Abstract

Neutron detection is used in a wide range of applications in nuclear physics, radiation protection, nuclear fuel cycle, reactor instrumentation, security and industrial measurement. Among the detectors used in this field, we notice the gas-filled 3He proportional counters which have been one of the main detecting tools for thermal and cold neutron detection for many years. This last characteristic has ensured that this detector is one of the best tools for thermal neutron flux measurements in a nuclear reactor control. In the instrumentation and detection laboratory of the Nuclear Research Center, of Birine, we are working toward the design and the development of this type of detectors, indeed, several prototypes of neutron detectors have been realized including the 3He proportional counters. Through this paper, we will present the experimental steps and the obtained results to carry out a 3He proportional counter prototype that was fully developed and tested in our laboratory. A comparison study was made between our detector and a commercial cylindrical 3He neutron detector which was considered in this work as a reference detector: LND252 (3He)-PC. The results showed that the characteristics of the gas amplification and the counting plateau for the two counters reference LND 252 (3He)-PC and our prototype was of the same order of scale. The experimental tests show that our developed prototype perfect fit with the standard International Electrotechnical Commission (IEC, www.iec.ch) in the operating principle, the technology adopted and obtained technical specifications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The design and construction of nuclear detectors remain a key strategic issue in the development of nuclear detection instrumentation. In general, neutron detectors, and in particular gas-filled proportional counters based on isotopic 3He, are on the way to being essential for the control command of several nuclear facilities around the world [1,2,3,4]. They are therefore used during monitoring in neutron experimentation taking place within channels of nuclear research reactors, in radiation protection instruments and non-destructive testing of materials [5,6,7].

In the instrumentation & detection laboratory of the Nuclear Research Center of Birine, we have initiated an ambitious program to develop a great variety of detectors; such as those filled with neutron-sensitive gases including 3He proportional counters and 10B boron-coated proportional counter [8, 9]. In this work, the main technical characteristics that determine the quality of 3He proportional counters will be underlined, then the results of the characterization of the proportional counters produced will be presented and extensively commented. In our laboratory, these 3He proportional counters are in the process of being systematically used in neutron diffraction experiments, whether for flux monitoring or for actual neutron spectrometry. Therefore, the gradual pursuit of the development program of this type of neutron detectors is for our laboratory a priority in the current perspective of equipping the piloting devices around the neutron flux channels by our prototype and we compared by another detector reference to confirm our results.

General theory

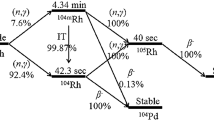

Detection principle

Helium-3 (3He) gas is the most suitable neutron-sensitive gas for filling neutron detectors due to its favorable properties such as a high thermal neutron absorption cross section and good performance in high pressure in the case of proportional counters. The effective detection of neutrons is done through the famous nuclear equation:

The detector gas is chosen according to well-chosen criteria in the field of neutron spectrometry. In the case of 3He + (CO2 or CH4), the incident neutron interacts with the nucleus of an atom of 3He (isotope of 4He) following reaction (1). The 3H and P ions cause ionization of the gas on their journey.

In this work, we are choosing of gas is of the following composition 3He + 10% Ar + 5%CH4, the 3He if to give the nuclear reaction (1) to generate the charged particles 3H and P with energies well to determine, these particles deposit their energy in the total composition of the gas, this deposit creates an avalanche phenomenon, the latter paralyzes the detector therefore necessitates the addition of another mixture which is called quisling gas, its role in eliminating this phenomenon, the pressure is inversely proportional to the dimensions of the detector i.e., for small dimensions we need high pressure, this work is carried out by prototypes according to pressure to optimize the pressure value.

This equation has motivating properties in many applications including thermal neutron detection and spectrometry. Its cross section for thermal neutrons (v = 2200 ms−1) is about 5400 barn and varies with 1/v [10,11,12]. In some applications, a neutron moderator, for example the paraffin, is used to exploit the 1/v cross section allowing even fast neutrons to be detected with higher efficiency [5, 13].

It should be noted here that the proton and the triton thus obtained, and which are, respectively, emitted with energy of 574 keV and 191 keV, are in fact charged particles. As a result, they are easily detected in the sensitive volume of the detector while ionizing the filling gas as they slow down. This ionization has the effect of creating pairs: electrons-ions. These latter entities can be collected through an electric field at the cathode and the anode of the detector, thus facilitating the development of pulsed signals, allowing the detection, processing and counting of the detected neutrons. Other technical aspects, which are not without importance to be cited in this context, it should be noted that the electrons, generated during the ionization process, move at a speed of about 1000 times larger than those of positive ions, so positive ions can be assumed to be inert on the timescale in which electrons are collected. Also, we specify here that very close to the cathode, which represents the external detector wall in our case, the electric field is weak enough and consequently, the electrons drifting toward the central anode wire do not gain sufficient energy between collisions to further ionize the gas under consideration. Another thing, that should also be mentioned here, is that, if the gas contains electronegative impurities such as oxygen, then electrons can attach themselves to these gas atoms to form heavy and slow negative ions which will effectively be lost of the process of drifting toward the anode. This is why gas purity is so important aspect in proportional counters: In particular, it is advised to keep the concentrations of oxygen and other electronegative species below 10 ppm during the detector-filling procedure [5, 14, 15].

The fundamental equations of sensitivity

With regard to the sensitivity of 3He proportional counters, which is a very important characteristic of nuclear detectors, it is noted that it is a function of the geometry of the detector, the neutrons kinetic energy and especially the partial pressure of the gas (3He) in the filling mixture. It is expressed in the number of counts updated per unit of neutron flux. And for a transverse flux, the sensitivity for thermal neutrons is given by the following formula [14]:

where R and L are, respectively, the effective radius and length of the counter and Σ = σ. N is the macroscopic cross section for thermal neutrons.

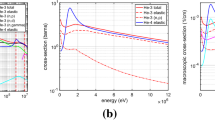

Gas amplification

The fundamental property of proportional counters is the gas amplification. Knowledge of the law of evolution of the gas amplification factor as a function of the geometrical parameters, pressure and type of filling gas and polarization voltage makes it possible to design proportional counters adapted to the experiment and the application for which they are dedicated. Several formulations are given in the literature, among these formulations, Diethorn and Shalev formulations [16,17,18].

Diethorn was the first to verify a gas multiplication formula at high pressures, the relationship he proposed is among the best known in this field:

where \(\Delta V = \frac{\ln 2}{{A_{2} }}, K = - \frac{{B_{2} }}{{A_{2} }}\), M is a gas multiplication factor, V the applied voltage, a: the anode radius, b the cathode radius, p the filling gas pressure.

\(\Delta V\): represents the potential difference for an electron to cover a medium traverse physically, it is close to the necessary energy required to produce a pair (ion + electron); K is the critical value of the field strength per unit of pressure \(\left( \frac{E}{P} \right)\).

The study of Shalev and Hopstone, performed a comparative study of different formulation applied to their experiences; they proposed the Eq. (4) particularly suitable for helium gas [18].

Regarding this formulation, study of (M/dV) showed that the gradient of the curve of propagation is inversely proportional to A6. In order to lengthen the life of 3He proportional counters, it is necessary to amplify the charge collected in the gas to be reduced as necessary factors. Indeed, according Brinckman and Gerber [19], the lifetime L is inversely proportional to the gas amplification factor.

Helium-based proportional counter technology

The Laboratory 3He PC 1″ n°1 prototype counter, produced in our laboratory, was designed by adopting, for the electrodes, an aluminum cathode 2 mm thick and a golden tungsten anode 25 µm in diameter, the current crossings are in metal ceramic. The detectors are filled with a He–Ar–CH4 mixture (10%), at a pressure of 4 bars, after a long degassing under secondary vacuum at a temperature of 90 °C [8, 15]. The characteristic of our prototype detector is presented in Table 1.

Our Laboratory 3He proportional counter is on the way to becoming systematically used in neutron diffraction experiments around neutron beams, whether for flux monitoring or for actual neutron spectrometry. Consequently, the gradual continuation of this development program for this type of neutron detector is a priority for our laboratory in the current perspective.

Wall effects and electronic attachment

In accordance with reaction (01), it is evident that when a thermal neutron is absorbed by a helium-3 (3He) nucleus, it splits into two fragments: a proton and a triton which share the energy released by the reaction and which is 0.765 meV. These two particles are emitted at an angle of 180 °C to each other. During their slowing down in the filling gas, it often happens that one of them, or perhaps, both at the same time, strike the internal walls of the cathode and lose the residual energy there without causing ionization in the sensitive environment of the detector. The total electrical charge resulting from this event is then reduced, this is what we call wall effect. The frequency of its appearance depends on the diameter of the outer wall of the detector as well as the nature of the gas mixture and the total filling pressure. Also, the electrical charge produced in the gas from the ionization trace of the two recoil particles is not always collected in its entirety, because another harmful effect occurs: This is the effect of electronic attachment. A capture of the electrons released can occur as they drift toward the anode by electronegative molecules present in trace in the chamber of the meter such as oxygen O2 and water H2O [5, 17]. Following this, and to improve the characteristics of the 3He proportional counter, it is necessary to carefully study these two effects in order to reduce their effect while acting on the parameters on which they depend such as the quality of the filling gas and its purity [20].

Gas and filling nature and pressure

3He proportional counters are generally filled with three types of gas: 3He, a heavy rare gas and a polyatomic gas for stabilization of gas amplification or quenching. For example, to fill a 3He proportional counter, we use gas mixtures based on 3He to which we add a fraction of heavy gas such as Argon or Krypton intended to effectively stop the proton and the triton and reduce the wall effect and finally a polyatomic gas such as CO2, N2 or CH4 in very small quantities (~ 1 to 5%) in order to reduce the temperature of the electrons and improve the spectrometric properties of the counter [21, 22]. The need for high purity of the gases used should be verified. This is explained by the presence of electronegative impurities increasing the probability of electronic attachment leading to degradation of the resolution of the counter. Mixing ratios as well as total filling pressure vary depending on the desired applications. The filling pressure can range from 4 to 40 bars [12, 15] to serve various purposes such as neutron flux monitoring, spectrometry, etc. [3, 20].

The anode wire and the cathode tube

The anode should be stretched between two guard rings in order to protect the signal from edge effects by limiting the useful length of the counter to the area where the electric field is not disturbed. The cathode is generally a cylindrical copper, stainless steel or aluminum tube 0.5 mm thick and with a diameter varying from 1 to 5 cm depending on the application.

Electrical insulation

Isolation of the measurement signal, the H.V from ground must be ensured using appropriate insulator technologies such as alumina (Al2O3), polyethylene, ceramic. [23].

Design and realization of the 3He detector

After the brief presentation of the main properties characterizing the3He proportional counters (PC) on which we carried out the design studies, we will now describe the prototype produced and tested.

The cylindrical geometry detector is adopted for our study (see Figs. 1 and 2). It mainly consists of a stainless-steel cylinder taken as a cathode with an external diameter of (25.4 mm:1″) and whose wall thickness is about 1 mm. The central anode is a 25 µm tungsten wire stretched along the axis of cathode by means of a spring assembly, an exhaustive list of the various detector constituents is given in Table 1.

To test the withstanding of the so obtained structure against some very hostile working conditions, we have undertaken the following operations: For first time, we have tested the mechanical behavior of the complete structure at 4 bars for high-pressure tolerance. After, and in order to verify the durability and stability of long-term operation, the detector was placed under vacuum (1, 33.10–4 Pa), for 5 consecutive days [15], at a temperature of 120 °C. Once these two tests were successfully passed, we proceeded to effectively fill the detector with a gas mixture comprising: 3He + 10% Ar + 5% CH4 at a total pressure of 4 bars [15, 22]. The electrical isolation of the high voltage power supply (HV) and it has been ensured through the use of a resistant material which is polyethylene. This choice was motivated by the fact that this material has a higher radiation resistance to gamma irradiation at 107 rad.

In reality, and for the sake of comparison, we have tried to design a 3He filled detector who’s metrological, mechanical and chemical characteristics are as close as possible to those of a commercial reference which has demonstrated its effectiveness in the field: LND 252 3He proportional counter. Once our methods are validated, through comparison of course, we can then design our own detectors according to our needs and the applications that arise. Through the data provided in Table 2, and before the starting of the electrical and nuclear tests, the two detectors seem to be very close to each other.

Characterization

A fairly complete series of characterization measurements is carried out, the results of which are summarized in following sections.

Electrical characterizations

Measurement of insulation resistance was done using the instrument: Keithley 617 electrometer, under a voltage of 100 V. The insulation resistance was found to be greater than 1012Ohmand leakage current less than 10–15 A [24].

Nuclear characterization results

Experimental setup

The nuclear tests and comparisons of our Laboratory. (3He)-PC no. 1prototype and the reference detector LND 252 (3He)-PC were first carried out under nearly ideal conditions, corresponding to low-intensity neutron fluxes, normal temperature and a total absence of vibrations, shocks and electromagnetic disturbances. All these conditions were met at the laboratory scale. We have used a neutron source of 241Am-Be (2 Ci) [25] confined in a paraffin wax tower (see Fig. 3).

The high-performance used electronic pulse measurement chain consists of a Canberra-2006E type charge pre-amplifier (PA), selected for its variable gain (1 or 5), its low noise and its speed (Rise Time < 20 ns). The research amplifier used (Ortec-450) makes it possible to optimize the shaping time constant suitable for this type of experience. The discrimination and plateau curves are obtained using a single-channel analyzer type SCA (Ortec-550A). The timer/counter Canberra model and a multi-channel analyzer (MCA 35 + Canberra) are used to collect energy spectra. These are systematically transferred to a microcomputer for processing and analysis. The high voltage precision modules voltage supply is with an output variable 0–5000 V DC positive at a current drain of 0–1 mA, used for the polarization of the counters. The PC-PA connecting cable has a length of around 70 cm.

The optimized experimental conditions in our laboratory as follow: The moderate temperature is around 25 °C.;normal humidity is about 40% to 50%; insulation all connection cables with all nuclear modules (HV: high voltage, pre-amplifier, amplifier, SCA: single-chanel analyzer, time counter, MCA35 +: multi-channel analyzer) during nuclear test.

Plateau curves

Using the experimental setup described above, we have plotted the curves of the plateau related to the two proportional counters: Lab. (3He)-PCn°1 prototype and the reference detector LND 252 (3He)-PC. It appears clearly that the so obtained curves depend on the polarization voltage [10, 15] see (Fig. 4).

The plateau has ΔV = 350 V and a slope of 0.04%/V for the proportional counter LND 252 (3He)-PC and ΔV = 350 V with the same slope for our proportional counter prototype with polarization of 700 V and 1200 V, respectively.

Pulse spectra curves

Under the polarization voltages applied to the two detectors (prototype HV = 850 V and the reference HV = 1200 V), respectively, we acquire the pulse spectrum. This spectrum is the differential curve of the discrimination curve, it shows the number of pulses per second, the amplitude is between two discrimination values, and in other words, it represents the distribution or the number of pulses as a function of their amplitude [11]. The spectra recorded using the multi-channel analyzer (MCA35 +) are shown in Figs. 5 and 6. The shape of the spectra is consistent with the theoretical spectrum for the two counters [10, 20]. However, the resolution of the Lab. (3He)–PCn°1 prototype is lower than the reference counter LND 252 (3He)-PC (see Figs. 5 and 6).

Gas amplification curves

The curves I = f (V), which give the ionization current as a function of the high polarization voltage clearly show the existence of an ionization chamber regime plateau going up to a voltage value of approximately: 350 V for the Lab. (3He)-PC n°1 and 350Vfor the LND 252 (3He)-PC, corresponding therefore to the saturation current and to an amplification gain M = 1 [15, 20]. From this value begins the linear part corresponding to the proportional regime, which is the operating regime of the proportional counters.

The amplification curves as a function of the high voltage were deduced from the current curves by dividing the current corresponding to the HT considered by the current corresponding to the ionization chamber regime (M = 1). The curves tendency of the two counters look almost the same (Fig. 7).

Characteristics of 3He gas according to the formulations of Diethorn and Shalev and Hopstone

A least square fit of the data in Eq. (3) gives a slope \(\left( {\ln 2/{\text{DV}}} \right)\) and an intersection \(\left( { - \ln 2} \right)\left( {\ln K} \right)/{\text{DV}}\) from which the constants \({\text{DV}}\) and \(K\) are calculated [15]. The slope and the intersection are obtained from the linear fit of the proportional region in the Diethorn plot the values of \({\text{DV}}\) and \(K\) are shown in Table 3 with the errors obtained from the uncertainties of the slopes and the intersections by error analysis. The exponential dependence of the gain on K tends to increase the uncertainty of the results. DV and K are constants for the composition of the fill gas and vary with the proportion of additive gas. The validity of our measurements and calculations is compared to benchmark results which are using a detector filled at 4 bars with (3He + Ar + CH4) and testing with a 241Am-Be source of neutron. The \({\text{DV}}\) and \(K\) values for pure isobutene obtained in literature are DV = 34.7 V and K = 0.95 104 V/cm. atm [20, 26, 27]\(.\)

For both neutron detectors (prototype Lab. (3He)-PC and reference LND 252 (3He)-PC), we performed characterizations at a paraffin tower with a241Am-Bi (2 Ci) neutron source and the results are summarized in Table 3. In the Table 4, results of nuclear characterizations of proportional counters to 3He examined in our laboratory during the development for those types of detectors. The electronic measurement system consists of two classical modes: the current mode and the pulse mode. The characteristics are given in the table below:

Discussions

This work allowed us to study, design and compare the main characteristics of a prototype detector (Lab. (3He)-PC) with another commercial reference detector (LND 252 (3He)-PC). The plotting of the various curves (energy spectrum, plateau curves, gas amplification, etc.), for each counter separately, was made using a fairly complete series of measurements.

The pulse amplitude spectrum contains a significant amount of information about the counter body, the filling gas, its nature, pressure and purity. We notice that there is a considerable improvement on the resolution of our detector (Lab. (3He)-PC) R = 3.26% compared to reference defector (LND 252 (3He)-PC) R = 8.88%, which shows us the best experimental conditions from a spectrometric point of view.

Regarding the gas amplification, which is an important design feature of proportional Counters, we have shown through Fig. 5 that the phenomenon of gas amplification is clearly manifested in the designed Counter in the same way as for the reference counter LND 252 (3He)-PC.

As for the counting plateau, an entity that specifies the operating range of the counter as well as its working voltage, we noticed that there is a significant improvement in the operation of our detector. These results in a decrease in the value of the HV voltage required establishing the counting plateau and it is of the order of 500 V for our counter compared to that of the reference counter which is around 1000 V (Figs. 8, 9).

Conclusion and perspectives

In this work, various steps and techniques have been used in the development of several types of gas-filled detectors. In order to validate our detector, a comparison study between our developed prototype and a reference detector whose performance has been demonstrated in the field of neutron detection was made. The results obtained show the relevance of the work carried out through the curves and tables produced. The detector produced is constitutes the first one from a series of detectors which we intend to produce for several applications around our nuclear installations, in addition, these detectors are on the way to becoming of systematic use in neutron diffraction experiments around the beams, whether for flux monitoring or for neutron spectrometry proper. Therefore, the gradual continuation of the development program for this type of counter is a priority for our laboratory with a view to the acquisition by the center of a neutron diffraction spectrometer.

References

R.T. Kouzes, J.H. Ely, L.E. Erikson, W.J. Kernan, A.T. Lintereur, E.R. Siciliano, D.L. Stephens, D.C. Stromswold, R.M. Van Ginhoven, Woodring, Neutron detection alternatives to 3He for national security applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 623, 1035–1045 (2010)

D.H. Beddingfield, N.H. Johnson, H.O. Menlove, 3He neutron proportional counter performance in high gamma-ray dose environments. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 455, 670–682 (2000)

Z.M. Zeng, H. Gong, Q. Yue, J.M. Li, A novel method to measure low flux ambient thermal neutrons with 3He proportional counters. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 866, 242–247 (2017)

P. Douet, J. Duchene, P. Dumesnil, P. Jover, Y. Plaige, R. Verdant, Study and development of instrumentation for nuclear reactor control. Bull. Inf. Sci. Tech. (Paris). 79–86 (1976)

D. Mazed, S. Mameri, R. Ciolini, Design parameters and technology optimization of 3He-filled proportional counters for thermal neutron detection and spectrometry applications. Radiat. Meas. 47, 577–587 (2012)

D.J. Loaiza, High-efficiency 3He proportional counter for the detection of delayed neutrons. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 422, 43–46 (1999)

P.M. Dighe, D. Das, Performance studies of boron lined proportional counters for reactor applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 770, 29–35 (2015)

M. Fares, A. Messai, S. Begaa, M. Messaoudi, K. Negara, M.Y. Debili, Design and study of the characteristics of a versatile ionization chamber for gamma-ray dosimetry. J. Radioanal. Nucl. Chem. 326, 1405–1411 (2020). https://doi.org/10.1007/s10967-020-07446-5

M. Fares, M.Y. Debili, M. Messaoudi, S. Begaa, K. Negara, A. Messai, Boron-10 lined proportional counter development for thermal neutron detection. Radiat. Detect. Technol. Methods. (2021). https://doi.org/10.1007/s41605-020-00226-5

H.O. Menlove, M.T. Swinhoe, D. Henzlova, L. Evans, J.B. Marlow, 3He Replacement for Nuclear Safeguards Applications-an Integrated Test Program to Compare Alternative Neutron Detectors (Los Alamos National Lab (LANL), Los Alamos, 2011).

M.M. Pickrell, A.D. Lavietes, V. Gavron, D. Henzlova, H.O. Menlove, J. Joyce, R.T. Kouzes, The IAEA workshop on requirements and potential technologies for replacement of 3He detectors in IAEA safeguards applications. J. Nucl. Mater. Manag. 41, 14–29 (2013)

M. Weyrauch, A. Casnati, P. Schillebeeckx, M. Clapham, Use of 4He-filled proportional counters as neutron spectrometers. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 403, 442–454 (1998)

T.J. Langford, C.D. Bass, E.J. Beise, H. Breuer, D.K. Erwin, C.R. Heimbach, J.S. Nico, Event identification in 3He proportional counters using risetime discrimination . Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 717, 51–57 (2013)

A. Tahri, Contribution à l’étude, la réalisation et la caractérisation de compteurs proportionnels à 3He et BF3, Mémoire Diplome Post Grad. Spécialisée En I C. DIC/CDSE (1993)

S.S. Desai, A.M. Shaikh, On studies of 3He and isobutane mixture as neutron proportional counter gas. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 557, 607–614 (2006)

W. Diethorn, A methane proportional counter system for natural radiocarbon measurements, United States Atomic Energy Commission, Technical Information Service (1956)

S. Shalev, Z. Fishelson, J.M. Cuttler, The wall effect in 3He counters. Nucl. Instrum. Methods 71, 292–296 (1969)

S. Shalev, P. Hopstone, Empirical expressions for gas multiplication in 3He proportional counters. Nucl. Instrum. Methods 155, 237–247 (1978)

H.F. Brinckman, D. Gerber, Investigation of BF3 Proportional Counters, Atomic Energy Research Establishment (1961)

A. Ravazzani, A.F. Para, R. Jaime, M. Looman, M.M. Ferrer, P. Peerani, P. Schillebeeckx, Characterisation of 3He proportional counters. Radiat. Meas. 41, 582–593 (2006)

T. Nakamura, Recent development of advanced neutron detection technology. J. Nucl. Radiochem. Sci. 4, R15–R24 (2003)

J. Balibrea-Correa, G.F. Ciani, R. Buompane, F. Cavanna, L. Csedreki, R. Depalo, F. Ferraro, A. Best, Improved pulse shape discrimination for high pressure 3He counters. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 906, 103–109 (2018)

G.F. Knoll, Radiation Detection and Measurement (Wiley, Hoboken, 2010).

C.C. Bueno, M.M. Fraga, J.A.C. Gonçalves, R.F. Marques, A. Policarpo, M.D. de S Santos, Rate effects in a proportional counter with resistive cathode. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 408, 496–502 (1998)

J. Beringer, Particle data group. Phys. Rev. D. 86 (2012)

D. Mazed, Experimental gas amplification study in boron-lined proportional counters for neutron detection. Radiat. Meas. 42, 245–250 (2007)

M. Baaliouamer, C. Belaragueb, D. Mazed, Gas gain measurement in helium-isobutane mixtures filled-proportional counters. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 382, 490–494 (1996)

Acknowledgements

We would like to thank all the engineers and technicians of the Detection and Measurement Department and the staff of the DEDIN Division, special thanks are extended to Mr. Idir Abdellani General Director of CRNB.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fares, M., Messai, A., Begaa, S. et al. 3He proportional counter development for thermal neutron detection. Radiat Detect Technol Methods 5, 264–272 (2021). https://doi.org/10.1007/s41605-021-00258-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41605-021-00258-5