effect on the bulk and tapped densities (p < 0.05). Moreover, the interaction of MA–GA–HT–HR statistically affected the bulk density of the samples. Powder flowability can be explained by the Carr Index (CI) and Hausner Ratio (HR). CI (%) values can be in the range of < 15, 15–20, 20–35, 35–45 and > 45, and flowability is classified as very good, good, fair, bad and very bad, respectively. Powder cohesiveness based on HR can be in the range of < 1.2, 1.2–1.4 and > 1.4, where cohesivenes is classified as low, intermediate and high, respectively (Jinapong et al. 2008). In this study, CI values of microencapsulated TG powders ranged between 23.86 and 51.54%, which can be classified between fair-very bad. In particular, for the freeze-dried samples, the powder particles have a higher contact surface and more cohesive forces can arise, which makes the powders resistant to flowing (Fitzpatrick 2005). The current study revealed that the composition of the coating material or the process variables did not have any significant effect on the CI (p > 0.05). Likewise, the HR values ranged between 1.31 and 2.06 and different powders were classified between intermediate-high cohesiveness. According to the HR findings, process variables and use of different coating materials did not have any significant effect (p > 0.05). Porosity, which is an important parameter for powdered products, has an impact on rewetting control especially for microencapsulated powders. Microencapsulated TG powders had porosity values between 65.46 and 94.27% and porosity of the samples increased when the casein ratio was higher. On the other hand, by usage of more mannitol, the porosity decreased. The ANOVA table represents the results for porosity and the model was significant (p < 0.05) whereas the lack of fit was not significant (p > 0.05). Also, the linear mixture and MA–GA interaction had a significant effect on the porosity of the samples.

Conclusion

In this study, the microencapsulation conditions of TG by freeze drying were optimized and the physical characteristics of different powder products were determined. The microencapsulation parameters namely the homogenization time and homogenization rate were investigated as independent variables. It was observed that a higher homogenization time and homogenization rate reduced enzyme activity. However, very low homogenization times and rates were not efficient enough to generate microencapsulates, which increased the activity loss. For this reason, an optimization study was carried out and the optimal conditions for producing powder TG with minimal activity loss were determined. The microencapsulated forms of TG were more resistant to the stresses which were caused by freeze drying when compared with the crude enzyme. Moreover, physical characteristics varied depending on the use of different coating materials. The current study indicated that microencapsulation of TG reduced the activity loss and determination of the optimum homogenization conditions helped to obtain better microencapsulated powders.

References

Adamiec J, Kaminski W, Markowski AS, Strumiłło C (2006) Drying of biotechnological products. In: Mujumdar AS (ed) Handbook of industrial drying. Taylor & Francis Group, LLC, Routledge, pp 905–926

Amid M, Manap Y, Zohdi NK (2014) Microencapsulation of purified amylase enzyme from pitaya (Hylocereus polyrhizus) peel in arabic gum-chitosan using freeze drying. Molecules 19(3):3731–3743

Andrea T, Marcela F, Lucía C, Esther F, Elena M, Simona M (2016) Microencapsulation of lipase and savinase enzymes by spray drying using arabic gum as wall material. J Encapsulation Adsorpt Sci 6(04):161

Anjani K, Kailasapathy K, Phillips M (2007) Microencapsulation of enzymes for potential application in acceleration of cheese ripening. Int Dairy J 17(1):79–86

Arakawa T, Prestrelski SJ, Kenney WC, Carpenter JF (2001) Factors affecting short-term and long-term stabilities of proteins. Adv Drug Deliv Rev 46(1):307–326

Bourneow C, Benjakul S, H-Kittikun A (2012) Impact of some additives on the stability of microbial transglutaminase from Providencia sp. C1112. Asian J Food Agric 5(3):226–233

Carr RL (1965) Evaluating flow properties of solids. Chem Eng 72:163–168

Cui L, Du G, Zhang D, Liu H, Chen J (2007) Purification and characterization of transglutaminase from a newly isolated Streptomyces hygroscopicus. Food Chem 105(2):612–618

Debulis K, Klibanov AM (1993) Dramatic enhancement of enzymatic activity in organic solvents by lyoprotectants. Biotechnol Bioeng 41(5):566–571

Desai KGH, Park HJ (2005) Recent developments in microencapsulation of food ingredients. Dry Technol 23(7):1361–1394

do Vale Morais AR, do Nascimento Alencar É, Júnior FHX, de Oliveira CM, Marcelino HR, Barratt G, Elaissari A (2016) Freeze-drying of emulsified systems: a review. Int J Pharm 503(1):102–114

Fitzpatrick JJ (2005) Food powder flowability. In: Onwulata C (ed) Encapsulated and powdered foods. Taylor & Francis Group, LLC, Routledge, pp 247–260

Gaspar ALC, Góes-Favoni SPD (2015) Action of microbial transglutaminase (MTGase) in the modification of food proteins: a review. Food Chem 171:315–322

Ghadge RS, Patwardhan AW, Sawant SB, Joshi JB (2005) Effect of flow pattern on cellulase deactivation in stirred tank bioreactors. Chem Eng Sci 60:1067–1083

Gharibzahedi SMT, Yousefi S, Chronakis IS (2019) Microbial transglutaminase in noodle and pasta processing. Crit Rev Food Sci 59(2):313–327

Gharsallaoui A (2007) Applications of spray-drying in microencapsulation of food ingredients: an overview. Food Res Int 40(9):1107–1121

Glab TK, Boratyński J (2017) Potential of casein as a carrier for biologically active agents. Top Curr Chem 375(4):71–91

Hausner HH (1967) Friction conditions in a mass of metal powder. Powder Metall 13:7–13

Heidebach T, Först P, Kulozik U (2010) Influence of casein-based microencapsulation on freeze-drying and storage of probiotic cells. J Food Eng 98(3):309–316

Izutsu KI, Yoshioka S, Terao T (1994) Effect of mannitol crystallinity on the stabilization of enzymes during freeze-drying. Chem Pharm Bull 42(1):5–8

Jinapong N, Suphantharika M, Jamnong P (2008) Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng 84(2):194–205

Katayama K, Chin KB, Yoshihara S, Muguruma M (2006) Microbial transglutaminase improves the property of meat protein and sausage texture manufactured with low-quality pork loins. Asian Aust J Anim 19(1):102

Kawai K, Suzuki T (2007) Stabilizing effect of four types of disaccharide on the enzymatic activity of freeze-dried lactate dehydrogenase: step by step evaluation from freezing to storage. Pharm Res 24(10):1883–1890

Kieliszek M, Misiewicz A (2014) Microbial transglutaminase and its application in the food industry: a review. Folia Microbiol 59(3):241–250

Kneifel W, Seiler A (1993) Water-holding properties of milk protein products—a review. Food Struct 12(3):3

Knorr D (1998) Technology aspects related to microorganisms in functional foods. Trends Food Sci Technol 9:295–306

Koç B, Eren I, Kaymak-Ertekin F (2008) Modelling bulk density, porosity and shrinkage of quince during drying: the effect of drying method. J Food Eng 85(3):340–349

Koç B, Sakin-Yılmazer M, Kaymak-Ertekin F, Balkır P (2014) Physical properties of yoghurt powder produced by spray drying. J Food Sci Technol 51(7):1377–1383

Kuraishi C, Yamazaki K, Susa Y (2001) Transglutaminase: its utilization in the food industry. Food Rev Int 17(2):221–246

Lin YS, Chao ML, Liu CH, Tseng M, Chu WS (2006) Cloning of the gene coding for transglutaminase from Streptomyces platensis and its expression in Streptomyces lividans. Process Biochem 41(3):519–524

Liu H, Nakagawa K, Kato DI, Chaudhary D, Tadé MO (2011) Enzyme encapsulation in freeze-dried bionanocomposites prepared from chitosan and xanthan gum blend. Mater Chem Phys 129(1):488–494

Macedo JA, Sette LD, Sato HH (2011) Purification and characterization of a new transglutaminase from Streptomyces sp. isolated in Brazilian soil. J Food Biochem 35(4):1361–1372

Motoki M, Seguro K (1998) Transglutaminase and its use for food processing. Trends Food Sci Technol 9(5):204–210

Ramos A, Raven N, Sharp RJ, Bartolucci S, Rossi M, Cannio R, Lebbing J, Oost JVD, de Vos WM, Santos H (1997) Stabilization of enzymes against thermal stress and freeze-drying by mannosylglycerate. Appl Environ Microb 63(10):4020–4025

Ray S, Raychaudhuri U, Chakraborty R (2016) An overview of encapsulation of active compounds used in food products by drying technology. Food Biosci 13:76–83

Shiga H, Joreau H, Neoh TL, Furuta T, Yoshii H (2014) Encapsulation of alcohol dehydrogenase in mannitol by spray drying. Pharmaceutics 6(1):185–194

Sun-Waterhouse D, Wadhwa SS, Waterhouse GIN (2013) Spray-drying microencapsulation of polyphenol bioactives: a comparative study using different natural fibre polymers as encapsulants. Food Bioprocess Technol 6(9):2376–2388

Taguchi S, Arakawa K, Yokoyama K, Takehana S, Takagi H, Momose H (2002) Overexpression and purification of microbial pro-transglutaminase from Streptomyces cinnamoneum and in vitro processing by Streptomyces albogriseolus proteases. J Biosci Bioeng 94(5):478–481

Thomas CR, Geer D (2011) Effects of shear on proteins in solution. Biotechnol Lett 33(3):443–456

Vikartovska A, Bucko M, Mislovicova D, Patoprsty V, Lacık I, Gemeiner P (2007) Improvement of the stability of glucose oxidase via encapsulation in sodium alginate–cellulose sulfate–poly(methylene-co-guanidine) capsules. Enzyme Microb Technol 41:748–755

Vinceković M, Viskić M, Jurić S, Giacometti J, Kovačević DB, Putnik P, Jambrak AR (2017) Innovative technologies for encapsulation of Mediterranean plants extracts. Trends Food Sci Technol 69:1–12

Yokoyama K, Nio N, Kikuchi Y (2004) Properties and applications of microbial transglutaminase. Appl Microbiol Biotechnol 64(4):447–454

Zhang Y, Zhong Q (2018) Freeze-dried capsules prepared from emulsions with encapsulated lactase as a potential delivery system to control lactose hydrolysis in milk. Food Chem 241:397–402

Zhu Y, Rinzema A, Tramper J, Bruin ED, Bol J (1998) Fed-batch fermentation dealing with nitrogen limitation in microbial transglutaminase production by Streptoverticillium mobaraense. Appl Microbiol Biotechnol 49:251–257

Acknowledgements

The authors acknowledge the Scientific and Technological Research Council of Turkey (TUBITAK, Project No: 115O216) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Isleroglu, H., Turker, I., Koc, B. et al. Optimization of microencapsulation conditions of transglutaminase by freeze drying. J Food Sci Technol 56, 4925–4937 (2019). https://doi.org/10.1007/s13197-019-03962-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03962-9