Abstract

The 2,4,6-trisubstituted pyridines constitute an important family of heterocyclic compounds widely used in industry, especially in pharmaceuticals, making their preparation a crucial challenge for organic chemists. In continuation of our approach in the preparation and development of new catalytic systems, we present in this paper a highly efficient one-step synthesis of triarylpyridine by Al/Ag3PO4 phosphate bimetallic catalysis from the condensation of acetophenone derivatives, aryl aldehydes, and ammonium acetate under mild and environmentally friendly conditions. This methodology offers several advantages: excellent yields and shorter reaction times. In addition, the catalyst exhibited remarkable reusable activity. Compared to previous methods, our procedure allows a very flexible, more straightforward, faster, and more efficient preparation of substituted pyridines.

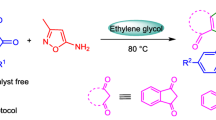

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

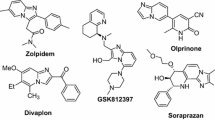

Pyridine derivatives are considered an important class of aza-heterocycles present in many natural products for pharmaceutical use [1, 2]. Due to their π-stacking ability, they are widely used in industry as anti-HIV and anticancer drugs in medicine, pesticides, and organic materials in agriculture, etc. Among the pyridine derivatives, 2,4,6-triarylpyridines are helpful in the industry since they are used as intermediates in synthesizing drugs as antioxidants, anticancer, and antibacterial agents [3,4,5].They are also used as intermediates in synthesizing insecticides, herbicides, surfactants, and photosensitizers [6]. Furthermore, 2,4,6-triarylpyridine derivatives possess exciting antibacterial activities against Gram-negative E. coli bacteria and Gram-positive S. albus bacteria. These derivatives have shown interesting antifungal activity against Candida albicans and are used as standard drugs against this fungi [7, 8].

Recently, a variety of methods have been reported for the synthesis of 2,4,6-triarylpyridine derivatives [9, 10]. However, the most common route involves the catalytic condensation of acetophenones, aldehyde, and another product, such as a nitrogen source. For example, in 2014, Moosavi–Zare et al. applied oxozirconium chloride (ZrOCl2) as catalytic support to develop an efficient method for synthesizing 2,4,6-triarylpyridines [11]. After that, Tabrizian et al. used nanoparticles of titanium-based sulfonic acid (NP-TSA) as a heterogeneous catalyst for synthesizing these derivatives [12]. In 2017, cerium (IV) carboxymethylcellulose (CMC CeIV) was found to be an efficient and recyclable heterogeneous catalyst for the synthesis of 2,4,6-triarylpyridine derivatives via the multicomponent reaction [13]. In 2019, Wu et al. developed the cyclization of acetophenone and ammonium acetate with methane release using copper catalysis to synthesize polysubstituted pyridines [14]. In 2020, Xiao-Yu et al. developed a chemo-selective synthesis of 2,4,6-trisubstituted pyridines under mild conditions using a heterogeneous solid-phase catalyst based on Merrifield resin [15]. Recently, Roozifar and Hazeri used salicylic acid as a catalyst under solvent-free conditions for one-pot synthesis of 2,4,6-triarylpyridine derivatives [16]. Despite their effectiveness, these methods are still limited to high temperatures, low yields, longer reaction times, and other harsh conditions. Therefore, an efficient way to quickly construct the pyridine motif is urgently desirable. Encouraged by our successful strategies which have already published regarding the preparation and application of new heterogeneous catalysts in organic chemistry [17,18,19], we present in this paper a novel method for the synthesis of 2,4,6-triphenylpyridine derivatives via catalyzed condensation by our bimetallic support Al/Ag3PO4 of NH4OAc with benzaldehyde and acetophenones derivatives. Our research teams prepared this catalyst for the first time by modifying the triple superphosphate with silver and aluminum. We have already applied Al/Ag3PO4 as a heterogeneous catalyst in organic chemistry. It showed excellent efficiency and selectivity, encouraging us to extend its use to other more complicated organic reactions [19].

Results and discussion

First, we chose the reaction between acetophenone (1a), NH4OAc, and benzaldehyde (2a) as a model reaction (Scheme 1) to test the catalytic efficiency of our support and optimize the reaction conditions (Table 1).

Indeed, using bimetallic support (Al/Ag3PO4) as a catalyst improved the conversion until it reached 66% in a minimum time of 40 min (Table 1, entry (2)). In comparison, the reaction only gave 25% after 360 min of reaction time in free-catalyst conditions (Table 1, entry (1)). In addition, using Ag3PO4 as a catalyst in the same condensation allows us to obtain the final product with a yield of 39% for 120 min of reaction time. From these results, we can conclude two essential things: Al/Ag3PO4 can be considered as an effective catalyst. At the same time, the modification by aluminum allowed us to improve the capacity and selectivity of the catalyst for the synthesis of triarylpyridine derivatives. Furthermore, the high catalytic activity of our modified catalyst prompted us to optimize the reaction conditions starting with the effect of the solvent on the kinetics and the yield of the reaction. For this, different solvents were tested on the model reaction (protic polar, aprotic polar, apolar) (Table 2).

From the experimental results (Table 2), it can be noticed that the kinetics of the reaction is greater and give excellent results when the condensation was carried out in the polar protic and polar aprotic solvents (Table 2, entries 2, 3, 6–9) up to 77% in a minimum time of 40 min, in presence of modified catalyst, using ethanol or DMF as solvent. Furthermore, the reaction was carried out under solvent-free conditions giving a yield of 44% in a time of 60 min, while the reaction gives low yields in a long time using apolar solvents (Table 2, entry (5). The stability of triarylpyridine intermediates can explain these results in polar solvents, making it easy to form the final product with a lower energy level than reactants. Also, the optimization of the temperature shows that this parameter can improve the yield of the reaction until it has become constant at reflux temperature.

Subsequently, considering the environmental context, it was concluded that ethanol was the best choice for synthesizing triarylpyridine derivatives catalyzed by Al/Ag3PO4. After that, we tried to optimize the amount of catalyst for model reactions. Our optimization studies revealed that yields increased smoothly with catalyst loading up to 8 mg, then remained unchanged after this mass (Table 3).

Encouraged by excellent results and optimized reaction conditions, the scope of this transformation was examined with different acetophenone and aromatic aldehyde. The complete set of results is presented in Table 4. Indeed, a wide range of aromatic aldehydes and acetophenones were found to be appropriate substrates for this condensation. It can be noted that the use of aldehyde or acetophenone with an electron-donating group increases the rate and yield of the reaction. Indeed, it makes it possible to obtain the final product with a good yield (92%) after 20 min of reaction time (entries 3 and 4). While, the excellent reaction yield (95%, 20 min) was obtained via the condensation of aldehyde and acetophenone substituted by e electron-donating groups (entry 5) [21]. This result can be explained by the activity of the carbonyl function of the aldehyde and acetophenone due to the electron donor groups and the mesomeric effect. Indeed, the donor group increases the interactions between the reagents and the catalyst, thereby affecting their adsorption on the catalytic surface, and thus making it possible to accelerate the reaction rate and to obtain the product with a good yield in short reaction times.

Based on previous studies reported in the literature [29, 30], a plausible reaction mechanism has been proposed to explain the intervention of our catalyst in the reaction medium and in the formation of intermediates and product 4a (Scheme 2). Initially, the catalyst activates an aldol condensation between the aldehyde and the first molecule of acetophenone to generate the intermediate (I) 1, 3-diaryl-2-propen-1. In contrast, the second acetophenone molecule reacts with ammonia, forming enamine (II). Then the latter reacts with intermediate (I) via Michael addition, followed by intramolecular cyclization to provide the dihydropyridine product. Finally, air oxidation yielded the final product.

To show the high catalytic activity of our catalyst and its durability, we have studied the reusability of Al/Ag3PO4. The model reaction of acetophenone (1a) with benzaldehyde (2a) and NH4OAc (3) was studied under optimized conditions. After the completion of the reaction (indicated by TLC), the catalyst was separated by filtration, washed with hot ethanol and acetone, and dried at 100 °C. The recovered catalyst was reused in subsequent reactions without a significant decrease in activity even after five trials (Fig. 1). The structural stability of our catalyst can explain this result during the recycling process, and we can conclude from the XRD and FTIR spectrum (Figs. 2, 3), which show that the structure of Al/Ag3PO4 remains unchangeable even after five cycles of reuse. Furthermore, the EDX spectrum (Fig. 4) shows that the chemical composition of our catalyst is unchangeable, which confirms the stability and heterogeneity of Al/Ag3PO4 in the reaction medium.

In the last part of this study, we compared our results with those existing in the literature using other catalysts (Table 5). According to this comparison, we can notice two main things; first, catalysts applied to the synthesis of 2,4,6-triarylpiridine derivatives are few, which shows the difficulty of this condensation. Second, most catalysts activate the reaction in a reasonably long time. While Al/Ag3PO4 can start the condensation between aromatic aldehyde, acetophenone, and ammonium acetate under mild ecological conditions and in a minimum time that ranges between 20 and 90 min, which makes it an efficient, ecological, and alternative catalyst that gives us a new process for the synthesis of triarylpyridine derivatives.

Conclusion

In conclusion, we presented a new and green catalytic method for synthesizing 2,4,6-triarylpyridine derivatives via Claisen–Schmidt condensation—Michael addition reaction using further bimetallic support Al/Ag3PO4 as heterogeneous catalyst. The results show that we have developed a highly efficient catalyst for the one-pot condensation of acetophenone derivatives, ethyl acetate, and aromatic aldehyde. The use of our catalyst offers advantages: accessibility to a wide range of triarylpyridine derivatives with excellent yields in short reaction times, the minimum amount of catalyst associated with promoting the reaction, use of inexpensive starting materials, eco-friendliness, and mild ecological conditions. The comparative study confirmed that the present method could be an alternative and a new way to synthesize 2,4,6-triarylpyridine derivatives.

Experimental

All reactions were carried out in dried glassware at a temperature of 150 °C. All reagents obtained from commercial sources (SigmaAldrich, Riedel-de-haen, and Fluka) were used without purification. The commercial grade purity of aldehydes, acetophenone derivatives, and ammonium acetate is ≥ 97%, ≥ 98%, and 99% respectively. Thin-layer chromatography (TLC) was performed on pre-coated glass plates of Silica Gel 60 F254 (0.25 mm, Merck), and UV light for TLC analysis was a UVGL-25 compact UV lamp (4 W/254 nm). Melting points were determined with a Kofler bench (MP-2D melting apparatus melting apparatus with a temperature range 0–260 °C). 1H NMR and 13C NMR were recorded by Bruker AC-300 F (300 MHz for 1H and 75 MHz for 13C). Chemical shifts are in ppm from Me4Si, generated from the CDCl3 signal at δ = 7.24 and 77.16 ppm for 1H and 13C NMR, respectively. Multiplicities are reports using the following abbreviations: s = singlet, d = doublet, t = triplet, q = quartet, p = pentet, m = multiplet, dd = doublet of doublets; J = coupling constant values in Hertz.

General procedure for the one-pot synthesis of 2,4,6-triarylpyridines

The synthesis of 2,4,6-triarylpyridine derivatives was carried out from a mixture of acetophenones (2 mmol), aromatic aldehydes (1 mmol), and ammonium acetate (0.8 mmol) in the presence of 8 mg of Al/Ag3PO4 as heterogeneous catalyst. This mixture was stirred at the reflux temperature of ethanol which was used as an optimum solvent. Once the reaction is complete (monitored by TLC), the reaction mixture is filtered to separate the catalyst. The filtrate was cooled in an ice bath, and the 2,4,6-triarylpyridine crystals precipitated. Finally, the desired compounds were obtained in their crystalline form by recrystallization using an ethanol solution.

Data availability

Data analyzed in this work were a re-analysis of existing data, which are openly available at locations cited in the reference section. Further documentation about data processing and analysis are available as supplementary data.

References

Joule J, Mills K, Smith GF (2020) Heterocyclic Chemistry, 3rd edn. CRC Press

Jones G, Abarca B (2010) Adv Heterocycl Chem 100:195

Tatsumi K, Fukushima M, Shirasaka T, Fujii S (1987) Jpn J Cancer Res 78:748

Milstein D (2010) Top Catal 53:915

Thapa P, Karki R, Yun M, Kadayat T, Lee E, Kwon H, Cho W, Kim N, Jeong B, Kwon Y, Lee E (2012) Eur J Med Chem 52:123

Sims G, O’Loughlin E, Crawford R (1989) Crit Rev Environ Control 19:309

Chavan V, Sonawane S, Shingare MS, Karale BK (2006) Chem Heterocycl Compd 42:625

Altaf A, Shahzad A, Gul Z, Rasool N, Badshah A, Lal B, Khan E (2015) J Drug Des Med Chem 1:1

Hill M (2010) Chem Eur J 16:12052

Baloutaki BA, Sayahi MH, Nikpassand M, Kefayati H (2020) Res Chem Intermed 46:1153

Moosavi-Zare A, Zolfigol M, Farahmand S, Zare A, Pourali A, Ayazi-Nasrabadi R (2013) Synlett 25:193

Tabrizian E, Amoozadeh A, Rahmani S, Imanifar E, Azhari S, Malmir M (2015) Chin Chem Lett 26:1278

Chen Y, Zhang T, Wang D, Zhou J, Zhang Y, Li Y (2017) J Chem Sci 129:421

Wu P, Zhang X, Chen B (2019) Tetrahedron Lett 60:1103

Zhang X, Wen H, Yang Q, Zhou R, Song J (2020) Inorg Chim Acta 507:119600

Roozifar M, Hazeri N, Faroughi Niya H (2021) J Heterocycl Chem 58:1117

El Hallaoui A, Chehab S, Malek B, Zimou O, Ghailane T, Boukhris S, Souizi A, Ghailane R (2019) ChemistrySelect 4:3062

El Hallaoui A, Chehab S, Ghailane T, Malek B, Zimou O, Boukhriss S, Souizi A, Ghailane R (2021) Polycycl Aromat Compd 41:2083

El Hallaoui A, Ghailane T, Chehab S, Merroun Y, Ghailane R, Boukhris S, Guedira T, Souizi A (2021) Mediterr J Chem 11:215

Nagarapu L, Aneesa Peddiraju R, Apuri S (2007) Catal Commun 8(12):1973–1976

Ding Y, Ma R, Hider R, Ma Y (2020) Asian J Org Chem 9:242

Heravi M, Bakhtiari K, Daroogheha Z, Bamoharram F (2007) Catal Commun 8:1991

Ren Y, Cai C (2009) Monatsh Chem 140:49

Maleki B, Azarifar D, Veisi H, Hojati SF, Salehabadi H, Yami R (2010) Chin Chem Lett 21:1346

Moosavi-Zare A, Zolfigol M, Rezanejad Z (2016) Can J Chem 94:626

Maleki A, Firouzi-Haji R (2018) Sci Rep 8:17303

Maleki A, Hajizadeh Z, Firouzi-Haji R (2018) Microporous Mesoporous Mater 259:46

Han J, Guo X, Liu Y, Fu Y, Yan R, Chen B (2017) Adv Synth Catal 359:2676

Gadekar S, Lande M (2018) Res Chem Intermed 44:3267

Zarnegar Z, Safari J, Borjian-Borujeni M (2015) Chem Heterocycl Compd 50:1683

Asressu K, Chan C, Wang C (2021) ACS Omega 6:7296

Kamble S, Shankarling G (2018) ChemistrySelect 3:10464

Li M, Wang T, Wang C (2020) ChemistrySelect 5:3600

Shaabani A, Borjian-Boroujeni M, Laeini MS (2016) RSC Adv 6:27706

Reza M, Shafiee M, Moloudi R, Ghashang M (2012) APCBEE Proc 1:221

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

El Hallaoui, A., Merroun, Y., Chehab, S. et al. One-pot synthesis of 2,4,6-triarylpyridines by cyclocondensation between aryl aldehyde, acetophenone derivative, and ammonium acetate using Al/Ag3PO4 as a new and green bimetallic catalyst. Monatsh Chem 154, 231–237 (2023). https://doi.org/10.1007/s00706-022-03023-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-022-03023-6