Abstract

During history, soil was always considered as the cheapest materials, but natural soil exist in site that may not be suitable for construction, and weakness is one of the main faults of soil mechanical characteristics against tension. With purpose of increasing strength and stability of soil particles, nowadays, soils reinforcement method is studying by several researchers. The main purpose of this research is study of effect of using polyvinyl alcohol (PVA) fiber on Babolsar sand behavior. Twelve consolidated drained triaxial (CD) test were conducted on samples with four confining pressures 50, 100, 300, and 500 kPa and three fiber contents (0, 0.5, and 1%). The experimental results indicate that fiber reinforcement improves the mechanical properties of sand. Adding PVA fiber to sand increases maximum shear strength, axial strain at failure point and decrease of strength loss after peak strength. Failure strain and strength increases by increasing confining pressure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The main weakness of soil as the main material used in soil structures is low tensile strength of these materials (Tavakoli and Kutanaei 2015; Choobbasti and Kutanaei 2017a; Kutanaei and Choobbasti 2017). When soil and reinforcement element are mixed, the produced composite materials has proper compressive and tensile strength in which reinforcement elements with tensile strength are inserted in to soil structure as a reinforce element (Rezaei et al. 2015; Choobbasti and Kutanaei 2017b; Anvari et al. 2017). Soil reinforcement is one of the branches of geotechnical that employs proper materials for reinforcing soil by using scientific principles and new method and improves engineering characteristics and mechanical properties such as strength, stiffness or elastic modulus, ductility, and bearing capacity (Pakar and Bayat 2011; Bayat et al. 2014, 2015, 2016; Pakar et al. 2014; Bayat and Bayat 2014; Bayat and Pakar 2012, 2013a, b; Kutanaei and Choobbasti 2016a; Mashhadban et al. 2016a).

The time for the first efforts to reinforce the soil is unknown (Bayat and Abdollahzade 2011; Edalati et al. 2016; Sarokolayi et al. 2015, 2016; Kutanaei and Choobbasti 2016b). More than 3000 years ago, Babylonian used reinforced earth for building ziggurats that in ancient Babylonian architecture was told tall tower (Choobbasti et al. 2015; Kutanaei and Choobbasti 2015a). About 2500 years, men putting branches of trees over swampy lands and soft lands were very common for establishment of road (Tavakoli et al. 2014a; Choobbasti et al. 2014; Kutanaei and Choobbasti 2015b; Mashhadban et al. 2016b). For the first time, statement or comment of soil reinforcement with fibers in geotechnical projects, by using plant roots was proposed as reinforcement element the effect of plant roots on increase of soil strength and as a result stability of natural house tops was reported.

The behavior of fiber-reinforced soil has been studied by many researchers (Kutanaei et al. 2012; Kutanaei and Choobbasti 2013; Janalizadeh et al. 2013; Tavakoli et al. 2014b). These studies show that addition of fibers to the sand increases the maximum shear strength and leads to a more ductile behavior. Diambra et al. (2007) explored the effect of confining pressure, fiber content and length on the mechanical behavior of fiber reinforcement soil. They concluded that the strain at failure increases with an increase in confining pressure, fiber content, and length and to a more ductile behavior. Yilmaz (2009) conducted several laboratory split tensile and unconfined compression tests on sand–clay mixtures reinforced with polypropylene fibers. They found that the ratio of unconfined compression and split tensile strength of sand–clay mixtures significantly improved by fiber reinforcement. Liu et al. (2011) investigated the static liquefaction resistance of saturated sand reinforced with polypropylene fibers in undrained ring shear tests. The results showed that the fibers inclusion fiber significantly reduces the potential for the occurrence of liquefaction. Maher and Ho (1993) carried out static and dynamic triaxial compression and extension tests on fiber-reinforced cemented soil. Their results showed an increase in the shear strength and energy absorption due to addition of fibers.

In this study, the effect of reinforcement by new synthetic fibers (PVA) with random distribution on triaxial shear behavior Babolsar sand was investigated by triaxial compression tests.

Experimental program

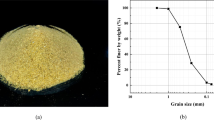

Babolsar sand were taken from the Caspian Sea located in north of Iran in Babolsar city. The grain size of Babolsar sand was presented in Fig. 1. This kind of sand, based on unified soil classification system, is classified as poorly graded sand (SP). All physical characteristics of Babolsar sand was presented in Table 1. PVA fibers shown in Fig. 2 were used to reinforce sand. PVA fibers with length of 12 mm, diameter of 0.1 mm were used. The properties of the PVA fibers are presented in Table 2.

To prepare PVA fiber-reinforced sand samples, the required amount of sand was first mixed with 5% water after which PVA fibers were added. Mixing was done using an electric mixer. The samples with a diameter of 52 mm and a height of 104 mm were prepared in five compressed layers for triaxial compression tests. The samples were hit to the desired height using a metal hammer for each layer, in order to achieve a relative density of 80%.

The specimens were saturated under back pressure of up to 350 kN/m, ensuring B values of at least 0.95 for all samples. The axial load were applied at a sufficiently low strain speed (rate) (0.02% per min) to ensure full drainage within the specimens. Drainage was also monitored by measuring the excess pore pressure at the opposite end of the specimen to the drainage. In this study, samples were tested in four confining pressures 50, 100, 300, and 500 kPa. Triaxial experimental setup is shown in Fig. 3.

Result and discussion

Deviatoric stress-axial strain behavior

Deviatoric stress-axial strain curves of unreinforced sand and fiber-reinforced sand with different percentages of fiber and confining pressures are shown in Fig. 4. The figure shows that the deviatoric stress increases with increasing fiber content. It can be seen at early stage of loading, that deviatoric stress is increased by applying deviatoric load. During shear loading, in fiber-reinforced sand samples, the shear stress at the sand particles is transferred to the reinforced elements through the particle interlocking (between fibers and sand particles). The reinforced elements that cross the shear zone undergo either breakage or pullout failure. Hence, tensile strength of fiber can be mobilized and the shear strength of sample increases. Moreover, it can be seen that the fiber inclusion causes a decrease in the deviatoric stress loss after the maximum shear strength. This behavior is more distinct as the percentage of reinforced elements increases. In other word, fiber-reinforced sand specimens behave more ductile than unreinforced sand specimens. This can be justified by two reasons. The first reason is that fiber elements have more flexibility than sand particles which can affect the ductility of the specimens. The second reason is that fiber elements prevent shear plane development in the specimens that is the main reason of deviatoric stress loss after maximum shear stress in non-reinforced sand specimens. According to the diagrams presented in Fig. 4, it can be clearly observed that the effect of confining pressure on deviatoric stress-axial strain curves is similar to the effect of fiber content. In other words, the tendency of samples to show clear maximum in the deviatoric stress-axial strain curves and the reduction in the post-peak loss strength behavior, restricted by increasing fiber content and confining pressure.

Volumetric strain-axial strain behavior

Volumetric strain-axial strain curves of unreinforced sand and fiber-reinforced sand (1% fiber) with different percentages of fiber and confining pressures are shown in Fig. 5. According to this figure, it is observed that the volumetric strain of unreinforced sand and fiber-reinforced sand decreases slightly during the initial deviatoric loading. As deviatoric loading continues, the volumetric response is reversed and reinforced and unreinforced samples show an increase in volumetric strain. Moreover, under higher confining pressures, the reinforced and unreinforced samples exhibit less dilation. In addition, adding of PVA fiber elements resulted in less volumetric expansion of specimens. This may be attributed to the fact that the confinement enhancement introduced by discrete fiber elements.

Brittle index

Figure 6 shows the ductility of Babolsar sand mixed with different percentages of PVA fiber in terms of relationship between the brittle index and corresponding fiber content and varying confining pressures. Brittle index is defined as follows:

where IB is the brittleness index and qmax and qres are the maximum deviatoric stresses and residual deviatoric stresses, respectively. As the brittleness index decreases, the failure behavior becomes more ductile. It can be seen that with increase of fiber content and confining pressure, the brittleness index increases. This result shows that the ductility of reinforced sand samples strongly depends on fiber content. Higher ductility and lower loss in post peak deviatoric stress of PVA fiber-reinforced sand specimens are the advantages of this reinforcing material in comparison with the non-reinforced sand samples. However the effect of PVA fiber content on the brittle index of samples decreases with increasing confining pressure. Brittle index of samples is almost same under confining pressure 500 kPa.

Axial strain

Figure 7 shows the variation of the axial strain at maximum deviatoric stress with fiber content which were measured at isotropic confining pressures, 50, 100, 300, and 500 kPa. As it is clear, it can be seen that the addition of PVA fiber strongly affects the behavior of sand and increases the axial strain at failure. This result is in good agreement with obtained results by other researchers which explored the behavior of sand reinforced by other types of fiber. Moreover, the axial strain the failure for tests performed under confining pressure of 500 kPa is greater than similar ones conducted under other confining pressures. Therefore, it can be concluded that the ductility of samples increases with increasing of confining pressure and fiber content. Increase in confining stress is achieved by increasing the overburden stress (increasing the depth). In particular, when applying reinforced soils at a shallow depth, the degree of brittle failure may be more pronounced due to a low confining stress. At shallow depth (low confining stress), the axial strain at the failure stress can be controlled by the inclusion of randomly distributed fibers.

Failure and residual strength envelops

The effect of adding of PVA fiber on the failure strength envelops and residual strength envelops shown in Fig. 8 as a function of the confining pressure, for various fiber content. It can be seen that the failure strength envelops and residual strength envelops move upward with an increase in percentage of fiber. This result can be justified according to this point that maximum deviatoric strength and residual strength increases with increase in percentage of fiber. Figure 8 also reveals that the difference between the failure strength envelops and residual strength envelops decreases with increasing PVA fiber content, which reveals more ductile response as percentage of PVA fiber increases.

Conclusion

This research investigated the combined impacts of confining pressure and PVA fiber content on the triaxial shear behavior of Babolsar sand. The results of this study can be summarized as follows:

-

1-

Increasing PVA fiber content and confining pressure causes maximum shear strength of sand increase.

-

2-

At higher confining pressure and fiber content, there is no significant strength loss at large strain; therefore, it can be concluded that the ductility of samples increases with increasing of confining pressure and fiber content.

-

3-

Increasing confining pressure and PVA fiber content increases axial strain at failure and reduces the brittleness index.

-

4-

Failure and residual strength envelops moves upward with an increase in percentage of fiber. Moreover, the difference between the failure and residual strength envelops decreases with increasing PVA fiber content

-

5-

Adding fibers and increasing confining pressure resulted in a decrease in dilatancy of Babolsar sand.

-

6-

Comparison results reveal that adding fibers and increasing confining pressure have same effect on triaxial shear response of sandy soil.

References

Anvari SM, Shooshpasha I, Kutanaei SS (2017) Effect of granulated rubber on shear strength of fine-grained sand. J Roc Mech Geotec Eng 9(5):936–944

Bayat M, Abdollahzade GR (2011) Analysis of the steel braced frames equipped with ADAS devices under the far field records. Lat Am J Solids Stru 8(2):163–181

Bayat M, Bayat M (2014) Seismic behavior of special moment-resisting frames with energy dissipating devices under near source ground motions. Steel Compos Struct 16(5):533–557

Bayat M, Pakar I (2012) Accurate analytical solution for nonlinear free vibration of beams. Struct Eng Mech 43(3):337–347

Bayat M, Pakar I (2013a) On the approximate analytical solution to non-linear oscillation systems. Shock Vib 20(1):43–52

Bayat M, Pakar I (2013b) Nonlinear dynamics of two degree of freedom systems with linear and nonlinear stiffnesses. Earthq Eng Eng Vib 12(3):411–420

Bayat M, Bayat M, Pakar I (2014) Nonlinear vibration of an electrostatically actuated microbeam. Lat Am J Solids Stru 11(3):534–544

Bayat M, Pakar I, Bayat M (2015) Nonlinear vibration of mechanical systems by means of Homotopy perturbation method. Kuwait J Sci Eng 42(3):64–85

Bayat M, Pakar I, Bayat M (2016) Nonlinear vibration of conservative oscillator’s using analytical approaches. Struct Eng Mech 59(4):671–682

Choobbasti AJ, Kutanaei SS (2017a) Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J Roc Mech Geotech Eng 9(5):981–988

Choobbasti AJ, Kutanaei SS (2017b) Effect of fiber reinforcement on deformability properties of cemented sand. J Adhes Sci Technol 31(14):1576–1590

Choobbasti AJ, Tavakoli H, Kutanaei SS (2014) Modeling and optimization of a trench layer location around a pipeline using artificial neural networks and particle swarm optimization algorithm. Tunn Undergr Space Technol 40:192–202

Choobbasti AJ, Vafaei A, Kutanaei SS (2015) Mechanical properties of sandy soil improved with cement and nanosilica. Open Eng 5(1):1–6

Diambra A, Russell AR, Ibraim E, Muir Wood D (2007) Determination of fibre orientation distribution in reinforced sands. Géotechnique 57:623–628

Edalati SA, Bayat M, Pakar I, Bayat M (2016) A novel approximate solution for nonlinear problems of vibratory systems. Struct Eng Mech 57(6):1039–1049

Janalizadeh A, Kutanaei SS, Ghasemi E (2013) Control volume finite element modeling of free convection inside an inclined porous enclosure with a sinusoidal hot wall. Sci Iran 20(5):1401–1409

Kutanaei SS, Choobbasti AJ (2013) Effect of the fluid weight on the liquefaction potential around a marine pipeline using CVFEM. EJGE 18:633–646

Kutanaei SS, Choobbasti AJ (2015a) Mesh-free modeling of liquefaction around a pipeline under the influence of trench layer. Acta Geotech 10(3):343–355

Kutanaei SS, Choobbasti AJ (2015b) Prediction of combined effects of fibers and cement on the mechanical properties of sand using particle swarm optimization algorithm. J Adhes Sci Technol 29(6):487–501

Kutanaei SS, Choobbasti AJ (2016a) Triaxial behavior of fiber-reinforced cemented sand. J Adhes Sci Technol 30(6):579–593

Kutanaei SS, Choobbasti AJ (2016b) Experimental study of combined effects of fibers and nanosilica on mechanical properties of cemented sand. J Mater Civil Eng 28(6):06016001

Kutanaei SS, Choobbasti AJ (2017) Effects of nanosilica particles and randomly distributed fibers on the ultrasonic pulse velocity and mechanical properties of cemented sand. J Mate Civil Eng 29(3):04016230

Kutanaei SS, Ghasemi E, Bayat M (2011) Mesh-free modeling of two-dimensional heat conduction between eccentric circular cylinders. Int J Phys Sci 6(16):4044–4052

Kutanaei SS, Roshan N, Vosoughi A, Saghafi S, Barari A, Soleimani S (2012) Numerical solution of stokes flow in a circular cavity using mesh-free local RBF-DQ. Eng Anal Bound Elem 36(5):633–638

Liu J, Wang G, Kamai T, Zhang F, Yang J, Shi B (2011) Static liquefaction behavior of saturated fiber-reinforced sand in undrained ring-shear tests. Geotext Geomembr 29(5):462–471

Maher MH, Ho YC (1993) Behavior of fiber-reinforced cemented sand under static and cyclic loads. Geotech Test J 16(3):330–338

Mashhadban H, Beitollahi A, Kutanaei SS (2016a) Identification of soil properties based on accelerometer records and comparison with other methods. Arab J Geosci 9(6):427–525

Mashhadban H, Kutanaei SS, Sayarinejad MA (2016b) Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr Build Mater 119:277–287

Pakar I, Bayat M (2011) Analytical solution for strongly nonlinear oscillation systems using energy balance method. Int J Phys Sci 6(22):5166–5170

Pakar I, Bayat M, Bayat M (2014) Accurate periodic solution for nonlinear vibration of thick circular sector slab. Steel Compos Struct 16(5):521–531

Rezaei S, Choobbasti AJ, Kutanaei SS (2015) Site effect assessment using microtremor measurement, equivalent linear method, and artificial neural network (case study: Babol, Iran). Arab J Geosci 8(3):1453–1466

Sarokolayi LK, Beitollahi A, Abdollahzadeh GR, Amreie STR, Kutanaei SS (2015) Modeling of ground motion rotational components for near-fault and far-fault earthquake according to soil type. Arab J Geosci 8(6):3785–3797

Sarokolayi LK, Kutanaei SS, Golafshani SMI, Haji SRH, Mashhadban H (2016) Control-volume-based finite element modelling of liquefaction around a pipeline. Geomat Nat Hazards Risk 7(4):1287–1306

Tavakoli H, Kutanaei SS (2015) Evaluation of effect of soil characteristics on the seismic amplification factor using the neural network and reliability concept. Arab J Geosci 8(6):3881–3891

Tavakoli HR, Omran OL, Kutanaei SS (2014a) Prediction of energy absorption capability in fiber reinforced self-compacting concrete containing nano-silica particles using artificial neural network. Lat Am J Solids Stru 11(6):966–979

Tavakoli HR, Omran OL, Shiade MF, Kutanaei SS (2014b) Prediction of combined effects of fibers and nanosilica on the mechanical properties of self-compacting concrete using artificial neural network. Lat Am J Solids Stru 11(11):1906–1923

Yilmaz Y (2009) Experimental investigation of the strength properties of sand–clay mixtures reinforced with randomly distributed discrete polypropylene fibers. Geosynth Int 16(5):354–363

Author information

Authors and Affiliations

Corresponding authors

Additional information

Editorial handling: David Giles

Rights and permissions

About this article

Cite this article

Choobbasti, A.J., Kutanaei, S.S. & Ghadakpour, M. Shear behavior of fiber-reinforced sand composite. Arab J Geosci 12, 157 (2019). https://doi.org/10.1007/s12517-019-4326-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-019-4326-z