Abstract

This study examines the use of pomegranate aqueous extract (PAE) for improvement of corrosion resistance of carbon steel (CS) in polluted NaCl solution (3.5% NaCl and 16 ppm Na2S). Mass loss, potentiodynamic polarization, electrochemical impedance spectroscopy, and electrochemical frequency modulation measurements were employed to study the corrosion behavior of CS in polluted NaCl solution. These electrochemical measurements improved that the presence of PAE decreased the corrosion rate, corrosion current densities (icorr), and double-layer capacities (Cdl). The inhibition efficiency (% IE) increases with the increase of extract concentration. The extract molecules were adsorbed physically on the metal surface following Temkin adsorption isotherm. The CS surface was analyzed by different techniques. The biological study of the extract on Escherichia coli activity showed that this extract can be applied safely without any harmful effect on the bacterial activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Corrosion is a fundamental process playing an important role in economy and safety, particularly for metals and alloys [1]. Various types of steel including CS are major construction material and are extensively used throughout industry (chemical and electrochemical industries, and food production), and also in everyday life. So, many natural products are used for analyzing antimicrobial [2], antifungal [3], etc., in several areas. Nowadays, need for growing corrosion inhibitors becomes increasingly necessary to stop or delay the attack of metals in the aggressive solutions. Corrosion inhibitors are substances which when added in small concentrations to corrosive media decrease or prevent the reaction of the metal with the media. Chloride and sulfide in aqueous media are particularly aggressive and accelerate corrosion [4]. Among numerous inhibitors that have been tested and applied industrially as corrosion inhibitors, those that are non-toxic or low-toxic are now far more strategic than in the recent past. Most of the effective inhibitors are used to contain heteroatom such as O, N, and S and multiple bonds in their molecules through which they are adsorbed on the metal surface. It has been observed that adsorption depends mainly on certain physicochemical properties of the inhibitor group, such as functional groups, electron density at donor atom, π-orbital character, and electronic structure of the molecule [5, 6]. Inhibitors are absorbed on the metal surface immersed in an aqueous phase replacing water molecules adsorbed on the surface. Electrostatic interaction between an inhibitor molecule and a metal is prominent during this action of inhibitors. Electron densities of different functional groups, polarizability, and electronegativity are the main factors in this interaction. There are several reviews on the use of plant extracts as corrosion inhibitors [7]. Recently, aqueous extract of Cocos nucifera—Coconut Palm—Petiole [8], Fennel (Foeniculum Vulgare) Essential [9], Cassia italica [10], Prosopis juliflora Plant [11] and Cinnamomum verum Leaf [12], paradisiac peels L [13], Ruellia tuberosa [14], Praziquantel [15] Cinnamomum verum Leaf [16], Hibiscus rosa-sinensis [17], Spirulina powder [18], Daucus carota [19] were used as eco-friendly corrosion inhibitors.

The aim of this work is to study (i) the inhibitive effect of PAE (which is non-expensive, ecologically friendly acceptable and possess no threat to the environment) on the CS in polluted NaCl solution, (ii) the effect of temperature on the % IE of the extract (iii) the morphology of the protective film formed on the CS by scan (SEM) and energy dispersive X-ray (EDX) and (iv) the biological effect of PAE on the bacterial activity.

2 Experimental Work

2.1 Samples Preparation

The material used is CS was provided from Talkha sanitation plant, Egypt. The chemical composition (weight%) is 0.21 C, 0.004 Si, 0.36 Mn, 0.25 P, and the remainder is Fe.

2.2 Preparation of the Extract

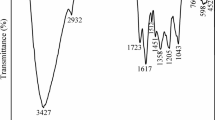

The extract used in this work is an aqueous plant extract of Pomegranate fruit (PAE). The used part is the leaves of Pomegranate fruit tree. The samples were picked from the trees of the Pomegranate and ground into a fine powder to give 500 g of powdered materials, a known quantity of the material was soxholated using double distilled water. Finally, the extract was dried, weighed, and preserved at 4 °C and used when required.

2.3 Preparation of Bacterial Agriculture Media

50 g of the medium was suspended in 1 L of distilled water and was dissolved by heating. And it was sterilized in autoclave at 121 °C for 15 min, cooled to 45–50 °C, mixed well, and dispensed into plates. The plates were allowed to solidify. The prepared medium was maintained at 8–15 °C. The color is violet-red.

2.4 Preparation of Corrosive Environment

The aggressive solutions of 3.5% NaCl and 16 ppm Na2S were prepared by dissolving the required amount of salts in double distilled water. All chemicals were analytical-grade reagents. The experiments were carried out under non-stirred and naturally aerated conditions. The addition of the extract did not change the pH of the aggressive media. For each set of experiment, freshly prepared polluted NaCl solutions were used to avoid effect of any contamination.

2.5 Electrochemical Procedure

Before the ML measurements, the seven samples of 2 × 2 × 0.1 cm as a dimension were polished using emery papers with different grits, followed by washing with ethanol and double distilled water, then immersed (complete immersion) in 100 mL of deaerated electrolyte in the absence and presence of different concentrations of PAE. To study the corrosion protection ability of the plant extract, the newest devices in recent years are used. The sheets were welded with Cu wire for electrical connection and mounted into glass tubes of appropriate diameter using Araldite to offer an active surface of (1 cm2) geometric area to contact the test solution. Prior to each experiment, these sheets were abraded as in ML tests, washed with double distilled water, degreased with ethanol, and then dried. A conventional electrochemical cell of capacity 100 mL was used containing three compartments for working, Pt foil counter (1 cm2), and saturated calomel electrode (SCE) as reference electrode. The measurements were carried out in aerated non-stirred 3.5% NaCl with 16 ppm Na2S in the presence of various concentrations of the PAE, as environmentally friendly corrosion inhibitor. For each run, a freshly prepared solution as well as a cleaned set of electrodes was used. Each run was carried out in aerated stagnant solutions at the required temperature, using a water thermostat.

The PP curves were carried out at a scan rate of 1 mVs−1 starting from − 1.7 V up to − 0.1 V (SCE). Before polarization, the open-circuit potential of the working electrode was measured as a function of time during 30 min, the time necessary to reach a quasi-stationary value for the open-circuit potential.

EIS measurements were carried out using AC signals of amplitude 5 mV peak to peak at the open-circuit potential in the frequency range 100 kHz and 0.2 Hz. All impedance measurements were recorded at open-circuit potential (OCP). EFM was carried out using two frequencies 2 and 5 Hz. The base frequency was 0.1 Hz, so the waveform repeats after 1 s. The larger peaks were used to calculate the corrosion current density (icorr), the Tafel slopes (βc and βa), and the causality factors CF-2&CF-3 [20, 21].

All electrochemical experiments were carried out using Potentiostat/Galvanostat/Zra analyzer (Gamry PCI300/4). A personal computer with DC105 software for polarization, EIS300 software for EIS, EFM140 software for EFM, and Echem Analyst 5.21 was used for data fitting and calculating.

2.6 Surface Morphology

The scanning electron microscopy (SEM) model JSM-6390AL was used to examine the specimen surface before and after immersion in corrosive media. Meanwhile, the energy dispersive spectrometer (EDX) was used to analyze the elements present on the specimens.

3 Results and Discussion

3.1 Mass Loss (ML) Measurements

ML measurement is a non-electrochemical technique for the determination of corrosion rates and inhibitor efficiency which provide more reliable results than electrochemical technique because the experimental conditions are approached in a more realistic manner yet the immersions testes are time-consuming [22]. Therefore, due to such differences (experimental condition), the values would obviously differ from the electrochemical values. The corrosion rates of carbon steel in 3.5% NaCl and 16 ppm Na2S at various concentration of PAE was determined after 3 h of immersion from 25 to 40 °C are presented in Table 1 and Fig. 1a–d give the weight loss-time curves in the absence and presence of PAE at 25–40 °C. From the experimental data of the ML measurements, the % IE was calculated from Eq. (1):

where W1, W2 are the ML in uninhibited and inhibited of solution, respectively. From Table 1, it was revealed that as the concentration of the extract increased, the percentage of inhibition efficiency (%IE) of PAE was also increased (concentration-dependent) [23]. The optimum value of % IE was obtained at the concentration of 300 ppm about 93.3% inhibition. This indicates that the adsorption process between the adsorbate (extract) and the CS surface was efficiently achieved and led to the formation of a metal–inhibitor interaction. The surface coverage of the CS was also reduced upon the addition of PAE which indicates that the extract acts as a good corrosion inhibitor for CS in 3.5% NaCl and 16 ppm Na2S.

3.2 Thermodynamic Kinetics

The temperature effect on the corrosion parameter of CS with the addition of various concentration of PAE was studied by ML. When the temperature raises, the corrosion rate increases as shown in Table 1, and the %IE decreases which is represented in Fig. 2. This is due to the desorption of the adsorbed extract molecules on the metal surface with the increase in the temperature. This behavior showed that the adsorption of the extract molecules is physically on the metal surface. The rate of corrosion (CR) can be expressed by Arrhenius equation as follows:

where CR is the corrosion rate, E*a is the apparent activation energy, R is the universal gas constant, T is the absolute temperature, and A is the frequency factor. Figure 3 is Arrhenius plot [log CR against the reciprocal of temperature (1/T)] for CS in polluted NaCl solution in the absence and presence of different concentrations of PAE. Straight lines of high correlation coefficients were obtained. The values of Ea*were 8.5, 61.2 kJ mol−1 for the blank and in the presence of PAE, respectively. The increase in Ea* with the addition of extract indicates that the energy barrier for the corrosion reaction increases. It is also indicated that the whole process is controlled by surface reaction, since the Ea*of the corrosion process is over 20 kJ mol−1 [24]. Enthalpy and entropy of activation (ΔH*, ΔS*) are calculated from transition state theory using the following equation [25].

An alternative formulation of Arrhenius equation is

where h is the Planck’s constant and N is the Avogadro’s number. Figure 4 shows a plot of log CR/T as a function of 1/T for CR. Straight lines were obtained with a slope of − ΔH*/R and an intercept of ln R/Nh + ΔS*/R from which the values of ΔH* and ΔS* were calculated for the blank and PAE. The values of the ΔH* were 6.0 and 57.9 kJ mol−1 and the values of the ΔS* were − 271.1 − 120.3 J mol−1 K−1 for the blank and PAE, respectively. Since, the absolute values of ΔH* obtained from this study were lower than 41.9 kJ mol−1, this indicates physisorption [26]. The increase in the ΔH* in the presence of the extract means that the addition of PAE to the corrosive media increases the height of the energy barrier of the corrosion reaction to the inhibitor which depends on the concentration of the PAE.

3.3 Adsorption Kinetics

Adsorption isotherm is importance to explain the mechanism of corrosion inhibitor of organoelectrochemical reactions. Process of adsorption occurs when a liquid or gas accumulates on the surface of a solid or liquid, forming a molecular or atomic film. The most frequently used isotherm include Langmuir, Frumkin, Hill de Boer, Person, Temkin, Flory–Huggins, and recently formulated thermodynamic/kinetic model of El Awady et al. [27,28,29]. Adsorption of the organic molecules occurs as the interaction energy between the molecules and the metal surface is higher than between the H2O molecule and the metal surface. This was usually described through isotherms and corrosion inhibition of metals by organic compounds [30]. The adsorption of the inhibitors can be described by two main types of interaction: physical adsorption and chemisorptions [31,32,33,34,35]. The adsorption of corrosion inhibitor on a metal surface depends on the nature as well as the surface charge of the metal, the adsorption mode, its chemical structure, and the type of the electrolyte solution [36]. These are influenced by the chemical structure of the inhibitor, the type of the electrolyte, and the charge and nature of the metal. The surface coverage Ɵ of the metal surface by the adsorbed inhibitor was calculated assuming no change in mechanism of the cathodic reaction using the following equation:

where ifree, iinh are the currents densities in the absence and presence of the extract, respectively. The θ values for different extract concentrations at different temperatures were tested by fitting to various isotherms. By far the best fit was obtained with the Temkin isotherm:

where a is the heterogeneity factor, C is the concentration of the extract, and Kads is the adsorption equilibrium constant, which is related to the standard free energy of adsorption (ΔGoads) by the following equation:

where 55.5 is the concentration of water in mol/L in the bulk of solution. The plot of surface coverage (Ɵ) as a function of logarithm of PAE concentration is shown in Fig. 5. From the plot, straight lines were obtained for PAE indicating that the experimental data fit well into Temkin adsorption isotherm. The Temkin isotherm characterizes the chemisorptions of uncharged molecules on heterogeneous surface [37]. The regression values (R2) are about 0.99 as shown in Table 2. The values of Kads decrease with increasing temperature, suggesting that the inhibitor is physically adsorbed on the CS surface. Generally, Kads denotes the strength between adsorbate and adsorbent. The ΔGºads values calculated from this plot were negative: this means spontaneous adsorption of the extract molecules on the surface of the CS. The enthalpy change of adsorption (ΔHºads) can be calculated according to the Van’t Hoff equation:

To calculate (ΔHºads), log Kads was plotted against 1000/T, and a straight line was obtained (Fig. 6). The absolute values of ΔHºads obtained in this study were lower than 100 kJ mol−1, this was indicative of physisorption, and supports the above mechanism of adsorption. The negative value of ΔHoads (− 41.2 kJ mol−1) in the presence of the extract reflects the exothermic nature of CS dissolution process. According to the basic equation,

The entropy of adsorption, ΔSoads was calculated. The negative values of entropies in the presence of this investigated extract indicates that a decreases in disordering takes place on going from reactants to the activated complex and the activated molecules were in higher order state than that at the initial state [38, 39].

The PAE components are adsorbed on the corroding site of metal surface, thus reducing the number of active sites involved in corrosion, which are found as represented in Eq. (9):

where Org(sol) and Org(ads) are the organic species dissolved in the aqueous solution and adsorbed onto the metallic surface, respectively. H2O(ads) is the water molecule adsorbed on the metallic surface and n is the size ratio representing the number of water molecules replaced by one organic adsorbate.

The adsorption of the extract on the metal surface leads to high degree of surface coverage and hence shows better inhibitive property.

3.4 PP Measurements

The nature of inhibition process has been established on the basis of polarization measurements; also it gives the mechanism of inhibition. The changes observed in the polarization curves after addition of the extract are usually used as criteria to classify inhibitors as cathodic, anodic, or mixed. Figure 7 shows the potentiodynamic anodic and cathodic polarization carried out at 25 °C in polluted NaCl solution in the absence and presence of different concentrations of the extract. From Fig. 7, it was seen that the Ecorr shifted towards more positive and negative directions upon the addition of PAE. These results indicate that PAE acts as a mixed-type inhibitor with predominant control of cathodic reaction [40]. This means that this natural product has significant effects on retarding the anodic dissolution of CS and inhibiting the cathodic hydrogen evolution reaction. From the result obtained in Table 3, the addition of the extract decreases the metal dissolution at the anode and the hydrogen evolution reaction at the cathode. Table 3 includes values of the corrosion potential (Ecorr), corrosion current density (icorr), Tafel slopes (βa and βc), and the %IE of the corrosion of CS at different concentrations of the extract. The values of icorr were estimated by Tafel extrapolation of cathodic and anodic curves to open-circuit corrosion potential. From this table, it can be concluded that (i) the icorr values decrease with the increase of the extract concentration, (ii) the change in βa from 507.6 to 348.9 mV dec−1 with the increase in extract concentration indicative to CS kinetics dissolution, (iii) the change in βc from − 320.8 to − 266.7 mV dec−1 with the increase in extract concentration indicating to the hydrogen evolution reaction [41], (iv) the IE of the extract increases with the increase of the extract concentration reaching to a maximum value 92.4% at 300 ppm, and (v) PAE is a mixed inhibitor but predominant cathodic effect. The values of % IE and the Ɵ at each concentration were calculated using the following equation [42, 43]

where icorr and icorr(inh) are the corrosion current densities of uninhibited and inhibited solution, respectively. An inspection of the results obtained from Table 3 revealed that, by increasing the extract concentration, the cathodic and anodic current densities decrease.

3.5 EIS Measurements

Impedance measurements provide information on both the resistive and capacitive behaviors of the interface, evaluation on the performance of studied extract as possible corrosion inhibitor, and investigation of the corrosion inhibition processes. More information about the corrosion behavior of CS, in polluted NaCl solution with and without PAE may be get using EIS measurements. The charge transfer resistance (Rct) values are calculated from the difference in impedance at lower and higher frequencies, as suggested by Tsuru et al. [44]. The double-layer capacitance (Cdl) and the frequency at which the imaginary component of the impedance is maximal (− Zmax) are found as represented in the following equation:

where fmax is maximum frequency at which the imaginary component of the impedance (Zim) is maximum at Rt is diameter of the loop. The IE got from the charge transfer resistance is calculated by

where Rct(free) and Rct(inh) are the charge transfer resistance values without and with extract, respectively.

Figure 8 showed that the addition of PAE enhances the values of Rct in polluted NaCl solution reaching to 89.7% at 300 ppm, which does not change the impedance shape. The Nyquist plots at Fig. 8 were not perfect semicircles as expected from the theory of EIS, that it represents a general behavior where the double layer on the interface of metal/solution does not behave as a real capacitor. Results listed in Table 4 showed that the charge transfer resistance, Rct, values increased and the capacitance values Cdl decreased with increasing extract concentration. Decreasing in the capacitance, which can result from a decrease in local dielectric constant and/or an increase in the thickness of the electrical double layer, suggested that the extract molecules acted by adsorption at the metal/solution interface. The addition of the extract resulted in lower Cdl value, which could be a consequence of the replacement of water molecules by extract molecules at the electrode surface. The extract molecules may also reduce the capacitance by increasing the double-layer thickness [45]. The EIS data were simulated using equivalent electric circuits as shown in Fig. 9 where RS represents the solution or electrolyte resistance, Cdl the double-layer capacitance, and Rct the charge transfer resistance.

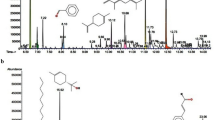

3.6 EFM Measurements

As the corrosion process is non-linear in nature, a potential perturbation by one or more sine wave will generate responses at more frequencies than the frequencies of the applied signal. Current responses can be measured at zero, harmonic, and intermodulation frequencies. Intermodulation spectra obtained from EFM measurements are presented in Fig. 10a, b as examples of CS in polluted NaCl solution and containing 300 ppm of PAE at 25 °C. Each spectrum is a current response as a function of frequency. With the addition of PAE at different concentrations in polluted NaCl solution, the corrosion kinetic parameters are calculated and listed in Table 5 at 25 °C giving the values of icorr, βc, βa, CF-2, CF-3, and %IE. From Table 5 we found that by the increase in extract concentration, the icorr decreases and the IE increases. Values of causality factors in Table 5 indicate that the measured data are of good quality [46]. The standard values for CF-2 and CF-3 are 2.0 and 3.0, respectively. The obtained results showed good agreement of IE obtained from the WL, PP, EIS, and EFM methods.

3.7 Surface Characterization

The surface morphology of CS in polluted NaCl solution in the absence and presence of PAE at 300 ppm concentration was studied using SEM (Fig. 11a–c). Figure 11a represents the image of pure CS surface and Fig. 11b represents the image of CS immersed in the corrosive solution for 24 h only, the surface was strongly damaged and the metal surface disappears. Figure 11c represents the image of CS in the presence of 300 ppm of PAE; the surface is almost free from damage and smooth due to the adsorption of extract molecules on the metal surface protecting it from the corrosive media. Figure 12a–c represents the EDX in the absence and presence of PAE. Figure 12a gives the EDX of CS surface giving the peaks of the metal constituent. Figure 12b gives the EDX of CS in the corrosive media, and represents its characteristic peaks indicating that the corrosion taking place on the metal surface forming oxide film which is porous does damage to the surface. Figure 12c is the EDX of CS surface with 300 ppm of PAE, giving its characteristic peaks with low concentration of Fe than in Fig. 12b and increasing of oxygen atoms of the extract. This indicates that the extract molecules almost cover the metal surface occupying all active sites on the metal surface protecting it from the corrosive media. This result proved that the adsorption of the extract molecules on the metal surface lead to decrease of metal oxide layer, and higher concentration of the extract is necessary to delay the corrosion process.

3.8 Biological Effect of PAE on Escherichia coli

From the bacterial agriculture of Escherichia coli in the absence and presence of PAE, we found almost no effect on the bacterial activity of E. coli according to Table 6 and Fig. 13. PAE components have oxygen donors atom, and it thought that it attached with the proteins and lipids of the bacterial tissues helping on its respiration process. So, this inhibitor has no toxicity on the bacterial activity, and can be applied safely on the sanitation plants without any problems in the treating operations.

3.9 Mechanism of Corrosion and Inhibitor Performance

The possible explanation of the inhibition is due to adsorption process which is considered as the key mechanism of inhibition action. It might be suggested that the inhibitor molecules adhere to the steel surface. This leads to a decrease of the surface area at which cathodic and anodic reactions take place. IE of the inhibitor compound depends on many factors [47], which include the number of adsorption active centers in the molecule and their charge density, molecular size, and mode of interaction with metal surface [48]. The iron metal/solution interface from a state of active dissolution to the passive state of great interest. The inhibition effect by extract is attributed to the adsorption of the extract molecules. Pomegranate is a rich source of tannins, flavonoids, and other phenolic compounds [49] via their functional group onto the metal surface, that extract can be adsorbed in the form of positively charged species (due to its protonation in acid medium) on the metal surface which can interact electrostatically with negatively charged CS surface (CS surface is positively charged in acid medium but Cl− ions get adsorbed on it making it negatively charged), leading to increase in the surface coverage and consequently protect efficiency controlling the anodic metal dissolution and cathodic hydrogen evolution. The adsorption rate is usually rapid and hence the reactive metal is shielded from the aggressive environment. The proposed inhibition model is shown in Fig. 14. Table 7 shows the numerous studies for various plant extracts in acid medium for different metals (% IE is reported at the maximum). This confirms why we use this plant extract as corrosion inhibitors for steel in the used corrosive solution.

4 Conclusions

According to the obtained results, the following conclusions can be drawn:

PAE acts as an inhibitor for the corrosion of CS in polluted NaCl solution. The IE increases with increase in the concentration of the extract, and this is due to the adsorption of the extract molecules on the metal surface by charge transfer or by the diffusion of the extract molecules. The adsorption of PAE on the metal surface follows Temkin’s adsorption isotherm. The − ΔGoads of adsorption indicates strong and spontaneous adsorption of PAE on the metal surface. Values of Tafel constant (βa and βc) confirm that the extract is a mixed type but predominant cathodic effect. The IE determined by different methods was in reasonable good agreement. Thus, PAE was proved to be an effective eco-friendly and low cost inhibitor. This extract has no effect on the biological activity of E. coli, and can be applied safely on sanitation plants.

References

El-Sayed A, Mohran HS, Abd El-Lateef HM (2012) Efficient complex surfactants from the type of fatty acids as corrosion inhibitors for mild steel C1018 in CO2-environments. J Korean Chem Soc 51(1):25–34

Mangale Sapana M, Chonde Sonal G, Raut PD (2012) Use of Moringa oleifera (Drumstick) seed as natural adsorbent and an antimicrobial agent for ground water treatment. Res J Recent Sci 1(3):31–40

Philippe S, Souabou F, Paulin A, Issaka Y, Dominique S (2012) In vitro antifungal activities of essential oils extracted from fresh leaves of Cinnamomum zeylanicum and Ocimum gratissimum against foodborne pathogens for their use as Traditional Cheese Wagashi conservatives. Res J Recent Sci 1(9):67–73

Trabanelli G (1991) Inhibition effect of potassium iodide on the corrosion of carbon steel (XC 38) in acidic medium. J Mater Environ Sci 47:410–419

Rahiman AF, Sethumanickam S (2017) Corrosion inhibition, adsorption and thermodynamic properties of poly (vinyl alcoholcysteine) in molar HCl. Arab J Chem 10:S3358–S3366

Loto RT, Loto CA, Joseph O, Olanrewaju G (2016) Adsorption and corrosion inhibition properties of thiocarbanilide on the electrochemical behavior of high carbon steel in dilute acid solutions. Results Phys 6:305–314

Sangeetha M, Rajendran S, Muthumegala TS, Krishnaveni A (2011) Green corrosion inhibitors-an overview, asafoetida extract (ASF) as green corrosion inhibitor for mild steel in sea water. Zastita Mater 52:3–19

Vijayalakshmi PR, Rajalakshmi R, Subhashini S (2011) Corrosion inhibition of aqueous extract of Cocos nucifera—coconut palm—petiole extract form destructive distillation for the corrosion of mild steel in acidic medium. Port Electrochim Acta 29(1):9–21

Lahhit N, Bouyanzer A, Desjobert JM (2010) fennel (foeniculum vulgare) essential oil as green corrosion inhibitor of carbon steel in hydrochloric acid solution. Port Electrochim Acta 29(2):127–138

Fouda AS, Al-Zehry H, Elsayed M (2018) Synergistic effect of potassium iodide with Cassia italica extract on the corrosion inhibition of carbon steel used in cooling water systems in 0.5 M H2SO4. J Bio Tribo Corros 4:1–17

Fouda AS, ElAwady GY, El Behairy WT (2018) Prosopis julifora plant extract as potential corrosion inhibitor for low carbon steel in 1 M HCl solution. J Bio Tribo Corros 4:1–12

Anupama KK, Joseph A (2018) Experimental and theoretical studies on Cinnamomum verum leaf extract and one of its major components, eugenol as environmentally benign corrosion inhibitors for mild steel in acid media. J Bio Tribo Corros 4:1–14

Tiwari P, Srivastava M, Mishra R, Ji G Prakash R (2018) Economic use of waste Musa paradisica peels for effective control of mild steel loss in aggressive acid solutions. J Environ Chem Eng 6:4773–4783

Kathiravan S, Ragul R, Raja G, Ravichandran J (2018) Theoretical and experimental studies about the inhibitive action of Ruellia tuberosa L on mild steel in hcl medium. J Bio Tribo Corros 4:46

Praveen BM, Prasanna BM, Narayana H, Kumar PS, Jagadeesh MR (2018) Experimental and Theoretical studies on inhibition efect of the Praziquantel on mild steel corrosion in 1 M HCl. J Bio Tribo Corros 4:21

Anupama KK, Joseph A (2018) Experimental and theoretical studies on Cinnamomum verum leaf extract and one of its major components, eugenol as environmentally benign corrosion inhibitors for mild steel in acid media. J Bio Tribo Corros 4:30

Rajendran S, Jeyasundari J, Selvi JA, Narayanasamy B, Regis APP, Rengan P (2009) Corrosion behaviour of aluminium in the presence of an aqueous extract of Hibiscus rosa-sinensis”. Port Electrochim Acta 27(2):153–164

Rajendran S, Paulraj J, Rengan P, Jeyasunbdari J, Manivannan M (2009) Corrosion behaviour of metals in artificial saliva in presence of spirulina powder”. J Dent Oral Hyg 1(1):1–8

Sirbharathy V, Rajendran S, Sathyabama J (2011) Inhibition of mild steel corrosion sea water by “DAUCUS CAROTA”. Int J Chem Sci Technol 1(3):108–115

Abdel-Rehim SS, Khaled KF, Abd-Elshafi NS (2006) Chemical and electrochemical investigations of l-arginine as corrosion inhibitor for steel in hydrochloric acid solutions. Electrochim Acta 51:3269–3277

Bosch RW, Hubrecht J, Bogaerts WF, Syrett BC (2001) Corrosion behaviour of some low chromium-molybdenum steels in sulphamic acid, electrochemical technique for online corrosion monitoring. Corrosion 57:60–70

Hussin MH, Kassim MJ (2011) The corrosion inhibition and adsorption behavior of Uncaria gambir extract on mild steel in 1 M HCl. Mater Chem Phys 125:461–468

Bentiss F, Traisnel M, Chaibi N, Mernari B, Vezin H, Lagrenee M (2002) 2,5-Bis(n-methoxyphenyl)-1,3,4-oxadizoles used as corrosion inhibitors in acidic media correlation between inhibition efficiency and chemical structure. Corros Sci 44:2271–2289

Fils J, Zakroczymski T (2012) Role of some phenylthiourea derivatives as corrosion inhibitors for carbon steel in HCl solution. J Korean Chem Soc 56(2):264–273

Fouda AS, Al-Sarawy AA, Ahmed FS, El-Addasy HM (2011) Effect of β-blocker inhibitors on aluminum corrosion. J Korean Chem Soc 55(2):268–278

Umoren SA, Eduok UM, Solomon MM, Udoh AP (2012) Corrosion inhibition and adsorption behaviour of Cocos nucifera L. coir dust for mild steel in 1 M HCl: synergistic effect of iodide ions. Int J Adv Sci Technol Res 1(2):338–360

Kamis E (1990) The effect of temperature on the acidic dissolution of steel in the presence of inhibitors corrosion. Int J Adv Sci Technol Res 46:476–484

El-Rehim SS, Ibrahim MAM, Khaled KF (1999) 4-Aminoantipyrine as an inhibitor of mild steel corrosion in HCl solution. J Appl Electrochem 29:593–599

Bataineh TT, Al-Qudah MA, Nawafleh EM, Al-Rawashdeh NAF (2014) Sinapis Alba extract as green corrosion inhibitor for aluminum in alkaline media. Int J Electrochem Sci 9:3543–3557

Maayta AK, Al-Rawashdeh NAF (2004) Inhibition of acidic corrosion of pure aluminum by some organic compounds. Corros Sci 46:1129–1140

Khadraoui A, Khelifa A, Boutoumi H, Hamitouche H, Mehdaoui R, Hammouti B, Al-Deyab SS (2014) Adsorption and inhibitive properties of Ruta chalepensis L. oil as a green inhibitor of steel in 1 M hydrochloric acid medium. Int J Electrochem Sci 9:3334–3348

Fouda AS, El-desoky AM, Ead DM (2013) Anhydride derivatives as corrosion inhibitors for carbon steel in hydrochloric acid solutions. Int J Electrochem Sci 8:8823–8847

Benali O, Ouazene M (2013) Inhibition effect of 3-bromo-2-phenylimidazol [1,2- α]pyridine towards C38 steel corrosion in 0.5M H2SO4 solution. Arab J Chem 4:443–448

Larabi L, Benali O, Harek Y (2007) Inhibition effect of 3-bromo-2 phenylimidazol[1,2- α] pyridine towards C38 steel corrosion in 0.5M H2SO4 solution. Mater Lett 61:3287–3291

Larabi L, Harek Y, Benali O, Ghalem S (2005) Application of some oligopolymers as effective corrosion inhibitors for mild steel in 1 M HCl: gravimetric, thermodynamic and electrochemical analysis. Prog Org Coat 54:256–262

Sherif EM, Erasmus RM, Comins JD (2006) Corrosion of copper in aerated acidic pickling solutions and its inhibition by 3-amino-1,2,4-triazole-5-thiol. Colloid Int Sci 306:96–104

Umoren SA, Solomon MM (2013) Kinetics of corrosion inhibition of aluminum in acidic media by water-soluble natural polymeric pectates as anionic polyelectrolyte inhibitors. Materials 6:2436–2451

Fouda AS, El-Desoky AM, Diab MA, Soliman AH (2014) Corrosion protection of carbon steel in hydrochloric acid solutions using heterocyclic compounds. Int J Adv Res 2(3):606–628

Abd El-Rehim SS, Refaey SA, Taha F, Saleh MB, Ahmed RA (2001) Inhibition of low carbon steel pipes of heat exchangers in industrial water medium by some plants extract. J Appl Electrochem 31:429–435

Gao B, Zhang X, Sheng Y (2008) Studies on preparing and corrosion inhibition behaviour of quanternized polyethyleneimine for low carbon steel in sulfuric acid. Mater Chem Phys 108:375–381

Benali O, Larabi L, Mekelleche SM, Harek Y (2006) Corrosion inhibition of mild steel by 4-Allyl-5-pyridin-4-yl-4H-1,2,4-triazole-3-thiol. J Mater Sci 41:7064–7073

Ammar IA, Darwish S (2011) Thermodynamic and quantum chemistry study for dimethylol-5-methyl hydantoin and its derivatives as corrosion inhibitors for carbon steel N-80 in raw water (cooling water system). J Mater Environ Sci 2(2):128–147

Fouda AS, Eldesoky AM, Elmorsi MA, El Sheik MY, El Said IA (2014) Benzamide, acetamide and acrylamide as corrosion inhibitors for carbon steel in hydrochloric acid solutions. Int J Adv Res 2(2):4–24

Tsuru T, Haruyama S, Gijutsu B (1978) Corrosion inhibition performance of 3,5-diamino-1,2,4-triazole for protection of copper in nitric acid solution. J Jpn Soc Corros Eng 27:573–581

Bentiss F, Lagrenee M, Traisnel M, Hornez JC (2003) The inhibition of benzimidazole derivatives on corrosion of iron in 1 M HCl solutions. Electrchim Acta 48:2493–/2503

Ramachandran S, Tsai M, Blanco M, Chen H, Tang WA (2003) Langmuir, molecular simulation, quantum chemical calculations and electrochemical studies for inhibition of mild steel by triazoles. Electrochim Acta 53:3484–3492

Avci G (2008) The inhibition of mild steel corrosion in 1 N HCl by imidazole derivatives. Colloid Surf A 317:730–736

Fouda AS, Abdallah M, Ahmed IS, Eissa M (2014) Corrosion inhibition of aluminum in NaOH solutions using some bidentate azo dyes compounds and synergistic action with some metal ions. Int J Electrochem Sci 9:4747–4760

Li Y, Guo C, Yang J, Wei J, Xu J, Cheng S (2006) Evaluation of antioxidant properties of Pomegranate extract in comparison with pomegranate pulp extract. Food Chem 96:254–260

Saleh RM, Ismail AA, El Hosary AA (1982) Corrosion inhibition by naturally occurring substances: VII. The effect of aqueous extracts of some leaves and fruit-peels on the corrosion of steel, Al, Zn and Cu in acids. Br Corros J 17(3):131–135

Shah AM, Rahim AA, Hamid SA, Yahya S (2013) Green inhibitors for copper corrosion by mangrove tannin. Int J Electrochem Sci 8:2140–2153

Anuradha K, Vimala R, Narayanasamy B, Selvi JA, Susai R (2007) Corrosion inhibition of carbon steel in low chloride media by an aqueous extract of hibiscus Rosa sinensis Linn. Chem Eng Commun 195(3):352–366

Sangeetha M, Rajendran S, Sathiyabama J, Prabhakar P (2012) Eco friendly extract of Banana peel as corrosion inhibitor for carbon steel in sea water. J Nat Prod Plant Resour 2(5):601–610

Abd-El-Nabey BA, El-Housseiny S, El-Naggar GA, Matter EA, Esmail G (2015) Inhibitive action of Alhagi maurorum plant extract on the corrosion of copper in 0.5 M H2SO4. Phys Chem 5(3):49–62

Deyab MA (2015) Egyptian licorice extract as a green corrosion inhibitor for copper in hydrochloric acid solution. J Ind Eng Chem 22:384–389

Flores-De los Ríos JP, Sánchez-Carrillo M, Nava-Dino CG, Chacón-Nava JG, González Rodríguez Z, Huape-Padilla E, Neri-Flores MA, Martínez-Villafañe A (2015) Opuntia ficusindica extract as green corrosion inhibitor for carbon steel in 1 M HCl solution. J. Spectroscopy 2015:14692–14701

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fouda, A.S., Eissa, M. & Fakih, M. Pomegranate Aqueous Extract (PAE) as an Eco-Friendly Inhibitor for Carbon Steel Used in Sanitation Plants: Kinetics and Bacteria Effect. J Bio Tribo Corros 5, 5 (2019). https://doi.org/10.1007/s40735-018-0197-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0197-1