Abstract

Microencapsulation process is applied to protect the core material or active agent against environmental factors and helps resist brittle material processing conditions improving flavor, aroma, stability, nutritional value, and appearance. Microencapsulation applications are found in agricultural, pharmaceutical, food, cosmetics, and fragrance industries (Madene et al. 2006). The retention of the active agent in this process is governed, among other factors, by type of wall material, so its selection is an important step. The most commonly used materials include carbohydrates such as maltodextrin (MD) and gum arabic (GA) and proteins such as whey and soy protein isolate (SPI) (Madene et al. 2006; Matalanis et al. 2011). During microencapsulation process, the final products are in the form of powder containing individual microparticles, agglomerates, or both. The food powders containing amorphous carbohydrates could experiment physical changes as stickiness and caking when the powder is exposed to temperature above the powder’s glass transition temperature (T g ). This temperature is a function of the moisture content and water activity (a w ) of the powder (Foster et al. 2005; Schebor et al. 2010). At the T g , the viscosity of amorphous materials decreases significantly, allowing greater molecular mobility, which has effect in sticky behavior (Foster et al. 2005). The caking of food powders is an unwanted and very common problem that occurs during processing, handling, and storage. The particles of amorphous powders may progressively be deformed until they stick to each other and, eventually, form great agglomerates (Saragoni et al. 2007). This phenomenon is affected by microstructure and hygroscopicity; however, other facts are reported as decisive like stress, humidity, and temperature for caking mechanism and caking kinetics (Hartmann and Palzer 2011). The caking phenomenon reduces the product quality and functionality, rehydration, dispersibility, and the shelf life and increases deterioration of organoleptic quality and the formation of lumps and agglomerates (Lipasek et al. 2012). Microscopy techniques have been applied to analyze powder microstructure, identifying useful factors to describe changes observed during processing and storage (Guadarrama-Lezama et al. 2014).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Microencapsulation process is applied to protect the core material or active agent against environmental factors. It helps to resist processing conditions of brittle materials, and improves flavor, aroma, stability, nutritional value, and appearance. Microencapsulation applications are found in agricultural, pharmaceutical, food, cosmetics, and fragrance industries (Madene et al. 2006). The retention of the active agent in this process is governed, among other factors, by type of wall material, so its selection is an important step. The most commonly used materials include carbohydrates such as maltodextrin (MD) and gum arabic (GA) and proteins such as whey and soy protein isolate (SPI) (Madene et al. 2006; Matalanis et al. 2011). During microencapsulation process, the final products are in the form of powder containing individual microparticles, agglomerates, or both. The food powders containing amorphous carbohydrates could experiment physical changes as stickiness and caking when the powder is exposed to temperature above the powder’s glass transition temperature (T g ). This temperature is a function of the moisture content and water activity (a w ) of the powder (Foster et al. 2005; Schebor et al. 2010). At the T g , the viscosity of amorphous materials decreases significantly, allowing greater molecular mobility, which has effect in sticky behavior (Foster et al. 2005). The caking of food powders is an unwanted and very common problem that occurs during processing, handling, and storage. The particles of amorphous powders may progressively be deformed until they stick to each other, and eventually form agglomerates (Saragoni et al. 2007). This phenomenon is affected by microstructure and hygroscopicity; however, other facts are reported as decisive like stress, humidity, and temperature for caking mechanism and caking kinetics (Hartmann and Palzer 2011). The caking phenomenon reduces the product quality and functionality, rehydration, dispersibility, and the shelf life and increases deterioration of organoleptic quality and the formation of lumps and agglomerates (Lipasek et al. 2012). Microscopy techniques have been applied to analyze powder microstructure, identifying useful factors to describe changes observed during processing and storage (Guadarrama-Lezama et al. 2014).

The aim of this work was to propose a correlation of caking with the glass transition temperature of different wall materials and the powder microstructure.

2 Materials and Methods

2.1 Materials

Soy protein isolate (SPI) (Cenit, México), maltodextrin 20 DE (MD) (Globe Corn Product International, Illinois, U.S.A.), and gum arabic (GA) (E number E414) (Morevo Quick Gum) were used as wall materials.

Suspensions of the wall materials SPI, MD, and GA were prepared according to Table 1, keeping constant a concentration of 20 % of total solids, using distilled water, and applying mechanical agitation during 12 h at room temperature (22 °C).

2.2 Methods

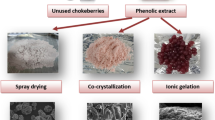

2.2.1 Obtaining Powdered Wall Materials by Spray Drying

Dispersions were fed into a spray dryer (Mobile Minor™ 2000, GEA Niro, Denmark). The equipment was operated with cocurrent flow, pneumatic nozzle, 150 °C as inlet drying-air temperature, and 70 °C as outlet drying-air temperature. The powders were stored in polyethylene bags with a hermetic seal until later analysis.

2.2.2 Water Activity and Moisture Content

Water activity (a w ) of each powder was analyzed using an AquaLab (four TE model, Decagon Devices, USA). The moisture content was determinate gravimetrically following the official AOAC method (AOAC 2005).

2.2.3 Wetting of Wall Materials

One gram of powdered wall materials was placed in a sealed flask containing a saturated solution of NaCl (75 % relative humidity, RH); after a week, the sample was weighed and the difference of moisture gained was expressed as g of moisture/100 g dry solids (Tonon et al. 2008).

2.2.4 Microstructural Changes During Caking Process

Determination of caking stages developed in the wetted samples of wall material blends (individually, in binary, and ternary mixtures) was performed according to the steps proposed by Aguilera et al. (1995). Considering that, water vapor acts to increase union between individual microparticles of powders forming stable agglomeration. This process involves binding, agglomeration, and compaction. These stages are identified as bridging, contact points between particles; agglomeration, an irreversible union of bridges, resulting in a particle clumps with structural integrity; and compaction, loss of system integrity and reduction of interparticle spaces and deformation. In the final stage of caking, bridges disappear as a result of liquefaction. The development of stable aggregates (caking) after storage of microparticles of powdered wall materials was evaluated visually, comparing relation between bridge diameter (D bridge) and particle diameter (D particle); bridging, agglomeration, compaction, and liquefaction were observed in images acquired by scanning electron microscopy (SEM), adapting method proposed by Aguilera et al. 1995.

2.2.5 Glass Transition Temperature (T g )

Differential scanning calorimetry (DSC, Perkin Elmer Diamond, USA) was used to measure wetted powder glass transition temperature range. Samples of powder (15 g) were prepared in a DSC aluminum pans (40 μL), and the pans were then hermitically sealed. All measurements were made at a scanning rate of 10 °C/min, from −20 to −120 °C (Acevedo et al. 2006).

3 Results and Discussion

All samples of powdered wall materials (spray dried) were constituted by individual microparticles of spherical geometry. The moisture content values varied between 2.21 and 4.38 (% dry base, d. b.) and a w between 0.10 and 0.16 (Table 1). Cuq et al. (2010) indicate that food powders with low water activity values are stable and could have low biochemical reactivity; similar materials were obtained in this study.

The moisture sorption by the wall materials is an important physicochemical property that regulates processing conditions and storage stability. Values moisture content achieved by the samples (individually, in binary, and ternary mixtures) exposed at 75 % RH are observed in Table 2; in this case, GA was the material that absorbed the highest % of water (20.167 % d. b.); it means five times the initial moisture content. This could be related to the water-holding capacity of the GA, 5.7 g of water/g gum arabic, and its solubility 0.5 g GA/mL 1 mL of water (Robertson and Eastwood 1981).

Evident changes in the microstructure of storage powders 75 % RH were detected (Fig. 1). Bhandari and Howes (1999) reported similar results; in this context, Rao and Labuza (2012) indicated that changes in powders properties during storage affect its functionality and production. All samples suggested caking process, except SPI sample (Fig. 1). This one kept microstructural integrity due to its low water solubility, although this sample adsorbed fourfold initial moisture content. However, blends containing SPI (SPI/GA, 13SPI/GA/MD, and SPI/GA/13MD) may develop caking process, but its intensity depends on concentration of highly water-soluble components. In case of GA and its blends showed caking process with evident bridging, agglomeration, and stages of compaction. In blends of GA with high concentration of maltodextrin the liquefaction phenomenon was developed (Fig. 1h). Microstructure of samples containing high concentration of maltodextrin (MD, MD/GA, APS/MD, SPI/GA/13MD) suffered collapse. This phenomenon is a microstructural compaction that is associated with a pronounced loss of the integrity of the system, as result of the increase of diameter of bridges interparticles and reduction of interspaces. Microparticles prepared with the formulations MD and APS/GA/13MD achieved a structural collapse where the junctions between particles disappeared, due to solubilization of the low molecular weight fractions (Aguilera et al. 1995). Similar results were observed by Hartmann and Palzer (2011), reporting that chemical composition is critical to the structural collapse of the particles. Also, these authors refer that systems with a higher amount of water-soluble compounds are more susceptible to collapse, as the case of maltodextrin; on the other hand, the addition of polymers with higher molecular weight (GA and SPI) could delay the physical changes.

SEM images of powders stored at 75 % relative humidity, illustrating stages of caking process. (a) SPI, magnification 12000×, (b) GA, magnification 12000×, (c) MD, magnification 1500×, (d) SPI/GA, magnification 24000×, (e) MD/GA, magnification 6000×, (f) SPI/MD, magnification 12000×, (g) 13SPI/GA/MD, magnification 12000×, and (h) SPI/GA/13MD, magnification 6000×

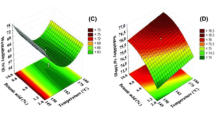

In addition to the moisture content that increases and the microstructural modifications, reduction of glass transition temperature was observed. In this context, amorphous solids obtained by spray drying are prone glass transition related changes, as collapse and caking. In this work, water acts as an effective plasticizer for SPI, MD, and their blends, since a greater amount of water is needed to diminish the value of T g , causing changes in its structure. Shrestha et al. (2007) indicated that proteins are large molecules that may affect the glass transition behavior of small molecules, as in the case of maltodextrin 20 DE.

In this regard, Foster et al. (2005) showed that changes in physical structure of amorphous sugar are linked to variable (T − T g ), where T is the storage temperature and T g is the glass transition temperature. For negative values of (T − T g ), the analyzed system was in a highly viscous glassy state and was expected to be very stable; whereas values of (T − T g ) were positive, the system is set to supercooled, and its viscosity is less susceptible to change state. In case of blends of wall materials, the analyzed variable (T − T g ) at the same temperature and relative humidity (RH) (Table 2) gave negative and positive values. Correlating (T − T g ) with microstructural changes (Fig. 1) developed during caking was possible. Positive values of (T − T g ) were observed in blends containing highest concentration of maltodextrin (MD and SPI/GA/13MD); that means blends with (T − T g ) positive reveal compaction or liquefaction, with irreversible microstructural deformation. In samples of blends that exhibit (T − T g ) with negative values, the stages of caking were bridging and agglomeration. SPI kept its microstructural integrity with (T − T g ) highly negative.

4 Conclusions

At 75 % relative humidity and 22 °C, blends of powdered wall materials containing the highest concentration of maltodextrin, exhibit irreversible microstructural changes (bridging, agglomeration, compaction and liquefaction) identified using SEM technique. In contrast, the use of high concentration of SPI may reduce the caking process, keeping negative values of (T−T g ).

Abbreviations

- SPI:

-

Soy protein isolate

- MD:

-

Maltodextrin

- GA:

-

Gum arabic

- T g :

-

Glass transition temperature

- a w :

-

Water activity

- DSC:

-

Differential scanning calorimetry

- d. b.:

-

Dry base

- D bridge :

-

Bridge diameter

- D particle :

-

Particle diameter

- B:

-

Bridging

- A:

-

Agglomeration

- C:

-

Compaction

- L:

-

Liquefaction

- T:

-

Storage temperature

References

Acevedo N, Schebor C, Buera MP (2006) Water-solids interactions, matrix structural properties and the rate of non-enzymatic browning. J Food Eng 77:1108–1115

Aguilera JM, del Valle JM, Karel M (1995) Caking phenomena in amorphous food powders. Trends Food Sci Tech 6:149–155

AOAC (2005) Official methods of analysis of AOAC International (16th ed). Gaithersburg, USA

Bhandari BR, Howes T (1999) Implications of glass transition for the drying and stability of dried foods. J Food Eng 40:71–79

Cuq B, Rondet E, Abecassis J (2010) Food powders engineering, between knowhow and science: constraints, stakes and opportunities. Powder Technol 208:244–251

Foster KD, Bronlund JE, (Tony) Paterson AH (2005) Glass transition related cohesion of amorphous sugar powders. J Food Eng 15:85–91

Hartmann M, Palzer S (2011) Caking of amorphous-Material aspects, modelling and applications. Powder Technol 206:112–121

Lipasek RA, Ortiz JC, Taylor LS, Mauer LJ (2012) Effects of anticaking agents and storage conditions on the moisture sorption, caking, and flowability of deliquescent ingredients. Food Res Int 45:369–380

Guadarrama-Lezama AY, Jaramillo-Flores ME, Gutiérrez-López GF, Pérez-Alonso C, Dorantes-Álvarez L, Alamilla-Beltrán L (2014) Effects of storage temperature and water activity on the degradation of carotenoids contained in microencapsulated chili extract. Drying Technol 32(12):1435–1447

Madene A, Jacquot M, Scher J, Stéphane D (2006) Flavour encapsulation and controlled release: a review. Int J Food Sci Technol 41:1–21

Matalanis A, Griffith JO, McClements DJ (2011) Structured biopolymer-based delivery systems for encapsulation, protection, and release of lipophilic compounds. Food Hydrocoll 25:1865–1880

Rao Q, Labuza TP (2012) Effect of moisture content on selected physicochemical properties of two commercial hen egg white powders. Food Chem 132:373–384

Robertson JA, Eastwood MA (1981) A method to measure the water-holding properties of dietary fibre using suction pressure. Br J Nutr 46:247–255

Saragoni P, Aguilera JM, Bouchon P (2007) Changes in particles of coffee powder and extensions to caking. Food Chem 104:122–126

Schebor C, Mazzobre MF, Buera MP (2010) Glass transition and time-dependent crystallization behavior of dehydration bioprotectant sugars. Carbohydr Res 345:303–308

Shrestha AK, Howes T, Adhikari BP, Wood BJ, Bhandari BR (2007) Effect of protein concentration on the surface composition, water sorption and glass transition temperature of spray-dried skim milk powders. Food Chem 104:1436–1444

Tonon RV, Bravet C, Hubinger MD (2008) Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J Food Eng 88:411–418

Acknowledgements

The authors wish to thank the Instituto Politécnico Nacional (National Polytechnic Institute) for the financial support provided through the SIP project: 20140253 and 20140554, BEIFI-IPN, COFAA-IPN, CONACyT, project 216044, and the scholarships for the PhD studies of Josefina Porras-Saavedra. The authors are grateful for experimental support of Universidad de Buenos Aires and Instituto Mexicano del Petróleo.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer Science+Business Media New York

About this chapter

Cite this chapter

Porras-Saavedra, J., Palacios-González, E., Yáñez-Fernández, J., Mazzobre, M.F., Buera, M.P., Alamilla-Beltrán, L. (2015). Caking Process and Microstructural Changes of Wall Materials Used in Spray-Drying Process. In: Gutiérrez-López, G., Alamilla-Beltrán, L., del Pilar Buera, M., Welti-Chanes, J., Parada-Arias, E., Barbosa-Cánovas, G. (eds) Water Stress in Biological, Chemical, Pharmaceutical and Food Systems. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4939-2578-0_60

Download citation

DOI: https://doi.org/10.1007/978-1-4939-2578-0_60

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4939-2577-3

Online ISBN: 978-1-4939-2578-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)