Abstract

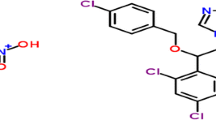

A novel method is reported, whereby screen-printed electrodes (SPELs) are combined with dispersive liquid–liquid microextraction. In-situ ionic liquid (IL) formation was used as an extractant phase in the microextraction technique and proved to be a simple, fast and inexpensive analytical method. This approach uses miniaturized systems both in sample preparation and in the detection stage, helping to develop environmentally friendly analytical methods and portable devices to enable rapid and onsite measurement. The microextraction method is based on a simple metathesis reaction, in which a water-immiscible IL (1-hexyl-3-methylimidazolium bis[(trifluoromethyl)sulfonyl]imide, [Hmim][NTf2]) is formed from a water-miscible IL (1-hexyl-3-methylimidazolium chloride, [Hmim][Cl]) and an ion-exchange reagent (lithium bis[(trifluoromethyl)sulfonyl]imide, LiNTf2) in sample solutions. The explosive 2,4,6-trinitrotoluene (TNT) was used as a model analyte to develop the method. The electrochemical behavior of TNT in [Hmim][NTf2] has been studied in SPELs. The extraction method was first optimized by use of a two-step multivariate optimization strategy, using Plackett–Burman and central composite designs. The method was then evaluated under optimum conditions and a good level of linearity was obtained, with a correlation coefficient of 0.9990. Limits of detection and quantification were 7 μg L−1 and 9 μg L−1, respectively. The repeatability of the proposed method was evaluated at two different spiking levels (20 and 50 μg L−1), and coefficients of variation of 7 % and 5 % (n = 5) were obtained. Tap water and industrial wastewater were selected as real-world water samples to assess the applicability of the method.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Miniaturization of both analytical methods and instrumentation has become very popular in recent years, and many efforts have focused on performing chemical analysis at a reduced scale. Miniaturization of sample preparation methods has substantially increased, with the development of many solid-phase and liquid-phase microextraction techniques [1, 2]. Compared with traditional liquid–liquid extraction techniques, liquid-phase microextraction (LPME) offers simplicity, ease of handling, minimal sample and solvent consumption, and an important reduction in residues generated. Since its appearance in the nineties, several LPME techniques have been developed, with single drop microextraction, hollow-fiber liquid-phase microextraction and dispersive liquid–liquid microextraction [3] (DLLME) the most commonly used. Organic solvents have traditionally been used as extractants in LPME techniques, but use of ionic liquids (ILs) has recently attracted interest as a promising alternative [4]. ILs are melted salts at room temperature and have unique properties; in particular, they are highly thermally and chemically stable, with negligible vapor pressure, tunable viscosity, electrolytic conductivity, a wide electrochemical window, and good extractability for organic compounds and metal ions [5]. Use of ILs has helped to overcome problems associated with LPME techniques using organic solvents [4] and has enabled the development of new methods, including temperature-controlled IL dispersive liquid-liquid microextraction [6], and in-situ IL formation dispersive liquid–liquid microextraction (in-situ IL-DLLME) [7, 8]. During in-situ IL-DLLME the extractant phase is formed into the sample solution via a metathesis reaction between a water-miscible IL and an ion exchange reagent, forming a water-immiscible IL. Homogeneously dispersed fine drops of the extractant phase are generated, and high enrichment factors are obtained with low extraction times because of the high contact surface between phases. Dispersion of the IL takes place via metathesis reaction, and a disperser agent is not needed; this avoids competition with the IL, which would reduce extraction efficiency. Moreover, this process does not need the additional devices, for example vortex or ultrasound bath, which have been used to assist IL-DLLME [9, 10].

Most LPME procedures are followed by chromatographic separation, in either liquid or gas modalities, coupled with different detection systems (UV–visible, inductively coupled plasma optical emission spectrometry, or mass spectrometry, among others). Most of these detection systems are slow, expensive and bulky, so analytical instrumentation used for detection has not achieved miniaturization to the same extent as sample preparation methods, miniaturized forms of which are more widely used. Furthermore, ILs have some disadvantages when chromatographic techniques are used. For example, special devices are needed when ILs are injected in gas chromatography, because of their high boiling points [11, 12], and shorter column life and resolution problems are challenges for liquid chromatography with ILs. Accordingly, electrochemical sensors are regarded as an attractive option for use in detection methods. Recent advances in microfabrication and screen-printing technology have enabled the development of miniaturized and easy-to-use electrochemical systems for rapid and decentralized onsite measurements. Screen-printed electrodes [13] (SPELs) are inexpensive, mass-produced, disposable devices, which are ideal for low volume sample analysis. The versatility and ease of modification of these electrodes are advantageous for improving their performance and adapting them to specific analytes.

As far as we are aware, this is the first report of an analytical method in which SPELs are used as electrochemical detectors for LPME. ILs have intrinsic conductivity, a wide electrochemical window, and thermal stability, and have therefore been recognized as ideal alternative electrolytes in electrochemical devices [14]. Taking into account the electrochemical properties of ILs and the low volume of IL-phase formed during in-situ IL–DLLME (10–20 μL), SPELs seem to be ideal and perfectly compatible candidates for analyzing IL drop after microextraction without any further modification. The explosive 2,4,6-trinitrotoluene (TNT) was used as a model analyte to develop the proposed method, because its electrochemical behavior has been widely characterized. Additionally, nitroaromatic explosives, including TNT, have been the subject of increasing interest in recent years. Concerns about terrorist activity have led to intensification of security measures in airports and public buildings, creating a demand for highly sensitive analytical methods to detect these compounds at trace levels. Furthermore, their presence in surrounding soils, waterways and reservoirs must be monitored in areas where they are produced, stored or detonated. The mutagenic and toxic properties of nitroaromatic explosives make their presence in the environment dangerous [15]. Many analytical methods using gas [16], liquid [17] and micellar electrokinetic [18] chromatography and immunoassay techniques [19] have been developed to determine TNT and other related explosives in environmental samples. However, the inherent redox activity of TNT makes electrochemical sensors a very suitable alternative. Electrochemistry offers simplicity, rapid response, and low-cost instrumentation with portable options, and meets the analytical requirements of sensitivity and reproducibility.

Screen-printed electrodes have previously been used in electrochemical devices for TNT analysis. Hydrogel-coated SPELs have been used to detect thermally-desorbed TNT from an integrated preconcentration system for both solid and liquid samples [20]. An electrochemically pre-anodized Nafion-coated screen-printed carbon electrode (SPCE) has been used in a disposable sensor developed to determine different nitroaromatic compounds [21]. With this system, TNT can be detected in spiked lake water at a concentration of 30 μmol L−1 (6.8 μg mL−1). A wearable textile-based screen-printed electrochemical sensor, which is highly suitable for monitoring the surroundings of the wearer, has been tested for detection of nitroaromatic explosives both in gas and liquid phase, obtaining a limit of detection (LOD) of approximately 1 μg mL−1 for TNT in water [22]. Recently, a very simple and low-cost sensor based on unmodified SPCEs has been described to determine TNT and 2,4-dinitrotoluene in aqueous solutions, obtaining LODs as low as 0.4 μmol L−1 (90 μg L−1) and 0.7 μmol L−1 (73 μg L−1), respectively [23].

The research presented here combines the advantages of LPME techniques with the benefits that SPELs offer as electrochemical sensors. The resulting novel method uses miniaturized systems in both sample preparation and detection. In addition, the use of an IL as the extractant phase not only provides the advantage of good extractability of organic compounds, but also provides the electrolyte behavior needed for detection. The proposed method has been optimized by use of a multivariate optimization strategy, and its ability to determine TNT in real-world water samples has been established.

Experimental

Reagents and real-world water samples

A TNT standard of 1,000 mg L−1 in acetonitrile was obtained from LGC Standards (Warsaw, Poland). Stock solution of TNT (10 mg L−1) in HPLC grade acetonitrile from Sigma-Aldrich (Seelze, Germany) was prepared and stored in the dark at 4 °C. Working solutions were prepared daily by appropriate dilution of this stock solution in ultrapure water from a water purification system (Milli-Q Biocel A10) supplied by Millipore (Bilerica, MA, USA). ILs 1-hexyl-3-methylimidazolium bis[(trifluoromethyl)sulfonyl]imide ([Hmim][NTf2]) (98 %) and 1-hexyl-3-methylimidazolium chloride ([Hmim][Cl]) (98 %) were purchased from Iolitec (Heilbronn, Germany). Lithium bis[(trifluoromethyl)sulfonyl]imide (LiNTf2) salt was supplied by Sigma-Aldrich (St. Louis, MO, USA), and reactive grade NaCl by ACS Scharlau (Barcelona, Spain).

Tap water from a drinking water treatment plant in Seville (Spain) and industrial wastewater from Ourense (Spain) were used as real-world water samples. The industrial wastewater contained a chemical oxygen demand of 1,004 mg O2 L−1, a biochemical oxygen demand of 278 mg O2 L−1, and 429 mg L−1 suspended solids. Samples were collected in amber glass containers and stored in the dark at 4 °C. Tap water was used without any further pretreatment. The wastewater was filtered with a 0.22 μm pore-size nylon filter before use. The real-world water samples were previously analyzed, and the target analyte was not detected.

In-situ IL-DLLME procedure

Under optimum conditions, 32 mg [Hmim][Cl] was placed in a conical-bottom glass tube and dissolved in 11 mL aqueous standard or 11 mL sample solution. An equimolar quantity of LiNTf2 (45.3 mg) relative to [Hmim][Cl] was added, and a cloudy solution immediately formed. The mixture was manually shaken for 0.5 min. To accelerate phase separation, the tube was then placed in an ice bath for 3 min. Next, the phases were separated by centrifugation for 5 min at 4,000 rpm. The aqueous phase was removed with a glass pipette, and 15 μL of the formed IL phase (i.e. [Hmim][NTf2]) was withdrawn with a syringe. Finally, this 15 μL IL phase was deposited on the screen-printed graphite electrode (SPGE) surface for electrochemical detection. The procedure is described in Fig. 1.

Electrochemical analysis

A μ-Autolab III potentiostat/galvanostat from Eco Chemie (Utrecht, The Netherlands) controlled by Autolab GPEs software version 4.9 for Windows XP was used for electrochemical experiments. All measurements were performed by use of three-electrode configuration SPGEs from Kanichi Research Services (Manchester, UK). SPGEs were manufactured as described elsewhere [24]. The working electrode, of 3.1 mm diameter, and the counter electrode were made from a graphite ink. A pseudo Ag/AgCl was the reference electrode. Connectors for the electrochemical connection of the SPGEs were also obtained from Kanichi Research Services Ltd. SPGEs were used without any pretreatment or modification of the working electrode surface, and a new SPGE was used for each experiment.

Differential pulse voltammetry (DPV) was selected as the electroanalytical technique. A variety of DPV variables were optimized by use of a one-at-a-time strategy, establishing the following optimum conditions: 100 mV modulation amplitude; 10 mV step potential; 0.05 s modulation time; and 0.5 s interval time. Pure N2 from Air Liquide (Madrid, Spain) flowed for 20 minutes before DPV experiments and was maintained during measurements. The signal corresponding to oxygen embedded in the IL [25] appears at the same reduction potential as the analyte, meaning purging with N2 was necessary to ensure a deoxygenated atmosphere in which the analyte could be detected at low concentrations. All electrochemical measurements were performed at room temperature.

Data processing

The current peak of the first cathodic wave of TNT at −0.80 V vs. pseudo Ag/AgCl was used to identify and quantify the analyte in order to evaluate the developed method. A multivariate optimization strategy was performed to determine the optimum conditions for the microextraction method. Statgraphics statistical computer package “Statgraphics Plus 5.1.” (Warrenton, VA, USA) was used to construct the experimental design matrices and evaluate the results.

Results and discussion

Multivariate optimization

Screening step

Plackett–Burman design is a two-level fractional factorial design for studying k = N − 1 variables in N runs, where N is a multiple of four [26]. Fractional factorial designs are very useful in the first steps of a project, when many variables are initially investigated but only a few have important effects. The Plackett–Burman design ignores interaction between variables so the main effects can be calculated by means of a reduced number of experiments, enabling more economical experimentation. A saturated Plackett–Burman design was used to construct the matrix of experiments, including 11 variables: eight real variables and three dummy variables. The effects of the dummy variables were used to evaluate experimental error [27, 28].

On the basis of the literature [7] and of the previous experience of the research group [29], the eight real experimental variables selected at two levels were: amount of [Hmim][Cl], sample volume, molar ratio between [Hmim][Cl] and the salt LiNTf2, ionic strength, extraction time, centrifugation speed, centrifugation time, and purge time with N2 before electrochemical measurements. Table 1 shows the experimental variables and levels considered in the Plackett–Burman design. A total of twelve experiments were performed, using aqueous standards of 100 μg L−1.

The data obtained were evaluated by use of an ANOVA test, and the results were displayed in the Pareto chart shown in Fig. S1(a) (see Electronic Supplementary Material). The length of each bar is proportional to the effect of the corresponding variable, and the effects that exceed the reference vertical line can be regarded as significant with a 95 % probability.

According to Fig. S1(a) (Electronic Supplementary Material), only the amount of [Hmim][Cl] was a statistically significant variable with 95 % probability, having a negative effect. This negative effect is in agreement with the fact that if a smaller amount of [Hmim][Cl] is used, a smaller volume of IL-phase is formed in the microextraction procedure, and a higher concentration of analyte is therefore obtained in the extraction phase.

Sample volume is the second most important variable; its positive effect is non-significant, but is much larger than the effect of purge time. Our previous experience indicated that sample volume is an important variable in microextraction techniques. In general, greater sample volume involves a greater amount of analyte and therefore increases the response. For this reason, the amount of [Hmim][Cl] and the sample volume were selected as the main variables affecting the response of the system, and were investigated during the optimization of significant variables. The other six real variables with non-significant effects were fixed at the most experimentally convenient level, specifically: stoichiometric molar ratio between [Hmim][Cl] and LiNTf2; ionic strength: 0 % NaCl; extraction time: 0.5 min; centrifugation speed: 4,000 rpm; centrifugation time: 5 min; and purge time: 20 min.

Optimization of significant variables

Central composite design (CCD) was used in this optimization step. CCD combines a two-level full factorial design (2k) with 2 k star points, where k is the number of variables being optimized, and one point at the center of the experimental region, that can be run n times. To ensure the rotatability of the model, star points were set at α = √k = 1.41, and the central point was repeated five times to provide an orthogonal design [26]. CCD was used to evaluate and optimize main effects, interaction effects and quadratic effects of the two significant variables. Table 2 shows the low and high levels, and the central and star points of the two variables in the optimization step. Thirteen experiments were performed, using aqueous standards of 100 μg L−1.

The data obtained were also evaluated by use of an ANOVA test and the results were displayed in the Pareto chart shown in Fig. S1(b) (Electronic Supplementary Material). As can be seen, both the amount of [Hmim][Cl] and the sample volume were significant variables, with a 95 % probability, confirming the predicted importance of sample volume effect. One of the quadratic effects was also significant, assuming the curvature of the system and fitting the second-grade polynomial model proposed. The response surface obtained by use of the CCD is shown in Fig. 2. The surface graph shows a pronounced increase in the analytical signal as the amount of [Hmim][Cl] decreases and the sample volume increases.

In summary, the results obtained from the optimization process led to the following experimental conditions: amount of [Hmim][Cl], 32 mg; sample volume, 11 mL; molar ratio [Hmim][Cl]:LiNTf2, 1:1; ionic strength, 0 % NaCl; extraction time, 0.5 min; centrifugation speed, 4,000 rpm; centrifugation time, 5 min; and purge time before electrochemical measurements, 20 min.

Electrochemical study of TNT in [Hmim][NTf2] at SPGEs

DPV of a blank and of four TNT standards of 10, 30, 50 and 70 mg L−1, prepared in commercial [Hmim][NTf2], was performed using SPGEs to study the electrochemical behavior of the analyte. According to previous studies [30, 31], using ILs as electrolytes usually leads to three consecutive reduction peaks of TNT, believed to correspond to each nitro group of the aromatic ring. Fig. 3 shows DPV curves obtained in this study. A well-defined cathodic peak appears at −0.80 V, corresponding to the reduction of one of the three nitro groups in the molecule; the two peaks corresponding to the remaining nitro groups cannot be clearly distinguished. The current peak at −0.80 V had a good linearity, between 10 and 70 mg L−1, with a correlation coefficient (r) of 0.996. The repeatability of the electrochemical response was evaluated for five repeated analyses of the 70 mg L−1 standard, and a coefficient of variation (CV) of 2 % was found.

Next, the electrochemical behavior of TNT in [Hmim][NTf2] generated in situ was studied. As shown in Fig. 4, the reduction peaks of the three nitro groups are perfectly well defined and, as in commercial [Hmim][NTf2], an identical peak appears at −0.80 V. However, the reductive peaks at −1.06 V and −1.27 V are not well defined at lower concentrations, and therefore the current peak at −0.80 V was chosen for evaluation of the proposed method.

Analytical figures of merit of the proposed method

Quality variables of the proposed method were evaluated. A concentration range from 10 to 100 μg L−1 was studied and the linear range was established to be from 10 to 80 μg L−1. The resulting calibration curve revealed a high level of linearity, with a correlation coefficient (r) of 0.9990 (N = 4). The sensitivity of the instrumental measurements estimated from the slope of the calibration curve was (0.0112 ± 0.0004) μA μg−1 L. The repeatability of the proposed method, expressed as CV, was evaluated for two spiking levels (20 and 50 μg L−1) by extracting five consecutive aqueous standards, and CV values were found to be 7 % and 5 %, respectively. The enrichment factor of the proposed procedure was 300, defined as the ratio of C o /C a , where C o is the concentration of analytes in the IL phase after extraction and C a is the original concentration of analytes in the aqueous phase.

The LOD and the limit of quantification (LOQ) were estimated by using the mean signal of the blank (n = three replicates) at −0.80 V plus three or ten times its standard deviation. The LOD was found to be 7 μg L−1, and the LOQ was 9 μg L−1. The LOD of the developed method is therefore equal to or lower than other recently reported detection limits for the electrochemical analysis of TNT obtained from more expensive and complex electrodes, using carbon nanomaterials, metallic nanoparticles or assembly procedures (Table 3). In addition, our approach combines a simple sample preparation step with unmodified, inexpensive SPGEs, thereby providing a lower LOD than those reported for other SPELs [20–23] (Table 3). Therefore, the developed method has unique benefits.

Real-world water sample analysis

The ability of the proposed method to determine TNT in real-world water samples was evaluated. Three replicated analyses of both tap water and wastewater were performed at a 40 μg L−1 spiking level. Wastewater was filtered with a 0.22 μm nylon filter after being spiked. It should be noted that in previous analyses none of the selected water samples had detectable initial TNT concentrations. Relative recoveries were calculated as the ratio of the signals obtained for real and ultrapure water samples spiked at the same concentration level. Relative recovery for tap water samples was found to be 114 % with a CV value of 16 %, whereas for wastewater samples the relative recovery was 109 % with 18 % CV. From these results, it can be concluded that matrix effects were not significant in TNT analysis of the two selected water samples. Therefore, the developed method can be successfully applied to both clean and complex water sample matrices.

Conclusions

Screen-printed electrode-based electrochemical detection has been successfully combined with LPME for the first time. The proposed analytical method uses miniaturized systems both in sample preparation and in the detection stage, and therefore has the advantage of avoiding expensive and bulky or immovable instrumentation. In-situ IL formation in the microextraction method avoids the use of harmful and toxic organic compounds as extractant and disperser solvents. The incorporation of a simple and fast sample preparation step before the electrochemical measurement by use of low-cost and disposable SPGEs has enabled a lower LOD than has been reported for other SPELs. The multivariate optimization strategy used here enabled us to rapidly and economically establish the optimum conditions for the main experimental variables involved in the sample preparation, thus providing complete information. Finally, the results prove the ability of the proposed method to determine TNT at trace levels in real-world water samples. Although the use of a nitrogen purge, ice bath and the centrifuge limits portability, this method is a step forward in the development of portable and economical systems available to any laboratory.

References

Risticevic S, Niri VH, Vuckovic D, Pawliszyn J (2009) Anal Bioanal Chem 393:781–795

Pena-Pereira F, Lavilla I, Bendicho C (2010) Trends Anal Chem 29:617–628

Rezaee M, Assadi Y, Milani Hosseini M-R, Aghaee E, Ahmadi F, Berijani S (2006) J Chromatogr A 1116:1–9

Aguilera-Herrador E, Lucena R, Cárdenas S, Valcárcel M (2010) Trends Anal Chem 29:602–616

Sun P, Armstrong DW (2010) Anal Chim Acta 661:1–16

Zhou Q, Bai H, Xie G, Xiao J (2008) J Chromatogr A 1177:43–49

Baghdadi M, Shemirani F (2009) Anal Chim Acta 634:186–191

Yao C, Anderson JL (2009) Anal Bioanal Chem 395:1491–1502

Sun X-M, Sun Y, Wu L-W, Jiang C-Z, Yu X, Gao Y, Wang L-Y, Song D-Q (2012) Anal Methods 4:2074–2080

Zhang Y, Lee HK (2012) Anal Chim Acta 750:120–126

Aguilera-Herrador E, Lucena R, Cárdenas S, Valcárcel M (2008) Anal Chem 80:793–800

Chisvert A, Román IP, Vidal L, Canals A (2009) J Chromatogr A 1216:1290–1295

Metters JP, Kadara RO, Banks CE (2011) Analyst 136:1067–1076

Buzzeo MC, Evans RG, Compton RG (2004) ChemPhysChem 5:1106–1120

Pichtel J (2012) Appl Environ Soil Sci 2012:1–33

Cortada C, Vidal L, Canals A (2011) Talanta 85:2546–2552

Sun Q, Chen Z, Yuan D, Yuan D, Yu C-P, Mallavarapu M, Naidu R (2011) Chromatographia 73:631–637

Giordano BC, Burgi DS, Collins GE (2010) J Chromatogr A 1217:4487–4493

Goldman ER, Anderson GP, Lebedev N, Lingerfelt BM, Winter PT, Patterson CH, Mauro JM (2003) Anal Bioanal Chem 375:471–475

Cizek K, Prior C, Thammakhet C, Galik M, Linker K, Tsui R, Cagan A, Wake J, La Belle J, Wang J (2010) Anal Chim Acta 661:117–121

Chen J-C, Shih J-L, Liu C-H, Liu C-H, Kuo M-Y, Zen J-M (2006) Anal Chem 78:3752–3757

Chuang M-C, Windmiller JR, Santhosh P, Santhosh P, Ramirez GV, Galik M, Chou T-Y, Wang J (2010) Electroanalysis 22:2511–2518

Caygill JS, Collyer SD, Holmes JL, Davis F, Higson S (2013) Analyst 138:346–352

Hallam PM, Kampouris DK, Kadara RO, Banks CE (2010) Analyst 135:1947–1952

Lee J, Murugappan K, Arrigan DWM, Silvester DS (2013) Electrochim Acta 101:158–168

Montgomery DC (2009) Design and Analysis of Experiments, 7th edn. Wiley, New Jersey

Heyden YV, Hartmann C, Massart DL, Michel L, Kiechle P, Erni F (1995) Anal Chim Acta 316:15–26

Fabre H, Mesplet N (2000) J Chromatogr A 897:329–338

Cortada C, Vidal L, Canals A (2011) J Chromatogr A 1218:17–22

Rabenecker P, Pinkwart K (2009) Propellants Explos Pyrotech 34:274–279

Xiao C, Rehman A, Zeng X (2012) Anal Chem 84:1416–1424

Zhang H-X, Cao A-M, Hu J-S, Wan L-J, Lee S-T (2006) Anal Chem 78:1967–1971

Zang J, Guo CX, Hu F, Yu L, Li CM (2011) Anal Chim Acta 683:187–191

Wang J, Hocevar SB, Ogorevc B (2004) Electrochem Commun 6:176–179

Hrapovic S, Majid E, Liu Y, Male K, Luong J (2006) Anal Chem 78:5504–5512

Shi G, Qu Y, Zhai Y, Liu Y, Sun Z, Yang J, Jin L (2007) Electrochem Commun 9:1719–1724

Wang J, Pumera M (2006) Talanta 69:984–987

Agüí L, Vega-Montenegro D, Yáñez-Sedeño P, Pingarrón JM (2005) Anal Bioanal Chem 382:381–387

De Sanoit J, Vanhove E, Mailley P, Bergonzo P (2009) Electrochim Acta 54:5688–5693

Tan SM, Chua CK, Pumera M (2013) Analyst 138:1700–1704

Acknowledgments

The authors would like to thank the Spanish Ministry of Science and Innovation (project n. CTQ2011-23968), Generalitat Valenciana (Spain) (projects n. ACOMP/2013/072 and PROMETEO/2012/038) and Universidad de Alicante (Spain) (project n. GRE12-45) for the financial support. E.F. also thanks Generalitat Valenciana for her fellowship.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Published in the topical collection Microextraction Techniques with guest editors Miguel Valcárcel Cases, Soledad Cárdenas Aranzana and Rafael Lucena Rodríguez.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 123 kb)

Rights and permissions

About this article

Cite this article

Fernández, E., Vidal, L., Iniesta, J. et al. Screen-printed electrode-based electrochemical detector coupled with in-situ ionic-liquid-assisted dispersive liquid–liquid microextraction for determination of 2,4,6-trinitrotoluene. Anal Bioanal Chem 406, 2197–2204 (2014). https://doi.org/10.1007/s00216-013-7415-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7415-y