Abstract

The protein content of ordinary white bread ranges from 8% to 9%. Specialty breads can be made with 13–16% protein by including soy protein. However, incorporating high levels of soy protein depresses loaf volume, gives poor crumb characteristics, and decreases acceptability. The objective of this study was to determine the influence of sodium stearoyl-2-lactylate (SSL), transglutaminase (TG), and xylanase (HE) on high-protein dough properties and bread quality and to improve dough handling and bread quality of soy–wheat bread by using an optimized additive combination. The influence of SSL, TG, and HE on soy–wheat dough and bread properties was modeled by response surface methodology. The negative effect of soy products on gluten network was confirmed. With regards to the additives tested and their combination, TG showed a major improving effect on dough rheological properties and crumb uniformity, whereas SSL and HE enhanced both dough and bread quality. The best formulation tested produced an increment of approximately 65% soy–wheat bread volume and a decrease of 79% and 71% crumb hardness and chewiness, respectively, compared with the standard formulation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Blending 10% soy flour with wheat flour not only provides high protein content but it also improves amino acid balance. The addition of soy products in wheat flour requires very little change in technology and no changes at all in process equipment. However, the incorporation of high levels of soy products has negative effects in gluten network formation, extensibility properties and gas retention of dough, and final bread quality (Ribotta et al. 2005).

Additives are used in bakery to facilitate processing, to compensate for variations in raw materials, to guarantee constant quality, and to preserve freshness and food properties. Sodium stearoyl-2-lactylate (SSL) is an anionic oil-in-water emulsifier that is used to improve the quality of bread. This kind of emulsifier, also called dough strengthener, improves mixing tolerance, gas retention, and resistance of the dough to collapse when added to dough. Concerning the final product, this substance improves loaf volume and endows it with resilient texture, fine grain, and slicing properties (Tamstorf et al. 1986).

Transglutaminase (TG) catalyzes acyl-transfer reaction, producing covalent crosslinks in proteins. Crosslinks are established between glutamine residues and lysine residues without affecting the nutritional value of the lysine (Seguro et al. 1996). Among the wheat proteins, gliadins and high molecular weight glutenins were reported as substrate for TG (Larré et al. 2000). Soy proteins, such as 11S and 7S globulins, act as good substrates for the TG reaction (Motoki and Seguro 1998). TG has been confirmed to effectively modify soy proteins, inducing their aggregation and changing some selected properties, such as emulsifying activities, hydration ability, thermal and texture properties, and gel- or film-forming ability (Babiker 2000). Basman et al. (2002) stated that TG can polymerize proteins from one or more sources through the formation of intermolecular crosslinks and that soy proteins were the best substrates of TG whereas barley and wheat proteins were similar in reactivity. Based on these findings, this enzymatic crosslinking has also been applied to improve the properties of combined soy–wheat proteins.

Endoxylanases have a strong impact on arabinoxylan (AX) structure and functionality. They attack the AX backbone in a random manner, causing a decrease in the degree of polymerization of the substrate and liberating oligomers, xylobiose, and xylose with retention of their configuration. Xylanases have been found to be a valuable tool to modify the functionality of pentosans in bread-making. The addition of xylanases to wheat flour has been reported to improve dough-handling properties and bread quality (Courtin and Delcour 2002).

The effect of the mentioned additives on wheat dough and bread has been extensively described; however, there is a lack of information about their combined effects on soy–wheat dough and bread quality. The combination of these additives could help to overcome detrimental effect on soy addition on bread quality. The present study was designed (1) to determine the influence of SSL, TG, and HE on high-protein dough properties and bread quality and (2) to improve dough handling and bread quality of soy–wheat bread by using an optimized additive combination.

Materials and Methods

Materials

Commercial wheat flour was provided by a local milling company (Tiranti SA, Argentina). Wheat flour had 27.4% wet gluten content, 329 s falling number, and 12.7% moisture content. Alveograph parameters were dough strength (W) = 276 × 10−4 J, tenacity (P) = 123.6 mm, extensibility (L) = 54.0 mm, P/L ratio = 2.29 (AACC 1995). Heat-treated defatted soy flour (HTSF) was obtained from Complementos Proteicos SA (Argentina). Protein, lipid, ash, and moisture contents of HTSF were 45.3 ± 0.6%, 1.5 ± 0.1%, 7.0 ± 0.3%, and 9.1 ± 0.0%, respectively. Soy flour particles can be sieved through a sieve of 100 mesh (150 μ opening). Compressed yeast (Calsa SA, Argentina) and other dough ingredients (food grade) were purchased at a local market. Chemicals used were of reagent grade. The additives sodium stearoyl-2-lactylate (SSL) was obtained from Alpha Emulsionantes (Argentina), transglutaminase active WM (TG) was obtained from Ajinomoto (Japan) and had an activity 100 U/g, and xylanase (1,4-endoxylanase) Pentopan Mono BG (HE) was obtained from Novozymes (Denmark) and had an activity of 2,500 FXU(W)/g.

Dough Properties

Microextension Procedure

Measurements were performed with a TA.XT2i texture analyzer (Stable Microsystems, Surrey, UK) using the SMS/KIEFFER RIG for dough extensibility measurements. Doughs were prepared using a standard dough formulation of 100% flour mixture (90:10 wheat flour/soy flour), 1.8% sodium chloride, and 64% water. The ingredients were mixed in a Philips HR 1495 mixer (Philips, Argentina) with dough hook for 2 min and rested for 15 min in a cabinet at 30 °C and 70% relative humidity (RH). Rounded dough (20 g) was pressed by the strip form and allowed to relax for 40 min. Ten strips by batch were placed on the platform, trimmed, and extended until their elasticity was exceeded and the dough broke. The dough strips were extended to 3.3 mm/s (Suchy et al. 2000). Resistance to extension (R m, maximum resistance), extensibility (E m, maximum extensibility), and area under the curve (A) were automatically calculated from the curves using the Texture Expert 1.22 (Stable Micro Systems, Surrey, UK).

Dough Stickiness

Dough textural properties were measured in triplicate with four trials per replicate using a TA.XT2i Texture Analyzer (Stable Microsystems, Surrey, UK). Dough stickiness was determined using the SMS/Chen-Hoseney Dough Stickiness cell coupled with a 25-mm perspex cylinder probe (5 kg load cell). Dough stickiness, which measures the force required to release the probe from the dough, was conducted using a force of 40 g through a distance of 4 mm at a pretest speed of 0.5 mm/s, a test speed of 0.5 mm/s, and a posttest speed of 10 mm/s.

Bread-making Procedure

The bread-making processes followed in this study are those currently employed in our country in the preparation of bread. The dough base formulation used in this study comprised of 100% wheat/soy mixtures (90:10 ratio), 3% compressed yeast, 2.2% sodium chloride, 0.02% ascorbic acid, 0.002% α-amylase (Bel’Ase A75, 75,000 SKB/g), and 64% water. The ingredients were mixed in an Argental L-20 mixer (Argental, Argentina). Yeast and salt were separately dissolved in water and the remaining ingredients were added as solids. The resulting dough (approximately 23 °C) was allowed to rest for 15 min in a cabinet at 30 °C and 70% RH, and then the bulk dough was sheeted in a Mi-Pan vf roller (Mi-Pan, Argentina) containing two rolls of 50 × 12.7 cm. The dough was then divided into 100 g pieces, molded, proofed at 30 ± 1 °C (96% RH) up to its maximum volume increment (proofing time ranged between 90 and 105 min), and baked at 210 °C for 18 min in a gas rotating rack oven.

Bread Properties

Bread Specific Loaf Volumes

The bread loaf volumes (SLV) were determined by rapeseed displacement and loaves were weighted 24 h after baking. The bread specific loaf volume (SLV) was expressed as the volume/mass ratio of finished bread.

Characterization of Crumb Structure

For each bread loaf, two slices were obtained from the central region and photographed with a digital camera (Sony, Japan) (2,048 × 1,536 image size). Illumination was generated with daylight lamps and the camera was placed at 60 cm from the samples. JPEG image file format were analyzed with an image analyzer (ImageJ 1.38n, National Institute of Health, USA). Color images were converted to 8-bits 256 gray level images. A single field of view (FOV) was evaluated for each image. The FOV captured the majority of the crumb area of each slice. Images were taken from the center of the slice and the rectangular FOV size was selected to exclude the crust and 1–1.3 cm of the crumb placed next to the crust. The thresholding method (conversion to a binary image) of the 256 gray level digital images was used for image segmentation. Crumb images were considered to contain gray level information from pixels of which the darkest individuals belong to the cell and the brightest individuals belong to the cell wall. A gray level histogram of each digital gray scale image was obtained by means of the ImageJ software. A gray level image composed by a dark, distinct, and uniform object on a brighter background contains homogenous regions with well-defined boundaries that generally lead to a bimodal histogram with sharply defined intensity peaks. The two peaks correspond to the relatively large number of points inside and outside the object. The dip between the peaks corresponds to the relatively few points around the edge of the object. The threshold is then placed in the valley between both peaks and then pixels with a gray level higher than the threshold value will be associated to the background, whereas the remaining pixels will be associated to the object. Nevertheless, in bread crumb images, the nonuniform transition between cell and noncell produce results in a histogram with bimodal characteristics. To obtain a representative gray level threshold, the gray level histogram obtained from each FOV was deconvoluted in two Gaussian peaks and finally fitted (coefficient of determination, R 2 > 0.996) by means of PeakFit v4 for win32 (Jandel Scientific, San Rafael, CA, USA). The intersection of the two Gaussian curves, peaks 1 and 2, was selected as the gray level threshold. A threshold level was obtained for each FOV and it was used to produce a binary image where pixels with a gray level higher than the threshold value will be associated to the cell wall, whereas the remaining pixels will be associated to the cells. The crumb cell features chosen were the total number of cells, total cell area, mean cell area, and cell to total area ratio (cell fraction). Grain uniformity was determined as the ratio of small to large cell counts (i.e., the ratio of the number of cells with areas less than to those greater than 4 mm2); higher values indicate greater uniformity of crumb grain (Zghal et al. 2001).

Crust Color

Bread color was determined with a Minolta 508d spectrophotometer, 8-mm measurement aperture, D65 illuminant, 10° angle of observer, CIE; according to Approved Methods 14–22 (AACC 1995). Crust color was measured from the top position of each bread loaf. At least three readings were taken from each bread and at least four breads from each test point and recorded as CIE-LAB, L* (lightness), a* (redness–greenness), and b* (yellowness–blueness) values.

Bread Crumb Texture

Texture profile analysis (TPA) parameters were determined by using a TA-XT2i texturometer (Stable Microsystems, Surrey, UK) equipped with a 25-kg load cell. A cylinder probe 3.6 cm in diameter was attached to a moving crosshead. The bread loaves were wrapped up into polyethylene bags and stored at 20 ± 1 °C and 75 ± 5% RH. After 24 h storage, the bread loaves were cut into two slices (2.5 cm thick) and the ends were discarded. Each slice was subjected to a double cycle of compression under the following conditions: crosshead speed, 1 mm/s and maximum deformation, 40%. The texture profile parameters were determined using the Texture Expert 1.22 (Stable Microsystems, Surrey, UK). The hardness (the force in grams required to compress the sample) and the chewiness (the quantity to simulate the energy required to disintegrate a solid food to a state ready for swallowing) of the crumb was calculated from a force–distance graph. Six slices were analyzed per point, and average values were reported.

Experimental Design and Statistical Methods

To study the effects of the additives on the properties of soy protein–wheat dough and bread, the following parameters were selected as independent variables: SSL (0–0.64 g/100 g flour), HE (0–0.025 g/100 g flour), and TG (0–0.38 g/100 g flour). Levels of variables were selected on the basis of manufacturer-recommended levels. A ratable central composite RSM with three factors and five levels was generated using response surface regression procedures (Statgraphics plus 5.0). Four replicates were made at the center point of design to allow the estimation of the pure error at the sum of the square. The experimental design is presented in Table 1. The results were analyzed by a multiple regression method. The quality of the models’ fitness was evaluated by ANOVA (Statgraphics plus 5.0). The experimental results were applied to obtain the regression models. The fit of each model to the experimental data was given by the coefficient of determination, R 2, which explains the extent of the variance in a modeled variable that can be explained with the model. Multiple regression equations included only significant coefficients (p < 0.05). The replicates at the center point made it possible to estimate the pure error of the analyses. Only models with high coefficient of determination were included in this study. Two-dimensional response surface plots were generated for each quality parameter. Calculation of the optimal processing conditions for the baking performance of soy–wheat bread was performed using a multiple response method called desirability. This optimization method incorporates desires and priorities for each of the variables.

Results and Discussion

The protein content of ordinary white bread ranges from 8% to 9%. The protein content of the defatted soy flour was about five times that of the wheat flour. Specialty breads can be made with 13–16% protein by including soy defatted flours. The results showed that mixing soy and wheat flours increased nearly 30% the protein content of mixtures, raising their nutritional status. However, incorporating high levels of soy protein depresses loaf volume, gives poor crumb characteristics, and decreases acceptability.

It is widely accepted that the quality criteria for breads are large volume, soft crumb, and a uniform crumb grain. Therefore, the objective was to maximize the responses for loaf-specific volume and the number of small cells and to minimize crumb firmness and the number of large cells.

Eighteen experiments were performed according to the experimental design, and dough rheological properties and bread quality for the enzyme combination were determined at each experimental point. For each response group, a quadratic equation was formed with relevant terms (p < 0.05) to obtain as high R 2 values as possible. Based on these equations, the behavior of the response can be predicted within the experimental area and presented as a response surface.

Dough Properties

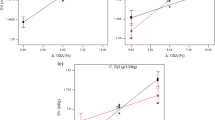

Table 2 shows the experimental responses relating to the dough properties. Quadratic models were fitted for stickiness, maximum resistance (R m), maximum extensibility (E m), and the area under the curve (A). The regression coefficients and the coefficients of determination for the statistically significant (p < 0.05) models are shown in Table 3. The response surface plots are presented in Figs. 1 and 2. R m, E m, and stickiness presented higher R 2 values than the area under the curve. The coefficients of determination of stickiness, R m, E m, and area accounted for 98.2%, 87.2%, 82.8%, and 76.0% of the variability in the data, respectively.

Previously, it was shown (Ribotta et al. 2005) that the inclusion of soy products at different levels increased the maximum resistance and decreased the extensibility and the area under the curve in comparison with wheat dough. In this study, the additives significantly changed soy–wheat dough extensional behavior and dough stickiness (Figs. 1 and 2).

Negative linear effect of SSL and HE, positive linear effect of TG, positive quadratic effect of SSL and HE, and crossed quadratic effect of SSL–HE were observed on R m. Major negative effects on dough resistance were provided by SSL and HE. Positive linear effect of HE, negative linear effect of TG, and crossed quadratic effect of SSL–HE were observed on E m. Major positive effect on dough extensibility was provided by HE. In general, dough resistance was decreased and dough extensibility was increased by SSL, HE, and TG combination, major effects were produced by both enzymes. A positive effect on area under the curve was provided by TG as it is showed by the significant linear coefficient (Table 3).

Two main theories have been proposed to explain the mechanism of emulsifier as dough improvers. One theory suggests that emulsifier may bind to the protein hydrophobic surface promoting aggregation of gluten proteins in dough. A strong protein network results in better texture and increased volume of bread (Kamel and Ponte 1993). Another theory is based on the ability of polar surfactants to form liquid–crystalline phases in water, which associates with gliadin. These structures may contribute to dough elasticity allowing gas cell to expand, thus resulting in an increased volume of baked food (Tamstorf et al. 1986).

With regards to TG, polymerization of gluten proteins should conduce to increase the dough elasticity and to improve the bread-making quality. Some authors found that this enzyme showed positive effects on dough rheology and bread-making process (Gerrard et al. 1998; Larré et al. 2000). Other authors established that the effects depend on the doses: low levels to TG had improving effects on bread quality, whereas higher levels showed detrimental effects (Bauer et al. 2003; Autio et al. 2005). Moreover, Rosell et al. (2003) showed that increasing levels of TG provoked a decrease of both gluten index and all alveographic parameters. In spite of the fact that published results about TG effects on dough quality are controversial, crosslink among the wheat proteins reinforced dough rheology. Similarly, Basman et al. (2003) found that TG treatment increased resistance and decreased extensibility of soy–wheat dough.

The improving effect of xylanases on bread-making is related to the degradation of water-unextractable-arabinoxylan (WU-AX). Degradation of WU-AX improved gluten development (lower physical barriers) and decreased the water-binding capacity of the xylan, leading to water redistribution from xylan to gluten, which facilitates the build-up of the gluten network (Wang et al. 2003). Besides, solubilization of the WU-AX increases the amount of water-extractable-arabinoxylan, which also showed a positive influence on bread-making. The effect is linked to a strengthening of the liquid films that surround the carbon dioxide gas bubbles during fermentation of the dough, which limited gas diffusion and maximized gas retention (Courtin and Delcour 2002). This positive effect may be explained by an increase in viscosity through the formation of a secondary, weaker network strengthening the gluten network through entanglement and perhaps formation of diferulic bridges (Wang et al. 2005).

Dough stickiness has showed to be a serious difficulty for dough machinability, particularly in automated bread-making processes and especially in soy–wheat dough, which has been described as sticky. Sometimes, farinograph absorption of soy–wheat flour mixtures should be reduced to facilitate handling of the sticky dough (Maforimbo et al. 2006). Minimized dough stickiness could be an important aim to provide good bread-making performance overall in automated processes.

Our results showed a positive linear effect of HE and TG, negative quadratic effect of SSL, HE, and TG, positive and negative quadratic effect of interaction between SSL and TG and between HE and TG, respectively, on stickiness. This crossed behavior of quadratic effect indicated that the response curve has a maximum (Fig. 2). HE showed the highest positive effects on dough stickiness.

Degradation of WU-AX, as consequence of HE activity, decreased their water-holding capacity (Courtin et al. 2001), which leads to a progressive increment of dough stickiness and softness.

Bread Properties

Crust color is an important attribute of bread, contributing to consumer preference. It is produced by chemical reactions including Maillard reaction and caramelization. The incorporation of soy flour modified the crust color of the breads from creamy white to dull brown. However, no significant difference was observed in crust color as a consequence of additive addition. It was not possible to fit a model for the crust color parameters and crumb cell fraction.

Table 4 shows the experimental responses relating to the bread properties. Quadratic models were fitted for SLV, crumb hardness and chewiness, and cell uniformity. The coefficients of determination of SLV, hardness, chewiness, and cell uniformity accounted for 91.4%, 96.6%, 73.1%, and 84.7% of the variability in the data, respectively (Table 5). Figures 3 and 4 show the response surface plots.

In the present study, standard soy–wheat bread (without SSL, HE, and TG) showed a SLV of 3.85 cm3/g. Major improving effects on bread volume were provided by SSL and HE. Positive linear and negative quadratic effects of SSL and HE were observed on SLV. TG had minor effects on SLV. These results indicated that SLV increased continuously as the level of SSL increased but the rate of increment was lower at higher levels of SSL. On the other hand, HE and TG had optimum values (0.0107 and 0.073 g/100 g flour, respectively) from which SLV decreased. Figure 5 shows photographs obtained from representative samples. As it was shown, there were a significant improvement of this parameter and the general quality of soy–wheat bread as a consequence of additive combination. Bread volume reached very high values which allowed overcoming the detrimental effects of soy incorporation.

Bread slice photographs obtained from selected experiments. Black bar is 1 cm long. Values in the figure are the SLVs. Control bread without SSL, HE, and TG addition. Experiment numbers from Table 1

Soy addition decreased the gas retention capacity of the dough and loaf volume (Ribotta et al. 2005). The deterioration in the bread-making properties of supplemented dough seems to be caused mainly by the loss of gas retention properties, which was related to CO2 more permeable gluten network. Fleming and Sosulski (1978), using scanning electron microscopy, found small pores in the gluten fibrils and the cell walls of breads supplemented with soy derivates and suggested that these pores may allow the loss of gas during fermentation and baking.

Cell uniformity was determined as the ratio of small to large gas cells. Higher values of cell uniformity indicated greater uniformity of crumb grain. Crumb uniformity showed a very complex behavior being TG that showed a major positive effect. SSL at high addition levels decreased crumb uniformity, which instead increased bread volume. Higher levels of SSL changed the increasing effect of TG and HE on cell uniformity. These results indicated that higher bread volumes were detrimental to crumb uniformity.

Zghal et al. (2000) stated that excessive breakdown of cell walls and gas cell coalescence, associated with weaker dough, leads to coarse and nonuniform crumb grain. With regards to TG, Larré et al. (2000) found that the formation of new covalent bonds in the gluten network, as a consequence of TG addition, affected its rheological behavior transforming very weak gluten into a very strong one. Dough hardening because of TG action, as was observed on dough resistance and extensibility, could explain the positive effect on crumb uniformity; however, it did not have positive influence on bread volume.

In the present study, standard soy–wheat bread (without SSL, HE, and TG) showed high initial hardness and chewiness (1,032 g and 597, respectively). Additives significantly changed soy–wheat bread texture properties (Fig. 4). Greater hardness and chewiness values are associated with worse bread quality. Negative linear effect of SSL and positive linear and quadratic effects of TG and SSL, respectively, were observed on crumb hardness. High negative quadratic effects of SSL, positive linear and quadratic effect of TG and SSL, respectively, were found on crumb chewiness. Major improving effects on crumb properties were provided by SSL.

As already stated, breadcrumb is composed mainly of a system of interwoven gluten and gelatinized starch strands. Starch granules, which are only partly gelatinized and swollen during baking, are inserted in the continuous phase. A proportion of amylose that has leached out of the granule into the intergranular spaces will have undergone a number of phase changes that ultimately provide structural elements to the crumb. Both amylose and amylopectin present in swollen starch granules and protein strands also contributed to the crumb structure. Protein modification, crosslinking, and polymerization are assumed responsible for the setting of bread and contribute to the final structure (Oates 2001).

Earlier studies (Every et al. 1998) have shown an inverse relationship between bread loaf volume and firmness. This was related to more entanglements and interactions that occur between the more densely packed polymers in samples derived from low-volume breads.

The function of emulsifiers as crumb-softening agents is related to the interaction with starch, particularly with linear amylose, but also with amylopectin (Kamel and Ponte 1993). But the most important factor in determining hardness and chewiness improvement seems to be related to bread volume increment. The strong relationship between SLV and hardness (Pearson coefficient r = −0.883, p < 0.001) found in this study reinforces this view. TG-induced strengthening effect could increase protein–protein and protein–starch interactions and favor crumb firmness.

Optimization

Besides explaining the behavior of variables by the contour curves, the models fitted in this study could also be applied for optimization using the desirability function (Ferreira et al. 2007). Thus, the latter procedure was conducted to maximize the SLV and uniformity and to minimize bread hardness and chewiness simultaneously (optimization 1). The results for this optimization suggested that a mixture containing 0.63% of SSL, 0.0046% of HE, and 0.081% of TG in flour could be a good mixture of this enzymes to achieve the best soy–wheat bread quality.

Dough rheological properties are important factors to improve dough machinability, particularly in automated bread-making processes and especially in soy–wheat dough. The multiresponse optimization was also applied to maximize the area under the curve, SLV, and uniformity and to minimize dough stickiness and bread hardness and chewiness simultaneously (optimization 2). The results for this optimization suggested that a mixture containing 0.56% of SSL, 0.0011% of HE, and 0.129% of TG in flour could be a good mixture of this enzymes to achieve the best soy–wheat bread quality. The values predicted by the equations of the model for each response are shown in Table 6. Optimization 2 showed higher value of TG and lower values of SSL and HE than optimization 1, which was related to the hardening and dryness effects linked with TG addition. Concerning the differences between dough and final bread quality, whereas optimization 1 showed the highest value of SLV, optimization 2 had a higher value of uniformity and a high SLV.

Conclusion

Response surface methodology was an efficient statistical tool able to model the influence of SSL, TG, and HE on soy–wheat dough and bread properties. These results also suggested that by modifying the proportion of these additives, a large range of variation may be obtained. As was demonstrated in other studies, the incorporation of high levels of soy products have a negative effect in gluten network formation, rheological properties and gas retention of dough, and final bread quality. TG had major improving effect on dough rheological properties and crumb uniformity, but soy–wheat bread volume was less influenced. SSL and HE both improved dough and bread quality. Finally, soy–wheat bread quality was significantly improved, as was confirmed by approximately 65% bread volume increment and 79% and 71% crumb hardness and chewiness decrease, respectively, achieved between the standard formulation (without SSL, HE, and TG) and the best formulation tested.

References

American Association of Cereal Chemists (AACC) (1995). Approved methods of the AACC. Methods, 14–22, 54–30A. St. Paul, USA: American Association of Cereal Chemists.

Autio, K., Kruus, K., Knaapila, A., Gerber, N., Flander, L., & Buchert, J. (2005). Kinetics of transglutaminase-induced cross-linking of wheat proteins in dough. Journal of Agricultural and Food Chemistry, 53(4), 1039–1045.

Babiker, E. (2000). Effect of transglutaminase treatment on the functional properties of native and chymotrypsin-digested soy protein. Food Chemistry, 70(2), 139–145.

Basman, A., Koksel, H., & Ng, P. (2002). Effects of increasing levels of transglutaminase on the rheological properties and bread quality characteristics of two wheat flours. European Food Research and Technology, 215(5), 419–424.

Basman, A., Köksel, H., & Ng, P. (2003). Effects of transglutaminase on SDS-PAGE patterns of wheat, soy, and barley proteins and their blends. Journal of Food Science, 67(7), 2654–2658.

Bauer, N., Koehler, P., Wieser, H., & Schieberle, P. (2003). Studies on effects of microbial tranglutaminase on gluten proteins of wheat. II. Rheological properties. Cereal Chemistry, 80(6), 787–790.

Courtin, C. M., & Delcour, J. A. (2002). Arabinoxylans and endoxylanases in wheat flour bread-making. Journal of Cereal Science, 35(3), 225–243.

Courtin, C. M., Gelders, G. G., & Delcour, J. A. (2001). Use of two endoxylanases with different substrate selectivity provides insight into the functionality of arabinoxylans in wheat flour bread-making. Cereal Chemistry, 78(5), 564–571.

Every, D., Gerrard, J., Gilpin, M., Ross, M., & Newberry, M. (1998). Staling in starch bread: The effect of gluten additions on specific loaf volume and firming rate. Starch/Stärke, 50(10), 443–446.

Ferreira, S., Bruns, R., Ferreira, H., Matos, G., David, J., Brandao, G., et al. (2007). Box–Behnken design: An alternative for the optimization of analytical methods. Analytica Chimica Acta, 597(2), 179–186.

Fleming, S., & Sosulski, F. (1978). Microscopic evaluation of bread fortified with concentrated plant proteins. Cereal Chemistry, 55(3), 373–382.

Gerrard, J., Fayle, S., Wilson, A., Newberry, M., Ross, M., & Kavale, S. (1998). The effect of microbial transglutaminase on dough properties and crumb strength of white pan bread. Journal of Food Science, 63(3), 472–475.

Kamel, B., & Ponte, J. (1993). Emulsifiers in baking. In Kamel, & Stauffer (Eds.) Advances in baking technology (pp. 179–222). New York, USA: VCH.

Larré, C., Denery-Papini, S., Popineau, Y., Deshayes, G., Desserme, C., & Lefebvre, J. (2000). Biochemical analysis and rheological properties of gluten modified by transglutaminase. Cereal Chemistry, 77(2), 121–127.

Maforimbo, E., Nguyen, M., & Skurray, G. (2006). The effect of l-ascorbic acid on the rheological properties of soy–wheat dough: A comparison of raw and physically modified soy flours. Journal of Food Engineering, 72(4), 339–345.

Motoki, M., & Seguro, K. (1998). Transglutaminase and its use for food processing. Trends in Food Science & Technology, 9(5), 204–210.

Oates, C. G. (2001). Bread microstructure. In Chinachoti, & Vodovotz (Eds.) Bread staling (pp. 149–162). Boca Raton, USA: CRC.

Ribotta, P. D., Arnulphi, S., León, A. E., & Añón, M. C. (2005). Effect of soybean addition on the rheological properties and breadmaking quality of wheat flour. Journal of the Science of Food and Agriculture, 85(11), 1889–1896.

Rosell, C. M., Wang, J., Aja, S., Bean, S., & Lookhart, G. (2003). Wheat flour proteins as affected by transglutaminase and glucose oxidase. Cereal Chemistry, 80(1), 52–55.

Seguro, K., Kumazawa, Y., Kuraishi, C., Sakamoto, H., & Motoki, M. (1996). The e-(g-glutamyl)lysine moiety in crosslinked casein is an available source for lysine for rats. The Journal of Nutrition, 126(10), 2557–2562.

Suchy, J., Lukow, O. M., & Ingelin, M. E. (2000). Dough microextensibility method using a 2-g mixograph and a texture analyzer. Cereal Chemistry, 77(1), 39–43.

Tamstorf, S., Jonsson, T., & Krog, N. (1986). The role of fats and emulsifiers in baked products. In Blanshard, Frazier, & Galliard (Eds.) Chemistry and physics of baking (pp. 75–88). London, UK: The Royal Society of Chemistry.

Wang, M. W., Oudgenoeg, G., van Vliet, T., & Hamer, R. (2003). Interaction of water unextractable solids with gluten protein: Effect on dough properties and gluten quality. Journal of Cereal Science, 38(1), 95–104.

Wang, M., van Vliet, T., & Hamer, R. J. (2005). How gluten properties are affected by pentosans. Journal of Cereal Science, 39(3), 395–402.

Zghal, C., Scanlon, M., & Sapirstein, H. (2000). Relationship between bread crumb texture and crumb grain uniformity determined by digital image analysis. In: 85th Annual Meeting of American Association of Cereal Chemists, Kansas City, USA.

Zghal, M., Scanlon, M., & Sapirstein, H. (2001). Effects of flour strength, baking absorption, and processing conditions on the structure and mechanical properties of bread crumb. Cereal Chemistry, 78(1), 1–7.

Acknowledgments

The authors would like to thank the Laboratorio de Idiomas (FCA-UNC) for providing useful suggestions to improve the English language in this paper, and both the Consejo Nacional de Ciencia y Técnica (CONICET) and the Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ribotta, P.D., Pérez, G.T., Añón, M.C. et al. Optimization of Additive Combination for Improved Soy–Wheat Bread Quality. Food Bioprocess Technol 3, 395–405 (2010). https://doi.org/10.1007/s11947-008-0080-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-008-0080-z