Abstract

Through tapping into the boundless resources provided by the sea and sun, scientists have created a sustainable and cost-effective drinking water supply using solar-powered desalination. In this manuscript, utilizing gravels, sand and wick materials as the energy storage medium is one of the key sustainability modifications made for bettering the rate of evaporation within solar stills, hence enhancing the freshwater yield. Here, experiments on a single basin solar still with and without energy storage components have been carried out. Typically, energy storage materials are employed to enhance the rate of evaporation in solar stills, aiming to increase the yield of distilled water during nocturnal hours. Consequently, it was observed that using locally available heat storage materials in a solar still during daylight and overnight production of distillate for 15 liter of water input resulted in increases of 54.39 and 58.08%, respectively. In the case of upgraded solar desalination systems, the maximum thermal efficiencies were notably improved, with increases of 90.843, 84.464, and 66.326% compared to conventional solar desalination systems for water inputs of 15, 20, and 25 liters, respectively. The suggested solar still design is particularly well-suited for generating freshwater in regions with a pronounced demand, such as areas characterized by excessively saline groundwater, coastal zones, and rural locations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The absence of clean water and traditional energy sources are world’s most significant issues the world is currently confronting. Water is a vital requirement for all forms of life to survive. Humans are regarded as the most advanced species of life. They require access to clean, fresh water for survival while using less fossil fuel or more renewable energy. The current situation calls for the adoption of effective water treatment techniques that protect the environment without harming it. Due to the perceived expanding industrial operations and a growing global population, energy consumption is increasing continuously [1]. Satisfying the growing demand has resulted in notable adverse effects from the consumption of fossil fuels, including elevated temperatures, unfavourable weather phenomena, and increased emissions of greenhouse gases. In this sense, solar energy provides a clean alternative to fossil fuels that may be utilized to produce electrical and thermal energies [2]. A steady supply of freshwater is another essential global necessity, along with energy [3]. Because the world’s freshwater supplies are finite, self-sustaining desalination method need to be developed to fulfil the needs for freshwater globally, particularly in desert regions and places where there is a water scarcity [4]. Researchers are increasingly focusing on solar-powered desalination techniques due to their cost-effectiveness and simplicity [5, 6]. Recently, several solar desalination methodologies have been introduced and researched [7]. Basically, solar stills gather distilled water by facilitating the evaporation of water from the basin and its subsequent condensation on the glass surface.

The utilization of multi-wick materials, as opposed to a single-wick material, has confirmed to be significantly boosts the distillate output. In distillation process conducted on an average cold day in Delhi, an impressive yield of 2.5 liters of water per square meter per day was achieved. This level of efficiency, reaching 34%, surpassed the maximum efficiency of 30% attainable with basin-type solar still [8]. Experimentation utilizing different kinds of heat-storing materials in a solar still revealed that highest output was achieved when employing black rubber material, leading to a remarkable increase of 38% in the output of desalinated water [9]. Experimental investigations were conducted to examine the efficiency of a new design for inclined solar stills, which incorporates rectangular grooves and ridges on its absorber plate. This study compared various wick materials placed on the absorber plate and revealed that incorporating energy-absorbing materials leads to increased production of distilled water [10]. An assessment of the effectiveness of integrating nanocomposite phase change materials (composed of Al2O3 disseminated in paraffin wax) into a single slope solar still was conducted. The findings demonstrate that the solar still integrated with nanocomposite phase change materials outperforms both the solar still without any phase change material and the solar still with phase change material alone in terms of performance [11]. Phase change materials (PCMs) employed in solar still comprises blend of water, paraffin wax, and aluminum turnings and the outcomes of this utilization included a production increase of 4.53 kg/m2 and a notable efficiency boost of 36.2% [12]. The thermal storage medium, i.e., black granite pebbles in solar still resulted an approximately 17% raise in desalination yield [13]. Evaluation of distillate yield in a solar still was conducted integrating different energy storage materials, such as marble fragments and sandstones. The study concluded that sandstones outperformed marble pieces in terms of performance. [14]. The study involved assessing the working of a stacked cascade solar still coupled with a thermal photovoltaic collector and resulted in an approximately 20% rise in freshwater productivity [15]. The efficiency of the solar still was studied by using graphite as the energy-storage material, revealing that daily yield for solar still equipped with graphite was approximately 7730 mL/m2, whereas conventional stills yielded around 4410 mL/m2 [16]. Sand and jute fabric were used as heat-storage materials to increase the efficiency of solar stills [17]. In an attempt to boost the effectiveness of the solar still, a composite support material is employed, consisting of a phase-change compound combined with black gravel [18]. To enhance the freshwater yield of the solar still, a proposal was made to incorporate cement-coated red bricks as a means of energy storage material. Subsequent studies revealed that employing a modified solar still with 20 liters of water resulted in an approximate 34% increase in water temperature. Furthermore, the production rate was 45% greater in comparison to the traditional solar still [19].

Examination of solar still performance was conducted by Modi and Modi incorporating heat storage material and a regenerative medium while varying water depths. The results indicated that for water levels of 1 and 2 cm, total yield could be enhanced by 18 and 24%, respectively [20]. Basalt stone was used to raise the overall output by roughly 33.7% over traditional basic solar stills [21]. Dumka et al., employed sand-filled cotton pouches to increase the modified solar still’s efficiency by 31.31 and 28.96% compared to conventional solar still for basin water quantities of 40 and 30 kg respectively [22]. Attempting to boost nightly production by utilizing materials readily available in the local vicinity, such as concrete fragments, bricks, and sand, while experimenting with different weight combinations [23]. In a weir-type cascade solar desalination system, high water productivity at night is attained through the dispersion of various nanopowders in the PCMs. Results show that solar desalination using CuO/PCM produces the highest hourly water output [24]. An effort was made to explore, both experimentally and theoretically, the effectiveness of integrating wax-filled metallic finned-cups (MSS) into a traditional solar still. The results indicated a noteworthy enhancement in the overall thermal efficiency of MSS by 24.64% in comparison to CSS [25]. The outcomes reveal that when the solar still uses glass cover cooling, the condensation heat transfer coefficient increases on average by approximately 20.8%. Furthermore, the distillate yield demonstrates a substantial improvement, coming in at about 3.32 times the initial figure [26]. For improving a solar still’s efficiency, a coating composed of nano particles of titanium oxide and a blend of black dye was applied as a foundational layer [27]. The efficiency of a solar still employing a combination of paraffin wax and sand to enhance thermal performance was investigated [28]. The research explored how well a solar still worked employing cotton sacks that were loaded with phosphate, aiming to enhance the conventional solar still efficiency [29, 30]. A functional analysis of an inclined solar still incorporating a coconut coir disk as the energy storage medium has been performed through experimentation. In contrast to traditional solar still, the energy storage materials still increased its productivity from 28 to 69.5%. The inclined “solar still” with simply wick materials increased production from 82.25 to 144.5% [31]. To elevate the effectiveness of a single-slope solar still, a modified version with a blackened surface was designed and installed. This improved solar still achieved efficacies of 7.41 and 7.95% when operated with water inputs of 20 and 30 liters, respectively. Additionally, rigorous testing verified that the distilled water’s purity met acceptable standards [32]. A significant performance improvement was obtained when a single-basin solar still was integrated with a Fresnel lens. Compared to the traditional layout, the distillate yield using the Fresnel lens attachment was found to be 3.5 to 4 times higher. Furthermore, the system’s overall efficiency increased significantly, surpassing the conventional method by nearly 32.19%. The distillate’s quality assessment revealed that it complied with international requirements [33].

Black magnetic powders have been investigated as a potential energy storage medium in solar desalination system performance. Contrary to a conventional solar still, an upgraded solar still’s cumulative productivity increased by 31.2% due to the implementation of magnetic particles in the water [34]. Both conventional solar stills (CSS) and CSS combined with permanent ferrite ring magnets (MSS) were evaluated experimentally and theoretically. As stated in the study, the results showed a significant improvement in MSS’s distillate output of 49.22% as compared to CSS [35]. An artificial neural network (ANN) model was developed for single basin solar stills, incorporating sand-filled cotton bags and ferrite ring permanent magnets. As observed in the study, the model demonstrated less than a 5% variation when compared to the experimental data [36]. Permanent ferrite magnets, triangular prismatic metallic structures and black cotton cloth were used to improve a double slope single basin solar still in order to lower water surface tension, reduce its characteristic length, and increase its surface area. As reported by the study, the augmentation produced a noticeable 60.24% boost in daily distillate output [37]. The research investigations were conducted using a single-slope solar still, where Egyptian red clay was employed as energy storage material in conjunction with PCM positioned in the basin. These findings were then compared how effectively traditional solar still performs and found that the output increased by approximately 21% through employing phase change material and by roughly 38.7% through utilizing the indigenous clay material [38]. The study examined the impact of integrating thermal storage units using phase change materials (PCMs) and natural dolomite powder-embedded PCMs on the efficiency of solar stills. Use of pebbles as heat storage mediums in solar stills has been explored and uncovered intriguing findings. Adamu et al., observed that the capacity of the basin to store heat went up as the water content did, leading to higher distillate output during times of diminished sunshine. However, it was found that keeping less water in the basin was best when the main goal was to optimize distillate output during the day [39]. The impact of incorporating a black cotton wick into the trough of the PCST-TSS was examined. Results revealed that the device equipped with the wick could generate 5.1 L/m2/day while reducing costs by 40.21% compared to the device lacking the wick [40]. Eggshell powder from Babcobb Broilers chicken gets added to the still basin to improve the efficiency of a tubular solar still by acting as an acceptable bed for energy storage [41]. A combination of naturally occurring and man-made porous absorbent materials, including materials like luffa fibres, blackened luffa, fine steel wool, and steel wool pads, with the aim of enhancing the performance of a solar still [42]. Composite heat storage materials achieved by blending beach sand with paraffin wax was used for improving a single-slope solar still output [43]. Recent research has shown that the efficiency of solar stills has been boosted through the application of several different heat-storage materials. The study assessed the thermo-economic performance and experimentally examined the efficiency of a hemispheric solar still outfitted with four distinct configurations. In fourth scenario, the best thermal performance and output were observed, with a daily output of 4737.5 ml/m2 and a thermal efficiency of 45% [44]. Four different modification scenarios were employed to evaluate the thermoeconomic and environmental performance of a hemispherical solar still (HSS). The result shows in daily yield increases of 43, 59.77, 78.77, and 95.2%, respectively [45]. The primary objective is to examine the distinctive heat transfer and flow patterns in a stepped single-basin solar still that incorporates constant and dynamic temperature differentials between the evaporating and condensing surfaces and solar still’s performance has improved significantly [46]. The research study analysed the impact of various operational and environmental factors on a desalination system’s water productivity. Statistical techniques such as Artificial Neural Networks (ANN) were employed to analyze the significance of these factors in predicting solar productivity [47]. Incorporating sand as a sensible heat thermal energy storage material in a solar still was implemented, and the findings indicated that the yield with sand was 35% greater compared to the yield without sand [48].

Based on the above review, the single-slope solar still with locally available energy storage materials i.e. combination of gravels, sand and wick materials over a conventional solar still is selected for the present study. The innovation of current effort intends to boost the output of solar still by employing a combination of low cost locally available heat storage materials (sand, pebbles and wick) on the solar still’s basin area. This blend of heat storage materials aims to enhance sensible heat energy storage during daylight hours and subsequently harness it during the night, thereby boosting the efficiency of the solar still. The proposed investigation is more intended for underdeveloped nations, rural areas without access to power, and localities where the groundwater is salty or unsafe for drinking. Two different sorts of solar stills were used in the trials to attain this goal. The original one is an unchanged conventional solar still, whereas the latter has used heat storage materials.

EXPERIMENTAL SETUP AND PROCEDURE

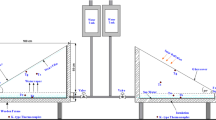

The prime objective of the present investigation is to evaluate the influence of several low cost heat-storage materials, including wick, gravels, and sand, on the performance of conventional single-slope solar still. In May 2023, during the hours of sunlight, several experiments were conducted at Krupajal Engineering College in Bhubaneswar, Odisha (20°17′45.8124″ N, 85°49′28.3404″ E). The general arrangement of the experimental setup is schematically illustrated in Fig. 1.

The experimental arrangement primarily comprised two solar stills with identical geometric characteristics: one remained unaltered, while the other underwent modification, as illustrated in Fig. 2. The solar still featured 1.5 mm thick galvanized steel sheet construction, 0.48 m2 effective basin area, a 525 mm back wall height, and a 150 mm front wall height. Additionally, the entire inside surface of the basin has been painted black to increase the solar absorption for maximum efficient thermal performance and 6 mm-thick transparent glass was installed on the upper side that was exposed to solar radiation. For complete effective thermal performance and to make sure the entire condensed water will flow into the freshwater collector’s channel, the glass cover had a 25° inclination towards the horizontal plane which faced south. To ensure that no air will leak through tiny gaps between the lid and still, silicon rubber band was employed. A channel was constructed to the bottom of the glass cover to capture the distilled output. A short pipe is attached to the end of the collecting channel so that the clean water may be drained into the external vessel. K-type thermocouples were employed for measuring diverse temperatures, encompassing the absorber, water, surroundings, and glass. Additionally, measurements were taken for the ambient temperature, solar intensity, and wind speed. Entire configuration is depicted in Fig. 2.

To increase the productivity during sunlight and overnight operation, the study will look into how the locally available energy storage materials affect the output of solar still under same condition. A conventional solar still’s daily productivity was measured by 24-hour monitoring which encompassed 9:00 AM to 9:00 AM. On an hourly basis, a number of variables, including various temperatures, solar intensity, wind velocity, humidity and distillation output, were recorded. The weight proportions of the energy storage materials sand, pebbles, and wick materials are kept constant throughout the experiment, and the input brackish water quantity variation in the experiment (15, 20, and 25 liters) was taken into consideration to understand its influence. In order to forecast how much water will progressively persuade a greater quantity of distillate production, the observation was made by adjusting the amount of input water supply.

Energy Storage Materials for Investigation

Sand, pebbles, and wick materials that are readily available locally were gathered for the experiment. Sand and pebbles are suitable choices for thermal storage materials in solar energy systems due to their relatively high specific heat capacity, which typically falls in the range of 0.16 to 0.19 . This characteristic enables them to effectively absorb and retain substantial thermal energy when exposed to heat. Wick materials, on the other hand, feature capillary action abilities that facilitate liquid movement, making them useful for cooling applications. The aforementioned materials enhanced the rate of evaporation by increasing the surface area of the water and increasing the efficacy of the solar still. Figure 3 depicts photos of the several low-cost and readily available energy storage materials employed in this experiment.

Instruments and Measurements

This section describes the instruments used to measure parameters like ambient temperature, solar radiation, and temperatures within the solar stills. During the experimentation days, the amount of solar radiation absorbed on the surface of a solar still was measured using a Lux Meter. Eight K-type thermocouples were attached at various positions in order to measure the temperatures in both the modified and conventional solar stills. One sensor was assigned to monitor the water temperature within the basin (Tb), one sensor to measure the ambient temperatures (Ta), and another two sensors to record the temperatures on both the inner and outer surface of the glass (Tgi and Tgo). Anemometer is being used to record the wind velocity at that time. The TDS value in the entering tap water and yield water was determined at the start and at the end of each working day utilizing a TH-TDS10 Digital TDS Meter. Both solar stills were subjected to testing under identical water depth conditions, and comprehensive measurements were taken and recorded during each experimental run.

The standard uncertainty(α) was calculated using the following expression [49]:

here, α represents the accuracy of the instruments.

THERMAL ANALYSIS OF SOLAR STILL

The following equation was used to determine a solar desalination system’s hourly thermal efficiency, which is the ratio of freshwater hourly energy to hourly energy input [50]:

The equation provided by [50] is used to determine the latent heat of water (hfg):

EXPERIMENTAL RESULT ANALYSIS AND DISCUSSION

With the adjustment in the amount of water input into the still, the thermal behavior of the conventional type of solar still is investigated. Three different distilled water volumes (15, 20, and 25 liters) were considered for the analysis, and the number of heat-storage materials (pebbles, sand) and wick materials remained consistent throughout all trials. The considerable period of May 2023 has been used for the study.

To ensure identical environmental conditions for the trials, the experiment was conducted in two sets of solar stills (one unmodified and one modified). The difference between modified and unmodified still is that modified still uses heat storage materials. The experiment results indicate that the modified still produced 435 mL of distilled water during the day and 202 mL at night for a 20-liter batch, whereas the unmodified still yielded 337 and 168 mL during the day and night, respectively, over a 24-h observation period. These resources are mostly used for correlations as well as to calculate the output increase percentage when using locally accessible heat storage materials.

Analysis of Solar Still with Different amount of Brackish Water

Figures 4, 5, and 6 depict the distribution of temperature and solar intensity over time for various amounts of brackish water in the solar still at different locations. It is evident from Figs. 4 to 6 that the difference in solar radiation is comparable on various trial days and reaches its peak value between 12:00 Noon and 2:00 PM. Additionally, it depicts the temperature variation across numerous days of experiments with varied amounts of water in the basin, such as (Tbm, Tbo), (Tgom, Tgou), (Tgim, Tgiu), and (Ta). The temperature rises from 9:00 AM until 2:00 PM, after which it begins to fall since all the heat-storing materials are exposed to less solar intensity.

Throughout the experimental period in April 2022, the solar irradiance varied from 18 200 to 79 200 lx. In the study, it was found that the temperature differential between the water in the basin and the inner surface of the glass cover was more prominent during the high radiation period, which took place between 11:00 AM and 2:00 PM. However, the temperature of the water inside the basin and the inner surface of the glass cover are closer to one another during the low radiation time (from 2:00 PM to 4:00 PM). The solar energy was not used to heat the water in the basin during low radiation and at night times since heat-storage materials absorb certain heat energy during times of high radiation intensity. Furthermore, while solar energy penetrates the glass cover, elevating both its temperature and that of the water in the basin, the absorption rate notably declines during periods of low radiation. This phenomenon suggests that the temperatures of the inner glass covers and the basin water become more closely aligned during such periods.

The fluctuations in wind speed and solar irradiation are shown in Fig. 7. It should be emphasized that throughout the trial, solar radiation increased from 09:00 AM in the morning to 12:00 in the noon. Later, it was changed from 12:00 to 4:00 PM hours in the evening. The greatest sun irradiation during this period was recorded at 12:00 and the minimum value was recorded at 4:00, both of which were 79 200 and 33 000 lx respectively for 20 L of water input. During these hours, the development of cloudy weather also has a significant impact on solar radiation intensity, which lowers system efficiency. In terms of wind speed, the values during the conduction of all experiments ranged from 3 to 24 km/h. During the observation hours for 20 liter. Water input, the direction of the wind above the setup for the experiment changed often. The experiment’s greatest and minimum wind speeds were 3 and 19 km/h, respectively. Impact from wind velocity on the glass cover’s surface speeds up condensation, increasing production [51].

Difference in Temperature and Output of the Suggested Solar Still

The difference in temperature between the condensing and evaporation surfaces has a strong impact on the output of the solar still i.e., ‘basin water’ and ‘inner surface of the glass temperature’. The output will increase as the temperature difference increases. An hourly temperature difference (Tbm – Tgim) with time is depicted in Fig. 8. These outcomes were attained employing two distinct 0.48 m2 conventional type solar stills. Figure 8 shows what is evident.

The maximum change in temperature occurred in between 10:00 AM and 2:00 PM. Nearing 10.1°C, the still produces 63 mL of distillate for every 15 L of water supplied. Additionally, for the 20 and 25 L of water input during that time, the distiller still produces 58 and 38 mL of distillate, respectively. Distillate yield on hourly basis is shown in Fig. 9. This figure displays the fresh water production increases throughout the morning until early afternoon as a result of an increase in solar intensity and then progressively falls down. This figure revealed the following: at 2:00 PM, the solar still achieved its peak distillate outputs, yielding 85, 86, and 73 mL, respectively, corresponding to a 49.41, 17.86, and 45.21% increase in output compared to the unmodified design. These improvements were achieved by varying the water input into the basin, with quantities of 15, 20, and 25 liters used, respectively.

Figure 10 shows the total production for different water input amounts to the basin. This figure shows that at the beginning, the cumulative output appears to be about equal for all the water input quantities. The difference in the cumulative production gets much bigger as the day goes on.

Figure 11 depicts the production of daytime and night-time hours over a 24-h period with varying water inputs into the basin (9:00 AM to 9:00 AM). The distillate output of the proposed still develops during the night-time hours as a result of the energy storage materials that are placed in the modified solar still’s basin capturing energy during the day and releasing it for the night-time hours. The 20 L of water inflows into the basin enhance the still’s night-time production.

Thermal Efficiency of the Proposed Solar Still

Table 2 shows the changes in hourly thermal efficiency for 15, 20 and 25 liters water inputs for modified and unmodified solar still respectively. When compared to conventional solar still (unmodified), the effect of the energy storage materials on modified solar still’s energy efficiency can be seen. The 15 L unmodified solar still had a thermal efficiency of 0.482%, while the 20 L modified solar still had a thermal efficiency of 43.299%, respectively, for all measured values. Even though the sun’s brightness declines after midday, thermal efficiency.

Water Quality

The initial assessment of a tap water sample for experimentation involves measuring and recording its TDS (Total Dissolved Solids) and pH values. Additionally, these quality parameters are re-evaluated for the distillate obtained at the conclusion of the experiment. Subsequently, the obtained results are compared against the established international standards for drinking water quality. The outcomes of the characterization are presented in Table 3, indicating a comparison with the international standards set for drinking water quality. The TDS value of the property, assessed for both drinking and sanitary uses, was found to be 140 ppm, falling within the acceptable range established by the Bureau of Indian Standards. The World Health Organization recommends that the TDS level in drinking water should not exceed 300 mg/L. Moreover, the minimum TDS for drinking water should not fall below 50 ppm.

CONCLUSIONS

One technical approach to achieving high water production in a solar still is the use of various medium as an energy storage medium. The performance of the solar desalination system using sand, pebbles and wick materials as an energy storage medium was assessed in the current work. Additionally, the modified and conventional solar stills thermal, and environmental aspects were compared. Following tests of the modified and conventional solar still under identical meteorological conditions, the following results were drawn:

(1) Modified solar desalination system’s water temperature for 15, 20 and 25 liters water inputs improve by 15.01, 17.81 and 19.61%, respectively over conventional solar desalination system.

(2) The productivity of the water is significantly influenced by the use of low-cost, locally available energy storage materials.

(3) The enhanced solar desalination system demonstrated a cumulative productivity increase of 55.281, 20.722, and 39.393% for water inputs of 15, 20 and 25 liters, respectively, compared to conventional solar desalination systems. This improvement is attributed to the utilization of locally available energy storage materials for heat retention and wick materials that enhance evaporation rates through capillary action within the water.

(4) Maximum thermal efficiencies in modified solar desalination systems were 90.843, 84.464, and 66.326% higher than in conventional solar desalination systems for 15, 20, and 25 liters water inputs, respectively.

(5) The qualitative analysis of the distilled collected revealed that its composition aligns with international standards.

(6) In this experiment, the absence of insulation in the solar still has led to a slightly lower yield. In future experiments, the solar still will be insulated to substantially improve the yield for both conventional and modified devices.

ABBREVIATIONS AND NOTATION

Symbols | |

Ab | Area of basin, m2 |

hfg | Latent heat of water, kJ/kg |

I(s) | Intensity of solar radiation, W/m2 |

I | Intensity of solar radiation, lx × 100 |

Tgi | Temperature of inner surface of glass cover, °C |

Tgo | Temperature of outer surface of glass cover, °C |

Ta | Ambient temperature, °C |

Tb | Basin water temperature, °C |

mw | Hourly accumulated distillate output, mL |

ηth | Thermal efficiency, % |

Subscript | |

a | Ambient |

b | Basin |

gi | Inner surface glass cover |

g0 | Outer surface glass cover |

w | Water |

m | Modified |

u | Unmodified |

L | Liter |

REFERENCES

Scott, K., Smith, C.J., Lowe, J.A., and Carreras, L.G., Demand vs supply-side approaches to mitigation: What final energy demand assumptions are made to meet 1.5 and 20C targets?, Global Environ. Change, 2022, vol. 72, p. 102448. https://doi.org/10.1016/j.gloenvcha.2021.102448

Selimefendigli, F., Sirin, C., and Oztop, H., Experimental performance analysis of a solar desalination system modified with natural dolomite powder integrated latent heat thermal storage unit, Sustainability, 2022, vol. 14, no. 5, p. 2650. https://doi.org/10.3390/su14052650

Shoeibi, S., Rahbar, N., Esfahlani, A.A., and Kargarsharifabad, H., A review of techniques for simultaneous enhancement of evaporation and condensation rates in solar stills, Sol. Energy, 2021, vol. 225, pp. 666–693. https://doi.org/10.1016/j.solener.2021.07.028

Makkiabadi, M., Hoseinzadeh, S., Nezhad, M.M., Sohani, A., and Groppi, D., Techno-economic study of a new hybrid solar desalination system for producing fresh water in a hot–arid climate, Sustainability, 2021, vol. 13, no. 22, p. 12676. https://doi.org/10.3390/su132212676

Zheng, Y., Gonzalez, R.A.C., Hatzell, K.B., and Hatzell, M.C., Large-scale solar-thermal desalination, Joule, 2021, vol. 5, pp. 1971–1986. https://doi.org/10.1016/j.joule.2021.07.005

Patel, S.K., and Modi, K.V., Techniques to improve the performance of enhanced condensation area solar still: A critical review, J. Cleaner Prod., 2020, vol. 268, p. 122260. https://doi.org/10.1016/j.jclepro.2020.122260

Alwan, N.T., Shcheklein, S.E., Ali, O.M., Majeed, M.H., and Agyekum, E.B., Experimental and theoretical investigations of a modified single-slope solar still with an external solar water heater, Sustainability, 2021, vol. 13, no. 22, p. 12414. https://doi.org/10.3390/su132212414

Sodha, M.S., Kumar, A., Tiwari, G.N., Tyagi, R.C., Simple multiple wick solar still: Analysis and performance, Sol. Energy, 1981, vol. 26, no. 2, pp. 127–131. https://doi.org/10.1016/0038-092X(81)90075-X

Akash, B.A., Mohsen, M.S., Osta, O., and Elayan, Y., Experimental evaluation of a single-basin solar still using different absorbing materials, Renewable Energy, 1998, vol. 14, nos. 1–4, pp. 307–310. https://doi.org/10.1016/S0960-1481(98)00082-2

Anburaj, P., Hansen, R.S., and Murugavel, K.K., Performance of an inclined solar still with rectangular grooves and ridges, Appl. Sol. Energy, 2013, vol. 49, no. 1, pp. 22–26. https://doi.org/10.3103/S0003701X13010027

Rajasekhar, G. and Eswaramoorthy, M., Performance evaluation on solar still integrated with nano-composite phase change materials, Appl. Sol. Energy, 2015, vol. 51, no. 1, pp. 15–21. https://doi.org/10.3103/S0003701X15010119

Naim, M.M. and Abd El Kawi, M.A., Non-conventional solar stills part 1. Non-conventional solar stills with charcoal particles as absorber medium, Desalination, 2003, vol. 153, nos. 1–3, pp. 55–64. https://doi.org/10.1016/S0011-9164(02)01093-7

Sakthivel, M. and Shanmugasundaram, S., Effect of energy storage medium (black granite gravel) on the performance of a solar still, Int. J. Energy Res., 2008, vol. 32, no. 1, pp. 68–82. https://doi.org/10.1002/er.1335

Panchal, H., Patel, P., Patel, N., and Thakkar, H., Performance analysis of solar still with different energy absorbing materials, Int. J. Ambient Energy, 2017, vol. 38, no. 3, pp. 224–228. https://doi.org/10.1080/01430750.2015.1086683

Mehdiabadi, E.H., Sarhaddi, F., and Sobhnamayan, F., Energy analysis of a stepped cascade solar still connected to photovoltaic thermal collector, Int. J. Automotive Mech. Eng., 2017, vol. 14, no. 4, pp. 4805–4825. https://doi.org/10.15282/ijame.14.4.2017.15.0376

Kabeel, A.E., Abdelgaied, M., and Eisa, A., Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials, J. Cleaner Prod., 2018, vol. 183, pp. 20–25. https://doi.org/10.1016/j.jclepro.2018.02.144

Kabeel, A.E., El-Agouz, S.A., Sathyamurthy, R., and Arunkumar, T., Augmenting the productivity of solar still using jute cloth knitted with sand heat energy storage, Desalination, 2018, vol. 443, pp. 122–129. https://doi.org/10.1016/j.desal.2018.05.026

Kabeel, A.E., Abdelaziz, G.B., and El-Said, E.M.S., Experimental investigation of a solar still with composite material heat storage: Energy, exergy and economic analysis, J. Cleaner Prod., 2019, vol. 231, pp. 21–34. https://doi.org/10.1016/j.jclepro.2019.05.200

Kabeel, A.E., El-Agouz, E.I.-S., et al., Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: An experimental approach, Environ. Sci. Pollut. Res., 2020, vol. 27, pp. 32218–32228. https://doi.org/10.1007/s11356-019-07288-z

Modi, K.V., and Modi, J.G., Performance of single-slope double-basin solar stills with small pile of wick materials, Appl. Therm. Eng., 2019, vol. 149, pp. 723–730. https://doi.org/10.1016/j.applthermaleng.2018.12.071

Mohamed, A.F., Hegazi, A.A., Sultan, G.I., and El-Said, E.M.S., Enhancement of a solar still performance by inclusion the basalt stones as a porous sensible absorber: Experimental study and thermo-economic analysis, Sol. Energy Mater. Sol. Cells, 2019, vol. 200, p. 109958. https://doi.org/10.1016/j.solmat.2019.109958

Dumka, P., Sharma, A., Kushwah, Y., Raghav, A.S., and Mishra, D.R., Performance evaluation of single slope solar still augmented with sand-filled cotton bags, J. Energy Storage, 2019, vol. 25, p. 100888. https://doi.org/10.1016/j.est.2019.100888

Laxmikant, D.J. and Ganesan, S., Assessing the performance of concave type stepped solar still with brick, sand, and concrete pieces, Int. J. Ambient Energy, 2022, vol. 43, no. 1, pp. 3468–3484. https://doi.org/10.1080/01430750.2020.1839551

Khanmohammadi, S. and Sabzpooshani, M., Theoretical assessment of a solar still system equipped with nano-phase change materials, Int. J. Green Energy, 2021, vol. 18, no. 2, pp. 111–127. https://doi.org/10.1080/15435075.2020.1831510

Dumka, P. and Mishra, D.R., Comparative experimental evaluation of conventional solar still (CSS) and CSS augmented with wax-filled metallic finned-cups, FME Transaction, 2020, vol. 48, no. 2, pp. 482–495. https://doi.org/10.5937/fme2002482D

Manjunath, M.S., Reddy, S.V.K., Shrikanth, V., et al., Experimental study of the influence of glass cover cooling using evaporative cooling process on the thermal performance of single basin solar still, J. Mech. Eng. Sci., 2020, vol. 14, no. 1, pp. 6334–6343. https://doi.org/10.15282/jmes.14.1.2020.11.0496

Parikh, R., Patdiwala, U., Parikh, S., Panchal, H., and Sadasivuni, K.K., Performance enhancement using TiO2 nanoparticles in solar still at variable water depth, Int. J. Ambient Energy, 2022, vol. 43, no. 1, pp. 4037–4044. https://doi.org/10.1080/01430750.2021.1873853

Asbik, M., Boushaba, H., Hafs, H., and Koukouch, A., Investigating the effect of sensible and latent heat storage materials on the performance of a single basin solar still during winter days, J. Energy Storage, 2021, vol. 44, p. 103480. https://doi.org/10.1016/j.est.2021.103480

Attia, M.E.H., Driss, Z., Kabeel, A.E., Afzal, A., Manokar, A.M., and Sathyamurthy, R., Phosphate bed as energy storage materials for augmentation of conventional solar still productivity, Environ. Prog. Sustainable Energy, 2021, vol. 40, no. 4, p. e13581. https://doi.org/10.1002/ep.13581

Attia, M.E.H., Driss, Z., Kabeel, A.E., Afzal, A., Manokar, A.M., and Sathyamurthy, R., Phosphate bags as energy storage materials for enhancement of solar still performance, Environ. Sci. Pollut. Res., 2021, vol. 28, no. 17, pp. 21540–21552. https://doi.org/10.1007/s11356-020-12018-x

Ramalingam, V.K., Karthick, A., Jeyalekshmi, M.P.V., Decruz, A.M.M.A.J., Manokar, A.M., and Sathyamurthy, R., Enhancing the freshwater produced from inclined cover stepped absorber solar still using wick and energy storage materials, Environ. Sci. Pollut. Res., 2021, vol. 28, pp. 18146–18162. https://doi.org/10.1007/s11356-020-12030-1

Biswal, D.K., Performance assessment of a solar still using blackened surface, Lecture Notes in Mechanical Engineering, 2021, pp. 329–336. https://doi.org/10.1007/978-981-15-6360-7_30

Bhambare, P.S., Kaithari, D.K., and AI Hosni, S.A.R., Performance enhancement of a single slope solar still with single basin using Fresnel lens, J. Mech. Eng. Sci., 2021, vol. 15, no. 1, pp. 7781–7791. https://doi.org/10.15282/jmes.15.1.2021.14.0614

Dhivagar, R., Shoeibi, S., Kargarsharifabad, H., Ahmadi, M.H., and Sharifpur, M., Performance enhancement of a solar still using magnetic powder as an energy storage medium-exergy and environmental analysis, Energy Sci. Eng., 2022, vol. 10, no. 8, pp. 3154–3166. https://doi.org/10.1002/ese3.1210

Dumka, P., Kushwah, Y., Sharma, A., and Mishra, D.R., Comparative analysis and experimental evaluation of single slope solar still augmented with permanent magnets and conventional solar still, Desalination, 2019, vol. 459, no. 1, pp. 34–45. https://doi.org/10.1016/j.desal.2019.02.012

Chauhan, R., Dumka, P., and Mishra, D.R., Experimental evaluation and development of artificial neural network model for the solar stills augmented with the permanent magnet and sandbag, 2022, vol. 9, pp. 9–23. https://doi.org/10.15377/2409-5826.2022.09.2

Dubey, M., and Mishra, D.R., Experimental evaluation of double slope solar still augmented with ferrite ring magnets and a black cotton cloth, Int. J. Ambient Energy, 2022, vol. 43, no. 1, pp. 1751–1762. https://doi.org/10.1080/01430750.2020.1722746

Mohammed, A.H., Attalla, M., and Shmroukh, A.N., Comparative study on the performance of solar still equipped with local clay as an energy storage material, Environ. Sci. Pollut. Res., 2022, vol. 29, pp. 74998–75012. https://doi.org/10.1007/s11356-022-21095-z

Adamu, N.I., Biswal, D.K., Pulagam, M.K.R., and Rout, S.K., Performance analysis of solar desalination system with thermal energy storage materials, Mater. Today: Proc., 2023, vol. 74, no. 4, pp. 801–807. https://doi.org/10.1016/j.matpr.2022.11.173

Ahmed, M.M.Z., Alshammari, F., Alqsair, U.F., Alhadri, M., Abdullah, A.S., and Elashmawy, M., Experimental study on the effect of the black wick on tubular solar still performance, Case Stud. Therm. Eng., 2022, vol. 38, p. 102333. https://doi.org/10.1016/j.csite.2022.102333

Thakur, A.K., and Sathyamurthy, R., Improving the potable water generation through tubular solar still using eggshell powder (bio-based energy source) as a natural energy storage material—an experimental approach, Environ. Sci. Pollut. Res., 2022, vol. 29, no. 1, pp. 40903–40920. https://doi.org/10.1007/s11356-022-18906-8

Ramzy, K., Abdelgaleel, M., Kabeel, A.E., and Mosalam, H., Performance of a single slope solar still using different porous absorbing materials: An experimental approach, Environ. Sci. Pollut. Res., 2023, vol. 30, no. 5, pp. 72398–72414. https://doi.org/10.1007/s11356-023-27465-5

Sampathkumar, A., Suraparaju, S.K., and Natarajan, S.K., Enhancement of yield in single slope solar still by composite heat storage material-experimental and thermo-economic assessment, J. Sol. Energy Eng., 2023, vol. 145, no. 2, p. 021005. https://doi.org/10.1115/1.4055100

Sharshir, S.W., Omara, M.A., Elsisi, G., Joseph, A., Kandeal, A.W., Ali, A., and Bedair, G., Thermo-economic performance improvement of hemispherical solar still using wick material with V-corrugated basin and two different energy storage materials, Sol. Energy, 2023, vol. 249, pp. 336–352. https://doi.org/10.1016/j.solener.2022.11.038

Sharshir, S.W., Omara, M.A., Joseph, A., Kandeal, A.W., Elsaid, A.M., El-Said, E.M.S., Alatawi, I., Elashmawy, M., and Abdelaziz, G.B., Thermoenviroeconomic performance augmentation of solar desalination unit integrated with wick, nanofluid, and different nano-based energy storage materials, Sol. Energy, 2023, vol. 262, p. 111896. https://doi.org/10.1016/j.solener.2023.111896

Varun, M., Subhani, S., and Senthil Kumar, R., Convection heat transfer of stepped basin single slope solar still: A numerical investigation, J. Mech. Eng. Sci., 2023, vol. 17, no. 2, pp. 9433–9442. https://doi.org/10.15282/jmes.17.2.2023.2.0746

Rao, K.D.V., Balu, M.A., Naveen, C., et al., Modelling of solar still production using operational and environmental parameters with artificial neural network for a tropical savanna climate, Appl. Sol. Energy, 2022, vol. 58, pp. 187–197. https://doi.org/10.3103/S0003701X22020165

Tei, E.A., Hameed, R.M.S., Illyas, M., and Athikesavan, M.M., Experimental investigation of inclined solar still with and without sand as energy storage materials, J. Energy Storage, 2024, vol. 77, p. 109809.

Holman, J.P., Experimental Methods for Engineers, New York: McGraw-Hill, 2011, 8th ed.

Hassan, H., Comparing the performance of passive and active double and single slope solar stills incorporated with parabolic trough collector via energy, exergy and productivity, Renewable Energy, 2020, vol. 148, pp. 437–450. https://doi.org/10.1016/j.renene.2019.10.050

Mohanraj, M., Karthick, L., and Dhivagar, R., Performance and economic analysis of a heat pump water heater assisted regenerative solar still using latent heat storage, Appl. Therm. Eng., 2021, vol. 196, p. 117263. https://doi.org/10.1016/j.applthermaleng.2021.117263

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct thisparticular research were obtained.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Allerton Press remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Dillip Kumar Biswal, Moharana, B.R., Muduli, K. et al. Investigation of a Single Slope Solar Still Integrated with Gravels, Sand and Wick Materials: An Experimental Approach. Appl. Sol. Energy 60, 370–382 (2024). https://doi.org/10.3103/S0003701X24602047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X24602047