Abstract

To date majority of bakery products are manufactured using emulsifiers in paste or gel form that restricts and causes many problems of storage, processing, and handling at the commercial level. Therefore, new developments are required to resolve the issues of the bakery industry. This review discusses the importance of α-tending emulsifiers in the bakery industry and the action of the α-form to produce superior quality products. Further, to produce desired results α-form of emulsifiers blend should be stable and functional at different operating and storage conditions. Emulsifiers in gel or paste form do not maintain the active α-gel phase over a longer storage period. Using emulsifiers blend in powder form can be a solution to all the mentioned difficulties. With the development of new technologies like spray drying and encapsulation has opened new doors to utilize emulsifiers blend in powder form. Few manufactures have tapped this opportunity and have developed improver powder that offers superior quality products as well as processing, storage, and handling benefits and is easy to use. Improver powder maintains its active and functional α-form when stored at ambient temperature. This development also increases the scope of dry premixes in the market and consumers can make products of their choice in the kitchen with minimal effort.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the 1930s, commercial emulsifiers, mostly in the form of mono- and di-glycerides, were introduced into the food industry. The emulsifying properties present in eggs were used prior to the introduction of commercial emulsifiers. Egg yolks contain natural food emulsifiers such as lecithin phospholipids (Ferreira et al. 2021). Emulsifiers in the food industry have evolved into highly functional ingredients. They are used in foods products at very low quantities, often in fractions of one percent, but can have an enormous impact on finished product, for example, emulsifying substances can aerate batters and foams, prolong the shelf life, boost fat aggregation and enhance the texture of food products (Jie & Chen 2022). The functionality of the emulsifiers is affected by the specific emulsifier used, the concentration, formulations, and manufacturing process of the finished food product (Hasenhuettl 2019). Synthetic emulsifiers have become widely used commercially in the last half of the 20th century. Propelled by the food processing sector, it needed to sell safe products across mass markets. Creamy salad dressings, for example, can be preserved for up to a year without visible separation (Awuchi et al. 2020; Hasenhuettl 2008).

Emulsifiers are usually important for baking and have been used for a long time (Garzón et al. 2018). Such additives are called surface-active agents or surfactants. They have both lipophilic and hydrophilic properties (Garzón et al. 2018; Kohajdová et al. 2009). The emulsifier can be concentrated at an oil/water junction with a specific chemical structure resulting in improved thermodynamically unstable systems stability. Emulsifying agents have an effect that exceeds their emulsifying capacity, since they can produce associations with proteins and starch due to their amphiphilic properties (Jie & Chen 2022). However, the emulsifiers contain compounds with an entirely different chemical structure and thus have different action mechanisms, with a deviating impact in bread and dough (Gómez et al. 2004; Yeşil & Levent 2022). Emulsifiers may therefore be labelled as ionic or non-ionic. The ionisation capability is related to the electrical activity of the emulsifier in aqueous systems (McClements et al. 2022). Because of their covalent bonds, non-ionic emulsifiers are not disassociated in water. Ionic emulsifiers can further be classified into cationic and anionic emulsifiers, but cationic emulsifiers are not used in food applications. Anionic and cationic groups are found in amphoteric emulsifiers (lecithin) and their surface-active attributes depend on pH (McClements & Jafari 2018; Stampfli & Nersten 1995).

Monoglycerides (MGs) exhibit four crystalline forms, namely, α, β, α-prime, and β- prime. The α-form is known to be much more functional among all these forms. It is formed by mixing emulsifiers in hot water and, upon cooling, crystallization leads to the sandwich structure of the emulsifier-water-emulsifier referred to as the α-gel phase. In the food industry, for development of bakery products emulsifiers are used in gel-form (Vyakhaya; David, John; Parvez, 2020). However, the α-gel phase loses its functionality upon aging but emulsifiers in gel phase are easy to manufacture and distribute uniformly. The hydration of the emulsifiers to convert it into a functional but unstable form is therefore quite impressive.

In order to increase the stability and functionality of hydrated emulsifiers, it should be able to maintain its α-form over a longer period of storage. One way of doing this is by encapsulation technique using spray drying and converting the hydrated emulsifier into powder form to maintain its functional properties. This will not only provide easy storage and accurate dosage of improver (also referred to as cake emulsifier) powder on an industrial scale, but will also allow the development of dry premixes of various bakery products. Few manufacturers have developed cake improver powder, but the composition and manufacturing process is secretive and some information is available from product information sheets or websites. This article discusses recent developments in the field of emulsifiers used in the bakery industry and further developments, needs and benefits of cake improver powder for the bakery market. This overview is the first to propose and provide the information on development of microencapsulated improver powder and shall form the basis for changing trend and future research related to emulsifiers.

Functions of emulsifiers in manufacturing of baked products

In practice, the expected attributes of the emulsifiers for the baking industry includes: enhanced dough handling with increased dough strength; improved hydration and water absorption with greater tolerance for rest periods, shocks and fermentation; improved crumb structure: fine and closed grain arrangement, smoother crumb, improved cell size consistency; better bread slice features; better crust thickness; reduction in fat emulsification and shortening; enhanced symmetry; enhanced gas retention leading to lower yeast demand, improved oven spring, higher proofing rate and bread loaf volume; extension to bread shelf life (Tebben et al. 2018; Vyakhaya; David, John; Parvez, 2020).

Emulsifiers are used in the food industry for dough strengthening [sodium stearoyl lactylate (SSL) and diacetyl tartaric acid esters of mono-di-glycerides] and crumb softening (glycerol monostearate and monoacylglycerols), SSL exhibit both crumb softening and dough strengthening characteristics (Yeşil & Levent 2022). According to one hypothesis firmness to wheat dough is provided by emulsifiers due to the formation of complex with wheat gluten proteins (McClements et al. 2022). The emulsifier may adhere to the hydrophobic protein surface that promotes gluten-protein aggregation in the dough. Strong network of proteins contributes to improved texture and increased bread volumes (Miyamoto et al. 2005; Selomulyo & Zhou 2007). Another hypothesis is that polar emulsifiers are capable of forming gliadin-associated liquid-crystalline phases in water. Such structures may help to increase the dough elasticity to allow the gas cell to expand, contributing to an increased baked good volume (Ribotta et al. 2010).

Fresh bread is a perishable commodity with limited shelf life, with chemical and physical modifications known as staling occurring in storage. Consequence of these modifications, the quality of bread gradually depreciates because its freshness and crispiness are lost, whereas its firmness and stiffness are increased (Asghar et al. 2006). Emulsifiers have been shown to prevent crumb from firming connected with staling (Azizi & Rao 2005). Their influence on the delay in staling of baked products was indicated by their engagement with starch (Ribotta et al. 2010; Tebben et al. 2022), delayed retrogradation and prevented moisture movement amid gluten and starch, thereby avoiding the absorption of water by starch. Distribution of moisture between starch and proteins of food systems may also be influenced by the emulsifiers. Decrease in water absorption by starch makes more water available for gluten hydration, which is also intended to retard staling (Selomulyo & Zhou 2007; Van Haften 1979).

The most necessary structure for personal care and food is the emulsifying structure, the α-gel phase. α-gel structure is formed in the presence of water through α-crystalline emulsifiers. The majority of emulsifiers contains a lengthy hydrocarbon chain connected to the head group which crystallize into a lamellar structure, whereas emulsifiers with a chain-length less than 14 carbons rarely have an α-gel phase (Sugahara et al. 2020; Vyakhaya; David, John; Parvez, 2020). These emulsifiers absorb water by hydrating a polarized head group and develop a lamellar liquid-crystalline structure (Lα phase) upon heating over their Krafft transition temperature (Tk) in aqueous phase. α-gel is formed once the system is cooled below Tk (Garti 2001; F. C. Wang & Marangoni 2016a, b). Emulsifier molecules are arranged hexagonally in the α-gel structure and the water layers are organized between the two layers (Fig. 1). They can also be self-assembled into cubic and hexagonal phases depending on the temperature and emulsifier concentration. These structures have high viscosity and a low water distribution and are therefore not suitable for food use (Gaonkar & McPherson 2006).

α-gel phase could entangle a few hundred angstroms of water between the lamellas. Such structures may be formed by electrostatic repulsive action among charged head groups of the emulsifier (Garti 2001; Krog & Sparso 1990). α-gel structure allows for a variety of physical and chemical interactions among different emulsifier molecules and, amongst other compounds, like proteins, carbohydrates and emulsifiers in pharmaceutical, cosmetic and food matrices (Gaonkar & McPherson 2006). In addition, the aeration and stabilization of foams are improved by α-gels and are commonly used for baked goods, including cakes (H. Batte et al. 2007a, b; Gaonkar & McPherson 2006; Marangoni et al. 2007;). α-gel phase maybe utilized as low fat shortening due to its semi solid texture (H. Batte et al. 2007a, b; KROG & JENSEN 1970; Marangoni et al. 2007). Increased water content throughout the lamellar α-gel form contributes to better skin hydration in topical cosmetic emulsions relative to non-lamellar structure (Sone et al. 1999).

A number of α-crystalline emulsifiers can be assembled into the α-gel structure. MGs have been the most thoroughly investigated amongst these emulsifiers. The α-gel process also includes other emulsifiers including propylene glycol monostearate (PGMS), polyglycerol fatty acid esters (PGE), acid esters of mono and di-glycerides (ACTEM), and SSL (Anvarinejad, Mahvash; Javadi, 2017; Krog & Sparso 1990). The molecular structure of these emulsifiers are summarized in Fig. 2.

α-tending emulsifiers

Monoglycerides

MGs are among the most commonly used food emulsifiers. MGs are lipids that are linked to a glycerol backbone by a single fatty acid chain. This chemical structure enables it amphiphilic as the head group of glycerol is polar besides it is non polar in the fatty acid chain. Nowadays, they are common in baked products, drinks, ice creams, toppings, shortenings, and margarines. They are manufactured industrially by the interesterification of triglycerides with glycerol in the alkaline catalytic at around 200–250 °C and produce between 40 and 60% (wt.) MG through certain diglycerides and triglycerides (Younes et al. 2017). A high vacuum, thin film molecular distillery process can be used to purify the mixture, producing pure MGs up to 95% (wt.) called the distilled monoglycerides (Krog & Sparso 1990; Moonen & Bas 2014). The process of interesterification makes it a natural combination of two stereoisomers, namely 1-monoglycerides and 2-monoglycerides. The hydrocarbon chain of the glycerol backbone MG molecules bound to C1 or C3 is termed the 1-monoglycerides, whereas the C2 hydrocarbon chain on glycerol backbone is called the 2-monoglycerides (Chapman 1962; Miao & Lin 2018). 1-monoglyceride content is typically between 90 and 95 per cent in commercial distilled MGs (F. C. Wang & Marangoni 2016a, b).

Upon crystallization 1-monoglycerides exhibit complex polymorphic behaviour whereas 2- monoglycerides exhibit only stable β-crystals (Vereecken et al. 2009). MGs functionality in emulsions is determined via saturation degree, chain length also polymorphic forms exhibited by molecules. In water and oil, saturated MGs typically crystallize in α-crystalline form, that self assembles to form α-gel structure like glycerol monopalmitate (GMP) and glycerol monostearate (GMS). Whereas unsaturated MGs, like glycerol monooleate, in water, do not form the α-gel phase (F. C. Wang & Marangoni 2016a, b).

Techno-functional properties of aerosol cream prepared using four different emulsifiers: (i) medium-chain saturated monoacylglyceride (MSMG), (ii) long-chain saturated monoacylglyceride (LSMG), (iii) medium-chain saturated mono/diacylglyceride (MSMDG) and (iv) long-chain unsaturated monoglyceride (LUSMG) were investigated by Blankart et al., (2020). Aerosol cream's apparent viscosities and fat globule sizes were reduced by MSMG, LSMG, and MSMDG, however LUSMG enhanced both by destabilizing the emulsion. MSMG promoted foam formation more than LSMG and MSMDG, whereas LUSMG inhibited foaming. Overall, saturated monoacylglycerides were more effective than unsaturated monoacylglycerides at emulsion and foam stabilization. In another study, L. Y. Lee et al., (2018a, b) revealed that unsaturated monoglycerides outperformed saturated monoglycerides alone and saturated monoglycerides combined with polysorbate 80 in frozen dessert stability based on the meltdown rate. Saturated and unsaturated monoglycerides showed a meltdown rate of 0.17–0.26 and 0.12–0.19% per min respectively. Similar results were reported by Loi et al., (2019) that unsaturated mono/diglycerides have emulsion stabilization effect than saturated mono/diglycerides.

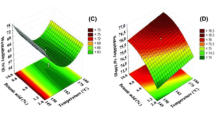

Recent research studies aim at improving the stability MG structured systems with α-gel phase because polymorphic transition into the coagel phase leads to water synersis, restricting their use in cosmetic and food products. Different external and internal factors affect the swelling capacity and stabilization of α-gel phase in complex ways (F. C. Wang & Marangoni 2016a, b). Figure 3 outlines some of these factors. Distilled MGs on their own are capable of structuring only 10–20 Å of water and are not capable of forming a gel-like structure. Water structuring capacity of distilled MGs can be improved to 100–200 Å by adding co-emulsifiers or impurities like di-glycerides and free fatty acids (Alfutimie et al. 2015).

In system of distilled MG and water development of a lamellar gel phase is assisted by anionic monovalent co-emulsifier, because negatively loaded head groups attracts water and produce electrostatic hinderance from bilayers of MG (Ren et al. 2021). Co-emulsifiers consisting of saturated fatty acid backbone and smaller head groups are reported to form α-gel phase with more stability. Large head groups are proposed to disrupt MGs' continuous lamellar structure (F. C. Wang & Marangoni 2015a). Zetzl et al., (2009) reported the use of SSL, PGMS, neutralized stearic acid (or sodium stearate), and soy lecithin in MG-based emulsions as effective co-emulsifiers. SSL and sodium stearate can improve the α-gel phase water swelling capacity. Reason for this increase in water swelling capacity is monovalent nature of these molecules attaching 18C hydrocarbon chain and increasing the electrostatic repulsion between MG-bilayers (F. C. Wang & Marangoni 2015a). Naturally, these co-emulsifiers crystallise in a stable α-form, and can be incorporated in the GMS lamellar structure (F. C. Wang et al. 2016). α-gel phase in MG-water and emulsion with GMS can be made stable for 5 weeks and 1 year at 45 °C and room temperature respectively by adding 10% (wt.) SSL (F. C. Wang & Marangoni 2015a, 2015b).

Although the majority of work in the past have focused on the water-MGs systems, but recently oil-MGs systems have been recognised to be important specially for forming creams. The phase behaviour of oil-MGs system differs greatly from that of aqueous systems. On cooling oil-MGs system from the well-mixed isotropic phase, two phase transitions are observed. In a hydrophobic surfactant solution, the inverse lamellar phase forms below the gelation transition temperature, as assumed. The arrangement of this inverse lamellar phase is identical to that of α-gel (the known phase of aqueous MG solutions). The inverse lamellar bilayers have a very distinct hexagonal in-plane ordering due to the unusual size ratio between the glycerol head and the lateral area of the aliphatic chain in the fully extended dense brush. The lower temperature phase emerges when the surfactant continues to cool below its crystallization point. With orthorhombic chain packing in the unit cell, the lateral hexagonal packing changes into a structure resembling the sub α-crystalline phase of pure MG melt (C.-H. Chen & Terentjev 2018). Alfutimie et al., (2019) investigated the effect of olive and palm oils on the gel phase generated by saturated and unsaturated MG mixtures. Although olive oil exhibited little interaction with the gel phase, some palm oil was integrated into the gel phase, enhancing its stability and causing it to swell significantly less in water. When palm oil was added to the gel phase of saturated MGs, the gel phase's stability improved and lasted for ten days, compared to only four hours when no palm oil was added. Furthermore, as compared to mixed saturated and unsaturated MGs, palm oil enhanced water vapour pressure substantially more than olive oil. The inclusion of triglyceride alkyl chains into the MGs alkyl chains boosted the hydrophobic impact of mixed MGs bilayers.

The presence of other ingredients like salts, acids, bases and hydrocolloids in foods and personal care products has complicated consequences on stabilizing the α-gel phase (Mao et al. 2014), hence such factors must be taken into account during product development. GMS-water hydrogels pH is influenced by the co-emulsifier used and at natural pH with no adjustments the α-gel phase was found to be more stable (F. C. Wang & Marangoni 2015c). Stability of structured emulsions is affected by addition of NaCl (salt) because it protects the electrostatic repulsion induced by negative charged co-emulsifiers between MG bilayers (H. D. Batte et al. 2007a, b). The addition of anionic hydrocolloids will improve stabilization of MG emulsion, as they may increase water viscosity, thereby slowing down water syneresis. GMS emulsion was found to be stable at 45 °C for more than 40 days by adding xanthan gum 0.1% (wt.) amount of water phase (F. Wang & Marangoni 2016a, b).

PGE

Other important categories of α-tending emulsifiers are PGEs. But their physical properties and uses have still not been extensively researched. Glycerol in vicinity of alkaline catalyst is polymerized and subsequently by fatty acid esterification to produce PGEs. PGE molecule contains one or two alkyl-hydrophobic chain and hydrophilic n-glycerol head group. The physical and molecular characteristics of PGEs vary from the level of glycerol polymerisation to the length of fatty acid chains. In contrast to MGs, PGEs are not polymorphic and produce a stabilized α-crystalline form. In presence of aqueous phase, PGEs with lower glycerol (3–5 glycerols) polymerization and containing long-chains of fatty acid (C16–C18) esters are capable of self-assembling to α-gel phase (Izquierdo et al. 2006; Shrestha et al. 2006; Contreras-Ramírez et al. 2020).

Comparable to MGs, PGE molecule pentaglycerol monostearate (C18G5) with saturated fatty acid chains is capable of forming α-gel phase, whereas pentaglycerol monooleate (C18:1G5) with unsaturated fatty acid chains do not form α-gel phase (Izquierdo et al. 2006). To achieve the α-gel form, heating over Tk is important because it enables the surfactant to hydrated and assemble the hexagonally packed channels into lamellar fluid crystalline structures. A α-gel structure was obtained when liquid crystal falls lower than Tk of PGE. At higher temperatures and higher emulsifier amount, greater thicknesses of water layer was observed (Duerr-Auster et al. 2007b; Izquierdo et al. 2006). The thickness of water layer in between PGE's bilayers depends on the system temperature and its water content.Impurities like salts and fatty acids enhanced the water-swelling capacity of PGE, at 2% (wt.) of PGE in system α-gel phase stable for over 4 weeks at room temperature was observed (Duerr-Auster et al. 2007b). The water swelling capacity of the glycerol head groups in both processes is attributed to greater number of hydroxyl groups. Co-surfactants such as salts of fatty acid improve water swelling capacity by adding electrostatic repulsions among PGEs or MGs bilayers (Duerr-Auster et al. 2007a; Shrestha et al. 2006). At natural pH, PGE-water systems can be stable for more than 2 years when stored at room temperature, although decreases in pH reduced stability and caused precipitation in the gel system (Curschellas et al. 2013). α-gel phases formed using PGEs exhibit more thermodynamic stability because of their inability to transform into β crystalline structure unlike formed by MG-structured systems (Shrestha et al. 2006). One point to mention though is that adding salt (NaCl) speeds up PGE precipitation in solution (Curschellas et al. 2013).

Shikhaliev et al., (2016) reported the emulsifying capabilities of polyglycerol and fatty acids esters with varying degree of polymerization (average = 5), fatty acids chain length (6–18), number of esterified hydroxyl groups. Maximum emulsifying capacity was reported for capric, caprylic and lauric acid derivatives containing 50% esterified hydroxyl groups. Polyglycerol and fatty acid esters with HLB value > 9 (monoesters, diesters, some triesters and tetraesters) formed oil in water (1:1) emulsion, whereas polyglycerol ester with HLB value < 9 (heptaesters and some triesters and tetraesters) formed water in oil (1:1) emulsion. Recently, F. Chen et al., (2022a, b) reported the emulsifying capabilities of triglycerol monocaprylate, hexaglycerol monooleate and decaglycerol monooleate to form curcumin loaded nanoemulsions. Results showed that nanoemulsions formed with and without curcumin were stable during the 60 days storage analysis. Nanoemulsions formed using triglycerol monocaprylate, hexaglycerol monooleate and decaglycerol monooleate showed droplet size of 20, 75 and 45 nm, respectively in 60 days study. Furthermore, curcumin retention in nanoemulsions prepared using triglycerol monocaprylate, hexaglycerol monooleate and decaglycerol monooleate was 86.1, 78.9 and 85.3%, respectively. In addition, Peng et al., (2018) reported the emulsion forming capabilities of long, medium and short chain PGEs in comparison to GMS. Emulsions prepared using long chain PGEs showed the best stability with smallest particle size of 16.8 nm with no oil droplet coalescence or separation of oil and water phase. In terms of degree of polymerization, Díaz-Lasprilla et al., (2021) reported that polyglycerol esters with higher degree of polymerization reduced the surface tension by 70% (from 71.49 to 22.05 mN/m) and particle size of palm oil in water emulsion. Also, with increase in the degree of polymerization the viscosity of emulsion increased.

Contreras-Ramírez et al., (2020) reported the physical stability of organogel-emulsions prepared using MGs as the geling agent while polyglycerol polyricinoleate as the surfactant and vegetable oils (canola and coconut oil). Oil type had no effect on the metastability of the organogels-emulsions. This was attributed to the synergistic effect of the polyglycerol polyricinoleate and MGs to reinforce the interface, increasing the electrostatic repulsion and better dispersion of water avoiding expelling it during the polymorphic transitions. In comparison to polyglycerol polyricinoleate, the glycerol hydrophilic head is smaller and less bulky (Contreras-Ramírez et al. 2020). A less voluminous shape allows molecules to be closer together and interact more closely with their neighbors. These interactions are short-range weak forces (hydrophobic interactions, dipole moment, and H-bonding) that resulted in the creation of stronger elastic structures and deformation resistance (Cerqueira et al. 2017). The effect of adding amphiphiles (Pluronic F68, Span 80, and Tween 60) to sunflower oil oleogels made with polyglycerol stearate and glycerol monostearate as organogelators was investigated by Keskin Uslu & Yılmaz, (2021). Amphiphiles were found to improve the stability of glycerol monostearate and polyglycerol stearate oleogels. Larger crystal aggregates with softer structure and lower melting points were observed in prepared oleogels, as well as improved oscillatory recovery abilities. The gels produced were thermo-reversible and stable up to 50 °C.

SSL

In classification of emulsifiers based on nature of charge SSL is anionic emulsifier and common food applications are baked foods, creams, and meat products. Manufacturing of SSL in presence of sodium hydroxide involves stearic acid esterification with lactic acid (Krog & Sparso 1990). The esterification process results in blend of SSL, salts of free fatty acids and free fatty acid.

In a single chain-length structure, SSL is usually found to be stable in α-crystalline form where SSL molecules interlock hydrocarbon chains. In solution, SSL produce stable α-gel phases but shown no polymorphism. In water, phase behaviour of SSL is significantly affected by pH due to presence of free fatty acids. SSL exhibit lamellar structure and reverse hexagonal phase at neutral and pH below 5 respectively (Krog & Sparso 1990). In tandem with MGs and PGEs, SSL is generally used to increase stabilization of α-gel phase rather than as an α-tending emulsifier. Adding 20% (wt.) or more amount of SSL with distilled GMS formed α-crystalline structure that was stable for 2 years when kept at room temperature as revealed by the phase diagram study of SSL and GMS (F. C. Wang et al. 2016). α-gel phase stability increased with increasing the concentration of SSL in GMS-water and structured emulsion system (F. C. Wang et al. 2016; F. C. Wang & Marangoni 2015a, 2015b). There are two mechanisms by which α-gel stability can be improved using SSL: (i) improving water swelling capacity by generating electrostatic repulsion among the bilayers of MG; and (ii) polymorphic emulsifiers are prevented from packing into dense coagel structures by α-stable SSL molecules (F. C. Wang & Marangoni 2015a, 2015b).

Recently, novel emulsion gels have been successfully fabricated through the synergistic stabilization using SSL and xanthan gum (Liu et al. 2023). Phase separation happened when SSL and xanthan gum were employed alone to produce emulsion gels. Meanwhile, ultrastable emulsion gels were created by combining SSL (2wt%) with xanthan (4wt%). Furthermore, the ratio of SSL and xanthan gum could be modified to alter the visual appearance, droplet size, microstructure, and gel strength of emulsion gels. In order to stabilize oil droplets, SSL was absorbed at the oil–water interface and dramatically decreased the interfacial tension value. To improve the gel structure, Xanthan formed an exterior network. The stabilization process indicated that the honeycomb structure generated to trap oil droplets was responsible for the ultra-stability of emulsion gels. Surprisingly, the electrostatic attraction and hydrophobic interactions between SSL and xanthan aided in the effective bonding at the interface and in the bulk. This structure supplied the emulsion gels with outstanding stability during high temperature storage, controlled settings, and pH change (Liu et al. 2023). Alkyl chain length of sodium fatty acyl lactylates has been reported to effect the adsorption behaviour (Fan et al. 2022). The CMC and equilibrium surface tension both dropped as the alkyl chain length increased, while the adsorption surface activity on the interface increased. The surface tension of the Cn lactylates was as low as 30 mN/m, and the CMC values ranged from 0.995 to 83.3 mmol/L. Increasing the alkyl chain length improved the wettability on a paraffin film as well as the ability to emulsify and produce foam.

PGMS

Certain emulsifiers like sorbitan esters of fatty acids, acid esters, and propylene glycol esters, also have potential to form α-crystalline structures; although their α-gel phase characteristics and uses are not much explored. Alkaline esterification of propylene glycol with edible fat at 200 °C produces propylene glycol esters (Krog & Sparso 1990). A mixture of palmitic and stearic acid is a commercially distilling propylene glycol ester, which differ from 60:40 to 30:70 C16: C18 still referred as PGMS (Sparsø, 2014). PGMS is highly soluble in oil and little in water, therefore it is mixed in oil and heated above its melting temperature followed by transferring into water phase to make an emulsion (J.-Q. Chen et al. 2022a, b; Hagemann 1988). Lamellar hydration can help in achieving α-gel structure. PGMS, together with MGs, has been used to improve the α-gel phase stability with a molar ratio of 1:1 in baked goods (Hagemann 1988; Silva 2000b).

Furthermore, in the presence of water, lactic acid esters and acetic acid esters of MGs and polysorbates can also develop an α-gel phase. However, characteristics of α-gel formed by these emulsifiers are not well described.

Using α-gel phases to improve baked products physical properties

Using emulsifiers in baked products can enhance aeration that improves their texture and gives a superior quality product. Other benefits offered by α-tending emulsifiers are crumb softening, anti-staling effect and improved volume of baked products (Sparsø, 2014; Yeşil & Levent 2022). Emulsifiers cause their crumb softening and anti-staling results to be caused by their interaction with starch, reducing the starch retrogradation rate. The straight fatty acid chain of the emulsifier molecules of an emulsifier-starch complex is incorporated into the helical form of amylose (Bize et al. 2017). Such dynamic mechanisms inhibit any physical modifications in the dissolved amylose and reduce the retrogradation of starch. Hydrated GMS (in α-gel) is usually applied as an anti-staling agent to bread batter to a point of 1% weight of flour.

Adding emulsifier in the α-gel phase has a positive effect on the incorporation of air in cake batters compared to emulsifiers in the β phase (Saito et al. 2020). The α-gel phase at the oil–water confluence has been shown to produce solid and elastic films that entrap oil while air is amalgamated in cake batters, avoiding protein-induced destabilization of foam. The use of the α-gel emulsifiers has made it possible to manufacture cakes in single stage mixing, also improved aeration and higher foam stability, helping to deliver finished goods with a finer texture and longer shelf life.

In α-emulsifiers for a higher overall quality, the synergistic mixtures of MG-PGE and MG-PGMS have been used for the cake batters. MG-PGE mixture can produce sponge cake with improved aeration and stability and take less time for mixing along with enhanced emulsion and foam stability (Krog & Sparso 1990; Richardson et al. 2004). Via enticing integrations and bridge formation between air bubbles in foams, this mixture can enhance the formulation of firm and durable gel. Whereas, micellar emulsifiers produce repelling inter bubble reactions and hence are not recommended for bakery purposes. Benefits of α-gel phase can also be utilized by whippable emulsions and toppings, where it facilitates aggregation of fat particles and absorption of water also increases viscosity, aeration and reduces coalescence (Jiang et al. 2018).

Several studies have reported the application of α-tending emulsifiers in different baked products such as bread (Frauenlob et al. 2018; Yeşil & Levent 2022), cake (Stemler & Scherf 2022), cookies (S. Li et al. 2022), and whipped creams (Jiang et al. 2018). Frauenlob et al., (2018) reported that the bread prepared using DATEM (0.5% flour weight) were superior to that prepared using 6 different lipases. Bread prepared using DATEM showed maximum height, significant anti-staling effect and lowest bread firmness throughout the 10 days storage period (20 °C). Therefore, suggesting the failure of lipase to replace DATEM in bread. Furthermore, Stemler & Scherf, (2022) investigated 7 lipases to replace DATEM in three different cake formulations (eggless cake, pound cake with eggs and yeast based cake). They reported that all lipases outperformed DATEM. These contrasting results may be due to the different lipases used in studies and also, different formulations of products prepared. However, both studies provided no information on the mechanistic background of the observed effects. Therefore, further studies are needed to clearly understand these varying findings. A study by (Yeşil & Levent 2022) used different emulsifiers (DATEM, SSL, MG and lecithin) and their combination to prepare gluten free breads with pseudocereals (buckwheat, quinoa and amaranth flour, respectively). They reported that SSL and combination of DATEM + SSL + MG + lecithin lead to an increase in volume and specific volume as well as decrease in hardness of gluten free breads. In addition, SSL and emulsifiers combination slowed the staling rate and provided higher sensory scores. Therefore, indicating the potential of these emulsifiers to prepare gluten free breads using pseudocereals.

In addition, Rahmati & Mazaheri Tehrani, (2014) studied the influence of different emulsifiers [distilled glycerol mono stearate (DGMS), lecithin and sorbitan mono stearate (SMS)] and their combinations on the quality of eggless cake containing soy milk. Based on the quality of cake produced emulsifiers were ranked to their different functionalities as shown in Table 1. SMS was ranked highest in terms of batter viscosity, batter density, cake firmness and cake density, while lecithin and DGMS for emulsion stability and moisture loss, respectively. However, in terms of cake volume DGMS and lecithin both were ranked highest. Overall, DGMS and lecithin blend produced highest quality of eggless cake with soy milk.

In a recent study, Li et al., (2022) investigated the role of α-crystal content of oleogels prepared using different emulsifiers [monoacylglycerol (MAG), sorbitol monostearate (SPAN), PGE and SSL] on hardness of cookies. Results showed that hardness of cookies prepared using oleogels of SSL and PGE was lower than that of SPAN with similar α-crystal content. In addition, cookies prepared using oleogel of MAG (without α-crystals) had similar hardness to that of cookies prepared with SPAN (with high α-crystal content), Surprisingly, this indicates that the content of α-crystals in emulsifiers based oleogels was not a decisive factor for cookies hardness. The explanation for the outcome reported was that the hardness of emulsifier oleogel-based cookies is affected by a variety of variables, and the α-crystals limited aeration (ability to absorb and retain air) is insufficient to play a major role in cookie quality. It was further reported that the shear viscosity of emulsifiers based oleogels is more important and emulsifiers based oleogels with higher shear viscosity results in softer cookies. Also, cookies prepared using oleogels with a higher HLB value had lower hardness. This study provides a different angle on the role of α-crystals in quality of cookies but further studies are needed to provide detailed information.

Jiang et al., (2018) investigated the interaction of three low molecular weight emulsifiers (SSL, phospholipid and sucrose ester) with caseinate for development of whipped creams (aerated emulsion). The three emulsifiers had varying interfacial characteristics, in turn influencing the texture of the whipped cream. The protein (caseinate) was easily displaced from the oil–water interface in the emulsions with sucrose ester, increasing the whipped cream's stiffness as a result of partial coalescence. The anionic emulsifier SSL created a foam that was more stable and had α-gel characteristics. The shear thickening caused by phospholipid was accompanied by the agglomeration of fat globules, whereas the cream's liquid-like characteristics precluded the creation of the stiff fat network structure necessary for the stabilization of air bubbles.

Need, process and advantages of improver powder and future prospects

When added to the production of the end product, the hydrated emulsifiers have superior functionality. For certain cases, though, food preparation is performed by the end consumer. For household-made items, hydrated emulsifiers are not used as not being popular ingredients, which are utilized on daily basis in kitchen. Thus, most emulsifiers are either used in emulsified shortenings or dried blends, making them an ingredient for making the final product. In such goods, the physical form of the emulsifier is very relevant.

Paste or gel baking aids are laborious and relatively costly to manufacture and maintaining an active α-crystalline phase over a long storage period is difficult. In recent times, some advancement has taken place to replace them by powdery product. This can be made by either dispersing the paste or gel form in water along with a suitable coating/ carrier material (such as skimmed milk powder, maltodextrin, sodium caseinate) and homogenized for uniform mixing followed by spray drying to produce a functional powder. Alternatively, an appropriate emulsion of carrier material and α-tending emulsifiers and spray drying can be used to obtain functional powder (Lai Yee Lee et al. 2014).

In the detailed process, first, the water and carrier material (called as aqueous phase) should be well mixed and in separate beaker oil plus emulsifiers (called as oil phase) should be heated above krafft temperature and mixed well. Oil and aqueous phase should be mixed while heating, because cooling can lead to the formation of solid α- gel phase with no shear and with shear it will form coagel phase, as shown in Fig. 4. After the formation of any of these phases it will be difficult to carry out spray drying process. In order to mix the oil and the aqueous phase, homogenization should be carried out at low shear for a few minutes without disturbing the lamella phase and maintaining the temperature of solution. Before homogenization, the co-emulsifier should be added to stabilize and maintain the α-gel phase for a longer period of time. Subsequently, it can be spray dried to obtain the dry powder. the emulsion should not be allowed to cool down during spray drying by keeping it in warm water. A schematic representation is shown in Fig. 5.

For these powder emulsifier mixtures to be aerating agents for cake batters, whipped desserts, and similar items, it is necessary for the powdered emulsifier to disperse and swell in aqueous phase at temperature of 20–25 °C at which the ingredients are normally mixed. Application of emulsifiers not only gives the consumer a homogenous and attractive cake, but also a cake with improved stability and good texture. Traditionally, baking aids have been used in the form of paste or gel (which require mixing with water before using) with an emulsifier content ranging from 20 to 40%.

It is important to consider the type of encapsulating agent used for spray drying since it affects the process parameter as well as the physio-chemical and functional characteristics of the spray dried powder. Carbohydrates (hydrolysed starch, maltodextrin, dextran, cellulose, and derived), gums (Arabic gums, agar, carrageenan), proteins (gluten, casein, albumin, haemoglobin, and peptides), lipids (wax, paraffin, diglycerides, and peptides), and biopolymers are the main types of encapsulating agents used in spray drying. A few studies have already gone into detail about the encapsulating agents and how they affect spray-dried powder (J. K. M. Lee et al. 2018a, b; Lu et al. 2021). As a result, we have focused on the few studies that have produced an encapsulated emulsifier system. Göksel Saraç & Doğan, (2021) encapsulated mono-diglycerides using two different encapsulating agents (skim milk powder and whey protein). Whey protein encapsulated emulsifier system showed better encapsulation efficiency and emulsion stability, while skim milk powder encapsulated emulsifier system provided better viscosity and powder properties like Carr index. These findings can help in the development of encapsulated emulsifier systems for specific applications. In another study, J. Li et al., (2022) encapsulated monoglycerides using different V-type granular starch produced via aqueous-ethanol heat treatment at different ethanol concentration (50, 60 and 70%). Results showed that V-type complex formation and granular surface adsorption were two mechanisms for monoglycerides encapsulation. Monoglycerides tended to dissolve in ethanol rather than be encapsulated at higher ethanol concentrations. Due to the breakdown of granular and crystalline structure at lower ethanol concentrations, V-type granular starch has a poorer encapsulation capability. The best encapsulation ethanol concentration was 70% in the encapsulation mode of granular surface adsorption. Furthermore, Loi et al., (2020) encapsulated different concentrations (33.6 and 47.0%) of glycerol monooleate to transform it into water dispersible powder, using maltodextrin with dextrose equivalent values of 10 and 18. The dextrose equivalent values had smaller effects on the final powder characteristics, while increase in the glycerol monooleate concentration reduced the encapsulation efficiency and poorer reconstitution properties. Spray dried powder with 33.6% glycerol monooleate concentration had encapsulation efficiency of 93–94% and surface oil of 3%. The result demonstrate that encapsulated emulsifier systems for food applications to boost product quality can be successfully produced by spray-drying.

Microencapsulation by spray drying is used for the development of improver powder. Recently, many manufacturers have developed improver powders that are commercially available. Owned by Sensory Effects®, Encap® 850 is a microencapsulated improver made using distilled propylene glycol monoesters (PGME), distilled monoglycerides, hydrophilic lecithin, and sodium stearoyl lactylate as a co-emulsifier. The Encap® improver is colloidally soluble and will dissolve completely, even in cold water, because it is microencapsulated. Since they are in solution, they are 100% active and do not require dispersion in hydrate form or high shear mixing for activation. Encap® 850 is suitable to be mixed with other dry ingredients and it is recommended to be mixed before adding oil so that it can help disperse the oil. The use of Encap® 850 will result in very quick batter whipping because of its aerating nature. Normally, the batter density is expected to be between 0.75 and 0.85. There may be a decrease in the requisite leavening. There is no requirement of creaming steps. The process of mixing is completed in one stage. This provides an effective method and saves time (Encap® 850, 2022).

Another powdered improver is Edifett SCP manufactured by Meggle, Germany using spray drying of emulsifiers emulsion. Edifett SCP is perfect for batters that are whipped up and stirred like sponge, pound, and madeira cakes as well as swiss rolls and muffins. Edifett SCP in aerated products imparts characteristics like quick whipping, efficient whipping, finer and consistent crumb with higher volume (Edifett, 2022).

Palsgaard® emulsifier has industrialized first palm-free powder emulsifier in the world. According to the corporation, Palsgaard SA 6615 addresses the challenges of the industry to eliminate palm oil used during cake preparation without compromising the product quality. Similar to the cake gel, quick and instant aeration and emulsification is offered by Palsgaard SA 6615, but exceeds the durability of gels because it remains whipping active for 18 months (Confectionery Production, 2022).

The advantages of powdered products are: (a) less complexity: powdered emulsifiers streamline production and reduce process steps compared to gels, shortening or other emulsifiers in paste form. Since there is no need for a pre-hydrating or pre-emulsifying step, it can be directly introduced in a fully automated process to the cake batter. Thus, it takes only a couple of minutes to add emulsifiers during cake production; (b) lower dosages: powdered emulsifiers are more emulsified than conventional cake gels, and need lower doses for high-quality results; (c) less waste, easier storage: scraping out of your container all the cake gel emulsifier could postpone your manufacturing process and inside there is always a little bit that is thrown away. Powder, on the other hand, appears to be leaving its bag, leaving behind only the smallest amount. When we speak of gels versus powders' physical handling, we should note that powdered emulsifier occupies lesser storage area, also less amount is required for providing same results, and partially because powder bags are easy to stack in comparison to buckets of gel; (d) leaner label: it contains one active emulsifier with one food product leaving more space for other labelling; (e) longer shelf life: powdered emulsifiers are expected to remain active for 18 months when stored at room temperature (Pedersen 2018), whereas gel is stored at refrigeration temperature.

Conclusion

For the development of bakery products, emulsifiers play a critical role in providing soft and uniform crumb with greater volume which results in higher acceptance by the consumer. Traditionally baking aids used are in paste or gel form. Paste or gel baking aids are laborious and relatively costly and their maintenance quality in an active α-crystalline shape is limited. They have thus been substituted to some extent by powdery goods. It is better to use powdery ingredients to make them more efficiently and quickly soluble than gel-formed ingredients that can then be used in dry cake blends and cookie mixtures that have been pre-mixed. Dry-mixes gives options of making a cake at home as it can be easily used and does not require ingredients out of an ordinary kitchen.

In the development of improver powder, a blend of emulsifiers is used, which should be used in a comparative concentration resulting in a good and uniform structure of the final product. Further, the emulsifier should be converted to the α-gel phase which is its active phase and, it should retain this phase throughout the processing conditions and storage. Owing to several technological, functional, and handling advantages improver powder is the need of the hour and few manufacturers have tapped that gap in the market. In conclusion, microencapsulated improver power is a potential replacement of emulsifier gel in future. Further research on the development of improver powder should be undertaken to optimize the development process and diverse application.

Abbreviations

- MGs:

-

Monoglycerides

- SSL:

-

Sodium stearoyl lactylate

- L α :

-

Lamellar liquid-crystalline structure

- T k :

-

Krafft transition temperature

- PGMS:

-

Propylene glycol monostearate

- PGE:

-

Polyglycerol fatty acid esters

- ACTEM:

-

Acid esters of mono and di-glycerides

- GMP:

-

Glycerol monopalmitate

- GMS:

-

Glycerol monostearate

- PGME:

-

Propylene glycol monoesters

References

Alfutimie A, Curtis R, Tiddy GJT (2015) The phase behaviour of mixed saturated and unsaturated monoglycerides in water system. Colloids Surf A 465:99–105. https://doi.org/10.1016/j.colsurfa.2014.10.033

Alfutimie A, Khudr MS, Al-Janabi N, Alkhalaf FA, Tiddy GJT (2019) Palm and olive oils differentially alter phase structure and repulsive interaction between bilayers of gel phase formed by mixed monoglycerides. Colloids Surf A. https://doi.org/10.1016/j.colsurfa.2019.123682

Anvarinejad M, Javadi A (2017) The impact of addition of agar gum and propylene glycol mono-stearate emulsifier on the qualitative and physicochemical properties of sponge cake. Spec J Eng Appl Sci 3(1):20–31

Asghar A, Anjum FM, Butt MS, Hussain S (2006) Functionality of different surfactants and ingredients in frozen dough. Turk J Biol 30(4):243–250

Awuchi CG, Twinomuhwezi H, Igwe VS, (2020). Food additives and food preservatives for domestic and industrial food applications. J Anim

Azizi MH, Rao GV (2005) Effect of storage of surfactant gels on the bread making quality of wheat flour. Food Chem 89(1):133–138. https://doi.org/10.1016/j.foodchem.2004.01.077

Batte HD, Wright AJ, Rush JW, Idziak SHJ, Marangoni AG (2007) Effect of processing conditions on the structure of monostearin–oil–water gels. Food Res Int 40(8):982–988. https://doi.org/10.1016/j.foodres.2007.05.001

Batte H, Wright A, Rush J, Idziak S, Marangoni A (2007b) Phase behavior, stability, and mesomorphism of monostearin–oil–water gels. Food Biophys 2:29–37. https://doi.org/10.1007/s11483-007-9026-7

Bize M, Smith BM, Aramouni FM, Bean SR (2017) The effects of egg and diacetyl tartaric acid esters of monoglycerides addition on storage stability, texture, and sensory properties of gluten-free sorghum bread. J Food Sci. https://doi.org/10.1111/1750-3841.13574

Blankart M, Kratzner C, Link K, Oellig C, Schwack W, Hinrichs J (2020) Technical emulsifiers in aerosol whipping cream – compositional variations in the emulsifier affecting emulsion and foam properties. Int Dairy J. https://doi.org/10.1016/j.idairyj.2019.104578

Cerqueira MA, Fasolin LH, Picone CSF, Pastrana LM, Cunha RL, Vicente AA (2017) Structural and mechanical properties of organogels: role of oil and gelator molecular structure. Food Res Int 96:161–170. https://doi.org/10.1016/j.foodres.2017.03.021

Chapman D (1962) The polymorphism of glycerides. Chem Rev 62(5):433–456. https://doi.org/10.1021/cr60219a003

Chen C-H, Terentjev EM (2018) Monoglycerides in oils. Edible Oleogels. https://doi.org/10.1016/b978-0-12-814270-7.00005-8

Chen F, Zhao F, Zhang J, Yu L, Zhang G, Liu C, Wang N, Xu B (2022a) Development of polyglycerol fatty acid ester-based low-energy nanoemulsion for the improvement of curcumin stability. J Dispers Sci Technol. https://doi.org/10.1080/01932691.2020.1844731

Chen J-Q, Liang M-Y, Qing C, Teng Y, White LV, Banwell MG, Li A, Wang Y, Lan P (2022b) Investigation of the emulsifying and in vitro digestive properties of high-purity sucrose monostearate esters. ACS Food Sci Technol 2(10):1662–1671. https://doi.org/10.1021/acsfoodscitech.2c00243

Contreras-Ramírez JI, Gallegos-Infante JA, Pérez-Martínez JD, Dibildox-Alvarado E, Rocha-Guzmán NE, Moreno-Jiménez MR, González-Laredo RF, Rosas-Flores W (2020) Influence of vegetable oil, monoglycerides and polyglycerol polyricinoleate into the physical stability of organogel-emulsion (w/o) systems. SN Appl Sci 2(8):1343. https://doi.org/10.1007/s42452-020-3144-y

Curschellas C, Nagy K, Windhab E, Limbach HJ (2013) Characteristics of polyglycerol ester and its different fractions. J Colloid Interface Sci. https://doi.org/10.1016/j.jcis.2012.10.063

Díaz-Lasprilla AM, Mercado RA, Ramírez-Caballero GE (2021) Glycerol polymerization degree effect on the emulsifying properties of polyglycerol esters. J Appl Polym Sci. https://doi.org/10.1002/app.50566

Duerr-Auster N, Kohlbrecher J, Zuercher T, Gunde R, Fischer P, Windhab E (2007a) Microstructure and stability of a lamellar liquid crystalline and gel phase formed by a polyglycerol ester mixture in dilute aqueous solution. Langmuir. https://doi.org/10.1021/la702242v

Duerr-Auster N, Kohlbrecher J, Zuercher T, Gunde R, Fischer P, Windhab E (2007b) Microstructure and stability of a lamellar liquid crystalline and gel phase formed by a polyglycerol ester mixture in dilute aqueous solution. Langmuir 23(26):12827–12834. https://doi.org/10.1021/la702242v

EDIFETT. (2020). EDIFETT SCP. https://www.ingredientsnetwork.com/edifett-scp-prod111689.html

Encap® 850. (2020). Encap® 850 - powdered cake emulsifier by sensoryeffects flavor company - food, beverage & nutrition. Ulprospector.com. https://www.ulprospector.com/en/na/Food/Detail/1420/46207/Encap-850---Powdered-Cake-Emulsifier

Fan J, Zhang J, Yang X, Bai L, Zhou Y, Wu Z, Qin Z (2022) Synthesis and properties of sodium fatty acyl lactylates. Colloids Surf A 653:129946. https://doi.org/10.1016/j.colsurfa.2022.129946

Ferreira GF, Pessoa JGB, Ríos Pinto LF, Maciel Filho R, Fregolente LV (2021) Mono- and diglyceride production from microalgae: challenges and prospects of high-value emulsifiers. Trends Food Sci Technol 118:589–600. https://doi.org/10.1016/j.tifs.2021.10.027

Frauenlob J, Scharl M, D’Amico S, Schoenlechner R (2018) Effect of different lipases on bread staling in comparison with Diacetyl tartaric ester of monoglycerides (DATEM). Cereal Chem. https://doi.org/10.1002/cche.10047

Gaonkar AG, & McPherson A (2006) Ingredient interactions efffects on food quality. 573

Garti N (2001) Crystallization processes in fats and lipid systems. Cryst Process Fats Lipid Syst. https://doi.org/10.1201/9781482270884

Garzón R, Hernando I, Llorca E, Rosell CM (2018) Understanding the effect of emulsifiers on bread aeration during breadmaking. J Sci Food Agric. https://doi.org/10.1002/jsfa.9094

Göksel Saraç M, Doğan M (2021) Encapsulation of mono,-diglycerides obtained from rendering waste oil: powder, interfacial, rheological and emulsion properties. J Food Process Preserv. https://doi.org/10.1111/jfpp.15520

Gómez M, Real S, Rosell C, Ronda F, Blanco C, Caballero PA (2004) Functionality of different emulsifiers on the performance of breadmaking and wheat bread. Eur Food Res Technol 219:145–150. https://doi.org/10.1007/s00217-004-0937-y

Hagemann JW (1988) Thermal behavior and polymorphism of acylglycerides. In: Crystallization and polymorphism of fats and fatty acids

Hasenhuettl GL (2008). Overview of food emulsifiers. In: Food emulsifiers and their applications: 2nd Edn, pp. 1–9

Hasenhuettl GL (2019). Overview of food emulsifiers. In: Food emulsifiers and their applications (pp. 1–9). Springer

Izquierdo P, Acharya DP, Hirayama K, Asaoka H, Ihara K, Tsunehiro T, Shimada Y, Asano Y, Kokubo S, Kunieda H (2006) Phase behavior of pentaglycerol monostearic and monooleic acid esters in water. J Dispers Sci Technol 27(1):99–103. https://doi.org/10.1081/DIS-200066805

Jiang J, Jin Y, Liang X, Piatko M, Campbell S, Lo SK, Liu Y (2018) Synergetic interfacial adsorption of protein and low-molecular-weight emulsifiers in aerated emulsions. Food Hydrocoll 81:15–22. https://doi.org/10.1016/j.foodhyd.2018.02.038

Jie Y, Chen F (2022) Progress in the application of food-grade emulsions. Foods 11(18):2883. https://doi.org/10.3390/foods11182883

Keskin Uslu E, Yılmaz E (2021) Preparation and characterization of glycerol monostearate and polyglycerol stearate oleogels with selected amphiphiles. Food Struct 28:100192. https://doi.org/10.1016/j.foostr.2021.100192

Kohajdová Z, Karovičová J, Schmidt Š (2009) Significance of emulsifiers and hydrocolloids in bakery industry. Acta Chimica Slovaca 2(1):46–61

Krog N, Jensen BN (1970) Interaction of monoglycerides in different physical states with amylose and their anti-firming effects in bread. Int J Food Sci Technol 5(1):77–87. https://doi.org/10.1111/j.1365-2621.1970.tb01544.x

Krog NJ, Sparso FV (1990) Food emulsifiers: their chemical and physical properties. Food Emul 12:127–180

Larsson K, Krog N (1973) Structural properties of the lipid—water gel phase. Chem Phys Lipids 10(2):177–180. https://doi.org/10.1016/0009-3084(73)90014-5

Lee LY, Chin NL, Lim CH, Yusof YA, Talib RA (2014) Saturated distilled monoglycerides variants in gel-form cake emulsifiers. Agric Agric Sci Proc. https://doi.org/10.1016/j.aaspro.2014.11.027

Lee JKM, Taip FS, Abdulla HZ (2018) Effectiveness of additives in spray drying performance: a review. Food Res. https://doi.org/10.26656/fr.2017.2(6).134

Lee LY, Chin NL, Christensen ES, Lim CH, Yusof YA, Talib RA (2018b) Applications and effects of monoglycerides on frozen dessert stability. LWT. https://doi.org/10.1016/j.lwt.2018.07.020

Li J, Zhou X, Jin Z (2022) Encapsulation of monoglycerides in V-type granular starch prepared under different ethanol concentrations. Food Hydrocoll 133:107935. https://doi.org/10.1016/j.foodhyd.2022.107935

Li S, Zhu L, Wu G, Jin Q, Wang X, Zhang H (2022) Relationship between the microstructure and physical properties of emulsifier based oleogels and cookies quality. Food Chem. https://doi.org/10.1016/j.foodchem.2021.131966

Liu C, Li Y, Liang R, Sun H, Wu L, Yang C, Liu Y (2023) Development and characterization of ultrastable emulsion gels based on synergistic interactions of xanthan and sodium stearoyl lactylate. Food Chem 400:133957. https://doi.org/10.1016/j.foodchem.2022.133957

Loi CC, Eyres GT, Birch EJ (2019) Effect of mono- and diglycerides on physical properties and stability of a protein-stabilised oil-in-water emulsion. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2018.07.016

Loi CC, Eyres GT, Silcock P, Birch EJ (2020) Preparation and characterisation of a novel emulsifier system based on glycerol monooleate by spray-drying. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2020.110100

Lu W, Yang X, Shen J, Li Z, Tan S, Liu W, Cheng Z (2021) Choosing the appropriate wall materials for spray-drying microencapsulation of natural bioactive ingredients: taking phenolic compounds as examples. Powder Technol. https://doi.org/10.1016/j.powtec.2021.08.082

Mao L, Calligaris S, Barba L, Miao S (2014) Monoglyceride self-assembled structure in O/W emulsion: formation, characterization and its effect on emulsion properties. Food Res Int. https://doi.org/10.1016/j.foodres.2014.01.042

Marangoni AG, Idziak SHJ, Vega C, Batte H, Ollivon M, Jantzi PS, Rush JWE (2007) Encapsulation-stucturing of edible oil attenuates acute elevation of blood lipids and insulin in humans. Soft Matter 3(2):183–187. https://doi.org/10.1039/B611985A

McClements DJ, Jafari SM (2018) Improving emulsion formation, stability and performance using mixed emulsifiers: a review. Adv Coll Interface Sci 251:55–79

McClements DJ, Lu J, Grossmann L (2022) Proposed methods for testing and comparing the emulsifying properties of proteins from animal, plant, and alternative sources. Colloids Interfaces 6(2):19. https://doi.org/10.3390/colloids6020019

Miao S, & Lin D (2018). Monoglycerides: categories, structures, properties, preparations, and applications in the food industry. In: Encyclopedia of food chemistry

Miyamoto Y, Sakamoto M, Maeda T, Morita N (2005) Application of polyglycerol mono-fatty acid esters to improve breadmaking. Food Sci Technol Res 11(1):19–25. https://doi.org/10.3136/fstr.11.19

Moonen H, Bas H (2014) Mono- and diglycerides. In: Norn V (ed) Emulsifiers in food technology. Wiley, Chichester, pp 73–92

Pedersen, A. (2018). 10 ways powdered emulsifiers can outperform gels. https://www.emulsifiersforgood.com/emulsifiers-for-good-all-posts/posts/2018/october/10-ways-powdered-emulsifiers-can-outperform-gels/.

Peng B, Xiong CY, Huang Y, Hu JN, Zhu XM, Deng ZY (2018) Enzymatic synthesis of polyglycerol fatty acid esters and their application as emulsion stabilizers. J Agric Food Chem. https://doi.org/10.1021/acs.jafc.8b00222

Confectionery Production. (2020). Palm-free, powdered cake emulsifier to solve industry challenges|Confectionery Production. Confectionery Production. https://www.confectioneryproduction.com/news/18679/palm-free-powdered-cake-emulsifier-solve-industry-challenges/

Rahmati NF, Mazaheri Tehrani M (2014) Influence of different emulsifiers on characteristics of eggless cake containing soy milk: modeling of physical and sensory properties by mixture experimental design. J Food Sci Technol. https://doi.org/10.1007/s13197-013-1253-y

Ren H, Tang X, Chen M (2021) Preparation and characterization of alpha gel formed by fatty alcohol and amino acid surfactants. J Surfactants Deterg. https://doi.org/10.1002/jsde.12539

Ribotta PD, Pérez GT, Añón MC, León AE (2010) Optimization of additive combination for improved soy-wheat bread quality. Food Bioprocess Technol 3(3):395–405. https://doi.org/10.1007/s11947-008-0080-z

Richardson G, Bergenståhl B, Langton M, Stading M, Hermansson AM (2004) The function of α-crystalline emulsifiers on expanding foam surfaces. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2003.11.003

Saito T, Ishii R, Akamatsu M, Sakai T, Sakai K, Sakai H (2020) α-gel (α-form hydrated crystal) prepared by eco-friendly cationic surfactant. J Oleo Sci. https://doi.org/10.5650/jos.ess20094

Selomulyo VO, Zhou W (2007) Frozen bread dough: effects of freezing storage and dough improvers. J Cereal Sci 45(1):1–17. https://doi.org/10.1016/j.jcs.2006.10.003

Shikhaliev KS, Stolpovskaya NV, Krysin MY, Zorina AV, Lyapun DV, Zubkov FI, Yankina KY (2016) Production and emulsifying effect of polyglycerol and fatty acid esters with varying degrees of esterification. JAOCS J Am Oil Chem Soc. https://doi.org/10.1007/s11746-016-2894-6

Shrestha LK, Acharya DP, Sharma SC, Aramaki K, Asaoka H, Ihara K, Tsunehiro T, Kunieda H (2006) Aqueous foam stabilized by dispersed surfactant solid and lamellar liquid crystalline phase. J Colloid Interface Sci 301(1):274–281

Silva RF (2000) Uses of alpha-crystalline emulsifiers in the sweet goods industry. Cereal Foods World 45(9):405–411

Silva RF (2000) Uses of alpha-crystalline emulsifiers in the sweet goods industry. Cereal Foods World 45(9):405–411

Sone T, Hanamizu T, Ichioka M, Yokokura T, Yoshikawa S, Kondo-Yanai N, Hiraki Y, Esumi K (1999) Moisturizing effect of vesicles formed from monoglycerides on human skin. Int J Cosmet Sci 21(1):23–31. https://doi.org/10.1046/j.1467-2494.1999.184030.x

Sparso FV (2014) Propylene glycol fatty acid esters. In: Norn V (ed) Emulsifiers in food technology. Wiley, Chichester, pp 231–250

Stampfli L, Nersten B (1995) Emulsifiers in bread making. Food Chem 52(4):353–360. https://doi.org/10.1016/0308-8146(95)93281-U

Stemler CD, Scherf KA (2022) Improvement of cake baking properties by lipases compared to a traditional emulsifier. Food Chem X 15:100442. https://doi.org/10.1016/j.fochx.2022.100442

Sugahara T, Akamatsu M, Iwase H, Takamatsu Y, Sakai K, Sakai H (2020) Structural change of an α-gel (α-form hydrated crystal) induced by temperature and shear flow in an oleic acid based Gemini surfactant system. Langmuir ACS J Surf Colloids 36(17):4695–4701. https://doi.org/10.1021/acs.langmuir.0c00507

Tebben L, Shen Y, Li Y (2018) Improvers and functional ingredients in whole wheat bread: a review of their effects on dough properties and bread quality. Trends Food Sci Technol 81:10–24. https://doi.org/10.1016/j.tifs.2018.08.015

Van Haften JL (1979) Fat-based food emulsifiers. J Am Oil Chem Soc 56(11):831A-835A. https://doi.org/10.1007/BF02667457

Vereecken J, Meeussen W, Foubert I, Lesaffer A, Wouters J, Dewettinck K (2009) Comparing the crystallization and polymorphic behaviour of saturated and unsaturated monoglycerides. Food Res Int 42(10):1415–1425. https://doi.org/10.1016/j.foodres.2009.07.006

Vyakhaya JD, Parvez R (2020) Emulsifier gel as a cake improver: a review. Pramana Res J 10(4):21–28

Wang FC, Marangoni AG (2015a) Effect of intrinsic and extrinsic factors on the stability of the α-gel phase of a glyceryl monostearate–water system. RSC Adv 5(54):43121–43129. https://doi.org/10.1039/C5RA05045F

Wang FC, Marangoni AG (2015b) Internal and external factors affecting the stability of glycerol monostearate structured emulsions. RSC Adv 5(113):93108–93116. https://doi.org/10.1039/C5RA18748F

Wang FC, Marangoni AG (2015c) pH and stability of the α-gel phase in glycerol monostearate–water systems using sodium stearoyl lactylate and sodium stearate as the co-emulsifier. RSC Adv 5(117):96746–96749. https://doi.org/10.1039/C5RA16457E

Wang FC, Marangoni AG (2016a) Advances in the application of food emulsifier α-gel phases: saturated monoglycerides, polyglycerol fatty acid esters, and their derivatives. J Colloid Interface Sci 483:394–403. https://doi.org/10.1016/j.jcis.2016.08.012

Wang F, Marangoni A (2016b) Microstructural basis for water release from glycerol monostearate structured emulsions upon transformation from the α-gel to the coagel phase. Food Struct 7:1–5. https://doi.org/10.1016/j.foostr.2015.11.001

Wang FC, Peyronel F, Marangoni AG (2016) Phase diagram of glycerol monostearate and sodium stearoyl lactylate. Cryst Growth Des 16(1):297–306. https://doi.org/10.1021/acs.cgd.5b01241

Yeşil S, Levent H (2022) The effects of emulsifiers on quality and staling characteristics of gluten-free bread containing fermented buckwheat, quinoa, and amaranth. J Food Process Preserv 46(7):e16668. https://doi.org/10.1111/jfpp.16668

Younes M, Aggett P, Aguilar F, Crebelli R, Dusemund B, Filipič M, Frutos MJ, Galtier P, Gott D, Gundert-Remy U, Kuhnle GG, Leblanc J-C, Lillegaard IT, Moldeus P, Mortensen A, Oskarsson A, Stankovic I, Waalkens-Berendsen I, Woutersen RA, Lambré C (2017) Re-evaluation of mono- and di-glycerides of fatty acids (E 471) as food additives. EFSA J 15(11):e05045. https://doi.org/10.2903/j.efsa.2017.5045

Zetzl A, Ollivon M, Marangoni A (2009) A coupled differential scanning calorimetry and x-ray study of the mesomorphic phases of monostearin and stearic acid in water. Cryst Growth Des 9(9):3928–3933. https://doi.org/10.1021/cg9000285

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Corresponding author confirms that all the authors have contributed significantly to the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Authors has no conflict of interest to declare.

Ethical approval

Not applicable.

Consent to participate

Authors consent to participate in reviewing at least 3 manuscripts submitted to JFST.

Consent for publication

Authors approve the publication of individual’s data or image.

Data availability

All the relevant data is available in the manuscript.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suhag, R., Dhiman, A. α-tending emulsifiers, microencapsulated improver powder and bakery applications. J Food Sci Technol 61, 39–52 (2024). https://doi.org/10.1007/s13197-022-05644-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05644-5