Abstract

Purpose

As the issue of sustainability gains importance in recent days, efforts to reduce or eliminate waste problems are gaining importance. The use of various industrial by-products is being investigated to produce edible packaging materials. In this study, red pepper pomace oil and protein were extracted and incorporated into corn starch film and their effects on the film properties were analyzed.

Method

Protein isolate was added to the films as 10–30% of the starch mass and oil as 15% of the solid mass of the film containing 10% protein isolate. The edible composite films characterized by physical, barrier, mechanical, antioxidant and antimicrobial properties and FTIR spectroscopy.

Results

Pomace oil addition increased the thickness. While pomace oil decreased water solubility, protein isolate increased it. Protein isolate and pomace oil did not alter swelling and water vapor permeability. The protein isolate decreased the L* value and the pomace oil decreased the a* value. Both protein isolate and pomace oil increased yellowness in the films. A low amount (10%) of protein isolates increased the transparency of films. The combined use of protein isolate and pomace oil decreased the elongation at break and increased the tensile strength of the films. Antimicrobial effect against Escherichia coli and antioxidant activity of oil containing film were observed.

Conclusion

The results suggest that valuable components can be obtained from red pepper pomace, and these components can be added to modify the characteristics of maize starch edible films.

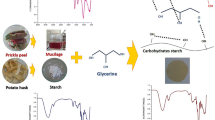

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, studies on biodegradable films have increased due to environmental concerns regarding non-biodegradable plastic packaging [1]. Biodegradable or edible packaging protect food products against physical, chemical and microbiological hazards without causing environmental damage. They can be produced from polysaccharide, protein and lipid compounds or their mixture [2]. Particularly, there is a lot of interest in high-molecular polymers such as starch, chitosan and cellulose [3]. Starch is a non-toxic biological polymer. It is an economical and abundant material with high film-forming ability [4,5,6]. Although starch is suitable for making films, its hydrophilic character and mechanical properties must be improved [7,8,9]. There are different studies to change the properties of starch films. Protein addition to the film formulation can increase water resistance because of the hydrophobic components of proteins [10].

The use of vegetable and fruit process wastes has been studied to find new and alternative protein sources [11, 12]. Wastes obtained during vegetable and fruit processing can also be considered as alternatives for the production of various functional components [13, 14]. Protein isolates draw attention to their bioactivity as well as their functional properties [15]. Red pepper (Capsicum annuum L.) is mainly grown for its fruit but can also be used as a spice. Red peppers are available in a wide variety of sizes, shapes, and flavors, from sweet to pungency [16]. They can be used directly in food preparation, as well as for flavoring and coloring products such as sauces, tomato paste, puree, and powder [17, 18]. They are excellent functional ingredients due to their antioxidant, dietary fiber, vitamin, and mineral content [19]. By-products from the red pepper processing industry are also sources of phenolic substances, dietary fiber, carotenoids, and pectin [20]. Red pepper pomace is rich in protein, cellulose, flavonoids, phenols, vitamins, carotenoids, minerals and contains a small amount of volatile oil [21].

Generally, raw and auxiliary materials exit the production process as a product and product-specific or non-product-specific waste. Product-specific wastes are inevitable as a result of the processing of raw materials. There are various methods for the evaluation of this waste. The two most commonly used traditional methods are animal feed and fertilizer. However, product-specific wastes are considered safe for human consumption since they are characterized by a high percentage of organic compounds and can be used in different areas [22]. In 2021, chillies and peppers production worldwide is 36,286,643 tons. The largest producer was China (16,749,718 tons), followed by Turkey (3,091,295 tons), Indonesia (2,747,018 tons), Mexico (2,584,143 tons), and Spain (1,511,560 tons) [23]. Every year a large amount of solid waste is produced by food factories. Solid wastes can contain various bioactive compounds and biopolymers [24]. It is an important task of the industry to evaluate or dispose of the remaining pomace after the processing of peppers into products.

There are studies on obtaining protein from red pepper seeds [18, 25]; however, there is no study on the use of red pepper pomace, which is an industrial waste. Firatligil-Durmus & Evranuz optimized the extraction of protein of red pepper seed (Capsicum frutescens) [18]. Lee et al. extracted red pepper seed protein and produced edible films containing that protein and oregano oil [25]. Strong protein and starch interactions can cause some changes in the matrix and physical and mechanical properties of the films [26]. Moreover, the high nutritional value contents of red pepper seed oil were reported. The most dominant fatty acid in red pepper seed oil was found to be linoleic acid and it has high γ-tocopherol content [27]. The objective of this study was to extract the valuable components from industrial waste red pepper pomace. Incorporation of red pepper pomace protein can change the properties of starch based films. Additionally, the extracted oil can provide nutritional and antimicrobial properties to the films. Therefore, the aim of this study is to investigate the effect of adding oils and proteins extracted from pepper pomace to maize starch films on film properties.

Materials and Methods

Materials

Pepper pomace was kindly received from Döhler Natural Food and Beverage Ingredients Factory (Karaman, Turkey). Hexane, sodium hydroxide, methanol and hydrochloric acid (Merck, Darmstadt, Germany); sodium chloride (Sigma-Aldrich, Søborg, Denmark); glycerol (%99.5, Panreac, Barcelona, Spain) were purchased from several chemical companies.

Pepper Pomace Preparation and Oil Extraction

The average oil and protein content of dry pepper pomace was 7.73% ± 0.21 and 14.32% ± 0.03, respectively. Oil-free red pepper pomace was obtained according to Firatligil-Durmus and Evranuz [18]. Red pepper pomace (100 g) was weighed and hexane was added as solvent (5:1 solvent:sample ratio). The mixture was stirred on a magnetic stirrer (Daihan Wisd, MSH-20 A, Zevenhuizen, Netherlands) for 24 h. Then the mixture was filtered under a vacuum. The supernatant was stored for oil extraction; the sediment was kept at room temperature for 20 min and dried in an oven for 2 h at 50 °C (Binder, KB53, Tuttlingen, Germany). The dried fraction was ground in a blender (Waring, Commercial, Darmstadt, Germany) and passed through a 500 μm sieve (Retsch, AS200, Haan, Germany). A rotary evaporator (Stuart, RE300, Stafford, England) was used to remove hexane from the supernatant (oil + hexane). The extracted oil was transferred in a dark glass bottle and stored at 4 °C in a refrigerator until use.

Protein Isolates Preparation

Protein isolate extraction were done according to Paraman et al. (2006) with some modifications. Oil-free red pepper pomace (100 g) was weighed and 0.5% NaCl solution was added at a ratio of 5:1 (solvent:sample). The pH of the mixture was adjusted to 11 with 0.5 N NaOH solution by stirring in a magnetic stirrer. Then the mixture was extracted for 3 h at 40 °C in a magnetic stirrer and transferred to centrifuge tubes. After centrifugation at 5000 rpm for 15 min (Nüve, NF200, Ankara, Turkey), the supernatant in the tubes was collected in a beaker with the help of a Pasteur pipette and the pH was adjusted to 3 with 0.1 N HCl solution by stirring in a magnetic stirrer. The solution was kept at refrigerator temperature for 24 h to precipitate the proteins. Then it was mixed and centrifuged at 5000 rpm for 15 min. The sediment in the tubes was collected and freeze-dried [28].

Preparation of the Starch-Protein Isolate Film

The protein obtained from red pepper paste was mixed with maize starch in the ratio of 10 and 30% by the starch weight. The total starch and protein content were mixed with distilled water to prepare 5% (w/v) suspensions. Glycerol (99.5% of purity) at 25% by mass of starch and protein was added. After 20 min mixing, mixture was gelatinized at 80 °C for 30 min with mixing at 400 rpm. The suspension was cooled at room temperature and air bubbles were removed under a vacuum. The mixture (15 mL) was poured into Teflon plates (12 cm diameter) and dried for 24 h at 50 °C. After that the films were removed from Teflon cups and were conditioned by storing them at 25 °C and 55% relative humidity for 2 d (in a desiccator containing Mg(NO3)2 saturated solution) [29]. The film containing maize starch and glycerol was named as Control (C) and the films containing protein isolate (PI) as the 10% and 30% of starch weight (w/w) were named as 10PI and 30PI, respectively. Pepper pomace oil (PO, 15% w/w by mass of the solid content) was added to the film solution containing 10% PI after gelatinization and cooling steps, and the film was named as 10PI + PO.

Film Analysis

Thickness

A micrometer (Insize, Germany) was used to measure the thickness of the films and three random positions around the films were measured.

Moisture Analysis

The moisture content of the films was determined by a moisture analyzer (AND, MX-50, Tokyo, Japan) at 105 °C. The moisture content of the pieces selected from random regions of the films.

Water Solubility

To determine the initial dry weight, three discs (diameter of 17.3 mm) sample were randomly cut, weighed and dried at 105 °C for 24 h. Then samples were immersed in 50 ml distilled water, kept in an orbital shaker at 25 °C for 24 h, filtered. To determine the final dry weight, samples were dried for 24 at 105 °C h. The water solubility was calculated by dividing the initial dry weight by the weight difference [30].

Swelling

Three discs (17.3 mm diameter) from each film were randomly weighed and kept for half an hour in distilled water (50 mL) with continuous shaking. At the end of the time, the immersed discs were dried on a filter paper to remove excess water and their weight was measured. The ratio of recovered water (g) to total solids (g) gives the swelling value [31].

Water Vapor Permeability

Water vapor permeability coefficient (WVP) was determined according to E96/E96M standard method [32] with some modifications defined by McHugh et al. (1993) [33]. Distilled water (20 mL) was added into the aluminum test cups and the cups were sealed with circular-shaped films. The cups were placed in a desiccator containing Mg(NO3)2 saturated solutions at 25 °C and 55 ± 2% relative humidity and then their weight loss was weighed for 8 h as described in the previous paper [34].

Color

The color values were measured by using a chroma meter (Minolta CR-400, Konica Minolta, Osaka, Japan). According to the CIELab system, the parameters L*, a* and b* indicate lightness to darkness, red to green and yellow to blue, respectively. Also, yellowness index (YI) was calculated by L* and b* values according to Khanzadi et al. (2015) [35].

Transparency

The D1746 standard method was used to determine the transparency [36]. Rectangular shape samples were cut and placed on the side surface of the cuvette used in the UV-Visible spectrophotometer. Transparency of the films was measured at 560 nm by a UV-Visible spectrophotometer (PG Instruments Ltd., T60, Lutterworth, England) and the percentage transparency was calculated as follows:

where Ir and I0 is the light intensity with the specimen and with no specimen in the beam, respectively.

Mechanical Properties

Standard testing method D882 was used to determine the mechanical properties of films [37]. Percent elongation at break (EAB) and tensile strength (TS) of films of film samples (15 mm x 70 mm) were measured by a texture analyzer (LAB3-2512 A, Mesdan LAB, Italy) equipped with 100 N load cell. Samples were attached to the grips of the texture analyzer at a 40 mm initial length with 25 mm/min crosshead speed.

Antioxidant and Antimicrobial Properties

Antioxidant capacity of pepper pomace oil and the film containing this oil was determined according to DPPH (2,2-diphenyl-1-picrylhydrazil) radical reduction analysis [38]. Ethyl acetate was used to prepare DPPH solution and extracts. Film (0.5 g) was extracted with 5 mL of ethyl acetate. The DPPH scavenging reaction was developed by mixing 0.1 mL of film extract of oil with 3 mL of 20 mg L− 1 DPHH solution. The results are expressed as percentage inhibition of DPPH radical.

Antimicrobial properties of pepper pomace oil containing films were analyzed with the well diffusion method. Films were cut into 1.2 cm diameter discs and placed on Nutrient agar plates previously inoculated with 0.1 mL of the culture of Bacillus cereus, Salmonella typhi, Escherichia coli, Staphylococcus aureus and Listeria monocytogenes. The plates were incubated at 37 °C for 24 h to analyze the inhibition zone.

Fourier Transform Infrared (FTIR) Spectroscopy

The chemical interactions of the film ingredients were determined by FTIR spectra of films by a Bruker Invenio S Spectrometer (Bruker Co., Ettlingen, Germany). The transmittance spectral regions were obtained between 4000 − 400 cm− 1 with a 4 cm− 1 resolution.

Statistical Analysis

The results were given as mean ± standard deviation of at least triplicate experiments. SPSS software (IBM SPSS Statistics, 19) was used to carry out one-way analysis of variance (ANOVA) to compare the results at the significant level p < 0.05. Also, Duncan multiple comparison test was used in the comparison of the groups.

Results and Discussion

Thickness

Film thickness varies according to the components in the film, the proportions of these components and the film making process [39]. Mechanical properties and barrier properties depend on film thickness. Therefore, it is a very important feature in the selection of packaging materials for foods [39,40,41]. The thickness of C film was 0.066 ± 0.005 mm (Table 1). Adding PI did not significantly (p > 0.05) alter the thickness. The solid amount in the film matrix did not increase for PI including films, so it did not affect the thickness. PO addition increased the thickness value significantly (p < 0.05). Similar results were reported by other researchers who studied essential oil addition into films. The oil microdroplets, which were generated during the homogenization of the film solution, increased amount of solid content after oil addition, or weak physical bonding between oil and other components can increase the films’ thickness [42, 43].

Moisture, Solubility and Swelling

The moisture content of the films is a very important feature in packaging applications. Because a packaging should be able to protect the moisture of the product from external factors and ensure that the product can maintain its quality [44]. Table 1 shows the moisture analysis results of the films. The sample with the highest moisture content is the 30% protein-added film (12.576% ± 0.657). Compared to the control sample (11.146% ± 0.014), this value was not significantly different (p > 0.05). There was a decrease in the moisture content of PI + PO film compared to the film containing the same amount of PI without oil, but it was not statistically significant.

The solubility of films is the ability to dissolve in water and significantly affects the storage quality of coated foods. While high solubility films are preferred for the proper digestion of food and its natural decomposition in the environment, low solubility films are also needed to preserve the integrity of food [45, 46]. Edible films based on polysaccharides are generally hydrophilic. Solubility can be reduced by changing the dry matter and glycerol concentration so that high solubility does not affect moisture loss or moisture gain in the product [46, 47]. The water solubility of C film was 15.332% ± 0.433 (Table 1). The PI addition to the film increased the solubility (p < 0.05) but PI amount did not affect it. The hydrophobic character of oil molecules decreased the solubility of films in water [48]. Therefore, PO addition significantly decreased the solubility of 10PI films from 19.133% ± 1.622 to 16.221% ± 0.617.

Swelling is an important feature for polysaccharides and proteins. Because there is a correlation between the amount of water absorbed and swelling correlation [49]. The swelling values of films were between 2.205 g/g to 2.991 g/g (Table 1). The addition of PI and PO did not change the swelling values significantly (p > 0.05).

Water Vapor Permeability

Water vapor permeability is an important factor that has an effect on the storage properties of food. During storage, the mass transfer through food or between the environment causes the formation of various physical and chemical reactions that cause the food to deteriorate. Migration of various components, especially water, should be controlled [50]. The WVP value of the C film was 0.628 ± 0.064 gmm/m2hkPa (Fig. 1). There was no statistically significant change in the WVP values of the films with the addition of PI and PO (p > 0.05).

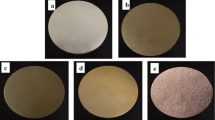

Color and Transparency

The color of an edible film is the first factor in the acceptability of packaged products [51]. L* values of film samples were between 84.064 and 92.695, a* values of film samples were between 2.304 and 4.744, and b* values of film samples were between 0.012 and 19.220 (Table 2). The control group was the brightest film and PI decreased the brightness of the films (p < 0.05). When the 10PI and 10PI + PO groups were compared it can be seen that PO caused a decrease in brightness (p < 0.05). The addition of PO significantly decreased a* value of the film; the addition of PI and PO significantly increased b* value of the film (p < 0.05). YI values of films were between 0.024 and 32.437. This parameter increased for PI and PO containing films. As can be also seen in photographs of film samples (Fig. 2), the films with protein and oil additives were slightly yellowish because of the characteristic color of PI and PO.

Transparency of film is an essential visual factor [52]. The addition of 10% PI to the control film increased the transparency values from 47.993 to 61.377 (p < 0.05). Consumers desire to see coated food items, so higher transparency is an important feature for edible films to reach consumer acceptance. Since the addition of PI at a low rate increases the transparency value, the studies with EO continued with this sample. While the addition of EO to the film caused a decrease in the transparency value, the result is not different from the C film (p > 0.05). The transparency decreased in the films containing high PI (30%), but this value did not show a statistically significant (p > 0.05) difference with the value of the C sample.

Mechanical Properties

The TS and EAB values of the films as mechanical properties are presented in Table 3. TS and EAB value for C film were 3.207 N/mm2 and 79.500%, respectively. As can be seen in the Tables 3, 10% addition of PI caused a significant increase to 4.246 N/mm2 (p < 0.05) in the TS value. The addition of PI at the rate of 30% did not cause a change (p > 0.05) compared to the C sample. Basiak et al. (2015) [53] reported increased TS values with the increased amount of whey protein isolate in wheat starch films. When the EAB values of the samples were examined, it was seen that PI caused a significant (p < 0.05) decrease, while the amount of PI did not cause a change (p > 0.05).

Surprisingly, a significant increase in the TS value and a significant decrease (p < 0.05) in the EAB value were observed in the samples with PO. Some researchers have reported a decrease in TS values with the addition of oil in films produced with various hydrocolloids. For example, coconut oil addition to films based on soy protein isolate [54] and sunflower oil addition to films based on quinoa protein-chitosan [55] showed a decrease in TS. They attributed this to the increase in heterogeneity in the film matrix and the increase in discontinuities in the polymer network. However, in some studies, similar to this study, it was observed that the TS values increased with the addition of oil. Liu et al. [56] found that 2.5% of corn oil addition increased the TS and decreased the EAB of pectin and gelatin/sodium alginate films. In this study, it was stated that oil molecules penetrated the film matrix and increased the bonding and showed a reinforcing effect on the network structure.

Antioxidant and Antimicrobial Properties

The DPPH free radical scavenging activity of red pepper pomace oil and oil added film were 42.189% ± 1.942 and 3.254% ± 0.456, respectively. Red pepper pomace is a waste containing skin, seed and pulp. It is known that the seed contains high amounts of oil [57]. Pepper seed oil shows antioxidant properties with tocopherol, carotene and phenolic components [27, 58, 59]. The oil obtained from red pepper pomace with its antioxidant activity, characteristic aroma and odor can be used in the packaging of meat products to increase the oxidative stability. Films containing pepper pomace protein and oil did not show any antimicrobial activity against Bacillus cereus, Salmonella typhi, Staphylococcus aureus and Listeria monocytogenes. However, as can be seen in Fig. 3, it demonstrated an inhibitory activity against Escherichia coli with a 4 mm diameter zone of inhibition. It is known that the capsanthin compound, a carotenoid found in red pepper, has antimicrobial and antioxidant effects [60].

FTIR

FTIR spectra of native maize starch, PI from red pepper pomace, and films containing starch, PI and pepper oil extracted from red pepper pomace were shown in Fig. 4. Peak shifts and new peak formations were not observed in the spectrum of the films, indicating that no new chemical group was formed. The broad band in the region of 3600 − 3000 cm− 1 indicates the OH stretching vibrations and the peaks around 2930 cm− 1 indicates the CH stretching. Strong hydrogen bonds in starch molecules and between water and starch caused that broad band [61]. The peaks in the region of approximately 1200 − 800 cm− 1 show the adsorption bands [62, 63]. These peaks indicate vibrations of CO, CC and COH stretching groups [63]. The peak around 1650 cm− 1 corresponds to water molecules present in the samples [61]. In the PI spectrum, the peaks at 1650 and 1530 cm− 1 correspond amide-I (carbonyl stretching vibrations) and amide-II (NH bending vibrations) bands, respectively [64]. It is seen that the water peak and the amide-I peak from the protein overlap [65]. The weak band around 1740 cm− 1 corresponds to CO stretching of carbonyl ester groups of fatty acids and triglycerides [66].

Conclusion

Extraction of protein and oil from red pepper pomace has been studied to add them into maize starch based edible film. This study showed that it is possible to extract protein and oil from red pepper pomace which is an industrial by-product. The incorporation of protein isolate and oil into starch film could modify the some properties of films. Pepper pomace oil addition increased thickness and decreased the water solubility of films. Both of them caused to produce edible film characterized by a slight yellowish and did not affect the water vapor permeability values of films. The lower amount of (10%) protein isolates increased the transparency of films. Moreover, pepper pomace protein and oil together increased the tensile strength and decreased the elongation at break values of starch films. In addition, edible films containing pepper pomace oil showed antimicrobial activity against Escherichia coli. The results suggest that valuable extracts of pepper pomace, as an industrial by-product, may be a good candidate to be used in the production of active films to extend the shelf life of sensitive foods such as fresh fruits, vegetables and meat products.

Data Availability

The datasets generated during and/or analyzed during the current study are available on request from the authors.

References

Rhim, J.W., Hong, S.I., Ha, C.S.: Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. LWT-Food Sci. Technol. 42, 612–617 (2009)

Lee, J.H., Song, K.B.: Preparation of a porcine plasma protein composite film and its application. Biosci. Biotechnol. Biochem. 79, 68–73 (2015)

Condés, M.C., Añón, M.C., Mauri, A.N., Dufresne, A.: Amaranth protein films reinforced with maize starch nanocrystals. Food Hydrocoll. 47, 146–157 (2015)

Azevedo, V.M., Borges, S.V., Marconcini, J.M., Yoshida, M.I., Neto, A.R.S., Pereira, T.C., Pereira, C.F.G.: Effect of replacement of corn starch by whey protein isolate in biodegradable film blends obtained by extrusion. Carbohydr. Polym. 157, 971–980 (2017)

Müller, C.M., Laurindo, J.B., Yamashita, F.: Effect of cellulose fibers addition on the mechanical properties and water vapor barrier of starch-based films. Food Hydrocoll. 23, 1328–1333 (2009)

Su, B., Xie, F., Li, M., Corrigan, P.A., Yu, L., Li, X., Chen, L.: Extrusion processing of starch film. Int. J. Food Eng. 5, (2009)

Wu, Z., Huang, Y., Xiao, L., Lin, D., Yang, Y., Wang, H., Yang, Y., Wu, D., Chen, H., Zhang, Q., Qin, W., Pu, S.: Physical properties and structural characterization of starch/polyvinyl alcohol/graphene oxide composite films. Int. J. Biol. Macromol. 123, 569–575 (2019)

Bourtoom, T.: Edible films and coatings: Characteristics and properties. Int. Food Res. J. 15, 237–248 (2008)

Santana, R.F., Bonomo, R.C.F., Gandolfi, O.R.R., Rodrigues, L.B., Santos, L.S., dos Santos Pires, A.C., de Oliveira, C.P., da Costa Ilhéu Fontan, Veloso, R.: C.M.: Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 55, 278–286 (2018)

Seligra, P.G., Jaramillo, C.M., Famá, L., Goyanes, S.: Biodegradable and non-retrogradable eco-films based on starch–glycerol with citric acid as crosslinking agent. Carbohydr. Polym. 138, 66–74 (2016)

Primozic, M., Duchek, A., Nickerson, M., Ghosh, S.: Effect of lentil proteins isolate concentration on the formation, stability and rheological behavior of oil-in-water nanoemulsions. Food Chem. 237, 65–74 (2017)

Quanhong, L., Caili, F.: Application of response surface methodology for extraction optimization of germinant pumpkin seeds protein. Food Chem. 92, 701–706 (2005)

Wani, A.A., Sogi, D.S., Grover, L., Saxena, D.C.: Effect of temperature, alkali concentration, mixing time and meal/solvent ratio on the extraction of watermelon seed proteins-A response surface approach. Biosyst Eng. 94, 67–73 (2006)

Al-Farsi, M.A., Lee, C.Y.: Optimization of phenolics and dietary fibre extraction from date seeds. Food Chem. 108, 977–985 (2008)

Garau, M.C., Simal, S., Rossello, C., Femenia, A.: Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. canoneta) by-products. Food Chem. 104, 1014–1024 (2007)

Bernadac, A., Latché, A., Roustan, J.P., Bouzayen, M., Pech, J.C.: Cucurbits, pepper, eggplant, legumes and other vegetables. In: Valpuesta, V. (ed.) Fruit and Vegetable Biotechnology, pp. 250–293. Woodhead Publishing, Cambridge (2002)

Li, M., Wen, X., Peng, Y., Wang, Y., Wang, K., Ni, Y.: Functional properties of protein isolates from bell pepper (Capsicum annuum L. var. Annuum) seeds. LWT-Food Sci. Technol. 97, 802–810 (2018)

Firatligil-Durmus, E., Evranuz, O.: Response surface methodology for protein extraction optimization of red pepper seed (Capsicum frutescens). LWT-Food Sci. Technol. 43, 226–231 (2010)

Minguez-Mosquera, M.I., Hornero-Mendez, D.: Separation and quantification of the carotenoid pigments in red peppers (Capsicum annuum L.), paprika, and oleoresin by reversed-phase HPLC. J. Agric. Food Chem. 41, 1616–1620 (1993)

Nath, P., Kale, S.J., Kaur, C., Chauhan, O.P.: Phytonutrient composition, antioxidant activity and acceptability of muffins incorporated with red capsicum pomace powder. J. Food Sci. Technol. 55, 2208–2219 (2018)

Kalak, T., Dudczak-Hałabuda, J., Tachibana, Y., Cierpiszewski, R.: Effective bioremoval of Fe (III) ions using paprika (Capsicum annuum L.) pomace generated in the food industry. J. Mater. Cycles Waste Manag. 23, 248–258 (2021)

Russ, W., Meyer-Pittroff, R.: Utilizing waste products from the food production and processing industries. Crit. Rev. Food Sci. Nutr. 44, 57–62 (2004)

FAO. Food and Agriculture Organization of the United Nations. FAO Statistical Databases: (2008). http://faostat.fao.org. Accessed December 2023

Roberta, M.S.A., Mariana, S.L.F., Édira, C.B.A.G.: Functional capacity of flour obtained from residues of fruit and vegetables. Int. Food Res. J. 21, 1675 (2014)

Lee, J.H., Yang, H.J., Lee, K.Y., Song, K.B.: Physical properties and application of a red pepper seed meal protein composite film containing oregano oil. Food Hydrocoll. 55, 136–143 (2016)

Chinma, C.E., Ariahu, C.C., Abu, J.O.: Development and characterization of cassava starch and soy protein concentrate based edible films. Int. J. Food Sci. Technol. 47, 383–389 (2012)

Cvetković, T., Ranilović, J., Gajari, D., Tomić-Obrdalj, H., Šubarić, D., Moslavac, T., Cikoš, A.-M., Jokić, S.: Podravka and slavonka varieties of pepper seeds (Capsicum annuum L.) as a new source of highly nutritional edible oil. Foods. 9, 1262 (2020)

Paraman, I., Hettiarachchy, N.S., Schaefer, C., Beck, M.I.: Physicochemical properties of rice endosperm proteins extracted by chemical and enzymatic methods. Cereal Chem. 83, 663–667 (2006)

Liu, C., Yu, B., Tao, H., Liu, P., Zhao, H., Tan, C., Cui, B.: Effects of soy protein isolate on mechanical and hydrophobic properties of oxidized corn starch film. LWT-Food Sci. Technol. 147, 111529 (2021)

Rangel-Marrón, M., Montalvo-Paquini, C., Palou, E., López-Malo, A.: Optimization of the moisture content, thickness, water solubility and water vapor permeability of sodium alginate edible films. Recent. Adv. Chem. Eng. Biochem. Computational Chem. 72–78 (2013)

Cao, N., Fu, Y., He, J.: Preparation and physical properties of soy protein isolate and gelatin composite films. Food Hydrocoll. 21, 1153–1162 (2007)

ASTM: Standard test Method for Water Vapor Transmission of materials – E96/E96M-15, West Conshohocken. PA: ASTM, Annual Book of American Standard Testing Methods (2015)

McHugh, T.H., Avena-Bustillos, R., Krochta, J.M.: Hydrophilic edible films: Modified procedure for water vapor permeability and explanation of thickness effects. J. Food Sci. 58, 899–903 (1993)

Yildirim-Yalcin, M., Seker, M., Sadikoglu, H.: Development and characterization of edible films based on modified corn starch and grape juice. Food Chem. 292, 6–13 (2019)

Khanzadi, M., Jafari, S.M., Mirzaei, H., Chegini, F.K., Maghsoudlou, Y., Dehnad, D.: Physical and mechanical properties in biodegradable films of whey protein concentrate–pullulan by application of beeswax. Carbohydr. Polym. 118, 24–29 (2015)

ASTM: Standard test Method for Transparency of Plastic sheeting – D1746-15, West Conshohocken. PA: ASTM, Annual Book of American Standard Testing Methods (2015)

ASTM: Standard test Method for Tensile Properties of thin Plastic sheeting – D882-12, West Conshohocken. ASTM, Annual Book of American Standard Testing Methods, PA (2012)

Cai, L., Cao, A., Aisikaer, G., Ying, T.: Influence of kernel roasting on bioactive components and oxidative stability of pine nut oil. Eur. J. Lipid Sci. Technol. 115, 556–563 (2013)

García, M.A., Pinotti, A., Martino, M.N., Zaritzky, N.E.: Characterization of starch and composite edible films and coatings. In: Embuscado, M.E., Huber, K.C. (eds.) Edible Films and Coatings for Food Applications, pp. 169–209. Springer, New York (2009)

Galus, S., Lenart, A.: Development and characterization of composite edible films based on sodium alginate and pectin. J. Food Eng. 115, 459–465 (2013)

McHugh, T.H., Aujard, J.F., Krochta, J.M.: Plasticized whey protein edible films: Water vapor permeability properties. J. Food Sci. 59, 416–419 (1994)

Bazzaz, A.E., Hakimzadeh, V., Noghabi, M.S.: Preparation and study of carboxymethyl cellulose biodegradable films properties containing Mentha pulegium essential oil. J. Thermoplast Compos. Mater. 34, 1213–1233 (2021)

Zhou, Y., Wu, X., Chen, J., He, J.: Effects of Cinnamon essential oil on the physical, mechanical, structural and thermal properties of cassava starch-based edible films. Int. J. Biol. Macromol. 184, 574–583 (2021)

Masamba, K., Li, Y., Hategekimana, J., Zehadi, M., Ma, J., Zhong, F.: Evaluation of mechanical and water barrier properties of transglutaminase cross-linked zein films incorporated with oleic acid. Int. J. Food Sci. 51, 1159–1167 (2016)

Pitak, N., Rakshit, S.K.: Physical and antimicrobial properties of banana flour/chitosan biodegradable and self sealing films used for preserving fresh-cut vegetables. LWT-Food Sci. Technol. 44, 2310–2315 (2011)

Pérez-Gago, M.B., Nadaud, P., Krochta, J.M.: Water vapor permeability, solubility, and tensile properties of heat‐denatured versus native whey protein films. J. Food Sci. 64, 1034–1037 (1999)

Gontard, N., Guilbert, S., Cuq, J.L.: Water and glycerol as plasticizers affect mechanical and water vapor barrier properties of an edible wheat gluten film. J. Food Sci. 58, 206–211 (1993)

Marzlan, A.A., Muhialdin, B.J., Abedin, N.H.Z., Manshoor, N., Ranjith, F.H., Anzian, A., Hussin, A.S.M.: Incorporating torch ginger (Etlingera elatior Jack) inflorescence essential oil onto starch-based edible film towards sustainable active packaging for chicken meat. Ind. Crops Prod. 184, 115058 (2022)

Lee, K.Y., Shim, J., Lee, H.G.: Mechanical properties of gellan and gelatin composite films. Carbohydr. Polym. 56, 251–254 (2004)

Lacroix, M.: Mechanical and permeability properties of edible films and coatings for food and pharmaceutical applications. In: Embuscado, M.E., Huber, K.C. (eds.) Edible Films and Coatings for Food Applications, pp. 347–366. Springer, New York (2009)

Ghasemlou, M., Khodaiyan, F., Oromiehie, A., Yarmand, M.S.: Development and characterisation of a new biodegradable edible film made from kefiran, an exopolysaccharide obtained from kefir grains. Food Chem. 127, 1496–1502 (2011)

Fang, Y., Tung, M.A., Britt, I.J., Yada, S., Dalgleish, D.G.: Tensile and barrier properties of edible films made from whey proteins. J. Food Sci. 67, 188–193 (2002)

Basiak, E., Galus, S., Lenart, A.: Characterisation of composite edible films based on wheat starch and whey-protein isolate. Int. J. Food Sci. 50, 372–380 (2015)

Carpiné, D., Dagostin, J.L.A., Bertan, L.C., Mafra, M.R.: Development and characterization of soy protein isolate emulsion-based edible films with added coconut oil for olive oil packaging: Barrier, mechanical, and thermal properties. Food Bioproc. Tech. 8, 1811–1823 (2015)

Valenzuela, C., Abugoch, L., Tapia, C.: Quinoa protein–chitosan–sunflower oil edible film: Mechanical, barrier and structural properties. LWT-Food Sci. Technol. 50, 531–537 (2013)

Liu, L., Kerry, J.F., Kerry, J.P.: Effect of food ingredients and selected lipids on the physical properties of extruded edible films/casings. Int. J. Food Sci. 41, 295–302 (2006)

Matthaus, B., Ozcan, M.M.: Chemical evaluation of some paprika (Capsicum annuum L.) seed oils. Eur. J. Lipid Sci. Technol. 111, 1249–1254 (2009)

Yılmaz, E., Arsunar, E.S., Aydeniz, B., Güneşer, O.: Cold pressed capia pepper (Capsicum annuum L.) oils: Composition, aroma and sensory properties. Eur. J. Lipid Sci. Technol. 117, 1016–1026 (2015)

Chouaibi, M., Rezig, L., Hamdi, S., Ferrari, G.: Chemical properties and compositions of red pepper seed oils extracted by different methods. Ind. Crops Prod. 128, 363–370 (2019)

Salih, A.A.: Extraction and identification of oil extract from Capsicum annuum L. fruits and study of its antimicrobial activity. Proteins, 12, (2006)

Shivaraju, V.K., Vallayil Appukuttan, S.: The influence of bound water on the FTIR characteristics of starch and starch nanocrystals obtained from selected natural sources. Starch-Stärke. 71, 1700026 (2019)

Choi, I., Shin, D., Lyu, J.S., Lee, J.S., Song, H.G., Chung, M.N., Han, J.: Physicochemical properties and solubility of sweet potato starch-based edible films. Food Packag. Shelf Life. 33, 100867 (2022)

Pozo, C., Rodríguez-Llamazares, S., Bouza, R., Barral, L., Castaño, J., Müller, N., Restrepo, I.: Study of the structural order of native starch granules using combined FTIR and XRD analysis. J. Polym. Res. 25, 1–8 (2018)

Gallagher, W.: FTIR analysis of protein structure. Course Man. Chem 455 (2009)

Chittur, K.K.: FTIR/ATR for protein adsorption to biomaterial surfaces. Biomaterials. 19, 357–369 (1998)

Bujok, J., Gąsior-Głogowska, M., Marszałek, M., Trochanowska-Pauk, N., Zigo, F., Pavľak, A., Komorowska, M., Walski, T.: Applicability of FTIR-ATR method to measure carbonyls in blood plasma after physical and mental stress. BioMed. Res. Int. (2019)

Acknowledgements

This work was funded by the Scientific and Technological Research Council of Turkey (TUBITAK, 2209B), Project No:1139B412101942.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, formal analysis, conceptualization, investigation and methodology were performed by Zeynep Kader Akıncı, Halil Karaman, Meral Yıldırım-Yalçın, Hatice Sena Olcay Mehmet Inan and Omer Said Toker. The first draft of the manuscript was written by Zeynep Kader Akıncı, Halil Karaman, Meral Yıldırım-Yalçın, Hatice Sena Olcay and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical Approval

Ethical approval was not applicable for this research.

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akinci, Z.K., Karaman, H., Yildirim-Yalcin, M. et al. Effects of Red Pepper Pomace Protein and Oil on the Properties of Starch-Based Edible Films. Waste Biomass Valor 15, 3579–3588 (2024). https://doi.org/10.1007/s12649-023-02414-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02414-y