Abstract

Herein, we introduce a novel modification process for carbon paste electrode by magnetic core–shell nanocomposite of graphene oxide/Fe3O4@SiO2 and n-hexyl-3-methylimidazolium hexafluoro phosphate as ionic liquid. Electrochemical features of this modified carbon paste electrode and its performance evaluation in simultaneous detection of acetaminophen and tyrosine via voltammetric oxidation was investigated. Moreover, diagnostic techniques including cyclic voltammetry, square wave voltammetry and chronoamperometry were applied in order to study the electrochemical oxidation behavior of this sensor toward acetaminophen. According to square wave voltammetry results, linear dynamic range between 1.0 × 10–6–1.0 × 10–3 M was observed for acetaminophen. The function of modified electrode in real samples containing acetaminophen and tyrosine was satisfactory.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

N-acetyl-p-aminophenol which is known as acetaminophen, is one the most common pain relief drugs which is taken by people in the world [1]. Acetaminophen is typically used as antipyretic and analgesic drug [2]. As analgesic drug it is used for mild to severe pain from treating headache and toothache to cancer pain and postoperative pain. As it is an antipyretic agent, it lessen the fevers with bacterial and viral origin [3, 4].

It has no carcinogenic effect, and is a suitable alternative for aspirin in patients who have allergy to aspirin [5]. The metabolization of acetaminophen mainly occur in liver generating toxic metabolites [6]. It is safe at recommended dosage without hazardous side effect. Although, overdose of acetaminophen had to liver and kidney failure because of accumulation of toxic metabolites [7].

Tyrosine is among the twenty standard amino acids which are considered as the building blocks of protein. It is a non-essential amino acid since it can be made from phenylalanine; another amino acid in the human body [8]. Body uses tyrosine in making chemical messengers such as dopamine, l-dopa, and epinephrine. It is also appeared in thyroid hormones, pigment melanin, and several opiate peptides as side chain (tyrosyl) in amino acid sequences. It is found in high protein foods, however, some pharmaceutical formulations contain tyrosine to make up its deficiency in vegetarian diets. Some psychological diseases such as depression, albinism, and alkaptonuria are related to the lack of tyrosine whilst taking much more tyrosine also leads to mental disorders and Parkinson’s disease [9–13].

The oxidation of acetaminophen and tyrosine at various electrodes, has distinctive electrochemical signals. However, their oxidation is at rather high overpotential at conventional electrodes [14]. Therefore, efforts for decreasing the overpotential and increasing the sensitivity, accuracy and simplicity with cost considerations in the development of sensors are growing up fast.

So far, various analytical techniques have been used for determination of acetaminophen and tyrosine, individually or simultaneously, featuring spectrophotometry [15], chromatography [16], fluorometry [17], and capillary zone electrophoresis [18]. These methods have limitations of prolonged and expensive procedure as well as requiring pretreatment steps.

But as we know, electrochemical-based sensors have attracted more attention in two decades due to quick response, low detection limit, low cost, simple operation and the absence of pretreatment [19].

From 1958, when carbon paste electrode (CPE) has been introduced by Adams, they have attracted much more attention than other carbon electrods and are used widely in electrochemistry and electroanalytical applications. CPEs, present priorities including ease of preparation and regeneration of the surface, economical preparation, low ohmic resistance, stable response, inertness to chemicals, rigidity, operation without internal solution and capability of being modified with various modifiers which makes them efficient sensors for the determination of wide variety of targets. In addition, they are non-toxic and eco-friendly electrodes. CPE is a homogenous graphite paste filled in a tube which has been easily prepared by dispersion of graphite in a hydrophobic binder [20–24].

In order to improve the efficiency of usual electrodes for sensor applications, a conventional modification method is applied. Modified electrodes not only render better electrocatalytic activity, higher sensitivity and selectivity but also lower detection limit than traditional electrodes [25–39].

Application of nanoparticles in the construction of electrochemical sensors has increased recently [40]. Nano materials are recognized as engineered particles with considerable surface to volume ratio and dimensions less than 100 nm.

In the modification of electrodes, Fe3O4 nanoparticles is commonly used since they provide large electrode surface, enhancement in the electrical conductivity, and improvement in the kinetic of electron transfer between the surface of electrode and the variety of electroactive targets [41, 42].

Coating the surface of magnetite nanoparticles with inert silica nanoparticles is a strategy to prevent aggregation of magnetite nanoparticles and improving their chemical stability.

Stabilization of the magnetite nanoparticles through silica coating occurs via two different processes. In fact, silica shell acts as shielding for the magnetic dipole interaction. Moreover, being negatively charged on the surface, nano silica is able to enhance the coulomb repulsion of the magnetic nanoparticles [43].

Graphene, is a single carbon layer of the graphite structure with two dimensional sp2-bonded carbon network. Graphene oxide (GO) structure as an important derivative of graphene has terminal COOH groups, C–OH and C–O–C bonds in its structure. GO demonstrate special properties including large surface area, high conductivity, and excellent mechanical strength [44].

Magnetic iron oxide nanoparticles such as maghemite (γ-Fe2O3) or magnetite (Fe3O4), are used in decoration of GO to obtain improved magnetic, optical, and electrochemical properties of GO. This combination which leads to improvement of the properties of GO, makes it a great option for the modification of electrodes [45].

Ionic liquids (ILs) have demonstrated promising and efficient electrochemical features such as good conductivity and wide electrochemical windows which make them an attractive candidate for application in electrochemical sensors. Therefore, nanostructure base electrodes modified with ILs operate very well in sensing biological and pharmaceutical species [46–49].

In this paper, we introduce a modification of carbon paste electrode by using an ionic liquid and magnetic core–shell nanocomposite of graphene oxide/Fe3O4@SiO2 (ILGFSCPE). The operation of this modified electrode was investigated in concurrent measurement of acetaminophen and tyrosine in aqueous solutions and in real samples.

EXPERIMENTAL

Apparatus and Chemicals

The electrochemical measurements were carried out by an Autolab potentiostat/galvanostat (PGSTAT 302N, Eco Chemie, the Netherlands). General Purpose Electrochemical System (GPES) software was applied to control the experimental conditions. A typical three electrode cell comprising of reference (Ag/AgCl/KCl (3.0 M), auxiliary (a platinum wire) and working (ILGFSCPE) electrodes were used at 25 ± 1°C. pH measurements were done by a Metrohm 710 pH meter.

Acetaminophen, tyrosine and all of the other analytical grade reagents were purchased from Merck (Darmstadt, Germany). Orthophosphoric acid and its salts were used to prepare a buffer solution in the pH range of 2.0–9.0.

Ionic liquid (n-hexyl-3-methylimidazolium hexafluoro phosphate) was purchased from Sigma Aldrich Co.

Synthesis of GO/Fe3O4@SiO2 Nanocomposite

The conversion of the –OH groups of GO to ‒COOH, was carried out in a typical procedure as follow:

An aqueous suspension of 50 mL GO (2 mg mL–1), was bath sonicated to obtain a clear solution, for 1 h. Then, to this suspension, 12 g NaOH and 10 g chloroacetic acid were added and bath sonicated for 2 h. Finally, neutralization and purification of resulting G–COOH was done [50].

A homogenous suspension of GO–COOH, was prepared by dissolving 0.06 g carboxylated GO in 42 mL water by ultrasonic irradiation within 20 min. Further vigorous stirring continued at 60°C for 30 min. Then, 106.2 mg FeCl3 · 6H2O was added and stirred vigorously under N2 atmosphere, for 30 min. To this solution, 57 mg of FeSO4 · 7H2O was added and stirred for 30 min. Droplets of 18 mL of NH4OH (6%), were added during 1 h, at 60°C. The reaction completed after 2 h. All the stages were performed under nitrogen atmosphere to prevent critical oxidation. The final, ready to use product is black precipitate of GO/Fe3O4 nanoparticles which attain after centrifuge, washing with double distilled water and drying.

Preparation of core–shell nanocomposites of GO/Fe3O4@SiO2 was done by the growth of silica layers on the surface of the GO/Fe3O4, according the procedure described by Lu et al as follow:

In a 250 mL three neck flask, 90 μL of TEOS, 15 mL ethanol, 0.6 mL give concentration ammonium hydroxide, and 0.6 mL water were added in a 40°C water bath. Afterward, to this solution GO/Fe3O4 was added while stirred mechanically. After 12 h, the prepared nanocomposite was separated by centrifugation, then washed and dried under vacuum at 60°C overnight [51].

Preparation of the Electrode

For the preparation of ILGFSCPE, 0.04 g of magnetic core–shell nanocomposites of GO/Fe3O4@SiO2, 0.96 g graphite powder, and about 0.8 mL of ionic liquid were mixed in a mortar. The resulting paste, was packed into the bottom of glass tube with 15 cm long and 3.4 mm diameters. The insertion of a copper wire into the carbon paste established the electrical contact.

For making an analogy, ionic liquid/carbon paste electrode (ILCPE), GFSCPE constituted of core–shell GO/Fe3O4@SiO2 nanocomposites powder plus paraffin oil, and bare CPE making by graphite powder and paraffin oil, were also prepared using the same procedure.

RESULTS AND DISCUSSION

FT-IR and SEM Characterization

Figure 1 shows the FT-IR spectra of (a) GOs–COOH, (b) GO/Fe3O4 and (c) GO/Fe3O4@SiO2. In Fig. 1a the peaks at 1629.92 and 1455.80 cm–1 correspond to C=O and C–O stretching, respectively. The observed peaks at 2923.25 and 3423.85 cm–1 correspond to the –CH stretching mode and COOH groups of GO surface, respectively. In addition, in Fig. 1b the peak at 565.50 cm–1 is the stretching vibration related to interactions of Fe–O–Fe in Fe3O4. Comparing between two spectra (b and c), the characteristic Si–O–Si peak at 1077.29 cm−1 (Fig. 1c) proves the formation of the silica shell.

Figure 2 depicts the SEM images of (a) GO–COOH, (b) GO/Fe3O4 and (c) GO/Fe3O4@SiO2 which demonstrate their surface morphologies.

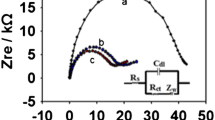

Electrochemical Behavior of Acetaminophen at the Surface of Various Electrodes

The electrochemical behavior of acetaminophen was studied on the surfaces of ILGFSCPE (curve d), ILCPE (curve c), GFSCPE (curve b) and bare CPE (curve a). The cyclic voltammograms (Fig. 3) show the electrochemical oxidation of 400.0 μM acetaminophen. The oxidation of acetaminophen at bare CPE gave very weak peak while with the introduction of IL, an enhancement in peak current and reduction in overpotential was obtained. Oxidation of acetaminophen at ILGFSCPE (curve d) and ILCPE (curve c) showed a considerable increase in current and notable negative shift of the peak potentials.

The observed notable negative shift of the peak potentials of acetaminophen start and considerable increase in current, demonstrate the catalytic ability of ILGFSCPE (curve d) and ILCPE (curve c) toward acetaminophen. However, much higher anodic peak current as the best result in the performance of electrode toward acetaminophen oxidation was achieved when core–shell nanocomposite of graphene oxide/Fe3O4@SiO2 nanocomposite were used. The results of electrochemical responses at various electrode surfaces at pH 7.0 are shown in Table 1.

Effect of Scan Rate

Figure 4 demonstrates how the oxidation current of acetaminophen changes with the potential scan rates in CV. The results revealed that increase in potential scan rate results in peak current amplification. Moreover, the anodic peak current (Ip) has a linear relation with the square root of the potential scan rate (v1/2) implying the control of oxidation by diffusion process.

Chronoamperometric Measurements

Chronoamperometric measurements at ILGFSCPE (Fig. 5), were performed by tuning the working electrode potential at 0.4 V vs. Ag/AgCl/KCl (3.0 M) for different concentrations of acetaminophen. Cottrell equation was used for describing the current of electrochemical reaction of electroactive moiety (acetaminophen) in the condition of limited mass transport as follow [52]:

where D and cb represent the diffusion coefficient (cm2 s–1) and the bulk concentration (mol cm–3) of acetaminophen. Experimental plots were constructed with the best fits by plots of I vs. t–1/2 for various concentrations of acetaminophen. Then, the resulting slopes were plotted versus the concentrations of acetaminophen. The obtained slope and Cottrell equation were used for the determination of mean value of D. Accordingly, the D value was determined to be 1.06 × 10–6 cm2/s for acetaminophen.

Chronoamperograms obtained at ILGFSCPE in 0.1 M PBS (pH 7.0) for different concentrations of acetaminophen. Numbers 1–5 correspond to 0.1, 0.5, 1.0, 1.5, and 2.0 mM of acetaminophen. Insets: (a) plots of I vs. t–1/2 obtained from chronoamperograms 1–5. (b) Plot of the slope of the straight lines against acetaminophen concentration.

Calibration Plot and Limit of Detection

Acetaminophen in solution was determined, at the surface of the modified electrode through the peak currents of acetaminophen oxidation (Fig. 6). Accordingly, square wave voltammetry (SWV) was used in varying concentrations of corresponding target at the surface of a modified electrode. According to SWV results, the oxidation peak currents of acetaminophen were proportional to the concentration of the acetaminophen in the range of 1.0 × 10–6 to 1.0 × 10–3 M with detection limits (3σ) of 4.0 × 10–7 M for acetaminophen.

SWVs of ILGFSCPE in 0.1 M PBS (pH 7.0) containing different concentrations of acetaminophen. Numbers 1–13 correspond to 1.0, 5.0, 10.0, 20.0, 40.0, 60.0, 80.0, 100.0, 200.0, 400.0, 600.0, 800.0, and 1000.0 μM of acetaminophen. Inset shows the plots of the peak current as a function of acetaminophen concentration in the range of 1.0–1000.0 μM.

Simultaneous Determination of Acetaminophen and Tyrosine

The simultaneous determination of acetaminophen and tyrosine using ILGFSCPE has not been reported yet. For this purpose, the concentration of two analyts was changed, simultaneously while recording the SWVs (Fig. 7). According to voltammetric results, two distinctive peaks observed at potentials of 330 and 630 mV related to oxidation of acetaminophen and tyrosine, respectively. This result as shown in Fig. 7, proves the efficiency of ILGFSCPE in the determination of two mentioned targets, simultaneously.

SWVs of ILGFSCPE in 0.1 M PBS (pH 7.0) containing different concentrations of acetaminophen and tyrosine in µM, from inner to outer: 40.0 + 100.0, 80.0 + 200.0, 100.0 + 300.0, 200.0 + 400.0, 300.0 + 500.0, 500.0 + 700.0, and 900.0 + 1000.0 respectively. Insets (a) plots of Ip vs. acetaminophen concentration and (b) plot of Ip vs. tyrosine concentrations.

The Repeatability and Stability of ILGFSCPE

The stability of the ILGFSCPE modified electrode was studied after being stored in atmosphere at ambient temperature for a period of 3-weeks. According to CV results, the peak potential oxidation of acetaminophen unchanged with small decrease of 2.6% in current signals compared to initial response. To study the antifouling properties relative to acetaminophen oxidation and its oxidation product, CVs were recorded before and after use of modified electrode in the presence acetaminophen. The recorded CVs in the presence of acetaminophen have been cycled the potential twenty times at a scan rate of 50 mV s–1. The results revealed no change in peak potentials and reduction in current less than 2.1%. Accordingly, the surface of ILGFSCPE demonstrated an increment in sensitivity and reduction in fouling effect of the target and its oxidation product.

Real Sample Analysis

The analytical applicability of the modified sensor was evaluated through the sensing of acetaminophen and tyrosine in acetaminophen tablet, acetaminophen syrup, and urine samples (Table 2). The experimental results were satisfactory for acetaminophen and tyrosine. The reproducibility of the analysis was tested by the mean relative standard deviation (RSD).

CONCLUSIONS

In this study, a modified carbon paste electrode by using an IL and magnetic core–shell nanocomposite of graphene oxide/Fe3O4@SiO2 (ILGFSCPE) was constructed. This modified electrode exhibited excellent properties including low detection limit, wide linear range, long-term stability, high reproducibility and repeatability. The performance of this electrochemical sensor in the simultaneous determination of acetaminophen and tyrosine was successfully varified.

REFERENCES

Moghadam, Z., Ghoreishi, S.M., Behpour, M., and Motaghedifard, M., A highly sensitive nanostructure-based surface covalently modification of gold for electrochemical sensing of epinephrine in presence of uric acid and acetaminophen, J. Electrochem. Soc., 2013, vol. 160, p. H126.

Cernat, A., Tertis, M., Sandulescu, R., Bedioui, F., Cristea, A., and Cristea, C., Electrochemical sensors based on carbon nanomaterials for acetaminophen detection: a review, Anal. Chim. Acta, 2015, vol. 886, p. 16.

Sharifian, S. and Nezamzadeh-Ejhieh, A., Modification of carbon paste electrode with Fe(III)-clinoptilolite nano-particles for simultaneous voltammetric determination of acetaminophen and ascorbic acid, Mater. Sci. Eng. C, 2016, vol. 58, p. 510.

Karimi-Maleh, H., Moazampour, M., Ahmar, H., Beitollahi, H., and Ensafi, A.A., A sensitive nanocomposite-based electrochemical sensor for voltammetric simultaneous determination of isoproterenol, acetaminophen and tryptophan, Measurement, 2014, vol. 51, p. 91.

Shahrokhian, S. and Asadian, E., Simultaneous voltammetric determination of ascorbic acid, acetaminophen and isoniazid using thionine immobilized multi-walled carbon nanotube modified carbon paste electrode, Electrochim. Acta, 2010, vol. 55, p. 666.

Chiavazza, E., Berto, S., Giacomino, A., Malandrino, M., Barolo, C., Prenesti, E., Vione, D., and Abollino, O., Electrocatalysis in the oxidation of acetaminophen with an electrochemically activated glassy carbon electrode, Electrochim. Acta, 2016, vol. 192, p. 139.

Beitollahi, H. and Nekooei, S., Application of a modified CuO nanoparticles carbon paste electrode for simultaneous determination of isoperenaline, acetaminophen and N-acetyl-L-cysteine, Electroanalysis, 2016, vol. 28, p. 645.

Bhakta, A.K., Mascarenhas, R.J., D’Souza, O.J., Satpati, A.K., Detriche, S., Mekhalif, Z., and Dalhalle, J., Iron nanoparticles decorated multi-wall carbon nanotubes modified carbon paste electrode as an electrochemical sensor for the simultaneous determination of uric acid in the presence of ascorbic acid, dopamine and L-tyrosine, Mater. Sci. Eng. C, 2015, vol. 57, p. 328.

Brillians-Revin, S. and Abraham-John, S., Selective determination of L-tyrosine in the presence of ascorbic and uric acids at physiological pH using the electropolymerized film of 3-amino-5-mercapto-1,2,4-triazole, Sens. Actuat. B-Chem., 2012, vol. 161, p. 1059.

Mahbubur-Rahman, M., Siraj-Lopa, N., Kim, K., and Lee, J., Selective detection of L-tyrosine in the presence of ascorbic acid, dopamine, and uric acid at poly(thionine)-modified glassy carbon electrode, J. Electroanal. Chem., 2015, vol. 754, p. 87.

Taei, M. and Ramazani, G., Simultaneous determination of norepinephrine, acetaminophen and tyrosine by differential pulse voltammetry using Au-nanoparticles/poly(2-amino-2-hydroxymethyl-propane-1,3-diol) film modified glassy carbon electrode, Colloids Surf. B, 2014, vol. 123, p. 23.

Tahernejad-Javazmi, F., Shabani-Nooshabadi, M., and Karimi-Maleh, H., Analysis of glutathione in the presence of acetaminophen and tyrosine via an amplified electrode with MgO/SWCNTs as a sensor in the hemolyzed erythrocyte, Talanta, 2018, vol. 176, p. 208.

Meyer, J.S., Welch, K.M.A., and Deshmuckh, V.D., Neurotransmitter precursor amino acids in the treatment of multi-infarct dementia and Alzheimer’s disease, J. Am. Geriatr. Soc., 1977, vol. 25, p. 289.

Kemmegne-Mbouguen, J.C., Toma, H.E., Araki, K., Constantino, V.R., Ngameni, E., and Angnes, L., Simultaneous determination of acetaminophen and tyrosine using a glassy carbon electrode modified with a tetraruthenated cobalt(II) porphyrin intercalated into a smectite clay, Microchim. Acta, 2016, vol. 183, p. 3243.

Sirajuddin, A.R., Khaskheli, A., Shah, M.I., Bhanger, A., and Mahesar, S.N., Simpler spectrophotometric assay of paracetamol in tablets and urine samples, Spectrochem. Acta A, 2007, vol. 68, p. 747.

Gioia, M.G., Andreatta, P., Boschetti, S., and Gatti, R., Development and validation of a liquid chromatographic method for the determination of ascorbic acid, dehydroascorbic acid and acetaminophen in pharmaceuticals, J. Pharm. Biomed. Anal., 2008, vol. 48, p. 331.

Wang, F., Wu, K.Z., Qing, Y., and Ci, Y.X., Spectrofluorimetric determination of the substrates based on the fluorescence formation with the peroxidase-like conjugates of hemie with proteins, Anal. Lett., 1992, vol. 25, p. 1469.

Huang, Y., Jiang, X., Wang, W., Duan, J., and Chen, G., Separation and determination of L-tyrosine and its metabolites by capillary zone electrophoresis with a wall-jet amperometric detection, Talanta, 2006, vol. 70, p. 1157.

Li, X. and Xu, G., Simultaneous determination of ranitidine and metronidazole in pharmaceutical formulations at poly(chromotrope 2B) modified activated glassy carbon electrodes, J. Food. Drug Anal., 2014, vol. 22, p. 345.

Beitollahi, H., Ghofrani Ivari, S., and Torkzadeh-Mahani, M., Application of antibody nanogold-ionic liquid-carbon paste electrode for sensitive electrochemical immunoassay of thyroid-stimulating hormone, Biosens. Bioelectron., 2018, vol. 110, p. 97.

Fouladgar, M., Application of ZnO nanoparticle/ion liquid modified carbon paste electrode for determination of isoproterenol in pharmaceutical and biological samples, J. Electrochem. Soc., 2016, vol. 163, p. B38.

Beitollahi, H. and Sheikhshoaie, I., Electrochemical behavior of carbon nanotube/Mn(III) salen doped carbon paste electrode and its application for sensitive determination of N-acetylcysteine in the presence of folic acid, Int. J. Electrochem. Sci., 2012, vol. 7, p. 7684.

Ganjali, M.R., Khoshsafar, H., Shirzadmehi, A., Javanbakht, M., and Faridbod, F., Improvement of carbon paste ion selective electrode response by using room temperature ionic liquids (RTILs) and multi-walled carbon nanotubes (MWCNTs), Int. J. Electrochem. Sci., 2009, vol. 4, p. 435.

Beitollahi, H., Nekooei, S., and Torkzadeh-Mahani, M., Amperometric immunosensor for prolactin hormone measurement using antibodies loaded on a nano-Au monolayer modified ionic liquid carbon paste electrode, Talanta, 2018, vol. 188, p. 701.

Beitollahi, H., Karimi-Maleh, H., and Khabazzadeh, H., Nanomolar and selective determination of epinephrine in the presence of norepinephrine using carbon paste electrode modified with carbon nanotubes and novel 2-(4-oxo-3-phenyl-3, 4-dihydro-quinazolinyl)-N′-phenyl-hydrazinecarbothioamide, Anal. Chem., 2008, vol. 80, p. 9848.

Lu, X.C., Song, L., Ding, T.T., Lin, Y.L., and Xu, C.X., CuS–MWCNT based electrochemical sensor for sensitive detection of bisphenol A, Russ. J. Electrochem., 2017, vol. 53, p. 366.

Mazloum-Ardakani, M., Beitollahi, H., Taleat, Z., Naeimi, H., and Taghavinia, N., Selective voltammetric determination of D-penicillamine in the presence of tryptophan at a modified carbon paste electrode incorporating TiO2 nanoparticles and quinizarine, J. Electroanal. Chem., 2010, vol. 644. p. 1.

Hu, Y., Huang, Y., Tan, C., Zhang, X., Lu, Q., Sindoro, M., Huang, X., Huang, W., Wang, L., and Zhang, H., Two-dimensional transition metal dichalcogenide nanomaterials for biosensing applications, Mater. Chem. Front., 2017, vol. 1, p. 24.

Tajik, S., Taher, M.A., and Beitollahi, H., First report for electrochemical determination of levodopa and cabergoline: application for determination of levodopa and cabergoline in human serum, urine and pharmaceutical formulations, Electroanalysis, 2014, vol. 26, p. 796.

Idris, A.O., Mafa, J.P., Mabuba, N., and Arotiba, O.A., Nanogold modified glassy carbon electrode for the electrochemical detection of arsenic in water, Russ. J. Electrochem., 2017, vol. 53, p. 170.

Azadbakht, A. and Abbasi, A.R., Fabrication of a highly sensitive hydrazine electro- chemical sensor based on bimetallic Au-Pt hybrid nanocomposite onto modified electrode, Nano-Micro Lett., 2010, vol. 2, p. 296.

Ganesh, P.S. and Kumara-Swamy, B.E., Voltammetric resolution of catechol and hydroquinone at eosin Y film modified carbon paste electrode, J. Mol. Liq., 2016, vol. 220, p. 208.

Karimi-Maleh, H., Keyvanfard, M., Alizad, K., Fouladgar, M., Beitollahi, H., Mokhtari, A., and Gholami-Orimi, F., Voltammetric determination of N-actylcysteine using modified multiwall carbon nanotubes paste electrode, Int. J. Electrochem. Sci., 2011, vol. 6, p. 6141.

Wang, P., Xiao, J., Guo, M., Xia, Y., Li, Z., Jiang, X., and Huang, W., Voltammetric determination of 4-nitrophenol at graphite nanoflakes modified glassy carbon electrode, J. Electrochem. Soc., 2015, vol. 162, p. H72.

Han, L., Tao, H., Huang, M., Zhang, Y., Qiao, S., and Shi, R., A hydrogen peroxide biosensor based on multiwalled carbon nanotubes-polyvinyl butyral film modified electrode, Russ. J. Electrochem., 2016, vol. 52, p. 115.

Beitollahi, H., Movahedifar, F., Tajik, S., and Jahani, S., A review on the effects of introducing CNTs in the modification process of electrochemical sensors, Electroanalysis, 2018, vol. 31, no. 7, pp. 1195–1203. https://doi.org/10.1002/elan.201800370

Yalcmer, F., Cevik, E., Senel, M., and Baykal, A., Development of an amperometric hydrogen peroxide biosensor based on the immobilization of horseradish peroxidase onto nickel ferrite nanoparticle-chitosan composite, Nano-Micro Lett., 2011, vol. 3, p. 91.

Yukird, J., Kongsittikul, P., Qin, J., Chailapakul, O., and Rodthongkum, N., ZnO graphene nanocomposite modified electrode for sensitive and simultaneous detection of Cd(II) and Pb(II), Synth. Met., 2018, vol. 245, p. 251.

Kalate-Bojdi, M., Mashhadizadeh, M.H., Behbahani, M., Farahani, A., Hossein-Davarani, S.S., and Bagheri, A., Synthesis, characterization and application of novel lead imprinted polymer nanoparticles as a high selective electrochemical sensor for ultra-trace determination of lead ions in complex matrixes, Electrochim. Acta, 2014, vol. 136, p. 59.

Beitollahi, H., Ghofrani-Ivari, S., and Torkzadeh-Mahani, M., Voltammetric determination of 6-thioguanine and folic acid using a carbon paste electrode modified with ZnO-CuO nanoplates and modifier, Mater. Sci. Eng. C, 2016, vol. 69, p. 128.

Kumar, N. and Goyal, R.N., Melamine/Fe3O4 nanoparticles based molecular imprinted highly sensitive sensor for determination of hydrochlorothiazide: an antihypertensive drug, J. Electrochem. Soc., 2017, vol. 164, p. B240.

Yu, L., Wu, H., Wu, B., Wang, Z., Cao, H., Fu, C., and Jia, N., Magnetic Fe3O4 reduced graphene oxide nanocomposites-based electrochemical biosensing, Nano-Micro Lett., 2014, vol. 6, p. 258.

Sun, Y., Duan, L., Guo, Z., Duan-Mu, Y., Ma, M., Xu, L., Zhang, Y., and Gu, N., An improved way to prepare superparamagnetic magnetite-silica core–shell nanoparticles for possible biological application, J. Magn. Magn. Mater., 2005, vol. 285, p. 65.

Beitollahi, H. and Garkani-Nejad, F., Graphene oxide/ZnO nano composite for sensitive and selective electrochemical sensing of levodopa and tyrosine using modified graphite screen printed electrode, Electroanalysis, 2016, vol. 28, p. 2237.

Huang, W., Xiao, X., Engelbrekt, C., Zhang, M., Li, S., Ulstrup, Je., Ci, L., Feng, J., Si, P., and Chi, Q., Graphene encapsulated Fe3O4 nanorods assembled into a mesoporous hybrid composite used as a high-performance lithium-ion battery anode material, Mater. Chem. Front., 2017, vol. 1, p. 1185.

Bagheri, H., Shirzadmehr, A., Rezaei, M., and Khoshsafar, H., Determination of tramadol in pharmaceutical products and biological samples using a new nanocomposite carbon paste sensor based on decorated nanographene/tramadol-imprinted polymer nanoparticles/ionic liquid, Ionics, 2018, vol. 24, p. 833.

Gasbarri, C. and Angelini, G., Polarizability over dipolarity for the spectroscopic behavior of azobenzenes in room-temperature ionic liquids and organic solvents, J. Mol. Liq., 2017, vol. 229, p. 185.

Zhang, J., Wang, X., Zhang, S., Wang, W., Hojo, M., and Chen, Z., An electrochemical sensor for simultaneous determination of ponceau 4R and tartrazine based on an ionic liquid modified expanded graphite paste electrode, J. Electrochem. Soc., 2014, vol. 161, p. H453.

Fernández, E., Vidal, L., Iniesta, J., Metters, J.P., and Banks, C.E., Screen-printed electrode-based electrochemical detector coupled with in-situ ionic-liquid-assisted dispersive liquid-liquid microextraction for determination of 2,4,6-trinitrotoluene, Anal. Bioanal. Chem., 2014, vol. 406, p. 2197.

Park, K.W. and Hwa-Jung, J., Spectroscopic and electrochemical characteristics of a carboxylated graphene-ZnO composites, J. Power Sources, 2012, vol. 199, p. 379.

Arvand, M. and Hassannezhad, M., Magnetic core-shell Fe3O4@SiO2/MWCNT nanocomposite modified carbon paste electrode for amplified electrochemical sensing of uric acid, Mater. Sci. Eng. C, 2014, vol. 36, p. 160.

Bard, A.J. and Faulkner, L.R., Electrochemical Methods: Fundamentals and Applications, 2nd ed., New York: Wiley, 2001.

Funding

The authors wish to thank Graduate University of Advanced Technology, Kerman, Iran for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors confirm that this article content has no conflict of interest.

Rights and permissions

About this article

Cite this article

Hadi Beitollahi, Fariba Garkani Nejad A Carbon Paste Electrode Modified by Graphene Oxide/Fe3O4@SiO2/Ionic Liquid Nanocomposite for Voltammetric Determination of Acetaminophen in the Presence of Tyrosine. Russ J Electrochem 55, 1162–1170 (2019). https://doi.org/10.1134/S1023193519120024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193519120024