Abstract

Black carrot pomace (BCP), a byproduct of juice processing, offers a cost-effective and sustainable source of polyphenols and anthocyanins for edible packaging. In this study, we incorporated BCP extract at varying concentrations of 0, 15, 25, 35, and 45% (v/v) into corn starch films blended with hydroxymethyl cellulose (HMC) and glycerol. Results indicated a consistent increase in film thickness, moisture content, and solubility with increase in BCP extract levels. Films with increase in extract concentrations from 15 to 45%, displayed reduced tensile strength (0.45to 0.31 MPa), decreased elongation at break (28.0 to 19.03%) and increased water vapor transmission rates (0.142to 0.173 g/h cm2).Incorporating BCP extract, 15 to 45% substantially enriched films with anthocyanins (8.03 to 11.53 milligram Cyanidin-3-glucoside equivalent per gram), flavonoids (4.42 to 19.96 milligram of catechol per gram), and total phenol content (10.14 to 13.96 micro gram of gallic acid equivalent per gram) enhancing their antioxidant properties. Higher anthocyanin content intensified film redness (a*) and opacity while reducing lightness (L). Morphological analysis (Fourier Electron Scanning Emission Microscopy, FESEM) revealed that control films without BCP extract, displayed smoother, fracture-free surface. In contrast, films with BCP extract exhibited surface agglomerations. Fourier transform infrared spectroscopy (FTIR) confirmed presence ofcrosslinking between protein, polyphenols and hydrocolloidsinthe matrix. Films enriched with anthocyanins demonstrated superior thermal stability (DSC) and enthalpy changes (TGA) compared to control films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid population growth has resulted in increased usage of plastic-based packaging, leading to significant environmental concerns in terms of the management of non-biodegradable waste [1]. The escalating production of synthetic polymers has prompted researchers to shift their focus towards creating novelpackaging using naturally derived polymers, which can be effectively applied in the food packaging industry [2]. Recently, there has been a growing interest in the development of edible films that utilize agricultural waste residues. The reason being their cost-effectiveness, biodegradability and biocompatibility [3] ease of procurement, and abundant availability [4]. Currently, there needs to be a focus onsustainable packaging solution that utilizes nutritionally rich processing and agricultural residual materials, which could otherwise pose significant environmental challenges [5]. These packaging systems can serve as a convenient replacement for synthetic polymers such as non-biodegradable plastic films.

Byproducts like seeds, peels and pomace are often discarded, irrespective of their valuable components such as vitamins, minerals, fibers, and bioactive compounds such as phenols compounds and antioxidants (Kapil et al. 2023). Black carrot pomace stands out as a functional ingredient due to its significant amount of protein (0.75-1%), fat (0.12–0.16%), carbohydrates (8.0-8.02%), and crude fiber (2.35–2.62%) [6]. The purple pigmentation in black carrot pomace is attributed to the presence of anthocyanins, a type of flavonoid. Previous researches have reported immense benefits of anthocyanins in human body by serving as an anti-inflammatory, anticarcinogenic, anti-postprandial hyperglycemic, antidiabetic and neuroprotective compound [7]. Due to the numerous health benefits of BCP, researchers currently are concentrating on the utilization of BCP in various applications. For example, there is a growing interest in extracting pigments like anthocyanins for use in bicolor applications. This increased interest is partly driven by regulatory restrictions on synthetic colorants and the growing consumer demand for natural pigments [8]. BCP is used for extraction of phytochemicals, as early reports suggest [9], polyphenols that are originally present in black carrot originally exist in pomace. BCP therefore, has widely been used in various food applications due to easy accessibility of transferring antioxidants and polyphenols from BCP into food products, thus enhancing nutritional value with potential health benefits.

Black carrot pomace (BCP) is a rich source of potential anthocyanins, antioxidants, and dietary fiber, playing a significant role in enhancing the nutritional quality of food. The antioxidant potential of black carrots is approximately 2.5 times that of orange-coloured carrots [9]. The dark purplish-black color of black carrot is attributed to anthocyanin pigments, belonging to the flavonoids group therefore possessing significant antioxidant potential (4.54–1740 mg/100 g fresh weight basis). These pigments offer health benefits such as antiproliferative, anti-inflammatory, antioxidant, antiviral, antiallergic, stomachic, and bactericidal properties [10]. Studies have explored the utilization of BCP in the form of nutraceutical tablets, the results indicated that best quality attributes of powdered BCP with retained phytochemicals were obtained through freeze-drying. The BCP nutraceutical tablets exhibited swift disintegration and rapid release of anthocyanins, indicating their facile absorption in the human body with potential health benefits [9, 10]. In addition to this, the high levels of dietary fibres in BCP pomace can act as natural jellying or thickening agents [9]. Previous research highlightets carrot pomace as a novel ingredient for fiber enrichment in food products due to its balanced soluble/insoluble fibres ratio, better hydration properties, fermentability, and the presence of phytochemicals [11]. Pomace powders with good hydration properties can serve as functional ingredients in food products, exerting their physiological effect by absorbing water in the gut and promoting stool bulking [1]. So far, BCP has been used in formulation of cookies [12], kulfi [13], fruit bars [14] cakes and cookies [15] and muffins [16]. In addition to potential waste utilization, there is a growing focus on the development of edible packaging using residual waste [5]. These valuable, underutilized components have been extensively used to enhance the bio-functional properties of biopolymer-based edible films. Residues from apple, banana, pomelo [17], pomegranate, papaya and jackfruit, blood orange, and potatoes peels so far have been utilized in the development of antioxidant and antimicrobial biopolymer-based edible films [5]. Due to the considerable antioxidant content in black carrot pomace, it holds a property of being utilized as promising valuable packaging material, capable of preventing oxidation in food products, therefore extending the shelf life of products by inhibiting microbial spoilage.

Reportedly, development of edible packaging derived from plant-based components, rely on structural composition of polysaccharides, proteins and lipids, or a combination of all [17]. BCP’s constitutional makeup of protein, fat, carbohydrates, and crude fiber can therefore be helpful in formulating potential edible packaging film. Apart from utilizing natural ingredients, the development of packaging film from BCP necessitates the inclusion of plasticizers. These substances play a crucial role in disrupting hydrogen bonding between polymer chains, thereby boosting flexibility and improving the permeability of gas and water vapor [18]. The common plasticizers used in development of biopolymer films include polyethylene glycol, sorbitol and glycerol.The addition of plasticizers to polymeric film-forming materials reduces the glass transition temperature by disrupting polymer-polymer interactions, decreasing ratio of crystalline regions to amorphous, thus lowering glass transition temperature [3]. The type and concentration of each plasticizers can have effect on the mechanical properties of the film whereas, addition of glycerol makes the film stronger and elastic than the standard biopolymer films. Integrating black carrot pomace into primary packaging formulations represents a promising and environmental friendly approach in creating biodegradable and edible food packaging materials. This innovation has the potential to not only produce sustainable packaging but also contribute to the reduction of waste generation [19]. Research on the production of edible, biodegradable films with antioxidant properties, utilizing black carrot pomace (BCP) as a key ingredient, is currently limited. Therefore, this study was initiated with the goal of incorporating BCP extract at varying concentrations into films made from a blend of corn starch and hydroxypropyl methylcellulose (HMC). When applied as a thinlayer barriers, these biofilms can effectively regulate the passage of moisture, gases, and flavor compounds [20]. The primary objective was to enhance the phytochemicals and antioxidants within these edible packaging materials. This research revolves around the use of waste resources to develop potential food packaging materials that not only exhibit improved mechanical and barrier characteristics.

Materials and methods

Colored carrots (variety Punjab Black Beauty), was procured from Department of Vegetable Science, Punjab Agricultural University. Further, Hydroxy methyl cellulose (HMC), Corn starch (14% moisture) was purchased from Nauge India (Haryana, India), HMC, used as binder and glycerol used as plasticizer were procured from Molychem (Mumbai, India), Chitosan was procured from Sisco Research Laboratories (Taloja, Maharashtra).

Preparation of BCP extract

Carrots were washed, trimmed, peeled, and subjected to juice extraction (Kalsi carrot juicer, a large-sized machine). The methodology as previously described by Singh et al. [1]. for the extraction and solubilization of anthocyanins was followed, with some modifications. Briefly, after juice extraction, black carrot pomace was subjected to lyophilization using a freeze dryer (Biotechnologies Inc., Delhi) to remove water content. The dried pomace was ground in pestle mortar and sieved through a 0.5 mm mesh size sieve. The resulting pomace powder at varying concentrations of 15, 25, 35 and 45 g, were mixed in 100 ml solution mixture of double distilled water and citric acid (0.25%). The pomace suspensions werefirstsubjected to continuous agitation by placing it ona magnetic stirrer (Bexco Exports) for 45 min at 30 °C in order todissolve powder into solution mixture and then subjected to water bath cum shaker for 1 h at 35 ℃ for solubilization and extraction of anthocyanins [17]. Subsequently, the contents were allowed to cool (25 °C), followed by centrifugation (1000 rpm for 15 min). The aliquot was separated from solid through filtration (Axiva Sichem Biotech, grade 100R, diameter 110 mm) and sedimented pomace powder was moved back into another 100 ml of distill water and citric acid blend for repeated extraction (twice). After complete extraction filtrated extract were mixed and estimated for anthocyanins content using the method explained in Sect. “Anthocyanins”. The extract obtained was stored in glass vials for further utilization.The obtained extract had total monomeric anthocyanins content of29.22, 33.36, 44.32, and 60.41 mg cyanidin-3-glucoside equivalents per gram (CGE/g) for 15%, 25%, 35%, and 45% pomace extracts respectively.

Preparation of film forming solution

The film preparation was performed according to the method previously published by Alzate et al. [21] with minor modifications. In brief, a film-forming solution was prepared by dissolving 4% (w/v) of corn dissolved in 100 ml of BCP extracts namely,15, 25, 35 and 45 (as obtained from 2.1) (for control film composites were added in 100 ml distilled water), placed upon magnetic stirrer at 40 °C for 45 min. On partial gelatinization of starch 2% (w/v) of Hydroxy methyl cellulose (HMC) was added with constant stirring. On complete dissolution of HMC and corn starch in the suspension mixture, 1 g of chitosan was added. The film forming slurry was allowed to cool at 25 °C ± 2 °C, and lastly 2% glycerol (v/v) was added as plasticizer. The obtained gelatinized slurries were then ultrasonicated (Macro scientific works sonicator, Delhi) for 2 min to avoid bubbles.The film forming solution thus obtained was poured (50 ml) into teflon plates and allowed to dry at 40 oC for 5 h. The teflon plates containing films were removed and conditioned at 64.4% RH using a saturated solution of NaNO2 at 25 ◦C for at least 24 h in a desiccator and peeled out gently for further analysis.

Preparation of films

50 ml of film-forming solutions were casted on Teflon-covered pans (230 mm x 230 mm) and placed in a hot air oven (Acumen Scientific, Delhi) at 40 °C for 5 h. The films formed were peeled off gently from the plates, packedand stored in airtight packs for further analysis.

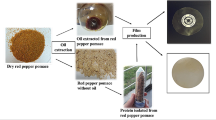

The digital images and codification of formulated films are presented in Fig. 1: (a) control film, (b) 15% BCP, (c) 25% BCP, (d) 35% BCP, and (e) 45% BCP extract film.

Physical characterization of edible films

Thickness

The mean thickness of the starch-based films was determined using a handheld micrometer (Mitutoyo—Absolute Digimatic, Japan) with a resolution of 0.001 mm. This was done by taking five separate measurements for from different areas of the film [22].

Moisture content (MC)

The technique outlined by [23] was used to test the moisture content of BCP films. 4 × 4 cm film samples were cut, then weighed (W0), and dried in a hot air oven (Acumen Scientific, Delhi) for 24 h at 105 ± 2 °C, weighing was continued until constant weight was achieved. The equation given below was used to calculate the moisture content and estimate the constant weight (W1):

Here, W0 represents the initial weight, and W1 is the film’s constant dry weight. The experiments were done in triplicates.

Water solubility

The estimation of water solubility (WS) was carried out in accordance with the method suggested byDudeja et al. [18]. Briefly, 20 mm × 20 mm uniformly sized films were weighed, submerged in 30 ml of distilled water in a glass beaker (50 ml), and incubated in a shaking incubator (Care Lab White Bod Incubator Cum Shaker, Delhi) for 24 h at 25ºC. The insoluble portions of the films that remained within the tubes were separated and further dehydrated for 24 h at 105 °C in a hot air oven, and then weighed. Thus, the solubility fraction was calculated using the following equation:

Where, % Wi is the commencing dry weight of the films, WS represents proportion of water solubility, while dry weight of the film’s insoluble section was given by Wf.

Water vapor transmission rate (WVTR)

The WVTR (Water Vapor Transmission Rate) was calculated using the desiccant method following the methodology described by Singh et al. [19]. Silica gel was used as a desiccant and was briefly inserted within the spoutless glass beaker (50 ml). Wax was employed to seal the generated edible films over the beaker’s mouth, and the final weight of the beaker was measured. Then, the beakers were stored for 24 h within a desiccator containing a saturated sodium chloride salt solution (75%) at the bottom (28 ± 0.1 °C) for 24 h. The beakers were subsequently weighed at periodic intervals of two hours of inactivity to conclude the water gain analysis. The weight slope from the gathered data was derived using a linear regression equation and WVTR of film was determine using the formula given below

Where Mv gave slope of beaker weight (g/h); A represents area of the sample film (cm²).

Swelling index

The swelling index (SI) was calculated using the methodology given by Kapil et al. [24], with a few minor adjustments. The films were divided into small pieces (2 cm x 2 cm), dried on aluminium petri plates at 105 ± 2 °C in a hot air oven (Acumen Scientific, Delhi) for 24 h, and weighed (W0). After complete drying, the films were submerged for an additional two-minute duration at 25 °C in 15 mL of distilled water.

Swelled samples had drops of liquid, and this excess water was wiped with filter paper and weighed (W1). The equation given above measures the final amount of water absorbed by the films. Where W1 represents the weight of the dried sample whereas W2 represents the weight of the wet sample.

Mechanical properties

A texture analyzer (Stable Micro Systems, Model: TA.TXT. Plus) was employed to measure the mechanical strength, examined by its elongation at break (Eb) and tensile strength (Ts). The films were cut into pieces measuring 5 × 5 cm and were subjected to a tension test with grip separation of around 50 mm and a cross-sectional speed of 5 m/s, with a strain value of 50%‘ [25]. Further evaluation of mechanical properties, namely Ts and Eb, was done using formulas.

In this, A is the area (m2) of the biofilm, and Fmax (MPa) is the maximum stress imposed for ripping of the edible pomace film.

Initial length of the edible biofilm is L0, and L gives length difference during stretch .

Morphology

FE-SEM (Joel, JSM-7610 F Plus, Japan) had been used to analyse the morphology of the produced film through its surface, with a working distance of 8 mm and a magnification range of 30,000 to 50,000. Gold coating was used on the respective samples to increase the conductivity of the films, and under 5 kV of accelerating voltage and 8 mA of current, the films were observed [26].

FTIR spectroscopy

To study the structural properties of the films, they were subjected to Fourier Transform Infrared spectroscopy (FTIR). The FTIR spectra of the prepared pomace edible films were acquired using a Cary Model 630 FTIR- Agilent, in the attenuated total reflectance mode, covering the wavelength region from 689 to 3559 cm-1 [24].

Thermogravimetric analyzer (TGA)

Thermal resistance studies of control and composite films were conducted and investigated using a thermogravimetric analyzer. In brief, a film sample (10–15 mg) was taken and heated continuously at a rate of 10 °C/min in a nitrogen-rich environment flowing at 30 mL/min, and the temperature range used was from 50 to 500 °C [23].

Differential scanning calorimetry (DSC)

Samples weighing 3.5 mg each were taken for analysis and were hermetically sealed in aluminum capsules to prevent mass loss during heating. The DSC model used was Mettler Toledo S.A.E., Barcelona, Spain. The heating rate and nitrogen flow rate were set at -50 to 250 °C (10 °C/min) and 10 mL/min, respectively [1].

Bioactive compounds and antioxidant activity

Total phenols content

The method given by Moghadam et al. [5] was followed for the estimation of total phenols. Briefly, 25 mg of each film was immersed in 10 ml of distilled water and subjected to continuous stirring for 2.5 h at room temperature (25 °C). After this, an aliquot of 0.5 ml was taken and mixed with 2 ml of Folin-Ciocalteaureagent. Subsequently, 2.5 ml of sodium carbonate solution (7.5% w/v) was added, and the mixture was stored in the dark at room temperature (25 °C) for 3 min. The absorbance at 760 nm was measured using a spectrophotometer. Gallic acid was used as a standard, and the results were obtained through the standard curve and expressed in terms of milligrams of gallic acid equivalent per gram weight of the film (mg GAE/g film).

Anthocyanins

The total anthocyanins were expressed as milligrams of cyanidin-3-glucoside equivalents per gram dry weight (mg CGE/g dw). The method employed for estimation was the pH differential method using two buffer systems: sodium acetate buffer (pH 4.5) at a concentration of 0.4 M and potassium chloride buffer at pH 1.0 (0.025 M) [27]. For analysis, a film sample of 0.5 ml was mixed with 3.6 ml of the respective corresponding buffers, with distilled water used as a blank, and absorbance was measured at 510 and 700 nm using a spectrophotometer [28].

Absorbance (A) was calculated as.

Total anthocyanin content of samples (mg cyanindin-3-glucoside/100 ml) was calculated by following equation:

Where A: absorbance:

MW: molecular weight (449.2); DF: dilution factor (10); MA: molecular absorptivity of cyanindin-3-glucoside (26,900).

Total flavanoids

The flavonoid content in the extracts was determined using a modified colorimetric method based on the procedure outlined by Barros et al. [29]. In this method, a 150 ml film extract was combined with a solution mixture comprising 1.25 mL of distilled water and 75 ml of a 5% sodium nitrite (NaNO2) solution. Subsequently, 150 ml of a 10% aluminum chloride (AlCl3) solution was introduced. After an interval of 3 min, 500 ml of 1 M sodium hydroxide (NaOH) and 275 ml of distilled water were added to the mixture. The solution was thoroughly mixed until a pink color developed, and the intensity was measured at a wavelength of 510 nm using a spectrophotometer. To establish a standard curve for quantification, catechin with concentrations ranging from 0.022 to 0.34 mM was utilized, and the standard curve equation was determined as Y = 0.9629X − 0.0002 with a correlation coefficient (R^2) of 0.9999. The results were then expressed as milligrams of (+)-catechin equivalents (CEs) per gram of extract.

Antioxidant activity

DPPHradical’s scavenging activity

A method developed by Barros et al. [29] was followed to assess the 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical scavenging activity. Two milliliters of various DPPH (0.15 mM) dilutions were added to one milliliter of the extract. One milliliter of methanol and 2 ml of DPPH were mixed to obtain a control sample. After blending the contents in the tubes and letting them stand for 30 min, absorbance at 517 nm was observed and recorded. Results were evaluated according to the equation below, and the data were represented as % radical scavenging activity:

Where: Asample= absorbance with the test compound whereas Acontrol gives the absorbance of the control reaction (contained all reagents except the test sample).

ABTS+ radical scavenging activity

The procedure of Brand-Williams [30] was followed to measure the ABTS + radical scavenging activity. Stock solutions of ABTS + were prepared by mixing 7 ml of ABTS + with potassium persulfate solution (2.45 ml) and incubating for 16 h at room temperature (25℃) in the dark. Then, for the working solution, 1 ml of the ABTS solution was mixed with 60 ml of ethanol and water (50:50, v/v), and absorbance was measured at 734 nm. Furthermore, 4.95 ml of the ABTS + solution was added to the extracts and allowed to react for one hour in the dark, and absorbance was measured at 734 nm. The equation given below was used to compute the percentage inhibition of ABTS + free radicals.

Ferric reducing power assay (FRAP)

FRAP (Ferric Reducing Antioxidant Power) was calculated based on the methodology of Mucha and Pawlak [31]. A film extract of 0.5 ml was taken and dissolved in phosphate buffer (0.2 M, pH 6.6) (0.5 ml) and potassium ferricyanide (1% w/v) (1.25 ml). The mixture was then incubated for 20 min at 50 °C. To this, 10% TCA (trichloroacetic acid) (1.25 ml v/v) was added, and the extract was centrifuged for 10 min at 4000 rpm. The supernatant was collected, and distilled water and 0.1% FeCl3 (w/v) were added to it. The absorbance of triplicate samples was recorded at 700 nm.

Color

Color characteristics were measured using the CIELAB color scale, with reference to L* (lightness/darkness), a* (red/green), and b* (yellow/blue). These characteristics were viewed and analyzed with the help of a handheld Minolta Chroma meter (Konica Minolta CR-400, Japan). The mean value of readings taken in triplicates was used for color evaluation, and the color difference (∆E*) was calculated using the following equation:

Opacity

The composite films were gently cut into square-shaped pieces (4 cm × 4 cm) and placed into a quartz spectrophotometer cell. An empty test cell was used as the reference sample. The equation given below was used to determine the transparency of the film, and absorbance was measured at 600 nm using a spectrophotometer [32].

where, O is the opacity, T stands for film thickness, while Abs600 represents the absorbance at 600 nm. The test analysis was done three times, and the mean value was provided.

Statistical analyses

WASP 2.0 was used to calculate the mean and standard deviations of the data. The information was presented as mean and standard deviation (n = 3). To compare these mean values, a one-way ANOVA was used, and the results were expressed at the 95% level of significance, using Tukey’s post hoc test. Graphs, where necessary, were plotted using Origin software.

Results and discussions

Thickness

The data presented in Table 1 show that the thickness of the control film was 0.22 mm, which increased significantly (p < 0.05) from 0.25 to 0.37 mm with increasing BCP extract levels from 15 to 45% (R = 0.885). This thickening may be attributed to certain conformational alterations in the hydrocolloid chains brought about by the inclusion of BCP in the extract. This might be due the alterations in the conformation of the polymeric chain with higher distribution of phytochemicals in the film as reported by Adilah et al. [33]in edible film using mango peel extract. Our results are consistent with those of Moghadam et al. [5], who showed that when pomegranate peel extract in higher concentrations was added to gelatin films, the thickness of the films increased progressively. Studies by Nouraddini et al. [8] also reported that the thickness of papaya edible coatings ranged from 0.13 to 0.32 mm, which is in agreement with the present study. Additionally, gelatinization of starch might have played a significant role in disturbing the orderly alignment of the starch matrix, resulting in obtaining highly viscous solutions and consequently thicker films. Our results are also supported by literature reports, such as those by Ribeiro et al. [34], indicating that the acceptable thickness of edible films produced in various research segments is usually less than 0.3 mm. Therefore, having films with low thickness values is imperative as packed food items can be ingested along with the edible films. Another reason for increased thickness can be justified by a study conducted by Merz et al. [35] on packaging film made from Jambolan (Syzygiumcumini) fruit anthocyanins, the reason for increased thickness was attributed to the electrostatic repulsion offered by the anthocyanins with the macromolecules (PVA, Chitosan) thereby altering film density.

Moisture content

Moisture content is crucial for enhancing the quality of packaging materials, as it plays a vital role in providing better flexibility and stretchability to films for various food applications [36]. The results of the present study indicated that, compared to the control, the addition of BCP extract significantly increased the moisture content (Table 1) (p < 0.05). This increase in moisture content (R = 0.972) was highly positively correlated with the concentration of the extract. It can be attributed to the presence of hydrophilic groups such as carbohydrates, minerals, and fiber within the pomace extract [37], which facilitated better interaction of film components with water molecules, consequently increasing the moisture content of the films. Wang et al. [38] in a study on chitosan film incorporating tea polyphenol concluded that the increased moisture content in packaging film is due to greater availability of hydroxyl groups in the matrix (starch, glycerol and anthocyanins).This increase in hydroxyl group evidently tend to increase interaction, thus resulted in the increased moisture content of fabricated films [1].

Water Solubility

Water solubility (WS) is a crucial factor that defines the integrity and water tolerance of packaging materials. The data for water solubility of composite films with varying levels of BCP extract, as presented in Table 1, showed that the control films exhibited a significant solubilizing property (61.54%), which, however, decreased significantly (p < 0.05) with increasing BCP extract content. This change in solubility may be attributed to the compositional structure of the control and BCP films. Control films, containing starch as the main ingredient, may have exhibited a hygroscopic nature, making them easily disintegrate in water [39]. In contrast, the incorporation of BCP extract affected the interaction and formed a complex matrix that allowed the interaction of hydrocolloids and polyphenols with water [40]. This can be further explained by the increased water-binding capacity of the polymer, associated with the greater hydrophilic nature of methylcellulose films at ambient temperature. The solubility data showed a significantly negative correlation with film thickness (R= -0.848) and moisture content (R= -0.953). A similar trend of decreased water solubility was reported in a study by Kurek et al. [7], who observed reduced water solubility of CMC films after substituting extracts of red grape skin and blueberry pomace into the polymer. In addition to this, similar trend in water solubility in anthocyanin packaging films was also reported by Zhang et al. [41] due to the cross linking and more significant molecular between starch and anthocyanin thereby reducing the hydrophilic and solubility of anthocyanin in formed film [42].

Water vapour transmission ratio

Water vapor transmission ratio (WVTR) is a critical parameter for assessing the water barrier properties of packaging materials. A low WVTR indicates better resistance to water, while a high WVTR implies poor water resistance. As depicted in Table 1, the control films exhibited the lowest WVTR (0.111 g/h.cm2), which increased (0.142 to 0.173 g/h.cm2) with an increase in extract concentration. At low pomace extract concentrations, there was a marginal increase in WVTR, which might be due to the presence of polyphenols and anthocyanins in the BCP extract. These compounds initially increased the tetramolecular and cross-linking interactions within the film matrix [43]. However, at higher extract concentrations, this interaction may have destabilized the corn starch, cellulose, and chitosan structure, leading to an increased WVTR. This increase in WVTR can be explained by a hypothesis proposed by Kamiloglu et al. [6], suggesting that the starch-cellulose matrix might have been disrupted by the previously existing cellulose, hemicellulose, mucilages, free sugars, and table soluble fibers present in the black carrot pomace cell wall. These components could have reduced the intramolecular forces of attraction within the polymer chain, allowing water permeation through the film. Findings by [44] also reported similar results with an increase in WVTR when adding pineapple peel extract into the PVOH-starch matrix. Furthermore, the presence of free hydroxyl groups in the extract at higher levels can result in increased WVTR due to interactions between film components (starch-cellulose). WVTR and free hydroxyl groups have a positive correlation with each other [45, 46]. In the present study, WVTR was highly positively correlated with moisture content (R = 0.993) and swelling index value (R = 0.922), while it showed a highly negative correlation with the water solubility (WS) of the films (R= -0.975).

Swelling index

The swelling index of edible films is indicative of their biodegradation, preservation of quality, and storage characteristics [11]. Our findings revealed that the control film had the lowest swelling index (24.26%), which increased (83.34–92.20%) as BCP extract levels increased in the film (Table 1). The addition of pomace extract and its constituent matrix, along with the polysaccharides used in the formulation, had an impact on the swelling index of the film, indicating a higher hydration capacity of the films—an essential quality for food packaging [47]. This increase in the greater absorption value of the edible film can be attributed to the ability of pomace in the extract to readily absorb water due to the presence of highly digestible fiber, which efficiently entrapped water compared to the control film without pomace extract. Additionally, starch granules tend to absorb water during gelatinization from the surrounding environment due to the presence of free hydroxyl groups [5]. Our results were in accordance with Chambi et al. [48], who observed that films made from low methoxy pectin (LMP) and jambolan juice showed a higher swelling index value. The swelling index of the film showed a highly positive correlation with moisture content (R = 0.962), WVTR (R = 0.922), and water solubility (WS) (R = 0.876) of the films.

Mechanical properties

The tensile strength (TS) and elongation at break (EAB) of composite films are essential for evaluating their strength and structural integrity. Tensile strength indicates the material’s strength when a force per unit area is applied to it. Table 2 presents the mechanical properties of the films.It is evident from the data presented in Table 2 that the tensile strength of composite films decreased significantly (p < 0.05) with the addition of BCP extract. This decrease might be due to the hindrance in binding caused by soluble fibers in pomace at higher concentrations [49]. The addition of pomace extract may have resulted in higher fiber inclusions, and these heterogeneous ingredients might not have shown compatibility with the film’s biopolymers. The FE-SEM images presented in Fig. 2 show that the incorporation of pomace extract at higher concentrations caused rough and uneven surfaces. Additionally, the addition of fibers may have hindered the binding of starch and HMC, causing the disruption of bonds. Gilfillan et al. [50] also stated that fibers can lead to increased agglomerations on the film surface, reducing the interactions within the film matrix.

The study by Crizel et al. [51] found that the incorporation of blueberry pomace extract in films decreased their mechanical properties compared to control films. The decrease in tensile strength with the increase in pomace extract concentration could be due to the compact and denser structure offered by the fiber in pomace. Its inclusion may have disrupted the intramolecular hydrogen bonding offered by the polyphenols in the extract with the corn starch, HMC, and glycerol, contributing to the decreased tensile strength of the composite extract films [52]. Similar results were reported by Jamroz et al. [53], who concluded that films formed from beetroot extract resulted in reduced tensile strength due to the interaction of fibers and polyphenol betacyanins that affected the film matrix by disrupting the formation of crosslinks through interactions within the structure.The addition of pomace extract to the corn starch film formulation had a significant effect on its elongation at break (Eb). The films exhibited a decrease in Eb compared to the control, which might be due to the hindrance in the starch-cellulose matrix caused by tiny particles of BCP in the extract. This ultimately resulted in films that were more fragile and brittle in nature.

Another possible reason for the decreased flexibility of the films could be the presence of natural sugars in the pomace extract (such as sucrose, glucose, and xylose). These sugars may have increased the crystallinity of the film by interacting with the film plasticizer glycerol, thus reducing its mechanical properties. A similar trend was reported by Sushmitha et al. [11], who reported a decrease in the elongation at break of corn starch films with the addition of mango pulp and pineapple pomace, along with a decrease in tensile strength.In the present study, it was also observed that as the tensile strength decreased, the elongation at break also decreased, showing a significant positive correlation (0.791) between them. Additionally, in the present study, Eb showed a highly negative correlation with parameters such as WVTR (R= -0.979), swelling index (R= -0.984), anthocyanin content (R= -0.992), and flavonoids (R= -0.953).

Film’s morphology

FE-SEM analysis was used to study the morphological and microstructural properties of the composite edible films. Figure 2a and e illustrate the morphological characteristics of BCP films by visualizing the top surface and cross-sectional area. The results demonstrate that the control film (Fig. 2a) had an organized surface structure, comparatively smoother and compact, without any micropores or fractures, as can be observed from the micrographs. This increase in roughness can be related to the thickening of polymeric films with inclusion of extract, the thickness and change in surface morphology in films may be attributed to certain conformational alterations in the hydrocolloid chains brought about by the inclusion of BCP in the extract. As previously reported by Adilah et al. [34] reported similar changes in conformation of hydrocolloid structure of films on addition of mango peel extract. The change in film microstructure can also be attributes to the water binding efficiency of the fibres present at higher BCP extract concentrations, fibres might have entrapped water compared to the control film without pomace extract. Additionally, starch granules might have tend to absorb water due to the presence of free higher hydroxyl groups and higher pomace concentration [5].

Moreover, all the films showed the presence of some agglomerations (depicted by small white bubbles and spots), which might be due to the precipitation of calcium ions in the polysaccharide system [54]. The corn starch films showed changes in morphology (surface turned from smooth to coarse) with the incorporation of the BCP extract (Fig. 2b and e). This may be due to the heterogeneous nature offered by the complex nature of pomace extract, which, when added to the film, caused uneven dispersion in the polymer, resulting in pores in the resultant matrix. On drying, the heterogeneous particles caused aggregation due to sedimentation [55]. Similar results were reported by a study carried out by Viana et al [56]. It was reported that control pectin films had neat and smooth surfaces compared to the ones made from mango peel and guava peel extracts, which had irregularities on the surface with roughness. Pomace extract may have increased the fiber inclusions, and as a result, these heterogeneous constituents may not have demonstrated compatibility with the biopolymers in the film.

According to the FE-SEM pictures in Fig. 2b and e, the integration of pomace extract at greater concentrations led to rough and uneven surfaces. Additionally, the addition of fibers may have hampered the binding of starch and HMC, breaking bonds.The film’s structural deformity can also be related to their mechanical strength which tend to have decrease significantly (p < 0.05) with the addition of BCP extract. This decrease might be due to the hindrance in binding caused by soluble fibers in pomace at higher concentrations [50]. The addition of pomace extract may have resulted in higher fiber inclusions, and these heterogeneous ingredients might not have shown compatibility with the film’s biopolymers thereby decreasing film’s tensile strength. Shams et al. [57] also reported roughness in the films, which was attributed to the hydrophobic portions of the orange peels extract that interacted with those of the polymer matrix, thus resulting in destroying the other interactions in the system due to the roughness in the cross-section of the films. Xiao et al. [58] in their study also concluded that adding fruit extract (Berberis crataegina) to chitosan films tended to generate aggregation of solids in the film compared to that of the control.

FTIR

An infrared spectroscopy study was carried out to gather evidence regarding the interactions within the networking molecules of phenolic compounds, starch, HMC, and chitosan, which have been inferred from the mechanical behavior (Fig. 3). With the incorporation of BCP extract, the FTIR spectra did not show distinctive polyphenol bands in the control film. Broad overlapping peaks at 842.37 and 849.833 cm-1 indicated the presence of corn starch, attributing to the vibration of glucose pyranose and C–O vibrations stretching of glucose units, respectively [59]. Similar peaks for hydrocolloids in film forming matrix i.e., corn starch, Hydroxy methyl cellulose were previously reported by Chhoden et al. [60], in their study on bifunctional edible films from red carrot pomace.The peaks exhibited at 1019.42, 1025.01, and 1036.19 cm-1 indicated the presence of aromatic ring vibration and = C-O-C group of flavonoids [61] in the BCP extract. The presence of flavonoids can be attributed to the significantly highly positive correlation between the extract and flavonoids in the film (R = 0.972). There was a deformation of polyphenols in the O-H plane at the band 1371.66, 1373.524, and 1455.52 cm-1 [62]. Flavaro et al. [63], reported similar polyphenolic peaks (138,110 and,1387.27 cm-1) in anthocyanin extract from Jussara fruit. This deformation may be due to the gelatinized corn starch and HMC in the film [19]. Further, the peaks at 1455.55 cm-1 indicated vibration in the ester group stretching. In the present study, a stretch at a peak of 1400–1500 cm-1 was also reported, which could be attributed to vibrations of C-C stretching, confirming the presence of polyphenols in the film absorbed at this region. Singh et al. [19] confirmed similar peaks at 1455.28–1496.11 cm-1 in corn starch films incorporated with blueberry pomace. The films with BCP showed distinct band absorptions at wavenumbers 2922.23 and 2927.83 cm-1, which were due to the vibrations of C-H and C-C bands, further confirming the presence of anthocyanins [8] The anthocyanins were significantly positively correlated with the flavonoids in the film (R = 0.866). The broad bands at 3322.92 and 3335.95 cm-1 were assigned to stretching of O-H groups of phenols and sugars present in the extract and carbohydrate components of the film. The enhanced phytochemical activity with respect to the addition of extract, such as flavonoids, anthocyanins, and polyphenols as shown in Table 3, also confirms the presence of elevated peaks at increased concentration of extract., A similar trend of FTIR spectra of anthocyanins films at 3000.29, 3211.01, and 3344.09 cm-1 was reported by Prietto et al. [63] for edible films from anthocyanin extract of red cabbage and black bean.

Phytochemical properties

Black carrot pomace is a significant source of anthocyanins; two are non-acylated and three are acylated. All of the anthocyanins are cyanidin-based and have various sugar moieties [6]. Films fortified with natural antioxidants are believed to enhance the nutritional value and visual appeal of food [64]. The anthocyanin structure in BCP extract film can exhibit different levels of interaction in the food system attributed to these groupings. No anthocyanins were identified in the control film; however, anthocyanins were observed to increase significantly (p < 0.05) (R = 0.904) with increased pomace concentration. Studies by Nogueira et al. [65] also showed a similar trend in anthocyanin content in arrowroot starch films made from grape pomace extract. Total flavonoid (R = 0.970) and total phenol (R = 0.933) content of the films also increased significantly (p < 0.05) as the level of BCP extract increased. The presence of peaks at wavelengths 3000.29–3344.09 cm-1, 1019.42–1036.19 cm-1, and 1400–1500 cm-1 in the FTIR spectra (Fig. 3) further confirms the presence of anthocyanins, flavonoids, and total phenols, respectively. Films containing extract showed common levels of similarities and generated a highly positive correlation with the increased extract concentration and within the phytochemical variables (Table 4).

Antioxidants play a vital role in inhibiting free radicals. Therefore, the films were tested for their antioxidant capabilities using the DPPH, ABTS, and Fe3 + reducing power assays (Table 3). The results showed that as the level of BCP extract increased, the antioxidant activity in terms of DPPH scavenging activity, ABTS, and Fe3 + reducing power assay also increased, while the control film exhibited the lowest antioxidant activity. Our findings demonstrated that the activity of DPPH scavenging was noticeable even in control films, although the impact of concentration was more pronounced (p < 0.05) when the pomace concentration was raised. This increase can possibly be linked to films with increased TPC content that have undergone polyphenolic enrichment.

The antioxidant values for ABTS+ (0.989), DPPH (0.853), and FRAP (0.919) were highly positively correlated with each other. The enhanced phytochemical activity with respect to the addition of extract might be a result of the high concentration of physiologically active substances in BCP, such as flavonoids, anthocyanins, and polyphenols [66]. A study by Adilah et al. [34] also revealed that adding jackfruit, papaya, and pomegranate peel significantly raised the flavonoids and DPPH activity of the prepared films because these biologically active chemicals allowed the films to receive more electrons or hydrogen atoms. A highly significant positive correlation of antioxidant activity with anthocyanins (R = 0.949), flavonoids (R = 0.976), and total phenols (R = 0.960) was found in the respective variables.

Color characteristics

The color characteristics of a packaging material are an important factor in consumer acceptability when purchasing a product. In the present study, it was observed that the incorporation of BCP extract significantly influenced the color characteristics of the film. The control film showed the highest lightness (L) and yellowness (b*) values, which decreased significantly (p < 0.05) as the level of BCP extract increased in the films (Table 5). The yellowness of the film was apparently due to the polymer matrix of corn starch and HMC, and this value showed a decreasing trend with a higher concentration of anthocyanin extract, depicting a significantly highly negative correlation between the L values and anthocyanins (R= -0.965). This result was confirmed by Wang et al. [67], who also reported a decrease in L value in k-carrageenan and corn starch films upon the addition of anthocyanin-rich onion peel extract. The onion peel extract contains the highest proportion of anthocyanins in its respective epidermal cells. Similarly, these anthocyanins must have greatly interacted with the hydrocolloids in the film and thus got oxidized by PPO, resulting in a reduced lightness value of the films [68]. The reduction in the L value correspondingly reduced the opacity of the film (-0.936), which can be a drawback at the consumer acceptancy level, as transparent packaging is highly demanded. However, on the contrary, this darkness of the film can protect against oxidative deterioration, thus preserving the nutrient quality [69].In contrast, the redness (a*) value of the films increased significantly as the level of BCP extract progressed in the films, depicting a significant positive correlation between anthocyanins and the a* value of the films (R = 0.889). This reduction in lightness and increase in redness value of the films was due to the presence of anthocyanin-derived pigments and polyphenols contained in the BCP extract, which impart a red color to the films and thus reduce their lightness. Our results were in accordance with Liu et al. [70], who reported a similar trend of decreasing L and b* values after incorporating mulberry polyphenolic extract into k-carrageenan edible films, as well asQin et al. [71], who observed similar increases in L* and b* values and decreases in a* and ∆E values upon substituting anthocyanins from Lyciumruthenicum Murr in cassava starch films.

Opacity

The inclusion of BCP extract resulted in high absorption of composite films below 300 nm, indicating that extract-containing films were able to block UV light and preventing deterioration of packed food. The UV light barrier properties provided by corn starch films made with BCP extract were greater than those observed for control films without BCP extract (Table 5). The opacity values were significantly positively influenced by parameters like thickness (R = 0.735), extract level (R = 0.904), and anthocyanins (R = 0.902), as well as lightness (Table 4). Luchese et al. [72] also reported that adding blueberry pomace negatively affected the transparency of films, as the pomace also contained traces of aromatic compounds implicated in the absorption at same wavelength. Additionally, anthocyanin-derived pigments may have contributed to the decreased transparency of the films [31, 71].

Thermal properties

Figure 4a represents the DSC of the composite films. DSC peaks were examined for temperature and enthalpy measurements. Control films (corn starch and cellulose) showed an intermediate peak at a temperature of 61 °C, while for the films made with black carrot pomace extract, this peak shifted higher, at up to 70 °C. The initial mass used for the samples was 6.2 mg for the control sample and 10.5 mg for the BCP extract film, this initial mass determines the amount of energy required to disintegrate the sample structure, which evidently was higher for BCP films compared to the control. This initial change is attributed to the loss of water from the films. BCP extract films had a significantly positive moisture content (R = 0.972) with a negatively correlated water solubility (R = 0.969), and therefore, more energy was required for dissociation.This increased moisture content was associated with the fiber content in extract films. Previous research claims a relationship between fiber content and enhanced thermal stability in films. According to a study conducted by Lu et al. [73], films incorporated with microfibril cellulose in PVA films had better thermal stability due to higher fiber content. Fiber might have built a denser structure that also might have led to higher associations with alterations in interand intramolecular interactions of polyphenols with the biopolymeric film matrix, causing changes in enthalpy values [74]. Gutierrez et al. [75] concluded that composite films made with natural fillers using pomace and starch claimed to have better structural and thermal properties. A similar trend was observed by Luchese et al. [73] when substances high in polyphenols and anthocyanins were added to film-forming solutions for cassava starch films containing blueberry pomace. There was a change in enthalpy values from a peak temperature of 80 ℃ for cassava starch without blueberry pomace to 90℃ for those with blueberry pomace, respectively. Also, Moghadam et al. [5] reported a similar trend in DSC peaks for pomegranate peel and mung bean protein edible films, which had higher thermal stability to thermal degradation due to increased associations between fibers, protein, and film-forming solutions.

The outcomes of the thermal breakdown behavior of composite films, including control film and BCP extract, are represented in Fig. 4c. The films showed high stability to weight loss above 200 °C. Both control and BCP extract films exhibited an initial weight loss at 230 °C. However, it was observed that improved thermal stability was obtained in films formed from BCP extract (35%). BCP’s high thermal stability may be caused by an increase in dissociation energy as a result of multiple interactions between the components of the polymer blend and the phytochemical and anthocyanin makeup of the extract [8]. The increased enthalpy values can be correlated with the increased thickness value of the biopolymeric films from the extract compared to the control film. Higher thermal stability can be attributed to the interaction of anthocyanins with hydrocolloids (starch, HMC) through hydrogen bonds formed between polysaccharides and anthocyanins, resulting in decreased mobility at higher viscosity and stable thermal properties in the films [76]. Similar results were reported by Gutierrez et al. [76], who confirmed that films formulated from ethanolic grape extract and arrowroot starch exhibited better structural and thermal resistance due to active participation of grape polyphenols with the hydrocolloid matrix compared to the control film (without grape extract). Kaya et al. [77] reported higher thermal resistance in chitosan films after incorporating P. terebinthus seed extract (rich in phenols) due to decreased crystallinity of the film.

Conclusion

Edible films and coatings formulations based on biopolymers and active compounds extracted from biowastes offer great opportunities to decrease the devastating overuse of plastic-based packaging.In addition, the increasing amount of food by-products poses a socioeconomic and environmental challenge. In order to attain sustainability and economic circularity, food loss and waste must be reduced by half and converted into value products. One way to reduce the usage of persistent plastics is to develop new packaging materials, such as edible ones. Because of the bioactivities of its constituents, edible films and coatings based on byproducts may also improve the performance of food packaging.The potential of using black carrot pomace to create biodegradable edible films was investigated.The films formed with BCP extract were compared to control films made from corn starch, HMC, and chitosan. It was found that films enriched with BCP extract tended to have better physical, mechanical, and thermal properties. Additionally, BCP has a high phytochemical constitution, so the films not only exhibited good barrier properties but also retained antioxidant properties. FTIR analysis revealed that the films had a smoother and more compact surface at lower pomace extract concentrations. TGA and DSC analysis were conducted to study the thermal properties of the films, which showed that films with BCP extract exhibited better resistance to degradation at higher temperatures. Producing such composite edible films can be an innovative approach to utilizing pomace that would otherwise be discarded and could have environmental implications. In previous researches edible films have been used to improve the gas and moisture barriers and to protect the product from damage including mechanical, chemical, and microbiological contamination. They can also improve sensory experiences and prolong the shelf life of goods, particularly perishables like dairy, shellfish, and baked goods. Additional functionalities may result from their combination with bioactive substances such vitamins, minerals, and polyphenols. These edible packaging also has the advantage of being environmentally friendly because it is made of renewable resources. Food items don’t need to be unpacked and thrown away before consumption. Biodegradable materials are notnecessarily edible and therefore, only food-grade ingredients are used to create edible packaging, meaning that plasticizers and any additional additions for the film-forming matrix and solvent must be widely acknowledged as safe as per suggested by USDA.

Further research is needed to explore waste utilization in effective packaging and to conduct larger-scale studies to investigate potential applications in the food packaging sector. The implementation of this study in tropical regions could benefit farmers and small to medium-sized businesses, potentially leading to increased revenue in the social sector.

Data availability

The data are available from the first (TC) and the corresponding (AS) authors upon reasonable request.

References

A. Singh, Y. Gu, S.D. Castellarin, D.D. Kitts, A.P. Singh, Foods. 9, 11 (2020). https://doi.org/10.3390/foods9111599

P. Singh, G. Kaur, A. Singh, T. Sharma, B.N. Dar, Mater. Chem. Phys. 308, 128267 (2023). https://doi.org/10.1016/j.matchemphys.2023.128267

S. Vahedi, A.M. Nafchi, A. Dara, Adv. Appl. Sci. 7, 52–58 (2022). https://doi.org/10.11648/j.aas.20220703.13

S. Paidari, N. Zamindar, R. Tahergorabi, M. Kargar, S. Ezzati, N. Shirani, S.H. Musavi, J. Food Meas. Charact. 15, 4205–4214 (2021). https://doi.org/10.1007/s11694-021-00979-7

M. Moghadam, M. Salami, M. Mohammadian, M. Khodadadi, Z.E. Djomeh, Food Hydrocoll. 104, 105735 (2020). https://doi.org/10.1016/j.foodhyd.2020.105735

S. Kamiloglu, J.V. Camp, E. Capanoglu, Phytochem Rev. 17, 379–395 (2018). https://doi.org/10.1007/s11101-017-9539-8

M. Kurek, L. Hlupić, I.E. Garofulić, E. Descours, M. Ščetar, Food Packag Shelf Life. 20, 100315 (2019). https://doi.org/10.1016/j.fpsl.2019.100315

M.E. Nouraddini, M. Smaiili, F. Mohtaram, Int. J. Biol. Macromol. 120, 639–1645 (2018). https://doi.org/10.1016/j.ijbiomac.2018.09.126

P. NKaur, S. Aggarwal, B. Kaur, Convers, 1–11. (2023) https://doi.org/10.1007/s13399-023-04511-3

M. Tavlasoglu, G. Ozkan, E. Capanoglu, ACS omega, 7, 32481-488. (2022). https://doi.org/10.1021/acsomega.2c03962

A. Susmitha, K. Sasikumar, D. Rajan, A.M. Padmakumar, K.M. Nampoothiri, Food Biosci. 41, 100977 (2021). https://doi.org/10.1016/j.fbio.2021.100977

H.K. Sharma, N. Kumar, Food Processing By-Products and their Utilization, 207–229 (2017). https://doi.org/10.1002/9781118432921.ch10

G. Kaur, N. Sharma, A. Singh, S. Kapoor, S.K. Khatkar, Int. J. Food Sci. Technol. 58, 2744–2753 (2023). https://doi.org/10.1111/ijfs.16102

N. Kaur, P. Aggarwal, S. Kaur, Biomass Conver Biorefin. 1–11 (2023). https://doi.org/10.1007/s13399-023-04511-3

P. Aggarwal, A.S. Brar, S. Kaur, N. Kaur, T.S. Dhillon, Agric. Res. J., 9, (2023)

J.P. Singh, A. Kaur, N. Singh, J. Food Sci. Technol. 53, 1269–1278 (2016). https://doi.org/10.1007/s13197-015-2103-x

C. Wu, Y. Zhu, T. Wu, L. Wang, Y. Yuan, J. Chen, Y. Hu, J. Pang, Food Chem. 288, 139–145 (2019). https://doi.org/10.1016/j.foodchem.2019.03.010

I. Dudeja, R.K. Mankoo, A. Singh, J. Food Meas. Charact. 1–15 (2023). https://doi.org/10.1111/ijfs.16105

P. Singh, G. Kaur, A. Singh, B.N. Dar, Food Chem. Adv. 100343 (2023). https://doi.org/10.1016/j.matchemphys.2023.128267

T. Sharma, G. Kaur, A. Singh, P. Singh, J. Food Meas. Charact. 17, 5550–5568 (2023). https://doi.org/10.1007/s11694-023-02062-9

P. Alzate, S. Miramont, S. Flores, L.N. Gerschenson, Starch-Stärke. 69, 5–6 (2017). https://doi.org/10.1002/star.201600261

S.K. Sucheta, K. Rai, S.K. Chaturvedi, Yadav, Food Hydrocoll. 91, 127–135 (2019). https://doi.org/10.1016/j.foodhyd.2019.01.022

A. Susmitha, K. Sasikumar, D. Rajan, A.M. Padmakumar, K.M. Nampoothiri, Food Biosci. 41, 100977 (2021). https://doi.org/10.1016/j.fbio.2021.100977

S. Kapil, R.K. Mankoo, I. Dudeja, A. Singh, J. Kaur, Int. J. Food Sci. Technol. (2023). https://doi.org/10.1111/ijfs.16118. 58,2772-81

J.F. Mendes, J.T. Martins, A. Manrich, A.S. Neto, A.C.M. Pinheiro, L.H.C. Mattoso, M.A. Martins, Carbohydr. Polym. 210, 92–99 (2019). https://doi.org/10.1016/j.carbpol.2019.01.058

I. Dudeja, R.K. Mankoo, A. Singh, J. Kaur, Sustain. Chem. Pharm. 36, 101307 (2023). https://doi.org/10.1016/j.scp.2023.101307

J. Lako, V.C. Trenerry, M. Wahlqvist, N. Wattanapenpaiboon, S. Sotheeswaran, R. Premier, Food Chem. 101, 1727–1741 (2007). https://doi.org/10.1016/j.foodchem.2006.01.031

M. Çam, Y. Hışıl, G. Durmaz, Food chem, 112, 721 – 26. (2009)https://doi.org/10.1016/j.foodchem.2008.06.009

L. Barros, P. Baptista, I.C.F.R. Ferreira, Food Chem. Toxicol. 45, 1731–1737 (2007). https://doi.org/10.1016/j.fct.2007.03.006

W. Brand-Williams, M.E. Cuvelier, C. Berset, (1995) Use of a Free Radical Method to Evaluate Antioxidant Activity 29,25–30 (1995). https://doi.org/10.1016/S0023-6438(95)80008-5

M. Mucha, A. Pawlak, Thermochim Acta. 427, 69–76 (2005). https://doi.org/10.1016/j.tca.2004.08.014

P. Singh, G. Kaur, A. Singh, P. Kaur, J. Food Meas. Charact. 17, 527–545 (2022). https://doi.org/10.1007/s11694-022-01635-4

A.N. Adilah, B. Jamilah, M.A. Noranizan, Z.A.N. Hanani, Food Packag Shelf Life. 16, 1–7 (2018). https://doi.org/10.1016/j.fpsl.2018.01.006

A.M. Ribeiro, B. Estevinho, N.F. Rocha, Food Bioprocess. Technol. 14, 209–231 (2021). https://doi.org/10.1007/s11947-020-02528-4

B. Merz, C. Capello, G.C. Leandro, D.E. Moritz, A.R. Monteiro, G.A. Valencia, Int. J. Biol. Macromol. 153, 625–632 (2020). https://doi.org/10.1016/j.ijbiomac.2020.03.048

N. Suderman, M.I.N. Isa, N.M. Sarbon, Food Biosci. 24, 111–1190 (2018). https://doi.org/10.1016/j.fbio.2018.06.006

M.I. Luca, M. Ungureanu-Iuga, S. Mironeasa, Appl. Sci. 12, 7989 (2022). https://doi.org/10.3390/app12167989

L. Wang, Y. Dong, H. Men, J. Tong, J. Zhou, Food Hydrocoll. 32, 35–41 (2013). https://doi.org/10.1016/j.foodhyd.2012.11.034

M.S. Pacheco, D. Barbieri, C.F. da Silva, M.A. de Moraes, Int. J. Biol. Macromol. 178, 504–513 (2021). https://doi.org/10.1016/j.ijbiomac.2021.02.180

E. Matta, M.J. Tavera-Quiroz, N. Bertola, Int. J. Biol. Macromol. 124, 292–1298 (2019). https://doi.org/10.1016/j.ijbiomac.2018.12.114

J. Zhang, X. Zou, X. Zhai, X. Huang, C. Jiang, M. Holmes, Food Chem. 272, 306–312 (2019). https://doi.org/10.1016/j.foodchem.2018.08.041

N. Gürler, Polym. Eng. Sci. 63, 426–440 (2023). https://doi.org/10.1002/pen.26217

K. Stanicka, R. Dobrucka, M. Woźniak, A. Sip, J. Majka, W. Kozak, I. Ratajczak, Polymers. 13, 3888 (2021). https://doi.org/10.3390/polym13223888

P. Kumar, R. Tanwar, V. Gupta, A. Upadhyay, A. Kumar, K.K. Gaikwad, Int. J. Biol. Macromol. 187, 223–231 (2021). https://doi.org/10.1016/j.ijbiomac.2021.07.136

A.S. Abreu, M. Oliveira, A. de Sá, R.M. Rodrigues, M.A. Cerqueira, A.A. Vicente, A.V. Machado, Carbohydr. Polym. 129, 127–134 (2015). https://doi.org/10.1016/j.carbpol.2015.04.021

H.Y. Park, S.J. Kim, K.M. Kim, Y.S. You, S.Y. Kim, J. Han, (2012). J. Food Sci. 77, 273–279 (2012). https://doi.org/10.1111/j.1750-3841.2012.02906.x

T. Nisar, Z.C. Wang, X. Yang, Y. Tian, M. Iqbal, Y. Guo, Int. J. Biol. Macromol. 106, 670–680 (2018). https://doi.org/10.1016/j.ijbiomac.2017.08.068

H.N.M. Chambi, B.S. da Costa, W.S. de Lima, D.C. Kassardjian, Afr. J. Food Sci. 14, 53–62 (2020). https://doi.org/10.5897/AJFS2020.1916

H. Aloui, K. Baraket, R. Sendon, A.S. Silva, K. Khwaldia, Int. J. Biol. Macromol. 139, 128–138 (2019). https://doi.org/10.1016/j.ijbiomac.2019.07.156

W.N. Gilfillan, D.M. Nguyen, P.A. Sopade, W.O. Doherty, Ind. Crops Prod. 40, 45–54 (2012). https://doi.org/10.1016/j.indcrop.2012.02.036

T.M. Crizel, T.M.H. Costa, A.O. Rios, S.H. Flôres, Ind. Crops Prod. 87, 218–228 (2016). https://doi.org/10.1016/j.indcrop.2016.04.039

Y. Qin, D. Yun, F. Xu, C. Li, D. Chen, J. Liu, Food Packag Shelf Life. 29, 100693 (2021). https://doi.org/10.1016/j.fpsl.2021.100693

E. Jamróz, P. Kulawik, P. Guzik, I. Duda, Food Hydrocoll. 97, 105211 (2019). https://doi.org/10.1016/j.foodhyd.2019.105211

Y. Xin, M.W. Bligh, A.S. Kinsela, Y. Wang, T.D. Waite, J. Membr. Sci. 475, 395–405 (2015). https://doi.org/10.1016/j.memsci.2014.10.033

J.F. Mendes, J.T. Martins, A. Manrich, A.S. Neto, A.C.M. Pinheiro, L.H.C. Mattoso, M.A. Martins, Carbohydr. Polym. 210, 92–99 (2019). https://doi.org/10.1016/j.carbpol.2019.01.058

R.M. Viana, N.M. Sa, M.O. Barros, M.D.F. Borges, H.M. Azeredo, Carbohydr. Polym. 196, 27–32. https://doi.org/10.1016/j.carbpol.2018.05.017

B. Shams, N.G. Ebrahimi, F Adv. Polym. Technol. 1973184 (2019). https://doi.org/10.1155/2019/1973184

R. Xiao, W. Yang, X. Cong, K. Dong, J. Xu, D. Wang, X Yang Energy. 201, 117537 (2019). https://doi.org/10.1016/j.energy.2020.117537

M.I.J. Ibrahim, S.M. Sapuan, E.S. Zainudin, M.Y.M. Zuhri, Int. J. Food Prop. 22, 925–941 (2019). https://doi.org/10.1080/10942912.2019.1618324

T. Chhoden, P. Aggarwal, A. Singh, S. Kaur, S. Grover, Biomass Convers. Biorefin. (2024). https://doi.org/10.1007/s13399-024-05339-1

F. Luzi, E. Pannucci, L. Santi, J.M. Kenny, L. Torre, R. Bernini, D. Puglia, Polym. 11, 1999 (2019). https://doi.org/10.3390/polym11121999

L.I. Favaro, V.M. Balcão, L.K. Rocha, E.C. Silva, J.J.M. Oliveira, M.M. Vila, M. Tubino, J. Braz Chem. Soc. 29, 2072–2088 (2018). https://doi.org/10.21577/0103-5053.20180082

L. Prietto, T.C. Mirapalhete, V.Z. Pinto, J.F. Hoffmann, N.L. Vanier, L.T. Lim, Z. E Da Rosa Lwt. 80, 492–500 (2017). https://doi.org/10.1016/j.lwt.2017.03.006

T.L. Ersedo, T.A. Teka, S.F. Forsida, E. Dessalegan, J.A. Adebo, M. Tamiru, T. Astatkie, Int. J. Food Prop. 26, 928–955 (2023). https://doi.org/10.1080/10942912.2023.2194576

G.F. Nogueira, I.H.B.T. Soares, C.T. Soares, F.M. Fakhouri, R.A. de Oliveira, Polysaccharides. 3, 250–263 (2022). https://doi.org/10.3390/polysaccharides3010014

K.W. Kulesza, A. Oniszczuk, T. Oniszczuk, M. Combrzyński, D. Nowakowska, A. Matwijczuk, Nutrients12, 5 (2020) https://doi.org/10.3390/nu12051401

C. Wang, Y. Lu, Z. Li, X. An, Z. Gao, S. Tian, Polym. 14, 2986 (2022). https://doi.org/10.3390/polym14152986

C.M.G.C. Renard, A.A. Watrelot, C. Le Bourvellec, Trends in Food Sci Technol 60, 43–51 (2017) (2015). https://doi.org/10.1016/j.tifs.2016.10.022

J.F. Rubilar, R.M. Cruz, H.D. Silva, A.A. Vicente, I. Khmelinskii, M.A. Vieira, J. Food Eng. 115, 466–474 (2013). https://doi.org/10.1016/j.jfoodeng.2012.07.009

Y. Liu, Y. Qin, R. Bai, X. Zhang, L. Yuan, J. Liu, Int. J. Biol. Macromol. 134, 993–1001 (2019). https://doi.org/10.1016/j.ijbiomac.2019.05.175

Y. Qin, D. Yun, F. Xu, C. Li, D. Chen, J. Liu, Food Packag Shelf Life. 29, 100693 (2021). https://doi.org/10.1016/j.fpsl.2021.100693

C.L. Luchese, T. Garrido, J.C. Spada, I.C. Tessaro, K.L. Caba, Int. J. Biol. Macromol. 106, 834–839 (2018). https://doi.org/10.1016/j.ijbiomac.2017.08.083

T. Lu, L.T. Wang, Drzal, Appl. Sci. Manuf. 39, 738–746 (2008). https://doi.org/10.1016/j.compositesa.2008.02.003

T. Nisar, Z.C. Wang, X. Yang, Y. Tian, M. Iqbal, Y. Guo, Int. J. Biol. Macromol. 106, 670–680 (2018). https://doi.org/10.1016/j.ijbiomac.2017.08.068

T.J. Gutiérrez, C.H. Julien, K. Álvarez, V.A. Alvarez, Carbohydr. Polym. 184, 135–143. https://doi.org/10.1016/j.carbpol.2017.12.039

S. Oancea, Antioxidants. 10, 1337 (2021). https://doi.org/10.3390/antiox10091337

M. Kaya, S. Khadem, Y.S. Cakmak, M. Mujtaba, S. Ilk, L.A. Kyuz, E. Deligöz, RSC Adv. 8, 3941–3950 (2018). https://doi.org/10.1039/C7RA12070B

Acknowledgements

The authors are grateful to the Punjab Agricultural University (PAU), Ludhiana for providing the necessary infrastructure and resources for conducting the research work.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Each author participated sufficiently in the work. Tenzin Chhoden: Investigation, formal analysis, methodology, validation, visualization, writing—original draft, writing—review and editing. Poonam Aggarwal: Project administration, supervision. Arashdeep Singh: Conceptualization, visualization, resources, writing—review and editing, project administration, supervision. Sukhpreet Kaur: Project administration, supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable in this section.

Consent for publication

All authors read and approved the final manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chhoden, T., Aggarwal, P., Singh, A. et al. Valorization of black carrot pomace for the development of anthocyanin rich bio functional edible films: implications on structural, morphological and thermal properties for a sustainable approach. Food Measure 18, 5489–5506 (2024). https://doi.org/10.1007/s11694-024-02582-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02582-y