Abstract

In this study, heterotrophic growth conditions for Micractinium sp. ME05 cells were investigated for the improvement of biomass production. Plackett Burman (PB) method was used to screen process variables, namely, pH, carbon source and yeast extract concentrations, temperature and inoculum ratio, that affect the biomass production. The Box-Behnken (BB) design of response surface methodology (RSM) was applied to evaluate the interaction effect of process variables and to optimize them. The biomass obtained from PB design was 1.07 g/L and pH, temperature and carbon source concentration were selected based on their positive effect on biomass production. Applying response optimizer tool of RSM, the highest biomass obtained was 2.08 g/L. The results revealed that a 1.9-fold increase in biomass concentration was achieved by manipulating cultivation conditions which would be valuable for large scale cost efficient industrial applications of biomass production.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are procaryotic or eucaryotic photosynthetic microorganisms that can grow rapidly and able to live in severe conditions due to their unicellular or simple multicellular structure. Cyanobacteria (Cyanophyceae) is an example to procaryotic microalgae wheras green algae (Chlorophyta) and diatoms (Bacillarophyta) are examples of eucaryotic microalgae [1].

Microalgae are useful sources for different industries such as cosmetic, health food, chemical and pharmaceutical industries producing high value products such as pigments, carbohydrates, lipids, proteins and vitamins [2]. Large scale production provides a wide variety of practical and metabolic products, such as food supplements, lipids, enzymes, biomass, polymers, toxins, pigments and ‘green energy’ products. Such products were produced by cultivating microlagae on various organic substrates such as glucose, acetate, sugarcane baggase and synthetic or real wastewaters [3, 4]. For a long time, microalgae have been known as effective biological system to use solar energy in order to produce biomass and different types of metabolites. Since they have the ability to adapt to varying cultural conditions, they can maximize the formation of targeted products [5].

The cultivation conditions of microalgae affect growth characteristics and cellular composition of microalgae [6]. There are four major types of cultivation conditions for microalgae; photoautotrophic, heterotrophic, mixotrophic and photoheterotrophic cultivation [7]. In photoautotrophic cultivation; microalgae use light (sunlight) as the energy source and inorganic carbon such as carbondioxide in order to produce chemical energy via photosynthesis [8]. In heterotrophic cultivation, organic compounds are used as carbon and energy sources [7]. In mixotrophic cultivation microalgae use both organic carbon and inorganic carbon (CO2) as a carbon source during photosythesis. In photoheterotrophic cultivation, microalgae require light while using organic carbons as carbon source [9]. Microalgae can use light efficiently but their photoautotrophic growth is often slow because of light limitation at high cell densities on a large scale [8, 10].

Heterotrophic cultivation can be a cost effective alternative for some microalgae that can use organic carbon substances as their sole carbon and energy source [11]. Heterotrophic growth of microalgae has some advantages over photoautotrophic cultivation such as; elimination of light requirement, enabling the control of cultivation process and since the cell density is higher in hetetotrophic cultivation, the harvesting cost is low. In heterotrophic cultivation, cell growth and biosythesis of products are significantly affected by medium nutrients and environmental factors. Carbon source is one of the most important components in heterotrophic cultivation of microalgae for the production of lipids [12]. Several microalgae such as Chlorella prothecoides and Crypthecodium cohnii can uptake carbohydrates such as glucose directly and transform to lipid. Such a heterotrophic metabolism results in higher cell density and neutral lipid content [13].

On the other hand, since the carbon source usually used in relatively higher concentrations in comparison to other medium components, it contributes to the raw material cost in high amounts. Therefore, utilization of cheaper carbon sources is strongly required. Molasses, a waste of sugar industry is one of the most favorable carbon source. It consists of approximately 45–50% (w/w) total sugars (mainly sucrose, glucose and fructose), 17–25% water and 2–5% polysachharides (dextrins, pentosans, polyuronic acid) [14]. Gaurav et al. [15] evaluated the usage of molasses to increase the biomass and lipid production of Chlorella pyrenoidosa. C. pyrenoidosa cells were maintained in 100 mL Fogg’s medium that contain different sugars (10 g/L), which include glucose, sugar mixture (8 g/L sucrose, 1 g/L glucose and 1 g/L fructose), treated and untreated molasses. The biomass obtained was 0.89, 0.81, 0.52 and 1.22 g/L with glucose, sugar mixture, untreated molasses and treated molasses, respectively. By taking into consideration the increase in biomass concentration from 0.89 to 1.22 g/L and the increase in lipid content from 0.27 to 0.66 g/g using molasses instead of glucose they reported the feasibility of using molasses as a carbon source for large scale low-cost lipid production by C.pyrenoidosa [15]. In addition, corn powder hydrolysate [16], sweet sorghum [17] and cassava [18] are other cheap organic carbon sources that were used as carbon source for the cultivation of microalgae.

In order to maximize the industrial productivity of microalgae, there is a need for optimization of high-density cell cultivation conditions. Such an optimization is performed via repeating experiments. Instead of performing repeating experiments, response surface methology (RSM) can be applied and thus optimized values can be determined with a less number of experiments [19]. Also, interactions between operating variables can be explained by RSM and optimum conditions for algal growth are determined [20].

Several researchers have studied the optimization of cultivation conditions and medium compositions of microalgae using RSM [20, 21]. Cheng et al. [21], used the Central Composite Design of RSM to investigate the effects of C/N (carbon source/nitrogen source) and yeast extract concentration on the biomass and lipid production of Chlorella prothecodies [21]. Kirrolia et al. [20] used the Box-Behnken Design of RSM for medium optimization of Chlorella spp. during biodiesel production [20]. However no study has been found on investigation of pH, incubation temperature, carbon source and yeast extract concentration and inoculum ratio on the heterotrophic biomass production by Micractinium sp. cells. Thus, the aim of this study was to enhance the biomass production of Micractinium sp. ME05 through optimization of cultivation conditions. For a cost efficient production of biomass, molasses was used as a carbon source. Different concentrations of carbon source, inoculum ratios of cells and media (basal medium and bold basal medium) were tested by one factor at a time approach and then by Plackett Burman method to screen the process variables that affect the biomass production. The interaction effect between process variables were also evaluated with Box-Benhken Design of response surface method (RSM). This study revealed the optimum heterotrophic cultivation parameters for the enhancement of biomass production of Micractinium sp. ME05 cells with the usage of molasses as a carbon source.

Materials and Methods

Materials

The algal cells used in this study were Micractinium sp. ME05, which were isolated from Haymana, Ankara (latitude 39.44°N, longitude 32.48°E) geothermal flora and characterized as previously described [22]. Microalgae were maintained on agar slants that contain tris-acetate-phosphate (TAP) medium [23].

Culture Medium and Cultivation Conditions

Micractinium ME05 strain, maintained on slant agars of TAP medium, was inoculated into 100 mL of liquid TAP medium. The TAP medium was composed of 2.4 g/L of Tris (hydroxymethyl) aminomethane, 0.8 g/L of NH4Cl, 0.1 g/L of CaCI2·2H20, 0.2 g/L of MgSO4·7H2O, 0.3 g/L of K2HPO4, 0.05 g/L of EDTA·2H2O, 5 mg/L of FeSO4·7H2O, 0.022 g/L of ZnSO4·7H2O, 5.2 mg/L of H3BO3, 5 mg/L of MnCI2·4H2O, 1 mg/L of CuCI2·2H2O, 2.6 mg/L of Na2·MoO·2H2O, and 1.6 mg/L of CoCI2·6H2O [23]. Cells were incubated at 25 ± 1 °C with shaking at 150 rpm for 4 days in a controlled growth chamber. These cells were used as seed cells for basal cultivation medium and bold basal cultivation medium.

Micractinium ME05 cells were cultivated in 250 mL basal medium and 250 mL bold basal medium in 500 mL flasks. The components of basal culture medium were; 0.7 g/L of KH2PO4, 0.3 g/L of K2HPO4, 0.7 g/L of MgSO4·7H2O, 3 mg/L of FeSO4·7H2O, 0.1 g/L of glycine, 0.01 mg/L of vitamin B1, 1 ml/L of A5 trace mineral solution (2.86 g/L of H3BO3, 0.04 g/L of Na2MoCo4·2H2O, 0.22 g/L of ZnSO4·7H2O, 1.81 g/L of MnCI2·4H2O, 0.074 g/L of CuSO4·5H2O) [24]. The components of bold basal culture medium were ; 0.175 g/L of K2HPO4, 0.025 g/L of CaCI2·2H2O, 0.075 g/L of MgSO47H2O, 0. 25 g/L of NaNO3, 0.075 g/L of K2HPO4, 25 g/L of NaCI, 11.42 mg/L of H3BO3, 1 ml/L of trace metal solution consisting of 8.82 g/L of ZnSO4·7H2O, 1.44 g/L of MnCI2·4H2O, 0.71 g/L of MoO3, 1.57 g/L of CuSO4·5H2O, 0.49 g/L of Co(NO3)2·6H2O, alkaline EDTA stock solution (1 ml/L) consisting of 50 g/L Na2EDTA and 31 g/L of KOH, and acidified iron stock solution (1 ml/L) consisting of 4.98 g/L of FeSO4 and 1 mL of H2SO4 [25].

All media and cultivation apparatus were sterilized by autoclaving at 121 °C for 15 min. After sterilization, 30 g/L glucose and 2 g/L yeast extract [26] were added to 250 mL basal medium in 500mL flasks by filtering through a milipore filter. Micractinium sp. ME05 in exponential phase was inoculated (0.2 and 5%, v/v) into basal cultivation medium.10 and 30 g/L glucose were added to 250 mL bold basal medium separately by filtering through a milipore filter. Micractinium sp. ME05 in exponential phase was inoculated (10%, v/v) into bold basal cultivation medium. Heterotrophic cultivation was carried out with air flowing (~ 0.5 L min) in the dark at 25 ± 1 °C for 5 days in a controlled growth chamber.

Pretreatment of Molasses

The molasses used in this study was obtained from Konya Sugar Factory, Konya, Turkey. Acidic pretreatment was applied to molasses. For this purpose 10 mL of molasses was mixed with 90 mL of 1% (w/v) and 3% (w/v) of H2SO4 seperately. The solutions were autoclaved at 121 °C for 40 min. The reducing sugar content was determined using 3,5-dinitrosalicylic acid (DNS) method [27].

Cell Growth and Biomass Measurement

Cell growth was monitored by optical density measurements at 680 nm using Shimadzu UV-1800 spectrophotometer. Microalgae biomass was harvested in stationary phase by centrifugation at 3000 g for 10 min at 4 °C [22]. The harvested biomass was washed with distilled water and then dried at 70 °C in a hot air oven. The biomass was determined gravimetrically [28].

Experimental Design

One Factor at a Time Approach

The approximate medium composition and inoculum ratio for the heterotrophic cultivation of Micractinium sp. ME05 was determined by varying one factor at a time while keeping all other factors constant. For this purpose two different inoculum ratios 0.2 and 5% (v/v) of Micractinium sp. ME05 cells were evaluated in terms of biomass production. Basal medium was used as a cultivation medium for these inoculum ratios. Bold basal medium was supplemented with 10 and 30 g/L glucose separately and 10% (v/v) of Micractinium sp. ME05 cells were inoculated into these media.

Screening of Process Variables by Plackett Burman Method

Plackett-Burman Design was used to screen factors that significantly affect biomass production. pH, temperature, glucose, yeast extract and inoculum size were selected as variables (Table 1). All experiments were conducted in triplicate. The independent variables; pH, temperature, glucose, yeast extract and inoculum size were coded as X1, X2, X3, X4 and X5 respectively. The predicted response (\(\widehat{\text{Y}}\)) was written as follows:

where Ŷ is the predicted response (biomass concentration), β0, β1, β2, β3, β4 and β5 are regression coefficients [29].

The statistical software MINITAB 16.0 (Minitab Inc., State College, PA, USA) was used to analyze the experimental design. A 24-run Plackett-Burman Design was used to screen 5 factors.

Box-Behnken Design

The interaction effect between process variables were studied using the Box-Behnken Design (BBD) with a quadratic model using MINITAB 16.0 (Minitab Inc., State College, PA, USA). Based on the outcome of Plackett-Burman Design experiments, BBD matrix was created using pH (X 1 ), temperature (X 2 ) and molasses hydrolysate concentration (g/L)(X 3 ). The ranges of process variables were 6–8 for pH, 25–37 °C for temperature and 10–30 g/L for glucose concentration. A set of 45 experiments were carried out. A second order polynomial equation was related to biomass production as follows:

where Ŷ is the predicted response (biomass concentration) and β0 the intercept, β1, β2 and β3 are linear coefficients, β4, β5 and β6 squared coefficients, β7, β8 and β9 interaction coefficients and X1,X2 and X3 independent variables used in this study. The optimum conditions for maximizing biomass production was determined by using Response Optimiser Tool in MINITAB16.0 (Minitab Inc., State College, PA, USA) .

Model Verification

The accuracy of the applied model was determined by comparing the results of the experiments with the results of the predicted biomass calculations. In order to evaluate the performance of the model a statistical difference measure test was performed. Root mean square error (RMSE) and mean absolute error (MAE) was calculated as follows:

where X pred,i and X exp,i are predicted and experimental biomass concentrations, respectively; N is the number of data points [29].

Results and Discussion

One factor at a Time Approach

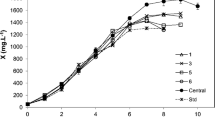

In order to determine the approximate medium composition and inoculum ratio for the heterotrophic cultivation of Micractinium sp. ME05 cells, two different inoculum ratios (0.2 and 5% v/v) of Micractinium sp. ME05 cells into basal medium were evaluated while keeping all other factors constant. When basal medium that contain 30 g/L glucose, was inoculated with 0.2% (v/v) cells, the biomass obtained was 1.33 g/L. With a 5% (v/v) inoculum, the biomass increased to 2.69 g/L. In bold basal medium containing 10 g/L glucose, the biomass obtained was 0.96 g/L, whereas at 30 g/L glucose, the biomass increased to 2.23 g/L (Table 2). These biomass results indicated that, basal medium inoculated with higher inoculum resulted in higher biomass. Also for bold basal medium, higher concentration of carbon source gave higher biomass results, which agreed well to other studies.

In the heterotrophic cultivation of Chlorella prothecoides using basal medium that contain 10 g/L glucose as carbon source and inoculum ratio of 10% (v/v), the biomass obtained was reported as 3.74 g/L after 144 h of incubation [16]. In a study of Yan et al. (2011), basal medium that contain 30 g/L glucose and 2 g/L yeast extract was inoculated with 10% (v/v) Chlorella prothecoides cells. After 120 h of incubation at 28 °C, the biomass reported as 12.8 g/L [26]. Wei et al. [18] evaluated cassava starch hydrolysate (CSH) instead of glucose to increase biomass and reduce the cost of heterotrophic cultivation of C. prothecoides. In order to compare glucose and CSH, different levels of glucose concentration (10, 20, 30, 40 and 50 g/L) were used in a glucose based medium and the same glucose concentrations were used in the CSH based medium by adding equivalent amount of CSH to basal medium. These media were inoculated with 5% (v/v) C. prothecoides cells. After incubation at 28 °C for 240 h under dark conditions, they reported that high glucose concentrations increased biomass but decreased the lipid content.On the other hand low glucose concentration decreased the biomass concentration and increased the lipid content. In terms of cassava starch hydrolysate, they reported that higher or lower glucose concentration in CSH inhibited the growth of Chlorella. As a result, a medium with 30 g/L glucose in CSH was preferred for the heterotrophic culture of Chlorella [18].

In our study, during heterotrophic cultivation of Micractinium sp. ME05, different inoculum ratios and glucose concentrations gave rise to different biomass results. In order to screen the important variables that affect biomass concentration, a 2-level Plackett-Burman Design was used prior to response surface optimization.

Screening of Process Variables by Plackett Burman Method

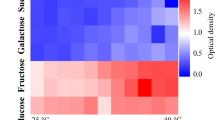

A 12 run Plackett-Burman design was used to screen five factors. All experiments were conducted in two replicates and the response was the average biomass concentration (g/L) after 120 h of incubation. For Plackett-Burman Design, experimental response (Y) and predicted response (Ŷ) are given in Table 3. The first order equation expressed in coded units for biomass production is as follows:

where X1, X2, X3, X4 and X5 are coded variables for pH, temperature, inoculum ratio (v/v %), yeast extract concentration (g/L) and glucose concentration (g/L), respectively.

Estimated effects and coefficients for each variable is given in Table 4. Pareto chart of design variables is given in Fig. 1. According to the results, pH and temperature indicated positive effects on biomass production, whereas inoculum ratio, yeast extract concentration and glucose concentration had negative effects on biomass production. On the other hand, the variables pH, temperature, yeast extract concentration and glucose concentration had significant (p < 0.05) effects on biomass production at confidence level of 95%. The variable, inoculum ratio was found to be insignificant (p > 0.05). Due to their negative effects on biomass production, in subsequent optimization study, the inoculum ratio and yeast extract concentration were used at the center point levels. Although glucose concentration also showed a negative effect on biomass production, it was included in the optimization part since it was the major raw material of this study.

Li et al. (2011) used a similar approach including Box-Behnken Design to optimize carbon, nitrogen and phosphorus concentration in the medium of Chlorella minutissima UTEX2341 and to increase the biomass. Carbon, nitrogen and phosphorus concentration were selected as variables with the maximum and minimum values 3.12–25 g/L, 0.78–3.12 g/L and 0.03 g/L and 0.52 g/L for carbon, nitrogen and phosphorus concentration, respectively. They reported that, carbon and nitrogen concentration significantly affected biomass production on the other hand phosophorus concentration had no significant efffect on biomass. The optimized carbon, nitrogen and phosphorus concentrations were 26.37, 2.61 and 0.03 g/L, respectively [30].

Box-Behnken Design

The results of Box-Behnken experiments to study the effects of pH, temperature and molasses hydrolysate concentration are presented in Table 5. The regression coefficients for biomass production is presented in Table 6. The coefficient of determination (R2) for biomass production was 0.94. As the R2 value gets close to 1.0, the model gets stronger [31]. The R2 value obtained here demonstrated that the model adequately fitted to the data. The insignificant lack of fit (P = 0.131 > 0.05) also demonstrated that the model fitted well to the experimental data.

Among the variables pH, temperature and molasses hydrolysate concentration showed insignificant effects (p > 0.05) under the tested range. Altough their linear effects were insignifcant, the quadratic effects of each variable showed significant effects (p < 0.05). The interaction between pH and molasses hydrolysate and temperature and molasses hydrolysate were significant (p < 0.05), whereas the interaction between pH and temperature was insignifcant (p > 0.05). The highest biomass concentration of 2.05 g/L was observed at a pH of 7, at a temperature of 31 °C with 20 g/L molasses hydrolysate. The second order polynomial equation for the prediction of biomass was:

where Ŷ is the predicted biomass concentration, X1, X2 and X3 are uncoded variables for pH, temperature and molasses hydrolysate concentration, respectively. The response surface plots described by the regression model were plotted for better understanding (Fig. 2). All surface plots demonstrated that as the level of variables increased, biomass production increased up to a certain level. In Fig. 2a biomass concentration demostrated a non-linear effect with the increase of pH from 6 to 8, and with the increase of temperature from 25 to 35 °C under constant molasses hydrolysate concentration. In Fig. 2b surface plots demonstrated that both high and low temperatures had negative effect on biomass production. Similarily high and low concentrations of molasses hydrolysate had negative effect on biomass production. The effects of temperature and carbon source concentration in our study are in accordance with the findings of Lakshmikandan et al. (2016), who reported that high and low concentrations of subtsrate and high and low values of temperature had negative effect on cell growth and biohydrogen production [32]. Such a behaviour may result from the fact that under sub-optimal temperature conditions, cytoplasmic viscosity of the cells change and carbon utilization becomes less efficient. On the other hand, increasing the temperature beyond the optimum reduces protein sythesis and as a result reduces cell growth rate [33]. An increase in pH with a simultaneous increase in molasses hydrolysate concentration (temperature constant) led to an increase in biomass production until they reached their optimal values (Fig. 2b). Such a behaviour was expected since pH determines the solubility of essential nutrients and maximum algal growth occurs around neutral pH [33]. When pH was held constant, an increase in temperature about to 30 °C and an increase in molasses hydrolysate concentration to 20 g/L caused an increase in biomass concentration, as denoted by the significant interaction term in Table 6. In Fig. 2c, the molasses hydrolysate concentration showed a non-linear effect on biomass production. As molasses hydrolysate concentration was increased to about 20 g/L, biomass concentration increased to about 1.5 g/L. An incrase in biomass concentration with an incrase in molasses hydrolysate concentration was due to the fact that biomass is mainly controlled by the carbon source and is essential for building up biomass [20].

Response surface plots showing the effect of a temperature and pH, b molasses hydrolysate concentration and pH, c temperature and molasses hydrolysate concentration on biomass production.The third factor, in all cases was held constant at the middle level (i.e. pH:7, temperature 31 °C and molasses hydrolysate: 20 g/L)

The highest biomass result obtained with BB Design experiments using 19 g/L molasses hydrolysate is 2.05 g/L and the biomass productivity is 0.27 g/L/day. Such a biomass productivity is higher than those obtained in the literature that were concerned with the optimization of biomass production from Micractinium species. For example, Karpagam et al. [28] focused on increasing biomass and lipid production of Coelastrella sp. M-60 and Micractinium sp. M-13 using sugarcane industry effluent (0.625, 1.2 and 2.5 mL/L), citric acid (10, 20, 30 mg/L) glucose (0.05, 0,1, 0,15 and 0.2%)and vitamin B12 (0.001, 0.002 and 0.003%) with BG-11 medium. Medium optimization studies were performed with Central Composite Design (CCD) and it was reported that the growth of Micractinium sp. M-13 was maximum for BG-11 medium containing 25 mg/L citric acid and 1.25 ml/L sugarcane industry effluent with a biomass productivity of 0.0615 g/L/day [28]. Beside this, there are different studies that are concerned with the enhancement of microalgal biomass production by using Response Surface Methdology and Multi-Objective Optimization [21, 34]. Kanaga et al. [34] focused on maximizing lipid and biomass production of Chlorella pyrenoidosa NCIM 2738 by using multi objective optimization strategy. Glucose, NaNO3 and K2HPO4 concentration were selected as variables and were investigated with Central Composite Design. It was reported that the optimal level of NaNO3, K2HPO4 and glucose concentration to maximize biomass concentration were 23.63 mM, 286.4 µM and 4.18% (w/w), respectively. Under such conditions the biomass obtained was 1.395 g/L [34]. Different biomass quantitites observed in the previous studies and in this study is due to the fact that between various species the lipid content, lipid and biomass productivites show significant differences [35].

In comparison with one factor at a time approach in this study, the decrease in the amount of carbon source concentration from 30 g/L glucose to 19 g/L waste molasses hydrolysate can remarkably reduce the cost of cultivation since the cost of glucose is estimated to be 80% of the total medium cost [36]. On the other hand, alternatively cheap carbon sources have been suggested to replace glucose for lowering culture costs [15, 18].

Model Verification Results

The optimum conditions for biomass production predicted by the model were found as temperature of 30.9 °C, a pH of 6.9 and molasses hydrolysate concentration of 19 g/L. Under these conditions the biomass was measured as 2.08 g/L. The biomass obtained was very close to corresponding predicted value of 1.95 g/L with a very low standart deviation (0.09) and very low coefficient of variation (0.04 or 4%). These results indicated that the model adequately estimates the biomass produced. The constructed model was also checked using error analysis.The RMSE and MAE values were calculated as 0.10 and 0.08, respectively, which both indicate low error and high accuracy of prediction.

Conclusion

This study presented optimization of heterotrophic cultivation conditions for Micractinium sp. ME05 to improve biomass production. Process variables were screened by PB method. The PB method gave 1.07 g/L biomass and 0.15 biomass yield (Yx/s) with 7.18 g/L glucose consumption. Response surface optimization resulted in 2.08 g/L biomass and 0.21 biomass yield (Yx/s) with 9.82 g/L molasses hyrdolysate consumption. The results demonstrated that cultivation conditions can be manipulated with RSM to increase the biomass about to 1.9-fold. Since molasses hydrolysate is a low cost substrate compared to glucose, this study provides useful information for further studies regarding cost efficient large scale production of biomass for industrial applications.

References

Brennan, L., Owende, P.: Biofuels from microalgae-A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 14, 557–577 (2010). doi:10.1016/j.rser.2009.10.009

Suali, E., Sarbatly, R.: Conversion of microalgae to biofuel., Renew. Sustain. Energy Rev. 16, 4316–4342 (2012). doi:10.1016/j.rser.2012.03.047

Perez-Garcia, O., Escalante, F.M.E., de-Bashan, L.E., Bashan, Y.: Heterotrophic cultures of microalgae: Metabolism and potential products. Water Res. 45, 11–36 (2011). doi:10.1016/j.watres.2010.08.037

Rattanapoltee, P., Kaewkannetra, P.: Utilization of agricultural residues of pineapple peels and sugarcane bagasse as cost-saving raw materials in Scenedesmus acutus for lipid accumulation and biodiesel production. Appl. Biochem. Biotechnol. 173, 1495–1510 (2014). doi:10.1007/s12010-014-0949-4

Agwa, O.K., Ibe S.N., Abu, G.O.: Heterotrophic cultivation of Chlorella sp. using different waste extracts. Int. J. Biochem. Biotechnol. 2, 289–297 (2013)

Sonmez, C., Elcin, E., Akın, D., Avni, H., Yucel, M.: Bioresource technology evaluation of novel thermo-resistant Micractinium and Scenedesmus sp. for efficient biomass and lipid production under different temperature and nutrient regimes. Bioresour. Technol. 211, 422–428 (2016). doi:10.1016/j.biortech.2016.03.125

Chojnacka, K., Marquez-Rocha, F.-J.: Kinetic and Stoichiometric Relationships of the Energy and Carbon Metabolism in the Culture of Microalgae. Biotechnology 3, 21–34 (2004). doi:10.3923/biotech.2004.21.34

Huang, G., Chen, F., Wei, D., Zhang, X., Chen, G.: Biodiesel production by microalgal biotechnology. Appl. Energy. 87, 38–46 (2010). doi:10.1016/j.apenergy.2009.06.016

Chen, C.-Y., Yeh, K.-L., Aisyah, R., Lee, D.-J., Chang, J.-S.: Cultivation, photobioreactor design and harvesting of microalgae for biodiesel production: A critical review. Bioresour. Technol. 102, 71–81 (2011). doi:10.1016/j.biortech.2010.06.159

Wen, Z.-Y., Chen, F.: Heterotrophic production of eicosapentaenoic acid by microalgae. Biotechnol. Adv. 21, 273–294 (2003). doi:10.1016/S0734-9750(03)00051-X

Chen, F.: High cell density culture of microalgae in heterotrophic growth. Trends Biotechnol. 14, 421–426 (1996). doi:10.1016/0167-7799(96)10060-3

Liu, J., Sun, Z., Zhong, Y., Gerken, H., Huang, J., Chen, F.: Utilization of cane molasses towards cost-saving astaxanthin production by a Chlorella zofingiensis mutant. J. Appl. Phycol. 25, 1447–1456 (2013). doi:10.1007/s10811-013-9974-x

Miao, X., Wu, Q.: Biodiesel production from heterotrophic microalgal oil. Bioresour. Technol. 97, 841–846 (2006). doi:10.1016/j.biortech.2005.04.008

Najafpour, G.D., Poi Shan, C.: Enzymatic hydrolysis of molasses. Bioresour. Technol. 86, 91–94 (2003). doi:10.1016/S0960-8524(02)00103-7

Gaurav, K., Srivastava, R., Sharma, J.G., Singh, R., Singh, V.: Molasses based growth and lipid production by Chlorella pyrenoidosa: A potential feedstock for biodiesel. Int. J. Green Energy. 5075, 150122092222001 (2015). doi:10.1080/15435075.2014.966268

Xu, H., Miao, X., Wu, Q.: High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J. Biotechnol. 126, 499–507 (2006). doi:10.1016/j.jbiotec.2006.05.002

Gao, C., Zhai, Y., Ding, Y., Wu, Q.: Application of sweet sorghum for biodiesel production by heterotrophic microalga Chlorella protothecoides. Appl. Energy. 87, 756–761 (2010). doi:10.1016/j.apenergy.2009.09.006

Wei, A., Zhang, X., Wei, D., Chen, G., Wu, Q., Yang, S.-T.: Effects of cassava starch hydrolysate on cell growth and lipid accumulation of the heterotrophic microalgae Chlorella protothecoides. J. Ind. Microbiol. Biotechnol. 36, 1383–1389 (2009). doi:10.1007/s10295-009-0624-x

Kim, W., Park, J.M., Gim, G.H., Jeong, S.-H., Kang, C.M., Kim, D.-J., Kim, S.W.: Optimization of culture conditions and comparison of biomass productivity of three green algae. Bioprocess Biosyst. Eng. 35, 19–27 (2012). doi:10.1007/s00449-011-0612-1

Kirrolia, A., Bishnoi, N.R., Singh, R.: Response surface methodology as a decision-making tool for optimization of culture conditions of green microalgae Chlorella spp. for biodiesel production. Ann. Microbiol. 64, 1133–1147 (2014). doi:10.1007/s13213-013-0752-4

Cheng, Y., Lu, Y., Gao, C., Wu, Q.: Alga-based biodiesel production and optimization using sugar cane as the feedstock. Energy Fuels. 23, 4166–4173 (2009). doi:10.1021/ef9003818

Onay, M., Sonmez, C., Oktem, H.A., Yucel, A.M.: Thermo-resistant green microalgae for effective biodiesel production: Isolation and characterization of unialgal species from geothermal flora of Central Anatolia. Bioresour. Technol. 169, 62–71 (2014). doi:10.1016/j.biortech.2014.06.078

Gorman, D.S., Levine, R.P.: Cytochrome f and plastocyanin: their sequence in the photosynthetic electron transport chain of Chlamydomonas reinhardi. Proc. Natl. Acad. Sci. USA. 54, 1665–1669 (1965). doi: 10.1073/pnas.54.6.1665

Xiong, W., Li, X., Xiang, J., Wu, Q.: High-density fermentation of microalga Chlorella protothecoides in bioreactor for microbio-diesel production. Appl. Microbiol. Biotechnol. 78, 29–36 (2008). doi:10.1007/s00253-007-1285-1

Abou-shanab, R.A., Raghavulu, S.V., Hassanin, N.M., Kim, S., Kim, Y.J., Oh, S.U., Oh, Y., Jeon, B.: Manipulating nutrient composition of microalgal growth media to improve biomass yield and lipid content of Micractinium pusillum, Afr. J. Biotechnol. 11, 16270–16276 (2012). doi:10.5897/AJB12.2628

Yan, D., Lu, Y., Chen, Y.F., Wu, Q.: Waste molasses alone displaces glucose-based medium for microalgal fermentation towards cost-saving biodiesel production. Bioresour. Technol. 102, 6487–6493 (2011). doi:10.1016/j.biortech.2011.03.036

Miller, G.L.: Use of dinitrosalicyclic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). doi:10.1021/ac60147a030

Karpagam, R., Raj, K.J., Ashokkumar, B., Varalakshmi, P.: Characterization and fatty acid profiling in two fresh water microalgae for biodiesel production: Lipid enhancement methods and media optimization using response surface methodology. Bioresour. Technol. 188, 177–184 (2015). doi:10.1016/j.biortech.2015.01.053

Uncu, O.N., Cekmecelioglu, D.: Cost-effective approach to ethanol production and optimization by response surface methodology. Waste Manag. 31, 636–643 (2011). doi:10.1016/j.wasman.2010.12.007

Li, Z., Yuan, H., Yang, J., Li, B.: Optimization of the biomass production of oil algae Chlorella minutissima UTEX2341., Bioresour. Technol. 102, 9128–9134 (2011). doi:10.1016/j.biortech.2011.07.004

Gurkok, S., Cekmecelioglu, D., Ogel, Z.B.: Optimization of culture conditions for Aspergillus sojae expressing an Aspergillus fumigatus α-galactosidase. Bioresour. Technol. 102, 4925–4929 (2011). doi:10.1016/j.biortech.2011.01.036

Lakshmikandan, M., Murugesan, A.G.: Enhancement of growth and biohydrogen production potential of Chlorella vulgaris MSU-AGM 14 by utilizing seaweed aqueous extract of Valoniopsis pachynema. Renew. Energy. 96, 390–399 (2016). doi:10.1016/j.renene.2016.04.097

Juneja, A., Ceballos, R., Murthy, G.: Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: A Review. Energies 6, 4607–4638 (2013). doi:10.3390/en6094607

Kanaga, K., Pandey, A., Kumar, S., Geetanjali: Multi-objective optimization of media nutrients for enhanced production of algae biomass and fatty acid biosynthesis from Chlorella pyrenoidosa NCIM 2738., Bioresour. Technol. 200, 940–950 (2016). doi:10.1016/j.biortech.2015.11.017

Mata, T.M., Martins, A.A., Caetano, N.S.: Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 14, 217–232 (2010). doi:10.1016/j.rser.2009.07.020

Xiufeng, W.Q. L., Han, X., Large-scale biodiesel production from microalga Chlorella protothecoides through heterotrophic cultivation in bioreactors. Biotechnol. Bioeng. (2007). doi:10.1002/bit.

Acknowledgements

We would like to thank to Dr. Melih Onay for his isolation and characterization of microalgal species used in this study. This study was carried out in the following laboratories: Middle East Technical University (METU) Central Laboratory Molecular Biology and Biotechnology R&D Center, METU Biology Department Plant Biotechnology Laboratory and METU Food Engineering Department Bioprocess Laboratory. We would like to thank to TUBITAK Project Number :114Z487 for providing funding to Iskin Kose Engin during this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kose Engin, I., Cekmecelioglu, D., Yücel, A.M. et al. Enhancement of Heterotrophic Biomass Production by Micractinium sp. ME05 . Waste Biomass Valor 9, 811–820 (2018). https://doi.org/10.1007/s12649-017-9846-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9846-8