Abstract

The largest users of food emulsifiers are used in bakery products. The quantity is about 50% or 400 million pounds/year with 2–4% growth per year. Emulsifiers are used in bread formulas to improve dough handling and the product’s overall quality. This results in improvements in machinability, shelf life and loaf volume. Emulsifiers have two major functions in yeast-raised products: dough conditioning/strengthening; and shelf life extension, or “crumb softening.” Other terms for shortenings can include “shortening”, surfactants, and compound shortenings. The composition of bakery products has progressed from natural fats to oil blends as well as trait modified oils, eliminating the hydrogenated and hard fats. Emulsifiers are surface active agents and are synonymous with the term surfactants and can be used interchangeably in literature. Emulsifying agents are chemical compounds capable of promoting emulsions or stabilization of emulsions by their effect on interfacial tension. As the trend continues toward healthier products that contain less fat, sugar and sodium, more fiber and no bromate, emulsifiers will play an important role as functional ingredients in baked goods.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Food Emulsifiers

- Bakery products

- Surface active agents

- Wheat flour composition

- Dough handling

- Loaf volume

- Approved food emulsifiers

- Trait modified oils

- Sorbitan

- Anionic emulsifiers

- Polyhydric emulsifiers

- Lecithin

- Crumb softening

- Fat free bakery

- Trans free bakery

10.1 Introduction

Emulsifiers are multifunctional ingredients when used in bakery products. The three major functions are (1) to assist in blending and emulsifications of ingredients, (2) enhance the properties of the shortening, and (3) beneficially interact with the components of the flour and other ingredients in the mix. Some of the specific functions are uniquely described as creaming, dough conditioning and crumb softening. This chapter discusses the activity and functional role of emulsifiers in baked products.

10.2 History of Bakery Emulsifiers

The development of emulsifiers for bakery products parallels the development of emulsifiers for shortenings. The term “shortening” was initially used to refer to the fats used to “shorten” or tenderize baked foods. The composition of the shortening has progressed from natural fats to blends of oils, hydrogenated fats and hard fats as well as trait modified oils , used in food preparation. Shortenings intended for bakery products, however, may include additives such as emulsifiers, antioxidants, antifoam and metal scavengers. Bakery shortenings may be the tenderizer as well as the ingredient that affect structure, stability, flavor, storage stability, eating characteristics and eye appeal. Many of the functional effects are due to, or are enhanced by, the emulsifier added as a component of the shortening.

Historically, animal fats were used for bakery products because of their natural plasticity and flavor (O’Brien 1996). Lard was the preferred animal fat because of its pleasing flavor. With the excess of cottonseeds and cottonseed oil in the market, vegetable shortenings were developed by the cottonseed industry early in the twentieth century. Initially, cottonseed oil was blended with lard as a “lard compound” or simply “compound shortening.” Hydrogenation was invented in 1910. This allowed the production of vegetable based substitutes for semi solid (plastic) animal fats and permitted the development of products with improved functional properties.

Along with a process to modify the melting properties of fats or oils (hydrogenation) improved methods for processing the oil including refining, bleaching and deodorization. The fully processed products possessed improved oxidative stability, uniformity and enhanced performance. Knowledge of lipid chemistry led to improvements in alcoholysis, esterification, interesterification and isomerization. These advances in lipid chemistry led to new emulsifiers and improved shortening formulations. High ratio shortening was introduced around 1933. These shortenings contained mono- and diglycerides. The emulsifiers produced finer dispersions of fat particles in the dough giving strengthened cake batters. Stronger cake batters permitted increased water and sugar addition resulting in sweeter tasting, more tender cakes. The high-ratio shortenings possessed excellent creaming properties. Moist, high volume, fine-grained, even-textured cakes were produced. Icings were also improved (Hartnett 1977).

Emulsifier development also advanced in the 1930s (Stauffer 1996a). Specialty shortenings were formulated. Commercial layer cakes, pound cakes, cake mixes, cream fillings, icing, whipped toppings, bread and sweet dough shortenings were created. This development of specialty emulsifiers resulted in improvements in processing and improved product performance for the retail, food service and food processing industries. In addition to the traditional plastic shortenings, liquid shortenings, fluid shortenings and powdered products were produced (O’Brien 1995). All these products involved formulations with emulsifiers.

10.3 Definition of Emulsifiers

Emulsifiers are surface active agents that promote the formation and stabilization of an emulsion. A surfactant is also a surface active agent. The terms emulsifiers and emulsifying agent, surfactant and surface active agent are synonymous and used interchangeably in the literature. The terms “emulsifier” and “emulsifying agents” are, strictly speaking, chemical compounds capable of promoting emulsions or stabilization of emulsions by their effect on interfacial tension. Surfactants for foods may include not only emulsifiers but also compounds with other functions such as protein or starch interaction.

The roles of emulsifiers and of the shortening are intimately bound in bakery products. Generally, the food emulsifiers for bakery products supplement and improve the functionality of a properly developed shortening. Emulsifiers act as lubricants, emulsify oil or fat in batters, build structure, aerate, improve eating quality, extent shelf life, modify crystallization, prevent sticking and retain moisture. A list of emulsifiers used in shortening is given in Table 10.1. The selection and addition of an emulsifier to a shortening base may significantly change the application of the shortening (Table 10.2).

10.4 Emulsifier Function in Baked Goods

Baked goods without emulsifiers have been described as tough, dry, stale, leathery, or tasteless (Brandt 1996). Current processing, distribution and storage of baked goods require the use of additives that maintain quality and freshness. Fewer bakeries, longer distribution and extra time before consumption require longer shelf life of finished baked goods.

Emulsifiers are commonly used in many food products. These supplementary materials or food additives are used to:

-

1.

Compensate for variations in raw materials

-

2.

Guarantee constant quality

-

3.

Produce alternative products

-

4.

Preserve freshness and eating properties

-

5.

Facilitate processing (Schuster and Adams 1984).

Emulsifiers promote the emulsification of oil in water. This is true for baking emulsifiers; however, emulsification is often of secondary importance in baked goods. Starch complexing, protein strengthening, and aeration may be the primary function. Fat sparing effects are also of importance.

Wheat flour contains numerous components (Table 10.3) that may interact with emulsifiers. Starch is the major flour component followed by protein. The interactions between protein, carbohydrates and lipids is significant for processing of wheat flour and flour/water doughs. The interactions between emulsifiers and flour components are multifaceted and account for the improved functionality and performance of baked products.

The use of surfactants in bakery products is regulated in most countries. The European Economic Community (EEC) number and US FDA Code of Federal Regulations (21 CFR) for the most common food emulsifiers are shown in Table 10.4. The specification and assay procedures for all emulsifiers are published in the Food Chemical Codex (2004).

Bakery products are the largest users of food emulsifiers (Stauffer 1996b). Yeast raised and chemically leavened products are the most important segments. Food emulsifiers are also included in cookies, crackers, pasta and snacks. Recent figures indicate about 400–500 million pounds of emulsifiers are used in the US, food industry with a market value of about $500 million. The baking industry accounts for about 50% of the total food emulsifiers market (Brandt 1996). Annual growth in the production of food emulsifiers is estimated at about 2.0–3.0%.

10.5 Role of the Shortening

The shortening when mixed into a hydrated dough or batter interrupts the development of the gluten network. Literally, the structure is “shortened” and the baked product is tender. The shortening also contributes to the quality of the finished product by imparting a creamy texture and rich flavor, tenderness and uniform aeration for moisture retention and size expansion. The oil or fat based ingredients are formulated and processed to a plasticity that allows spreadability and dispersion thoroughly and uniformly in a dough, icing or batter over a wide temperature range. The ability of the fat to disperse in streaks or films helps to lubricate the structure of the dough during mixing. The fat dispersion prevents the starch and protein in the flour from compacting into dough mass (Stauffer 1996b).

The characteristics of the fat that are important for shortening formulations include melting point, oxidative stability, solid fat index and plasticity. Plasticity is used to define the characteristics of the shortening that are most important to its functionality (Erickson and Erickson 1995).

Shortenings are processed to various plasticity ranges (Weiss 1983; O’Brien 1995). Narrow plastic range ingredients have a steep solids profile and melt rapidly. These ingredients are commonly used in cream icing products or as a filler fat for hard cookies where melting near body temperature is required. Wide plastic range shortenings contain 15–30% solids over a broad temperature range and resist breakdown during creaming. Their plastic nature enables them to spread readily and combine thoroughly with the other solids or liquids without breaking or having liquid oil separating from the crystalline fat. Commercial shortenings are prepared by carefully cooling, plasticizing and tempering of correctly formulated blends of melted fats and oils. The plasticizing process is often referred to as “Votation.”

The size of the fat crystals in a plasticized shortening has a major influence on the rheological properties of the shortening. A small crystal size with a large surface area is required to bind the liquid oil in the shortening. Typical crystal sizes are from 5 to 9 μm (Chawla and deMan 1990). Crystal size is controlled by the source of the hard fat used (O’Brien 1996). The smaller crystalline form is referred to as β′ and the larger form is β. Plastic shortenings in the β′ configuration consist of small, uniform needle-like crystals with a smooth texture. These aerate well and have excellent creaming properties.

Two major sources of β′ crystalline fats are often used in formulation of votated shortenings. These are cottonseed and palm oil, often, fully hydrogenated to less than I.V. (iodine value) of 10. The use level varies from 8% to 15% of the final shortening formula.

10.6 Role of the Emulsifier

Addition of emulsifier to the shortening promotes the emulsification of the shortening in the dough or batter. Much of the development of shortenings has concentrated on the addition of the emulsifier or emulsifier system to an all-purpose shortening base although specialty liquid, narrow plastic range and special purpose emulsified products have been produced (O’Brien 1995). Today, because of the focus on trans fatty acid free ingredients, much interest has focused on emulsifier systems that permit the use of non-hydrogenated, trait modified oils as the shortening.

The general benefits of including emulsifiers in shortenings are:

-

1.

Increased shelf life.

-

2.

Improved tenderness and flavor release.

-

3.

Reduced mixing time and mixing tolerance.

-

4.

Improved machinability.

-

5.

Better water absorption.

-

6.

Improved volume.

-

7.

Improved hydration rate of flour and other ingredients.

-

8.

Better texture and symmetry.

-

9.

Reduced egg and shortening usage.

10.6.1 Monoglycerides and Derivatives in Bakery

The monoglycerides in their many forms are the most used emulsifier in bakery products. Seldom is an ingredient label found that does not list this type of emulsifier. The preparation of monoglycerides begins with reacting glycerin with edible fats and oils or fatty acids in the presence of a catalyst (Henery 1995). The important characteristics are melting point and monoglyceride content. Commercially available products vary from 40% to 95% monoglyceride content. Two crystalline forms are generally present: alpha and beta. The alpha form is the most functional in bakery products. The major variables involved in the production of monoglycerides are source of the fat, monoglyceride content, iodine value or degree of unsaturation, and fatty acid composition. Approximately 300 million pounds of monoglycerides are used in the United States in yeast-raised bakery products (Knightly 1988). An equal amount was believed to be used in cakes, icings, and other applications. Cakes prepared with shortenings containing monoglycerides have improved aeration and sugar holding capacity. Breads possess an improved shelf life due to retarded staling rate. Various techniques have been used to improve monoglycerides through chemical modification or formulation with additional emulsifiers. The form of monoglycerides marketed for bakery applications include plastic, hydrated, powdered and distilled monoglycerides.

In addition to their anti-staling benefit, monoglycerides in bakery products results in:

-

Reduction of interfacial tension.

-

Improved dispersion of ingredients.

-

Increased aeration.

-

Greater foam stability.

-

Modification of fat crystal.

Several derivatives of monoglycerides have been prepared (Fig. 10.1). Two main functional types are generally found in bakery applications: dough strengtheners and alpha-tending monoglycerides. The “dough strengtheners” include succinylated monoglycerides (SMG), ethoxylated monoglycerides (EMG), and diacetyl tartaric acid esters of monoglycerides (DATEM). They are also used as emulsifiers, starch and protein complexing agents and foam stabilizers. The alpha-tending emulsifiers include GMS (glycerol monostearate), LacMG (lactylated monoglycerides), AcMG (acetylated monoglycerides) and PGME (propylene glycol monoesters). The alpha-tending emulsifiers, normally used in cake mix production, contribute to the emulsification of the shortening in the water phase of the batter as well as incorporating air into the fat phase. The alpha-tending monoglycerides are believed to form a film at the oil/water interface resulting in a stable emulsion that prevents the liquid oil present in the shortening from interfering with aeration during cake batter mixing.

10.6.2 Sorbitan Emulsifiers

Sorbitan monostearate is a commonly used oil soluble, low HLB nonionic emulsifier. Reaction of the sorbitan esters with ethylene oxide results in the formation of the polyoxyethylene sorbitan monostearate or polysorbate emulsifiers (PS60 or polysorbate 60) (Fig. 10.2). Sorbitan esters are excellent emulsifiers for improving aeration, gloss and stability of icings and coatings. They generally function as emulsifiers, aeration agents, and lubricants in cakes, toppings, cookies and crackers. Polysorbate 60 is often used as a dough strengthener at about 0.2% of flour weight. Polysorbate 60 is also used in combination with glycerol monostearate and propylene glycol monostearate in fluid cake shortenings.

10.6.3 Anionic Emulsifiers

The anionic emulsifiers include SMG, DATEM and other lactic acid derivatives (Fig. 10.3). Sodium stearoyl lactylate (SSL) and the calcium form (CSL) are widely used. Both are employed as dough strengtheners.

SSL may be added as a stabilizer to the hydrated monoglycerides preparations. The lactic acid emulsifiers also act as anti-staling, aeration aids and starch/protein complexing agents.

10.6.4 Polyhydric Emulsifiers

The main polyhydric emulsifiers are the polyglycerol esters and sucrose esters (Fig. 10.4). Both have multiple applications as emulsifiers for foods and bakery products, particularly the sucrose esters. They provide emulsifying, stabilizing and conditioning properties in baked goods. A maximum of eight hydroxyl groups in sucrose may be esterified. The degree of esterification affects the hydrophilic-lipophilic balance (HLB) of the sucrose ester (Table 10.5). Sucrose esters are used as a noncaloric fat substitute when six or more of the hydroxyls are esterified. Deep fried snacks have reduced caloric content due to noncaloric sucrose esters of the frying oil substitute.

10.6.5 Lecithin

Commercial lecithin is a co-product of soybean oil production. Limited quantities are produced also from corn oil and sunflower oil. Lecithin is obtained by water washing of the filtered crude soybean oil. The hydrated lecithin is easily separated from the oil and is vacuum dried. Crude lecithin is a dark colored, viscous mixture composed mainly of a mixture of phospholipids (Fig. 10.5). Triglycerides, to copherols, sterols and glycolipids are present. Various purified grades of lecithin are produced by bleaching and fractionation as well as by chemical modification (Schmidt and Orthoefer 1985). Commercial lecithin products are specified based on the acetone insoluble fraction (a measure of the phospholipid content), viscosity and color. Lecithin is also found in egg yolk, butter, beans and nutmeats. Lecithin is usually an inexpensive emulsifier used for anti-stick properties as well as emulsification and controlled wetting of dry mixes.

10.7 Emulsifier Interaction with Bakery Components

Emulsification and lubrication (shortening) by the emulsifier accounts only partially for the beneficial effects observed when they are added to baked products. Proteins and lipids contribute to the functional properties of the flour. Emulsifiers interact with various flour components especially the starch, protein and lipids, as well as the added ingredients.

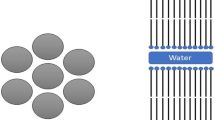

10.7.1 Starch

Starch exists in a helical, coiled structure with six glucose residues per turn of the helix. This structure is a hollow cylinder with a hydrophilic outer surface and a hydrophobic inner core. The inner space is about 45 nm in diameter. Straight-chain alkyl molecules such as palmitic or stearic acid will fit in the inner space. The n-alkyl portion of emulsifiers such as present in GMS form a complex with the helical regions of the starch. It is this complex that retards starch crystallization, often called “retrogradation,” slowing the staling process.

Emulsifiers affect the cooking and swelling properties of starch (gelatinization). This may be due to the rate of gelatinization, gelatinization temperature, peak viscosity or gel strength. Trials with starch pastes containing monoglycerides showed that maximum complexation occurs with monopalmintin (Lagendijk and Pennings 1970). Longer and shorter chain saturated fatty acid monoglycerides reacted to a lesser extent. Unsaturated fatty acid monoglycerides react to a lesser extent due to the bend in the fatty acid chain at the unsaturated bond (Hahn and Hood 1987).

Other surfactants also modify the gelatinization of starch. DATEM is generally found to be less interactive than GMS or SSL. GMS raises the swelling temperature and results in increased paste viscosity. SSL also increases paste viscosity (Schuster and Adams 1984). Overall the interaction between emulsifier and starch takes place at the surface of the starch granule and the starch/surfactant complex stabilizes the granule, retarding water penetration and swelling as the temperature is increased (Lakshmi Narayan et al. 2006).

During bread making, only small amounts of emulsifiers are bound to starch in the sponge stage and during mixing. Binding does not occur until the temperature is increased to near the gelatinization temperature. The formation of the starch complex is principally with the amylose or linear starch fraction. Both the degree of interaction and solubility of the complexes are dependent upon the type of emulsifier.

10.7.2 Protein

The wheat flour proteins, gliadin and glutenin, form a viscous, colloidal complex known as “gluten” when mixed into dough. Lipids are involved in the formation of the gluten complex. The properties of gluten are dependent upon the lipids and emulsifiers present. Lipophilic portions of surfactants interact with hydrophobic regions of proteins contributing to unfolding or denaturation of the protein. Generally, surfactants contribute to protein denaturation, enhancing interfacial adsorption and emulsion stabilization. The desired result of the protein interaction with emulsifiers is called dough strengthening.

Most commercial dough strengtheners are anionic surfactants. The association of the lipophilic portion of the emulsifier with the hydrophobic area of the protein incorporates the negative charge into the complex with subsequent aggregation in the dough. The overall effect is aggregation of the gluten protein and an increase in dough strength.

The ionic surfactants induce protein insolubilization resulting in increased viscosity and elasticity of the dough. Nonionic surfactants disrupt the hydrophobic portion of the protein leading to reduced dough viscosity and elasticity and increased protein extractability. A blend of emulsifiers generally shows the best dispersability and functionality.

10.7.3 Lipids

Wheat flour contains 1.4–2.0% lipids divided into free (0.8–1.0%) and bound (0.6–1.0%) forms. They may be further divided into nonpolar (50.9%) and polar (49.1%) forms. The bound lipids exist as starch inclusion complexes. The nonstarch free lipids, about 85% of the total, participate in the chemical, physical and biochemical processes important for the preparation of baked goods. The nonstarch lipids consist of glycolipids, phospholipids and stearoyl esters. Interaction between nonstarch lipids and emulsifiers is limited.

Nonpolar lipid addition to untreated flour results in deterioration of baking properties (Schuster and Adams 1984). Addition of polar lipids to untreated flour increases loaf volume in bread making. The improvement is likely based on the effect of galactolipids and phospholipids. Emulsifiers may interact with the water phase of the dough, forming associated lipid-water structures with free polar flour lipids (Krog 1981). Emulsifiers may compete with the naturally occurring lipids in wheat flour for the reactive groups of the wheat flour dough. Their effect on protein components was reduced as well.

10.8 Applications in Baked Goods

10.8.1 Yeast-Raised Products

The function of emulsifiers in yeast-raised products includes dough conditioning, strengthening and crumb-softening. The direct and indirect action of the emulsifier begins with dough preparation and ends with oven baking and storage (Fig. 10.6). The first stage begins with wetting and dispersing activity then follows with interaction with flour components during mixing and in the baking process itself.

Influence of emulsifiers on production and quality of baked products. (Adapted from Schuster and Adams 1984)

10.8.1.1 Dough Conditioning

Dough conditioning refers to the development of less tacky, more extensible doughs. They may be processed through machinery without tearing or sticking. These doughs result in a product of finer crumb structure, improved volume and symmetry. These characteristics include:

-

Increased mixing and machining tolerance of the dough.

-

Increased tolerance to variation in ingredients.

-

Diminished knockdown during handling.

-

Assist in maximum dough absorption.

-

Reduced shortening requirements.

-

Improved loaf volume, structure, texture and other quality attributes.

-

Extended keeping quality.

-

Facilitates variety bread production.

In the production of yeast-raised products, the mixing of the dough results in gluten-gluten bonding through disulfide linkages. Development of the linkage is often incomplete resulting in weak dough structure. The gas produced by the yeast escapes through the weak portion of the gluten films. Gas cells having weak gluten cell walls have a tendency to collapse.

Dough strengthening emulsifiers increase the degree of gluten-gluten binding sites and/or bridges that supplement disulfide linkages. This results in stronger gluten films. The benefits from the dough conditioners are:

-

Improved tolerance to variation in flour quality.

-

Drier doughs with greater resistance to abuse.

-

Improved gas retention giving lower yeast requirement, shorter proof times and greater finished product volumes

-

Uniform internal grain, stronger side walls and reduction of “cripples.”

-

Reduced shortening requirements without loss of volume, tenderness or slicing ease.

The highly functional dough strengtheners are calcium stearoyl lactylate (CSL), ethoxylated monoglycerides (EOM), polyoxyethylene sorbitan monostearate (PS-60), succinylated monoglycerides (SMG) and sodium stearoyl lactylate (SSL) (Tenney 1978). Loaf volumes for the various conditioners were compared for fully proofed dough shocked to mimic abuse in production. An increase in loaf volume of about 10% was found for CSL and SSL, with EOM and PS-60 giving slightly less increase, and SMG giving only about 5% increase in loaf volume.

10.8.1.2 Crumb Softening

Emulsifiers that complex with starch are referred to as “crumb softeners.” The mechanism of activity is the result of an amylose complex being formed. The staling of bread is also believed to result from amylose crystallization. During bread preparation and baking, amylose polymers associate upon cooling forming a rigid gel after 10–12 h. After baking, amylopectin, the branched chain starch fraction, crystallizes more slowly resulting in firming of the bread in 3–6 days. When crumb softeners are added, less free amylose occurs and therefore less is available to form a rigid gel. The emulsifier softens the initial crumb. No change occurs with the amylopectin fraction. It gradually crystallizes to a firmer texture whether or not treated with crumb softeners.

The effects of various crumb softeners as measured by compressibility after 96 h of storage were compared by Tenney (1978). The most effective softeners were the lactylates and SMG. Plastic mono- and diglycerides and hydrated distilled monoglycerides were also effective. The polysorbate 60, EOM and lecithin had little starch complexing activity. The lactylates and SMG act as both conditioners and crumb softeners.

The use level of crumb softeners varies. The most commonly used crumb softeners are the water emulsions or hydrates, of mono-diglycerides. The hydrates contain 22–25% solids and are used from 0.5% to 1% flour weight. The hydrates are significantly more functional than the nonhydrated forms. Water dispersible blends of distilled monoglycerides are also utilized. These blends contain unsaturated monoglycerides to promote rapid hydration in the sponge, brew or dough stage.

10.8.1.3 Emulsifier Blends

Lecithin has been used in breads and baked goods longer than any other emulsifier. Lecithin gives higher ductility through interaction with the gluten. Other activity claimed for lecithin is delayed staling and reduction of shortening. A synergistic effect also occurs between lecithin and monoglycerides. The monoglyceride-lecithin blends produce a better crumb grain, softer bread and higher loaf volumes. Ethoxylated monoglycerides combined with monoglycerides is also an effective dough conditioner. The negative effects of liquid oils in place of “solid” shortenings in bread production are overcome with this combination.

DATEM also acts as a dough conditioner, spares shortening and is an antistaling agent in combination with glycerol monostearate. Others include SMG, sucrose esters, polysorbate 60, SSL and CSL. The SSL and CSL can form complexes with gluten acting as a dough strengthener.

10.8.2 Chemically Leavened Products

10.8.2.1 Cakes

The role of the emulsifier in layer cakes or snack cakes is diverse and includes aeration, emulsification and crumb softening. The aerated structure of batters depends on whipped-in-air and gas (CO2) from the leavening agent. The emulsifier lowers the surface tension of the aqueous phase improving the amount of air that can be whipped into the batter. Large amounts of finely divided air cells are important for the development of uniform grain (Handlemann et al. 1961). The dissolved CO2 evolves at air cell sites and does not spontaneously form bubbles. If the original batter contains many small air cells, the final cake will have a larger volume and fine (close) grain. The creaming of the sugar and shortening has a major influence on air incorporation. The incorporation of monoglycerides in the plastic shortening (3–5% alpha-monoglycerides) ensures numerous small air cells being created during beating or creaming.

Cake batter is an aerated emulsion. The integrity of the air cells determines cake volume and uniformity. Shortening is antifoam that disrupts foam cells. Emulsifiers, however, coat the exterior of the fat particles, protecting the integrity of the air cell (Wooten et al. 1967). Use of appropriate emulsifiers has permitted the use of liquid oils where only solid shortening could previously be used.

Light, tender, moist cakes are preferred by the consumer. Emulsifiers provide the desired aeration, emulsification and crumb softening. Crumb softening in cakes is a function of moisture retention, shortening activity and starch complexing. It is the same as for breads. The emulsifier complex with the starch softens the product.

Several types of emulsifiers are used in cakes. Propylene glycol monoester (PGME) is used at 10–15% of the shortening. Monoglycerides and mixtures of lactated monoglycerides with PGME are also used in cake mixes.

In baker’s cakes, emulsifier selection depends on formula, production equipment and labeling requirements. Using soybean oil as the shortening, a hydrated blend of emulsifiers such as PS-60, SSL, sorbitan monostearate and distilled monoglycerides works well. Fluid shortenings are produced containing lactated monoglycerides. The traditional baker’s cake system is a plastic shortening with 5–10% monoglycerides (4% alpha-monoglyceride content). Packaged cake mixes often use emulsified PGME at 10–15% of the oil. The cakes are unusually tender and are not suited to commercial cake production.

Emulsified cake shortenings are also used for cake donuts. The amount of air entrapped during creaming determines the grain in the final donut.

10.8.2.2 Cookies and Crackers

Emulsifier use in cookies and crackers is limited. However, they do play a role in controlling spread during baking, improve cutting and appearance, and improve texture.

Certain emulsifiers control spread of the cookie dough during baking (Table 10.6). This likely occurs because of modification of the viscosity of the dough. Cookie dough with SSL shows increased spread compared to a nonemulsified control (Rusch 1981). The SSL may interact with the starch granule delaying hydration of the granule and subsequent gelatinization (Tsen et al. 1973).

Lecithin that is highly fluidized with other oils or fatty acids is widely used as a release agent in cookie baking for release from rotary dies. Heat-resistant lecithins, such as those modified with acetic anhydride are especially adaptable to this application. Lecithin is used in cookie and cracker formulations at 0.25–1.0% of flour weight. It may be added with the shortening at the creaming stage or simply combined with the shortening when votated.

Antistaling is of less significance in cookies and crackers since they are of lower moisture content. The greasiness of high shortening levels is reduced by the addition of small amounts of lecithin. Lecithin in general produces a “drier” dough with equivalent moisture and shortening levels. The drier dough is more machinable. Other benefits attributed to lecithin are reduced mixing times and dough development with more tender cookies.

SSL is also promoted for cookies and cracker improvement. When incorporated into the dough at 0.25%, flour basis, the SSL produces a finer grained, more uniform pattern of surface cracks. The resistance to shear (firmness) decreases improving eating quality and permits reduction in shortening (Tenney 1978). Levels are 0.25% SSL in cookies and 0.1% in crackers based on flour weight.

10.8.3 Extruded Snacks/Cereals

Extrusion cooked snacks, pasta and cereals often include emulsifiers in their formulas. Gelatinization of the starch occurs during the cooking/extrusion step. Monoglycerides and SSL have been found to reduce the energy required for the extrusion and to produce a desirable texture in the final product. Monoglycerides are added to improve the appearance and smoothness of the extrudate and produce a finer pore structure. Use levels are 0.25–0.5% of the starch weight and is added at the dough make up stage.

10.8.4 Fat-Free Bakery Products

Fat-free and low-fat foods are marketed in almost every segment of the food industry. In most instances, there is no single solution for removal of fats from the formulation. Skillful formulation using fat replacers, emulsifiers, bulking agents, flavors and other ingredients have been applied to fat replacement.

Low-fat and fat-free cakes have been produced using additional emulsifiers in conjunction with starch-based replacers and gums or hydrocolloids for moisture retention and functionality. PGME and DATEM have proved to be particularly useful.

Emulsifiers are not generally regarded as fat substitutes or replacers. Emulsifiers affect the texture and mouthfeel by their surface activity. The caloric value of emulsifiers varies depending on their composition and digestibility. They tend to have fat-like properties through their hydration and dispersing effects in processed foods. The general function of emulsifiers in low-fat and no-fat applications are:

-

Prevent separation of components.

-

Reduce size of fat globules and improve dispersion of remaining fat.

-

Provide fat sparing action.

-

Provide texture perception of higher fat contents.

-

Texturize and provide lubricity.

-

Complex with starches and proteins.

Mono- and diglycerides are the most used emulsifiers. Distilled monoglycerides have lower calories compared to the lower mono content preparations. Other emulsifiers in reduced fat products include the polysorbates, DATEM, polyglycerol esters and sorbitan esters. Emulsifiers used in products having sucrose esters and mixed esters of short and long chain tri-ester replacers are very likely similar to that utilizing traditional caloric versions.

10.8.5 Gluten-Free Bakery Products

Celiac disease is an auto-immune disorder caused by an intolerance to gluten, a structural protein in wheat. It affects approximately 1% of the population in the Western World (Catassi et al. 2010). An additional sub-population regard a gluten-free diet as healthy. Gluten-free baked goods have seen a dramatic rise in interest over the past decade or so as consumers seek gluten-free items as a lifestyle choice (Masure et al. 2016). Early commercial products tended to crumble, dry out, and exhibit off-flavors. In the recent review by Roman et al. (2019), in a survey of emulsifiers used in gluten-free breads currently on the market, 28% used mono- and diglycerides (MDG ), 9% used lecithin, 4% used SSL, 3% used DATEM, and 6% used other emulsifiers. Here, the purpose of the emulsifier is not to strengthen the gluten network, but primarily to prevent staling. Thus, DATEM is not so commonly used since its primary function is dough strengthening and MDG is preferred instead. Other functions of the emulsifier might include reducing surface tension to help stabilize air cells and improving grain structure.

Ingredient statements on gluten-free bakery products are very complex and include other surface-active ingredients. Egg and milk proteins have a significant number of lipophilic amino acid residues that migrate to oil droplets and air cells. Milk proteins are not common because they can contain lactose, which is also not tolerated well by some. Further, some hydrocolloids contain proteins that are surface-active. All of these molecules can interact with divalent metals, acids, electrolytes, and one another in a complex dough/bread matrix. Sorting out these interactions will be a challenge for many future years. Further work is needed to clarify the role of different emulsifiers on attributes of gluten-free baked goods.

10.8.6 Other Applications

Emulsifiers also find various other applications in the baking world. These range from icings, to release agents, to emulsifier-based shortenings.

10.8.6.1 Cream Icings

Cream icings are prepared by creaming sugar with fat, then adding flavor, egg white and perhaps a small amount of water. The emulsified shortenings used contain 2–3% alpha-monoglyceride. PS-60 at 0.5% is included in some icings to assist in aeration. PGME, when incorporated into the shortening, produces icings with excellent gloss and gloss retention.

10.8.6.2 Release Agents

A separate application of emulsifiers in bakery products, although not incorporated in the dough, is release agents or pan sprays. Lecithin is the primary emulsifier used. Often the pan sprays are formulated with an oil in combination with mold inhibitors and lecithin. Lecithin levels of 1–6% are added. Modified lecithins that possess improved heat stability may be used. The pan spray may simply be brushed on or sprayed to achieve a thin film promoting easy release of baked products from pans or belts.

10.8.6.3 Trans-Free Shortening

Consumption of trans fatty acids have negative health consequences. As much as 40% of the trans fatty acids in the diet are from shortenings used in bakery product. These originate from the partial hydrogenation process used to produce the shortening. Partial hydrogenation results in oxidatively stable products with the desired properties of shortenings. Alternatives to partially hydrogenated shortenings include simple blending of commodity oils with fully hydrogenated hard fats, interesterified products, use of naturally saturated oils such as palm oil and fractions and trait modified oils (Cowan and Husum 2004). For those applications using trans-free shortening, the traditional emulsifiers such as GMS function similarly. Shelf stability of the finished products, particularly with the trait modified oils, seems to not be affected.

10.8.6.4 Oleogels

A recent trend in many fat-based foods is to replace saturated fats in semi-solid fat-based products (e.g., shortening) with oleogels, solid-like materials based on solidification of a liquid oil with some organic gelator. Gelators can take many forms, including low-molecular weight organogelators (LMOG) and polymeric gelators (Co and Marangoni 2018). The LMOG include emulsifiers such as fatty acids, monoglycerides, sorbitan esters, and lecithin. Oleogels are now available that quite closely mimic the pertinent properties of shortenings and other fats. They have been tested in a variety of foods, including baked goods, primarily in an effort to reduce saturated or total fat levels (Patel and Dewettinck 2016).

For example, Blake and Marangoni (2015) evaluated structured-lipid oleogels based on monoglycerides of different chain length with different vegetable oils as replacement for shortening in puff pastry. They concluded that “the findings were very promising”, suggesting that a structured-lipid olegel based on monoglycerides could be used to replace regular shortening in puff pastries. Along a similar line, Meng et al. (2019) evaluated oleogels based on SSL for use in bread as a replacement for traditional fats. They replaced margarine in bread with an oleogel made with 9% SSL in sunflower oil to reduce saturated fat content by 30%. They argued that the structure of the oleogel matched that of triglycerides in margarine well enough to make bread with acceptable loaf volume and other physical and sensory characteristics.

As seen here, there is significant potential for emulsifier-based oleogels to serve as fat replacement in many baked goods. Further work is warranted to evaluate broader applications.

10.9 Summary

The market for emulsifiers for bakery products continues to increase. As with many industries, bakeries have undergone consolidation. Fewer producers have placed greater requirements on the final products such as longer distribution, longer time from production to consumption, greater stability and shelf-life. The function of the emulsifier is of ever greater importance. Growth in food service increases the need for bakery products having desirable sensory and performance characteristics to meet the demands of tomorrow’s market place. New trends and consumer preferences are likely to make the role of emulsifiers in baked goods even more important in the future.

References

Brandt L (1996) Emulsifiers in baked goods. Food Prod Des 64–76

Blake AI, Marangoni AG (2015) Factors affecting the rheological properties of a structured cellular solid used as a fat mimetic. Food Research International 74:284–293

Catassi C et al (2010) Natural history of celiac disease autoimmunity in a USA cohort followed since 1974. Ann Med 42:530–538. Early Online 1–9, ISSN: 0785-3890 print/ISSN: 1365-2060

Chawla P, deMan LF (1990). J Am Oil Chem Soc 67:329

Co ED, Marangoni AG (2018) Oleogels: an introduction. In: Marangoni AG (ed) Edible oleogels, 2nd edn. AOCS Press, Urbana, IL, pp 1–29

Cowan D, Husum TL (2004) Enzymatic interesterification: process advantage and product benefits. INFORM 15(3):150–157

Erickson DR, Erickson MD (1995) Hydrogenation and basestock formulation procedures. In: Erickson DR (ed) Practical handbook of soybean processing and utilization. AOCS Press, Urbana, IL, pp 235–237

Food Chemicals Codex (2004) Food Chemicals Codex, Effective 1 Jan 2004. National Academic Press, Washington, DC

Hahn DE, Hood LF (1987) Factors affecting corn starch lipid complexing. Cereal Chem 64:81–85

Handlemann AR et al (1961) Bubble mechanisms in thick foams and their effects on cake quality. Cereal Chem 38:294

Hartnett DJ (1977). J Am Oil Chem Soc 54:557

Henery C (1995) Monoglycerides: the universal emulsifier. Cereal Foods World 40(10):734–738

Knightly WH (1988). Cereal Foods World 33:405–412

Krog N (1981) Theoretical aspects of surfactants in relation to their use in breadmaking. Cereal Chem 58:158–164

Lagendijk J, Pennings HJ (1970). Cereal Sci Today 15:354–356, 365

Lakshmi Narayan SM et al (2006) Effect of maltodextrin and emulsifiers on the viscosity of cake batter and on the quality of cakes. J Sci Food Agric 86(5):706–712

Masure HG, Fierens E, Delcour JA (2016) Current and forward looking experimental approaches in gluten-free bread making research. J Cereal Sci 67:92–111

Meng Z, Guo Y, Wang Y, Liu Y (2019) Oleogels from sodium stearoyl lactylate-based lamellar crystals: structural characterization and bread application. Food Chem 292:134–142

O’Brien RD (1995) Soybean oil products utilization: shortenings. In: Erickson DR (ed) Practical handbook of soybean processing and utilization. AOCS Press, Urbana, IL, pp 363–379

O’Brien RD (1996) Shortening types and formulations. In: Hui VH (ed) Bailey’s industrial oil and fat products, vol 3. Wiley, New York, pp 161–193

Patel AR, Dewettinck K (2016) Edible oil structuring: an overview and recent updates. Food Funct 7:20–29

Roman L, Belorio M, Gomez M (2019) Gluten-free breads: the gap between research and commercial reality. Compr Rev Food Sci Food Saf 18:690–702

Rusch DT (1981) Emulsifiers: uses in cereal and bakery foods. Cereal Foods World 26(3):111–115

Schmidt JC, Orthoefer FT (1985) Modified lecithins, Chap. 10. In: Szuhaj BF, List GR (eds) Lecithins. AOCS, Champaign, IL, pp 203–213

Schuster G, Adams WF (1984) Emulsifiers as additives in bread and fine baked products, Chap. 4. In: Pomeranz Y (ed) Advances in cereal science and technology. AACC, St. Paul, MN, pp 139–242

Stauffer CE (1996a) Emulsifiers for the food industry. In: Hui Y (ed) Bailey’s industrial oil and fat products, vol 3, 5th edn. Wiley, New York, pp 483–516

Stauffer CE (1996b) Properties of emulsifiers. In: Fats and oils. American Association of Cereal Chemists, St. Paul, MN, pp 29–47

Stauffer CE (1996c) Emulsifiers for the food industry. In: Baileys’ industrial oil and fat products, vol 3, 5th edn. Wiley, New York, pp 483–516

Tenney RJ (1978) Dough conditioners/bread softeners. Bakers Dig 52(4):24–32

Tsen CC et al (1973) High protein cookies: effect of soy fortification and surfactants. Bakers Dig 47(3):34–39

Weiss TJ (1983) Food oils and their uses. Avi, Westport, CT

Wooten JC et al (1967) The role of emulsifiers in the incorporation of air into layer cake batter systems. Cereal Chem 44:333

Acknowledgments

Thanks to Serena Wu for help with graphics in this chapter.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Orthoefer, F., Kim, D. (2019). Applications of Emulsifiers in Baked Foods. In: Hasenhuettl, G., Hartel, R. (eds) Food Emulsifiers and Their Applications. Springer, Cham. https://doi.org/10.1007/978-3-030-29187-7_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-29187-7_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-29185-3

Online ISBN: 978-3-030-29187-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)