Abstract

Gasification is one of the efficient upcycling technologies to treat the biomasses and convert them from a low-value product to a high-value and hydrogen rich syngas. Gasification performances of the indigenous biomasses of West Azerbaijan province of Iran are comprehensively investigated in this study based on thermodynamic modeling. Wheat straw, chickpea straw, sunflower seed shell, and lentil straw were collected from the farms of West Azerbaijan province. They were finely chopped, and the CHNS test was conducted to identify their chemical formula. The gasification process of these indigenous biomasses of West Azerbaijan province is modeled. Chickpea straw gasification resulted in higher cold gas efficiency (ηc), lower carbon dioxide emission and higher syngas lower heating value (LHVs). As a consequence, multi-criteria decision analysis revealed that chickpea straw biomass ranked the first between the indigenous biomasses of West Azerbaijan province. Parametric study indicated that increasing gasification temperature and reducing steam to biomass ratio improved ηc and LHVs. Also, the carbon dioxide emission was mitigated by increasing gasification temperature and reducing steam to biomass ratio. The multi-objective optimization showed that the optimum ηc of 48.5%, the carbon dioxide emission of 19.3 g/mol and LHVs of 411 kJ/mol were achieved at gasification temperature of 1000 °C and steam to biomass ratio of 1.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, researchers have shown an increased interest in gasification process for upcycling solid waste and biomass. Biomass is upcycled by gasification process and converted into a hydrogen rich syngas. This process needs a gasifying agent carrying oxygen such as air and steam. Recently, considerable literature has grown up around biomass gasification [1, 2]. Yan et al. [3] proposed a three-dimensional model for steam gasification of biomass using a granular kinetic theory in a dual fluidized bed gasifier. The sensitivity analysis showed that the order of the parameters on cold gas efficiency was flow rate of biomass followed by steam/biomass ratio and gasification temperature, respectively. Kartal and Özveren [4] conducted an Aspen HYSYS simulation on gasification of livestock and agricultural wastes. They analyzed the influences of steam/biomass ratio and gasification temperature on components of syngas and indicated that the optimum hydrogen concentration was optimized for a specific gasification temperature. Singh and Tirkey [5] modeled gasification of waste poultry litter pellets with air agent and evaluated higher heating value of syngas, mole fraction of hydrogen, and cold gas efficiency with respect to moisture content of biomass, gasification temperature, and equivalence ratio. Their results showed that all parameters significantly affected the outputs. Puig-Gamero et al. [6] simulated air gasification of pine and eucalyptus biomasses in Aspen Plus for a bubbling fluidized bed gasifier and assessed the influences of equivalence ratio and gasification temperature on the system performance. Dang et al. [7] developed a kinetic-based model for gasification of wood residue in Aspen Plus and evaluated the influences of process parameters. They illuminated that syngas hydrogen concentration was enhanced at higher gasification temperatures, higher steam/biomass ratio, lower equivalence ratio, and lower moisture content. Steam gasification of softwood pellet was modeled by Aghaalikhani et al. [8] using Aspen Plus. They analyzed the composition of syngas against gasification temperature and showed that the yield of hydrogen was improved, carbon monoxide was declined, methane was mitigated, and carbon dioxide was increased with temperature. Vecten et al. [9] analyzed the steam gasification of wood pellets and its char in a microwave-induced plasma gasifier and showed that increasing gasifier temperature increased hydrogen concentration in the syngas. Cao et al. [10] developed a kinetic model for gasification of pine sawdust using a composite air/steam agent. They analyzed the system performance with respect to processing parameters. Increasing gasifier temperature enhanced hydrogen content of syngas, improved gas yield amount, increased cold gas efficiency and enhanced higher heating value of syngas. Ismail et al. [11] proposed a detailed study theoretically and experimentally on gasification of peach stone and miscanthus in a fluidized bed gasifier. The results of their study conveyed that lower gasification temperature was favorable from concentration of hydrogen and carbon monoxide viewpoint. Zaman and Ghosh [12] developed a model for biomass gasification in Aspen Plus by steam agent for several biomass types. They employed response surface methodology for analyzing the system performance considering gasifier temperature and steam/biomass ratio. Lower steam/biomass ratio was favorable for cold gas efficiency gasifier temperature while the influence of steam/biomass ratio was more predominant. Ozbas et al. [13] predicted hydrogen production in gasification of olive pits using machine learning algorithms. They employed four different machine learning techniques and concluded that linear regression algorithm predicted hydrogen production with R2 value of 0.999 followed by support vector machine regression with R2 value of 0.997. Vikram et al. [14] modeled gasification of wood residue using a composite agent of steam-carbon dioxide in Aspen Plus. They studied the influence of gasifier agent composition on the gasification performance from pure steam to pure carbon dioxide. Increasing concentration of carbon dioxide in steam-carbon dioxide agent resulted in improving higher heating value of syngas and declining hydrogen/carbon monoxide ratio.

Pollution is a major environmental problem, and the main cause is using fossil fuels. Developing novel clean technologies to tackle this issue is of interest nowadays. Upcycling biomasses employing gasification technology is growing fast becoming a key solution to produce a hydrogen rich syngas efficiently. A search of the literature revealed no studies on the gasification performance of the indigenous biomasses of West Azerbaijan province in Iran. In addition, no research has been found that surveyed the gasification of chickpea straw and lentil straw. Therefore, the novelties and contributions of the present research work could be considered as the following goals: developing gasification of the indigenous biomasses of West Azerbaijan province in Iran, addressing gasification of chickpea straw and lentil straw biomasses for the first time, a systematic comparison analysis between gasification performances of the indigenous biomasses of West Azerbaijan province, multi-criteria decision analysis on gasification of the indigenous biomasses of West Azerbaijan province to select the best biomass type, multi-objective optimization of the best biomass gasification.

In the following, the gasification process is modeled and the gasification of the indigenous biomasses of West Azerbaijan province is developed employing their ultimate analyses using the CHNS test. A comprehensive systematic comparison analysis is conducted on gasification performances of these biomasses with respect to syngas composition and gasification indicators of lower heating value of syngas, cold gas efficiency, and carbon dioxide emission. Multi-attributed decision analysis is conducted using TOPSIS approach to select the best indigenous biomass of West Azerbaijan province for steam gasification. Multi-objective optimization of this best gasification is performed employing response surface methodology.

2 Materials and methodology

In this study, gasification performance of indigenous biomasses of West Azerbaijan province is evaluated. In this regard, steam is considered as the gasifying agent because a steam gasification results in a hydrogen-rich syngas and steam gasification is modeled as follows. Taking place gasification reaction between the gasifying agent and the feedstock leads to a syngas containing components with valuable heating value of hydrogen, carbon monoxide, and methane and emits some contents of carbon dioxide. External heating elements are considered as the heating source of the process.

These assumptions have been considered in the modeling procedure [15, 16]:

-

• The gasifier has been considered insulated, and the heat loss has been considered negligible.

-

• 298.15 K of temperature and 101.3 kPa of pressure have been considered as ambient conditions.

-

• Tar formation has been considered negligible.

-

• Gases have been considered as ideal gas.

-

• Kinetic and potential energy changes have been considered negligible.

Wheat straw, chickpea straw, sunflower seed shell, and lentil straw are considered as feedstocks for steam gasification process. These biomasses are the main agricultural biomasses of West Azerbaijan province and were collected from the farms of West Azerbaijan province in Iran. They were finely chopped, and Fig. 1 shows the biomasses prepared for ultimate analysis.

A CHNS testing devise, LECO Corporation model 932, USA, was used for ultimate analysis. The results are presented in Table 1.

The reaction of steam gasification is considered as [17]:

where in the reactant side, \({\mathrm{CH}}_{x1}{\mathrm{O}}_{x2}{\mathrm{N}}_{x3}{\mathrm{S}}_{x4}\) indicates the chemical formula of the biomass obtained from CHNS analysis, \({x}_{i}\) is the molar ratio of the ith element to the carbon. The chemical formula of the indigenous biomasses of West Azerbaijan province is presented in Table 2. \(\alpha\) is the biomass moisture content, and \(\beta\) is the feeding steam which is the gasifying agent. In the product side, \({\gamma }_{i}\) denotes the molar number of the ith syngas component and obtaining its value is the aim of gasification modeling. In this regard, Lagrange of undetermined multipliers is coupled with Gibbs free energy minimization method to develop a gasification modeling in this study.

G (the total Gibbs free energy) is defined as [18]:

where \(\overline{G }\) denotes the standard G, R and T are universal gas constant and temperature and \({\delta }_{i}\) indicates the molar flow.

Conserving the gasification process of biomass is achieved as follows [19]:

where \({\varepsilon }_{i,e}\) indicates the ith element total atom number.

\(\lambda\) (Lagrangian multipliers) is as follows [20]:

G is minimized using \(\lambda\) as follows [20]:

Coupling these methods result in the following equations to obtain the molar number of the syngas components [20]:

Syngas composition, lower heating value of syngas (\({LHV}_{s}\)), cold gas efficiency (\({\eta }_{c}\)), and carbon dioxide emission (\({\omega }_{{CO}_{2}}\)) are considered as the performance indicators to study the gasification performance of indigenous biomasses of West Azerbaijan province and to conduct the comparison analysis.

\({\eta }_{c}\) is defined as follows [21]:

where \({LHV}_{i}\) is the lower heating value of ith syngas component. \({n}_{\mathrm{biomass}}\) denotes the mole numbers of the biomass entering the gasifier and \({LHV}_{\mathrm{biomass}}\) indicates the biomass lower heating value. \({n}_{\mathrm{steam}}\) is the mole numbers of the steam entering the gasifier as the agent, \({\overline{h} }_{\mathrm{steam}}\) is the enthalpy of the steam, and \({Q}_{\mathrm{in}}\) is the required heat for the gasification process.

\({LHV}_{s}\) is calculated as [22]:

\({\omega }_{{CO}_{2}}\) is measured as [21]:

where \({\mu }_{{\mathrm{CO}}_{2}}\) is the mass of carbon dioxide produced through the gasification process.

The heating value of biomass is a characteristic required for biomass gasification process. This value can be estimated using different models. In this study, four models based on the ultimate analysis are considered presented in Table 3.

The heating value of biomass is calculated based on the models considered and a mean value of these four models is utilized in the gasification modeling.

The gasification of indigenous biomasses of West Azerbaijan province is modeled in the Engineering Equation Solver (EES) software.

3 Results and discussion

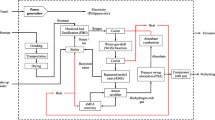

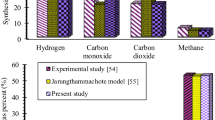

Firstly, the validation of the model is performed by comparing the syngas composition predicted by the model developed in this study with the results available for biomass gasification. Afterwards, an evaluation study is performed on the syngas composition, lower heating value of syngas, cold gas efficiency and carbon dioxide emission by considering gasification temperature and steam to biomass ratio as the gasifying processing conditions. The performances of the best indigenous biomasses of West Azerbaijan province are discussed and multi-objectively optimized in detail.

3.1 Model validation

Figure 2 compares the syngas composition of a biomass gasification predicted by this model with the experimental results presented in [27] and the results of a model presented in [28]. Steam was considered as gasifying agent and olivine particle biomass was fed to the gasifier as the feedstock. The gasification conditions were set at gasification temperature of 770 °C, steam to biomass ratio of 1 and gasifier pressure 101 kPa of pressure. Comparing the syngas composition results reveal a good agreement between the results of the present model with the experimental results [27] with errors smaller than 7%. The model developed in the present study is also in line with the model developed in [28]. Therefore, the validity of the model presented in this study is confirmed for investigation of steam biomass gasification.

3.2 Evaluation of syngas composition

The syngas composition of biomass gasification is evaluated versus gasification temperature and steam to biomass ratio. Concentrations of hydrogen, carbon monoxide, methane, and carbon dioxide are studied with respect to processing conditions and their changes are discussed in detail. A comparison is conducted between syngas composition of different biomasses.

3.2.1 Hydrogen

Figure 3 depicts the variations of hydrogen concentration versus temperature and steam to biomass ratio. Figure 3a shows that hydrogen concentration of syngas is reduced by increasing temperature, and this trend is valid for all biomasses. This decrement in hydrogen concentration is justified by water–gas shift reaction [29]:

This reaction is endothermic, and it is favorable at higher temperatures. Therefore, more hydrogen is consumed, and decrement of hydrogen concentration with temperature is logical. Mehrpooya et al. [30] also reported decreasing hydrogen concentration with temperature for gasification of rice husk, Larch wood, and wood chip. Gasification of raw pine wood at higher temperatures also resulted in lower hydrogen concentrations as reported by Vikram et al. [14].

A comparison between the performance of gasification of indigenous biomasses of West Azerbaijan province from hydrogen production viewpoint indicates that chickpea straw has the best performance. The CHNS test shows that chickpea straw biomass has the highest carbon and hydrogen elements. More carbon element is favorable for solid carbon conversion reaction. Although wheat straw biomass has the same carbon element as the chickpea straw biomass, its hydrogen element is lower, and it ranks the third from hydrogen production viewpoint. Lentil straw biomass has more hydrogen element compared with wheat straw biomass, and therefore, its performance in hydrogen production is better and ranks the second. Sunflower seed shell has the lowest carbon and hydrogen elements, and hence, its performance in hydrogen production is the last.

Figure 3b indicates that more hydrogen concentration is produced at higher steam to biomass ratios. Improving hydrogen concentration with steam to biomass ratio is justified by water–gas shift reaction (Eq. (14)). More \({\mathrm{H}}_{2}\mathrm{O}\) is available at higher steam to biomass ratios and the left side is favorable in this condition. Therefore, more hydrogen is produced. Increasing hydrogen concentration with steam to biomass ratio was also conveyed by AlNouss et al. [31] for steam gasification of coir pith and coir pith char. Higher steam to biomass ratio in steam gasification of raw empty fruit bunch also enhanced hydrogen concentration as reported by Yong and Rasid [32].

Performance assessment of the indigenous biomasses of West Azerbaijan province reveals that at all steam to biomass ratios, chickpea straw biomass produces more hydrogen concentration compared to other biomasses. Lentil straw and wheat straw are in the next ranks followed by sunflower seed shell which is in the last rank.

As a conclusion, improvement of hydrogen concentration in the syngas is obtained by decreasing temperature and increasing steam to biomass ratio for all indigenous biomasses of West Azerbaijan province. From hydrogen concentration in syngas viewpoint, gasification of chickpea straw biomass has the best performance. Lentil straw biomass and wheat straw biomass gasification are in the second and the third ranks with respect to hydrogen production. Sunflower seed shell gasification is in the last rank.

3.2.2 Carbon monoxide

The variations of carbon monoxide concentration versus temperature and steam to biomass ratio are presented in Fig. 4. Figure 4a shows that increasing temperature significantly enhances the carbon monoxide production, and this phenomenon is similar for all biomasses. This trend may be explained by water–gas shift reaction (Eq. (14)). The product side is favorable at higher temperatures because it is an endothermic reaction. Therefore, more CO is achieved. This finding is consistent with that of Mehrpooya et al. [30] who performed gasification of rice husk and Larch wood and showed that CO concentration was improved by temperature. This also accords with the observations of Samimi et al. [33] which showed that steam gasification of pinewood at higher steam to biomass ratio resulted in higher CO concentrations.

Comparing the performance of the indigenous biomasses of West Azerbaijan province shows that chickpea straw biomass leads in more CO concentration compared to other biomasses. With a small difference, wheat straw is in the second rank. Lentil straw biomass produced lower CO concentrations than wheat straw. The CHNS results show that wheat straw biomass has more carbon element which participates in Boudouard reaction, and therefore, more CO is achieved. Sunflower seed shell in the last rank from CO production viewpoint. This sequence is valid at all temperatures.

Figure 4b illuminates that increasing steam to biomass ratio mitigates the concentration of CO for all biomasses. The observed decline in CO concentration could be attributed to water–gas shift reaction (Eq. (14)). Increasing steam to biomass ratio backs forwarded this reaction due to higher H2O content. Therefore, CO production is mitigated. There are similarities between the behaviors of CO concentration with steam to biomass ratio in this study and those described by AlNouss et al. [31] for steam gasification of coir pith and coir pith char. Yong and Rasid [32] also reported similar observation, i.e., declining CO concentration with steam to biomass ratio, for steam gasification of raw empty fruit bunch biomass.

At all steam to biomass ratios, gasification of chickpea straw biomass results in the highest CO production. From this viewpoint, wheat straw and lentil straw gasification are in the next ranks and sunflower seed shell gasification is in the last rank.

Overall, higher CO production is achievable at higher temperatures and lower steam to biomass ratio for all indigenous biomasses of West Azerbaijan province. Chickpea straw gasification result in the maximum CO production.

3.2.3 Methane

Figure 5 presents the variations of methane production versus temperature and steam to biomass ratio. It is apparent from the results that the methane production is very low and almost negligible. However, since the heating value of methane is remarkable [34], its tiny variation is also important. Figure 5a indicates that the methane production is reduced by increasing temperature, and this behavior is similar for all indigenous biomasses of West Azerbaijan province. Figure 5b also shows that increasing steam to biomass ratio decreases methane production for all biomasses. A possible explanation for these results may be the methane reforming reaction [35]:

It is an endothermic reaction and is favorable at higher temperatures. Also, more H2O available at higher steam to biomass ratio trigger this reaction. Therefore, both higher temperatures and higher steam to biomass ratios shift this reaction, and therefore, more methane is consumed, and its concentration is declined. In steam gasification of coir pith and coir pith char conducted by AlNouss et al. [31], declining methane concentration by temperature and steam to biomass ratio was also reported. Decreasing the concentration of methane in this study also corroborates the earlier findings of Yong and Rasid [32] for gasification of raw empty fruit bunch biomass.

The findings reveal that chickpea straw gasification offers the maximum methane production at all temperatures and steam to biomass ratios. Wheat straw gasification and lentil straw gasification are in the second and the third ranks with respect to methane production. According to the results, sunflower seed shell gasification produced almost no methane, and its concentration in syngas of this biomass gasification is almost zero.

3.2.4 Carbon dioxide

Figure 6 depicts the variations in carbon dioxide concentration with respect to temperature and steam to biomass ratio. It is apparent from Fig. 6a that increasing temperature reduces carbon dioxide production, and this observation is valid for all indigenous biomasses of West Azerbaijan province. A possible reason for this declining trend is Boudouard reaction [36]:

Being an endothermic reaction results in favorable products at higher temperatures. Therefore, more carbon dioxide is consumed in Boudouard reaction by increasing temperature, and its concentration is declined. This finding was also reported by Kartal and Özveren [4]. They showed that increasing temperature decreased carbon dioxide yield in gasification of 10 types of conventional biomass. This finding is also consistent with that of Tauqir et al. [37] who reported that steam gasification of hardwood chips at higher temperatures produced low concentrations of carbon dioxide.

Comparing between the performance of the indigenous biomasses of West Azerbaijan province shows that chickpea straw biomass has the best performance with respect to carbon dioxide concentration. It produces the lowest levels of carbon dioxide yield. Lentil straw and wheat straw produces the same values of carbon dioxide at all temperatures. Gasification of sunflower seed shell is not favorable from carbon dioxide concentration viewpoint because it produces almost 60% higher carbon dioxide compared to chickpea straw.

Figure 6b indicates that increasing steam to biomass ratio increases carbon dioxide concentration for all indigenous biomasses of West Azerbaijan province. This observation is justified based on water–gas shift reaction (Eq. (14)). The left side is more favorable at higher steam to biomass ratios because more H2O available for this direction. Therefore, more carbon dioxide is produced. In accordance with the present results, Dang et al. [7] demonstrated that steam gasification of wood residue at higher steam to biomass ratio resulted in higher carbon dioxide concentration. It is encouraging to compare this result with that found by Kartal and Özveren [4] who found that increasing steam to biomass ratio in gasification of 10 types of biomass increased carbon dioxide concentration.

Comparing the performance of the indigenous biomasses of West Azerbaijan province in steam gasification with respect to carbon dioxide concentration versus steam to biomass ratio indicates that chickpea straw gasification produces the lowest concentrations of carbon dioxide. Wheat straw biomass has a slightly better performance compared to lentil straw at all steam to biomass ratios from carbon dioxide concentration viewpoint. Sunflower seed shell gasification results in the highest concentrations of carbon dioxide.

3.3 Evaluation of cold gas efficiency and lower heating value of syngas

Figure 7 depicts the influence of temperature on cold gas efficiency and syngas lower heating value. What stands out in the results is the improvement of \({\eta }_{c}\) and \({LHV}_{s}\) by increasing temperature. As the previous results lightened, increasing temperature reduces hydrogen and methane production and enhances carbon monoxide production. Enhancing carbon monoxide production overcomes the reduction of hydrogen and methane productions, and therefore, \({\eta }_{c}\) and \({LHV}_{s}\) are improved by increasing temperature. These findings were also reported by Zaman et al. [38] for gasification of rice husk and almond shell. They reported that increasing temperature enhanced cold gas efficiency and syngas lower heating value. Increasing cold gas efficiency with temperature was also reported by Khan et al. [39] for gasification of pine sawdust.

Comparing the gasification performance of the indigenous biomasses of West Azerbaijan province shows that chickpea straw gasification results in higher \({\eta }_{c}\) and \({LHV}_{s}\) at all temperatures. Lentil straw gasification offers syngas with more heating value compared to wheat straw gasification while the latter one results in higher cold gas efficiency. The lowest cold gas efficiencies and lower heating values of syngas belong to sunflower seed shell gasification at all temperatures.

Figure 8 shows the influence of steam to biomass ratio on \({\eta }_{c}\) and \({LHV}_{s}\). The results indicate that cold gas efficiency is markedly reduced and lower heating value of syngas is slightly decreased by increasing steam to biomass ratio. Slight decrement of syngas lower heating value is due to decrement of carbon monoxide and methane production with steam to biomass ratio (see Fig. 4 and Fig. 5). Although hydrogen production is increased by increasing steam to biomass ratio (see Fig. 3), decrement of carbon monoxide and methane is predominant phenomenon, and therefore, lower heating value is reduced. Two factors could explain the significant reduction of cold gas efficiency. Firstly, reductions of carbon monoxide and methane are the possible explanations for this decline. Secondly, more heat is required for gasification at higher steam to biomass ratios, and therefore, cold gas efficiency is decreased based on Eq. (11). These findings were also reported by Zaman et al. [38]. They reported reduction of cold gas efficiency and syngas lower heating value versus steam to biomass ratio for gasification of rice husk and almond shell. These results reflect those of Khan et al. [39] who also found that increasing steam to biomass ratio decreased cold gas efficiency in gasification of pine sawdust.

Between the gasification of the indigenous biomasses of West Azerbaijan province, chickpea straw gasification provides the maximum \({\eta }_{c}\) and \({LHV}_{s}\) at all steam to biomass ratio. Wheat straw gasification is in the second rank from cold gas efficiency viewpoint while lentil straw gasification ranks the second with respect to lower heating value of syngas. Sunflower seed shell gasification results in the lowest cold gas efficiencies and syngas lower heating values at all steam to biomass ratios.

3.4 Evaluation of carbon dioxide emission

Figure 9 depicts the influences of temperature and steam to biomass ratio on carbon dioxide emission. According to the results of Fig. 9a, increasing temperature mitigates the carbon dioxide emission due to shifting the Boudouard reaction (Eq. (16)). Figure 9b indicates that the carbon dioxide emission is increased by increasing steam to biomass ratio because of taking place of water–gas shift reaction (Eq. (14)). Chickpea straw is the best indigenous biomass of West Azerbaijan province with respect to carbon dioxide emission at all temperatures and steam to biomass ratios. Wheat straw and lentil straw are in the next ranks from carbon dioxide emission viewpoint. Sunflower seed shell emits the highest carbon dioxide values.

3.5 Multi-criteria decision analysis

In this section, a multi-criteria decision analysis is conducted using TOPSIS technique to select the best indigenous biomass of West Azerbaijan province for steam gasification. Wheat straw, chickpea straw, sunflower seed shell, and lentil straw are considered as alternatives. Cold gas efficiency, lower heating value of syngas, and carbon dioxide emission are the criteria. The decision matrix is as Table 4. The results of the TOPSIS technique are presented in the last column. The results show that the chickpea straw gasification ranks the first by considering all the criteria among indigenous biomasses of West Azerbaijan province. Steam gasification of chickpea straw results in the higher cold gas efficiency of 32%, more lower heating value of syngas of 402.4 kJ/mol and lower carbon dioxide emission of 29.27 g/mol compared to other biomasses. Therefore, it is subjected to a multi-objective optimization procedure in the next section.

3.6 Multi-objective optimization

In this section, steam gasification of chickpea straw as the best indigenous biomass of West Azerbaijan province is multi-objectively optimized using response surface methodology. Temperature in the range of 700–1000 °C and steam to biomass ratio ranging from 1 to 3 are the variable parameters. Figure 10 shows the single-objective optimization of chickpea straw steam gasification. The results indicate that there is a significant interaction between temperature and steam to biomass ratio on lower heating value of syngas and carbon dioxide emission; however, the interaction between them on cold gas efficiency is not noticeable. Figure 10a indicates that the maximum cold gas efficiency is as high as 48.9% and is obtained at steam to biomass ratios smaller than 1.1 for all temperatures. Figure 10b shows that the maximum lower heating value of syngas is 411 kJ/mol at temperatures larger than 950 °C and steam to biomass ratios lower than 1.2. Figure 10c reveals that the minimum carbon dioxide emission is 19.5 g/mol at temperatures larger than 975 °C and steam to biomass ratios smaller than 1.1.

Figure 11 shows the results of multi-objective optimization of steam gasification of chickpea straw. The maximization of cold gas efficiency, the maximization of lower heating value of syngas and the minimization of carbon dioxide emission are defined as the targets. The results indicate that the highest level of temperature, i.e., 1000 °C, and the lowest level of steam to biomass ratio, i.e., 1, are the optimum conditions to achieve the maximum cold gas efficiency of 48.5%, the maximum lower heating value of syngas of 411 kJ/mol and the minimum carbon dioxide emission of 19.3 g/mol.

4 Conclusions

Gasification performance of indigenous biomasses of West Azerbaijan province was studied in details and the variations of syngas composition, cold gas efficiency, carbon dioxide emission, and lower heating value of syngas were evaluated versus temperature and steam to biomass ratio. Wheat straw, chickpea straw, sunflower seed shell, and lentil straw were considered as the feedstock for steam gasification. The main conclusions could be summarized as:

-

• Chickpea straw gasification produced syngas with higher hydrogen, methane, and carbon dioxide concentrations at all gasification temperatures and steam to biomass ratios.

-

• Lentil straw had better performance than wheat straw in producing syngas with higher hydrogen concentration.

-

• Wheat straw gasification was better from lentil straw gasification from syngas with higher carbon monoxide and methane concentrations viewpoint.

-

• Gasification of chickpea straw resulted in the syngas with the minimum carbon dioxide concentration at all gasification temperatures and steam to biomass ratios.

-

• Sunflower seed shell gasification ranked the last between the indigenous biomasses of West Azerbaijan province with respect to all criteria.

-

• Chickpea straw gasification led to the highest syngas heating value and cold gas efficiency.

-

• Gasification of wheat straw provided more cold gas efficiency compared with gasification of lentil straw while the latter one was better from lower heating value of syngas viewpoint.

-

• Multi-criteria decision analysis confirmed that chickpea straw was the best alternative for steam gasification between the indigenous biomasses of West Azerbaijan province.

-

• Multi-objective optimization revealed that achieving an efficient and low-pollutant gasification is possible using the indigenous biomasses of West Azerbaijan province.

The reader should bear in mind that the study was based on thermodynamic modeling, and it is beyond the scope of this study to perform the experimental gasification of the indigenous biomasses of West Azerbaijan province. Since the performances of the chickpea straw and lentil straw were desirable, this is an important issue for future researches for more investigation of the gasification processes of these potential biomasses.

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Abbreviations

- \({\overline{h} }_{\mathrm{steam}}\) :

-

Enthalpy of steam (J/kg.K)

- \(\overline{G }\) :

-

Standard total Gibbs free energy (J)

- \({LHV}_{\mathrm{biomass}}\) :

-

Biomass lower heating value (J/mol)

- \({LHV}_{s}\) :

-

Syngas lower heating value (J/mol)

- \({Q}_{\mathrm{in}}\) :

-

Required heat for gasification process (W)

- \({n}_{\mathrm{biomass}}\) :

-

Mole numbers of the biomass entering the gasifier (mol)

- \({\gamma }_{i}\) :

-

Molar number of the ith syngas component (mol)

- \({\eta }_{c}\) :

-

Cold gas efficiency (%)

- \({\mu }_{{\mathrm{CO}}_{2}}\) :

-

Mass of carbon dioxide (g)

- \({\omega }_{{CO}_{2}}\) :

-

Carbon dioxide emission (g/mol)

- C:

-

Carbon

- G :

-

Total Gibbs free energy (J)

- H:

-

Hydrogen

- N:

-

Nitrogen

- O:

-

Oxygen

- R :

-

Universal gas constant (J/mol.K)

- S:

-

Sulfur

- T :

-

Temperature (°C)

- \(\alpha\) :

-

Biomass moisture content (mol)

- \(\beta\) :

-

Feeding steam (mol)

- \(\lambda\) :

-

Lagrangian multipliers

References

Liu W, Tian Y, Yan H, Zhou X, Tan Y, Yang Y, Li Z, Yuan L (2021) Gasification of biomass using oxygen-enriched air as gasification agent: a simulation study. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02035-2

Anniwaer A, Yu T, Chaihad N, Situmorang YA, Wang C, Kasai Y, Abudula A, Guan G (2020) Steam gasification of marine biomass and its biochars for hydrogen-rich gas production. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00868-x

Yan L, Cao Y, Zhou H, He B (2018) Investigation on biomass steam gasification in a dual fluidized bed reactor with the granular kinetic theory. Biores Technol 269:384–392

Kartal F, Özveren U (2021) A comparative study for biomass gasification in bubbling bed gasifier using Aspen HYSYS. Bioresour Technol Rep 13:100615

Singh DK, Tirkey JV (2022) Process modelling and thermodynamic performance optimization of biomass air gasification fuelled with waste poultry litter pellet by integrating Aspen plus with RSM. Biomass Bioenerg 158:106370

Puig-Gamero M, Pio DT, Tarelho LAC, Sánchez P, Sanchez-Silva L (2021) Simulation of biomass gasification in bubbling fluidized bed reactor using aspen plus®. Energy Convers Manage 235:113981

Dang Q, Zhang X, Zhou Y, Jia X (2021) Prediction and optimization of syngas production from a kinetic-based biomass gasification process model. Fuel Process Technol 212:106604

Aghaalikhani A, Schmid JC, Borello D, Fuchs J, Benedikt F, Hofbauer H, Rispoli F, Henriksen UB, Sárossy Z, Cedola L (2019) Detailed modelling of biomass steam gasification in a dual fluidized bed gasifier with temperature variation. Renew Energy 143:703–718

Vecten S, Wilkinson M, Bimbo N, Dawson R, Herbert BM (2021) Hydrogen-rich syngas production from biomass in a steam microwave-induced plasma gasification reactor. Biores Technol 337:125324

Cao Y, Bai Y, Du J (2021) Air-steam gasification of biomass based on a multi-composition multi-step kinetic model: a clean strategy for hydrogen-enriched syngas production. Sci Total Environ 753:141690

Ismail TM, Abd El-Salam M, Monteiro E, Rouboa A (2018) Fluid dynamics model on fluidized bed gasifier using agro-industrial biomass as fuel. Waste Manage 73:476–486

Zaman SA, Ghosh S (2021) A generic input–output approach in developing and optimizing an Aspen plus steam-gasification model for biomass. Biores Technol 337:125412

Ozbas EE, Aksu D, Ongen A, Aydin MA, Ozcan HK (2019) Hydrogen production via biomass gasification, and modeling by supervised machine learning algorithms. Int J Hydrogen Energy 44(32):17260–17268

Vikram S, Rosha P, Kumar S, Mahajani S (2022) Thermodynamic analysis and parametric optimization of steam-CO2 based biomass gasification system using Aspen PLUS. Energy 241:122854

Mojaver M, Azdast T, Hasanzadeh R (2021) Assessments of key features and Taguchi analysis on hydrogen rich syngas production via gasification of polyethylene, polypropylene, polycarbonate and polyethylene terephthalate wastes. Int J Hydrogen Energy 46(58):29846–29857

Habibollahzade A, Ahmadi P, Rosen MA (2021) Biomass gasification using various gasification agents: optimum feedstock selection, detailed numerical analyses and tri-objective grey wolf optimization. J Clean Prod 284:124718

Hasanzadeh R, Mojaver M, Azdast T, Park CB (2022) A novel systematic multi-objective optimization to achieve high-efficiency and low-emission waste polymeric foam gasification using response surface methodology and TOPSIS method. Chem Eng J 430:132958

Hasanzadeh R, Mojaver M, Azdast T, Park CB (2021) Polyethylene waste gasification syngas analysis and multi-objective optimization using central composite design for simultaneous minimization of required heat and maximization of exergy efficiency. Energy Convers Manage 247:114713

Mojaver P, Jafarmadar S, Khalilarya S, Chitsaz A (2019) Study of synthesis gas composition, exergy assessment, and multi-criteria decision-making analysis of fluidized bed gasifier. Int J Hydrogen Energy 44(51):27726–27740

Mojaver P, Hasanzadeh R, Chitsaz A, Azdast T, Mojaver M (2022) Tri-objective central composite design optimization of co-gasification of eucalyptus biomass and polypropylene waste. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-02597-9

Hasanzadeh R, Mojaver P, Azdast T, Chitsaz A, Park CB (2022) Low-emission and energetically efficient co-gasification of coal by incorporating plastic waste: a modeling study. Chemosphere 299:134408

Hasanzadeh R, Azdast T, Mojaver M, Park CB (2022) High-efficiency and low-pollutant waste polystyrene and waste polystyrene foam gasification: comprehensive comparison analysis, multi-objective optimization and multi-criteria decision analysis. Fuel 316:123362

Sheng C, Azevedo JLT (2005) Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenerg 28(5):499–507

Thipkhunthod P, Meeyoo V, Rangsunvigit P, Kitiyanan B, Siemanond K, Rirksomboon T (2005) Predicting the heating value of sewage sludges in Thailand from proximate and ultimate analyses. Fuel 84(7–8):849–857

Yin CY (2011) Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 90(3):1128–1132

Callejón-Ferre AJ, Velázquez-Martí B, López-Martínez JA, Manzano-Agugliaro F (2011) Greenhouse crop residues: energy potential and models for the prediction of their higher heating value. Renew Sustain Energy Rev 15(2):948–955

Rapagnà S, Jand N, Kiennemann A, Foscolo PU (2000) Steam-gasification of biomass in a fluidised-bed of olivine particles. Biomass Bioenerg 19(3):187–197

Karmakar MK, Datta AB (2011) Generation of hydrogen rich gas through fluidized bed gasification of biomass. Biores Technol 102(2):1907–1913

Hussain M, Zabiri H, Uddin F, Yusup S, Tufa LD (2021) Pilot-scale biomass gasification system for hydrogen production from palm kernel shell (part A): steady-state simulation. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01474-1

Mehrpooya M, Khalili M, Sharifzadeh MMM (2018) Model development and energy and exergy analysis of the biomass gasification process (based on the various biomass sources). Renew Sustain Energy Rev 91:869–887

AlNouss A, Parthasarathy P, Shahbaz M, Al-Ansari T, Mackey H, McKay G (2020) Techno-economic and sensitivity analysis of coconut coir pith-biomass gasification using ASPEN PLUS. Appl Energy 261:114350

Yong YS, Rasid RA (2021) Process simulation of hydrogen production through biomass gasification: introduction of torrefaction pre-treatment. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2021.07.010

Samimi F, Marzoughi T, Rahimpour MR (2020) Energy and exergy analysis and optimization of biomass gasification process for hydrogen production (based on air, steam and air/steam gasifying agents). Int J Hydrogen Energy 45(58):33185–33197

Unpaprom Y, Pimpimol T, Whangchai K, Ramaraj R (2021) Sustainability assessment of water hyacinth with swine dung for biogas production, methane enhancement, and biofertilizer. Biomass Convers Biorefinery 11(3):849–860

Callén MS, Martínez I, Grasa G, López JM, Murillo R (2022) Principal component analysis and partial least square regression models to understand sorption-enhanced biomass gasification. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-02496-z

Konttinen JT, Moilanen A, DeMartini N, Hupa M (2012) Carbon conversion predictor for fluidized bed gasification of biomass fuels—from TGA measurements to char gasification particle model. Biomass Convers Biorefinery 2(3):265–274

Tauqir W, Zubair M, Nazir H (2019) Parametric analysis of a steady state equilibrium-based biomass gasification model for syngas and biochar production and heat generation. Energy Convers Manage 199:111954

Zaman SA, Roy D, Ghosh S (2020) Process modeling and optimization for biomass steam-gasification employing response surface methodology. Biomass Bioenerg 143:105847

Khan MM, Xu S, Wang C (2022) Catalytic biomass gasification in decoupled dual loop gasification system over alkali-feldspar for hydrogen rich-gas production. Biomass Bioenerg 161:106472

Author information

Authors and Affiliations

Contributions

Parisa Mojaver: methodology, conceptualization, software, validation, investigation; formal analysis, and writing—original draft. Shahram Khalilarya: investigation, writing—review and editing, supervision. Ata Chitsaz: investigation, writing—review and editing, supervision. Samad Jafarmadar: investigation, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Ethical approval

This manuscript is the authors’ own original work, which has not been previously published elsewhere.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Indigenous biomasses of West Azerbaijan province gasification in Iran was modeled.

• Chickpea straw and lentil straw gasification were developed.

• Multi-criteria decision analysis was conducted using TOPSIS technique.

• Multi-objective optimization was performed using RSM method.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mojaver, P., Khalilarya, S., Chitsaz, A. et al. Performance assessment and optimization of gasification of indigenous biomasses of West Azerbaijan province to attain a hydrogen-rich syngas based on thermodynamic modeling. Biomass Conv. Bioref. 14, 14665–14678 (2024). https://doi.org/10.1007/s13399-022-03676-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03676-7