Abstract

In this work, catalyst composition–activity relationship of supported catalysts in Biginelli and Hantzsch reactions was investigated under mild conditions. Biginelli dihydropyrimidinone/thiones were prepared over Fe–Cu/ZSM-5 as an efficient, convenient, and environmentally benign catalyst under ultrasonic irradiation in aqueous media in very good yields. The Fe–Cu/ZSM-5-catalyzed synthesis of 1,4-dihydropyridines and their aromatization to polysubstituted pyridines and also a new one-pot, two-step, and sequential protocol for the synthesis of pyridine derivatives, employing an aldehyde, ethyl acetoacetate, and ammonium acetate under the same green experimental conditions were illustrated. Three-component condensation in the presence of supported reagent with operational simplicity, inexpensive reagents, short reaction time, high yield of products, and use of non-toxic reagents makes this synthetic protocol an attractive one.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Green chemistry is a branch of chemistry, which covers all chemical processes that reduce or preferably eliminate waste generation and avoid the use of toxic and/or hazardous substances and solvents [1–3].

One-pot multicomponent reactions have been applied as an efficient tool in combinatorial chemistry and drug discovery for the synthesis of diverse and complex compounds, as well as small and drug-like heterocycles from easily available starting materials via a green synthetic approach by reducing the number of steps, energy consumption, and waste production [4–7].

In recent years, 1,4-dihydropyridines (DHPs) and 3,4-dihydropyrimidinone/thiones (DHPMs) have occupied an important place in organic and medicinal chemistry, mainly due to their diverse therapeutic and pharmacological properties [8, 9]. A number of Hantzsch dihydropyridines, namely azelnidipine and nifedipine, have been introduced as potential drugs for the treatment of congestive heart failure due to their calcium antagonistic effect (Fig. 1) [10–13]. In addition, DHPs are used as organocatalysts for asymmetric reactions such as hydrogenation of quinolones in the synthesis of alkaloids, asymmetric reductive amination of aldehydes, and hydrogenation of α,β-unsaturated aldehydes and ketones. Besides, the oxidation of readily accessible Hantzsch 1,4-DHP provides one of the shortest routes to polysubstituted pyridine derivatives [10–13, 32, 33]. The dihydropyrimidinone/thione moiety constitutes an active backbone in exciting medications, e.g., monastrol (anti-cancer agent), SQ 32926, and SQ 32547 (antihypertensive drugs) (Fig. 1). Also their particular structure is present in natural marine alkaloid Batzelladine A and B for the development of AIDS therapy [9, 14–17].

This versatile applicability highlights the importance of access to efficient synthetic routes to well benign DHP and DHPM derivatives. Ultrasonic-irradiation technique provides an efficient and powerful tool to perform reactions faster with enhanced product yields with high purity by reducing the unwanted formation of byproducts [18–20]. One of the key areas of green chemistry is green catalysis. The extensive application of metal oxides supported on various inorganic solid supports has attracted the attention of many chemists in different areas of chemistry [19, 21, 22]. The use of various copper-exchanged zeolites as active and stable heterogeneous catalysts in synthetic organic chemistry can make the synthetic process more efficient from both environmental and economic points of view [23, 24]. On the other hand, the catalysis of organic reactions in aqueous medium is fully compatible with green chemistry [2, 3, 21, 22].

In this work, we have investigated Biginelli and Hantzsch condensation reactions in the presence of supported catalysts with different transition metals (Mn, Fe, Co, and Cu) and γ -alumina (γ-Al2O3), Zeolite Socony Mobil-5 (ZSM-5), as an aluminosilicate zeolite, and silicoaluminophosphate molecular sieve (SAPO-34) under ultrasonic irradiation in various solvents. The desired products were obtained in excellent yields using Cu–Fe/ZSM-5 bimetallic oxide nanocatalyst as an “E” catalyst (efficient, eco-friendly, and economic) via zeolite-catalyzed multicomponent reactions (ZCMCRs) in aqueous medium. Also some of the Hantzsch-polysubstituted pyridines were prepared efficiently by Cu–Fe/ZSM-5 under the same green conditions in very good yields.

Result and discussion

Because of the wide use of solid acid catalysts in different areas of organic chemistry and due to our continuing interest to use various catalysts in multicomponent reactions transformation [8, 25–31], here we wish to report an efficient and environmentally benign method for the synthesis of DHPs, DHPMs, and polysubstituted pyridines via one-pot three-component condensation reactions in the presence of metal-supported nanocatalysts as recyclable catalysts in water under ultrasonic irradiation (high intensity) at ambient temperature (Scheme 1).

We initiated our study with the supported catalysts with different transition metals (Mn, Fe, Co, and Cu) and supports (γ-Al2O3, ZSM-5, and SAPO-34) on the Hantzsch condensation reaction. In order to optimize the reaction parameters, the cyclo-condensation reaction of benzaldehyde (1 equiv.), ethyl acetoacetate (2 equiv.), and ammonium acetate (1 equiv.) was investigated in water at room temperature for preparation of diethyl 1,4-dihydro-2,6-dimethyl-4-phenylpyridine-3,5-dicarboxylate (5b) as a model reaction.

Acidity of catalysts is one of the important parameters to determine their performance during cyclo-condensation processes. Among the zeolite-supported metal nitrates, Cu(NO3)2 has attracted much attention because of its suitable acidity, eco-friendliness, easy availability, and low cost, thereby acting as a promising reagent. Also the activity of catalysts with metal loading of 10 wt% is lower with 5 wt%. This decrease can be attributed to excessive metal agglomeration, leading to the formation of large metal particles. Besides, further content of metal blocks the pores and active sites of the catalyst so the catalytic activity decreases. Therefore, the metal content was kept at 5 wt% for monometallic catalysts. To evaluate and optimize the catalytic system, three-component condensation was examined with different supported Lewis acid catalysts to give 5b. Interestingly, it was found that Cu(NO3)2 supported on zeolite H-ZSM-5 with low loading (5 wt%) was proved to be an efficient catalyst, and gave 5b in 61 % yield under ultrasonic irradiation in water. The sequence of acidic property of supports is as follows:

The γ-Al2O3 has the least acidity, and the acidity of H-ZSM-5 is more than H-SAPO-34. Therefore, Cu-ZSM-5 has shown higher activity than Cu-SAPO-34. Mn-based catalysts show poor activity during the cyclo-condensation reaction due to the formation of many other side products.

More investigation of the metal-supported nanocatalysts revealed that metal has more influence than support on catalyst activity at supported catalysts. Hence, Cu-ZSM-5 has shown higher activity than Cu-SAPO-34 for the preparation of 5b. However, the reaction proceeded rather slowly, and no significant acceleration was observed.

Incorporation of different transition metals into Cu(NO3)2/H-ZSM-5 for preparation of a series of M–Cu/ZSM-5 (M: Mn, Co, and Fe) bimetallic oxide nanocatalysts has become a target for optimizing the catalytic system of monometallic oxide catalysts for the synthesis of DHP derivatives. The study of catalytic ability of Fe–Cu/ZSM-5 catalyst showed that incorporation of Fe over Cu/ZSM-5 increased the product yield to 95 %, and the reaction time (5 min) was decreased with the decrease of the catalyst loading (3 wt%) (Table 1, entry 15). This result is in agreement with our working hypothesis that the favorable synergetic effects of iron and copper, acidity, and reactant adsorption ability of the support might be the main factors for improving the cyclo-condensation reaction on Fe–Cu/ZSM-5. The other reason may be the phenomenon called ‘acoustic cavitationsʼ produced by ultrasound irradiation. It is worthy to note that ultrasound with frequencies less than 50 kHz and using solid catalysts in the reaction mixture could increase the reaction rate. Molecules of the liquid are separated during the rarefaction cycle of the wave, generating bubbles that undergo subsequent implosive collapse in a liquid that produces unusual chemical and physical environments. These rapid and violent implosions of the bubbles generate localized ‘hot spots.ʼ Such localized hot spots can be considered as microreactors in which the energy of sound is transformed into a useful chemical form next to the surface of the catalyst/reactants [18–20].

We studied the effect of various solvents under ultrasound irradiation and also solvent-free conditions on the model reaction. As shown in Table 2, polar solvents and solvent-free conditions afforded better yield than the nonpolar ones, and the best result was obtained in aqueous medium in which Fe–Cu/ZSM-5 catalyst worked most efficiently by phasing out of the desired product.

To further show the applicability of this method, the preparation of derivatives 5(a–f) with variety of aromatic aldehydes bearing electron-withdrawing or electron-donating groups was investigated under the same experimental conditions, and the corresponding products were obtained in high yields without the formation of any side products (Table 3). Some of the Hantzsch dihydropyridines was confirmed by IR, NMR, elemental analyses, and melting points.

In addition to the benefits from economical point of view, reuse of catalysts is very important to avoid wastes. Therefore, we investigated the catalytic performance of the recycled Fe–Cu/ZSM-5 in the model reaction. For this purpose, all the water added for filtering and washing the product was collected and washed with ethanol (2 × 10 mL) to remove the organic impurities. Then the water was evaporated, and the extracted catalyst was dried. As shown in Fig. 2, the recovered catalyst could be reused three times without significant decrease in its catalytic activity.

Results of the reusability of Fe–Cu/ZSM-5 in the synthesis of diethyl 1,4-dihydro-2,6-dimethyl-4-phenylpyridine-3,5-dicarboxylate (5b) in water under ultrasonic irradiation (Table 3, entry 2)

To our knowledge, the use of metal-supported nanocatalyst to oxidize 1,4-DHPs has never been reported before. Herein, we examined the possibility of using Fe–Cu/ZSM-5 as a novel environmentally benign reagent to effect the oxidative aromatization of Hantzsch 1,4-dihydropyridines. Also a one-pot, two-step, and sequential protocol will provide new alternative in the synthesis of polysubstituted pyridines. In this work, for example, DHPs (5b, 5e, and 5f) were converted to the corresponding pyridines 6(a–c) efficiently in excellent yields by Fe–Cu/ZSM-5 (6 wt%) in water under ultrasonic irradiation in the presence of oxygen in air at ambient temperature (Scheme 2).

This work proposes a mechanism for the formation of polysubstituted pyridines 6a, 6b, and 6c (Scheme 3). In analogy to the mechanisms involving high-valence metal ions, the oxidation of 1,4-DHP is presumed to be initiated by a single electron transfer to acceptor Cu(II) and/or Fe(III) to produce a radical cation a, and Cu(I) and/or Fe(II). This is followed by a proton loss from radical cation a, to generate radical b. The latter is further oxidized by another molecule of Cu(II) and/or Fe(III) to form the oxidized pyridine c (in the protonated form) and Cu(I) and/or Fe(II). Cu(I) and/or Fe(II) is oxidized by molecular oxygen to regenerate Cu(II) and/or Fe(III) along with the formation of hydroperoxide radical via superoxide ion. Hydroperoxide radical can, in turn, oxidize another Cu(I) and/or Fe(II) ion to produce H2O2. Both the hydroperoxide radical and H2O2 can oxidize 1,4-DHP, thereby accounting for less than the stoichiometric consumption of O2 in the oxidation [32].

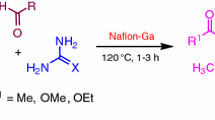

Encouraged by these results, we next focused our efforts to study the effect of the supported catalysts with different transition metals (Mn, Fe, Co, and Cu) and supports (γ-Al2O3, H-ZSM-5 and H-SAPO-34) under ultrasonic irradiation in various solvents on the Biginelli condensation reaction for the synthesis of dihydropyrimidinone/thiones (DHPMs) (Scheme 1). In order to achieve the optimum conditions, the reaction of benzaldehyde (1 equiv.) with ethylacetoacetate (1 equiv.) and urea (1.5 equiv.) was selected as a model. The trials were begun by comparing the catalytic efficiency of Fe-Cu/ZSM-5 with other Cu-supported nanocatalysts in this work. The yield of Biginelli product is up to 42, 53, and 65 % with Cu/γ-Al2O3, Cu/SAPO-34, and Cu/ZSM-5, respectively. The effect of different solvents was then studied. Biginelli product is obtained in moderate to good yields in CH3CN, THF, ethanol, and water. However, the reaction in water under ultrasonic irradiation at ambient temperature gave very good yield of the desired product.

Also the different experiments showed that the best result was obtained by the application of Fe-Cu/ZSM-5 (3 wt%) in water under ultrasonic irradiation (high intensity) at ambient temperature within 5 min.

In order to study the scope and generality of this methodology, ferrocenecarboxaldehyde was tested in the previous reaction. Unfortunately, it was observed that even under optimized conditions, the corresponding 1,4-DHPM was isolated in very low yield due to the formation of many other side products. Also the starting material was still present in the crude products (according to 1H NMR spectrum). In comparison, the reaction was amenable to a wide range of aromatic aldehydes bearing either electron-donating or electron-withdrawing groups, and in all cases, gave the desired products in very good yields (Table 4). By replacing urea with thiourea in the reaction system, the corresponding Biginelli products were also obtained in high yields.

Conclusion

In summary, for investigation of the relationship between catalyst composition and catalytic performance in a cyclo-condensation process, one-pot three-component synthesis of dihydropyrimidinone/thione and dihydropyridine derivatives via Biginelli and Hantzsch condensations was studied using the catalysts with different metals (Mn, Fe, Co, and Cu) and supports (γ-Al2O3, ZSM-5, and SAPO-34) at ambient temperature. The results revealed that Fe–Cu/ZSM-5 bimetallic oxide nanocatalyst is the best and least expensive catalyst for the preparation of 1,4-DHPs and 3,4-DHPMs in water as a suitable green solvent under ultrasonic irradiation in excellent yields. Also we successfully developed a new and easy to perform method for efficient oxidation of Hantzsch 1,4 dihydropyridines, and a new one-pot potentially efficient, absolutely clean, versatile, green procedure for the synthesis of polysubstituted pyridines under the same experimental conditions. These simple procedures combined with easy recovery and reuse of this catalyst make this method economically and environmentally benign.

Experimental

Material and technique

Chemicals were either prepared in our laboratory or purchased from Merck, Fluka, and Aldrich. Commercial products were used without further purification. The 1H and 13C NMR spectra were recorded with a Bruker FT-400 MHz spectrometer at room temperature and with CDCl3 and/or DMSO-d6 as solvent. The FTIR spectra were recorded on a Bruker Tensor 270 spectrometer. The reactions were carried out using an ultrasonic processor probe (SONOPULS Ultrasonic Homogenizers). The elemental analyses were carried out with an Elementar Vario EL III instrument. The abbreviations used for NMR signals are s = singlet, d = doublet, t = triplet, and m = multiplet. The melting points were recorded on a Büchi B-545 apparatus in open capillary tubes.

Synthesis of nanocatalysts

All mono and bimetallic nanocatalysts were prepared through the excess-solution impregnation method. The precursors of used metals were Cu(NO3)2·3H2O, Co(NO3)2·6H2O, Fe(NO3)3·9H2O, and Mn(NO3)2·4H2O, and the used supports were H-ZSM5 (Si/Al2 = 50), γ-Al2O3, and SAPO-34. The type of metal was chosen based on our previous research results [28]. The metal content was kept at 5 wt% for monometallic catalysts and for bimetallic catalysts, and the second metal content was kept at 3 wt%. The first determined amount of precursors was dissolved in 30 mL of the mixture of distilled water and ethanol with a volume ratio of 50 %. Then the support was added to the solution, and the suspension was stirred at 45 °C until the solvent was totally evaporated. Subsequently, the catalysts were dried in an oven at 100 °C overnight and then calcined at 550 °C for 4 h. Under these conditions, complete decomposition of metal nitrate into metal oxide occurred. The prepared catalysts were kept in desiccator until testing time to prevent water and contaminant adsorption.

General procedure for preparation of Hantzsch 1,4-dihydropyridine (DHP) derivatives 5(a–f)

In a typical experiment, aromatic aldehyde (1 mmol), β-ketoester (2 mmol), ammonium acetate (1 mmol), and Fe-Cu/ZSM-5 (3 wt%) in 2 ml water were introduced in a 20-mL heavy-walled pear-shaped two-necked flask with nonstandard-tapered outer joint. The flask was attached to a 12-mm tip diameter probe, and the reaction mixture was sonicated at ambient temperature at 20 % power of the processor. After completion of the reaction (monitored by TLC, within 5–8 min), the solid product was filtered, washed with water and ethanol, dried, and recrystallized from ethanol. The supported reagent was washed thrice with water and ethanol and dried under vacuum before reuse. Data for the selected compounds are as shown below:

Diethyl 1,4-dihydro-2,6-dimethyl-4-phenylpyridine-3,5-dicarboxylate (5b)

White powder; yield 95 %; M.P. = 150–152 °C; FTIR (KBr, cm−1): 3416 (str, N–H), 3093 (str, ArCH), 2981 (str, Aliphatic C–H), 1692 (str, O–C=O), 1490 (str, C=C), 1211 (str, C–O). 1H NMR (400 MHz, CDCl3, ppm): δ 1.21 (t, J = 8.0 Hz, 6H, 2 O–CH2CH 3), 2.32 (s. 6H, 2CH3), 4.04–4.09 (q, J = 8.0 Hz, 4H, 2 O–CH 2CH3), 4.98 (s, H, C4–H), 5.64 (s, 1H, N–H), 7.11–7.28 (m, 5H, Ar–H). 13C NMR (100 MHz, CDCl3, ppm): δ 13.22, 18.60, 38.57, 58.70, 103.14, 125.07, 126.79, 126.99, 127.08, 127.41, 142.80, 146.72, 166.59 (C=O). Anal. Calc. for C19H23NO4: C 69.28, H 7.04, N 4.25 %. Found: C 69.41, H 6.99, N 4.12 %.

Diethyl 4-(benzo[d] [1, 3] dioxol-5-yl)-1,4-dihydro-2,6-dimethylpyridine-3,5-dicarboxylate (5d)

White powder; yield 95 %; M.P. = 200–203 °C; FTIR (KBr, cm−1): 3352 (str, N–H), 3096 (str, ArCH), 2979 (str, Aliphatic C–H), 1690 (str, O–C = O), 1651, 1559, 1489 (str, C=C), 1237, 1211 (str, C–O). 1H NMR (400 MHz, CDCl3, ppm): δ 1.23 (t, J = 7.1 Hz, 6H, 2 O–CH2CH 3), 2.31 (s. 6H, 2CH3), 4.09–4.13 (q, J = 7.1 Hz, 4H, 2 O–CH 2CH3), 4.90 (s, H, C4–H), 5.71 (s, 1H, N–H), 5.87 (s, 2H, O–CH2–O), 6.64 (d, J = 8.4 Hz, 1H, Ar–H), 6.74 (d, J = 8.4 Hz, 1H, Ar–H), 6.77 (s, 1H, Ar–H). 13C NMR (100 MHz, CDCl3, ppm): δ 13.29, 18.63, 38.31, 58.74, 99.62, 103.35, 106.54, 107.58, 119.98, 140.99, 142.49, 166.57 (C=O). Anal. Calc. for C20H23NO6: C 64.33, H 6.21, N 3.75 %. Found: C 64.10, H 6.35, N 3.70 %.

General procedure for the oxidation of 1,4-dihydropyridines to the corresponding polysubstituted pyridines 6(a–c)

In a typical experiment, aromatic aldehyde (1 mmol), β-ketoester (2 mmol), ammonium acetate (1 mmol) and Fe–Cu/ZSM-5 (6 wt%) and/or the Hantzsch 1,4-dihydropyridine (1 mmol), and Fe–Cu/ZSM-5 (3 wt%) in 2 ml water were introduced in a 20-mL heavy-walled pear-shaped two-necked flask with nonstandard-tapered outer joint. The flask was attached to a 12-mm tip diameter probe, and the reaction mixture was sonicated at ambient temperature at 20 % power of the processor. After completion of the reaction (monitored by TLC, within 10–15 min), the solid product was filtered, washed with water and ethanol, dried, and recrystallized from ethanol. The supported reagent was washed thrice with water and ethanol and dried under vacuum before reuse. Data for the selected compound are as shown below:

Diethyl 4-(4-hydroxyphenyl)-2,6-dimethylpyridine-3,5-dicarboxylate (6b)

White powder; yield 100 %; M.P. = 172–174 °C; FTIR (KBr, cm−1): 3414 (str, O–H), 3054 (str, ArCH), 2983 (str, Aliphatic C–H), 1720 (str, O–C=O), 1612, 1564, 1512, 1441 (str, C=C), 1372, 1331, 1239, 1168 (str, C–O), 835, 763. 1H NMR (400 MHz, CDCl3, ppm): δ 1.00 (t, J = 7.1 Hz, 6H, 2 O–CH2CH 3), 2.59 (s. 6H, 2CH3), 4.04–4.09 (q, J = 7.1 Hz, 4H, 2 O–CH 2CH3), 6.30 (s, 1H, O–H), 6.74–6.84 (m, 2H, Ar–H), 7.09–7.12 (m, 2H, Ar–H), 6.77. 13C NMR (100 MHz, CDCl3, ppm): δ 12.71, 21.65, 60.53, 114.15, 114.46, 126.34, 127.27, 128.48, 128.84, 154.13, 155.35, 167.19 (C=O). Anal. Calc. for C19H21NO5: C 66.46, H 6.16, N 4.08 %. Found: C 66.31, H 6.28, N 4.22 %.

General procedure for preparation of Biginelli 3,4-dihydropyrimidinone/thione (DHPM) derivatives 7(a–i)

In a typical experiment, aromatic aldehyde (1 mmol), β-ketoester (1 mmol), urea, or thiourea (1.5 mmol) and of Fe–Cu/ZSM-5 (3 wt%) in 2 ml water were introduced in a 20-mL heavy-walled pear-shaped two-necked flask with nonstandard-tapered outer joint. The flask was attached to a 12-mm tip diameter probe, and the reaction mixture was sonicated at ambient temperature at 20 % power of the processor. After completion of the reaction (monitored by TLC, within 5–8 min), the solid product was filtered washed with water and ethanol, dried, and recrystallized from ethanol. The supported reagent was washed thrice with water and ethanol and dried under vacuum before reuse. Data for selected compounds are as shown below:

Methyl 1,2,3,4-tetrahydro-6-methyl-4-phenyl-2-thioxopyrimidine-5-carboxylate (7a)

White powder; yield 95 %; M.P. = 211–213 °C; FTIR (KBr, cm−1): 3312, 3178 (str, N–H), 3098 (str, ArCH), 2925 (str, Aliphatic C–H), 1670 (str, O–C=O), 1567 (str, C=C), 1338 (str, C–O), 1232 (str, C–N), 1104 (str, C=S), 750. 1H NMR (400 MHz, CDCl3, ppm): δ 2.36 (s, 3H, CH3), 3.64 (s, 3H, O–CH3), 5.40 (s, H, C4–H), 7.26–7.35 (m, 6H, Ar–H and 3-NH), 7.95 (s, 1H, 1-NH). 13C NMR (100 MHz, CDCl3, ppm): δ 17.51, 50.47, 55.18, 101.78, 125.64, 127.45, 127.79, 127.97, 141.17, 141.75, 164.65 (C=O), 173.81 (C=S). Anal. Calc. for C13H14N2O2S: C 59.52, H 5.38, N 10.68, S 12.22 %. Found: C 59.29, H 5.21, N 10.75, S 12.01 %.

Methyl 4-(benzo[d][1, 3]dioxol-5-yl)-1,2,3,4-tetrahydro-6-methyl-2-thioxopyrimidine-5-carboxylate (7c)

White powder; yield 95 %; M.P. = 193–195 °C; FTIR (KBr, cm−1): 3313, 3187 (str, N–H), 3088 (str, ArCH), 2997 (str, Aliphatic C–H), 1671 (str, O–C=O), 1579 (str, C=C), 1485, 1343 (str, C–O), 1191 (str, C–N), 1120 (str, C=S), 803. 1H NMR (400 MHz, CDCl3, ppm): δ 2.36 (s, 3H, CH3), 3.65 (s, 3H, O–CH3), 5.30 (s, H, C4–H), 5.94 (s, 2H, O–CH2–O), 6.74–6.75 (m, 3H, Ar–H), 7.37 (s, 1H, 3-NH). 7.96 (s, 1H, 1-NH). 13C NMR (100 MHz, CDCl3, ppm): δ 17.46, 50.52, 54.91, 100.27, 101.74, 106.08, 107.40, 119.27, 135.20, 141.73, 146.67, 147.12, 164.65 (C=O), 173.36 (C=S). Anal. Calc. for C14H14N2O4S: C 54.89, H 4.61, N 9.14, S 10.47 %. Found: C 54.74, H 4.77, N 9.08, S 10.40 %.

Methyl 1,2,3,4-tetrahydro-6-methyl-2-thioxo-4-p-tolylpyrimidine-5-carboxylate (7d)

White powder; yield 92 %; M.P. = 154–156 °C; FTIR (KBr, cm−1): 3339, 3189 (str, N–H), (str, ArCH), 2926 (str, Aliphatic C–H), 1668 (str, O–C=O), 1562 (str, C=C), 1343 (str, C–O), 1178 (str, C–N), 1111 (str, C=S), 803. 1H NMR (400 MHz, CDCl3, ppm): δ 2.31 (s, 3H, CH3), 2.35 (s, 3H, CH3), 3.63 (s, 3H, O–CH3), 5.35 (s, H, C4–H), 7.12 (d, J = 7.8 Hz, 2H, Ar–H), 7.20 (d, J = 7.8 Hz, 2H, Ar–H), 7.59 (s, 1H, 3-NH), 8.35 (s, 1H, 1-NH). 13C NMR (100 MHz, CDCl3, ppm): δ 17.29, 20.12, 50.44, 54.71, 101.79, 125.55, 128.13, 128.55, 137.20, 138.32, 141.96, 164.75 (C=O), 173.40 (C=S). Anal. Calc. for C14H16N2O2S: C 60.85, H 5.84, N 10.14, S 11.60 %. Found: C 60.64, H 5.99, N 10.31, S 11.51 %.

Ethyl 1,2,3,4-tetrahydro-6-methyl-2-thioxo-4-p-tolylpyrimidine-5-carboxylate (7e)

White powder; yield 93 %; M.P. = 187–189 °C; FTIR (KBr, cm−1): 3326, 3174 (str, N–H), 3105 (str, ArCH), 2981 (str, Aliphatic C–H), 1673 (str, O–C=O), 1575(str, C=C), 1284 (str, CO–O), 1180 (str, C–N), 1118 (C–O), 1113 (str, C=S), 803, 759, 739. 1H NMR (400 MHz, DMSO-d6, ppm): δ 1.10 (t, J = 7.1 Hz, 3H, CH 3–CH2–O), 2.26 (s, 3H, CH3), 2.28 (s, 3H, CH3), 3.97–4.03 (q, J = 7.1 Hz, 2H, CH3–CH 2–O), 5.13 (s, H, C4–H), 7.09 (d, J = 8.0 Hz, 2H, Ar–H), 7.14 (d, J = 8.0 Hz, 2H, Ar–H), 9.61 (s, 1H, 3-NH), 10.30 (s, 1H, 1-NH).

Ethyl 1,2,3,4-tetrahydro-6-methyl-2-oxo-4-phenylpyrimidine-5-carboxylate (7f)

White powder; yield 95 %; M.P. = 201–203 °C; FTIR (KBr, cm−1): 3242, 3113 (str, N–H), 3109 (str, ArCH), 2978 (str, Aliphatic C–H), 1726 (str, O–C=O),1700 (N–C=O, 1648, 1599 (str, C=C), 1220 (str, CO–O), 1174 (str, C–N), 1090 (Et–O), 783, 757. 1H NMR (400 MHz, DMSO-d6, ppm): δ 1.09 (t, J = 7.0 Hz, 3H, CH 3–CH2–O), 2.24 (s, 3H, CH3), 3.95–4.01 (q, J = 7.0 Hz, 2H, CH3–CH 2–O), 5.17 (s, H, C4–H), 7.23–7.33 (m, 5H, Ar–H), 7.74 (s, 1H, 3-NH), 9.19 (s, 1H, 1-NH).

Methyl 1,2,3,4-tetrahydro-4-(4-methoxyphenyl)-6-methyl-2-oxopyrimidine-5-carboxylate (7i)

White powder; yield 94 %; M.P. = 189–191 °C; FTIR (KBr, cm−1): 3250, 3114 (str, N–H and str, ArCH), 2956 (str, Aliphatic C–H), 1722 (str, O–C=O and N–C=O), 1650, 1589 (str, C=C), 1237 (str, CO–O), 1180 (str, C–N), 1096 (Me–O), 779. 1H NMR (400 MHz, DMSO-d6, ppm): δ 2.24 (s, 3H, CH3), 3.52 (s, 3H, CH3–O), 3.72 (s, 3H, CH3–O–Ar), 5.08 (s, H, C4–H), 6.87 (d, J = 8.6 Hz, 2H, Ar–H), 7.14 (d, J = 8.6 Hz, 2H, Ar–H), 7.69 (s, 1H, 3-NH), 9.18 (s, 1H, 1-NH).

References

F. Shirini, A. Yahyazadeh, K. Mohammadi, C.R. Chimie, Chin. Chem. Lett. 25, 341 (2014)

S.S. Panda, S.C. Jain, Mini. Rev. Org. Chem. 8, 455 (2011)

S.S. Panda, Mini. Rev. Med. Chem. 13, 784 (2013)

N. Isambert, M. Del Mar Sanchez Duque, J.-C. Plaquevent, Y. Ge´nisson, J. Rodriguez, T. Constantieux, Chem. Soc. Rev. 40, 1347 (2011)

C.O. Kappe, Acc. Chem. Res. 33, 879 (2000)

S.R. Shaikh, G.M. Nazeruddin, J. Chem. Pharm. Res. 6, 505 (2014)

B.B. Shingate, Organic Chem. Curr. Res. 1, 3 (2012)

S.D. Bajaj, O.A. Mahodaya, P.V. Tekada, Pharm. Chem. J. 48, 681 (2015)

B. Schnell, U.T. Strauss, P. Verdino, K. Faber, C.O. Kappe, Tetrahedron 11, 1449 (2000)

R.H. Bockert, F.P. Guengerich, J. Med. Chem. 29, 1596 (1986)

C. Lo´pez-Alarco´n, L.J. Nu´n˜ez-Vergara, J.A. Squella, Electrochim. Acta 48, 2505 (2003)

M.M. Heravi, FSSh Moosavi, YSh Beheshtiha, M. Ghassemzadeh, Heterocycl. Commun. 10, 415 (2004)

S. Dehghanpour, M.M. Heravi, F. Derikvand, Molecules 12, 433 (2007)

S.R. Mistry, R.S. Joshi, S.K. Sahoo, K.C. Maheria, Catal. Lett. 141, 1541 (2011)

K.R. Kumar, V.L. Harika, A.B. Shaik, Indo. Am. J. Pharm. Res. 4, 2773 (2014)

F.S. Falsone, C.O. Kappe, ARKIVOC 2(2), 122 (2001)

S.S. Panda, P. Khanna, L. Khanna, Curr. Org. Chem. 16, 507 (2012)

D. Azarifar, D. Sheikh, Helv. Chim. Acta 95, 1217 (2012)

J. Safari, L. Javadian, Ultrason. Sonochem. 22, 341 (2014)

G.–.F. Chen, H.–.Y. Li, N. Xiao, B.–.H. Chen, Y.–.L. Song, J.–.T. Li, Z.–.W. Li, Aust. J. Chem. 60, 146 (2014)

B.S.P. Anil Kumar, K. Harsha Vardhan Reddy, B. Madhav, K. Ramesh, Y.V.D. Nageswar, Tetrahedron Lett. 53, 4595 (2012)

D.I. MaGee, M. Dabiri, P. Salehi, L. Torkianb, ARKIVOC 11, 156 (2011)

K. Sivakumar, A. Kathirvel, A. Lalitha, Tetrahedron Lett. 51, 3018 (2010)

M.J. Climent, A. Corma, S. Iborra, RSC Adv. 2, 16 (2012)

S.R. Mistry, K.C. Maheria, J. Mol. Catal. A 355, 210 (2012)

K.D. Safa, M. Allahvirdinesbat, H. Namazi, Mol. Divers. 19, 29 (2015)

K.D. Safa, M. Abolfathi, K. Ghorbanpour, J. Chem. Res. 36, 575 (2012)

K.D. Safa, L. Sarchami, M. Allahvirdinesbat, A. Feyzi, P. Nakhostin Panahi, J. Chem. Res. 38, 571 (2014)

K.D. Safa, M. Allahvirdinesbat, H. Namazi, Synth. Commun. 45, 1205 (2015)

K.D. Safa, A. Zeinolabedini, H. Abbasi, R. Teimuri-Mofrad, J. Iran. Chem. Soc. 10, 447 (2013)

K.D. Safa, T. Shokri, H. Abbasi, R. Teimuri-Mofrad, J. Heterocyclic Chem. 51(1), 80–84 (2013)

S.H. Mashraqui, M.A. Kamik, Tetrahedron Lett. 39, 4895 (1998)

N. Nakamichi, Y. Kawashita, M. Hayashi, Org. Lett. 4, 3955 (2002)

A.S. ParaSkar, A. Sudalai, Indian J. Chem. 46B, 331 (2007)

S.-X. Wang, Z.-Y. Li, J.-C. Zhang, J.-T. Li, Ultrason. Sonochem. 15, 680 (2008)

M. Nasr-Esfahani, M. Montazerozohori, R. Raeatikia, Maejo Int. J. Sci. Technol. 8, 32 (2014)

X. Liao, W. Lin, J. Lu, C. Wang, Tetrahedron Lett. 51, 3859 (2010)

M. Mahmoodi Hashemi, M.S. ZaKeri, S. Arianfar, Iran. J. Chem. Chem. Eng. 22, 9 (2003)

F. Heidarizadeh, E. Rezaee Nezhada, S. Sajjadifar, Scientia Iranica C 20, 561 (2013)

C. Ramalingan, Y.-W. Kwak, Tetrahedron 64, 5023 (2008)

B. Boumoud, I. Mennana, T. Boumoud, A. Debachea, Lett. Org. Chem. 10, 8 (2013)

P. Salehi, M. Dabiri, M.A. Zolfigol, M.A. Bodaghi, Fard. Tetrahedron Lett. 44, 2889 (2003)

Acknowledgments

The authors would like to acknowledge the financial support from the University of Tabriz, and Iranian Nanotechnology Initiative.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safa, K.D., Esmaili, M. & Allahvirdinesbat, M. Aqua-mediated one-pot synthesis of Biginelli dihydropyrimidinone/thiones (DHPMs), Hantzsch dihydropyridines (DHPs), and polysubstituted pyridines sonocatalyzed by metal-supported nanocatalysts. J IRAN CHEM SOC 13, 267–277 (2016). https://doi.org/10.1007/s13738-015-0734-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0734-5