Abstract

In this work, a blackened solar still has been fabricated and experimentally investigated for distillation of water. A tilted flat plate blackened-type solar still was designed for this purpose and fabricated. Solar still productivity is investigated by changing the input water quantity in the basin of the solar still. Indoor experimental testing was carried out. The effect of input water flow rate on the still productivity and purity of output water is investigated together. With the increase in quantity of input water, the solar still efficiency increases. The tests were conducted using the irradiance from a lamp array. It is found that 150 ml of distilled water is collected for a working period of 2 hours at 800 W input. An average overall efficiency of the designed solar still is found to be 7.95% for the 30 L of input water. With increase in water input to the solar still, its efficiency increases marginally. For the water input of 20 and 30 L, the solar still efficiencies are 7.41 and 7.95%, respectively. The quality of the distilled water is also determined experimentally and found to be satisfactory. Preliminary tests on the quality of distillate proved the possible use of the fabricated solar still for the production of distilled water for different uses in the college premises. By using the fabricated solar still, conductivity and TDS value of the sample water reduced significantly.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Along with food and air, the two important items which are absolutely necessary for human civilization are energy and water. Renewable energy, i.e., sun energy, can play a very vital role to meet a major part of our future energy needs. Survey shows that more than 90% of the water resources contain salts and harmful bacteria and cannot be used for drinking purposes. Many processes have been developed to purify the excess amount of dissolved salts and harmful bacteria to make the water purified which can be used for drinking purpose.

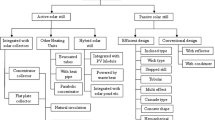

A good method to obtain purified water is the distillation process. For large amount of purified drinking water, it is not feasible for the conventional distillation processes to meet the high demand. A source of energy, i.e., solar energy, which is available naturally can be used as energy input to the distillation of water processes. Therefore, solar distillation process used to purify the water seems to be a promising method and an alternative way for supplying small communities with purified water. There are several methods of water distillation process available using solar as the energy source. Simple equipment named ‘solar still’ can be used effectively and efficiently to provide purified water to a small community. Solar still system contains a deep basin containing water which is to be purified covered with a transparent material [1]. Although, the solar still system requires large area for installation and initial investments cost high, its operation and maintenance cost is low. In previous research, several types of solar still designs have been proposed by different authors, and many designed have found useful application all over the world. However, it is the best solution for inaccessible areas and small communities with lack of drinking water. In this work, a tilted flat plate blackened-type solar still was fabricated and used for distillation of water, and effect of various factors on the still productivity is investigated experimentally.

2 Literature Review

A double-condensing chamber solar still (DCS) had been designed by Tiwari et al. [2] in which the water is being transformed in to vapor in the first chamber by solar radiation and the water vapor is passed into a second chamber through a vent. Experiments were carried out to measure the DSC and compared with a conventional solar still. A novel low cost solar still design which reduced the overall cost of the solar still by 20% has been proposed by Kudish et al. [3]. Yadav et al. [4] designed, fabricated and tested an asymmetric line-axis compound parabolic concentrating single-basin ‘solar still.’ Meukam et al. [5] proposed a single-compartment model and a two compartment-type solar still, and experiment has been conducted to find out its effectiveness. Different types of single and double-slope solar stills are constructed by Khalifa et al. [6], and tests were conducted with the help of preheated feed water to show the effect of solar still performance. The efficiency and output of the solar still improves by using preheated feed water. The thermal analysis of solar distillation has been carried out by Tiwari et al. [7] to optimize the inclination angle of the glass cover for maximum output. A single-basin solar still has been fabricated by Farid and Hamad [8] made up of galvanized steel sheet with an inclined glass cover. By increasing the ambient temperature of water and decreasing the wind velocity, it is observed that the productivity of the solar still increases. Different plates in the solar stills were used by Panchal et al. [9, 10] to improve the solar still efficiency, and they found that by using M. S. Plate and G. I. Sheet the solar still efficiency increases by 15 and 20%, respectively. The effect of copper and aluminum plates on purified water output is investigated experimentally by Hitesh et al. [11] at different water depths under the same climate conditions and found that the output varies with the variation of plates and increases with the increase in water depth. Sahoo and Subushi [12] used jute cloth to improve the productivity of a solar still. Kaviti et al. [13] shows that the productivity of a solar still is greatly affected by the inclination angle of the glass cover. In comparison to 23° and 30° glass inclination angles, it is found that 30° gives more productivity compared to the 23° inclined glass cover Dinesh et al. [14]. Rashidi et al. [15, 16] found that solar still productivity can be enhanced by using porous media and nanofluid. Jani and Modi [17] carried out experimental investigation on double-slope single-basin solar still to improve the productivity by incorporating circular and square cross-sectional hollow fins.

From the literature review, it is observed that to remove harmful stuffing from water, solar still can be used as one of the key equipment. With appropriate modifications in design of glass cover (angles to the horizontal) and basin, solar still effectiveness can be improved. With this aim, the present work is designed to exploit solar energy for elimination of harmful content from drinking water by using a solar still. The simple modifications to the solar still are done by the use of blackened absorbed surface. Due to some limitations, in this experiment, electrical energy is used instead of solar energy.

3 System Description and Experimental Investigation

Figures 1a, b shows a schematic diagram of the designed solar still. The experimental setup of the ‘solar still’ is shown in Fig. 2a, b. The ‘solar still,’ with a base area of 39 × 42 inch, is fabricated from 1.5 inch thickness of glass fiber mixed with resin and CaCO3 (chalk powder). The inner part of the basin is painted with blackened base liner to form a matt black surface for better absorptivity or very less reflectivity and very less transmissivity. The 5 mm thick transparent glass cover of the solar still is placed at an angle of 9°74′ with the horizontal edge of the container to ensure maximum transmission of solar radiation into the still as well as enabling condensed vapor to filter down to the channel which is built in the still basin. The edges of the glass plate are sealed using rubber gasket to prevent heat losses and to make the basin air tight. The design incorporates a supply fill port at the upper half of the apparatus through which water is added into the still. The water in the basin was heated by the help of electrical energy, and the evaporated water was condensed near the cover. The output collector is kept along the lower edge of the glass cover and is used to collect the distilled water from the condensed water, and the output water is analyzed at Eastern Academy of Science and Technology, Bhubaneswar.

3.1 Result and Discussion

The area of the glass cover (1.138 m2) is exposed to radiation, and transmissivity of the glass cover is taken from literature as 0.85 [8]. By using a thermometer, the initial temperature of the water is measured before putting into the solar still basin. Before keeping the glass cover in the solar still, the volume of water is also measured. Then, the measured amount of water is put into the solar still basin, and glass cover is placed above it to cover the basin. The volumetric output rate of the purified water from the solar still is obtained by collecting water in a jar and measured it with the help of a beaker. This experiment is conducted for estimating still efficiency for 20 and 30 L of water. Five quantities of electric bulb having 200 W were used in this experiment for 2 hours, to illuminate and heat the basin water instead of solar radiation, and the distilled water is collected from the basin. Due to external radiation, the calculated value of the input heat is taken as 800 W.

The efficiency of the solar still can be calculated by the formula [18]

where

Mass of the output water \( m_{\text{v}} = 150\;{\text{ml}} = 0.15\;{\text{kg}} \)

Specific heat capacity of water \( {\text{Cp}}_{\text{w}} = 4.21\;{\text{kJ/kg}}\;{\text{K}} \)(Constant for water)

Latent heat of vaporization of water \( h_{\text{fg}} = 2267\,{\text{kJ/kg}} \)

Temperature of saturated water \( t_{\text{sat}} = 100\;^{ \circ } {\text{C}} = 373\,{\text{K}} \)

Temperature of input water \( t_{\text{wi}} = 35\,^{ \circ } {\text{C}} = 308\,{\text{K}} \)

Transmissivity of glass \( \tau = 0.85 \)

Area of the glass \( A_{\text{g}} = 1.138\,{\text{m}}^{2} \)

Area of water stored in still base \( A_{\text{s}} = 1.1\,{\text{m}}^{2} .\)

The solar still efficiencies are calculated for 20 and 30 L of water of operation and are calculated to be 7.41 and 7.95%, respectively. It is found that with increase in water input to the solar still, its efficiency increases marginally because the heat capacity increases with increasing water contents in the solar still basin whereas heat rejected from the basin remains constant.

Figure 3 shows the comparison between tap water and distilled water for pH value, conductivity and TDS value, respectively. From Fig. 3a for sample 1, it can be seen that, the pH value of distilled water was found to be 4.81 whereas it should be in between 6.5 and 7.5. The conductivity and TDS value for sample 1 also varied whereas these should be within 11 µs and less than 1 ppm, respectively. The conductivity was measured using an electronic conductivity meter, which generates a voltage difference between two electrodes submerged in the water. The drop in voltage due to the water resistance is used to calculate the conductivity per centimeter. This resulted due to the exposure of resulted water to the atmosphere (when the distilled water comes in contact with carbon dioxide, CO2, it gets contaminated and turns acidic in nature). The variation was also caused due to the presence of dust particles and chemicals in the paint. The base of the solar still was not washed properly at first testing, and the water kept in the base remained unchanged for 15 days, which also had an effect on the pH, conductivity, TDS and temperature of water.

Therefore, to avoid such variations, the stored water was drained out and the base was cleaned thoroughly and wiped properly to avoid any contamination. Then, fresh water was poured into the base though the inlet channel. Again, the bulbs were illuminated, and the process was repeated. A pipe was connected to the outlet of the base through a connector to collect the distilled water in a bottle and was sealed properly to avoid contamination. The collected distilled water was taken in a beaker, and tap water was taken in another beaker to be tested in the environmental engineering laboratory of Eastern Academy of Science and Technology, Bhubaneswar.

3.2 Measurement Error

The measurement errors allied with the solar still performance have been calculated by using sequential perturbation techniques [20]. As it a function of volume of purified water output, temperature of input water, area of glass cover and heat input to the solar still, it can be represented as

By considering the measurement errors in volume of purified water output (1%), temperature of input water (0.5%), area of the glass cover (0.1%) and heat input to the solar still (0.1%), the solar still efficiency was supposed to be accurate within \( \pm 2\% \).

3.3 Comparison of productivity of different solar still

As in this paper, due to some limitations, in this experiment, we used electrical energy as the input source instead of solar energy. We have calculated the input electrical energy as 800 W and considered to be the equivalent solar intensity and calculated the solar still efficiency. Compared to the result of Sahoo et al. [19], the authors reported the still efficiency was 7.28, 7.78 and 8.1%, respectively, for 10, 15 and 20 L of water, respectively, in mode I. Here in this work, we got 7.41 and 7.95% efficiency for 20 and 30 L of water, respectively. This is mainly because heat input and time duration is less compared to the previous work. In future work, the efficiency of the still can be increased by modifying different parameters which affect the still efficiency and using proper instruments for the measurement purpose.

4 Conclusion

In the present work, an attempt has been made to fabricate a tilted flat plate blackened-type solar still and the same has been used for the purpose of producing purified drinking water for a small community. The observations of the investigation may be summarized as follows.

-

The pH value is found to be 6.2, which shows a good agreement with the previous results.

-

By using the fabricated solar still, TDS value has been reduced around 90% compared to the sample taken from tap water (untreated).

-

With increase in water input to the solar still, its efficiency increases marginally. For the water input of 20 and 30 L, the solar still efficiencies are 7.41 and 7.95%, respectively.

In future, the same setup can be experimented by using solar power as the heat input and compared with the present result.

References

Abdel-Rehim ZS, Lasheen A (2005) Improving the performance of solar desalination systems. Renew Energy 30:1955–1971

Tiwari GN, Kupfemann A, Aggarwal S (1997) A new design for a double-condensing chamber solar still. Desalination 114:153–164

Kudish AJ, Gale J, Zarmi Y (1982) A low cost design solar desalination unit. Energy Convers Manage 22:269–274

Yadav YP, Yadav AK, Anwar N, Eames PC, Norton B (1996) An asymmetric line-axis compound parabolic concentrating single basin solar still. In: Proceedings of world renewable energy congress, Denver, USA, pp. 737–740

Meukam P, Njomo D, Gbane A, Toure S (2004) Experimental optimization of a solar still: application to alcohol distillation. Chem Eng Process 43:1569–1577

Khalifa AJN, Al-Jubouri AS, Abed, MK (1999) An experimental study on modified simple solar stills. Energy Convers Manage 40:1835–1847

Tiwari GN, Thomas JM, Khan E (1994) Optimisation of glass cover inclination for maximum yield in a solar still. Heat Recov Syst CHP 14:447–455

Farid M, Hamad F (1993) Performance of a single-basin solar still. Renew Energy 3:75–83

Panchal HN, Shah PK (2012) Performance Improvement of Solar stills via experimental Investigation. Int J Adv Des Manuf Technol 5(5):19–23

Panchal HN, Shah PK (2012) Investigation on Solar stills having floating plates. Int J Energy Environ Eng 3(3):3–8

Hitesh N, Panchal PK (2014) Shah improvement of solar still productivity by energy absorbing plates. J Renew Energy Environ 1(1):1–7

Sahoo BB, Subudhi C (2019) Performance enhancement of solar still by using reflector-jute cloth-improved glass angle. J Eng Res 16(1):1–10

Dinesh K, Himanshu P, Zameer A (2013) Performance analysis of single slope solar still. Int J Emerg Technol Adv Eng 3(3):66–72

Kaviti AK, Yadav A, Shukla A (2016) Inclined solar still designs: a review. Renew Sustain Energy Rev 54:429–451

Rashidi S, Rahbar N, Valipour MS, Esfahani JA (2018) Enhancement of solar still by reticular porous media: experimental investigation with exergy and economic analysis. Appl Therm Eng 130:1341–1348

Rashidi S, Bovand M, Rahbar N, Esfahani JA (2018) Steps optimization and productivity enhancement in a nanofluid cascade solar still. Renew Energy 118:536–545

Jani HK, Modi KV (2019) Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Solar Energy 179:186–194

Tiwari GN, Dimri V, Singh U, Chel A, Sarkar B (2007) Compressive thermal evaluation of an active solar distillation system. Int J Energy Res 31(15):1465–1482

Sahoo BB, Sahoo N, Mahanta P, Borbora L, Kalita P, Saha UK (2008) Performance assessment of a solar still blackend surface and thermocol insulation. Renew Energy 33:1703–1708

Kline SJ, Mc Slintock FA (1953) Describing uncertainties in single-simple experiments. Mech Eng 3–8

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Biswal, D.K. (2021). Performance Assessment of a Solar Still Using Blackened Surface. In: Ramgopal, M., Rout, S.K., Sarangi, S.K. (eds) Advances in Air Conditioning and Refrigeration. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-6360-7_30

Download citation

DOI: https://doi.org/10.1007/978-981-15-6360-7_30

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6359-1

Online ISBN: 978-981-15-6360-7

eBook Packages: EngineeringEngineering (R0)