Abstract

Influence of composition and annealing temperature on structure and magnetic properties of amorphous and nanocrystalline Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0, 78.4) alloys was investigated by X-ray diffraction (XRD) and the temperature dependence of permeability. According to the initial crystallization temperature (Tx1) from differential scanning calorimetry (DSC) curves of as-quenched amorphous alloys, 490–700 °C isothermal annealing was carried out to obtain the characteristic nanocrystalline structure. Furthermore, the soft magnetic properties were measured by temperature evolution of magnetic permeability to obtain the correlation between Co content, annealing temperature and magnetic permeability. The results show that, on the one hand, the annealing temperature exerts a significant effect on phase structure and initial permeability (μi). The higher-temperature (from 550 to 610 °C) annealed Co content nanocrystalline samples can remain higher μi at elevated temperature. On the other hand, partial substitution Fe by Co can improve the high-temperature magnetic stability; however, the room-temperature permeability of higher Co content alloys decreases obviously at the same time. This phenomenon was analyzed from the viewpoint of the saturation magnetic induction (Bs), magnetic anisotropy (<K>) and magnetostriction (λs).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Fe-based nanocrystalline alloys firstly reported by Yosizawa et al. [1] are considered to be potential soft magnetic materials for practical application. In the past few years, they have been extensively studied due to their high saturation magnetization, high permeability and low core loss [2,3,4,5,6,7,8,9]. In these materials, the random magneto-crystalline anisotropy is fluctuating on a scale much smaller than the domain wall width and is therefore averaged out by exchange interaction [10], so they have excellent soft magnetic properties at room temperature. However, due to lower Curie point of the residual amorphous phase in dual-phase nanocrystalline alloys, the initial permeability deteriorated sharply at a higher temperature, so they can only be used under the temperature of 300 °C [11,12,13]. To overcome this limitation of the existing Fe-based alloys, partial substitution of Co for Fe was carried out to meet the desire for high-temperature applications [14,15,16,17,18]. However, when Co was added to FeCuNbSiB alloys, although both the Curie temperature and the high-temperature permeability were enhanced [19], the room-temperature permeability was reduced in a large part especially in higher Co content nanocrystalline alloys. Some people attribute the above phenomenon to the increase in the magnetic anisotropy constant [20]. But it is well known that the magnetostriction and the saturation magnetic induction also have influence on permeability of amorphous and nanocrystalline alloys [21, 22]. Study of the origin of above magnetic phenomena is in favor of exploitation new-type high-permeability nanocrystalline alloys in both room-temperature and high-temperature applications.

In this paper, Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0, 78.4) alloys with different annealing temperatures were investigated to obtain a relationship between the magnetic permeability and annealing temperature. And furthermore, the change of initial permeability with Co content at room temperature was also analyzed from the viewpoint of magnetic anisotropy, magnetostriction and saturation magnetic induction.

2 Experimental

Experiments were carried out on samples of amorphous alloys with nominal composition of Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0, 78.4) prepared by single-roller melt spinning method. The as-quenched amorphous ribbons, with 3–4 mm in width and 20 μm in thickness, were wound into 16-mm-inner-diameter and 20-mm-outer-diameter toroidal cores and then were annealed under vacuum atmosphere (1 × 10−3 Pa) at temperatures ranging from 490 to 700 °C. X-ray diffractometer (XRD, Rigaku Dmax-RB) with Cu Kα radiation (λ = 0.154056 nm) was used to determine the structure of the alloys. Differential scanning calorimetry (DSC, SII DSC6220) with a heating rate of 20 °C·min−1 was used to determine the thermal processes of as-quenched alloy studied. The permeability was determined by an impedance analyzer (HP4294A) through a conventional induction method at 10 kHz, with a maximum AC magnetic field of 0.4A·m−1 in a temperature range from 20 to 800 °C, and the heating rate was about 10 °C·min−1. The saturation magnetic induction (Bs) was evaluated from the hysteresis loops obtained at room temperature, and the saturation magnetostriction (λs) was measured by a small-angle magnetization rotation [23], respectively.

3 Results and discussion

DSC curves of as-quenched Fe78.4−xCo x Si9B9Nb2.6Cu1 alloys are presented in Fig. 1. The two crystalline exothermic peaks of each curve are corresponding to initial crystallization temperature of α-FeCo soft magnetic phase (Tx1) and the secondary crystallization temperature of Fe(Co)B hard magnetic phase (Tx2), respectively. It can be seen that the ΔT x (= Tx2 − Tx1) are increasing with Co content (x), which indicates that higher Co content is in favor of forming a single soft magnetic crystalline phase in a broad temperature range.

According to the initial crystallization temperature (Tx1), 490–700 °C isothermal annealing was selected to obtain the characteristic nanocrystalline structure. Figure 2 gives the μi–T curves of as-quenched and annealed Fe27.4Co51Si9B9Nb2.6Cu1 alloys. A characteristic Hopkinson peak is observed at the Curie temperature of the amorphous phase in μi–T curves of as-quenched sample, which is due to a faster decrease in magnetic anisotropy than that of saturation magnetization with temperature increasing, and thus, the permeability diverges at the Curie point [24]. However, the sharp Hopkinson peak vanishes in annealed samples, which indicates that the dual-phase structure has formed when annealing temperature (Ta) > 490 °C [25], and the variation of μi with temperature depends on Ta. When Ta = 490 °C, μi decreases with T increasing and falls nearly to zero at about 470 °C which corresponds to the Curie temperature of the intergranular amorphous phase (\(T_{\text{C}}^{\text{A}}\)), but when Ta ≥ 550 °C, μi no longer reduces to zero at the Curie temperature of the residual amorphous phase, which suggests that when annealing temperature is much higher than the crystallization temperature (Tx1), a lot of ferromagnetic crystallites are precipitated from amorphous matrix during the annealing progress, so the thickness of the amorphous layer gradually gets smaller, which is in favor of forming a stronger exchange coupling between α-FeCo nanograins and μi remains a higher value even at the temperature of much higher than \(T_{\text{C}}^{\text{A}}\), and eventually, μi values of all samples quickly decrease above 700 °C, which is attributed to the formation of a hard magnetic boride other than to the magnetic transition from ferromagnetic to paramagnetic state [26].

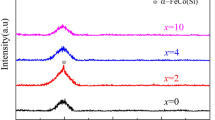

To analyze the change of initial magnetic permeability with T, XRD was used to determine the structure of Fe27.4Co51Si9B9Nb2.6Cu1 alloys annealed at different temperatures, as shown in Figs. 3 and 4. It can be seen that XRD patterns reflect a successive crystallization process which is correlated initially with the crystal growth of the bcc-FeCo phase (Fig. 3) and finally with the formation of fcc-FeCo, hcp-Co and Fe2B phases at the annealing temperature of higher than 640 °C (Fig. 4). When Ta is lower than 610 °C, the patterns are mainly composed of characteristic (110), (200) and (211) diffraction peaks which correspond to bcc α-FeCo crystalline precipitates. Owing to the ultrafine structure of ferromagnetic grains in the crystalline phase, the nanocrystalline alloys have very higher magnetic permeability. However, with Ta increasing, the peaks of α-FeCo become more intense and narrower, indicating an increase in the average grain size (D), so the effective anisotropy increases, which makes room-temperature permeability decrease. However, when T > 640 °C, due to the precipitation of small fractions of Fe2B, hcp-Co and fcc-FeCo, soft magnetic properties drastically deteriorate although bcc-FeCo crystallites remain existence. By contrasting XRD patterns of 670 °C annealed sample with that of 700 °C annealed one in Fig. 4, one can easily see that the diffraction peak intensity of bcc-FeCo is gradually weakening and that of fcc-FeCo is gradually getting stronger with Ta increasing, which indicates that the bcc-FeCo phase is transformed into the fcc-FeCo phase through high-temperature annealing. So, the fcc-Fe with antiferromagnetism and Fe2B with hard magnetic properties make excellent soft magnetic properties vanish.

Usually in dual-phase Fe-based nanocrystalline alloys, a single bcc-Fe nanocrystalline phase precipitates from the amorphous matrix after the first stage of crystallization, then a coarse bcc-Fe grains appears, and small fractions of FeB boride phase precipitates simultaneously after a second stage [27]. This crystallization process is different from that of the present study; the formation of the fcc-FeCo phase and hcp-Co phase in the second stage of crystallization in this experiment may be related to a large content of Co.

For clarifying the evolution of initial permeability with Co content, μi–T curves for Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0, 78.4) annealed at 610 °C were measured, as shown in Fig. 5. The initial permeability declines significantly with the increase in Co content at room temperature; however, it decreases slowly at elevated temperature. That is to say appropriate substitution of Fe by Co can improve high-temperature magnetic stability, but excessive Co content can make soft magnetic properties deteriorate, especially at room temperature. This may be related to the effective magnetic anisotropy (<K>), the saturation magnetic induction (Bs) and the saturation magnetostriction (λs).

In order to ascertain the main reasons for the change of room-temperature permeability with Co content, the average grain size (D), the saturation induction (Bs) and the saturation magnetostriction (λs) were measured. Table 1 shows the average grain size of FINEMET and Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0) with different Ta. One can see that the average grain size of FINEMET is smaller than that of Co-contained alloys; on the other hand, Co content has little impact on D in FeCo-based alloys, which may be related to the kinetics of Cu clustering [20]. The clustering temperature (Tclust) shifts to a higher temperature when substituting Fe by Co, and it becomes higher than Tx1 when x > 20.0. Cu clustering does not appear, which makes D remain roughly constant with Co content increasing. As all known that the effective magnetic anisotropy (<K>) is strongly influenced by D, so there will not have a noticeable increase in <K> with Co content increasing.

The dependence of Bs on Co content for Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0) alloys annealed at 610 °C is shown in Fig. 6. Bs reduces sharply with the increase in x, and this can be explained from Slater–Pauling curve [28]. Bs increases when Co is added to Fe-based nanocrystalline alloys, but when Co content (the ratio of x/78.4 in this paragraph) of FeCo alloy is nearly 30 at%, the magnetic moment reaches a maximum value; then with adding Co continuing, the magnetic moment begins to decline, which is related to the energy band of Fe atoms. It can be seen from Fig. 6 that Bs monotonically decreases with Co content increasing, and this is due to that the smallest Co content of the studied materials is 35 at%.

Figure 7 shows the change of saturation magnetostriction with Ta for different Co content alloys. The increase in λs with Ta indicates that λs is gradually increasing after nanocrystallization for Co-contained alloys. As magnetostriction of crystalline phase (\(\lambda_{\text{s}}^{\text{cry}}\)) of α-FeCo(Si) is positive and larger than magnetostriction of amorphous phase (\(\lambda_{\text{s}}^{\text{am}}\)) of the residual amorphous phase, with the increase in annealing temperature, the volume of crystalline phase becomes large, which results in the increase in λs. But the evolution of λs with Co content does not change obviously. When Co content increases from x = 27.4 to x = 40.0 and 51.0, the λs values of all annealed samples increase by about 5 × 10−6 and 6 × 10−6, respectively, which indicates that Co content has little effect on λs in FeCo-based alloys, and this is different from Fe-based alloys [29]. Considering the evolution of <K>, Bs and λs, Bs is the main reason why room-temperature permeability decreases sharply with Co content in FeCo-based nanocrystalline alloys.

4 Conclusion

Influence of composition and annealing temperature on structure and magnetic properties of amorphous and nanocrystalline Fe78.4−xCo x Si9B9Nb2.6Cu1 (x = 27.4, 40.0, 51.0, 78.4) alloys was studied. Improved high-temperature magnetic softness is observed for the annealed Fe27.4Co51Si9B9Nb2.6Cu1 alloys. The initial permeability (μi–T) of higher-temperature (Ta > 550 °C) annealed samples remains a higher value even at the temperature of much higher than \(T_{\text{C}}^{\text{A}}\), and this may be ascribed to a large crystalline content and a stronger exchange coupling between α-FeCo nanograins. Owing to a large Co content, hcp-Co and fcc-FeCo phases are precipitated from α-FeCo phase, and the high-temperature permeability quickly drops after T > 650 °C. On the other hand, the effective magnetic anisotropy and saturation magnetostriction are little influenced by Co content, but the saturation magnetic induction reduces sharply with the increase in Co content at room temperature, which may be the main reason for lower room-temperature initial permeability of higher Co content FeCo-based nanocrystalline alloys.

References

Yoshizawa Y, Oguma S, Yamauchi K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys. 1988;64(10):6044.

Herzer G. Anisotropies in soft magnetic nanocrystalline alloys. J Magn Magn Mater. 2005;294(2):99.

Liu XL, Wang LS, Luo Q, Xu L, Yuan BB, Peng DL. Preparation and high-frequency soft magnetic property of FeCo-based thin films. Rare Met. 2016;35(10):742.

Zhou J, Zhu ZH, Li XM, Du K, Qiao BY, Fu Y. Force-sensitive properties of FeCuNbSiB powder/silicone rubber composite films. Rare Met. 2016;35(10):784.

Shivaee HA, Celegato F, Tiberto P, Castellero A, Baricco M, Madaah Hosseini HR. The effects of thickness on magnetic properties of FeCuNbSiB sputtered thin films. Scientia Iranica F. 2017;24(6):3521.

Madugundo R, Geoffroy O, Waeckerle T, Frincu B, Kodjikian S, Rivoirard S. Improved soft magnetic properties in nanocrystalline FeCuNbSiB Nanophy®cores by intense magnetic field annealing. J Mag Mag Mat. 2017;422(15):475.

Fan XD, Zhu FL, Wang QQ, Jiang MF, Shen BL. Effect of magnetic field annealing on microstructure and magnetic properties of FeCuNbSiB nanocrystalline magnetic core with high inductance. Appl Microsc. 2017;47(1):29.

Weltsch Z, Klam K, Lovas A. The comparison of hardness and coercivity evolution in various Fe–B based glasses (including FINEMET precursor) during relaxation and crystallization. Acta Phys Pol A. 2017;131(4):669.

Varga LK, Kovac J. Decomposing the permeability spectra of nanocrystalline finemet core. AIP Adv. 2018;8(4):047205.

Herzer G. Grain structure and magnetism of nanocrystalline ferromagnets. IEEE Trans Magn. 1989;25(5):3327.

Tho ND, Chau N, Yu SC, Lee HB, Tuan LA, Hoa NQ. Annealing effect on soft magnetic properties and magnetoimpedance of Finemet Fe73.5Si13.5B9Nb3Au1 alloy. J Mag Mag Mater. 2006;304(1):e195.

Suzuki K, Cadogan JM. Role of the residual amorphous phase in the intergranular magnetic coupling in nanocrystalline magnetic alloys. J Mag Mag Mater. 1999;203(1–3):229.

Skorvanek I, Kim C, Kovac J, Svec P, Turtelli R. Soft magnetic behaviour and permeability spectra in amorphous and nanocrystalline Fe80.5Nb7B12.5 alloys. J Mag Mag Mater. 2000;215-216:440.

Blázquez JS, Franco V, Conde CF, Ferenc J, Kulik T, Kiss LF. Correlation between microstructure and temperature dependence of magnetic properties in Fe60Co18(Nb, Zr)6B15Cu1 alloy series. J Appl Phys. 2009;105(9):291.

Knipling KE, Daniil M, Willard MA. Fe-based nanocrystalline soft magnetic alloys for high-temperature applications. Appl Phys Lett. 2009;95(22):222516.

Heil TM, Willard MA. Structure and magnetic properties of Co-rich nanocrystalline soft magnetic alloys with low coercivity. J Appl Phys. 2007;101(9):291.

Willard MA, Claassen JH, Stroud RM, Harris VG. Structure and magnetic properties of (Co, Fe)-based nanocrystalline soft magnetic materials. J Appl Phys. 2002;91(10):8420.

Willard MA. Core-loss analysis of an (Fe Co, Ni)-based nanocrystalline soft magnetic alloy. J Appl Phys. 2005;97(10):10F502.

Gómez-Polo C, Pérez-Landazabal JI, Recarte V, Campo J, Marín P, López M. High-temperature magnetic behavior of FeCo-based nanocrystalline alloys. Phys Rev B. 2002;66:012401.

Ohnuma M, Ping DH, Abe T, Onodera H, Hono K. Optimization of the microstructure and properties of Co-substituted Fe–Si–B–Nb–Cu nanocrystalline soft magnetic alloys. J Appl Phys. 2003;93(11):9186.

Murillo N, González J, Blanco JM, Valenzuela R, González JM, Echeberría J. Creep-induced magnetic anisotropy and magnetostriction in a nanocrystalline Co based alloy. J Appl Phys. 1997;81(8):5683.

Herzer G. Soft magnetic nanocrystalline materials. Scripta Metall Mater. 1995;33(10–11):1741.

Nartia K, Yamasaki J, Fukunage H. Measurement of saturation magnetostriction of a thin amorphous ribbon by means of small-angle magnetization rotation. IEEE Trans Magn. 1980;16(2):435.

Blázquez JS, Franco V, Conde A, Kiss LF. Soft magnetic properties of high-temperature nanocrystalline alloys: permeability and magnetoimpedance. J Appl Phys. 2003;93(4):2172.

Wang Z, He KY, Jin J, Zhang L. Temperature dependence of permeability for Fe–Cu–M–Si–B alloys. Mater Sci Eng A. 2001;304–306:1046.

Han YM, Wang Z, Che XH, Chen XG, Li WR, Li YL. Influence of Co content on the structure and magnetic permeability of nanocrystalline (Fe1-xCo x )73.5Cu1Nb3Si13.5B9 alloys. Mater Sci Eng B. 2009;156(1-3):57.

Multigner M, Hernando A, Crespo P, Stiller C, Eckert J, Schultz L. Structural and magnetic properties of mechanically alloyed (Fe x Cu1-x)93Zr7 (x = 0.5, 0.7) solid solutions. J Magn Magn Mater. 1999;196–197:214.

Kakehashi Y, Hosohata O. Curie-temperature “slater-Pauling curve”. Journal de Physique. 1988;49(C-8):C8–73.

Wang Z, Yang J, Han YM, Zhang DX, Fu B, Ye RC. Magnetostriction and effective magnetic anisotropy of Co-contained Finemet nanocrystalline alloys. J Appl Phys. 2010;107(9):09A308.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 11604242) and the Tianjin Research Program of Application Foundation and Advanced Technology, China (No. 14JCQNJC04000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, B., Han, J., Guo, SQ. et al. Room-temperature and high-temperature magnetic permeability of Co-doped nanocrystalline alloys. Rare Met. 37, 427–432 (2018). https://doi.org/10.1007/s12598-018-1037-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1037-7