Abstract

The behavior of soil reinforced with barley straw fibers was investigated in the current study. Several static triaxial tests were performed to assess the mechanical behavior of Babolsar sand reinforced with randomly positioned barley straw fibers. The soil was supplemented with fibers that ranged in length from 6 to 12 mm at 0%, 0.3, 0.6, and 0.9% by dry weight. In static triaxial testing, confining pressures of 50, 100, and 200 kPa were used. The examination of sand reinforced with barley straw showed that fibers increased the sand’s shear strength, yield strain, and stiffness. The findings showed that adding fiber increased the soil’s peak strength. However, this strength improvement was minor for weight percentages of 0.3 and much larger for weight percentages of 0.6 and 0.9. According to the results, adding fibers at a weight ratio of 0.9% might increase the soil’s peak strength by as much as 60%. Additionally, the failure strain was increased with the addition of barley straw fibers compared to unreinforced soil. It is important to note that the internal friction angle of unreinforced soil was 43 degrees. This number equated to 51 degrees when 0.9% fiber was added to the soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Building on weak or soft soil involves very high risk since it is vulnerable to asymmetric settlements due to insufficient shear strength and excessive compressibility (Htut et al. 2019; Esker and Buscetin 2022). Increments in bearing capacity, shear strength, and soil permeability characteristics can be achieved in several ways; one of these methods is to strengthen the soil with discrete fibers dispersed randomly (Zhang and Russell 2021). The addition of discrete flexible fibers, which mimic the activity of plant roots, increases the strength and stability of soil layers close to the ground (Vafaei et al. 2022a). Engineers employ this technique for many geotechnical engineering tasks including stabilizing thin soil layers, fixing slope failures, hardening the soil surrounding foundations, defending buildings, and improving road foundations (Choobbasti et al. 2015).

The use of natural and synthetic fibers and the addition of discrete elements with random distribution are physical methods for improving soil performance (Sahin et al. 2021). The results show that boosting the fiber content mostly enhances the soil’s shear strength (Kutanaei et al. 2022). Studies have also shown that the strength and stress-strain properties of reinforced soils with a random distribution of fibers are influenced by the soil and soil type and by the amount and level of fiber friction (Vafaei et al. 2022b).

For the construction of stabilized pavement bases, canal linings, and support layers for shallow foundations, the enhancement of local soils with fibers and cement offers significant economic and environmental benefits by eliminating the need for a spoiled area and the need to borrow materials from somewhere else. In earlier studies, the shear strength of synthetically cementing sandy soil was examined (Choobbasti et al. 2018). According to the literature, cement increases maximum shear strength and dilatation. Additionally, by raising the confining pressure, soil cement’s stiff nature is transformed into one that is more flexible (Choobbasti et al. 2015). Materials such as cement sand are simply mixed with fibers at random. Fibers placed at random produce increased isotropic strength (Ghadakpour et al. 2021).

Numerous experts have studied the behavior of reinforced soil in recent years. Application areas for reinforced soil include creating embankments, strengthening the substrate, and minimizing cracks brought on by clay soil shrinkage and swelling (Turk and Nehdi 2021). The use of discrete fibers to improve the engineering properties of soils is something that many specialists from all around the world are interested in. To use these strategies in geotechnical work and better understand their benefits and disadvantages, more research is required. Several researchers performed numerous triaxial, unconfined, CBR, direct shear, flexural, and tensile strength experiments on reinforced soil samples. The results of this research demonstrate that the addition of discrete fibers with a random distribution improves the soil’s strength properties and changes its behavior from brittle to more flexible (Karimzadeh et al. 2022). The following section includes a few laboratory experiments in this area.

The impact of short polymeric fibers on crack development was examined by Ziegler et al. (1998). According to the test results, the fibers were successful in minimizing the amount of desiccation cracking that developed in clays that were dried. The presence of fibers improved the clay’s tensile strength and gave it a ductile behavior that was missing from the samples without fibers. Gray and Ohashi (1983) showed that discrete fiber reinforcement of soil increased peak shear strength while reducing the drop-in strength after the peak strength based on the results of direct shear studies. The number of fibers, their length, and their modulus are factors affecting the increase in strength. During their examination, they did not notice any stiffening of the soil-fiber mixture. Gray and Al-Refeai (1986) discovered that discrete fibers with random distribution increased ultimate strength but decreased compressive stiffness at low strains (less than 1%) in triaxial testing on reinforced sand. They also showed that fiber reinforcement increases the axial strain at failure and generally reduces the loss of residual strength.

Kumar et al. (2006) looked at the connection between soil particle size and fiber strength. They found that fiber bonds in finer sands were far stronger than those in coarser sands, making them less likely to collapse in slippery situations. Furthermore, based on the triaxial experiment and static analysis, Yetimoglu and Salbas (2003) concluded that the presence of fibers boosts shear strength and decreases the reduction in residual strength. In direct shear testing, Nataraj and McManis (1997) found that the polypropylene fibers improved the angle of friction and cohesion and that the reinforced clay’s shear strength envelope was slightly nonlinear. Additionally, they found that the equivalent friction angle is a little bit larger for low confining pressures compared to higher confining pressures.

According to these studies, fiber insertion enhances the sand’s maximum shear strength and results in a more ductile behavior. To investigate the effects of effective stress (30, 60, 100, and 200 kPa), fiber content (polypropylene), and fiber length on the mechanical behavior of fiber-reinforced soil, Diambra et al. (2010) used consolidated drained triaxial compression and extension. They concluded that as confining pressure, fiber content, and length increase and behavior becomes more ductile, the strain at failure increases. The samples containing 0.3%, 0.6%, and 0.9% of fiber had relative improvements in internal friction angles of 9%, 18%, and 30%, respectively. In undrained ring shear experiments, Liu et al. (2011) looked into the static liquefaction resistance of saturated sand reinforced with polypropylene fibers. The findings demonstrated that the liquefaction potential was greatly decreased by the addition of fibers. The residual shear strength of the loose sample significantly rises with the addition of fiber (72%, 100%, 71%, and 70% for 0.2%, 0.4%, 0.6%, and 0.8% of fiber, respectively).

Gao and Zhao (2013) investigated how fiber orientation impacted the behavior of fiber-reinforced sand. The findings demonstrated that horizontally oriented fibers considerably improved the triaxial test’s shear strength characteristics. Shao et al. (2014) performed a series of ring shear experiments under various normal pressures to evaluate the shear strength of Mississippi sands reinforced with polypropylene fiber. They claimed that the inclusion of fiber significantly affected the sand’s shear strength measurements. Cohesion and the internal friction angle both grew by 700% and 32%, respectively. On fiber-reinforced cemented soil, Maher and Gray (1990) conducted static and dynamic triaxial compression and extension investigations. Fibers enhanced the material’s shear strength and energy absorption, according to their research. Peak shear strength rises by 100 and 200% for fiber concentrations of 0.2% and 3%, respectively.

Polypropylene (PP) and polyester (PE) fibers’ effects on the mechanical characteristics of soils stabilized with cement were examined by Consoli et al. (2004). They discovered that while the deviatoric stresses at failure were only marginally reduced, the addition of polypropylene fiber greatly enhanced the brittle behavior of cement-stabilized soils. Additionally, the initial stiffness of the samples barely changed when PE fiber was added. However, it significantly decreased when PP fiber was included. Triaxial compression experiments were utilized by Consoli et al. (2010) to investigate the effects of polypropylene fiber reinforcement on the mechanical characteristics of sand. Based on fiber concentration, cement content, and confining stress, they suggested polynomial equations to calculate residual and peak strength.

In order to develop an empirical equation for the prediction of the mechanical behavior of polypropylene fiber–reinforced cemented sandy soil, Kutanaei and Choobbasti (2015) conducted several unconfined compression experiments. Unconfined compression experiments were carried out by Yaghoubi et al. (2018) to examine the effects of cement and waste tire fiber addition on the mechanical properties of sand. They discovered that supplementing cemented sand with 3% residual tire fiber boosted the unconfined compression strength by more than 25%.

Silveria et al. (2022) evaluated the effect of silica and polymer on the mechanical behavior of a sand matrix reinforced with the aforementioned fibers. Because sisal fibers offered shear strength capabilities that were superior to those of unreinforced soil, their study’s results justified the long-term use of sisal fibers in engineering projects like temporary landfills. Zhou et al. (2022) looked into the liquefaction resistance of calcareous sands reinforced with polypropylene fibers. The findings demonstrated that calcareous sands’ liquefaction resistance was raised along with their deformation and pore pressure accumulation rates by increasing fiber content and fiber length. When the fiber concentration was greater than 0.8 percent, the likelihood of soil liquefaction may also be decreased.

Zhang et al. (2021) investigated the pore water pressure accumulation laws in sand reinforced with randomly scattered fibers using cyclic triaxial compression testing. Relative density, the ratio of cyclic stresses, fiber content, and fiber length were all studied for their impacts. According to the test results, randomly dispersing fibers throughout the sand effectively delayed the pore water pressure’s growth and markedly boosted liquefaction resistance. In the work by Vakili et al. (2022), lignosulfonate was used as a binder and polypropylene (PP) fiber as a reinforcing material to protect the features of marl soils from the detrimental effects of freeze-thaw (F-T) cycles. The stress-strain pattern of the samples changed from strain-softening to hardening behavior as a result while simultaneously enhancing ductility behavior. This process of weathering is called freeze-thaw. The application of lignosulfonate and PP fibers at the same time was found to bind soil particles and create interlocking zones around the fiber strands, enhancing particle bonding. The findings of the Fourier transform infrared (FTIR) experiment also lent credence to the idea that the lignosulfonate contained in the marl soil and the voids between its mineral layers were what ultimately led to the creation of ionic connections.

Natural fibers have drawn a lot of interest as reinforcing components because of their high tensile strength, widespread availability in regions where they are made from native plants, and advantages to the environment when natural materials are substituted with synthetic materials (Tang et al. 2012). Annual barley straw plants can reach heights of 1.5 to 3.5 m. Barley straw stems are 1–2 cm in diameter and have a woody base. In addition to it, Iran is one of several places in the globe where fiber is grown. The manufacturing of biodegradable polymers, textiles, paper, building materials, and biofuels are just a few businesses that use barley straw fibers. Barley straw fiber was subjected to a full year of exposure to a natural weathering environment (Akil et al. 2011). The following are the main advantages of using barley straw fibers over other types of fibers, according to Akil et al. (2011): low cost, low energy use, the strongest natural fiber available, and biodegradability.

The fact that natural fibers, like barley straw fiber, have gotten relatively little attention when all of the scenarios presented here are taken into account is noteworthy and extremely helpful, and as a result, the present paper thoroughly discusses the behavior of reinforced soil with barley straw fiber. It is crucial to note that this study focuses especially on various fiber contents. Another interesting feature is that, due to the accessibility and availability of barley straw fibers, a thorough examination of the behavior of sand reinforced with this sort of fiber is urgently needed. The foundations of buildings in the village, for example, can be strengthened because this type of fiber provides the benefits mentioned above and is less expensive than synthetic fibers.

The main objective of this study is to investigate the effects of reinforcement on metrics for peak strength, sample stiffness, stress-strain behavior, volumetric behavior, and shear strength. Studies on fiber-reinforced sand have been done thus far, even though natural fibers and barley straw fiber have received less attention. The mechanical behavior of Babolsar sand reinforced with barley straw fiber is the subject of this study’s extremely in-depth and broad experimental research. The study’s innovation and novelty is the evaluation of natural fiber through the execution of very thorough experimental procedures. To specifically examine the impacts of the expressed parameters, notably the volumetric strain for natural fibers like barley straw fiber, a static triaxial test was employed in this study.

2 Experimental Program

In this study, several triaxial experiments (CD tests) on Babolsar sand reinforced with natural fibers were conducted in order to investigate the stress-strain properties and how different factors affect the behavior of materials. The use of fibers in geotechnical and transportation engineering can be applied to the five categories of pavement, retaining walls, slope stability, foundations, and earthquake, according to a thorough assessment of this research on reinforced soil. The results of this study’s investigation into the behavior of sand reinforced with straw barley fiber will be highly helpful to civil-geotechnical and civil-transportation engineers.

The mechanical behavior of Babolsar sand, when combined with barley straw fibers, has been studied in numerous consolidated drained triaxial tests utilizing fiber weight ratios of 0, 0.3, 0, 6, and 0.9 percent and confining pressures of 50, 100, and 200 kPa.

2.1 Materials

2.1.1 Babolsar Sand

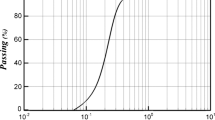

Sand from Babolsar was used as the subject of this study’s soil. The mean grain size (D50) of this sand is 0.22 mm, and it has a specific gravity of 2.78, a curvature coefficient of 1.32, a uniformity coefficient of 2.12, a maximum voids ratio of 0.8, and a minimum voids ratio of 0.526. It is clean and uniform quarts. Babolsar sand was categorized as poorly graded sand according to ASTM Unified (SP). The Babolsar sand particle distribution curve is shown in Fig. 1 and its physical characteristics are listed in Table 1.

2.1.2 Barley Straw Fiber

One of the fibers employed for reinforcing is cut barley straw. It is a member of the grass family, barley straw. Barley straw is widely available and can be farmed in colder areas as well as in temperate ones. A renewable material called barley straw is made of cellulose, glucose, lignin, wax, and water. Barley straw has been used for centuries to remove oil from soil surfaces and to stop the growth of algae. The straw utilized in this study was gathered from agricultural fields and is one of the typical forms of straw in Iran. Straw strands with a length of 6 to 12 mm were selected at random since the straw used in the studies had variable lengths and it was very difficult to utilize a certain length. The results of measuring the straw strands’ width for a sample taken at random from a kilogram of straw indicate that the fibers’ width falls between 0.4 and 2 mm. The barley straw utilized in this study is seen in Fig. 2.

2.2 Sample Preparation

Fiber is a ductile substance. Ang and Loehr (2003) investigated the size effect and discovered that there were no size effects for the sample with a diameter of 70 mm for fibers with lengths of 10, 15, 20, and 52 mm. Consoli et al. (2009) conducted triaxial studies using a sample diameter of 50 mm and a fiber length of 23 mm with a ratio of 2.1. Triaxial studies were performed by Malidarreh et al. (2018) using a sample with a diameter of 38 mm and a fiber length of 15 with a ratio of 2.2. Triaxial tests were carried out by Noorzad and Zarinkolaei (2015) using a sample with a diameter of 38 mm and a fiber length of 18 with a sample length to fiber length ratio of 2.1. Because fiber-reinforced soil is employed at high densities (pavement, slope, foundation), all samples were prepared at a constant relative density of 80% (Choobbasti & Kutanaei 2017). At confining pressures of 50 kPa (which mimicked a low depth, such as pavement), 100 kPa (which simulated a medium depth, such as a foundation), and 200 kPa, triaxial tests were conducted (simulating high depth: deep mixing). We examined a pressure range that corresponds to what most geotechnical structures experience frequently. Actual loading circumstances were used to determine the confining pressure (Hamidi & Hooresfand 2013).

It should be noted that the percentage of fiber utilized for soil reinforcement in the majority of earlier experiments ranged around 1%. The homogeneity of the sand mixture is reduced by the addition of fibers. When fiber is added in large amounts, mixing is challenging. As a result, by weight of the dry sand, the fiber contents in this investigation were 0.0%, 0.3%, 0.6%, and 0.9% (Tang et al. 2007). In other words, a maximum selected percentage of 1% was used, which is a very valuable and accurate number, according to earlier studies on the percentage of fibers needed to be mixed with soil. The best potential homogeneity and mixing in the samples was found in 0.9% of the fibers, according to the findings of the project that was presented and several experiments that were carried out as part of our research. In addition, it is worth noting that heterogeneous samples lessen resistance.

Sample preparation is one of the most crucial stages of an experimental study. The compaction technique was used to create the samples for this experiment following Ladd’s (1978) approach. Due to segregation, dry sand and fiber cannot be blended. The required amount of sand was first blended with 5% water, and then hemp fibers were added to make samples of sand reinforced with hemp fiber. The mixing was carried out with an electric mixer. Since all of the investigations were performed in a dry state, wet materials were put in an oven to dry. The samples were carefully poured into a divided mold with a little spoon.

It should be noted that mixing was simpler in sandy soils than in clayey soils. To do this, soil and water were combined first, and then fibers were added and combined. Due to the absence of cohesion in granular soils, the experiments for this study were conducted in dry conditions. In the dry state, the fiber did not interact with the sand and separation occurred during mixing. The initial 5% of the dry weight of the sand was therefore added to the water and the fibers were then gradually incorporated into the soil and blended. The reason 5% moisture content was chosen for the mixing process was that it had the maximum surface tension. The apparent cohesiveness that resulted from this surface tension led to more sand and fibers being involved and improved mixing. The mixing took place with a mixer. The components were thoroughly blended after 15 min of mixing using a mixer.

The weight of soil, water, and fibers was determined as the specimen volume was determined using the specific dry weight for the soil and similarly the necessary moisture content. Five layers were created from the mixture’s weight and the weight of each layer was calculated. Organized reinforced specimens had a height of 104 mm and a diameter of 52 mm. Specific dry-weight specimens that were 80% of standard density were finished. Each layer’s necessary amount of mixture was placed into a mold, and each layer’s specimen was then compacted using static compaction. On the surface of the first and second layers, grooves up to 10% of the layer thickness were made to prevent weak plates and ensure proper connecting between the layers. The samples were then put in an oven set at 105 °C for 24 h before being evaluated because all experiments in this study were performed in a completely dry state. Hamidi and Hooresfand proposed this method (2013). At that time, a numerical caliper was used to precisely measure the sample’s dimensions before the test. The average of the specimen was three heights in a location 120 degrees of the specimen height while calculating the specimen’s height, average diameter, and location of each quarter of the specimen’s diameter. The various stages of specimen preparation are shown in Fig. 3.

2.3 Test Equipment and Procedure

Figure 4 shows the equipment used in this study to conduct the experiments. HEICO Company’s triaxial method was used to conduct static, strain-controlled triaxial tests. A ring-type load cell was used to assess the axial load on the sample. The actuator and load frame, water/air bladder, distribution panel, IMACS controller, triaxial cell, automatic volume change device, and servo reservoir assembly were the organization’s key components. In this study, a triaxial device had a data control association installed on it. Sensors delivered all data to the control association. They were given to the software by the control association as numbers. A displacement transducer was used to measure the axial displacement with a range of 50 mm, and the axial load was delivered to the load cell. Up to 1500 kPa and 2000 kPa of pressure were applied to the load cell’s cylinder. A 15 KN load cell was used to control the axial load. The bladder IMACS controller provided the necessary cell pressure and also collects data and transducer communication for computer analysis. In this investigation, several static triaxial tests were performed following ASTM D7181. With a strain rate of 0.02%, strain-controlled consolidated drained triaxial tests were performed.

3 Results and Discussion

The CD test results of sandy soil such as peak strength, residual strength, failure axial strain, strength increase ratio, brittle index, and volumetric strain are acquired (Table 2). By comparing the peak strength and residual strength to peak strength ratio, the brittle index assesses the sample’s ductility. The strength increase ratio is defined as the peak strength of reinforced specimens divided by the peak strength of unreinforced specimens.

3.1 Effect of Reinforcement on Stress-Strain Behavior

Figures 5, 6, 7, show the stress-strain curves of Babolsar’s unreinforced and reinforced sand (barley straw). These data show that barley straw fibers, compared to other fibers like hemp fibers, have a substantially smaller impact on improving soil strength attributes. This is because barley straw fibers are smaller in diameter and interact with sand less than hemp filaments do. According to the statistics, adding fibers causes the soil’s peak strength to increase; however, this strength gain is much less pronounced for weight percentages of 0.3 than it is for weight percentages of 0.6 and 0.9. These results are in line with the study conducted by Choobbasti et al. (2019a, b). Their triaxial tests on clay reinforced with carpet fibers showed that the addition of carpet fibers minimizes the decline in clay strength (resistance drop).

This can be due to the physical contact between dirt particles and fibers. Due to the strain at the fiber-soil interface, the soil matrix’s fibers find it difficult to slip, and they can withstand tensile stress, which eventually increases soil strength and improves soil behavior. This outcome is consistent with the study performed by Choobbasti et al. (2019a, b). The stiffness of the reinforced soil is dependent on the density, confining pressure, and fiber contents as demonstrated by the reinforced triaxial investigations on drained sand reinforced with PVA fibers that Choobbasti et al. (2019a, b) carried out. In addition, compared to unreinforced specimens, reinforced barley straw specimens exhibit higher failure strain and stiffness.

In specimens reinforced with straw, the ratio of increasing strength to increasing confining pressure decreases. For instance, the increase in strength of a reinforced specimen with a weight ratio of 0.6% straw is 1.29 under confining pressures of 50 kPa and 200 kPa, and it is 1.29 under both of these pressures (Table 2). These results are consistent with those of the investigation of Kutanaei and Choobbasti (2016). Kutanaei and Choobbasti (2016) assert that the reduced interaction between soil and fibers brought on by an increase in confining pressure restricts the capacity of fibers to increase strength. It has already been determined that the reason for the diminishing is the ratio of resistance growth to damping pressure rise. The reason for this is that when confining pressure increases, the interaction between the fibers and the sand reduces. At low confining pressures, sand will interact more with the fibers because it tends to dilate (volume increase) as a result of shear. These findings are consistent with the research done for the published paper (Choobbasti et al. 2019a, b; Ghadakpour et al. 2021).

3.2 Effect of Reinforcement on Volumetric Behavior

In this part, the volumetric behavior of reinforced specimens with random fiber distributions is explored. The research’s conclusions about the samples’ volumetric behavior are presented below. Diagrams illustrating the volume change in axial strain for sand reinforced with strands of barley straw are shown in Figs. 8 and 9. This pattern of decreasing volume rises with increasing confining pressure can be found in practically all samples reinforced with barley straw fibers (see Fig. 8). Figure 9 clearly shows that the fibers of barley straw have little to no effect on the volumetric behavior of sand. Similar results in minimizing sandy soil dilatation due to the addition of Kenaf fibers were reported by Koutenaei et al. (2021).

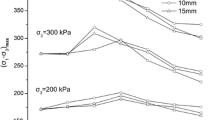

3.3 Effect of Reinforcement on Peak Strength

The results show that the peak strengths of reinforced specimens have always been higher than those of unreinforced specimens. As the weight ratio of barley straw increases, as shown in Fig. 10, the peak strength rises. For the weight ratio of 0.3%, this rise is hardly noticeable, but for the weight ratios of 0.6 and 0.9%, it becomes more substantial. Peak strength increases along with confining pressure, which nearly seems to be decreasing as it increases. Two essential reinforcement qualities are tensile strength and contact surface shear strength. Tensile strength is undoubtedly an essential quality considering that the reinforcer needs to be able to withstand the tensile pressures that the soil transmits. The most important component of the soil and reinforcing mechanism is the shear strength of the contact surface, which is responsible for transferring stresses from the soil to the reinforcing. Failure in reinforced soil happens as a result of the reinforcement materials gradually failing or slipping within the soil bulk. Ghadakpour et al. (2020) conducted several experimental tests on cement sand reinforced with kenaf fiber and found that the addition of hemp fiber boosted compressive and tensile strength. Fiber tires, however, enhance tensile strength in additional ways than merely compressive strength. These findings are consistent with the research conducted and presented in the study (Choobbasti et al. 2019a, b).

3.4 Effect of Reinforcement on Failure Strain

With the addition of straw fibers, the failure strain on bare soil rises. However, altering the weight ratio of the fibers had no appreciable effect on the failure strain. Additionally, as confining pressure rises, the failure strain does too (Table 2). For instance, the failure strain is increased by 24% from the unreinforced sand’s 4.2% failure strain to 5.2% at 200 kPa confining pressure and 0.9% barley straw weight ratio. These findings align with prior studies in the literature (Ghadakpour et al. 2021).

3.5 Effect of Reinforcement on Residual Strength

Since it is the resistance that soil exhibits after failure, a strain resistance of 15% is often regarded as residual strength. The strength the soil retains after failure and deformation increases in direct proportion to how little damage is done to the building built on it. This is due to a smaller strength decline following the peak strength. According to the technical manuals, adding fibers to reinforced soil reduces the loss of strength after peak strength. This behavior illustrates that the presence of the fibers causes reinforced materials to act more flexibly than unreinforced samples. This is because fiber stops the samples’ shear bands from developing. The formation of the shear band in unreinforced sand samples is what causes the strength loss that happens after the peak strength. Another explanation for this is that when the specimens are loaded, the fibers act as bridges, increasing the soil’s strength to high deformation. The samples reinforced with barley straw fibers show no significant trend in the brittle index. In terms of the fragile index, there is little distinction between samples with and without barley straw reinforcing. According to Ghadakpour et al. (2019), when PVA fiber content increases, the pace at which cementitious soil strength drops decreases substantially.

3.6 Effect of Reinforcement on Stiffness

Stiffness is one of the factors affecting soil behavior that controls the rate of deformation and settling under loads. The findings indicate that samples reinforced with barley straw fibers have higher stiffness. However, this gain in stiffness is minimal, especially at the weight ratio of 0.3% barley straw, where stiffness has even been demonstrated to decrease when compared to unreinforced specimens. According to Kutanaei and Choobbasti (2017), the inclusion of fibers decreased the tendency of lateral deformations and increased the stiffness of the soil.

3.7 Effect of Reinforcement on Failure Envelope

In this section, the failure envelope for discrete fibers with a random distribution on the soil strength parameters (φ and C) is studied (Table 3, and Fig. 11). It should be noted that “apparent cohesion” refers to the cohesiveness that results from the reinforcement of non-cohesive materials. In general, it is obvious how soil strength characteristics or shear strength are improved by reinforcing the failure envelope. Results reveal that the strength properties of reinforced sand are unaffected by the weight ratio of 0.3% barley straw in comparison to unreinforced sand.

As the weight ratio increases, the barley straw’s strength properties improve. Koutenaei et al. (2021) showed similar results on soil strength measurements related to the addition of Kenaf fibers in sandy soils. It is interesting to note that this study only looked at Babolsar sand and one kind of soil. Different types of soil may be used in future projects, and the effect of durability on reinforced soil may also be studied and examined.

For typical building projects, sand with an internal friction angle of 43 degrees is a great choice. However, due to the numerous loads that must be applied to the soil, strengthening and reinforcing the soil with fibers is very practical and essential while carrying out other tasks like erecting high-rise structures and towers. In reality, the goal of fiber-based soil improvement is not only to boost resistance but also to balance out residual behavior and make it flexible.

4 Conclusion

In order to evaluate the resistive behavior of Babolsar sand reinforced with randomly distributed straw barley fibers, numerous static triaxial experiments were conducted in this study, incorporating 0.3, 0.6, and 0.9 percent by dry weight of straw barley fibers into the soil. Confining pressures of 50, 100, and 200 kPa were used during static triaxial testing. The results are summarized as follows:

The stress-strain diagrams show that adding barley straw fiber makes the soil more resilient; however, this improvement in resistance is noticeably less prominent at weight percentages of 0.3 and more pronounced at weight percentages of 0.6 and 0.9. In practically all samples equipped with straw strands, the amount of developing volume reduces with increasing confining pressure, according to an analysis of the test data. With increasing strength, barley straw’s weight-to-volume ratio increases. The maximal strength rises as the confining pressure does. Barley straw fibers enhance the failure strain in comparison to unreinforced soil. The failure strain, however, does not significantly change when the weight ratio of the fibers was changed. With rising confining pressure, the failure strain also rises. The samples with barley straw fiber reinforcement do not exhibit any discernible trends in the brittle index. The stress-strain graphs for samples reinforced with fibers from barley straw show that the sample stiffness increases. The weight ratio of 0.3% barley straw in contrast to unreinforced sand does not affect the strength characteristics of reinforced sand. However, the barley straw’s strength characteristics improve as the weight ratio rises.

Data Availability

All data, models, and code generated or used during the study appear in the submitted article.

References

Akil, H., Omar, M.F., Mazuki, A.A.M., Safiee, S.Z.A.M., Ishak, Z.M., Bakar, A.A.: Kenaf fiber reinforced composites: a review. Mater Des. 32(8–9), 4107–4121 (2011). https://doi.org/10.1016/j.matdes.2011.04.008

Ang, E.C., Loehr, J.E.: Specimen size effects for fiber-reinforced silty clay in unconfined compression. Geotech Test J. 26(2), 191–200 (2003). https://doi.org/10.1520/GTJ11320J

Choobbasti, A.J., Kutanaei, S.S.: Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J Rock Mech Geotechn Eng. 9(5), 981–988 (2017). https://doi.org/10.1016/j.jrmge.2017.03.015

Choobbasti, A.J., Vafaei, A., Kutanaei, S.S.: Static and cyclic triaxial behavior of cemented sand with nanosilica. J Mater Civ Eng. 30(10), 04018269 (2018). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002464

Choobbasti, A.J., Kutanaei, S.S., Ghadakpour, M.: Shear behavior of fiber-reinforced sand composite. Arab J Geosci. 12(5), 1–6 (2019). https://doi.org/10.1007/s12517-019-4326-z

Choobbasti, A.J., Samakoosh, M.A., Kutanaei, S.S.: Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr Build Mater. 211, 1094–1104 (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.306

Choobbasti, A.J., Vafaei, A., and Kutanaei, S.S. (2015). Mechanical properties of sandy soil improved with cement and nanosilica. Open Engineering, 5 (1). https://doi.org/10.1515/eng-2015-0011

Consoli, N.C., Montardo, J.P., Donato, M., Prietto, P.D.M.: Effect of material properties on the behavior of sand–cement–fibre composites. Ground Improvement. 8(2), 77–90 (2004). https://doi.org/10.1680/grim.8.2.77.36370

Consoli, N.C., Vendruscolo, M.A., Fonini, A., Dalla Rosa, F.: Fiber reinforcement effects on sand considering a wide cementation range. Geotext Geomembr. 27(3), 196–203 (2009). https://doi.org/10.1016/j.geotexmem.2008.11.005

Consoli, N.C., Bassani, M.A.A., Festugato, L.: Effect of fiber-reinforcement on the shear strength of cemented soils. Geotext Geomembr. 28(4), 344–351 (2010). https://doi.org/10.1016/j.geotexmem.2010.01.005

Diambra, A., Ibraim, E., Wood, D.M., Russell, A.R.: Fibre reinforced sands: experiments and modeling. Geotext Geomembr. 28(3), 238–250 (2010). https://doi.org/10.1016/j.geotexmem.2009.09.010

Eker, H., Bascetin, A.: Influence of silica fume on mechanical property of cemented paste backfill. Constr Build Mater. (2022). https://doi.org/10.1016/j.conbuildmat.2021.126089

Gao, Z., Zhao, J.: Evaluation on failure of fiber-reinforced sand. J Geotech Geoenviron Eng. 139(1), 95–106 (2013). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000737

Ghadakpour, M., Janalizadeh Choobbasti, A., Soleimani Kutanaei, S.: Investigation of the deformability properties of fiber reinforced cemented sand. J Adhes Sci Technol. 33(17), 1913–1938 (2019). https://doi.org/10.1080/01694243.2019.1619224

Ghadakpour, M., Choobbasti, A. J., & Kutanaei, S. S. (2020). Investigation of the Kenaf fiber hybrid length on the properties of the cement-treated sandy soil. Transportation Geotechnics, 22, 100301. https://doi.org/10.1016/j.trgeo.2019.100301.

Ghadakpour M, Fakhrabadi A, Choobbasti A.J., Kutanaei S.S., Vafaei A, Taslimi M.P.A., and Eisazadeh N. (2021). Effect of post-construction moisture condition on mechanical behavior of fiber-reinforced- cemented-sand (FRCS). Geomechanics and Geoengineering, 1-13. https://doi.org/10.1080/17486025.2021.1980230.

Gray, D.H., Al-Refeai, T.: Behavior of fabric-versus fiber-reinforced sand. J Geotech Eng. 112(8), 804–820 (1986). https://doi.org/10.1061/(ASCE)0733-9410(1986)112:8(804)

Gray, D.H., Ohashi, H.: Mechanics of fiber reinforcement in the sand. J Geotech Eng. 109(3), 335–353 (1983). https://doi.org/10.1061/(ASCE)0733-9410(1983)109:3(335)

Hamidi, A., Hooresfand, M.: Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotext Geomembr. 36, 1–9 (2013). https://doi.org/10.1016/j.geotexmem.2012.10.005

Htut Z. M., Azhar M. M., Chao K. C. (2019). Evaluation of the relationship between swelling pressures determined by consolidation-swell test and constant volume test. 7th Asia-Pacific Conference on Unsaturated Soils (AP-UNSAT 2019), 7(2), 250-255. 10.3208.jgssp.v07.039.

Karimzadeh, A.A., Leung, A.K., Fardad, Amini P.: Energy-based assessment of liquefaction resistance of rooted soil. J Geotech Geoenviron Eng. 148(1), 06021016 (2022). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002717

Koutenaei, R.Y., Choobbasti, A.J., Kutanaei, S.S.: Triaxial behavior of a cemented sand reinforced with kenaf fibres. Europ J Environ Civ Eng. 25(7), 1268–1286 (2021). https://doi.org/10.1080/19648189.2019.1574607

Kumar, A., Walia, B.S., Mohan, J.: Compressive strength of fiber-reinforced highly compressible clay. Construc Build Mater. 20(10), 1063–1068 (2006). https://doi.org/10.1016/j.conbuildmat.2005.02.027

Kutanaei, S.S., Choobbasti, A.J.: Mesh-free modeling of liquefaction around a pipeline under the influence of trench layer. Acta Geotechnica. 10(3), 343–355 (2015). https://doi.org/10.1007/s11440-015-0381-0

Kutanaei, S.S., Choobbasti, A.J.: Triaxial behavior of fiber-reinforced cemented sand. J Adhes Sci Technol. 30(6), 579–593 (2016). https://doi.org/10.1080/01694243.2015.1110073

Kutanaei, S.S., Choobbasti, A.J.: Effects of nanosilica particles and randomly distributed fibers on the ultrasonic pulse velocity and mechanical properties of cemented sand. J Matern Civ Eng. 29(3), 04016230 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.000176

Kutanaei, S.S., Choobbasti, A.J., Fakhrabadi, A., Ghadakpour, M., Vafaei, A., Taslimi, M.P.A.: Application of LRBF-DQ and CVBFEM methods for evaluating saturated sand liquefaction around buried pipeline. J Pipeline Syst Eng Pract. 13(1), 04021077 (2022). https://doi.org/10.1061/(ASCE)PS.1949-1204.0000625

Ladd, R.: Preparing test specimens using under compaction. Geotech Test J. 1(1), 16–23 (1978). https://doi.org/10.1520/GTJ10364J

Liu, J., Wang, G., Kamai, T., Zhang, F., Yang, J., Shi, B.: Static liquefaction behavior of saturated fiber-reinforced sand in undrained ring shear tests. Can Geotech. 29, 462–471 (2011). https://doi.org/10.1016/j.geotexmem.2011.03.002

Maher, M.H., Gray, D.H.: Static response of reinforced with randomly distributed fibers. J Geotech Eng. 116(11), 1661–1677 (1990). https://doi.org/10.1061/(ASCE)0733-9410(1990)116:11(1661)

Malidarreh, N.R., Shooshpasha, I., Mirhosseini, S.M., Dehestani, M.: Effects of reinforcement on mechanical behavior of cement treated sand using direct shear and triaxial tests. Intl J Geotech Eng. 12(5), 491–499 (2018). https://doi.org/10.1080/19386362.2017.1298300

Nataraj, M.S., McManis, K.L.: Strength and deformation properties of soils reinforced with fibrillated fibers. Geosynth Intl. 4(1), 65–79 (1997). https://doi.org/10.1680/gein.4.0089

Noorzad, R., Zarinkolaei, S.T.G.: Comparison of mechanical properties of fiber-reinforced sand under triaxial compression and direct shear. Open Geosci. 7(1), 547–558 (2015). https://doi.org/10.1515/geo-2015-0041

Sahin, D.D., Isik, E., Isik, I., Cullu, M.: Artificial neural network modeling for the effect of fly ash fineness on compressive strength. Arab J Geosci. (2021). https://doi.org/10.1007/s12517-021-09120-w

Shao, W., Cetin, B., Li, Y., Li, J., Li, L.: Experimental investigation of mechanical properties of sands reinforced with discrete randomly distributed fiber. Geotech Geol Eng. 32(4), 901–910 (2014). https://doi.org/10.1007/s10706-014-9766-3

Silveira, M. V., Ferreira, W.D.S., Casagrande, M.D.T., (2022). Effect of surface treatment on natural aging and mechanical behavior of sisal fiber–reinforced sand composite. Journal of Materials in Civil Engineering, 34(6). https://doi.org/10.1061/(ASCE)MT.1943-5533.0004237.

Tang, C.S., Shi, B., Gao, W., Chen, F., Cai., Y.: Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr. 25(3), 194–202 (2007). https://doi.org/10.1016/j.geotexmem.2006.11.002

Tang, C., Shi, B., Cui, Y., Liu, C., Gu, K.: Desiccation cracking behavior of polypropylene fiber-reinforced clayey soil. Can Geotech J. 49(9), 1088–1101 (2012). https://doi.org/10.1139/t2012-067

Turk, K., Nehdi, M.L.: Flexural toughness of sustainable ECC with high-volume substitution of cement and silica sand. Construct Build Mater. 270, 121438 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121438

Vafaei, A., Choobbasti, A.J., Kutanaei, S.S., Taslimi, M.P.A.: The presence of colloidal nano silica in sandy soils: a review. Arab J Geosci. 15, 582 (2022). https://doi.org/10.1007/s12517-022-09908-4

Vafaei, A., Choobbasti, A.J., Koutenaei, R.Y., Vafaei, A., Taslimi, M.P.A., Kutanaei, S.S.: Experimental investigation of the mechanical behaviour and engineering properties of sand reinforced with hemp fibre. Arab J Geosci. 15, 1679 (2022). https://doi.org/10.1007/s12517-022-10966-x

Vakili, A.H., Salimi, M., Lu, Y., Shamsi., M., Nazari Z.,: Strength and post-freeze-thaw behavior of a marl soil modified by lignosulfonate and polypropylene fiber: an environmentally friendly approach. Construct Build Mater 332, 127364 (2022). https://doi.org/10.1016/j.conbuildmat.2022.127364

Yaghoubi, M., Shukla, S.K., Mohyeddin, A.: Effects of addition of waste tyre fibers and cement on the engineering behavior of Perth sand. Geomech Geoeng. 13(1), 42–53 (2018). https://doi.org/10.1080/17486025.2017.1325941

Yetimoglu, T., Salbas, O.: A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext Geomembr. 21(2), 103–110 (2003). https://doi.org/10.1016/S0266-1144(03)00003-7

Zhang, X., Russell, A.R.: Liquefaction potential and effective stress of fiber-reinforced sand during undrained cyclic loading. J Geotech Geoenviron Eng. 147(7), 04021042 (2021). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002530

Zhang, J., Yang, Z., Yang, Q., Li, G., Liu, J.: Pore water pressure model for sands reinforced with randomly distributed fibers based on cyclic triaxial tests. Soil Dyn Earthq Eng. 148, 106812 (2021). https://doi.org/10.1016/j.soildyn.2021.106812

Zhou., Chen J.F., Peng M., Zhu Y.,: Liquefaction behavior of fiber-reinforced calcareous sands in unidirectional and multidirectional simple shear tests. Geotext Geomembr. 50, 794–806 (2022). https://doi.org/10.1016/j.geotexmem.2022.04.003

Ziegler, S., Leshchinsky, D., Ling, H.I., Perry, E.B.: Effect of short polymeric fibers on crack development in clays. Soils and Foundations. 38(1), 247–253 (1998). https://doi.org/10.3208/sandf.38.247

Author information

Authors and Affiliations

Contributions

Ali Vafaei: writing—original draft; investigation; data curation; visualization; formal analysis.

Asskar Janalizadeh Choobbasti: conceptualization; methodology; formal analysis; supervision; writing—review and editing; project administration.

Reza Younesi Koutenaei: methodology, data curation.

Amir Vafaei: writing—review and editing; data curation.

MobinaTaslimi Paein Afrakoti: writing—review and editing; data curation.

Saman Soleimani Kutanaei: methodology, resources, data curation, formal analysis.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable

Consent for Publication

Not applicable

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vafaei, A., Choobbasti, A.J., Koutenaei, R.Y. et al. Effect of Barley Straw Fiber as a Reinforcement on the Mechanical Behavior of Babolsar Sand. Transp. Infrastruct. Geotech. 11, 216–235 (2024). https://doi.org/10.1007/s40515-023-00281-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-023-00281-7