Abstract

Biodiesel production from microalgae is considered a sustainable alternative to fossil fuel sources. The economic feasibility of algae-based biodiesel is highly related to biomass, lipid and FAME yield of the species. Thus, optimization of the culture conditions plays an important role in biodiesel production. The aim of this study is to compare lipid and FAME yield and biodiesel quality of two green algae species, Chlorella vulgaris, and Botryococcus sudeticus, under nitrogen deficiency conditions. For this purpose, algae species were cultured under optimum conditions until the stationary phase, then in the second phase the effect of nitrogen stress on total lipid, FAME content, and biodiesel quality were assessed. Although nitrogen-deficiency had negative impact on the growth and survival of both species, complete nitrogen removal from the medium stimulated the total lipid and FAME yield and the level of enhancement varied among species. FAME yield increased by 21% in B. sudeticus and 28% in C. vulgaris cultures under nitrogen deficiency conditions. The biodiesel properties of both cultures met European standards, on the other hand the absence of nitrogen did not reveal a significant effect on the cetane number values of C. vulgaris. However, it caused a reduction in B. sudeticus cultures. Nitrogen deficiency had a negative impact on the oxidative stability of B. sudeticus, reducing its ability to resist oxidation. However, it enhanced the oxidative stability of C. vulgaris in long-term storage. The results highlighted the importance of species-specific approaches to maximize both lipid content and biodiesel quality.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This paper considers the implications of two different microalgae species to produce high-quality biodiesel and assesses the significance of nutrient deficiency conditions to create stress on organisms to produce higher biodiesel yields. Furthermore, the study represents one of the first investigations on the potential of B. sudeticus as an alternative feedstock in biodiesel production under nitrogen-manipulated conditions. Overall, this investigation makes an important contribution to biodiesel production and quality and provides practical information on culturing conditions for enhanced biodiesel yield.

Introduction

The use of fossil sources, such as oil, natural gas, and coal is known to have a negative effect on the environment by increasing greenhouse gas emissions [1]. The demand for sustainable energy resources has increased due to not only the damage caused by fossil resources to the environment, but also their limited availability. Thus, biodiesel is considered one of the important alternative fuel sources that is renewable, nontoxic, non-flammable, and eco-friendly [2, 3]

Biodiesel production from microalgae has been highlighted as a promising approach compared to other resources such as vegetable oils and recycled greases [4,5,6]. Microalgae has a greater biomass growth rate than that terrestrial crops as well as they do not compete with crops for land and water in cultivation which are significant advantages over terrestrial crops [3, 7]. Microalgae have the potential to produce a wide range of high-value bioactive compounds, along with their rapid growth rates, high lipid productivity, and the ability to efficiently manage CO2 capture through photosynthesis [8]. Therefore, it further increases its attractiveness as a sustainable feedstock for biodiesel production.

Although algae-based biodiesel production provides advantages over crude oil, one of the main drawbacks is the production costs that conflict with the marketing of biodiesel [9, 10]. The economic feasibility of algae-based biodiesel depends on high biomass yields and lipid productivity, as well as improved biodiesel properties [4, 11]. Therefore, process optimization is necessary to increase lipid content and reduce the environmental impacts and costs of the overall process. Achieving a balance between maximizing lipid yield and maintaining desired biodiesel properties can significantly reduce the cost of producing microalgal biodiesel [12]. This may involve optimizing the duration and intensity of nutrient stress to achieve the desired fatty acid profile.

Nitrogen deficiency is a well-known strategy for increasing lipid accumulation in microalgae [13, 14]. Optimizing nutrient-stressed conditions to obtain high biomass as well as lipid yield has been taken into consideration by many researchers [10, 15, 16]. Nitrogen deficiency leads to more lipid accumulation compared to other stress conditions, since nitrogen is related to lipid metabolism in algae [16,17,18] Diacylglycerol Acyltransferase (Acyl CoA) is a key enzyme involved in triglyceride synthesis [19], and in nitrogen-stressed conditions, stimulation of Acyl CoA has been observed in which the overstimulation leads to the accumulation of lipids [20]. Furthermore, nitrogen stress conditions reveal differences in total lipid and fatty acid compositions [17, 23]. The effect of nitrogen stress on the Fatty Acid Methyl Ester (FAME) composition, which is the basis for determining biodiesel properties, may vary depending on the species [10]. Biodiesel properties are assessed based on the overall composition of Fatty Acid Methyl Esters (FAME), which includes saturated fatty acids (SFAs), monounsaturated fatty acids (MUFAs), and polyunsaturated fatty acids (PUFAs) [22]. These properties of biodiesel should comply with worldwide biodiesel standards such as European standards (EN14214) [23], and The American Society for Testing and Materials (ASTM D6751) [24]. It is important to conduct further studies on the optimization of species-specific culture conditions on FAME composition and biodiesel properties.

The ease of growing conditions of Chlorella [25] and the high hydrocarbon content and favorable fatty acid composition of Botryococcus [26] have made them the most extensively studied freshwater genera for biodiesel production. In particular, Chlorella vulgaris, is a commonly used species for large-scale cultivation due to its small cell size, which makes it easy to circulate in the growing medium [27]. Additionally, it has a high oil content and ability to withstand extreme environments [25, 28]. For these reasons, C. vulgaris was chosen as a reference strain to compare the analysis of the FAME production to B. sudeticus.

There are numerous studies showing B. braunii has the potential to serve as a viable biomass for biodiesel due to its favorable fatty acid composition [3, 29,30,31]. Although B. sudeticus has a higher growth rate compared to B. braunii and other strains [32, 33], there is a relatively less amount of literature that is concerned with biodiesel production from the alga B. sudeticus [3, 34]. Gaining insights into how B. sudeticus reacts under nutrient stress conditions can offer valuable knowledge for refining its cultivation to achieve improved biodiesel yield and quality. This study represents the one of the first investigations evaluating the potential of B. sudeticus as an alternative feedstock in biodiesel production under nitrogen-manipulated conditions.

Maximum biodiesel yield from microalgae can be obtained with high biomass and appropriate FAME composition. This study aims to compare the main advantages, including growth rate and biodiesel quality, and provide insights into the potential of nutrient limitation as biodiesel feedstocks for C. vulgaris and B. sudeticus. Therefore, a two-step experiment was planned within the scope of this study. The first step aimed to obtain high biomass from Botryococcus and Chlorella under optimum conditions until the stationary phase of algal growth. In the second stage, in order to investigate to examine the effect of nitrogen stress on total lipid %, FAME content (wt%), and biodiesel quality, nutrient-replenishment and nitrogen-deficiency conditions were tested.

The study intends to contribute valuable information regarding the suitability of these algae species for biodiesel production under nutrient-limited conditions.

Materials and Methods

Microalgal Species and Experimental Set Up

Strains of green microalgae were obtained from culture collections of Culture Collection of Algae at the University of Texas at Austin (UTEX) and Culture Collection of Algae and Protozoa (CCAP). Botryococcus sudeticus (UTEX B 2629) and Chlorella vulgaris (CCAP 211/79) were maintained in batch cultures (5 L Erlenmeyer flask) and grown at 25 μmol m−2 s−1 light provided by cool white fluorescent lights in a photoperiod regime (12:12 h light: dark) at 24 °C. Aeration and agitation of the cultures were achieved by bubbling with dry air gasses twice a day.

Media and flasks were sterilized in an autoclave at 121 °C for 20 min to avoid contamination before starting the experimental sets. Sterile BG-11 [35] culture medium was used in this experiment which consisted of (g L−1): 1.5, NaNO3 (sodium nitrate); 0.04, K2HPO4 (potassium phosphate); 0.075, MgSO4·7H2O (magnesium sulfate); 0.0036, CaCl2·2H2O (calcium chloride); 0.006, (NH4)5[Fe(C6H4O7)2 (ferric-ammonium citrate); 0.006, C6H8O7 (citric acid); 0.001, EDTA-2Na (EDTA, disodium salt); and 0.02, Na2O3 (sodium carbonate). 1 ml of trace metals mixer was used in BG-11 medium, having 2.86 g of H3BO3, 1.81 g of MnCl2.4H2O, 0.39 g of NaMoO4.2H2O, 0.079 g of CuSO4.5H2O, and 0.494 g of Co(NO3)2.6H2O in 1 L of ultrapure water.

The experiment was conducted in two stages. In the first stage, which lasted for 6 weeks, stock cultures with an initial cell density of approximately 15 × 106 cells ml−1 were inoculated into BG-11 medium containing NaNO3. During 6 weeks, all cultures were kept under the same growth conditions. In the second stage, which lasted for 3 weeks, two different conditions were applied to the cultures.

-

Nutrient-replenishment set: The cultures were centrifuged at the end of the 6th week, and after removal from the medium, they were re-inoculated into normal BG-11 medium.

-

Nitrogen–deficiency set: The cultures were centrifuged at the end of the 6th week, and after removal from the medium, they were re-inoculated into BG-11 medium without NaNO3.

Biomass Estimation

Culture growth was monitored weekly by Chlorophyll-a (chl-a) measurement. Chl-a was determined according to the ISO 10260 standard method [28]. The specific growth rate was determined based on chl-a values according to [29]. The specific growth rate (µ) was calculated from the Eq. (1):

where, N2 and N1 are the chl-a values at the times t2 and t1, respectively.

Harvesting and Lipid Extraction

Cultures were harvested by centrifuging at 3500 rpm for 5 min. After centrifugation, the pellets were removed from the medium and washed several times with distilled water. All pellet was collected and placed in a centrifuge tube and then dried using a freeze dryer.

The lipids were extracted using the modified Bligh and Dyer [36] protocol, with chloroform: methanol: water (1:2:0.8 v/v). Briefly, 100 mg lyophilized microalgae culture was extracted with 1.25 ml chloroform, 2.5 ml methanol, and 1 ml distilled water and the mixture was kept for 4 h at 22 °C in the incubator at 300 rpm rotation (N-Biotek NB-205lf). After incubation, it was filtered through 0.45 µm PVDF membrane (MillexHV) for the separation of cell debris. The filtrate was centrifuged for 10 min at 4500 rpm and the top layer with water and methanol was poured off, and the bottom layer containing the lipid and chloroform was transferred to a clean pre-weighed tube. Then the chloroform was evaporated under N2 gas and remaining lipids measured gravemetrically. The lipid yield was calculated using the following Eq. (2):

Transesterification and FAME Analyses

The extracted lipids were transesterified to fatty acid methyl ester (FAME) form according to Lepage and Toy [37] and the composition of FAME was determined from crude biodiesel. Briefly, lipids were saponified with 1 mL of 2 N methanolic KOH–CH3OH solution at 75 °C for 10 min and then exposed to methanolysis with 5% HCl in methanol at 75 °C for another 10 min. After the reaction was completed, FAMEs were extracted with 5 mL hexane. For the phase separation, 1 mL Milli-Q water was added and the hexane layer was filtered with anhydrous sodium sulphate. Thereafter, hexane evaporated under N2 gas and weighed for determination of transesterified FAME amount as mass. Samples were redissolved in 1 ml of hexane and for quantification of FAME content 1 mL solution of methyl nonadecanoate (C19:0) in hexane (mg mL−1) was spiked as an internal standard. FAME was analyzed by a gas chromatography (A Clarus 680, Perkin Elmer, USA) equipped with a flame ionization detector (FID) using an HP-88 column (100 m length 0.25 mm ID, 0.2um film thickness). Hydrogen was used as a carrier gas with a flow rate of 1 mL min−1. The split ratio was 50:1. GC oven temperature was programmed from 50 °C (5 min) to 230 °C (11 min) at a rate of 4 °C min−1. GC peaks were identified by the mixture of 37 fatty acids methyl esters (Supelco™ 37 Component FAME Mix). FAME content was determined as mass percentage according to EN14103:20 [38] method using the following Eq. 3.

AX is the peak area of individiual meyhl ester X, RX is GC-FID corrector factor for relative to the internal standard, AEI is the peak area corresponding to C19:0 standard, WEI is the weight in mg of the C19:0 being used as internal standard, W is the weight, in mg of transesterified fatty acid methyl ester.

FAME yield was calculated as follows: Eq. 4.

Evaluation of Biodiesel Quality

The property of biodiesel was determined from FAME composition. The carbon chain sizes and the number and position of double bonds which determine the molecular structure of FAME, affect the quality of biodiesel [39, 40]. These main parameters that greatly affect the biodiesel property are cetane number (CN), Iodine Value (IV), Cold Filter Plugging Point (CFPP), oxidation stability, Degree of Unsaturation (DU) and Long-Chain Saturated Factor (LCSF).

The cetane number (CN) shows the time delay in the ignition of fuel for diesel cycle engines. A shorter CN indicates a longer ignition time. In the present work, CN was estimated using an empirical correlative model (CN = a + b/x + cy) based on various vegetable oils that were previously characterized according to Krisnangkura et al. (1986) [41]. The x value in the model is associated with the saponification number (SV), measured in milligrams of Potassium Hydroxide required to saponify 1 g of oil, while the Y value is associated with the iodine number (IV), which represents the number of double bonds in the oil.

CN, SV, and IV for each microalgae biodiesel were estimated by derived from Krisnangkura (1986) [41] in Eq. 5–7.

where D is the number of double bonds, M is the FA molecular mass, and N is the percentage of each FA component of the microalgae oil.

Parameters such as other (CFPP), oxidation stability, DU and long chain saturated factor (LCSF) related to the quality of biodiesel used empirical equations as the other studies [39, 41, 42] that have been accurately before.

Degree of unsaturation (DU) is the amount of monounsaturated (MUFA) and polyunsaturated (PUFA) FAs present in the microalgae oil and they were shown in Eq. 8.

The long-chain saturated factor (LCSF) was also directly used to calculate Cold Filter Plugging Point (CFPP). These two factors are related to chain saturation and the length of FAME. LCSF and CFPP were shown in Eq. 9, 10.

Statistical Analysis

The data were analyzed by one-way analysis of variance (ANOVA) and Tukey HSD test with a significance level of P < 0.05. Statistical analyses were performed using SPSS 17.0 (Statistical Product and Service Solutions).

Results and Discussions

Microalgal Biomass Production

The optimization of cultivation conditions of microalgae plays a crucial role in biomass yields and lipid amounts, as well as cost-effectiveness [43]. Selecting an appropriate medium is essential for achieving rapid growth and high lipid content in microalgae [44]. Previous studies have highlighted the importance of having a certain nitrogen concentration in the medium to promote biomass production. Choi et al. [45] reported that initial nitrate concentration below 0.37 mM resulted in low biomass but high lipid production. Similarly, Vishwakarma et al. [21] found that a NaNO3 concentration of 1.5 g L−1 in the BG-11 medium increased biomass yield compared to the BBM medium. BG-11 medium is known to be rich in nitrogen (N), phosphorus (P), and carbon (C), which are essential nutrients for the growth of green algae [21]. Therefore, in this study, the BG-11 medium with sufficient nitrogen concentration was used to achieve high biomass production at the first stage.

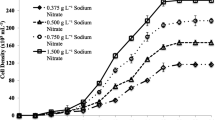

The growth rates, determined through weekly chlorophyll-a (chl-a) analysis, indicated that the stationary phase was observed by the end of the 6th week (Fig. 1). During the first stage of the experiment, the weekly variation of chl-a values was in a range of 599 to 2575 µg L−1 for B. sudeticus and 222 to 1377 µg L−1 for C. vulgaris (Fig. 2). In the second stage of the experiment, higher chl-a values were observed in the nutrient-replenishment set compared to the nitrogen deficiency set. The chl-a values in the nutrient-replenishment set ranged from 2553 to 3796 µg L−1 in B. sudeticus and from 1798 to 2642 µg L−1 in C. vulgaris. On the other hand, in the nitrogen deficiency set, the chl-a values ranged from 2464 to 2997 µg L−1 in B. sudeticus and from 1643 to 2285 µg L−1 in C. vulgaris.

A declining trend was observed in the growth rates of the nitrogen deficiency set and cell death was started after the 2nd week. These observations indicated that lack of nitrogen has a negative impact on both the viability and growth of the microalgae.

Generally, during the stationary phase of algal growth, essential nutrients such as nitrogen and phosphorus are likely to deplete. In this phase, microalgae allocate a significant portion of the photosynthetically reduced carbon to the biosynthesis of hydrocarbons [46]. Nitrogen deficiency has been shown to reduce chlorophyll content in microalgae [47]. Furthermore, under nitrogen-deficient conditions, the metabolic products of photosynthesis shift from protein synthesis to the production of carbohydrates and lipids [48]. This metabolic adjustment allows microalgae to redirect their resources towards the accumulation of energy-rich compounds, such as lipids, which are of particular interest for biodiesel production.

Comparing the chl-a contents of the two sets revealed that B. sudeticus reached higher chl-a values than that of C. vulgaris. Several studies showed that the cell growth rate of Botryococcus strains is slower than other green algae [31, 44, 49]. However, depending on culture conditions (light, temperature, etc.) there may not be a linear relationship between cell growth rate and chlorophyll content [50]. Additionally, other studies highlighted the importance of light sources on photosynthetic active radiation (PAR) [1, 7, 50]. The higher chl-a content of B. sudeticus may be explained by the fact that the use of the white light source may have promoted PAR on B. sudeticus rather than the growth rate.

Lipid Yield and Total FAME Content

The results indicated that the nitrogen deficiency had a clear effect on the total lipid yields. There was a significant variance between the nitrogen deficiency and nutrient-replenishment set (ANOVA p < 0.05). In both cultures, the highest fatty acid content was obtained in the nitrogen deficiency set (Fig. 2).

The total lipid content of C. vulgaris increased from 24.1% to 28.4% in the nitrogen deficiency set compared to the nutrient-replenishment set. These results reflect those of Converti et al. [51] who also found the significant impact of reducing the nitrogen concentration on the total lipid content of C. vulgaris. They stated that by decreasing the nitrogen concentration by 75% compared to the optimum nitrogen value (1.5 g L−1 NaNO3), the total lipid content of C. vulgaris increased substantially from 5.90% to 16.41%. Additionally, the Tan et al. [25] have examined the effects of various amounts of nutrients addition in the cultivation medium, and reported a wider range of total lipid content, ranging from 26 to 37% wt%. Overall, these findings suggest that manipulating nitrogen concentration and other culture conditions can significantly impact the total lipid content of C. vulgaris.

On the other hand, in both sets, B. sudeticus exhibited lower total lipid content compared to C. vulgaris. In the nitrogen deficiency set, the total lipid content increased from 21.1% to 23.8% compared to the nutrient replenishment set. This is in line with previous findings by Ashokkumar et al. [3], who reported a total lipid content of 22.6% wt% for B. sudeticus. However, there is a very limited information on the fatty acid composition and biodiesel quality of B. sudeticus in response to nitrogen deficiency.

Under N-limiting conditions, cells prioritize the synthesis of fatty acids and lipids as a means of efficient carbon and energy storage instead of the synthesis of N-containing compounds such as proteins, nucleic acids, and chlorophyll [10, 52]. The fatty acids required for biodiesel serve as an efficient carbon and energy source that can be produced without requiring as much nitrogen [53]. FAME content in many microalgae may vary in response to different environmental factors in culture conditions [45, 54]. Several studies showed that a decrease in nitrogen concentration in the medium leads to an increase in FAME content % in microalgae [17, 45]. The total FAME content (wt%) was detected in the range of 20.9 to 22.6% in C. vulgaris, 21.1 to 22.5 in B. sudeticus, in the nutrient replenishment set and nitrogen deficiency set respectively (Fig. 3.). The total FAME contents (wt%) of C. vulgaris were significantly higher in the nitrogen-deficiency set compared with the nutrient replenishment set (Anova P < 0.05). On the other hand, there were no statistically significant differences between the sets in B. sudeticus (Anova P > 0.05).

Total FAME yield % varied with a range of 4.45–5.4 in B. sudeticus and 5.0–6.4 in C. vulgaris in nutrient replenishment and nitrogen deficiency sets, respectively (Fig. 2.). Nitrogen deficiency led to an increase in FAME yield for both species. Specifically, in B. sudeticus, nitrogen deficiency resulted in a 21% increase in FAME yield, while in C. vulgaris, the yield was 28% higher under nitrogen deficiency conditions compared to the nutrient-supplemented set.

The Composition of Fame and its Effect on the Biodiesel Quality

The fatty acid composition of algal species affects the quality of biodiesel, such as engine performance and emission characteristics [55]. Therefore, it is essential to analyze the fatty acid composition of algae to understand their potential as a feedstock. The fatty acid profile of C. vulgaris and B. sudeticus is shown in Table 1. Although the derivatives of C16:0 (palmitic acid), C18:0 (Stearic acid), C18:1cis (oleic acid), and γ- C18:3n6 (linolenic acid) were the main fatty acids in both species, the percentage of FAME composition of individual fatty acids varied between the sets. When the nitrogen-deficiency set compared with the nutrient-replenishment set, the FAME content (wt%) of C16:0 (palmitic acid), C18:0 (Stearic acid), C18:1trans (Elaidic acid), C18:1cis (oleic acid), C18:2cis (linoleic acid), C18:2 trans (linolelaidic acid), γ- C18:3n6 (linolenic acid) were statistically significant in both species (Anova P < 0.05).

The carbon chain length, degree of unsaturation, and percentage composition of FAME are known to affect biodiesel properties [13]. The C16–C18 chain length is the most significant range of FAME composition for biodiesel application [56, 57]. In the present study, the C16–C18 chain length ranged between 87.5–93.7 in B. sudeticus and 90.2–91.9 in C. vulgaris (Table 1). These results agree with the findings of other studies, in which Ashokkumar et al. [58] found that the percentage of total FAME C16-C18 in B. sudeticus was 87.4%, while Moradi-Kheibari et al. [59] found that it was in the range of 87.7- 89.4% in C. vulgaris. Furthermore, Previous studies have reported that fatty acids such as C16:0 and C18:1 are commonly synthesized fatty acids by the Chlorophyceae family and are desirable fatty acids for biodiesel production [17, 29, 60]. Our results are also in agreement with those studies in which C16 had the highest percentage of FAME composition while C18:1 was a significant fatty acid in both cultures. The C16-C18 of the total FAME composition was higher in the nitrogen deficiency set in both species revaling that the nitrogen stress promotes the accumulation of fatty acids suitable for biodiesel production.

The biodiesel properties of C. vulgaris and B. sudeticus has been compared with ASTM 6751-3 and EN 14214 and are shown in Table 2. Cetane number (CN) of fuel is related to the ignition delay time, which means to shorter the ignition delay time, the higher the CN. It is one of the key parameter in determining the quality of biodiesel [11, 17] The higher CN value of biodiesel also means that it has better ignition characteristics and gives better engine performance [17]. The high percentage of saturated fatty acids (SFAs) in biodiesel can contribute to a higher cetane number, which is desirable for better combustion properties [61]. According to the worldwide biodiesel quality standards such as ASTM D6751, and Fuel Standard (Biodiesel) Determination, minimum CN values should be above 47 and 51, respectively. As seen in Table 2, CN values for both species were above 51 the CN values (57.5–58.5) did not show significant variation in C. vulgaris sets (ANOVA P > 0.05). However, there was a remarkable variation in B. sudeticus (55.6–61.9) sets (Anova P < 0.05). Since microalgae generally contain saturated fatty acids, mainly palmitic (C16:0) and stearic (C18:0) acids, these fatty acids have a great effect on cetane number. Previous research has shown that nitrogen deficiency tends to increase fatty acid saturation [15, 62]. However, the nitrogen threshold required to optimize the production of these fatty acids may vary between microalgae species. For instance, Wu et al. [63] reported that a nitrogen-free medium (0 g L−1 nitrogen) in Scenedesmus obliquus led to a decrease in C16:0 and total SFAs, and a minimum of 0.3 g L−1 nitrogen was necessary to achieve maximum C16:0 value. Contrarily, they also found that a nitrogen-free medium resulted in maximum SFAs values in Chlorella pyrenoidosa. In our study, it was found that the nitrogen-deficiency set (45 wt%) resulted in a lower percentage of SFAs compared to the nutrient-replenishment set (57.4 wt%) in the B. sudeticus. The use of a nitrogen-free medium (0 g L−1 nitrogen) in the case of B. sudeticus may limit the increase of saturated fatty acids (SFAs), such as C16:0. These results suggest that the presence of a certain amount of nitrogen in the medium is likely to promote higher saturation levels and cetane number (CN) values in B. sudeticus. On the other hand, nitrogen deficiency did not significantly affect the saturation of fatty acids in C. vulgaris (ANOVA P > 0.05). This further supports the notion that the effects of nitrogen deficiency on saturated microalgae may vary in a species-specific manner.

The saponification value (SV) is defined as to measure of milligrams of potassium hydroxide required to completely saponify one gram of oil [64]. Although the SV is not evaluated by the Biodiesel standards, it is an important value that is used to calculate the CN of biodiesel. As seen in Table 2, SV values changed in B. sudeticus in the range of 179.3- 182.5 and in Chlorella 183.4–185.0 between the sets. The results showed that nitrogen deficiency had no significant effect on SV values of both species (ANOVA P > 0.05).

According to European Standards (EN14214), biodiesel must have the specified limits of 12% linolenic acid methyl ester (C18:3). The presence of higher amounts of C18:3 is not preferred as it leads to the lower stability of biodiesel due to oxidation [60]. In our study, C18:3 varied between 14.3–26.7% in B. sudeticus and 11.5–17.8% in C. vulgaris. Stephenson et al. [20] showed that the C18:3 fatty acid percentage of C. vulgaris decreased from 21 wt% to 15 wt% resulting of under nitrogen-limitation conditions. In the present study, a-linolenic acid (C18:3) fell from 17.8% (nutrient-replenishment set) to 11.5% (nitrogen-deficiency set) in C. vulgaris which did not meet with the upper limit of 12% of European standards (EN14214). On the other hand, C18:3% of all sets of B. sudeticus was above the preferred limit for biodiesel production. In several studies on the fatty acid composition of B. braunii, C18:3 fatty acid was reported to be one of the main components [34, 65]. However, the presence of C18:3 was not reported in B. sudeticus.

High PUFA (≥ 2 double bonds) content in the fatty acid composition negatively impacts the oxidative stability of biodiesel making them more susceptible to oxidation and free radical attack [56]. Especially during storage high PUFA content of biodiesel undergoes oxidation reactions, resulting in the formation of peroxides, and other degradation products [39]. Therefore, to ensure good oxidative stability and improve the quality of biodiesel, it is generally preferred to have a higher proportion of saturated and monounsaturated fatty acids in the composition [56]. According to European regulation EN 14214, fatty acids with more than three double bonds (≥ 4 double bonds) should not exceed 1%. In this study, the amount of FAME with more than three double bonds was measured at a maximum of 0.7 in B. sudeticus under the nutrient-replenishment set, while it was not detected in C. vulgaris showing that both cultures exhibit a percentage within this range.

The iodine value (IV) defines the content of unsaturated fatty acids. IV increases with the number of double bonds in the fatty acid chain and expresses the mass of iodine in grams consumed by 100 g of the chemical substance [57]. When higher unsaturated fatty acids are heated, they cause the polymerization of glycerides and lead to deposit formation or degradation of the lubricating oil [42]. As a result, biodiesel with a higher IV, indicating higher unsaturation, is more likely to undergo oxidative degradation. Therefore, biodiesel with a lower IV value, indicating lower unsaturation and fewer double bonds in the fatty acid composition, tends to have higher oxidative stability and is considered more suitable for long-term storage without significant degradation [63]. For this reason, it is not desirable for the IV to be above a certain amount in terms of the suitability of biodiesel fuel. The European standard (EN 14214) defines a maximum value for IV as 120 g I2 100 g−1 for biodiesel. In the present study, the maximum IV was found in the nitrogen deficiency set for both cultures, with 91.7 g I2 100 g−1 in B. sudeticus and 81.2 g I2 100 g−1 in C. vulgaris. It is determined that all biodiesel samples produced by both species in both sets had lower IV than the upper limits set by European standards (EN14214).

The degree of unsaturation (DU) is the sum of the MUFA and PUFA masses. DU affects the oxidative stability of biodiesel conditions and low DU makes the more stable of biodiesel in long-term storage [17]. Although European standards (EN 14214), and American Biodiesel Standards ASTM D6751 do not include any limits for DU, it has a direct effect on the determination of the iodine number of biodiesel [66]. In our study, the DU values changed within the range of 62.6 to 87.2 in B. sudeticus and 63.7 to 74.6 in C. vulgaris. Interestingly, nitrogen deficiency had contrasting effects on the DU values of B. sudeticus and C. vulgaris. In B. sudeticus, nitrogen deficiency resulted in an increase in DU values, indicating a decrease in oxidative stability. On the other hand, in C. vulgaris, nitrogen deficiency led to a decrease in DU values, suggesting an improvement in oxidative stability. This observation suggests that nitrogen deficiency negatively affected the oxidative stability of B. sudeticus, while it contributed to enhancing the oxidative stability of C. vulgaris during long-term storage.

The Cold Filter Plugging Point (CFPP) is one of the important biodiesel quality parameters used mainly to determine the low-temperature flow performance of biodiesel [17]. The CFPP is defined as the lowest temperature that 40 mL of oil safely passes flow through the filter within 60 s. It is an indicator of the cold flow properties of biodiesel and helps determine its suitability for specific climatic conditions [67]. The low-temperature properties of biodiesel are influenced by the percentage of saturated fatty acids in the total FAME. A higher CFPP value indicates poor low-temperature biodiesel properties [68], showing that biodiesel has a higher tendency to precipitate and clog the filter [69]. CFPP is correlated with the long-chain saturated factor (LCSF). In this study, lower CFPP and LCSF values were observed in both B. sudeticus and C. vulgaris cultures under a nitrogen-deficiency set. The LCSF values for B. sudeticus ranged from 9.2% to 11.5%, andfor C. vulgaris ranged from 7.9% to 8.4%. The CFPP values for B. sudeticus was between 12.4 °C and 19.7 °C, and for C. vulgaris between 8.3 °C and 10.0 °C (Table 2). It was found that nitrogen stress decreased the CFPP values of biodiesel, thereby increasing its usability in colder climates. The findings indicated that C. vulgaris may exhibit better flow performance in colder climates due to its lower CFPP values compared to B. sudeticus. Besides, it shows that nitrogen stress decreases the CFPP values of biodiesel and improves its low-temperature properties.

Overall nitrogen deficiency is a well-known strategy for increasing lipid content in various microalgae species, which can significantly impact biodiesel production. However, it's important to consider that while initially having sufficient amount of nitrogen in the growth medium is advantageous for achieving high biomass and maintaining healthy cell cultures, completely removing nitrogen from the medium to enhance lipid and FAME content may involve additional energy and labor costs. Therefore, for sustainable and commercial-scale biodiesel production, it is essential to optimize nitrogen manipulation based on the specific needs and characteristics of the microalgae species being used.

Conclusion

The findings of this study showed that microalgae exhibit complex lipid production metabolisms, and the response to nitrogen manipulation varies among species. The nitrogen deficiency generally increased lipid levels in both Chlorella vulgaris and Botryococcus sudeticus. However, their response to the nitrogen deficiency showed high variation in terms of the growth rate, total lipid content, and biodiesel properties. These findings highlighted that green algae exhibit complex and species-specific responses to nitrogen deficiency and nutrient conditions should be optimized to achieve high biomass and lipid content. This research contributes to the growing body of knowledge in the field of microalgae-based biodiesel production and highlights the importance of species-specific approaches to maximize both lipid content and biodiesel quality.

Data Availability

All data generated or analyzed during this study are included in this paper.

Abbreviations

- ANOVA:

-

Analysis of variance

- ASTM:

-

American Society for Testing and Materials

- CN:

-

Cetane number

- CFPP:

-

Cold flow plugging properties

- Chl-a :

-

Chlorophyll-a

- DU:

-

Degree of unsaturation

- FA:

-

Fatty Acid

- FAME:

-

Fatty acid methyl ester

- IV:

-

Iodine value

- LCSF:

-

Long chain saturated factors

- MUFAs:

-

Monounsaturated fatty acids

- SFAS :

-

Saturated fatty acids

- PUFAs:

-

Polyunsaturated fatty acid

- SV:

-

Saponification value

- Acyl CoA:

-

Diacylglycerol acyltransferase

- wt%:

-

Weight percentage (%)

- DW:

-

Dry weight percentage (%)

- UTEX:

-

Culture Collection of Algae at the University of Texas at Austin

- CCAP:

-

Culture collection of algae and protozoa

- FID:

-

Flame ionization detector

- GC:

-

Gas chromatography

References

Chai, F., Cao, F., Zhai, F., Chen, Y., Wang, X., Su, Z.: Transesterification of vegetable oil to biodiesel using a heteropolyacid solid catalyst. Adv. Synth. Catal. (2007). https://doi.org/10.1002/adsc.200600419

Abbaszaadeh, A., Ghobadian, B., Omidkhah, M.R., Najafi, G.: Current biodiesel production technologies: a comparative review. Energy Convers. Manag (2012). https://doi.org/10.1016/j.enconman.2012.02.027

Ashokkumar, V., Agila, E., Sivakumar, P., Salam, Z., Rengasamy, R., Ani, F.N.: Optimization and characterization of biodiesel production from microalgae Botryococcus grown at semi-continuous system. Eng. Convers. Manag (2014). https://doi.org/10.1016/j.enconman.2014.09.019

Tsukahara, K., Sawayama, S.: Liquid fuel production using microalgae. J. Japan Pet. Inst (2005). https://doi.org/10.1627/jpi.48.251

Rosenberg, J.N., Oyler, G.A., Wilkinson, L., Betenbaugh, M.J.: A green light for engineered algae: redirecting metabolism to fuel a biotechnology revolution. Curr. Opin. Biotechnol. (2008). https://doi.org/10.1016/j.copbio.2008.07.008

Mahfouz, A.B., Ali, A., Crocker, M., Ahmed, A., Nasir, R., Show, P.L.: Neural-Network-Inspired Correlation (N2IC) model for estimating biodiesel conversion in algal biodiesel units. Fermentation (2023). https://doi.org/10.3390/fermentation9010047

Nigam, P.S., Singh, A.: Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. (2011). https://doi.org/10.1016/j.pecs.2010.01.003

El-Sheekh, M., Abomohra, A.E.F., Hanelt, D.: Optimization of biomass and fatty acid productivity of Scenedesmus obliquus as a promising microalga for biodiesel production. World J. Microbiol. Biotechnol. (2013). https://doi.org/10.1007/s11274-012-1248-2

Al-Humairi, S.T., Lee, J.G.M., Harvey, A.P., Salman, A.D., Juzsakova, T., Van, B., Le, P., La, D.D., Mungray, A.K., Show, P.L., Nguyen, D.D.: A foam column system harvesting freshwater algae for biodiesel production: an experiment and process model evaluations. Sci. Total. Environ. (2023). https://doi.org/10.1016/j.scitotenv.2022.160702

Hasnain, M., Abideen, Z., Hashmi, S., Naz, S., Munir, N.: Assessing the potential of nutrient deficiency for enhancement of biodiesel production in algal resources. Biofuels (2023). https://doi.org/10.1080/17597269.2022.2106640

Islam, M.A., Magnusson, M., Brown, R.J., Ayoko, G.A., Nabi, M.N., Heimann, K.: Microalgal species selection for biodiesel production based on fuel properties derived from fatty acid profiles. Energies (2013). https://doi.org/10.3390/en6115676

Chu, F.-F., Chu, P.-N., Cai, P.-J., Li, W.-W., Lam, P.K.S., Zeng, R.J.: Phosphorus plays an important role in enhancing biodiesel productivity of Chlorella vulgaris under nitrogen deficiency. Bioresour. Technol. (2013). https://doi.org/10.1016/j.biortech.2013.01.131

Ikaran, Z., Suárez-Alvarez, S., Urreta, I., Castañón, S.: The effect of nitrogen limitation on the physiology and metabolism of chlorella vulgaris var L3. Algal Res. (2015). https://doi.org/10.1016/j.algal.2015.04.023

Shen, X.F., Liu, J.J., Chu, F.F., Lam, P.K.S., Zeng, R.J.: Enhancement of FAME productivity of Scenedesmus obliquus by combining nitrogen deficiency with sufficient phosphorus supply in heterotrophic cultivation. Appl. Energy (2015). https://doi.org/10.1016/j.apenergy.2015.08.057

Singh, P., Guldhe, A., Kumari, S., Rawat, I., Bux, F.: Investigation of combined effect of nitrogen, phosphorus and iron on lipid productivity of microalgae Ankistrodesmus falcatus KJ671624 using response surface methodology. Biochem. Eng. J. (2015). https://doi.org/10.1016/j.bej.2014.10.019

Nagappan, S., Bhosale, R., Duc Nguyen, D., Pugazhendhi, A., Tsai, P.-C., Chang, S.W., Ponnusamy, V.K., Kumar, G.: Nitrogen-fixing cyanobacteria as a potential resource for efficient biodiesel production. Fuel (2020). https://doi.org/10.1016/j.fuel.2020.118440

Ruangsomboon, S.: Effects of different media and nitrogen sources and levels on growth and lipid of green microalga Botryococcus braunii KMITL and its biodiesel properties based on fatty acid composition. Bioresour. Technol. (2015). https://doi.org/10.1016/j.biortech.2015.01.091

Markou, G., Nerantzis, E.: Microalgae for high-value compounds and biofuels production: a review with focus on cultivation under stress conditions. Biotechnol. Adv. (2013). https://doi.org/10.1016/j.biotechadv.2013.07.011

Farese, R.V., Cases, S., Smith, S.J.: Triglyceride synthesis: Insights from the cloning of diacylglycerol acyltransferase. Curr. Opin. Lipidol. (2000). https://doi.org/10.1097/00041433-200006000-00002

Stephenson, A.L., Dennis, J.S., Howe, C.J., Scott, S.A., Smith, A.G.: Influence of nitrogen-limitation regime on the production by Chlorella vulgaris of lipids for biodiesel feedstocks. Biofuels (2010). https://doi.org/10.4155/bfs.09.1

Vishwakarma, R., Dhar, D.W., Saxena, S.: Influence of nutrient formulations on growth, lipid yield, carbon partitioning and biodiesel quality potential of Botryococcus sp and Chlorella sp. Environ. Sci. Pollut. Res. (2019). https://doi.org/10.1007/s11356-019-04213-2

Knothe, G.: “Designer” biodiesel: optimizing fatty ester composition to improve fuel properties. Energy Fuels (2008). https://doi.org/10.1021/ef700639e

European Standard EN 14214 (2004) Automotive fuels-fatty acid methyl esters (FAME) for diesel engines-requirements and test methods. European Committee for Standardization, Brussels

American Society for Testing and Materials (ASTM) D6751 (2008) Standard Specification for Biodiesel Fuel (B100) Blend Stock for Distillate Fuels, ASTM International: West Conshohocken, PA

Tan, X.B., Lam, M.K., Uemura, Y., Lim, J.W., Wong, C.Y., Ramli, A., Kiew, P.L., Lee, K.T.: Semi-continuous cultivation of Chlorella vulgaris using chicken compost as nutrients source: Growth optimization study and fatty acid composition analysis. Energy Convers. Manag. (2018). https://doi.org/10.1016/j.enconman.2018.03.020

Zhou, R., Wolk, C.P.: Identification of an akinete marker gene in Anabaena variabilis. J. Bacteriol. (2002). https://doi.org/10.1128/JB.184.9.2529-2532.2002

Sarayloo, E., Simsek, S., Unlu, Y.S., Cevahir, G., Erkey, C., Kavakli, I.H.: Enhancement of the lipid productivity and fatty acid methyl ester profile of Chlorella vulgaris by two rounds of mutagenesis. Bioresour. Technol. (2018). https://doi.org/10.1016/j.biortech.2017.11.105

Yeh, K.-L., Chang, J.-S.: Effects of cultivation conditions and media composition on cell growth and lipid productivity of indigenous microalga Chlorella vulgaris ESP-31. Bioresour. Technol. (2012). https://doi.org/10.1016/j.biortech.2011.11.103

Rao, A.R., Dayananda, C., Sarada, R., Shamala, T.R., Ravishankar, G.A.: Effect of salinity on growth of green alga Botryococcus braunii and its constituents. Bioresour. Technol. Rep. (2007). https://doi.org/10.1016/j.biortech.2006.02.007

Hidalgo, P., Ciudad, G., Navia, R.: Evaluation of different solvent mixtures in esterifiable lipids extraction from microalgae Botryococcus braunii for biodiesel production. Bioresour. Technol. (2016). https://doi.org/10.1016/j.biortech.2015.11.031

Jin, J., Dupré, C., Yoneda, K., Watanabe, M.M., Legrand, J., Grizeau, D.: Characteristics of extracellular hydrocarbon-rich microalga Botryococcus braunii for biofuels production: Recent advances and opportunities. Process Biochem. (2016). https://doi.org/10.1016/j.procbio.2015.11.026

Eroglu, E., Okada, S., Melis, A.: Hydrocarbon productivities in different Botryococcus strains: comparative methods in product quantification. J. Appl. Phycol. (2011). https://doi.org/10.1007/s10811-010-9577-8

Sun, D., Zhu, J., Fang, L., Zhang, X., Chow, Y., Liu, J.: De novo transcriptome profiling uncovers a drastic downregulation of photosynthesis upon nitrogen deprivation in the nonmodel green alga Botryosphaerella sudeticus. BMC Genomics (2013). https://doi.org/10.1186/1471-2164-14-715

Kalacheva, G.S., Zhila, N.O., Volova, T.G., Gladyshev, M.I.: The effect of temperature on the lipid composition of the green alga Botryococcus. Microbiol (2002). https://doi.org/10.1023/A:1015898426573

Rippka, R., Deruelles, J., Waterbury, J.B.: Generic assignments, strain histories and properties of pure cultures of cyanobacteria. Microbiol 111(1), 1–61 (1979)

Bligh, E.G., Dyer, W.J.: A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. (1959). https://doi.org/10.1139/o59-099

Lepage, G., Roy, C.C.: Improved recovery of fatty acid through direct transesterification without prior extraction or purification. J. Lipid Res. (1984). https://doi.org/10.1016/s0022-2275(20)34457-6

EN 14103:20 (2020) Fat and Oil Derivatives-Fatty Acid Methyl Esters (FAME) - Determination of Ester and Linolenic Acid Methyl Ester Contents; European Committee for Standardization, Brussels, available at https://www.en-standard.eu/une-en-14103-2020-fat

Knothe, G.: Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process. Technol. (2005). https://doi.org/10.1016/j.fuproc.2004.11.002

Nascimento, I.A., Marques, S.S.I., Cabanelas, I.T.D., Pereira, S.A., Druzian, J.I., de Souza, C.O., Vich, D.V., de Carvalho, G.C., Nascimento, M.A.: Screening microalgae strains for biodiesel production: lipid productivity and estimation of fuel quality based on fatty acids profiles as selective criteria. Bioenergy Res. (2013). https://doi.org/10.1007/s12155-012-9222-2

Krisnangkura, K.: A simple method for estimation of cetane index of vegetable oil methyl esters. J. Am. Oil Chem. Soc. 63(4), 552–553 (1986)

Francisco, E.C., Neves, D.B., Jacob-Lopes, E., Franco, T.T.: Microalgae as feedstock for biodiesel production: carbon dioxide sequestration, lipid production and biofuel quality. J. Chem. Technol. Biotechnol. (2010). https://doi.org/10.1002/jctb.2338

Sharma, A.K., Sahoo, P.K., Singhal, S., Patel, A.: Impact of various media and organic carbon sources on biofuel production potential from Chlorella spp. 3 Biotech (2016). https://doi.org/10.1007/s13205-016-0434-6

Cheng, P., Ji, B., Gao, L., Zhang, W., Wang, J., Liu, T.: The growth, lipid and hydrocarbon production of Botryococcus braunii with attached cultivation. Bioresour. Technol. (2013). https://doi.org/10.1016/j.biortech.2013.03.150

Choi, G.G., Kim, B.H., Ahn, C.Y., Oh, H.M.: Effect of nitrogen limitation on oleic acid biosynthesis in Botryococcus braunii. J. Appl. Phycol. (2011). https://doi.org/10.1007/s10811-010-9636-1

Dunstan, G.A., Volkman, J.K., Barrett, S.M., Garland, C.D.: Changes in the lipid composition and maximisation of the polyunsaturated fatty acid content of three microalgae grown in mass culture. J. Appl. Phycol. 5, 71–83 (1993)

Syrett, P.J.: Nitrogen assimilation. In: Lewin, R.A. (ed.) Physiology and Biochemistry of Algae, pp. 171–188. Academic Press, Newyork (1962)

Mandalam, R.K., Palsson, B.: Elemental balancing of biomass and medium composition enhances growth capacity in high-density Chlorella vulgaris cultures. Biotechnol. Bioeng. 59(5), 605–611 (1998)

Tanoi, T., Kawachi, M., Watanabe, M.M.: Effects of carbon source on growth and morphology of Botryococcus braunii. J. Appl. Phycol. (2011). https://doi.org/10.1007/s10811-010-9528-4

Mohsenpour, S.F., Richards, B., Willoughby, N.: Spectral conversion of light for enhanced microalgae growth rates and photosynthetic pigment production. Bioresour. Technol. (2012). https://doi.org/10.1016/j.biortech.2012.08.072

Converti, A., Casazza, A.A., Ortiz, E.Y., Perego, P., Del Borghi, M.: Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem. Eng. Process. Process Intensif (2009). https://doi.org/10.1016/j.cep.2009.03.006

Bibi, F., Ishtiaq Ali, M., Ahmad, M., Bokhari, A., Shiong Khoo, K., Zafar, M., Asif, S., Mubashir, M., Han, N., Loke Show, P.: Production of lipids biosynthesis from Tetradesmus nygaardii microalgae as a feedstock for biodiesel production. Fuel (2022). https://doi.org/10.1016/j.fuel.2022.124985

Piorreck, M., Baasch, K.H., Pohl, P.: Biomass production, total protein, chlorophylls, lipids and fatty acids of freshwater green and blue-green algae under different nitrogen regimes. Phytochemistry (1984). https://doi.org/10.1016/S0031-9422(00)80304-0

Yoo, C., Jun, S.Y., Lee, J.Y., Ahn, C.Y., Oh, H.M.: Selection of microalgae for lipid production under high levels carbon dioxide. Bioresour. Technol. (2010). https://doi.org/10.1016/j.biortech.2009.03.030

Shanmugam, S., Mathimani, T., Anto, S., Sudhakar, M.P., Kumar, S.S., Pugazhendhi, A.: Cell density, lipidomic profile, and fatty acid characterization as selection criteria in bioprospecting of microalgae and cyanobacterium for biodiesel production. Bioresour. Technol. (2020). https://doi.org/10.1016/j.biortech.2020.123061

Rai, M.P., Gupta, S.: Effect of media composition and light supply on biomass, lipid content and FAME profile for quality biofuel production from Scenedesmus abundans. Energy Convers. Manag (2017). https://doi.org/10.1016/j.enconman.2016.05.018

Knothe, G.: Improving biodiesel fuel properties by modifying fatty ester composition. Energy Environ. Sci. (2009). https://doi.org/10.1039/b903941d

Ashokkumar, V., Salam, Z., Sathishkumar, P., Hadibarata, T., Mohd Yusoff, A.R., Ani, F.N.: Exploration of fast growing Botryococcus sudeticus for upstream and downstream process in sustainable biofuels production. J. Clean. Prod. (2015). https://doi.org/10.1016/j.jclepro.2015.01.004

Moradi-kheibari, N., Ahmadzadeh, H., Hosseini, M.: Use of solvent mixtures for total lipid extraction of Chlorella vulgaris and gas chromatography FAME analysis. Bioprocess Biosyst. Eng. (2017). https://doi.org/10.1007/s00449-017-1794-y

Ashokkumar, V., Rengasamy, R.: Mass culture of Botryococcus braunii Kutz. under open raceway pond for biofuel production. Bioresour. Technol. (2012). https://doi.org/10.1016/j.biortech.2011.10.093

Deshmukh, S., Bala, K., Kumar, R.: Selection of microalgae species based on their lipid content, fatty acid profile and apparent fuel properties for biodiesel production. Environ. Sci. Pollut. Res. (2019). https://doi.org/10.1007/s11356-019-05692-z

Xin, L., Hong-ying, H., Ke, G., Ying-xue, S.: Effects of different nitrogen and phosphorus concentrations on the growth, nutrient uptake, and lipid accumulation of a freshwater microalga Scenedesmus sp. Bioresour. Technol. (2010). https://doi.org/10.1016/j.biortech.2010.02.016

Wu, H., Miao, X.: Biodiesel quality and biochemical changes of microalgae Chlorella pyrenoidosa and Scenedesmus obliquus in response to nitrate levels. Bioresour. Technol. (2014). https://doi.org/10.1016/j.biortech.2014.08.017

Mandotra, S.K., Kumar, P., Suseela, M.R., Ramteke, P.W.: Freshwater green microalga Scenedesmus abundans: a potential feedstock for high quality biodiesel production. Bioresour. Technol. (2014). https://doi.org/10.1016/j.biortech.2013.12.127

Fang, J.Y., Chiu, H.C., Wu, J.T., Chiang, Y.R., Hsu, S.H.: Fatty acids in Botryococcus braunii accelerate topical delivery of flurbiprofen into and across skin. Int. J. Pharm. (2004). https://doi.org/10.1016/j.ijpharm.2004.02.026

Mandotra, S.K., Kumar, P., Suseela, M.R., Nayaka, S., Ramteke, P.W.: Evaluation of fatty acid profile and biodiesel properties of microalga Scenedesmus abundans under the influence of phosphorus, pH and light intensities. Bioresour. Technol. (2016). https://doi.org/10.1016/j.biortech.2015.11.042

Dunn, R.O., Bagby, M.O.: Low-temperature properties of triglyceride-based diesel fuels: transesterified methyl esters and petroleum middle distillate/ester blends. J. Am. Oil Chem. Soc. (1995). https://doi.org/10.1007/BF02542067

Wu, M., Wu, G., Han, L., Wang, J.: Low-temperature fluidity of bio-diesel fuel prepared from edible vegetable oil. Pet. Process. Petrochem. 36, 57–60 (2005)

Mittelbach M, Remschmidt C (2004) Biodiesel: the comprehensive handbook. Martin Mittelbach

Acknowledgements

We would like to thank Dr. Zeynep DORAK for her help in statistical analysis, and Dr. Cenk Gürevin, and Cansu Atar for their technical support in the laboratory.

Funding

This study was funded by Scientific Research Projects Coordination Unit of Istanbul University (Project number: 36334).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Oğuz, A., Köker, L., Ozbayram, E.G. et al. Biodiesel Production from Botryococcus sudeticus and Chlorella vulgaris: Assessment of Nitrogen Deficiency on Lipid, Fame Yield and Biodiesel Properties. Waste Biomass Valor 15, 2757–2768 (2024). https://doi.org/10.1007/s12649-023-02359-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02359-2