Abstract

Due to growing consumer preference towards natural ingredients in food products, the production of flavors by microbial biotransformation of agrowastes provides an eco-friendly, cost-effective and sustainable pathway for biovanillin production. In the present study, biovanillin was produced by microbial biotransformation of ferulic acid (FA) using Streptomyces sp. ssr-198. The strain was able to grow in glucose medium supplemented with 1 g/L FA and produce 20.91 ± 1.11 mg/L vanillin within 96 h, along with 5.78 ± 0.13 mg/L vanillic acid in 144 h. Estimation of enzymes involved in FA degradation detected maximum feruloyl-CoA synthetase activity (1.21 ± 0.03 U/mg protein) at 96 h and maximum vanillin dehydrogenase activity (0.31 ± 0.008 U/mg protein) at 168 h, with small amounts of ferulic acid esterase activity (0.13 ± 0.002 U/mg protein) in the fermentation medium. Further, the glucose deficient production medium supplemented with 3 g/L of ferulic acid when inoculated with Streptomyces sp. ssr-198 (6% wet weight) produced maximum vanillin (685 ± 20.11 mg/L) within 72 h at 37 °C under agitation (150 rpm) and declined thereafter. Furthermore, in a one-pot experiment, wherein crude ferulic acid esterase (700 IU/g of substrate) from Enterococcus lactis SR1 was added into 10% w/v wheat bran (natural source of ferulic acid) based medium and was inoculated with 1% w/v of Streptomyces sp. ssr-198 resulted in maximum vanillin production (1.02 ± 0.02 mg/g of substrate) within 60 h of incubation. The study provides an insight into synergistic effect of using FAE of E. lactis SR1 and Streptomyces sp. ssr-198 for bioproduction of biovanillin using agro residues.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

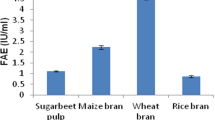

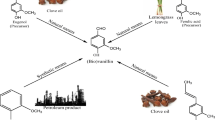

Vanilla, is one of the most used flavoring agent in the food industry due to its unique flavor (Yang et al. 2013). It is naturally extracted from pods of Vanilla planifolia and is a complex mixture of more than 200 molecules. The natural production of vanilla from vanilla pods is a very expensive and labor-intensive process (Chattopadhyay et al. 2018). Interestingly, the distinctive flavor of vanilla is majorly due to a phenolic aldehyde, vanillin. The compound can be made synthetically also and is available at a much lower cost (300-times lower than natural vanillin), but due to the growing consumer preferences for natural food products including the flavor compounds, the microbial production of flavors provide a suitable alternative to natural as well as chemical/synthetic routes (Banerjee and Chattopadhyay 2018; Galadima et al. 2019). The European Commission (EU) legislation on flavors defines biovanillin as naturally identical vanillin that is produced by microbial or enzymatic biotransformation of suitable natural precursor compounds like ferulic acid, eugenol, or isoeugenol (Zamzuri and Abd-Aziz 2012; Gallage and Molle, 2015). Ferulic acid [4-hydroxy-3-methoxy cinnamate (FA)], a phenylpropanoic acid is associated to plant cell walls by cross-linking with lignin and polysaccharides via ester bonds and can be released by enzymatic/chemical hydrolysis (Boz 2016). Enzymatic hydrolysis involves the use of enzymes, ferulic acid esterases (FAEs), which cleave the ester bonds between FA and other plant cell components (Zamzuri and Abd-Aziz 2012; Banerjee and Chattopadhyay 2018; Galadima et al. 2019). FAEs are produced by various microorganisms like Talaromyces cellulolyticus (Watanabe et al. 2015); Aspergillus niger (Wu et al. 2018); Lactobacillus fermentum (Su et al. 2019); Enterococcus lactis (Sharma et al. 2020); Lactobacilli (Xu et al. 2020; Xie et al. 2021). Lignocellulosic agroresidues provide a rich source of ferulic acid, which can be extracted through alkali extraction or by the action of microbial FAEs. The feasibility of using agro-industrial wastes for ferulic acid extraction either chemically or enzymatically has been reported by many authors. The extracted ferulic acid can then be converted to vanillin by several microorganisms like Streptomyces sp. (Yang et al. 2013), S. sannanensis (Ghosh et al. 2006; Chattopadhyay et al. 2018), Rhodococcus strains (Phaggenborg et al. 2006), Pseudomonas fluorescens ( Di Gioa et al. 2011); Pseudomonas putida (Graf and Altenbuchner 2013); Bacillus subtilis (Yan et al. 2016), Phanerochaete chrysosporium (Galadima et al. 2019); Serpula lacrymans (Nurika et al. 2020), Aspergillus niger (Tang and Hassan 2020). In these microorganisms, vanillin is either an intermediate or final product formed during ferulic acid metabolism (Brink et al. 2019). Such strains, generally use a consistent coenzyme-A-dependent, a non-β-oxidative pathway for ferulic acid bioconversion. The pathway involves genes encoding feruloyl-CoA synthetase, enoyl-CoA hydratase/aldolase, and vanillin dehydrogenase organized in a catabolic cluster (Plaggenborg et al. 2006). In our previous study (Sharma et al. 2020), we have extracted ferulic acid from various agroresidues (wheat bran, maize bran, rice bran, and sugarbeet pulp) through alkaline extraction as well as by the action of crude FAE produced by Enterococcus lactis SR1 in conjunction with commercial holocellulase. In the present work, we have attempted biotransformation of ferulic acid supplemented in the production media to vanillin using resting cells of Streptomyces sp. ssr-198. Further, in a one-pot experiment for bioconversion of FA present in agrowastes to vanillin, FAE of E. lactis SR1 was added into wheat bran based production media for the release of FA from the wheat bran and was inoculated with Streptomyces sp. ssr-198 for the subsequent bioconversion of the released FA to vanillin by the metabolic pathway of the actinomycete sp.

Materials and methods

Chemicals

Ferulic acid, Vanillin, Vanillyl alcohol, Guaiacol, Coenzyme A hydrate (CoA), and Adenosine triphosphate disodium salt hydrate (ATP) were all purchased from Merck (St. Louis, MO, USA). Other chemicals and media components were purchased from SRL, Mumbai, India. Wheat bran was procured from the local market.

Microorganisms used in the study

Enterococcus lactis SR1 (Accession no. MH169741), isolated in our laboratory from sauerkraut and maintained on MRS-agar (Man Rogosa Sharpe) as described previously (Sharma et al. 2020) was used for FAE production. Streptomyces sp. ssr‐198, also procured from our laboratory (Singh et al., 2014) and maintained on potato dextrose agar (PDA) was used for the biotransformation of ferulic acid to biovanillin.

Growth of Streptomyces sp. ssr-198 in glucose media supplemented with ferulic acid

Streptomyces sp. ssr-198 (1% w/v from culture grown on PDA) was inoculated in glucose and ferulic acid supplemented minimal media containing g/L: glucose 10.0, ferulic acid 1.0, peptone 10.0, K2HPO4 5.0, (NH4)SO4 1.7, MgSO4 0.2, CaCl2 0.02, MnSO4·H2O 0.02 mg, FeSO4.7H2O 0.02 mg, pH 7.0, and incubated at 37 °C, 150 rpm for 240 h. Culture aliquots (1 ml) were withdrawn every 24 h, collected in pre-weighed tubes, and centrifuged at 10,000 rpm for 15 min. The residual cells were washed twice with distilled water and dried to a constant weight at 100 °C, and the cell biomass was quantified gravimetrically. While the supernatants were analyzed for vanillin and vanillic acid using HPLC as well as for the enzymes involved in FA degradation viz. ferulic acid esterase (FAE), feruloyl-Co-A synthetase (FCS), and vanillin dehydrogenase (VDH). Further, the FA concentration in the growth media was also varied from 0.5–2.0 g/L, and fermentation with Streptomyces sp. ssr-198 was carried out for 96 h. After the incubation period, biomass was weighed and the supernatants were analyzed for vanillin and vanillic acid production.

Biotransformation of ferulic acid to vanillin using resting cells of Streptomyces sp. ssr-198

Cells of Streptomyces sp. ssr-198 were grown in growth media as described by Singh et al. (2014) under submerged fermentation (SmF) at 37 °C, 150 rpm for 48 h. The contents of the flasks were centrifuged and the pelleted biomass was inoculated @ 4% wet weight (w/v) in ferulic-acid-based production media (similar composition as growth media but deficient in glucose, while supplemented with 1 g/L FA) and incubated at 37 °C, 150 rpm for 240 h. The culture aliquots (1 ml) after centrifugation were analyzed for ferulic acid, vanillin, and vanillic acid every 24 h using HPLC. Further, ferulic acid concentration (1.0–5.0 g/L) that is to be supplemented in the production media was also optimized to achieve maximum biotransformation by Streptomyces sp. ssr-198. Furthermore, rate of inoculum in terms of wet biomass (1–10% w/v) of Streptomyces sp. ssr-198 was also optimized in the production media for maximum substrate biotransformation.

FAE production from Enterococcus lactis SR1 using wheat bran as carbon source

The primary culture of E. lactis SR1 was grown in MRS broth by inoculating loop full of the culture maintained on MRS-agar and incubated at 37 °C under static conditions for 48 h. The secondary culture was grown by inoculating 1% v/v of primary culture in MRS broth and incubated at 37 °C under static conditions for 18 h. The secondary inoculum of E. lactis SR1 @ 0.2% v/v was then inoculated in MRS-broth, deficient in glucose but containing 1% w/v of wheat bran as carbon source and kept at 37 °C under static conditions for 72 h (Sharma et al. 2020). The culture was centrifuged at 10,000 rpm for 15 min at 4 °C and estimated for FAE (Sharma et al. 2020). The crude FAE was concentrated by precipitating with acetone. The precipitate was dissolved in citrate buffer, pH 6.5 to concentrate it by tenfold.

One-pot bioconversion of ferulic acid present in wheat bran to vanillin by the action of FAE from E. lactis SR1 and Streptomyces sp. ssr-198

The acetone precipitated FAE (500 IU/g of substrate) produced from E. lactis SR1 was added in wheat bran based production media containing g/L; wheat bran 10, peptone 10.0, K2HPO4 5.0, (NH4)SO4 1.7, MgSO4 0.2, CaCl2 0.02, MnSO4.H2O 0.02 mg, FeSO4.7H2O 0.02 mg, pH 7.0 and was inoculated with 1% wet weight of the cells of Streptomyces sp. ssr-198. The inoculated media was incubated at 37 °C, 150 rpm for 96 h, and aliquots of 1 ml were withdrawn after every 12 h, centrifuged at 13,000 rpm for 10 min and the supernatants were analyzed for biotransformed products formed using HPLC. In the control set of the experiment, FAE from E. lactis SR1 was not added into the production medium.

Optimization of process parameters for maximum FA bioconversion to vanillin in the one-pot

Process parameters that maximize bioconversion of FA to vanillin in the one-pot viz. FAE dose, substrate loading, and inoculum amount of Streptomyces sp. ssr-198 were optimized using one-factor-at-a-time approach. Firstly, FAE dose was optimized for maximum release of ferulic acid from wheat bran by adding different FAE doses (100–1000 IU/g substrate) into the production media inoculated with 1% w/v of the wet weight of Streptomyces sp. ssr-198 cells and incubated at 37 °C, 150 rpm for 60 h. Secondly, optimization of substrate loading was performed by taking different amounts of wheat bran (5–20% w/v) in production media containing FAE dose of 700 IU/g of wheat bran and inoculated with 1% wet weight of Streptomyces sp. ssr-198 cells. The reaction mixtures were incubated at 37 °C, 150 rpm for 60 h. Finally, optimization of inoculum level was done by inoculating different concentrations of wet biomass of Streptomyces sp. ssr-198 (0.5–2% w/v) in production media with 10% substrate loading, FAE (700 IU/g of substrate), incubated at 37 °C, 150 rpm for 60 h. In all the three optimization studies, after the incubation period, the contents of the flasks were centrifuged at 13,000 rpm for 10 min and the supernatants were analyzed for biotransformed products formed using HPLC.

Analytical methods

Ferulic acid esterase (FAE) assay: The assay for FAE was done in tubes containing 800 μl of 100 mM Na-Phosphate buffer (pH 6.5), 200 and 15 μl of ethyl ferulate (10 mg/ml) as described by Sharma et al., (2020). The reaction was initiated by adding 200 μl of culture filtrate and incubated at 37 °C for 2 h. The reaction was stopped by keeping the tubes in a boiling water bath for 5 min. The concentration of ferulic acid in the reaction mixture was determined by HPLC (Waters) equipped with PDA detector 2998. A Biorad C-18 column (300 mm × 7.8 mm) was eluted with an isocratic mixture of (35:65) methanol: 0.3% acetic acid. The column oven was set at 37 °C. The eluent was monitored at 310 nm, using a waters PDA detector 2998 for quantification of ferulic acid released as described previously (Sharma et al. 2020). One unit of enzyme is the amount of enzyme that is required to release one µM of ferulic acid in one minute.

Feruloyl Co-A synthetase (FCS) assay: the enzyme assay for FCS was performed according to the method described by Yang et al. (2013). The reaction mixture (1 ml) consisted of 100 mM potassium phosphate buffer (pH 7.0), 25 mM MgCl2, 0.7 mM ferulic acid, 2 mM ATP, 0.4 mM coenzyme A and 0.5 ml of sample. The reaction was initiated by the addition of ATP and absorbance was measured at 345 nm using a UV–Visible spectrophotometer (Thermo Scientific, Evolution 300).

Vanillin dehydrogenase (VDH) assay: VDH activity was estimated according to the method given by Kaur et al. (2013). Equal volumes of culture supernatant and vanillin synthetic medium (1 g/L vanillin, 2 g/L triammonium citrate, 2 g/L sodium acetate, 0.1 g/L MgSO4, 0.05 g/L MnSO4, and 2 g/L di-potassium hydrogen phosphate) were incubated at 37 °C for 24 h. on ml of the reaction mixture was mixed with 5 ml of HCl (24% v/v) and 2 ml of 1% w/v of thiobarbituric acid and heated at 55 °C for 10 min. and subsequently stored at room temperature for 20 min. The decrease in absorbance was then recorded at 434 nm in a UV–vis spectrophotometer.

Quantitative determination of biotransformed products: the supernatants obtained after centrifugation of the fermented cultures were acidified (pH 1.0–2.0) with 1 M hydrochloric acid (HCl) and extracted with an equal volume of ethyl acetate. The ethyl acetate was evaporated in a vacuum evaporator and the residue was dissolved in 80% methanol and analyzed for ferulic acid, vanillin, and vanillic acid. The compounds formed were quantified using an HPLC equipped with a PDA detector 2998 set at 310 and 363 nm. A Biorad C-18 column (300 mm × 7.8 mm) was eluted with an isocratic mixture of methanol: 0.3% acetic acid (35:65) at a flow rate of 0.6 ml/min. The column oven was set at 37 °C and the standard curves of ferulic acid, vanillin, and vanillic acid were prepared in the range of 25–250 mg/L.

Results and discussion

Time course of Streptomyces sp. ssr-198 growth in glucose media supplemented with FA

It was observed that Streptomyces sp. ssr-198 grew well in glucose media supplemented with 1 g/L FA. The time-course experiments showed a lag phase of 24 h followed by a log phase till 96 h with maximal biomass (dry weight) of 25.6 ± 0.65 g/L, which remained stationary till 168 h and declined thereafter (Fig. 1). Similarly, on studying FA biotransformation by Streptomyces sp. ssr-198, it was observed that vanillin production increased from 0.82 mg/L at 24 h to 20.91 ± 1.11 mg/L in 96 h and decreased afterward. The results suggest that vanillin production is closely related to cell growth as both vanillin as well as biomass were produced maximally at 96 h. A decrease in vanillin production was observed after 96 h, which may indicate that ferulic acid was exhausted and transformed to vanillin within 96 h leading to termination of increase in vanillin concentration as well as the increase in cell numbers. However, the produced vanillin was simultaneously biotransformed to vanillic acid by the microbial cells, which started increasing from 0.21 ± 0.09 mg/L in 72 h to 5.78 ± 0.13 mg/L in 144 h and remained constant till 216 h and declined slightly thereafter. Hua and co-workers (2007) achieved high vanillin productivity in the batch biotransformation of ferulic acid by Streptomyces sp. V-1. In a study by Yang et al. (2013), fcs (ferolyl-Co-A synthetase) and ech (enoyl-Co-A hydratase) encoding genes from Streptomyces sp. were identified and heterologously expressed in E. coli. The authors then used the recombinant cells of E. coli for the bioconversion of ferulic acid to vanillin.

Furthermore, when the concentration of FA in the growth media was varied from 0.5 to 2.0 g/L (Fig. 2) maximum biomass (28.9 g/L ± 0.99) of the Streptomyces sp. was observed after 96 h at 0.5 g/L FA supplementation. However, on increasing the FA concentration from 0.5 to 1.0 g/L, there was a decline in biomass to 25.6 g/L ± 0.87, but a considerable increase in vanillin concentration from 13.45 ± 0.15 mg/L to 21.23 ± 0.21 mg/L was observed (Fig. 2). Ferulic acid at higher concentrations has been reported to be toxic to microorganisms as it damages intracellular hydrophobic sites and thereby causes ion leakage by altering membrane permeability, thus leading to cell death (Gioia et al., 2011; Yan et al., 2016; Chen et al., 2016). In our study also, FA concentrations > 0.5 g/L caused a decrease in biomass production. On further increasing the FA concentration > 1.0 g/L, vanillin production was also affected negatively. This may be because, in the case of a lower initial concentration, the entire amount of ferulic acid could be metabolized by the microbial cells, resulting in a higher product formation. But at higher FA concentrations, due to the lack of sufficient microbial cells to metabolize the additional FA, bioconversion efficiency also decreases. Thus, at high FA concentration, vanillin production also declines.

Further, in the control experiment wherein no FA was added to the medium, growth was less and no detectable levels of vanillin and vanillic acid were detected (Fig. 2). Calisti and co-workers (2008) reported that a cluster of genes (ech, vdh, and fcs) is essential for the degradation of ferulic acid to vanillin/ vanillic acid is expressed only in ferulic acid grown cells. Similarly, Parke and Ornston (2003) reported that in the absence of hydroxycinnamate, the genes involved in FA degradation are repressed by HcaR (hydroxycinnamic acid repressor). The authors demonstrated that HcaR-mediated repression is relieved by hydroxycinnamoyl-Co-A thioesters and concluded that induction of FA catabolic genes is triggered by the Co-A thioester produced from the FA added to the culture medium. Further, our results are in agreement with that of Chen et al. (2016) who also concluded a similar FA tolerance range with actinomycetes.

Estimation of enzymes involved in FA biotransformation

To confirm the biotransformation events, the key enzymes (FAE, FCS and VDH) involved in FA degradation/transformation were estimated as shown in Fig. 3. Streptomyces sp. ssr-198 was found to exhibit small amounts of FAE activity, with maximum (0.13 ± 0.002 U/g protein) at 48 h and declined after that (Fig. 3). While, FCS activity was found to increase gradually from 0.11 ± 0.01 U/mg protein at 24 h to 0.76 ± 0.02 U/mg protein in 48 h, subsequently reaching 1.21 ± 0.03 U/mg protein at 96 h following the accumulation of vanillin as shown in the previous section and started decreasing afterward (Fig. 3). On the other hand, there was almost no VDH activity detected in the media till 48 h, which started increasing gradually from 0.05 ± 0.001 U/mg protein at 72 h and subsequently reaching up to 0.31 U/mg ± 0.008 protein at 168 h, similar to the increase in vanillic acid concentration during the period (Fig. 3). Due to the high chemical reactivity of aldehyde compounds like vanillin, they are seldom stored as the end product in biological systems. As a result, various enzymes like VDH exist in cells for the metabolization of aldehydes into less reactive carboxylic acids (Ahmed et al. 2019). Based on the results, the pathway for ferulic acid degradation by Streptomyces sp. ssr-198 is shown in Fig. 4. The annotated protein sequences from the genome sequence of Streptomyces eurythermus ATCC 4975 (closely related to Streptomyces sp. ssr-198, as shown in Supplementary Fig. 1) present in the NCBI database (http://www.ncbi.nlm.nih.gov/), the sequences for acetyl-xylan esterases as well as enoyl-Co-A hydratase (ECH) were found. ECH catalyzes the hydration and non-oxidative cleavage of feruloyl-S-CoA (formed by the action of feruloyl-Co-A synthetase from ferulic acid) to vanillin. Similar to our results, Plaggenborg et al. (2006) after studying the genome sequence data of Rhodococcus strains suggested degradation of FA to vanillin via Co-A dependent, a non-β-oxidative pathway involving fcs, ech, and vdh genes encoding for feruloyl-CoA synthetase, enoyl-Co-A hydratase, and vanillin dehydrogenase, respectively. Our results are also in accordance with Kaur et al. (2013), who reported the occurrence of FA, vanillin, 4-ethyl phenol, vanillyl alcohol during biotransformation of rice bran to phenolics by the action of FA metabolizing enzymes produced by the bacterium. Recently, Margesin et al. (2021) studied the biodegradation of six lignin monomers (syringic acid, p-coumaric acid, 4-hydroxybenzoic acid, ferulic acid, vanillic acid, and benzoic acid) by Paraburkholderia aromaticivorans AR 20–38 and reported the degradation of 5 mM and 10 mM FA accompanied by stable accumulation of 760 mg/L and 1540 mg/L of vanillic acid. The genome analysis of the bacteria also revealed the presence of ech and fcs genes, thereby suggesting their role in ferulic acid degradation/transformation.

Biotransformation of FA to vanillin by resting cells of Streptomyces sp. ssr-198

Streptomyces sp. ssr-198 when used at the 4% w/v produced 89.98 ± 2.79 mg/L of vanillin from 1 g/L of FA in the media within 72 h and declined thereafter with the corresponding depletion of ferulic acid in the media. The amount of vanillic acid was produced maximally (17.8 mg/L ± 0.18) at 144 h and remained almost constant till 216 h (Fig. 5). Since, maximum vanillin was produced at 72 h, for further experiments, the fermentation was carried out only up to 72 h. Optimization of the concentration of FA that has to be supplemented in the production media for its maximum bioconversion revealed that 3 g/L of FA produced maximum vanillin (370.78 ± 10.81 mg/L) and vanillic acid (25.62 ± 1.89 mg/L) within 72 h (Fig. 6a). Gunnarson and Palmqvist, (2006) observed higher FCS activity compared to VDH activity when a higher concentration of FA in the fermentation medium of S. setonii were provided, thereby channeling the metabolic flow towards vanillin accumulation. However, at FA concentration > 3 g/L in the medium resulted in a decline in the production of both vanillin and vanillic acid due to substrate toxicity towards microbial cells. In addition, optimization of cell biomass concentration showed better results in terms of vanillin (685.45 ± 20.11 mg/L) and vanillic acid (45.63 ± 2.99 mg/L) formation when 6% w/v wet weight of the Streptomyces sp. ssr-198 cells were used as biocatalyst (Fig. 6b). Similar to our work, Abdelkafi et al. (2006) also produced vanillic acid from resting cells of Halomonas elongata strain Mar (4% dry weight pre-grown in FA supplemented medium) inoculated in production medium supplemented with 5 mM FA. Luziateli et al. (2019) also optimized culture conditions for maximum FA bioconversion by recombinant resting E. coli cells carrying Pseudomonas genes (fcs and ech) and obtained the highest vanillin concentration (7.8 mM) with supplementation of 15.5 mM FA.

One-pot experiment for biotransformation of FA present in wheat bran to biovanillin

To investigate the biotransformation of FA present in wheat bran to biovanillin, biotransformation experiments were performed using a microbial enzyme system (FAE from E. lactis SR1) that releases bound FA from agroresidues (Sharma et al. 2020) followed by its bioconversion to vanillin by cells of Streptomyces sp. ssr-198 through the action of its FA metabolizing enzymes. The amount of FA released from wheat bran in the medium by the action of added enzymes was estimated at regular intervals and the results showed maximum FA (1.95 ± 0.02 mg/g of wheat bran) was released within 24 h (Table 1). The FA is released from wheat bran by the action of the added FAE from E. lactis SR1 as well as by the innate FAE of the Streptomyces sp. ssr-198 (Fig. 3). In our previous work (Sharma et al., 2020), FAE (500 IU/g of substrate) from E. lactis SR1 along with commercial holocellulase was used for the release of 1.39 ± 0.04 mg/g FA from wheat bran in 16 h. However, in the present study, higher amounts of FA were released from the wheat bran even without the addition of any additional holocellulases. Singh and co-workers (2014) found Streptomyces sp. ssr-198 to produce high titers of holocellulolytic enzymes (endoglucanase, exoglucanase and xylanase) when grown on lignocellulosic agroresidues. Further, Singh et al., (2015) performed proteomic analysis of the secretome of Streptomyces sp. ssr-198 by tandem mass spectrometry and found acetyl xylan esterases as well as putative feruloyl esterases along with glycoside hydrolases, proteases and other hypothetical proteins. Similar to our results, Perez-Rodriguez and co-workers (2016) also used crude enzyme extract of Aspergillus terreus containing FAE and xylanase activities for the release of ferulic acid from vine trimming shoots (2.05 mg/g) and corn cob (1.87 mg/g).

The released FA was subsequently used by the cells of Streptomyces sp. ssr-198 in a glucose deficient medium for growth as well as conversion to vanillin by the action of FCS enzyme as the amount of FA in the medium declined, thereafter, while vanillin was being detected at 24 h. The highest vanillin (0.57 ± 0.03 mg/g) was formed within 60 h, after which its concentration started declining, while the maximum amount of vanillic acid (0.09 ± 0.001 mg/g) was produced at 84 h and remained constant till 96 h (Table 1). In the control set of experiments, wherein the FAE from E. lactis SR1 was not added, no vanillin and vanillic acid were formed. This indicates the role of synergistic action of FAE (from E. lactis SR1 and Streptomyces sp. ssr-198) and holocellulases of Streptomyces sp. ssr-198 in the release of FA from wheat bran and its subsequent conversion to vanillin and vanillic acid by FCS and VDH of Streptomyces sp. ssr-198, respectively. Since maximum vanillin was produced in 60 h and the concentration declined after that, hence for further experiments, the fermentation was carried out till 60 h. Earlier, Chakraborty and co-workers (2017) reported that Pediococcus acidilactici strain BD16 could produce 1.06 g/L of vanillin from rice bran-based medium, which was more than that obtained on MRS + FA-based medium (0.075 g/L). The authors concluded that FA from rice bran was released in the medium during autoclaving and also by the action of FAE activity of the isolate. Further, the released FA was then bioconverted to vanillin through a novel metabolic pathway present in the strain that involved the enzyme carboxylic acid reductase. Further, Chattopadhyaya et al. (2018) performed biotransformation of ferulic acid esters from wheat bran (10% w/v) to vanillin (708 mg/L) by Streptomyces sannanensis in sucrose medium. The authors also estimated various enzyme activities in the culture filtrate and concluded that the strain converts FA ester into FA with the help of ferulic acid esterase produced by the microbe and then catabolized it through Co-A-dependent non-β-oxidation of FA. Taira et al. (2018) investigated phenolic biotransformation, including vanillin production in Aspergillus luchuensis during fermentation of rice koji. The authors detected FA in steamed rice before mash indicating its presence in the raw material, which got accumulated in the fermentation medium by the action of FAEs of the fungal strain. The FA was subsequently biotransformed to vanillin and vanillic acid by ferulic acid degrading enzymes of the fungus. Further, investigation of the annotation information of amino acid sequences from A. luchuensis genome revealed the presence of fcs, ech and vdh genes. While, Rejani and Radhakrishan (2020) used agrowaste, coir pith for the chemical extraction of FA which was used as a substrate for biotransformation by Aspergillus niger to vanillic acid (0.773 g/L) which, in turn, was fermented by Phanerochaete chrysosporium to vanillin (0.628 g/L). Similarly, Tang and Hassan (2020) evaluated the potential of pineapple peel (PP) and pineapple crown leaves (PCL) as the substrate for the production of vanillin and vanillic acid. The authors optimized the conditions for maximum chemical extraction of FA from the substrates and obtained 1055 mg/L and 328 mg/L of FA from PP and PCL, respectively. The authors also found large feeding volumes (10 ml on days 3 and 4) of both PP and PCL liquor containing FA in the fermentation medium more efficient for the bioconversion of FA to vanillin by A. niger I-1472 than small feedings volume of the liquors (1.5 ml from day 3 to day 6). The authors produced maximum vanillin (5 mg/L) and vanillic acid (7 mg/L) by using large feeding volumes of PP liquor in fermentation medium by the fungal strain. The yields of vanillin acid obtained were more than that obtained with control (3.9 mg/L) containing 300 mg/l commercial FA, but less (15 mg/L) than that obtained with 1000 mg/L ferulic acid. The authors proposed the novel use of food wastes for microbial bioconversion of ferulic acid to vanillin. On similar lines, Nurika et al. (2020) demonstrated the potential of using rice straw inoculated with Serpula lacrymans for the production of a mixture of high-value bio-based compounds, including vanillin, and also optimized extraction conditions from maximum vanillin recovery using 60 ml ethyl acetate for 160 min.

Optimization of process parameters for maximum bioconversion of ferulic acid to vanillin in the one-pot experiment with wheat bran as a source of FA

Optimization of FAE dose in the medium showed that lower FAE dose led to reduced production of vanillin in the medium (Fig. 7a). With an increase in enzymatic dose, an appreciable upsurge in vanillin production was observed. The highest vanillin production (1.02 ± 0.02 mg/g) was achieved with 700 IU/g of FAE in the medium within 60 h of incubation (Fig. 7a). On further increasing the enzyme dose, there was no subsequent increase in product formation. While, optimizing % substrate loading, it was observed that maximum vanillin (1.02 ± 0.04 mg/g) was produced at 10% substrate loading (Fig. 7b). Further increase in substrate loading led to a decrease in vanillin production (Fig. 7b). It is because high solid loadings may result in the limited FA release by the enzyme due to mass transfer limitation (Tchuidjang et al. 2021). Knutsen and Liberatore (2009) concluded that the efficiency of enzymatic digestibility and fermentation is significantly reduced at high concentrations of biomass, as mixing becomes difficult with increased viscosity. This also leads to a slowing down of the formation of the enzyme–substrate complex (Asabjeu et al. 2020). Additionally, high substrate density can also inhibit enzymatic action (Knutsen and Liberatore 2009). Finally, optimization of % inoculation of Streptomyces sp. ssr-198, revealed that 1% w/v wet biomass of Streptomyces sp. ssr-198 produced maximum vanillin (1.02 ± 0.06 mg/g) in 60 h (Fig. 7c). But higher inoculum levels did not increase product formation. Contrarily, Erten and co-workers (2006) observed an increase in the amounts of flavor compounds in the fermentation of wine at high yeast inoculum levels.

Conclusion

The results suggested that Streptomyces sp. ssr-198 has considerable potential as a biocatalyst for the synthesis of vanillin and vanillic acid from ferulic acid. Both the products are of industrial significance and biotransformation experiments provide the feasibility of the process. Further, the use of agro residues that are rich in ferulic acid like cereal brans and beets can provide an inexpensive and renewable source of phenolic acid to be biotransformed into high-value chemicals like vanillin and vanillic acid using microbes and their enzymes in a biorefinery approach. Furthermore, increasing knowledge of the microbial metabolic pathways for vanillin production from ferulic acid along with the identification and characterization of the enzymes involved present future research opportunities with regard to cloning and expression of corresponding genes in industrially important strains for the bioproduction of vanillin. The study also gives opportunity to use various statistical approaches for the enhancement of vanillin yields in the bioprocess by optimization of significant process parameters and to also understand the interaction between the variables.

References

Abdelkafi S, Sayadi S, Ali Gam ZB, Casalot L, Labat M (2016) Bioconversion of ferulic acid to vanillic acid by Halomonas elongate isolated from table-olive fermentation. FEMS Microbiol Lett 262(1):115–120. https://doi.org/10.1111/j.1574-6968.2006.00381.x

Ahmed Laskar A, Younus H (2019) Aldehyde toxicity and metabolism: the role of aldehyde dehydrogenases in detoxification, drug resistance and carcinogenesis. Drug Metab Rev 51(1):42–64. https://doi.org/10.1080/03602532.2018.1555587

Asabjeu AC, Noubissie E, Carly DZS, Ali A (2020) Optimization of the enzymatic hydrolysis of cellulose of Triplochiton scleroxylan sawdust in view of the production of bioethanol. Scientific African 8:e00438. https://doi.org/10.1016/j.sciaf.2020.e00438

Banerjee G, Chattopadhyay P (2018) Vanillin biotechnology: the perspectives and future. J Sci Food Agric 99(2):499–506. https://doi.org/10.1002/jsfa.9303

Boz H (2016) Ferulic acid in cereals: a review. Czech Journal of Food Sciences 33(1):1–7. https://doi.org/10.17221/401/2014-cjfs

Brink DP, Ravi K, Lidén G, Gorwa-Grauslund MF (2019) Mapping the diversity of microbial lignin catabolism: experiences from the eLignin database. Appl Microbiol Biotechnol 103:3979–4002. https://doi.org/10.1007/s00253-019-09692-4

Calisti C, Ficca AG, Barghini P, Ruzzi M (2008) Regulation of ferulic catabolic genes in Pseudomonas fluorescens BF13: involvement of a MarR family regulator. Appl Microbiol Biotechnol 80(3):475–483. https://doi.org/10.1007/s00253-008-1557-4

Chakraborty D, Kaur B, Obulisamy K, Sevam A, Wong JWC (2017) Agrowaste to vanillin conversion by a natural Pediococcus acidilactici strain BD16. Environmental Technol 38(13–14):1823–1834. https://doi.org/10.1080/09593330.2016.1237556

Chattopadhyay P, Banerjee G, Sen SK (2018) Cleaner production of vanillin through biotransformation of ferulic acid esters from agroresidue by Streptomyces sannanensis. J Cleaner Production 182:272–279. https://doi.org/10.1016/j.jclepro.2018.02.043

Chen P, Yan L, Wu Z, Li S, Bai Z, Yan X (2016) A microbial transformation using Bacillus subtilis B7-S to produce natural vanillin from ferulic acid. Scientific Reports. 6(1). https://doi.org/10.1038/srep20400

Di Gioia D, Luziatelli F, Negroni A, Ficca AG, Fava F, Ruzzi M (2011) Metabolic engineering of Pseudomonas fluorescens for the production of vanillin from ferulic acid. J Biotechnol 156(4):309–316. https://doi.org/10.1016/j.jbiotec.2011.08.014

Erten H, Tanguler H, Cabaroglu T, Canbas A (2006) The influence of inoculum level on fermentation and flavour compounds of white wines made from cv. Emir. J Inst Brew 112(3):232–236. https://doi.org/10.1002/j.2050-0416.2006.tb00718.x

Galadima AI, Salleh MM, Hussin H, Chong CS, Yahya A, Mohamad SE (2019) Biovanillin: production concepts and prevention of side product formation. Biomass Conversion Biorefinery 10(2):589–609. https://doi.org/10.1007/s13399-019-00418-0

Gallage NJ, Møller BL (2015) Vanillin-Bioconversion and bioengineering of the most popular plant flavor and its de novo biosynthesis in the Vanilla orchid. Mol Plant 8(1):40–57. https://doi.org/10.1016/j.molp.2014.11.008

Ghosh S, Sachan A, Sen SK, Mitra A (2006) Microbial transformation of ferulic acid to vanillic acid by Streptomyces sannanensis MTCC 6637. J Ind Microbiol Biotechnol 34(2):131–138. https://doi.org/10.1007/s10295-006-0177-1

Graf N, Altenbuchner J (2013) Genetic engineering of Pseudomonas putida KT2440 for rapid and high-yield production of vanillin from ferulic acid. Appl Microbiol Biotechnol 98(1):137–149. https://doi.org/10.1007/s00253-013-5303-1

Gunnarsson N, Palmqvist EA (2006) Influence of pH and carbon source on the production of vanillin from ferulic acid by Streptomyces setonii ATCC 39116. Developments Food Sci 23:73–76. https://doi.org/10.1016/S0167-4501(06)80018-X

Hua D, Ma C, Song L, Lin S, Zhang Z, Deng Z, Xu P (2007) Enhanced vanillin production from ferulic acid using adsorbent resin. Appl Microbiol Biotechnol 74(4):783–790. https://doi.org/10.1007/s00253-006-0735-5

Kaur B, Chakraborty D, Kumar B (2013) Phenolic biotransformations during conversion of ferulic acid to vanillin by lactic acid bacteria. BioMed Res Int 2013:1–6. https://doi.org/10.1155/2013/590359

Knusten JS, Liberatore MW (2009) Rheology of high-solids biomass slurries for biorefinery applications. J Rheol 53(4):877–892. https://doi.org/10.1122/1.3143878

Luziatelli F, Brunetti L, Ficca AG, Ruzzi M (2019) Maximizing the efficiency of vanillin production by biocatalyst enhancement and process optimization. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2019.00279

Margesin R, Voggler G, Wagner AO, Zhang D, Poyntner, (2021) Biodegradation of lignin monomers and bioconversion of ferulic acid to vanillic acid by Paraburkholderia aromaticivorans AR20-38 isolated from Alpine forest soil. Appl Microbiol Biotechnol 105:2967–2977. https://doi.org/10.1007/s00253-021-11215-z

Nurika I, Suhartini S, Azizah N, Barker GC (2020) Extraction of vanillin following bioconversion of rice straw and its optimization by Response Surface Methodology. Molecules 25(24):6031. https://doi.org/10.3390/molecules25246031

Parke D, Ornston LN (2003) Hydroxycinnamate (hca) catabolic genes from Acinetobacter sp. strain ADP1 are repressed by HcaR and are induced by hydroxycinnamoyl-Coenzyme A thioesters. Appl Environ Microbiol. 69(9):5398–409. https://doi.org/10.1128/aem.69.9.5398-5409.2003

Plaggenborg R, Overhage J, Loos A, Archer JAC, Lessard P, Sinskey AJ (2006) Potential of Rhodococcus strains for biotechnological vanillin production from ferulic acid and eugenol. Appl Microbiol Biotechnol 72(4):745–755. https://doi.org/10.1007/s00253-005-0302-5

Rejani CT, Radhakrishnan S (2020) Microbial conversion of vanillin from ferulic acid extracted from raw coir pith. Natural Product Res 19:1–9. https://doi.org/10.1080/14786419.2020.1849194

Sharma A, Sharma A, Singh J, Sharma P, Tomar GS, Singh S, et al (2020) A biorefinery approach for the production of ferulic acid from agroresidues through ferulic acid esterase of lactic acid bacteria. 3 Biotech. 10(8). https://doi.org/10.1007/s13205-020-02360-9

Singh S, Pranaw K, Singh B, Tiwari R, Nain L (2014) Production, optimization and evaluation of multicomponent holocellulase produced by Streptomyces sp. ssr-198. J Taiwan Inst Chem Eng 45(5):2379–2386. https://doi.org/10.1016/j.jtice.2014.07.014

Singh S, Tiwari R, Renuse S, Pranaw K, Nain L (2015) Proteomic analysis of Streptomyces sp. ssr-198 grown on paddy straw. J Basic Microbiol 55(6):790–797. https://doi.org/10.1002/jobm.201400639

Su R, Ni K, Wang T, Yang X, Zhang J, Liu Y (2019) Effects of ferulic acid esterase-producing Lactobacillus fermentum and cellulase additives on the fermentation quality and microbial community of alfalfa silage. PeerJ 7:e7712. https://doi.org/10.7717/peerj.7712

Taira J, Toyoshima R, Ameku N, Iguchi A, Tamaki Y (2018) Vanillin production by biotransformation of phenolic compounds in fungus. Aspergillus Luchuensis AMB Expr 8:40. https://doi.org/10.1186/s13568-018-0569-4

Tang PL, Hassan O (2020) Bioconversion of ferulic acid attained from pineapple peels and pineapple crown leaves into vanillic acid and vanillin by Aspergillus niger I-472. BMC Chem 14:7. https://doi.org/10.1186/s13065-020-0663-y

Tchuidjang TT, Noubissie E, Ali A (2021) Optimization of the pre-treatment of white sawdust (Triplochiton scleroxylon) by the organosolv process for the production of bioethanol. Oil Gas Sci. tehnol. 76 (23) https://doi.org/10.2516/ogst/2021004

Watanabe M, Yoshida E, Fukada H, Inoue H, Tokura M, Ishikawa K (2015) Characterization of a feruloyl esterase B from Talaromyces cellulolyticus. Biosci Biotechnol Biochem 79(11):1845–1851. https://doi.org/10.1080/09168451.2015.1058700

Wu D, Cai G, Li X, Li B, Lu J (2018) Cloning and expression of ferulic acid esterase gene and its effect on wort filterability. Biotech Lett 40(4):711–717. https://doi.org/10.1007/s10529-018-2511-x

Xie Y, Guo J, Li W, Wu Z, Yu Z (2021) Effects of ferulic acid esterase-producing Lactic Acid Bacteria and storage temperature on the fermentation quality, in vitro digestibility and phenolic acid extraction, yields of Sorghum (Sorghum bicolor L.) silage. Microorganisms 9(1):114. https://doi.org/10.3390/microorganisms9010114

Xu Z, Kong J, Zhang S, Wang T, Liu X (2020) Comparison of enzyme secretion and ferulic acid production by Escherichia coli expressing different Lactobacillus Feruloyl Esterases. Front Microbiol. https://doi.org/10.3389/fmicb.2020.568716

Yan L, Chen P, Zhang S, Li S, Yan X, Wang N (2016) Biotransformation of ferulic acid to vanillin in the packed bed-stirred fermentors. Scientific Reports 6(1). https://doi.org/10.1038/srep34644

Yang W, Tang H, Ni J, Wu Q, Hua D, Tao F (2013) Characterization of two Streptomyces enzymes that convert ferulic acid to vanillin. PLoS ONE 8(6):e67339. https://doi.org/10.1371/journal.pone.0067339

Zamzuri NA, Abd-Aziz S (2012) Biovanillin from agro wastes as an alternative food flavour. J Sci Food Agric 93(3):429–438. https://doi.org/10.1002/jsfa.5962

Acknowledgements

Abha Sharma acknowledges the fellowship received from the Department of Science and Technology (File No. LS/700/2016) under WoS-A scheme. All the authors thank ICAR-IARI, New Delhi for providing essential facilities for the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sharma, A., Singh, J., Sharma, P. et al. One-pot microbial bioconversion of wheat bran ferulic acid to biovanillin. 3 Biotech 11, 462 (2021). https://doi.org/10.1007/s13205-021-03006-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-021-03006-0