Abstract

The addition of cementitious admixtures and/or inclusion of fibers are frequently used in practice to stabilize soils and to improve their mechanical properties. In this study, ring shear tests were conducted to investigate mechanical properties such as shear strength, angle of friction and cohesion values of randomly distributed discrete fiber-reinforced sand mixtures. The length and aspect ratio of the fibers used in the current study were 12 mm and 120, respectively. Specimens were prepared at four different fiber ratios (0.1, 0.3, 0.6, and 0.9 % by weight of sand). A series of ring shear tests were carried out on sand alone and fiber-reinforced sand mixtures at different normal stresses. The test results indicated that the addition of fiber had a significant effect on the shear strength of the sand. Shear stress of the unreinforced sand increases 1.29–2.32, 1.16–1.39, and 1.07–1.5 times at a normal stress of 50, 150, and 250 kPa, respectively with fiber inclusion. Fiber content had positive effects on improving the shear strength parameters (angle of internal friction and cohesion) of the mixtures. The cohesion and angle of internal friction of fiber-reinforced sand prepared at different ratios of fiber increased by 5.3–27.4 kPa and 2.0°–7.3° respectively. The inclusion of fibers improves the ductility of the soil by preventing the loss of post-peak strength.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The improvement of the mechanical properties of locally available soils through addition of cementitious materials such as cement, lime, fly ash, steel slag and inclusion of discrete elements such as fibers are very common (Arora and Aydilek 2005; Cetin et al. 2010; Dos Santos et al. 2010; Consoli et al. 2011). These reinforcement techniques has been widely used in many different geotechnical engineering applications such as the construction of road and railway embankments, stabilization of slopes, and improvement of soft ground (Zhang et al. 2006; Babu and Chouksey 2011; Gao and Zhao 2013). Randomly distributed fibers have evoked considerable interest among both highway engineers and manufacturers for use as reinforcing materials for highway base layer stabilization. Past literature agrees that fiber reinforcement increases the shear strength and ductility of soils (Maher and Ho 1994; Consoli et al. 2009a; Casagrande et al. 2006). Utilization of randomly distributed discrete fibers in soil improvement applications is more advantageous than the use of conventional reinforcement materials (Dos Santos et al. 2010). The mixing of discrete fibers with soil mass is simple and quite similar to other admixtures, such as cement and lime. In addition, randomly distributed discrete fibers limit potential planes of weakness that can be developed parallel to oriented reinforcement and support an isotropic material behavior of the finer-reinforced soils (Maher and Gray 1990; Consoli et al. 2011).

Significant efforts have been made on the use of randomly oriented discrete fibers to reinforce sand. Gray and Ohashi (1983) carried out a large number of direct shear tests on dry sand reinforced with different types of fibers. Test results showed that fiber reinforcement increased the peak shear strength and limited post-peak reductions in shear resistance. Gray and Al-Refeai (1986) performed large number of triaxial compression tests to compare the stress–strain response of sand reinforced with continuous, oriented fabric layers, as opposed to randomly distributed discrete fibers. Test results showed that both types of reinforcement improved strength, increased the axial strain at failure, and in most cases reduced post-peak loss of strength. Gopal et al. (1994) performed triaxial compression tests to determine stress strain behavior of fine sand reinforced with discrete, randomly distributed plastic fibers, and also observed the influence of fiber properties (nature of fibers, fiber length, fiber aspect ratio, etc.) and confining stress on shear strength of reinforced sand. Santoni and Webster (2001) conducted laboratory and field tests using a new fiber stabilization technique for sands. Yetimoglu and Salbas (2003) investigated the shear strength of sands reinforced with randomly distributed discrete fibers by carrying out direct shear tests. This study found that the inclusion of fibers into soil increased the residual strength occurring after peak stress and decreased the brittle behavior of the soil. Consoli et al. (2009b) conducted standard triaxial tests on artificially cemented Osorio sand specimens reinforced with randomly oriented discrete extensible polypropylene fibers. Ibraim et al. (2010) investigated the possibility of improving the monotonic undrained response of loose clean sand which normally appears susceptible to the phenomenon of static liquefaction by mixing the sand with discrete flexible fibers. The tests showed that the reinforcement inclusions reduced the potential for the occurrence of liquefaction in both compression and extension triaxial loadings and converted a strain softening response into a strain hardening response. Dos Santos et al. (2010) investigated the shear strength of fiber-reinforced sands under different confining pressures. This study concluded that the effects of the inclusion of fibers on the shear strength of soil significantly depended on testing confining pressure and claimed that the shear strength of fiber-reinforced soil was reduced with an increase in confining pressure. Moreover, Gao and Zhao (2013) investigated the effect of fiber orientations in the fiber-reinforced sand mixtures. It was determined that the fibers aligned to the horizontal direction in triaxial test will improve the resistance of soil tension strength significantly.

All of these previous studies have shown that the addition of fiber reinforcement caused significant improvement in shear strength of fiber-reinforced soils. Therefore, the randomly distributed discrete fiber can be considered a good reinforcement material which causes significant modification and improvement in the engineering properties of sand. However, there is limited information about the effect of fiber content on the mechanical behavior and engineering properties of the coarse grained materials such as sand. Therefore, these fiber reinforced soil composites require further investigation.

The main objective of this study is to investigate the effect of fiber reinforcement on the mechanical properties of locally available sand. A series of ring shear tests were carried out on soil alone and fiber-reinforced sand specimens that were prepared at different percentages (0.1, 0.3, 0.6, and 0.9 %) of fiber content. The tests results and reinforcement mechanisms were discussed.

2 Theoretical Model

The fiber–sand reinforcement model based on limit equilibrium of forces was proposed by Waldron (1977), which can be used to predict shear strength of reinforced sand. Waldron’s model meanwhile is based on only partial mobilization of fiber tensile strength depending upon the amount of inclusion elongation during shear. This model does not place any constraint on either the distribution or the location of the reinforcing fibers. The fiber reinforcement model consists of a long, elastic plane in sand as shown in Fig. 1. The fiber may be oriented initially perpendicular to the shear plane (Fig. 1a) or at some arbitrary angle (Fig. 1b). Shearing causes the reinforcement to distort as shown in (Fig. 1b) thereby mobilizing tensile resistance in the fiber. The tensile force in the fiber can be divided into a component normal and tangential to the shear plane. The normal component increases the confining stress on the failure plane thereby mobilizing additional shear resistance in the sand whereas the tangential component directly resists shear. The total reinforcement area ratio (A R /A) is expressed as a ratio of total reinforcement shear cross-sectional area to total area.

The shear strength increase from this type of fiber-reinforced sand composites can be estimated from the following expressions:

in which \(\Delta S_{R \bot }\) is the shear strength increase from fiber reinforcement oriented initially perpendicular to the shear plane; \(\Delta S_{R\angle }\) is the shear strength increase from fiber reinforcement which is oriented at any arbitrary angle; t R is the mobilized tensile strength of fibers per unit area of sand; ϕ is the angle of internal friction of sand; θ is the angle of shear distortion; i is the initial orientation angle of fiber with respect to shear surface; x is the horizontal of shear displacement; z is the thickness of shear zone; k is the shear distortion ratio (k = x/z).

The mobilized tensile strength per unit area of sand (t R ) is the product of the tensile stress in the fiber at the shear plane and the reinforcement area ratio:

in which σ R is the tensile stress developed in the fiber at the shear plane; and A R /A is the reinforcement area ratio.

3 Materials

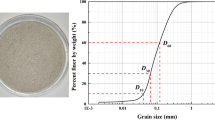

Uniform, clean, quartz sand was used as the main soil in the current study (Fig. 2a). It was collected from Jackson, Mississippi in the United States. Its specific gravity is approximately 2.64. Relative density tests were performed on the sand materials in accordance with ASTM D 4914. The minimum and maximum unit weights are measured as γ min = 14.9 kN/m3 and γ max = 17.5 kN/m3, respectively, from the relative density test. The minimum and maximum void ratios are also calculated as e min = 0.48 and e max = 0.74, respectively. The average particle diameter of the sand (D 50) is 0.31 mm. The D 10, D 30, and D 60 are 0.1, 0.28, and 0.35 mm, respectively. The coefficient of uniformity (C u ) is 3.5 and the coefficient of gradation (Cc) is 2.24.

Fibermesh 150 synthetic fibers were used throughout this investigation during the reinforcement of the sand (Fig. 2b). This fiber is one of the most commonly used fibers both by the concrete and geotechnical engineering industry. It is non-magnetic, rustproof, alkali proof, highly durable. The efficiency of the fibers used to reinforce of the soil is highly depended on the properties of the fiber used for this purpose such as nature of fibers, fiber length, and fiber ratio (Dos Santos et al. 2010; Shukla et al. 2010). Fibermesh 150 is 100 % homopolymer polypropylene multifilament fiber. It is very light material with a specific gravity (G s ) of 0.91 and it possesses high acid salt resistance (Fibermesh 150). It is chemically inert and has uniform characteristics. The length and thickness of the fibers used in this study is 12 and 0.1 mm, respectively with an aspect ratio of 120. Consoli et al. (2009b) worked on the reinforcement of similar sand used in this study with similar fibers which have different lengths. It was concluded that fibers with an aspect ratio above 300 experienced strain-hardening behavior which caused significant mechanical problems. The aspect ratio of the fiber used in this study is lower than the upper limit determined in the previous studies indicating that it should provide efficient reinforcing performance for the sand.

4 Experimental Methods

4.1 Sample Preparation

Moist tamping technique was used in the preparation of all specimens. This technique generally preferred to compact coarse grained and silty soils. Each layer is compacted to desired density by measuring the height of the layer during compaction process. The moist tamping technique has the advantage of a relatively well density control of the specimen which also prevents the segregation of fibers, and produces fiber-reinforced sand samples that are similar to the ones compacted in the field (Diambra et al. 2010). The average content of fibers included in a fiber-reinforced sand specimen is defined as a percentage of dry weight of sand:

where W f is the weight of the fibers, and W s is the weight of the dry sand. In the previous studies, the fiber content varied between 0.5 and 10 % in the fiber-reinforced soils. In addition most of these soils were also amended with other cementitious materials such as lime and cement (Consoli et al. 2002, 2012; Dos Santos et al. 2010). However, none of these studies have determined that the optimum fiber content alone that improves the mechanical behavior of the reinforced sand specimens which is one of the main objectives of this study. Therefore, fiber-reinforced sand mixtures were prepared at four different fiber and these ratios were as follows: 0.1, 0.3, 0.6, and 0.9 % fiber by weight of sand. Fibers were mixed and then compacted in the ring shear box. In the preparation of all samples, the required water was first added into the dry sand to prevent floating of the fibers in the soil matrix, and then the proposed content of fibers was mixed in small increments by hand to obtain a uniform mixture. It is important to ensure that all fibers are mixed thoroughly. After that, the mixtures were put into the ring shear box. The diameter and height of the cylindrical specimens prepared for ring shear test were 63.5 and 25.4 mm respectively. The specimens were added by layers to achieve target unit weight (15.7 kN/m3) via moist tamping technique. The relative density of specimens is 34 %. The samples were directly formed in the testing apparatus, as shown in Fig. 3.

4.2 Ring Shear Test

To investigate the effects of reinforcement of fibers on the shear strength of sand, series of ring shear tests in accordance with ASTMD-6467 were performed on the unreinforced sand and sand reinforced with different ratios of fibers. All tests were conducted inside a cylindrical shear box of 63.5 mm in diameter and 25.4 mm in depth. Based on recommendation of Sadek et al. (2010), tests were performed at three different vertical normal stresses of σ n = 50, 150 and 250 kPa in order to completely define the shear strength parameters such as the angle of internal friction (ϕ) and cohesion (c) for both the unreinforced and fiber-reinforced sand mixtures. All fiber-reinforced sand specimens and sand alone were subjected to direct shear tests with at a shearing rate of 1 % per minute. The shear stress was recorded as a function of horizontal displacement up to an average shear strain of 20 %.

5 Results and Discussion

5.1 Stress–Strain Curves

The stress–strain relationship is important to determine the mechanical behavior of modified soils (Heineck et al. 2009; Consoli et al. 2009b; Dos Santos et al. 2010). Therefore, through studying the shear stress–strain curves, a better understanding can be developed as to how the fiber reinforcement affects behavior of the fiber-reinforced sand (Fig. 4). It is well known that the effectiveness of the inclusion of fibers into soil is greatly affected by the fiber content (Gray and Al-Refeai 1986; Maher and Ho 1994; Santoni et al. 2001; Consoli et al. 2011). Moreover, the amount of the confining pressure that is applied on the fiber-reinforced sand has a direct impact on the shear strength of fiber-reinforced soils. Therefore, this study was particularly focused on determining the effects of fiber content and different confining pressures on the mechanical behavior of reinforced soils. The original sand material was prepared with fiber contents of 0.1, 0.3, 0.6 and 0.9 % by weight and tested at normal stresses of 50, 150 and 250 kPa in the ring shear tests. Figure 4 shows the typical shear stress–strain curves of the unreinforced sand and fiber-reinforced sand specimens under three different normal stresses.

As shown in Fig. 4, the presence of fiber affected the trend of stress–strain curves. The stress–strain curves of sand reinforced with different ratios of fibers showed the similar change trends at the same vertical normal stress. In the shearing period, the shear strength of reinforced sample increased gradually until it reached a steady state accompanying further shearing. However, unlike the reinforced sample, the shear strength of the unreinforced sample showed a sharp increase until reaching peak shear strength in the initial shearing period and then decreased slowly until it reached a steady state. This finding is consistent with the results of past studies. Dos Santos et al. (2010) found inclusion of fibers is more effective at higher strain rates. Furthermore, previous studies indicated that no effect of fiber reinforcement was found at very small strains while it increased the shear strength of soil significantly at large strains (Heineck et al. 2009; Casagrande et al. 2006; Consoli et al. 2007). Shukla et al. (2010) also found that the ultimate strength of the sand reinforced with randomly distributed discrete fibers was increased but resulted in a loss of strength at low strains.

Figure 4 shows that the effect of fiber reinforcement is not observed until 2 % horizontal strain is reached, then the specimens prepared with fiber tend to show higher resistance against shearing, consistent with findings of the Consoli et al. (2009b). It is speculated that the fibers amended in sand are generally slipping and yielding at small strains which is at the beginning of the shearing process. Then, all fibers start being yielded and being stretched at large strains which are the two mechanisms helping to increase the shear strength in fiber-reinforced sand matrix (Dos Santos et al. 2010; Consoli et al. 2011).

Figure 4 shows that fiber reinforcement tended to increase the ultimate shear strength of specimens substantially, compared to unreinforced sand. In addition, the peak stress increased gradually with an increase in fiber content and the inclusion of fiber into sand material at any ratio also prevents peak shear stress from reducing in value. Ranjan et al. (1996) also found that peak strength of fiber-reinforced soil increased with fiber content and limited the reduction in shear strength after it was reached. Furthermore, Yetimoglu and Salbas (2003) reported that inclusion of fibers into sand pose great potential to reduce the brittleness of soils and improve its ductility and limited loss of post peak strength. One of the main advantages of fiber reinforcement of sand is to improve ductility of sand (Kumar et al. 1999; Consoli et al. 2002; Yetimoglu and Salbas 2003; Babu and Chouksey 2011). As shown in Fig. 4, the fiber-reinforced sand exhibits more ductile behavior than sand alone and limit reductions in post peak shearing resistance. Fiber-reinforced specimens are able to maintain the shear stress with continuing deformation even at large strains, suggesting that these materials are very ductile.

5.2 Shear Strength and Strength Parameters

In order to evaluate the effects of fiber on the shear strength of the fiber-reinforced sand, a strength ratio parameter (R) is introduced and defined as

where \(\sigma_{f}^{R}\) is stress of fiber-reinforced sand at failure and σ f is stress of unreinforced sand at failure.

According to this definition, the variation of shear strength ratio with normal stress under different experimental cases (normal stresses) can be calculated, as shown in Fig. 5. Table 1 shows that the rate of increase in the shear strength of fiber-reinforced sand mixtures increases with fiber content and decreases under higher confining pressures, even though higher normal stresses yield higher ultimate shear strength. For fiber-reinforced sand specimens, the greater the fiber contents of reinforced sand, the greater the shear strength ratio of reinforced sand at the same normal stress. In addition, the shear strength ratio of reinforced sand decreased significantly with the increase of vertical normal stress from 50 to 150 kPa. The shear strength ratio is observed to be as high as 2.6 for fiber-reinforced sand prepared with a fiber content of ρ = 0.9 % at a normal stress of 50 kPa, and decreased to about 1.4 at a normal stress of 150 kPa. For sand reinforced with fiber content of 0.1, 0.3 and 0.6 %, the shear strength ratio varied from 2.1, 1.8 and 1.4 to 1.3, 1.2 and 1.1 between normal stresses from 50 to 150 kPa, respectively. However, the shear strength ratio increased slightly with the increase of vertical normal stress from 150 to 200 kPa. This finding is consistent with the results of the previous studies (Gray and Al-Refeai 1986; Dos Santos et al. 2010). Therefore the fiber reinforcement is more effective for samples at low vertical normal stress. The utilization of fiber reinforcing techniques are suggested to be used to improve mechanical properties of the near surface geotechnical applications such as designs of highway base/subbase, subgrade, shallow foundation, earth retaining walls and slope.

The effect of fiber reinforcement on shear strength can be shown in linear shear strength envelopes. Linear shear strength envelopes for reinforced sand with different fiber ratios are shown in Fig. 6. The shear strength parameters (angle of internal friction and cohesion) obtained from linear regression analyses for different fiber reinforcement contents are summarized in Table 2.

The experimental results indicate that for sand reinforced with different ratios of fiber, both cohesion and angle of internal friction have exhibited a significant increase with an increase in fiber content in the soil matrix. Generally, it is expected to observe opposite trends between these two strength parameters, angle of friction and soil. For instance, when the angle of friction increases, the cohesion of soils usually decreases. However, the inclusion of fibers yields an increase in both of these parameters. The increase in angle of friction is most probably associated with mobilization of friction between the soil particles and fibers (Gao and Zhao 2013; Yetimoglu and Salbas 2003). On the other hand, cohesion increases due to an increase of ductility of soil through the stretching of fibers (Kumar et al. 1999; Consoli et al. 2009a, b). As compared to unreinforced sand, the cohesion and angle of internal friction of fiber-reinforced sand prepared at different ratios of fiber increase by 5.3–27.4 kPa and 2.0°–7.3° respectively. The presence of fibers in the sand is providing apparent cohesion which contributes to the shear strength (Shukla et al. 2010). Fibers are the main components in the fiber-sand composites that cause an increase in cohesion values. Fibers in the soil matrix are stretched due to their highly extensible nature during shearing process and behave as cohesive soils, increasing the tension resistance of the reinforced soil which ultimately increases the shear strength (Consoli et al. 2012; Gao and Zhao 2013). Friction occurring between the sand particles and fiber also contributes to shear strength of the fiber-reinforced sand mixtures by increasing the angle of friction of the soil matrix as observed in this study.

5.3 Practical Implications

The randomly distributed discrete fibers may act as a spatial three-dimensional network to interlock sand grains, helping the grains to form a unitary coherent matrix and restricting the displacement. As the fibers were mixed and samples were compacted, the hard sand particles impacted and abraded the fiber surface, resulting in plastic deformation and even removal of part of the surface layer. It is speculated that pits and grooves that formed on the fiber surface constituted an interlock and improved the interactions between the fiber surface and the sand matrix. The interlock effect increases with an increased fiber content, which is one of the main reasons causing an increase in the shear strength of specimens prepared with high fiber contents. This phenomenon is tested with a ring shear test in the current study. Ring shear test was selected to determine the strength parameters of fiber-reinforced soils over direct shear test and triaxial tests since it can shear soil continuously in one direction at any magnitude of displacement. It is also very simple and practical to perform compared to triaxial test. However, it should be noted that more precise and accurate results could have been obtained from a triaxial test because it provides more uniform stress distribution in soil and more accurate volume change measurements during the shearing process. This is one of the limitations of this study. During the shearing process, the fiber is re-oriented gradually due to the sand rearrangement and rotation, and this fiber orientation in a shear zone might lead to the increase of shear resistance. These orientations increase with the fiber content (Liu et al. 2011). In addition, fiber inclusion increases the cohesive properties of the soil matrix due to its extensibility properties. Fibers stretch and do not deteriorate even at large strains (Consoli et al. 2007). The increase in cohesion reflects as improvement in tension resistance of the fiber-reinforced soil which contributes to peak and post-peak shear strength values of reinforced soils (Babu and Chouksey 2011).

6 Conclusions

In this paper, a series of ring shear tests were carried out on sand alone and fiber-reinforced sands specimens prepared fiber contents of 0.1, 0.3, 0.6, and 0.9 %, in order to study the mechanical behavior of these mixtures and their reinforcement mechanisms. The following conclusions can be drawn from the results of this study:

As compared to unreinforced sand, fiber reinforcement increased the shear strength of sand soil when fiber contents were increased from 0 to 0.9 %. It should be noted that inclusion of extreme fiber content into sand soils may cause a decrease in the shear strength. The shear strength increased gradually with an increase in fiber content. In addition, the fiber reinforced sand exhibited more ductile behavior and limited reductions in post peak shearing resistance.

There is no evidence of an increase in the shear stress values with inclusion of fibers for reinforcement until 2 % of strain for any of the fiber-reinforced sand mixtures. This is observed due to fiber slippage occurring at low strains. However, at large strains the results clearly indicate that inclusion of fibers into sand definitely improves the shear stress and ultimate strength of the soil.

Strength ratio parameter (R) is introduced to evaluate the effects of fiber on the shear strength of the reinforced sand. For fiber reinforced sand, the greater the fiber content of reinforced sand, the greater the shear strength ratio of reinforced sand at the same normal stress. For the same reinforcement material, the shear strength ratio of reinforced sand decreased significantly with the increase of vertical normal stress from 50 to 150 kPa. However, the shear strength ratio increased slightly with the increase of vertical normal stress from 150 to 200 kPa.

Evaluation of the comparison of the strength ratios of the fiber-reinforced sand mixtures suggests that fiber reinforcement is more efficient for geotechnical structures that are close to ground surface such as highway base/subbase/subgrade layers, shallow foundations, earth retaining structures, slopes. Fiber reinforcement can increase the critical height of the slope and decrease the potential slippage failure that may occur. Fibers can also be used as a fill material in loosely filled earth retaining structures. In addition, inclusion of fibers improves the bearing capacity of the soil underneath shallow foundation by increasing the angle of friction and cohesion parameters. One of the other advantages of the inclusion of fibers which is not covered in the current study is an increase in the hydraulic conductivity of the soil which allows excess pore water pressure to dissipate very quickly and reduces settlement of soils in shallow foundation design.

For sand reinforced with different ratios of fiber, both cohesion and angle of internal friction have exhibited a significant increase with the increase of fiber content. As compared with unreinforced sand, the cohesion and angle of internal friction for sand reinforced with different ratios of fiber increased by 5.3–27.4 kPa and 2.0°–7.3° respectively.

It should be noted that these results are valid only for the materials used in this study. Length and aspect ratio of fibers were also kept constant in this study. The orientation of the fibers was not considered. Further investigations are needed with different types of soils, different fiber lengths, different aspect ratios and orientation of the fibers to fully evaluate the effect of fiber inclusion to the soils. In addition, fiber reinforced soils were only subjected to ring shear test which does not provide as accurate results as the triaxial test. Moreover, effect of fibers on settlement and hydraulic conductivity of fine grain soils should be investigated. These are noted as limitations of this study.

References

Arora S, Aydilek AH (2005) Class F fly ash amended soils as highway base materials. J Mater Civ Eng ASCE 17(6):640–649

Babu GLS, Chouksey SK (2011) Stress–strain response of plastic waste mixed soil. Waste Manag 31:481–488

Casagrande MDT, Coop MR, Consoli NC (2006) The behavior of a fiber-reinforced bentonite at large shear displacements. J Geotech Geoenviron Eng ASCE 132(11):1505–1508

Cetin B, Aydilek AH, Guney Y (2010) Stabilization of recycled base materials with high carbon fly ash. Resour Conserv Recycl 54:878–892

Consoli NC, Montardo JP, Prietto PDM, Pasa GS (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron Eng 128(6):462–472

Consoli NC, Casagrande MDT, Coop MR (2007) Performance of a fibre-reinforced sand at large shear strains. Geotechnique 57(9):751–756

Consoli NC, Vendruscolo MA, Fonini A, Rosa FD (2009a) Fiber reinforcement effects on sand considering a wide cementation range. Geotext Geomembr 27:196–203

Consoli NC, Festugato L, Heineck KS (2009b) Strain-hardening behavior of fiber-reinforced sand in view of filament geometry. Geosynth Int 16(2):109–115

Consoli NC, Zortea F, de Souza M, Festugato L (2011) Studies on the dosage of fiber-reinforced cemented soils. J Mater Civ Eng ASCE 23(12):1624–1632

Consoli NC, Corte MB, Festugato L (2012) Key parameter for tensile and compressive strength of fiber-reinforced soil–lime mixtures. Geosynth Int 19(5):409–414

Diambra A, Ibraim E, Wood DM, Russell AR (2010) Fiber reinforced sands: experiments and modelling. Geotext Geomembr 28:238–250

Dos Santos APS, Consoli NC, Baudet BA (2010) The mechanics of fiber-reinforced sand. Geotechnique 60(10):791–799

Gao Z, Zhao J (2013) Evaluation on failure of fiber-reinforced sand. J Geotech Geoenviron Eng ASCE 139(1):95–106

Gray DH, Al-Refeai T (1986) Behavior of fabric versus fiber-reinforced sand. J Geotech Eng 112(8):804–820

Gray DH, Ohashi H (1983) Mechanics of fiber reinforcement in sand. J Geotech Eng 109(3):335–353

Heineck KS, Coop MR, Consoli NC (2009) Effect of microrefinement of soils from very small to large shear strains. J Geotech Geoenviron Eng ASCE 131(8):1024–1033

Ibraim E, Diambra A, Muir Wood DM, Russell AR (2010) Static liquefaction of fiber reinforced sand under monotonic loading. Geotext Geomembr 28:374–385

Kumar R, Kanaujia VK, Chandra D (1999) Engineering behavior of fiber-reinforced pond ash and silty sand. Geosynth Int 6(5):509–518

Liu J, Wang GH, Kamai T, Zhang FY, Yang J, Shi B (2011) Static liquefaction behavior of saturated fiber-reinforced sand in undrained ring-shear tests. Geotext Geomembr 29:462–471

Maher MH, Gray DH (1990) Static response of sand reinforced with randomly distributed fibers. J Geotech Eng 116(11):1661–1677

Maher MH, Ho YC (1994) Mechanical properties of kaolinite/fiber soil composite. J Geotech Eng ASCE 120(8):1381–1393

Ranjan G, Vasan RM, Charan HD (1994) Behavior of plastic-fiber reinforced sand. Geotext Geomembr 13:555–565

Ranjan G, Vasan RM, Charan HD (1996) Probabilistic analysis of randomly distributed fiber-reinfroced soil. J Geotech Eng 122(6):419–426

Sadek S, Najjar SS, Freiha F (2010) Shear strength of fiber-reinforced sands. J Geotech Geoenviron Eng ASCE 136(3):490–499

Santoni RL, Webster SL (2001) Airfields and road construction using fiber stabilization of sands. J Transp Eng 127(2):96–104

Santoni RL, Tungle SJ, Webster SL (2001) Engineering properties of sand–fiber mixtures for road construction. J Geotech Geoenviron Eng ASCE 127(3):258–268

Shukla SK, Sivakugan N, Singh AK (2010) Analytical model for fiber-reinforced granular soils under high confining stresses. J Mater Civ Eng ASCE 22(9):935–942

Waldron LJ (1977) Shear resistance of root-permeated homogeneous and stratified soil. Soil Sci Soc Am Proc 41:843–849

Yetimoglu T, Salbas O (2003) A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext Geomembr 21:103–110

Zhang MX, Javadi AA, Min X (2006) Triaxial tests of sand reinforced with 3D inclusions. Geotext Geomembr 24:201–209

Acknowledgments

Financial support for this study was provided by Recycled Materials Resource Center (RMRC) funded through Federal Highway Administration. The opinions and conclusions described in this paper are those of the writers and do not necessarily reflect the opinions or policies of the sponsors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, W., Cetin, B., Li, Y. et al. Experimental Investigation of Mechanical Properties of Sands Reinforced with Discrete Randomly Distributed Fiber. Geotech Geol Eng 32, 901–910 (2014). https://doi.org/10.1007/s10706-014-9766-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-014-9766-3