Abstract

Renewable energy-based desalination (RED) technique is gaining more importance over the desalination techniques as it appeared to be a promising technique towards low-cost desalination for sustainable growth as the energy demand towards other developments is continuously increasing. This study aims to incorporate energy storage materials and wick materials in the inclined solar to improve the fresh water produced. In this work, the performance of inclined solar still using coconut coir disk and energy storage material is analyzed experimentally. Characterization results showed that the porosity, absorbency, capillary rise, and heat transfer coefficient of 1-year dried coconut coir disk were found as 73.25%, 2 s, 10 mm/h, and 37.21 W/m2K, respectively, which is higher as compared with that of other coconut coir disks. The experimental results on the performance showed that total distillate from novel inclined solar still with hybrid techniques (energy storage materials and wick materials) were recorded as 3645, 4080, 4570, and 4890 ml for 3 months, 6 months, 9 months, and 1 year, respectively. While the total distillate outputs of an inclined solar still with only wick materials were recorded as 2560, 2670, 2930, and 3390 ml for 3 months, 6 months, 9 months, and 1-year coconut coir disk wick materials. The novel hybrid techniques used in the inclined solar still with energy storage materials enhanced the yield from 82.25 to 144.5% than the conventional solar still, whereas the inclined solar still with only wick materials enhanced the yield from 28 to 69.5% than the conventional solar still.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is a crucial requirement of a human, along with food and air. Water is one of the most important substances on earth. About 97% of water resources on the earth are saline, and only the remaining 3% is fresh drinkable in condition (Attia et al. 2020a, b; Vaithilingam et al. 2020; Balachandran et al. 2020; Muthu Manokar et al. 2020). Nowadays, freshwater demand is increasing continuously because of industrial development, intensified agriculture, upgrading living standards, and a growing world population (Sathyamurthy et al. 2014, 2017). There is a great need to convert seawater into potable water to overcome and meet the current demand for freshwater. Solar still is a traditional, economical, and eco-friendly device that converts saline/brackish water into potable drinking water (Kabeel et al. 2019a, b, c, d; Mu et al. 2019; Sharon and Reddy 2015; Sathyamurthy et al. 2016, 2020; Nagarajan et al. 2017; Thakur et al. 2020). The solar still works on a process involving evaporation (by heating) and condensation as the rainfall occurs naturally (Essa et al. 2020; Taamneh et al. 2020; Chamkha et al. 2020). Solar still has much significance like high quality, negligible maintenance, suitable for all kinds of water, less wastage, and so forth. Like significance, solar still has few limitations like air leakage due to poor fitting and joining in structures, cracking or breakage of transparent cover (glass), algae formation, deposition of dust and bird droppings and salt deposits, and so forth. These factors affect the performance of the solar still (Muthu Manokar et al. 2020; Manokar et al. 2020a, b; Sasikumar et al. 2020; Madhu et al. 2018). Production of solar still can be improved in many ways as follows. In wick type solar distillers, insulation thickness plays an essential role in freshwater produced (Yeh and Chen 1986). In general, solar distillers without proper insulation, the distillate water production was lower. By using wick materials, the freshwater produced from the inclined solar still increased as the wick material reduced the mass flow rate of flowing water by absorbing the water (Sheeba et al. 2012). The mass flow rate of water was reduced by using wick material, and it improves the performance of the still (Mahdi et al. 2011). Instead of the single wick material, equipping with multi-wick materials was used as the material, which significantly enhanced the productivity (Sodha et al. 1981). Flowing the water over the transparent glass cover of the solar still improved the productivity slightly for about 10% over the conventional system (Dhiman and Tiwari 1990). Solar radiation plays a significant role in the performance of a solar still. During the year around comparison, the summer season gives higher productivity than in the winter season (Agboola and Egelioglu 2011). Integration of different still-like basin types with inclined wick types improves productivity (Minasian and Al-Karaghouli 1995). Incorporating an external heat exchanger along with the solar still increases the productivity considerably (Badran et al. 2004). The addition of an external reflector along with the still increases the production of freshwater (Tanaka and Nakatake 2009). Instead of a flat plate, the incorporation of a stepped absorber plate reduced the mass flow rate and helps in increasing the productivity and even more, by the inclusion of a mini solar pond (Velmurugan et al. 2009a, b). Incorporation of the reflector in the still enhanced the productivity of the still and even with azimuth tracking in the tilted wick solar still (Aybar et al. 2005). Non-distilled water comes out from the still that have enough temperature for domestic usage. Water flowing over the transparent cover helps to increase the temperature difference between evaporate water and glass temperature. Due to the high-temperature difference, productivity also increases (Janarthanan et al. 2006). Incorporating the condenser in a solar still as an inbuilt component also increases the productivity considerably (Fath and Hosny 2002). Taamneh et al. (2020) used PV as basin material of inclined solar still and integrated a spiral tube collector for improved thermal efficiency at higher flow rates of water and compared the performance during summer and winter conditions. Results showed that solar thermal efficiency still improved with integration, and electrical efficiency drop was observed for an increased temperature of panel temperature. Sasikumar et al. (2020) studied an inclined solar still with varied water flow rates in an inclined PV panel solar still under passive condition. Results exhibited that the thermal and electrical efficiency are inversely proportional as the flow rate increases the thermal performance decreases with improved electrical efficiency of PV panel. Hilarydoss et al. (2020) made thermal modeling and made a detailed enviro-economic investigation on inclined solar still for improved fresh water. Results showed that the proposed solar thermal and exergy efficiency still was superior while compared with other solar still. Similarly, the exergy destruction was lower and higher exergy efficiency over the glass cover material while the flat absorber and without a felt sheet. The greenhouse emission was reduced using felt sheet in the absorber with a lower payback period of 4 years with a CPL of 1.51 INR/l. Sharon (2020) compared the energy, environmental, and exergy of passive-type double-sided vertical solar distiller under different operating conditions such as salinity, absorber area, gap, and feed water flow. Results showed that solar distiller performance decreased with increased water, absorber area, and gap. The optimum feed water flow was found as 40 kg/day. The annual average energy, exergy, and recovery ratio for the proposed solar distiller were found as 62.16, 4.73, and 31.7%, respectively. The distiller’s average yield was found as 4.18 kg/m2 with CPL of 2 INR/l and reduced green house gas emission of 33 to 87 tons. Sharon et al. (2020) made a year around analysis on a novel vertical multi-chamber solar still. It was reported that the exergy efficiency of 23.15% using vertical multi-chamber solar still which produced a daily yield of 11.13 kg/m2. Also, it was reported that the CPL of produced water was about 0.9 INR/l with 67.9 CO2 mitigation for a period of 20 years.

Analyzing the characterization for wicking materials like black cotton cloth, jute cloth, coir mate, waste cotton pieces, wood pulp paper wick, water coral fleece fabric, and polystyrene sponge was used in solar still application. Few of them show higher productivity also (Anburaj et al. 2013). Analyzing wick material characteristics and its testing methods to select the best suit wick material for solar still application is done already. The characteristic analysis helps improve the productivity of the solar still (Hansen et al. 2015). A review of the literature reveals that there is no significant work carried out on characterizing the coconut coir disk as wick material and its application in solar still. This paper describes the critical wicking characters (like porosity, capillary rise, absorption, and heat transfer coefficient, and water repellency) to select wick material for solar distillate production application along with its performance statistics. The latest literature related to renewable energy has been studied (Mammeri and Lallam 2019; Hysa 2019; Nazir 2019; Topçuoğlu 2019). From the detailed literature survey, it is found that no research has been published on the incorporation of coconut coir disk and energy storage materials in the inclined solar stills. The study aims to analyze the performance from the inclined solar still using biodegradable material along with energy storage materials. The present study also deals with the characterization of wick material, experimental setup and procedure, and a detailed analysis of the reported results followed by conclusions.

Wick and energy storage material characteristics

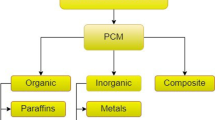

Based on the review of literature, wick material for a solar still application requires certain characters (Wang and Torng 2001; Pal et al. 2006; Glover 2001; Tanaka and Nakatake 2007). The characteristics of wick materials include porosity, capillary effect, absorbency, shrinkage, wrinkle, density, durability, absorptivity, spreading speed, water repellency, ability to conduct thermally, and heat transfer coefficient. In the present investigation, the characteristics of wick material, such as porosity, absorbency, repellent, capillary rise, and heat transfer coefficient, are considered in selecting a suitable wick material for the application of solar desalination technique (Hansen et al. 2015). The coconut coir wick material under different seasoning conditions was tested in the South India Textile Research Association, Coimbatore, Tamil Nadu, India, and also at the department of chemistry, National Engineering College, Kovilpatti, Tamil Nadu, India.

The characteristics of coconut coir disk under different seasoning conditions are tabulated in Table 1. The examined attributes of wick materials for the best stuff to use in solar still increase productivity. Concluding that 1-year coir disk has the right wick property under porosity, absorbency, capillary rise, and heat transfer coefficient and found as 73.25%, 2 s, 10 mm/h, and 37.21 W/m2 K, respectively. The different seasoned coconut coir disk were made with a 50mm dimension and 25mm thick. Similarly, copper scraps with dimensions of 1 mm diameter, 18 wire gauge, and approximately 75 mm length are used as energy storage material. It is used to absorb the radiation from the source utmost. Its thermal conductivity is 394 W/m K, and specific heat is 0.398 kJ/kg K.

Experimental system and procedure

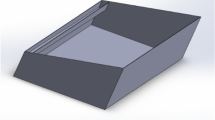

The illustrative diagram of inclined type solar still with rectangular groove absorber is shown in Fig. 1. Furthermore, the heated wastewater collected in the outlet is re-circulated into the storage tank. The single slope stepped absorber plate inclined type solar still was constructed using locally available materials in the Kovilpatti market, and the fabricated system was tested at the Department of Mechanical Engineering, National Engineering College, Kovilpatti, Tamil Nadu, and India during March 2016. The total dimensions of the still are 1 × 0.75 × 0.157 m. Two different absorbers, namely flat absorber and rectangular groove absorber, are fabricated and fitted into the basin. A transparent cover made of glass with a thickness of 3 mm is used to cover the rectangular tray. The bottom and side of the rectangular tray are packed with 10-mm thickness thermocol insulation. A 24 V DC water pump was used to pump the hot water from the hot water storage tank to the main storage tank. Additional makeup water arrangements are made to maintain a constant pressure head. The rectangular groove absorber is made up of a 1-mm aluminum sheet and coated with black paint. A condensate channel is provided at the lower end, and the distributor pipe is provided at the higher end of inclined solar still for the free flow of water. The entire experimental setup is inclined at an angle of 30°. The details of the instruments used in the experimental investigation are tabulated in Table 3.

The instrumental uncertainty is calculated using the empirical formula of Rahbar et al. (2017) (Equation (1)) and it is mathematically expressed as

The uncertainty associated with determining the daily efficiency of solar still depends on the distillate collected in the calibrated flask and the input solar radiation. Mathematically, it is given as

The different phases of coconut coir disk-like 3 months, 6 months, 9 months, and 1 year are laid on the absorber plate to increase the water film thickness. The distributor pipe is made up of hardened polyvinyl chloride material. At the equal interval, 20 holes each of the 3 mm diameter are drilled in the distributor pipe to make the water flow on the entire absorber area through gravity. Through the distributor pipe, the water is evenly distributed, covering the entire absorber plate, and it is ensured that the layer of water is formed on the entire surface of the absorber plate. The transmitted solar radiation heats the absorber, and thereby the flowing water is heated. The evaporated water from the absorber surface is condensed in the inner cover surface as water droplets. By gravity, the water droplets flow to the lower end of the glass and get collected in the condensate channel. The measuring jar collects the condensate collected in the channel. The un-evaporated hot water from the still was stored in an insulated tank and re-circulated using a DC powered water pump for a regular time interval. Figures 2, 3, and 4 show the photographic view of the inclined type stepped absorber solar still, photograph of absorber materials, and research methodology of the inclined type stepped absorber solar still, respectively. Experiments are conducted on inclined solar still using different seasoned wick materials (3 months, 6 months, 9 months, and 1 year). The copper scarps are spread in the absorber’s entire surface area while the coconut coir disk is placed in the rectangular grooves. The total mass of the copper scraps used in the basin is 1.24 kg. The performances are analyzed experimentally on the respective dates mentioned in Table 2.

Experimental photograph of inclined type stepped absorber plate solar still. Detailed parts are (1) feed water tank, (2) temperature indicator unit, (3) thermocouple wires, (4) stepped absorber, (5) distribution pipe, (6) glass cover, (7) insulation, (8) supporting stand, (9) collecting jar, (10) DC pump, (11) hot water storage tank

Wick materials in the basin area are the most crucial parameter, affecting the still’s performance. In addition to the inclined type stepped absorber plate solar still, the yield and efficiency are enhanced using wire mesh with the wick material. Various temperatures like inlet water temperature, absorber plate temperature (Fin-1 and Fin-2), condensate temperature, and glass inside and outside temperature, un-condensate water temperature is measured with the help of K-type thermocouple (chromel-alumel) that ranges from − 40 to + 375 °C with an error of 0.4% that is used in the present study, along with digital temperature indicator. Solar radiation is measured by PV type sun meter (TES-1333). A standard measuring jar is used to estimate daily productivity by collecting the condensate.

Results and discussion

The performance analysis is carried out for various stages of seasoned coir disk wick materials like 3, 6, 9, and 12 months in a stepped absorber plate under the actual solar condition. The hourly variations in solar intensity and wind velocity during the experimentations are shown in Fig. 5

Performance analysis of solar still using various phases of wicked coir disk without energy-storing materials

Figure 6 shows that the productivity varies of different wick materials incorporated solar still hour to hour from morning 6 am to next day morning 6 am for 1-h time interval. On an hourly basis, the different temperatures involved in the production enhancement of the inclined solar still with different seasoned wick materials are shown in Fig. 6a–d. Here, solar radiation is low in morning hours, reaches a maximum at around 14:00 h, and gradually reduces in evening hours. Similarly, the different water and absorber plate temperatures gradually increase from morning to peak hours and gradually decrease towards the evening. Compared with 1-year seasoned coconut coir disk, wick material-trialed experiments obtained the maximum temperatures in all aspects than others. The reduced temperature of inner glass and absorber temperature were noticed with 6- and 9-month seasoned coconut coir wick material as the absorbency, and capillary rise is higher. Similarly, the level of porosity increases with different seasoning coconut coir increases, which affects the coconut coir’s wettability.

The hourly variations of productivity from the solar still with different coir disk phases without any energy-storing material are shown in Fig. 7. One-year seasoned coconut coir disk wick material obtained maximum hourly productivity of 360 ml between 13:00 and 14:00 h. Others obtained lower productivity at the same time interval, like 290 ml for 9 months, 280 ml for 6 months, and 270 ml for 3-month dried coconut coir disk wick materials. The increased capillary effect and heat transfer coefficient by the wick material improved the fresh water yield from inclined solar still. Furthermore, the yield from 12-month seasoned coconut coir is improved by 19.4, 22.2, and 25% than 9-, 6-, and 3-month seasoned coconut coir disk. It is also depicted that the yield from solar still during lower solar intensity using 12-month seasoned coconut coir is higher. The absorbance of the water with the coconut coir is higher in the case of increasing the seasoning of coconut coir with the absorber of solar still.

Cumulative production of the solar still with different phased coconut coir disks is given in Fig. 8. Moreover, the result shows that solar still using 1-year phased coconut coir disk wick material gives higher productivity of 3390 ml per day. Comparably, other wick materials provide lower productivity, such as 2930 ml for 9 months, 2670 ml for 6 months, and 2560 ml for 3-month dried coconut coir disk wick materials. The improvement in fresh water yield using 1-year seasoned coconut coir disk as wick material is found as 16% higher than 9 months, 27% higher than 6 months, and 32% higher than 3-month dried wick materials.

Performance of inclined stepped absorber plate using various phases of wicked coir disk with energy-storing materials

The inclined solar still with different seasoned coconut coir disk is also investigated with energy storage materials under the same climatic condition on the respective dates mentioned in Table 2. The hourly variations in temperatures involved in enhancing the freshwater produced from inclined solar still with different seasoned wick materials and energy-storing material are shown in Fig. 9a–d. Here, solar radiation is low in morning hours, reaches a maximum at around 14.00 h, and gradually reduces in evening hours. Similarly, the different water and absorber plates’ different temperatures gradually increase from morning to peak hours and then gradually decrease towards the evening. Comparably, 1-year seasoned coconut coir disk as the wick material-trialed experiments obtained the maximum temperatures in all aspects than others. In the modified solar still, basin temperature and water temperature are higher than the conventional solar still. The higher temperature difference between the modified solar still resulted in higher water and glass temperature, resulting in higher productivity than the conventional solar still.

Figure 10 shows that the productivity varies of the various wick materials used in the still with an energy storage material hour to hour from morning 6 am to next day morning 6 am for a 1-h interval. One-year coir disk was obtained the maximum hourly productivity of 550 ml between 1:00 PM and 2:00 PM. While others obtained lower productivity at the same time interval like 500 ml for 9 months, 460 ml for 6 months, and 400 ml for 3-month dried coconut coir disk wick materials with energy storage material.

Figure 11 shows the increasing production of distilled water per day in the inclined type stepped absorber plate solar still with various staged coconut coir disk and energy storage material. The daily productivity from the inclined stepped absorber solar still using wick materials with energy storage material at 12-month, 9-month, 6-month, and 3-month coir disk was 4890, 4570, 4080, and 3645 ml, respectively. Similarly, without energy, storage material produced the yield of 3390, 2930, 2670, and 2560 ml, respectively.

In this experimentation, the various stages of coir disk such as 3 months, 6 months, 9 months, and 1 year were used to analyze the maximum yield of fresh water produced. The cumulative yield of fresh water produced from inclined type solar still is increased using a rectangular stepped absorber plate with wick materials and energy storage material. The still with 1-year coir disk and energy storage productivity gives maximum value than other stages of coir disk materials used as a wick. The capillary effect brings the maximum distillate in the still, which is comparable 7% higher than 9 months, 16% higher than 6 months, and 34% higher than 3-month older wick material with energy storage material.

Evaporative heat transfer

Figure 12 shows the evaporative heat transfer variation from inclined solar with different seasoned coconut coir disk and coconut coir disk with wire mesh as energy storage. The evaporative heat transfer between water and glass using seasoned coconut coir disk is lower than coconut coir disk with wire mesh energy storage material. This is due to the higher absorption of water with coconut coir and energy heat absorption by the wire mesh, which simultaneously increased water evaporation rate from the absorber surface. Also, the heat transfer between water and glass follows a similar curve followed by the hourly yield.

Overall productivity comparison, instantaneous and daily thermal efficiency of various phases of coir disk with and without energy-storing materials

Figure 13 shows the cumulative productivity from the solar still at different periods of coir disk with and without energy-storing materials. Comparing with all phases of coir disk, 1-year coir disk with energy-storing material on a rectangular stepped absorber plate produced the maximum distillate output.

The result shows that 1-year seasoned coconut coir disk as wick material along with energy storage material gives higher productivity of 4890 ml. On comparing the cumulative yield from solar still using different seasoned coconut coir with energy storage material, the yields obtained using 3, 6, and 9 months are found as 3645, 4080, and 4570 ml, respectively. Similarly, the cumulative yields obtained using 3-, 6-, 9-, and 12-month seasoned coconut coir without ESM are found as 2560, 2670, 2930, and 3390 ml, respectively. The still with 1-year dried coconut coir disk with energy storage material shows an improvement of about 6.5% which is higher compared with the 9 months. Similarly, about 20.2% and 10.6% in fresh water yield improvement while using 6- and 3-month seasoned coconut coir disk, respectively, along with energy storage material. It is also observed using 12-month seasoned coconut coir disk without energy storage material; the cumulative yield from the solar still is improved by 24.4% than 3-month seasoned coconut coir. The improvement in fresh water using 6- and 9-month seasoned coconut coir without ESM is found as 4.1 and 12.6%, respectively. The improvement in fresh water using increased coconut coir disk increased seasoning due to the fact that coconut coir increased heat transfer coefficient and higher porosity.

The hourly instantaneous thermal efficiency of the system is estimated using Equation (3).

whereas β-latent heat of vaporization (kJ/kg K)

where

a1 = 2.5 × 106, a2 = − 2.369 × 103, a3 = 2.678 × 101, a4 = − 8.103 × 10−3, a5 = − 2.079 × 10−5

The variations on thermal efficiency from inclined solar still using coconut coir disk and coconut coir with ESM as energy storage are plotted in Fig. 14a, b. It is seen that the peak hourly thermal efficiency occurs with the maximum solar intensity of the inclined solar still using 3-, 6-, 9-, and 12-month seasoned coconut coir disk and found as 28.08, 29.57, 30.65, and 37.48%, respectively. This is due to the excellent absorption of higher seasoned coconut coir disk for better evaporation. Similarly, from Fig. 14b, it is seen that on adding wire mesh along with the coconut coir, the maximum hourly thermal efficiency of 42.42, 48.07, 50.89, and 59.45% is observed for 3, 6, 9, and 12-month seasoned coconut coir disk with ESM, respectively. It is also seen that the hourly thermal efficiency beyond the lower intensity period is higher in both cases as the coconut coir disk absorbs the energy with and without energy storage for efficient evaporation.

The variations on daily efficiency from inclined solar still using coconut coir disk and coconut coir with energy storage material under different seasoning period are plotted in Fig. 15. It is seen that the daily efficiency of the solar still increases with the increased seasoning period. The daily efficiency of solar still using 3-, 6-, 9-, and 12-month seasoned coconut coir disk is found as 32.8, 36.39, 41.46, and 48.13%, whereas, in addition of wire mesh as energy storage material along with coconut coir, the daily efficiency is improved and found as 47.46, 55.95, 61.78, and 64.54%, respectively. Figure 16 shows the improvement in the yield of fresh water produced from the inclined solar still using different seasoned coconut coir disk and energy storage materials in the absorber. It is clear that the amount of fresh water produced using ESM along with the coconut coir disk is improved compared with that of coconut coir disk alone. The 1-year seasoned coconut coir disk with ESM produced a daily improvement of about 66.32% in fresh water compared with coconut coir disk alone. The solar still using 3-, 6-, and 9-month seasoned coconut coir disk with ESM improved the fresh water to about 77.8, 80.1, and 82.07%, respectively, while compared with coconut coir disk alone.

Economic analysis

Cost and economic analysis of the inclined stepped absorber solar still with wicked coir disk and inclined stepped absorber solar still with coconut coir disk and energy-storage materials are tabulated in Tables 4, 5, and 6. The payback period of inclined solar still includes manufacturing (fabrication), maintenance, feed water cost, operating cost, and the rate of distilled water cost. Tables 5 and 6 show that in all the cases of inclined solar still with coconut coir disk and ESM, the payback period is less as compared with the inclined stepped absorber solar still with coconut coir disk. The payback period of the novel inclined solar still with hybrid techniques (energy storage materials and wick materials) was calculated to be 170, 148, 130, and 120 days for 3-month, 6-month, 9-month, and 1-year coconut coir disk wick materials with energy storage materials, respectively. The payback period is calculated as 257, 243, 215, and 179 days for 3-month, 6-month, 9-month, and 1-year seasoning period, respectively. It is also observed that the inclined stepped absorber solar still with 1-year wicked coir disk and energy storage materials is 59 days less than the inclined stepped absorber solar still with only wicked coir disk.

The net profit is calculated using Equation (4),

Conclusion

This research reported the investigation on inclined stepped type solar still for increasing the availability of freshwater in remote areas. The performance of the still was studied with varying phases of coconut coir disk as wick materials (3-month, 6-months, 9-months, 1-year dry condition incorporated with wire mesh) in a stepped absorber plate with and without using energy-storing materials. From the experiments, the following conclusions have arrived.

-

The freshwater production from the inclined stepped type solar still using 1-year, 9-month, 6-month, and 3-month coconut coir disk wick materials was 3390, 2930, 2670, and 2050 ml per day, respectively.

-

The freshwater production from the inclined stepped type solar still using 1-year, 9-month, 6-month, and 3-month coconut coir disk wick materials with energy storage materials were 4890, 4570, 4080, and 3645 ml per day, respectively.

-

It is found that the 1-year seasoned coir disk material obtained maximum productivity from the modified solar still than other seasonings of wick materials due to the higher absorbency, capillary rise, and heat transfer coefficient.

-

The 1-year seasoned coir disk inclined stepped type solar still with energy-storing material increased the freshwater production rate by 30.6% as compared with the without energy-storing material.

From the analysis, it is found that the proposed solar still is more suitable in the production of fresh water in the locations where there is a great need for fresh water (ground water too salty, coastal region, rural). From the economic analysis, it is clear that solar still maintenance is more reliable by incorporating a low-cost biodegradable material mixed with energy-storing wire mesh in the stepped absorber plate.

Data availability

Not applicable.

References

Agboola OP, Egelioglu F (2011) An experimental investigation of an improved incline solar water desalination system in Famagusta. Sci Res Essays 6(15):3298–3308. https://doi.org/10.5897/SRE11.596

Anburaj P, Hansen RS, Murugavel KK (2013) Performance of an inclined solar still with rectangular grooves and ridges. Appl Solar Energy 49(1):22–26

Attia MEH, Driss Z, Manokar AM, Sathyamurthy R (2020a) Effect of aluminum balls on the productivity of solar distillate. J Energy Storage 30:101466

Attia MEH, Karthick A, Manokar AM, Driss Z, Sathyamurthy R, Sharifpur M (2020b) Sustainable potable water production from conventional solar still during the winter season at Algerian dry areas: energy and exergy analysis. J Therm Anal Calorim 1–11. https://doi.org/10.1007/s10973-020-10277-x

Aybar HŞ, Egelioğlu F, Atikol U (2005) An experimental study on an inclined solar water distillation system. Desalination 180(1-3):285–289

Badran AA, Assaf LM, Kayed KS, Ghaith FA, Hammash MI (2004) Simulation and experimental study for an inverted trickle solar still. Desalination 164(1):77–85

Balachandran GB, David PW, Rajendran G, Ali MNA, Radhakrishnan V, Balamurugan R, Athikesavan M, Sathyamurthy R (2020) Investigation of performance enhancement of solar still incorporated with Gallus gallus domesticus cascara as sensible heat storage material. Environ Sci Pollut Res 1–14. https://doi.org/10.1007/s11356-020-10470-3

Chamkha AJ, Rufuss DDW, Kabeel AE, Sathyamurthy R, Abdelgaid M, Manokar AM, Madhu B (2020) Augmenting the potable water produced from single slope solar still using CNT-doped paraffin wax as energy storage: an experimental approach. J Braz Soc Mech Sci Eng 42(12):1–10

Dhiman NK, Tiwari GN (1990) Effect of water flowing over the glass cover of a multi-wick solar still. Energy Convers Manag 30(3):245–250

Essa FA, Omara ZM, Abdullah AS, Shanmugan S, Panchal H, Kabeel AE, Sathyamurthy R, Alawee WH, Manokar AM, Elsheikh AH (2020) Wall-suspended trays inside stepped distiller with Al2O3/paraffin wax mixture and vapor suction: experimental implementation. J Energy Storage 32:102008

Fath HES, Hosny HM (2002) Thermal performance of a single-sloped basin still with an inherent built-in additional condenser. Desalination 142:19–27

Glover P (2001) Formation evaluation MSC course notes. Chapter 5: Porosity, Aberdeen University, pp. 43-52

Hansen RS, Narayanan CS, Murugavel KK (2015) Performance analysis on inclined solar still with different new wick materials and wire mesh. Desalination 358:1–8

Hilarydoss S, Delhiraja K, Reddy KS, Philip L, Chand D, Benny B (2020) Thermal modeling, characterization, and enviro-economic investigations on inclined felt sheet solar distiller for seawater desalination. Environ Sci Pollut Res 1–17. https://doi.org/10.1007/s11356-020-10831-y

Hysa A (2019) Modeling and simulation of the photovoltaic cells for different values of physical and environmental parameters. Emerg Sci J 3(6):395–406

Janarthanan B, Chandrasekaran J, Kumar S (2006) Performance of floating cum tilted-wick type solar still with the effect of water flowing over the glass cover. Desalination 190(1-3):51–62

Kabeel AE, Sharshir SW, Abdelaziz GB, Halim MA, Swidan A (2019a) Improving performance of tubular solar still by controlling the water depth and cover cooling. J Clean Prod 233:848–856

Kabeel AE, Muthu Manokar A, Sathyamurthy R, Prince Winston D, El-Agouz SA, Chamkha AJ (2019b) A review on different design modifications employed in inclined solar still for enhancing the productivity. J Solar Energy Eng 141(3)

Kabeel AE, Sathyamurthy R, El-Agouz SA, El-Said EM (2019c) Experimental studies on inclined PV panel solar still with cover cooling and PCM. J Therm Anal Calorim 138(6):3987–3995

Kabeel AE, Harby K, Abdelgaied M, Eisa A (2019d) A comprehensive review of tubular solar still designs, performance, and economic analysis. J Clean Prod:119030

Madhu B, Balasubramanian BE, Kabeel AE, El-Agouz SA, Manokar AM, Prakash N, Ravishankar S (2018) Experimental investigation on the effect of sensible heat energy storage in an inclined solar still with baffles. Desalin Water Treat 116:49–56

Mahdi JT, Smith BE, Sharif AO (2011) An experimental wick-type solar still system: design and construction. Desalination 267(2-3):233–238

Mammeri A, Lallam M (2019) Elaboration of an analytical formula for the calculation of the surface temperature. Civil Eng J 5(10):2260–2269

Manokar AM, Vimala M, Sathyamurthy R, Kabeel AE, Winston DP, Chamkha AJ (2020a) Enhancement of potable water production from an inclined photovoltaic panel absorber solar still by integrating with flat-plate collector. Environ Dev Sustain 22(5):4145–4167

Manokar AM, Vimala M, Prince Winston D, Rajendran DR, Sathyamurthy R, Kabeel AE (2020b) A comparative study of 3E (energy, exergy, and economy) analysis of various solar stills. Heat Transf 49(8):4394–4409

Minasian AA, Al-Karaghouli AA (1995) An improved solar still: the wick-basin type. Energy Convers Manag 36(3):213–217

Mu L, Xu X, Williams T, Debroux C, Gomez RC, Park YH, Wang H, Kota K, Xu P, Kuravi S (2019) Enhancing the performance of a single-basin single-slope solar still by using Fresnel lens: experimental study. J Clean Prod 239:118094

Muthu Manokar A, Kabeel AE, Sathyamurthy R, Mageshbabu D, Madhu B, Anand P, Balakrishnan P (2020) Effect of mass flow rate on fresh water improvement from inclined PV panel basin solar still. Mater Today Proc 32(3):374–378

Nagarajan PK, El-Agouz SA, Harris Samuel DG, Edwin M, Madhu B, Sathyamurthy R, Bharathwaaj R (2017) Analysis of an inclined solar still with baffles for improving the yield of fresh water. Process Saf Environ Prot 105:326–337

Nazir CP (2019) Solar energy for traction of high speed rail transportation: a techno-economic analysis. Civil Eng J 5(7):1566–1576

Pal L, Joyce MK, Fleming PD (2006) A simple method for calculation of the permeability coefficient of porous media. TAPPI J 5(9):10–14

Rahbar N, Gharaiian A, Rashidi S (2017) Exergy and economic analysis for a double slope solar still equipped by thermoelectric heating modules-an experimental investigation. Desalination 420:106–113

Sasikumar C, Muthu Manokar A, Vimala M, Prince Winston D, Kabeel AE, Sathyamurthy R, Chamkha AJ (2020) Experimental studies on passive inclined solar panel absorber solar still. J Therm Anal Calorim 139(6):3649–3660

Sathyamurthy R, Kennady HJ, Nagarajan PK, Ahsan A (2014) Factors affecting the performance of triangular pyramid solar still. Desalination 344:383–390

Sathyamurthy R, Samuel DH, Nagarajan PK (2016) Theoretical analysis of inclined solar still with baffle plates for improving the fresh water yield. Process Saf Environ Prot 101:93–107

Sathyamurthy R, El-Agouz SA, Nagarajan PK, Subramani J, Arunkumar T, Mageshbabu D, Madhu B, Bharathwaaj R, Prakash N (2017) A review of integrating solar collectors to solar still. Renew Sust Energ Rev 77:1069–1097

Sathyamurthy R, Balasubramanian M, Devarajan M, Sharshir SW, Manokar AM (2020) Experimental study on enhancing the yield from stepped solar still coated using fumed silica nanoparticle in black paint. Mater Lett 127873. https://doi.org/10.1016/j.matlet.2020.127873

Sharon H (2020) Energy, exergy and enviro-economic assessment of productivity enhanced passive double sided vertical convection solar distiller for fresh water production. Sustain Energy Technol Assess 42:100846

Sharon H, Reddy KS (2015) A review of solar energy driven desalination technologies. Renew Sust Energ Rev 41:1080–1118

Sharon H, Reddy KS, Gorjian S (2020) Parametric investigation and year round performance of a novel passive multi-chamber vertical solar diffusion still: Energy, exergy and enviro-economic aspects. Sol Energy 211:831–846

Sheeba KN, Jaisankar S, Prakash P (2012) Performance study on an inclined solar water distillation system. Int J Chem Environ Eng 3(1)

Sodha MS, Kumar A, Tiwari GN, Tyagi RC (1981) Simple multiple wick solar still: analysis and performance. Sol Energy 26(2):127–131

Taamneh Y, Manokar AM, Thalib MM, Kabeel AE, Sathyamurthy R, Chamkha AJ (2020) Extraction of drinking water from modified inclined solar still incorporated with spiral tube solar water heater. J Water Process Eng 38:101613

Tanaka H, Nakatake Y (2007) Improvement of the tilted wick solar still by using a flat plate reflector. Desalination 216(1-3):139–146

Tanaka H, Nakatake Y (2009) One step azimuth tracking tilted-wick solar still with a vertical flat plate reflector. Desalination 235(1-3):1–8

Thakur AK, Sathyamurthy R, Sharshir WS, Ahmed MS, Hwang JY (2020) A novel reduced graphene oxide based absorber for augmenting the water yield and thermal performance of solar desalination unit. Mater Lett 128867. https://doi.org/10.1016/j.matlet.2020.128867

Topçuoğlu K (2019) Trombe wall application with heat storage tank. Civil Eng J 5(7):1477–1489

Vaithilingam S, Gopal ST, Srinivasan SK, Manokar AM, Sathyamurthy R, Esakkimuthu GS, Kumar R, Sharifpur M (2020) An extensive review on thermodynamic aspect based solar desalination techniques. J Therm Anal Calorim:1–17

Velmurugan V, Pandiarajan S, Guruparan P, Harihara Subramanian L, Prabaharan DC, Srithar K (2009a) Integrated performance of stepped and single basin solar stills with mini solar pond. Desalination 249:902–909

Velmurugan V, Naveen Kumar KJ, NoorulHaq T, Srithar K (2009b) Performance analysis in stepped solar still for effluent desalination. Energy 34:1179–1186

Wang CN, Torng JH (2001) Experimental study of the absorption characteristics of some porous fibrous materials. Appl Acoust 62(4):447–459

Yeh HM, Chen LC (1986) The effects of climatic, design and operational parameters on the performance of wick-type solar distillers. Energy Convers Manag 26(2):175–180

Author information

Authors and Affiliations

Contributions

Conceptualization, methodology, resources, formal analysis, and investigation were carried out by Vignesh Kumar Ramalingam, Alagar Karthick, Manoj Praveen Vijayan Jeyalekshmi, Arul Marcel Moshi Antony Joseph Decruz, Athikesavan Muthu Manokar; writing-original draft preparation, review and editing, supervision were carried out by Ravishankar Sathyamurthy.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interest

The authors declare that they have no competing interest.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramalingam, V.K., Karthick, A., Jeyalekshmi, M.P.V. et al. Enhancing the fresh water produced from inclined cover stepped absorber solar still using wick and energy storage materials. Environ Sci Pollut Res 28, 18146–18162 (2021). https://doi.org/10.1007/s11356-020-12030-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-12030-1