Abstract

The demand for fresh water is rapidly growing as a consequence of the increasing population and urbanization. Tubular solar still offers larger evaporative and condensing surface area as compared to single slope solar still. The aim of this study is to improve the performance of tubular solar still by employing eggshell powder (collected from Babcobb Broilers chicken) as the sensible energy storage material in form of bed, placed inside the basin of still to improve the water production. Results showed that the influence of eggshell powder as energy storage material in the basin improved the average water temperature by 3%, 6.2%, and 3.2% for the water thickness of 10, 15, and 20 mm, respectively. The usage of eggshells as a sensible energy storage in the basin augmented the peak hourly water yield by 67.64% with minimum water thickness. The total observed distillate output from the solar still is 1.45 kg without eggshell powder and 2.67 kg for with eggshell powder in the absorber at the lowest water thickness of 10 mm. TSS with eggshell powder as energy storage has a daily energy efficiency of 48.17%, 42.38%, and 36.38%, respectively, for water thicknesses of 10, 15, and 20 mm in the basin. Water thickness of 10, 15, and 20 mm has performance improvement ratios of 1.83, 1.81, and 1.78, respectively. Using cost analysis, it was found that the cost of drinkable water generated using eggshell as an energy storage material is 0.011$/kg, but the cost of water by traditional still without any storage material was 0.021$/kg.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The demand for fresh water is quickly rising as a result of the increasing population and rapid urbanization. Besides serving as a source of drinking water, fresh water is essential in a wide range of industrial uses, including batteries, pharmaceutical manufacturing, and research facilities. Even though India has a population that accounts for 16% of the world’s total population, the nation possesses just 4% of the world’s freshwater resources. India is experiencing water scarcity as a result of shifting weather patterns and recurrent droughts (Sathyamurthy et al. (2017); Vaithilingam et al. (2021); Arani et al. (2021)). Wells and ponds are drying up as groundwater supplies are depleted owing to excessive usage. This has exacerbated the water situation, placing an even larger strain on water resources. Water desalination with solar energy is the ideal option for developing water desalination systems in developing nations. In counties like India where availability of solar energy is abundant, the water shortage problem can be solved using the solar based distillation. Solar distillation has been utilized for thousands of years and is still in use today. It is a promising technique, which is one of the most sustainable method of supplying potable water to the rural and remote places and gaining significant attention (Chamkha et al. (2020); Madhu et al. (2017, 2019)). Ahmed et al. (2021) carried out a comprehensive review on tubular and basin type solar still. It was concluded in the future directions that the use of nanoparticles in PCM could be more cost-effective for optimized fresh water production. Furthermore, it was concluded that efficient materials which are more lightweight can be used for higher performance. Balachandran et al. (2021) reported that the potable water produced from the solar still using eggshell as energy storage improved the yield to 2.46 L/m2, whereas, the CSS could able to produce a cumulative yield of 2.07 L/m2. In addition, the exergy and energy efficiency also improved as compared to the still without any eggshell. Exergy, environment, and economic (3E) analysis of different solar stills was comprehensively reviewed by Shoeibi et al. (2021a, b). The review recommended the utilization of low-cost material as cover material could be more effective on the environmental and economic aspects. A similar review on the simultaneous augmentation on the rate of evaporation and condensation from solar still was reviewed by Shoeibi et al. (2021a). It reported that the condensation parameter is controlled by reducing the cover temperature through fluid mediums, while the rate of evaporation could be improved by coupling the solar still with PV/T collectors, concentrators, energy storing materials (sensible and latent heat), collector based system, and thermoelectric modules. The use of thermoelectric modules in solar still is not advisable as it is not cost-effective (energy consumption, additional accessories to cool the cold side). The use of PCM, nano-enhanced PCM (NPCM), and natural sensible heat energy storing materials is more advisable as they are more cost-effective. The annual performance and economic study of the tubular still using NPCM as heat storage in basin were experimentally analyzed by Athikesavan et al. (2021). Graphene nanoparticles were used in the paraffin wax. It was reported that the NPCM augmented the annual yield by 45.57% than tubular solar still (TSS) without any energy storage. The prediction of water generated using still with an external condenser was estimated using the ensemble random vector functional network method (Abd Elaziz et al. (2021)). The solar still performance was studied using nanofluids such as alumina (Al2O3) and copper oxide (Cu2O). It was reported that the influence of copper oxide and alumina nanoparticles enhanced the potable water produced by 140 and 100%, respectively. Additionally, the external condenser improved the efficiency to about 36.02 and 32.82% for copper oxide and alumina nanoparticles, respectively. It was found that prediction of water generated by ensemble random vector was more efficient than random vector functional network. Arunkumar et al. (2020) studied the influence of adding a sensible heat energy storage medium inside a traditional solar still to augment freshwater production. Different materials such as pebbles, clay balls, CuO nano-coated absorber, and PVA sponges were used in their study. It was found that fresh water produced from the solar still using pebbles, clay balls, CuO nano-coated absorber, and PVA sponges were 2.8, 2.62, 2.9, and 1.9 L/m2, respectively, with their corresponding cost per liter for water produced as 0.0073, 0.008, 0.007, and 0.012$. Conductive clay balls with superior porosity improved the water generation. Kabeel et al. (2019) studied the influence of using composite heat storage medium on energy and exergy analysis of traditional solar still. Black gravels were added to the paraffin wax for improving the thermophysical properties. The cumulative yield from the SS with PCM and composite PCM were found as 2.44 and 3.72 L/m2 with an average energy efficiency of 48.22 and 66.87%, respectively. It was also found that average exergy efficiency using composite PCM was higher as compared to SS with only base PCM. Kabeel et al. (2017) also used a parabolic solar concentrator along with PCM in the bottom of the solar still to augment the potable water production. Pumice stones were used as an energy storage medium in a conventional type of solar still for augmenting the potable water yield by Bilal et al. (2019). The mass of the storage medium was varied between 5 and 10 kg inside the basin. Results revealed that the use of Pumice stones reduced the daytime productivity by 10.38 and 17.02% for 5 and 10 kg stone mass, respectively, as compare to the daytime yield of conventional solar still without any storage medium. This phenomenon was completely due to the change in internal heat energy storage by the material inside the basin. While comparing the distillate output during the overnight, there is a significant improvement of about 1.58 and 12.67% using 5 and 10 kg of pumice stones inside the absorber. The effect of convex type of absorber with wicks (jute and cotton) spread in the absorber of TSS was experimentally studied by Essa et al. (2021). Along with the proposed modification, composites (graphene and TiO2) were added to the basin water as a working fluid. The convex type of absorber increases the surface contact of water with the solar radiation for maximum evaporation which leads to increased thermal efficiency and potable water yield. Dehmukh and Thombre (2017) used sand and servotherm oil as energy storage material and optimized the depth of SE material for improved thermal performance. In both cases, the depth of material was varied from 0.5 to 1.5 cm while the depth of water is constantly maintained at 0.6 cm. It was reported that with the increasing depth of material, the daylight productivity decreases, and the overnight productivity increases. The heat stored in the daytime is utilized during night time by water, which improved the rate of evaporation. The effect of mushrooms and carbon black-based nanoparticles deposited mushrooms on improving the potable water inside TSS was experimentally analyzed by Sharshir et al. (2021). Three different quantities of carbon black, namely, 25, 50, and 75 g/m2, were coated on mushrooms and a comparison was made with and without mushrooms. The mushrooms increase the capillary effect for effective evaporation, which leads to significantly higher water productivity. The thermal performance improvement of TSS using circular and hollow fins filled with phase change material was experimentally investigated by Abdelgaied et al. (2021). Results revealed that the use of square fins improved the daily potable water by 33% (5.52 L/m2) compared to TSS with a flat absorber (4.15 L/m2). On using hollow circular fins, heat exposure area was further improved that leads to improvement in yield by 47.12% than that of TSS with only a flat absorber. Adding paraffin wax into the circular and square fins attached to the absorber further improves the potable water production by 90.2% than the conventional case. The thermal performance of multi effect tubular solar still using immersion cooling was experimentally analyzed by Yan et al. (2021). Results showed that the water immersion cooling improved the rate of condensate as compared to the air cooling with an optimized vacuum pressure of 40 kPa. The average daily productivity using immersion water cooling method and natural air cooling method was found as 10.7 and 7.2 L/day, respectively. Kabeel et al. (2020) integrated parabolic concentrators with TSS to increase the output. It was observed that the varied thickness of water in semicircular trough improved the fresh water production by 87.9, 90.8, 81.9, and 68.1% for the water thickness of 1, 2, 3, and 4 cm, respectively, as compared to rectangular absorber without parabolic concentrator. Kabeel et al. (2021) explored the role of corrugated absorber and wick material to improve the water output of TSS. Thermal modeling analysis was carried out to assess the performance of the proposed modification in TSS. Results showed that the corrugated fins with wick material increased the potable water production by 44.82% as compared to conventional TSS. Abdelaziz et al. (2021) proposed five different configurations of TSS for augmenting the potable water production. SS with modifications such as corrugated absorber, corrugated absorber with wick material, corrugated absorber with wick material, and carbon black nanoparticles in working fluid and corrugated absorber with wick material, NPCM (carbon black nanoparticles in PCM), and carbon black nanoparticles were proposed. Results show that the use of wick material in corrugated absorber improves the potable water produced by 30.3% and 16.2% than the use of flat absorber and corrugated absorber without wick material. Furthermore, using carbon black nanoparticles in PCM and nanofluids as working fluid in corrugated absorber improved the potable water production by 88.84% than the conventional TSS. The effect of thickness of water using sensible energy storage in the conventional solar still was experimentally investigated by Kabeel et al. (2018a, b). Along with the sensible heat storage material, jute cloth was knitted to augment fresh water production. It was reported that the production of fresh water is fully dependent on characteristics like sensible energy material mass along with basin depth. With the use of jute cloth woven in the sensible heat energy storage, the augmentation in fresh water production was found as 25% than solar still without jute cloth on energy storage. The increase in the freshwater was completely due to the higher capillary effect exhibited by the jute cloth on the energy storage material placed in the basin. Employing low-cost heat storage materials, Samuel et al. (2016) augmented the performance of solar still by 22.73%.

It is inferred from the above discussion that addition of sensible or latent heat energy storage material in conventional solar still is relatively simple as the basin area is higher, whereas it is difficult to place the energy storage materials inside the basin of tubular still, as the area of condensing cover is closer to the exposure area in basin. The properties of various sensible heat energy storage materials used in the previous work has been compared and presented in Table 1.

Different sensible energy materials are being used for performance improvement of the TSS; however, the lower thermal conductivity and their sustainable production are two of the major concerns while using in still. It was also revealed that the influence of eggshell as energy storage in solar desalination is very limited and till the best of the author’s knowledge, usage of eggshell powder as bed in still has not been reported. In this regard, the present research sought to combine the benefits of cost-effective and readily accessible bio-waste material in order to assess the performance of TSS. The eggshells appeared to be an effective organic energy storage material which can be collected from the domestic waste and easy to handle. In this study, the effect of eggshells (from chicken) collected from the hostel mess is utilized as an energy storage material (bio-energy resources/bio-waste is converted into useful energy storage material) in the basin of TSS to improve the potable water production. The eggshells are characterized for its thermophysical properties and morphological behavior to analyze its role in high temperature heating application. Three different water layer thicknesses of 10, 15, and 20 mm were selected to optimize the best water thickness and its effect on the performance of solar still. Furthermore, the effect of energy storage material on hourly potable water produced and energy efficiency was analyzed in comparison to TSS without energy storage. An economic analysis was also presented to find the cost per liter of water produced from the proposed modification.

Experimentation and procedure

Preparation of eggshell powder

Initially, eggshell (which is mainly from the eggs of chicken) was collected from mess of KPR Institute of Engineering and Technology, India, and afterward, it was cleaned to remove the outer thin layer of the skin and other surface impurities. To use this as energy storage material, uniform structure is preferable and therefore, ball milling was done under dry conditions at 300 rpm for 20 min to achieve uniform eggshell powder. The collected powdered eggshell is made into a thick layer as a bed inside the absorber for effective absorptivity of solar radiation. The detailed procedure in the preparation of eggshell powder is provided in Fig. 1.

Characterization and thermal properties of eggshell powder

The crushed eggshell powder is initially placed in a muffle furnace for 30 min at two different temperatures namely 150 °C and 250 °C for calcination. The morphological behavior of eggshell powder is determined using field emission scanning electron microscope (FESEM, ZEISS sigma 300) and using energy dispersive X-ray spectroscopy (EDX), the elemental analysis of the sample are determined. Elemental mapping revealed that there is a higher content of oxygen, calcium, and carbon content with smaller quantities of magnesium. The presence of carbon in the powder is completely due to the heating of eggshell powder in the muffle furnace. The EDX analysis also revealed that the elements present in the eggshell exhibits similar properties of natural bones.

The FESEM analysis also revealed that there are nano-pores available (Fig. 2a–d). The EDX of the eggshell powder is presented in Fig. 3, which clearly highlights the major presence of O (50.4%), followed by Ca (34.1%) along with C (15%) and a very meager amounts of Mg. The size of the pores present in the eggshell powder is averaged as 286.60 nm and the Gaussian fit is provided in Fig. 4. Figures 5 and 6 depict the elements mapping of eggshell powder and clearly, the calcium, carbon, and oxygen are seen in mapping. Thermal conductivity of the storage material plays an important role in improving the water yield of TSS, and therefore, the thermal conductivity of eggshell powder was measured using TEMPOS thermal analyzer with RK-3 probe sensor (60 mm length, 3.9 mm diameter). Initially, the powder of eggshell was taken into the glass bottle and it was filled very tightly to avoid the air-gap. Then, the probe sensor was inserted in the center and the bottle was closed properly. Three measurements were taken to ascertain the result. The thermal conductivity of eggshell powder was measured to be 2.298 W/m2 K. Similar results were also reported by Denys et al. (2004).

Figure 7 shows the XRD (X-ray diffraction) pattern of heated eggshell powder obtained from the muffle furnace. CaO, CaCO3, and Ca(OH)2 are the three chemical compounds identified through the XRD patterns. It is also found that the higher the calcination temperature, the lower the possibilities of CaO. The highest peak of 29.45° is observed for both heating temperatures.

Experimental set-up

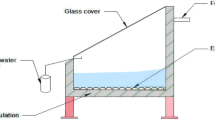

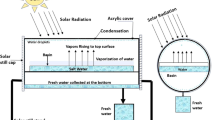

The experimental test rigs were developed based on two different experimental setups, namely, TSS without eggshell and with TSS with eggshell powder in the form of bed inside the absorber for energy storage to improve the thermal performance of tubular still.

Figure 8 represents the base case of the tubular solar still with a flat absorber. In both cases, the dimensions of the cover and the basin are the same. The material used to fabricate the solar still basin was made from mild steel with 2 mm thickness. The absorber plate of still was having the dimension of 27 cm width and 50 cm length. The transparent cylindrical cover was made using acrylic “poly(methyl 2-methylpropenoate)” with diameter and length of 29 cm and 53 cm, respectively, with a tube thickness of 4 mm. The height of the rectangular tray was fixed as 50 mm. A storage tank with a capacity of 40 L is used to store the water and it is constantly supplied to the basin in order to maintain a constant level of water. A calibrated steel ruler is fixed to the basin to see the level of water available in the basin. Figure 9 shows the dimensions of the tray and Fig. 10 represents the mechanism and photograph of the experimental setup.

The experimental data such as solar radiation, temperature, wind velocity, and distillate output were recorded on an hourly basis. Thermocouples were used to monitor the absorber, water, cover, and the surrounding ambient temperature. In order to determine the quantity of condensed water vapor collected via the flexible hoses of the distillate water storage tank, a scaled vessel was employed. The solar power meter was used to record the solar radiation received throughout the testing period. A vane-type anemometer was used to measure the wind velocity. Table 2 shows the range and uncertainty of the measuring instruments. The entire experiments were carried out in the outdoor rooftop facility available in KPR Institute of Engineering and Technology, between 9:00 h and 19:00 h. The eggshell in powder form is added to the basin of tubular solar still with a thickness of 3 cm in the basin. Based on the method by Holman (1994), the experimental uncertainties are calculated. The smallest possible error is equal to the product of the least number of counts and the smallest possible value of the output measured. As stated by Holman (1994), the following equation may be used to quantify the degree of uncertainty in a specific outcome:

The uncertainty of individual variables is given as A1, A2, A3,… An, whereas, AR is the total uncertainty.

With reference to Eq. (1), the uncertainty for hourly potable water produced may be stated as follows:

Similarly, the uncertainty that occurred to daily thermal efficiency is calculated as follows:

Based on Eq. (3), the total experimental uncertainty that occurred to determine the daily thermal efficiency is found as 2.3%.

Results and discussion

The major objective of this work is to optimize the water depth and explore the role of eggshell powder as sensible energy storage material for improving the performance of tubular solar still. The performance was evaluated by measuring the ambient temperature, solar radiation, wind velocity, and the different junction temperature in the still, along with the fresh water production capacity during the experimental study. The following sections discuss the performance and water generation potential of the still using eggshell powder as sensible energy material.

Thermal performance of conventional tubular solar still

To optimize the effect of water depth without using any energy storage material in the conventional still, experimental studies were conducted and following outcomes were observed. Figure 11a–c depicts the temperatures of the different elements such as absorber, water, cover, and ambient temperature, which increase steadily and reach the maximum value once the solar radiation reaches its peak in all the cases. Initially the solar radiation was 420 W/m2 at the start of the experimentation, which steady increases and reached a peak value of 910 W/m2 at 12 noon and later, it gradually reduced and reached the minimum value at 7 PM. Similarly, the ambient air temperature reaches a peak value of 35.6 °C and the average ambient air temperature was 33.38 °C. Additionally, the average wind velocity was 2.13 m/s. All the experimental of TSS without energy storage material was conducted on the same day under the same surrounding conditions to explore the effect of water depth on water production by TSS.

As can be seen in the figure, TSS with water depth of 10 mm exhibited the peak absorber, water, and cover temperature of 56 °C, 54 °C, and 47 °C, respectively. However, TSS with water depth of 15 mm exhibited the respective absorber, water, and cover temperature of 55 °C, 53 °C, and 46 °C, respectively. In addition, the average temperature of absorber, water, and cover were 44.1, 44, and 38.3 °C for 15 mm water depth, whereas it was 47.3, 45.3, and 39.7 °C for TSS with 10 mm water depth. The peak and average temperature of the TSS with 15 mm water depth that was lower than 10 mm depth is owing to the higher sensible energy of water and with large mass of water, more heat energy is required to escalate the temperature. With higher water mass, the heat transfer reduces, leading to lower gain in temperature across the junctions. Moreover, with further increase in the water depth to 20 mm inside TSS, the temperature of absorber, water, and cover was notably reduced and reaches a maximum of 53 °C, 51 °C, and 46 °C, respectively. With maximum mass of water in the basin of TSS (20 mm), there was a peak temperature reduction of 5.66%, 5.88%, and 2.17% in absorber, water, and cover, respectively, as compared to TSS with least water depth (10 mm). The above reduction is attributed to higher water mass which hindered the heat transfer and leads to lower gain in temperature.

It is also important to note that the water–cover temperature difference is very important in promoting higher evaporation and generating higher water yield. Therefore, the water–cover temperature difference was analyzed and similar trend of increasing water depth on reduction of temperature difference was noticed. For TSS with 10 mm water depth, the peak temperature difference of water–cover was 9 °C and the average temperature difference was 5.63 °C. With increasing the water depth to 15 mm, the peak water-cover temperature difference was only 7 °C and the average temperature difference was 4.18 °C. For higher water depth, the temperature difference significantly reduced, which is owing to the mass of water that restricted the heat transfer from water to cover, leading to lower temperature difference. With further increase in depth to 20 mm, the peak temperature difference even reduced further and reached a peak of 6 °C with average temperature difference of 3.36 °C. The lower temperature difference is not favorable for improved evaporation and it will restrict the heat transfer from water to cover, leading to lower water production.

Performance of tubular solar still with eggshell powder as energy storage material

The major objective of this work is to explore the role of low-cost bio-waste, i.e., eggshell powder as the sensible heat storage material for improving the performance of TSS. After the eggshell powder preparation, it was made in form of bed inside the basin of TSS and its effect on thermal performance is analyzed in this section.

Figure 12a–c depicts the variations on wind velocity, solar radiation, ambient, absorber, water, and the cover temperature of TSS with eggshell powder as sensible heat storage material with different water thicknesses of 10, 15, and 20 mm inside the basin. As seen in the figure, with eggshell as sensible heat storage material and water depth of 10 mm, the absorber, water and cover temperatures were 57 °C, 55 °C, and 41 °C, respectively. In addition, the respective average temperatures were 48.72 °C, 46.72 °C, and 36.45 °C. It is interesting to note that the synergetic effect of optimum water depth along with the energy storage material has improved the temperatures at different junction inside TSS and an increase in peak temperature of ⁓2% was observed in case of absorber and water for 10 mm depth with eggshell as compared to TSS with the same depth without eggshell. It is also important to highlight that there was a significant reduction in cover temperature using eggshell from 47 °C (TSS with 10 mm water depth without eggshell) to 41 °C (TSS with 10 mm water depth and eggshell). This could be due to higher evaporation of water with the usage of eggshell that promoted higher evaporation, which leads to higher condensate deposition onto the TSS cover and later, faster movement of the water droplet from cover to distillate collection point. The faster gliding of water leads to lower cover temperature and improved performance of the TSS.

With increasing the water depth from 10 to 15 mm, the temperature of absorber, water, and cover reached 55 °C, 53 °C, and 40 °C, respectively. The reduction in temperature of TSS with eggshell through increased water depth is already explained in the previous section. It is also interesting to note that eggshell based TSS with 15 mm water depth exhibited higher average temperature gain than the same water depth TSS without eggshell. The average temperature of absorber, water, and cover were 47.18 °C, 45.18 °C, and 35.04 °C, respectively. In addition, during off-peak hour, i.e., after 2 PM, the energy storage potential of eggshell allowed to store energy for longer during and later, released into the water to achieve optimum water temperature even during low solar intensity. During 2–7 PM, the average temperature of absorber and water were 46.33 °C and 44.33 °C, respectively, whereas it was only 42 °C and 40.5 °C for TSS (15 mm water depth) without eggshell as sensible heat storing material. The increases in temperature are attributed to the stored energy in eggshell which maintained higher temperature during off-peak hours also.

With further increase in water depth from 15 to 20 mm with eggshell powder, there was further reduction in temperature across the still. The peak temperature of absorber, cover, and water reached 52 °C, 41 °C, and 51 °C, respectively. It is found that there is significant reduction of ~ 5 °C in temperature of absorber and water with increasing the water depth. Moreover, as compared to the TSS with the same depth without any eggshell powder, the average temperature of water and absorber augmented by 3.2% and 4.2%, respectively, using eggshell powder as storage material. It is obvious that higher water depth will restrict the heat transfer and allow lower temperature gain across various junctions in TSS. It is also important to highlight the effect of eggshell powder as energy storage material in improving the temperature difference of water-cover. The peak temperature difference of water-cover was 14 °C for TSS with 10 mm water depth using eggshell. The average temperature difference of water–cover was 11 °C. The temperature difference using eggshell has increased noteworthy than the conventional case, owing to the excellent energy storage potential of the eggshell. For the water depth of 15 mm and 20 mm, peak temperature differences of water–cover were 10.85 °C and 7.8 °C, respectively.

Comparison of potable water produced with and without eggshell powder

Because of the higher amount of solar radiation available at 13:00 h, all the stills achieved their highest hourly potable water produced at that time. The potable water produced continues and rises in the morning session and reaches its peak in the afternoon session, after which it begins to decline as a result of the decreased solar radiation. The critical parameter in the performance of solar still is its amount of potable water produced. On an hourly basis, the potable water produced from the tubular solar still without energy storage and tubular solar still with eggshell as energy storage is plotted in Fig. 13a, b. The peak recorded yield from the solar still under the maximum solar intensity was found to be 0.34 kg (without eggshell powder, conventional) and 0.57 kg (with eggshell powder), respectively, for solar still at a constant water thickness of 10 mm maintained inside the basin. On daylight hours, the variations on the potable water produced at increased water thickness are decreasing and the same is reversed under the lower solar radiation period (evening hours) which simultaneously denoted that the reported yield is more stable.

For 15 mm water depth, hourly water yield with and without eggshell powder as energy storage material were 0.48 kg and 0.29 kg, respectively. It is clearly seen from the results that usage of eggshell powder as storage material has improve the hourly water yield. However, with increasing the water depth, the hourly yield decreased significantly. As can be seen from the graph, there was a reduction of 15.78% in the hourly yield of TSS with eggshell when the water depth is increased from 10 to 15 mm. It is obvious that the higher water depth hindered the rate of heat transfer, leading to lower evaporation and causing less accumulation of the vapor on the cover. For the water depth of 20 mm, the hourly water yield with and without eggshell powder were 0.34 kg and 0.22 kg, respectively. With higher mass of water and loading of eggshell powder as bed material, the potable water production significantly reduced. Therefore, it is suggested to use lower water depth inside the basin to improve the heat transfer and evaporation rate, which leads to higher water production in the TSS.

Comparison of daily yield and daily average thermal energy efficiency

The efficiency of any thermal system is a very critical parameter which is used to assess the feasibility and performance of the system. The daily average thermal efficiency of the system is mathematically expressed as (Sharshir et al. (2018)),

For calculating the daily average thermal efficiency of the solar still, Eq. (4) was utilized. As can be seen in the formula, the efficiency is mainly depending upon the portable water generated using the still. The daily water production of TSS without any eggshell at 10 mm water height was measured to be 1.45 kg. However, with usage of eggshell powder as sensible storage material for the same depth, the production significantly improved and reached 2.67 kg. The noteworthy enhancement in the water production was due to the superior energy storage potential of the eggshell, which prolonged the additional stored energy to water and improved the evaporation throughout the off-peak hour, leading to improved water output. It is also important to note that during off-peak hours (2 PM–7 PM), the total water production was only 0.81 kg for TSS without any eggshell at 10 mm water depth. Moreover, with eggshell, this production improved significantly and reached 1.74 kg. In addition, the productivity enhancement ratio (which is the defined as the ratio of total water production of TSS with eggshell as material to the total water production of TSS without any storage material) of TSS at 10 mm water depth was 1.83. With increasing the water depth to 15 mm, the total water production of TSS without any eggshell powder was found to be 1.26 kg (15% reduced as compared to TSS without eggshell at 10 mm water depth), and it significantly improved to 2.29 kg with the usage of eggshell powder as storage material. The notable improved water generation is attributed to eggshell as bed material, which possessed highly porous structure and stored energy inside the bed. Additionally, during off-peak hours (2 PM–7 PM), the total water production was only 0.72 kg for TSS without any eggshell at 15 mm water depth. Moreover, with eggshell, this production improved significantly and reached 1.49 kg. The productivity enhancement ratio for TSS at 15 mm water depth was found to be 1.81. With further increasing the water depth to 20 mm, TSS without any eggshell powder showed total water production of 1.02 kg, which was increased to 1.83 kg using the eggshell powder.

Moreover, during off-peak hour (2 PM–7 PM), total water production was 0.58 kg and 1.2 kg, respectively, for TSS without and with eggshell powder. In addition, the productivity enhancement ratio for TSS at 20 mm water depth was 1.78.

The daily average thermal efficiency was calculated based on the total water production and TSS without any storage material at 10 mm water depth exhibited the efficiency of 31.47%. It is astonishing to note that usage of eggshell as sensible heat material in form of bed improved the average daily thermal efficiency to 48.17%. With increasing the water depth to 15 mm, conventional TSS without any eggshell powder showed the efficiency of 27.36%, whereas with eggshell, the efficiency reached 42.38%. It is owing to the higher generated water through the sensible heat material, which improved the water production and consequently, it improved the efficiency. For 20 mm depth, TSS without any eggshell powder exhibited the thermal efficiency of 22.20% and 36.38% for TSS with eggshell. Table 3 present the comparison of different kind of modification performed in solar still to improve the water production by various research group. It is inferred from the above results that the eggshell as bed material inside the basin of TSS significantly improved the total water production, which leads to higher thermal efficiency of the system.

Cost analysis of developed system

In addition to improved water production, it is also important to assess the developed system in terms of its cost and therefore, the cost analysis is presented in the following section. The reliability of distillation system is normally assessed through the economic performance (Bait (2019; Kandeal et al. 2021; Sharshir et al. 2020). The total cost during fabrication of the standalone TSS is presented in Table 4. The literatures revealed that the total lifetime of the system is considered as 10 years, while the rate of interest is considered as 10% for optimal selling price of potable water. The economical correlation on various components used in finding the cost per liter (CPL) of water is tabulated in Table 5. From the analysis, it was found that the usage of eggshell as bed material (energy storage) is more efficient and economical as the CPL is found to be 0.011$/L. The yearly productivity from the solar still is estimated by considering 292 days (80% sunny days).

Future recommendations

The results showed excellent performance of the still under eggshell as sensible heat storage material and it has given promising results both in terms of performance and cost. Although the results are fascinating, it is suggested to optimize the bed height of eggshell. In addition, the effect of eggshell size on the thermo-physical properties can also be investigated to optimize the suitable size. It is also important to highlight that eggshell exhibited excellent behaviors even under high temperature exposure, and thus, it is recommend to analyze its suitability as composite may be with sand-bed and other sensible-based material to effectively improve the performance of still without comprising the cost.

Conclusions

The following are the primary conclusions reached as a consequence of the experimental work:

-

Using eggshell powder as the energy storage medium, it was found that the off-peak hours (2 PM–7 PM) water average temperature improved by 5.44%, 9.45%, and 14.94% for the water thicknesses of 10, 15, and 20 mm, respectively, as compared to conventional TSS.

-

With high conductivity eggshell as energy storage material in the absorber, the average temperature of the water is enhanced by 3%, 6.2%, and 3.2% for water thicknesses of 10, 15, and 20 mm, respectively, compared to conventional still without storage material.

-

The peak hourly potable water generation was improved by 67.64% with the use of eggshells as energy storage in the basin with minimum water depth. In addition, the total potable water generation using eggshell was increased by 1.22 kg with minimum water depth than the conventional case without eggshell.

-

For water thicknesses of 10, 15, and 20 mm in the basin, the daily average thermal energy efficiency of TSS with eggshell powder as energy storage is found to be 48.17%, 42.38%, and 36.38%, respectively.

-

The cost of potable water produced using eggshell as energy storage material is found as 0.011$/kg; whereas, the cost of water generated by conventional TSS was 0.021$/kg.

Data Availability

Not applicable.

Abbreviations

- AC:

-

area of cover (m2)

- CSS:

-

conventional solar still.

- hfg:

-

latent heat of condensation (J/kg).

- I(t):

-

solar radiation (W/m2).

- me:

-

mass of distillate collected (kg).

- PCM:

-

Phase change material

- TSS:

-

tubular solar still.

References

Abdelaziz GB, Algazzar AM, El-Said EM, Elsaid AM, Sharshir SW, Kabeel AE, El-Behery SM (2021) Performance enhancement of tubular solar still using nano-enhanced energy storage material integrated with v-corrugated aluminum basin, wick, and nanofluid. J Energy Storage 41:102933

Abdelgaied M, Zakaria Y, Kabeel AE, Essa FA (2021) Improving the tubular solar still performance using square and circular hollow fins with phase change materials. J Energy Storage 38:102564

Abd Elaziz, Mohamed, F. A. Essa, and Ammar H. Elsheikh. “Utilization of ensemble random vector functional link network for freshwater prediction of active solar stills with nanoparticles.” Sustainable Energy Technologies and Assessments 47 (2021): 101405.

Ahmed MM, Alshammari F, Abdullah AS, Elashmawy M (2021) Basin and tubular solar distillation systems: a review. Process Saf Environ Protect 150:157–178

Alshammari F, Elashmawy M, Ahmed MM (2021) Cleaner production of freshwater using multi-effect tubular solar still. J Cleaner Prod 281:125301

Arani RP, Sathyamurthy R, Chamkha A, Kabeel AE, Deverajan M, Kamalakannan K, Balasubramanian M, Manokar AM, Essa F, Saravanan A (2021) Effect of fins and silicon dioxide nanoparticle black paint on the absorber plate for augmenting yield from tubular solar still. Environ Sci Pollut Res 28(26):35102–35112

Arunkumar T, Wang J, Rufuss DDW, Denkenberger D, Kabeel AE (2020) Sensible desalting: investigation of sensible thermal storage materials in solar stills. J Energy Storage 32:101824

Athikesavan, M. M., Márquez, F. P. G., Rafeek, M. T. M., & Sathyamurthy, R. (2021, August). Annual yield, energy and economic analysis of tubular solar stills with phase change material and nano-enhanced phase change material. In International Conference on Management Science and Engineering Management (pp. 463–472). Springer, Cham.

Bait O (2019) Exergy, environ–economic and economic analyses of a tubular solar water heater assisted solar still. J Clean Prod 212:630–646

Balachandran GB, David PW, Rajendran G, Ali MNA, Radhakrishnan V, Balamurugan R, Athikesavan M, Sathyamurthy R (2021) Investigation of performance enhancement of solar still incorporated with Gallus gallus domesticus cascara as sensible heat storage material. Environ Sci Pollut Res 28(1):611–624

Bilal A, Jamil B, Haque NU, Ansari MA (2019) Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundw Sustain Dev 9:100228

Čáchová M, Koňáková D, Vejmelková E, Keppert M, Černý R (2016). Mechanical and thermal properties of the Czech marbles. In AIP Conference Proceedings (Vol. 1738, No. 1, p. 280010). AIP Publishing LLC

Chamkha AJ, Rufuss DDW, Kabeel AE, Sathyamurthy R, Abdelgaid M, Manokar AM, Madhu B (2020) Augmenting the potable water produced from single slope solar still using CNT-doped paraffin wax as energy storage: an experimental approach. J Braz Soc Mech Sci Eng 42(12):1–10

Denys S, Pieters JG, Dewettinck K (2004) Computational fluid dynamics analysis of combined conductive and convective heat transfer in model eggs. J Food Eng 63:281–290

Deshmukh HS, Thombre SB (2017) Solar distillation with single basin solar still using sensible heat storage materials. Desalination 410:91–98

El-Sebaii AA, Yaghmour SJ, Al-Hazmi FS, Faidah AS, Al-Marzouki FM, Al-Ghamdi AA (2009) Active single basin solar still with a sensible storage medium. Desalination 249(2):699–706

Essa FA, Alawee WH, Mohammed SA, Dhahad HA, Abdullah AS, Omara ZM (2021) Experimental investigation of convex tubular solar still performance using wick and nanocomposites. Case Studies in Therm Eng 27:101368

Holman JP (1994) Experimental methods for engineers, 6th edn. McGraw-Hill, Singapore

Kabeel AE, Elkelawy M, El Din HA, Alghrubah A (2017) Investigation of exergy and yield of a passive solar water desalination system with a parabolic concentrator incorporated with latent heat storage medium. Energy Convers Manage 145:10–19

Kabeel AE, Abdelgaied M, Eisa A (2018a) Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J Clean Prod 183:20–25

Kabeel AE, El-Agouz SA, Sathyamurthy R, Arunkumar T (2018b) Augmenting the productivity of solar still using jute cloth knitted with sand heat energy storage. Desalination 443:122–129

Kabeel AE, Abdelaziz GB, El-Said EM (2019) Experimental investigation of a solar still with composite material heat storage: energy, exergy and economic analysis. J Clean Prod 231:21–34

Kabeel AE, Harby K, Abdelgaied M, Eisa A (2020) Performance of the modified tubular solar still integrated with cylindrical parabolic concentrators. Sol Energy 204:181–189

Kabeel AE, Harby K, Abdelgaied M, Eisa A (2021) Performance improvement of a tubular solar still using v-corrugated absorber with wick materials: numerical and experimental investigations. Sol Energy 217:187–199

Kandeal AW, El-Shafai NM, Abdo MR, Thakur AK, El-Mehasseb IM, Maher I, Rashad M, Kabeel AE, Yang N, Sharshir SW (2021) Improved thermo-economic performance of solar desalination via copper chips, nanofluid, and nano-based phase change material. Sol Energy 224:1313–1325

Kedida, D. K., Amibe, D. A., & Birhane, Y. T. (2019). Performance of a pebble bed thermal storage integrated with concentrating parabolic solar collector for cooking. Journal of Renewable Energy, 2019.

Madhu B, Balasubramanian E, Nagarajan PK, Ravishankar S, Kabeel AE, Arunkumar T, Mageshbabu D (2017) Improving the yield of fresh water from conventional and stepped solar still with different nanofluids. Desalin Water Treat 100:243–249

Madhu, B., Balasubramanian, E., Kabeel, A. E., Sathyamurthy, R., El‐Agouz, E. S., & Muthu Manokar, A. (2019). Experimental investigation on the effect of photovoltaic panel partially and fully submerged in water. Heat Transfer—Asian Research, 48(5), 1709–1721.

Murugavel KK, Srithar K (2011) Performance study on basin type double slope solar still with different wick materials and minimum mass of water. Renewable Energy 36(2):612–620

Murugavel KK, Sivakumar S, Ahamed JR, Chockalingam KK, Srithar K (2010) Single basin double slope solar still with minimum basin depth and energy storing materials. Appl Energy 87(2):514–523

Samuel DH, Nagarajan PK, Sathyamurthy R, El-Agouz SA, Kannan E (2016) Improving the yield of fresh water in conventional solar still using low cost energy storage material. Energy Convers Manage 112:125–134

Sathyamurthy R, El-Agouz SA, Nagarajan PK, Subramani J, Arunkumar T, Mageshbabu D, Madhu B, Bharathwaaj R, Prakash N (2017) A review of integrating solar collectors to solar still. Renew Sustain Energy Rev 77:1069–1097

Sharshir SW, Peng G, Elsheikh AH, Edreis EM, Eltawil MA, Abdelhamid T, Kabeel AE, Zang J, Yang N (2018) Energy and exergy analysis of solar stills with micro/nano particles: a comparative study. Energy Convers Manage 177:363–375

Sharshir SW, Elkadeem MR, Meng A (2020) Performance enhancement of pyramid solar distiller using nanofluid integrated with v-corrugated absorber and wick: an experimental study. Appl Therm Eng 168:114848

Sharshir SW, Hamada MA, Kandeal AW, El-Said EM, Elsaid AM, Rashad M, Abdelaziz GB (2021) Augmented performance of tubular solar still integrated with cost-effective nano-based mushrooms. Sol Energy 228:27–37

Shoeibi S, Rahbar N, Esfahlani AA, Kargarsharifabad H (2021) A comprehensive review of Enviro-Exergo-economic analysis of solar stills. Renew Sust Energ Rev 149:111404

Shoeibi S, Rahbar N, Esfahlani AA, Kargarsharifabad H (2021) A review of techniques for simultaneous enhancement of evaporation and condensation rates in solar stills. Sol Energy 225:666–693

Vaithilingam S, Gopal ST, Srinivasan SK, Manokar AM, Sathyamurthy R, Esakkimuthu GS, Kumar R, Sharifpur M (2021) An extensive review on thermodynamic aspect based solar desalination techniques. J Therm Anal Calorim 145(3):1103–1119

Yan T, Xie G, Chen W, Wu Z, Xu J, Liu Y (2021) Experimental study on three-effect tubular solar still under vacuum and immersion cooling. Desalination 515:115211

Acknowledgements

Amrit Kumar Thakur would like to acknowledge KPR Institute of Engineering and Technology, Coimbatore, India for providing the Fellowship.

Author information

Authors and Affiliations

Contributions

Amrit Kumar Thakur: conceptualization, methodology, investigation, validation, and writing — reviewing; formal analysis.

Ravishankar Sathyamurthy: conceptualization, methodology, investigation, validation, and writing — reviewing; formal analysis, project administration, and supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thakur, A.K., Sathyamurthy, R. Improving the potable water generation through tubular solar still using eggshell powder (bio-based energy source) as a natural energy storage material — an experimental approach. Environ Sci Pollut Res 29, 40903–40920 (2022). https://doi.org/10.1007/s11356-022-18906-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-18906-8