Abstract

Ground improvement using stone column reinforcement is an effective treatment technique to increase the stiffness and reduce the total and differential settlement of the soft deposits. Even though stone column reinforcement is a well-established technique, detailed experimental study regarding the load-sharing characteristics and parameters influencing the stress concentration ratio (SCR) between the soil and column is very limited. In the present study through a systematic laboratory investigation, time-dependent and peak SCR between the stone column and surrounding soil has been evaluated for a practical range of stone column, surrounding soil, top sand blanket thickness and column material properties. Stress experienced from the foundation loading to stone column and surrounding soil in a unit cell has been measured using earth pressure cells. Peak SCR has been observed to be in the range of 4–6 for the set of material parameters investigated in the present study. Peak SCR is in the range of 4–5.5 when internal friction angle of the stone column material varies from 38° to 42°. SCR is significantly influenced by the thickness of the top sand blanket. However, an insignificant influence of sand blanket material properties on the SCR has been observed. Additionally, surrounding soil strength significantly influences the SCR of the composite system. The results of the present study will be useful for the estimation of stiffness and settlement of the stone column-reinforced composite ground.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stone column is an effective and economic in situ ground-reinforcing technique to improve the strength and stiffness of the soft clay deposits. Installation of stone column increases the bearing strength, accelerates the consolidation mechanism and reduces the consolidation time in the case of soft soils. Stone columns are successfully used to support the earthen embankment, LPG storage tank, raft foundation and bridge approach fill. A large numbers of analytical, laboratory and field studies had contributed in greater understanding of settlement, bearing capacity and deformation behaviour of the stone column-reinforced ground [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20].

Analytical and numerical studies show that the stress concentration ratio (SCR), i.e. the ratio of stress carried by the stone column to the surrounding soil, significantly influences the consolidation behaviour of the stone column-reinforced ground [7, 21,22,23]. However, an accurate determination of the stress concentration ratio plays an important role in estimation of the settlement and composite stiffness of the improved ground. Usually, field or experimental tests are performed to determine the SCR between the stone column and surrounding soil. For the usual range of properties of stone column and surrounding soil, the SCR varies in the range of 2–6 [24,25,26]. Based on the experimental and field test results, Barksdale and Bachus [27] suggested that the SCR between stone column and surrounding soil lies in the range of 3–10. Xueyi et al. [28] investigated the influence of addition of the dry sand, lime and cement separately with stone column material to examine the SCR through small-scale laboratory model tests. The loading condition is similar to foundation loading in the real field scenario. SCR between the stone column and surrounding soil was found to be in the range of 4–7.6. Also, the SCR was found to be dependent on the unconfined strength of the surrounding soil, stone column material and time elapsed after loading. Fattah et al. [29] performed model studies through instrumented load tests on single and group of stone column-reinforced soft soil to determine the SCR. Cement and sand were then added separately to the column material for strengthening the stone column. SCR was found to be in the range of 1.2–3.8 for different parameters and testing conditions adopted in the study. Poon and Chan [30] determined the SCR of the stone column through 2D finite element analysis. The stone column-improved ground was replaced with a strip of appropriate width and equivalent properties to represent the stone column-improved soil. The SCR was investigated along the length of equivalent strip for floating and end-bearing conditions. The SCR on the equivalent strip was also compared with the results from 3D and axisymmetry finite element analysis. Das and Deb [31] measured the SCR between the stone column and surrounding soil subjected to embankment loading. Earth pressure cell placed at the top of the stone column and surrounding soil was used to measure the stresses. The SCR was found to be dependent on the critical height of the embankment, time and modular ratio of the stone column and surrounding soil.

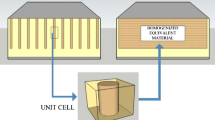

A sand blanket is usually placed at the top of the stone column-improved ground for uniform distribution of stress and also acts as a horizontal drain to dissipate the pore water. In the field, area replacement ratio of the stone column, properties of the stone column and surrounding soil, sand blanket thickness and material properties may vary over a wide range. However, studies on the influence of these parameters on the SCR between stone column and surrounding soil are very limited in the literature. In the present study, SCR between stone column and surrounding soil has been investigated through laboratory investigation using unit cell idealization. Earth pressure cells have been used to measure the stresses on the stone column and surrounding soil for the entire unit cell area loading conditions. Variation in the SCR with time has been investigated and reported in this paper. Time-dependent and steady-state SCR between the stone column and surrounding soil has been studied for a practical range of different parameters of stone column-reinforced soft soil, i.e. area replacement ratio, stone column material properties, top sand blanket thickness and its material properties and undrained shear strength of the surrounding soil.

Experimental study

Usually, stone columns are installed in triangular or square pattern in a group having certain influence area of each column. The equilateral triangle pattern is most commonly used since the influence area of a single column in triangular pattern is greater than the square pattern. The equivalent cylindrical influence area of a single column within a group of columns is called the unit cell. In the present experimental study, unit cell idealization of a single column within a group of columns has been used. All the laboratory tests are performed in a cylindrical tank representing the unit cell having 185 mm diameter and 600 mm height. Area replacement ratio, i.e. ratio of the area of a single column to its unit cell area/influence area, depends on the diameter, centre-to-centre spacing and pattern of the stone column in a group. In the present study, area replacement ratio has been calculated for triangular pattern of stone column arrangement in a group with centre-to-centre spacing of three times the diameter of stone column. Properties of the different materials used for stone column, soft soil test bed and top sand blanket are described below.

Soft soil medium (C)

To prepare the soft soil medium for stone column installation, soil sample was collected from nearby of Roorkee, Uttarakhand. The liquid limit, plastic limit and unit weight at optimum moisture content are 40%, 28% and 16.4 kN/m3, respectively. The soil is classified as clayey silt of medium plasticity (CI – MI) as per Indian Standard Classification System (IS: 1498). Grain size distribution of the soil is shown in Fig. 1. The sample consists of 74% of silt and 26% of clay. The other properties of the sample are shown in Table 1. Unconfined compressive strength (UCS) has been used as an indicator/controlling parameter for the soft test bed preparation. Initially, the variation in UCS with different water content has been evaluated preparing the sample in standard proctor compaction energy. Based on the test results, UCS and corresponding water content values are plotted. Figure 2 shows the variation in the UCS with water content. For the present study, UCS of the soft clay bed is fixed at 15 kPa. For 15 kPa UCS of the soft clay bed, the corresponding water required may be fixed using Fig. 2. Then, the required amount of water is mixed with the soil to get the necessary consistency.

Column/sand blanket material

Stone aggregates (S)

A mixture of sand and stone aggregates is used to form the stone columns only. The stone aggregates are angular granite chips of size in the range of 4.75–10 mm. The grain size distribution curve of the mix sample is also shown in Fig. 1. The mix sample consists of 70% sand and 30% gravel. The mix sample can be classified as SP as per Indian Standard Classification System. The peak angle of internal friction of the mix is found to be 42°, evaluated through the large-size direct shear test. Other properties of the mix sample are listed in Table 1. For stone column formation, the mix sample was compacted to a unit weight of 16 kN/m3. The usual range of relative density of the stone column in the field varies in the range of 60–80% [4]. In the present study, the relative density of the finished stone column calculated from the consumption of material is found to be 70 ± 2%, which is well within the field density. It is expected that the small variation in the relative density of the stone column has an insignificant effects on the overall behaviour of the stone column-improved soft soil.

Sand

Three different types of sands are used as the stone column and top sand blanket material. Rounded Solani Sand (SS) obtained from nearby Solani River and two different Standard Ennore Sands (ES-I and ES-II) are also used as stone column and sand blanket material in the present study. The grain size distribution of the different sands are also shown in Fig. 1 All the sand has been classified as SP as per Indian Standard Classification System. SS sand consists of 100% fine-sized sand (0.425–0.75 mm). ES-I consists of 3% fine sand, 77% medium sand (2–0.425 mm) and 20% coarse sand (4.75–0.425 mm). ES-II consists of 3% fine sand and 97% medium sand. Different properties, i.e. coefficient of uniformity (Cu), coefficient of curvature (CC) and internal friction angle, are given in Table 1. Angle of internal friction for the three different sands is evaluated through small-sized direct shear box at 75% relative density equivalent to stone column formation density usually adopted in the field. Three different sands and mix of sand and stone show a different angle of internal friction as shown in Table 1. Table shows that the angle of internal friction of three different sand materials varies in the range of 36°–40°. The shear strength vs normal stress relationship for the stone aggregates (S), Solani Sand (SS), Ennore Sand-I (ES-I) and Ennore Sand-II (ES-II) are shown in Fig. 3.

Preparation of soft bed

The soil was initially pulverized and oven dried for 24 h at 105° before the sample preparation. Then, the required quantity of water is added to the dry soil and mixed vigorously to produce a homogenous paste of required consistency. The main assumption in the unit cell idealization is that the vertical side of the unit cell acts as a frictionless boundary/roller support. In the present model study, to minimize the wall friction and boundary effects between the soft soil and vertical boundary of the unit cell, a thin coat of grease was applied on the vertical side of the unit cell before the filling of soft bed. Then, the prepared sample was transferred to the unit cell tank and placed in layers of uniform thickness to achieve the required consistancy. The unit cell was filled in five equal layers and each layer was properly compacted with a hammer of 45 N to achieve a compacted height of 120 mm. After compaction of each layer, undisturbed samples were taken out using a sampling tube to evaluate the in situ UCS and water content of the prepared soft bed. In situ water content and UCS of the prepared bed have been taken as quality control criteria of the prepared bed. A 5% variation in the UCS values of the prepared soft bed was considered to be acceptable in the present study. Prepared bed showing variation more than the above-mentioned criteria was prepared and checked again before the test.

Installation of stone column

Method of formation of stone column significantly influences the behaviour of the reinforced ground. Most commonly, replacement or displacement method of stone column formation is followed in the field/laboratory. In the present study, stone column within the unit cell has been formed through replacement technique, i.e. removal of soil from unit cell tank using a casing pipe having outer diameter equal to the column diameter. Replacement technique has been proved to produce stone column of excellent consistency in small-scale model test [6]. Using guide plates, the pipe was pushed vertically through hydraulic jack into the prepared bed until it reaches the bottom of the tank. The soil inside the tube was then removed carefully leaving hole at the centre. The stone column is formed in five equal layers of 120 mm height each. The quantity of material required for each layer was calculated priori and placed inside the bore hole. Before placing, the materials are moistened at natural moisture content to prevent absorption of water from surrounding soil. Then, the material was compacted using a hammer to achieve the desired unit weight. Then, the casing tube was lifted ensuring a minimum depth of 25 mm below the top level of compacted stone aggregates to prevent the collapsing of the soil inside the hole. Current method of cased stone column formation is usually followed in the field where borehole stability is a problem due to high groundwater level or surrounding soft soil [27]. The above-mentioned procedure was repeated to complete the column up to the full height (Fig. 4). After column installation, the top surface was carefully levelled and remaining top soil was removed. After column installation, the top blanket was formed using sand pluviation method. The sand was poured from prefixed height to achieve a maximum density of 75% for the selected thickness.

Test procedure

After installation of the stone column, load tests were performed. For measuring the stress distribution, two miniature earth pressure cells, one at centre of stone column and other at the top surface of the soft soil, were placed. Capacity of the earth pressure is 500 kPa with an accuracy of 0.001 kPa. The location of earth pressure cells for typical load tests is shown in Fig. 5a. The load taken by the stone column or soft soil can be measured directly from a single earth pressure cell placed either on soft soil or stone column. The purpose of using two earth pressure cells in the present study is to validate the one earth pressure cell reading from other. Also, test can be useful even if one of the earth pressure cell malfunctioned during the test. After placing earth pressure cell, top sand blanket layer of 150 mm thickness was laid over the composite system. Typical completed view of the constructed stone column is shown in Fig. 5b. For evaluating SCR, surface loading test, i.e. loading plate having a diameter of 183 mm and a thickness of 3 mm, was selected and placed at the top of the sand blanket layer. The small difference in diameter between surface loading plate and unit cell is beneficial to avoid the internal friction between the side of loading plate and inner side of unit cell. A constant load of 1200 N was applied to the composite ground. During testing, the load was maintained constant till the settlement seizes or shows a rate less than 0.001 mm/min. The settlement of the composite system was measured through a set of three duly calibrated dial gauges placed at an angle of 120° with each other. The load coming to the composite system was measured through a load cell placed between the plunger of hydraulic jack and loading plate. The capacity of the load cell is 2.5 T with an accuracy of 0.001% of full-scale output. The complete loading arrangement for the test is shown in Fig. 5c. The reading of the earth pressure cells and dial gauges was continuously recorded and monitored through a 48-channel online data acquisition system. The following subsections describe the effects of different parameters of the stone column-reinforced composite ground on the SCR of the system. The methods of soft bed preparation, stone column formation, installation of earth pressure cells, top sand blanket formation and application of load remain the same for all the series of tests in the present study.

Results and discussions

The test program consists of five different series and a total of 21 surface loading tests where different parameters of the stone column-reinforced composite system were varied. The parameters include area replacement ratio of stone column, material properties of the stone column, sand blanket thickness, sand blanket material properties and undrained shear strength of the surrounding soil. For all the varying parameters, time-dependent and peak SCR (SCRP) of the composite system has been studied. Table 2 shows the details of different parameters and number of tests performed in the present study.

Effect of area replacement ratio

Area replacement ratio plays an important role on the response of the composite ground. The settlement and bearing capacity of the stone column-reinforced ground primarily depend on the area replacement ratio. Usually, the area replacement ratio in the field varies in the range of 10–30% [4]. Area replacement ratio below 10% is not effective for ground improvement, and higher than 30% is not economical. In the present study, soft clay bed was reinforced with three different stone column diameters, i.e. 63 mm, 76 mm and 88 mm, representing area replacement ratios of 11.6%, 17% and 22.6%, respectively. For this series of test, mixture of sand and stone aggregates S has been used as stone column material having an angle of internal friction (φ) of 42°. Solani River sand SS of 150 mm thickness has been used as top sand blanket. The angle of internal friction of the SS is 36°. The applied load creates an average stress level of 120 kPa at the top surface of the composite ground. In the present study, time-dependent SCR and SCRp of the composite system have been evaluated. Total consolidation settlement of the system can be calculated from the SCRP. Also, from knowledge of the time-dependent SCR of the composite system, change in the consolidation properties of the surrounding soil can be employed in the analysis to realistically estimate the rate of consolidation and total settlement of the system. Figure 6 shows the variation in SCR with time for different area replacement ratios. A nonlinear behaviour of SCR with time has been observed for all the area replacement ratios. Initially, SCR increases rapidly with time and reaches the peak and then becomes almost constant. Accelerated consolidation of the stone column-reinforced soft soil started with the application of surcharge load. The consolidation results in a settlement and gradual transfer of load from soft soil to stone column. The gradual load transfer from soft soil to stone column results an increase in the SCR of the reinforced ground. Consolidation of the stone column-reinforced soft soil leads to the progressive vertical and lateral deformation of the stone column. When SCR reaches peak, the consolidation of the soft soil almost became complete and the deformation of the stone column and soft soil stops under given surcharge load. At completion of consolidation under given surcharge load, the SCR became almost constant. The observed peak values for the selected area replacement ratio ranges from 5.2 to 6.2, and columns with higher area replacement ratio show maximum values of SCRP. For higher area replacement ratio, the presence of larger stone column carries majority of load, thus preventing the soft soil from experiencing excess pressure, which resulted in higher values of SCR. It can also be observed from the test results that the stress taken by columns increases with area replacement ratio, whereas the stress experienced by soil surface reduces [21].

SCRP is plotted against the area replacement ratio in Fig. 7. The present results are also compared with the experimental results of Juneja et al. (2013). They investigated the SCR of the sand compaction pile-reinforced soft soil for different over-consolidation ratios (OCR) of surrounding soil through small-scale laboratory test. The test results from the present study show that a almost linear relationship exists between SCRP and area replacement ratio. The range of SCR found in the present study matches well with the previous study. SCR and SCRP are dependent on the area replacement ratio and plays a major role in transferring load between column and soil for stone column-reinforced ground.

Effect of column material property

Relative stiffness of the stone column and surrounding soil plays a major role in stress distribution between the column and surrounding soil [21]. In this series of test, the variation in SCR and SCRp with the stone column material properties has been investigated. In this series of test, material with different angles of internal friction has been used as stone column while surrounding soil and top sand blanket thickness and material properties, applied stress level and area replacement ratio remain the same as described previously. SCR and SCRp of the composite system have been evaluated for S, ES-I and ES-II as stone column material. Usually in the field, well-graded clean sand, mixture of sand and gravel are used as stone column material. The angle of internal friction of the stone column material to be used in the field should be in the range of 36°–44° [27]. In the present study, material having an angle of internal friction in the range of 38°–42° has been chosen as stone column material. Figure 8 shows the variation in SCR with time for different stone column materials. A similar variation in SCR with time as described previously is also observed in this case. The stone column material S (42°) shows the highest angle of internal friction followed by ES-I (40°) and ES-II (38°). Results show that the stone column made of S material shows the highest SCR followed by the ES-I and ES-II.

Figure 9 shows the variation in SCRP with angle of internal friction of stone column material. Results show that SCRP depends significantly on the angle of internal friction of stone column material and increases linearly with increase in the angle of internal friction of the stone column material. In the present study, SCRP varies from 4.2 to 5.5 when angle of internal friction of the stone column material varies from 38° to 42°. A similar observation about the load sharing between different elements of the stone column-improved ground, and improvement in load bearing capacity with the variation in stone column material has also been reported by previous researchers. Relative stiffness of the stone column-reinforced soft soil increases with increase in the angle of internal friction of stone column material. Higher stiffness of stone column material attracts more load and shares a larger portion of load, which results in higher SCR. Das and Deb [31] from the experimental test on the stone column-improved soft soil-supported embankment also reported that the lower modular ratio causes poor transfer of stress, which leads to a reduction in SCR. Stone column material properties show a more pronounced effects on the SCRP when compared with the area replacement ratio of the as evident from the slope of the graphs.

Effect of top blanket layer thickness

The top blanket layer laid over the composite system plays a significant role in load distribution. Selection of adequate thickness and material is essential since it ensure the load transfer mechanism between column and soil and also helps pore water pressure dissipation at top. As stresses near the top of the treated group are significantly influenced by the presence of granular mat, hence it is important to consider the effect of the granular mat in composite system. As per authors’ review, there are no experimental investigation performed on the load distribution mechanism due to the thickness of top blanket material layer and its material characteristics. In the present study, time-dependent SCR and SCRp are investigated for different top layer thicknesses. In this series of test, area replacement ratio was kept as 17% and top blanket layer was prepared with soil having an angle of internal friction of 38° at 75% density. SCR of the composite system has been investigated for 150 mm, 300 mm and 450 mm top sand blanket thicknesses and different stone column materials having an angle of internal friction angle in the range of 38°–42°. Figure 10 shows the variation in SCR with time for different stone column materials for top blanket thickness of 150 mm. A similar variation in SCR with time as described previously has also been observed for this case. Figure 11 shows the variation in SCRP with varying thickness of top blanket. The result shows that the SCRP decreases with the increase in the top blanket thickness for all the stone column material properties. Increasing the thickness of the top sand blanket is beneficial in reducing the applied stress level at the top of the stone column. This beneficial effect on the stone column is due to the settlement of the top sand blanket and uniform distribution of the load at the top of the stone column and surrounding soft soil. Due to this, SCRP reduces with increase in the top sand blanket thickness. As the stone column is the stiffer component and carries larger stress in the composite system, a suitable thickness of top blanket thickness reduces the stress in the column and prevents it from the local failure within the column. As stresses near the top of composite ground are high, provision of granular blanket of adequate thickness will result in reduction in SCR and subsequently SCRP and prevent the column from reaching its yield capacity and failure can be controlled. This will be highly helpful where high area replacement ratio is not possible; provision of granular blanket will improve the performance of treated ground.

Effect of top blanket material property

In this series of test, time-dependent SCR and SCRP of the composite system have been investigated for the different material properties of top sand blanket. Material properties of the top sand blanket may vary over a wide range in the field. In this series of test area replacement ratio, top sand blanket thickness and applied load level are kept as 17%, 300 mm and 1200 N, respectively. SS, ES-I and ES-II having angle of internal friction of 36°, 38° and 40°, respectively, have been chosen as top sand blanket materials. Also, for each sand blanket material, three different stone column materials (S, SS and ES-I) have been used to study the variation in time-dependent SCR and SCRp. Figure 12 shows the variation in SCR with time for different stone column material properties. A similar pattern of SCR with time has also been observed here as discussed previously.

Figure 13 shows the variation in SCRP with top blanket materials properties for different column materials. SCRP reduces linearly as angle of internal friction of top blanket material increases. The stiffer top blanket helps in distributing the load coming to the top of stone column and surrounding soil more uniformly, which results a decrease in the peak SCR of the composite system. The observed reduction was found to be constant for all column materials. From the observed test results, it is suggested that the use of well-graded top blanket layer with adequate thickness will reduce the stresses developed near column surface, facilitate pore water dissipation and improve the performance of treated ground. Thickness of the sand blanket shows more pronounced effects on the SCR and SCRP when compared with material properties as is evident from the slope of the graphs.

Effect of surrounding soil strength

In this series of test, effect of undrained shear strength of the surrounding soil on the time-dependent SCR and SCRP has been evaluated. In this series of test, area replacement ratio, sand blanket properties, thickness and applied stress level are kept as 17%, 38°, 150 mm and 120 kPa, respectively. S has been used as stone column material. Undrained shear strength of the surrounding soil has been changed in the range of 15–45 kPa. Figure 14 shows the variation in SCRP with undrained shear strength of surrounding soil. The results show that SCRP reduces linearly with increase in the undrained shear strength of surrounding soil. The relative stiffness of the stone column and surrounding soil reduces with increase in the undrained shear strength of surrounding soil. As the time-dependent SCR and SCRP depend on the relative stiffness of stone column and surrounding soil, an increase in the undrained shear strength of the surrounding soil decreases the SCRP. The findings of the present study have also been compared with the experimental results of Ambily et al. [1]. A similar trend has been observed from both the studies.

Discussions and conclusions

The present work describe details of the experiments conducted on unit cell to understand the factors affecting the time-dependent and peak SCR of soft soil reinforced with stone column through surface loading conditions. The present study uses unit cell idealization to model single-column behaviour within an infinite group of stone columns in the field. The unit cell offers infinite stiffness in radial direction, thereby preventing any radial deformation of it, which may not be the realistic simulations of the field conditions due to finite stiffness in radial direction. Due to this, the settlement and SCR may be under- and overestimated in the unit cell idealization when compared with the field conditions. Also, behaviour and stress conditions of the edge columns in an infinite group of stone columns are significantly different from the middle or any other column. The unit cell fails to realistically idealize the behaviour of stone columns situated at the edge of a group. The findings of the present study are not applicable to the edge column or stone column group with limited number of stone columns. To measure the SCR, earth pressure cells are used. Area replacement ratio and material properties of stone column, top sand blanket thickness and its material properties, surrounding soil strength on the estimation of time-dependent SCR and peak SCR of the composite system have been evaluated. The following conclusions may be drawn from the results obtained for the material properties and parameter used in the present study.

- 1.

Stress concentration ratio of the stone column-improved composite system varies nonlinearly with the application of surcharge load. Initially, SCR increases rapidly with time after application of load and then becomes constant and reaches steady-state stage. A similar time-dependent variation in SCR is observed for the different parameters tested of the composite system.

- 2.

Area replacement ratio influences SCR of the stone column-improved composite system. Peak SCR is observed to increase with increase in the area replacement ratio of the stone column. The observed values of peak SCR range from 5.1 to 6.2 when area replacement ratio changes from 11.6 to 22.6%, respectively.

- 3.

Peak SCR increases with increase in angle of internal friction of column material. From experimental results, the peak SCR increases from 4.2 to 5.5 when angle of internal friction of stone column material changes from 38° to 42°. Also, the stone column material properties show dominating influence on the peak SCR over the area replacement ratio of stone column.

- 4.

Thickness and material properties of the top blanket significantly influence the peak and time-dependent SCR of the composite system. Peak SCR decreases with the increase in thickness and angle of internal friction of sand blanket material. However, thickness of the top sand blanket shows a significant influence on the peak SCR over the material properties of the top blanket.

- 5.

The undrained shear strength of surrounding soil plays a major role in stress concentration ratio. Relative stiffness of the stone column and surrounding soil decreases with the increase in undrained shear strength of the surrounding soil, which results in a decrease in the peak SCR of the composite system.

- 6.

The results show that the peak SCR is significantly influenced by the stone column material properties, top sand blanket thickness and surrounding soil strength among the various parameters experimented in the present study.

References

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng (ASCE) 133(4):405–415

Bahadori H, Farzalizadeh R, Barghi A, Hasheminezhad A (2018) A comparative study between gravel and rubber drainage columns for mitigation of liquefaction hazards. J R Mech Geotech Eng 10(5):924–934

Black AJ, Sivakumar V, Madhav RM, Hamill AG (2007) Reinforced stone columns in weak deposits: laboratory model study. J Geotech Geoenviron Eng (ASCE) 133(9):1154–1161

Black JA, Sivakumar V, Bell A (2011) The settlement performance of stone column foundations. Geotechnique 61(11):909–922. https://doi.org/10.1680/geot.9.p.014

Castro J, Sagaseta C (2009) Consolidation around stone columns: influence of column deformation. Int J Numer Anal Methods Geomech 33(7):851–877

Castro J, Karstunen M (2010) Numerical simulation of stone column installations. Can Geotech J 47:1127–1138. https://doi.org/10.1139/T10-019

Indraratna B, Basack S, Rujikiatkamjorn C (2013) A numerical solution of stone column improved soft soil considering arching, clogging and smear effects. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000789

Krisch F (2006) Vibro installations and its effect on ground improvement. In: Numerical modelling of construction processes in geotechnical engineering for urban environment. Taylor and Francis Group, London, ISBN 0415 397480

McKelvey D, Sivakumar V, Bell A, Graham J (2004) Modeling vibrated stone columns in soft clay. Proc Inst Civil Eng Geotech Eng 157(3):137–149

Mohanty P, Samanta M (2015) Experimental and numerical studies on response of the stone column in layered soil. Int J Geosynth Ground Eng 1:27. https://doi.org/10.1007/s40891-015-0029-z

Ng KS, Tan SA (2015) Simplified homogenization method in stone column designs. Soils Found 55(1):154–165

Sexton BG, McCabe BA, Karstunen M, Sivasithamparam N (2016) Stone column settlement performance in structured anisotropic clays: the influence of creep. J R Mech Geotech Eng 8(5):672–688

Shahu JT, Reddy YR (2014) Estimating long-term settlement of floating stone column groups. Can Geotech J 51(7):770–781

Sivakumar V, Glynn D, McNeill J (2007) A laboratory model study of the performance of vibrated stone columns in soft clay. In: Proceedings of the 17th international conference on soil mechanics and foundation engineering, vol 3, Madrid, Spain

Sivakumar V, Jeludine MNKD, Bell A, Glynn TD, Mackinnon P (2011) The pressure distribution along stone columns in soft clay under consolidation and foundation loading. Géotechnique 61(7):613–620. https://doi.org/10.1680/geot.9.P.086

Samanta M, Sawant VA, Ramasamy G (2010) Ground improvement using displacement type sand pile. In: Indian geotechnical conference, IGC-2010, GEOtrendz, December 16–18, 2010 IGS Mumbai Chapter & IIT Bombay, pp 629–632

Priebe HJ (1995) The design of vibro replacement. Ground Eng 28(12):31–37

Verma S, Kumar Vikash, Priyadarshee A (2018) An experimental test study on ring footing resting on clay bed reinforced by stone column. Innov Infrastruct Solut 3:64. https://doi.org/10.1007/s41062-018-0169-9

Wood DM, Hu W, Nash DFT (2000) Group effects in stone column foundations: model tests. Geotechnique 50(6):689–698

Watts KS, Johnson D, Wood LA, Saadi A (2000) An instrumented trial of vibro ground treatment supporting strip foundations in a variable fill. Géotechnique 50(6):699–708. https://doi.org/10.1680/geot.2000.50.6.699

Han J, Ye SL (2001) Simplified method for consolidation rate of stone column reinforced foundations. J Geotech Geoenviron Eng (ASCE) 127(7):597–603

Han J, Ye SL (2002) A theoretical solution for consolidation rates for stone column reinforced foundations accounting for smear and well resistance effects. Int J Geomech 2(2):135–151

Pulko B, Majes B (2005) Simple and accurate prediction of settlements of stone column reinforced soil. In: Proceedings of the 16th international conference on soil mechanics and geotechnical engineering, pp 1401–1404. https://doi.org/10.3233/978-1-61499-656-9-1401

Aboshi H, Ichimoto E, Enoki M, Harada K (1979) The “Compozer”—A method to improve characteristics of soft clays by inclusion of large diameter sand columns. In: Paper presented at the proceedings of the international conference on soil reinforcement: reinforced earth and other techniques (Coll. Int. Reinforcements des Sols.), Paris

Goughnour RR, Bayuk AA (1979) A field study of long term settlements of loads supported by stone columns in soft ground. In: Paper presented at the proceedings of the international conference on soil reinforcement: reinforced earth and other techniques (Coll. Int. Renforcements des Sols.), Paris

Vautrain J (1977) Reinforced earth walls on stone columns in soil. In: Proceedings of international symposium on geotechnical aspects of soft clays, AIT, Bangkok, pp 613–628

Barksdale RD, Bachus RC (1983) Design and construction of stone columns, vol I. Federal Highway Administration, US Department of Transportation, Washington, DC

Xueyi L, Shubber AAM, Hongsong L, Juanjuan R (2009) The stress concentration ratio of stone columns under confined condition. In: International conference on transportation engineering (ASCE), pp 4247–4255

Fattah MY, Shlash KT, Al-Waily MJM (2013) Experimental evaluation of stress concentration ratio of model stone columns strengthened by additives. Int J Phys Model Geotech 13(3):79–98. https://doi.org/10.1680/ijpmg.12.00006

Poon B, Chan K (2013) Stress concentration ratio and design method for stone columns using 2D FEA with equivalent strips. In: Proceedings of the 18th international conference on soil mechanics and geotechnical engineering, Paris, pp 2585–2588

Das AK, Deb K (2018) Experimental and 3D numerical study on time-dependent behavior of stone column-supported embankments. Int J Geomech (ASCE) 18(4):04018011-16. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001110

Acknowledgements

The authors would like to thank the Director, CSIR - Central Building Research Institute, Roorkee, for providing infrastructure and giving permission to publish this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, G., Samanta, M. Experimental evaluation of stress concentration ratio of soft soil reinforced with stone column. Innov. Infrastruct. Solut. 5, 18 (2020). https://doi.org/10.1007/s41062-020-0264-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-0264-6