Abstract

In this paper, we describe the effects of substituting Co for Fe on the microstructure, crystallisation behaviour, and soft magnetic properties of (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) alloys. The results demonstrate that as the Co content in the alloy increases, the heat treatment temperature also improves. When x = 0.35 Co was substituted for Fe in Fe84Si4B8P3Cu1 alloy, there was a significant enhancement in the interval temperature (ΔT x ) between the two crystallization temperatures, and this resulted in the largest crystalline volume fraction (V cry ). When annealing at 625–800 K, we observed a dual-phase nanocrystalline structure in all the specimens, which was composed of nanocrystals with average grain size of about 9–28 nm embedded in the residual amorphous matrix. The (Fe0.65Co0.35)84Si4B8P3Cu1 nanocrystalline alloy exhibited a high saturation magnetic flux density, B s , of 1.68 T; a low coercivity, H c , of 5.4 A/m; and a high effective permeability, µ e , of 29,600 at 1 kHz. Hence, these results indicate that this alloy is promising for use as a soft magnetic material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of their excellent soft magnetic properties, Fe-based nanocrystalline soft magnetic alloys, such as Finemet [1], Nanoperm [2, 3], Hitperm [4] and their derivatives, have been widely investigated both experimentally [5–7] and theoretically [8–10] from viewpoint of physics, material science [2, 11, 12], and engineering [13–15]. Of these, one has been shown to improve the magnetic properties of existing alloys. Researchers have been seeking alternative alloys with better properties and/or low production costs [16, 17]. For example, a series of new Fe-based nanocrystalline alloys with the high magnetic flux density B s, based on the system of Fe–Si–B–P–Cu, have aroused great interest in both academic and industrial fields [7, 18, 19]. A much low crystallization temperature and a shorter annealing time make them attractive, especially when compared with traditional nanocrystalline soft magnetic alloys [8]. It is well known that the substitution of Fe to additional elements in Finemet alloys, such as Co, Al or Cr, could extend their outstanding soft magnetic properties to elevated temperatures [20]. Therefore, we decided to partially substitute Co for Fe and prepare (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) alloys, in the hopes that doing so would enhance the magnetic softness at elevated temperatures. The effects of Co addition on the microstructure, crystallization behavior, and soft magnetic properties of the amorphous and nanocrystalline phases turned out to be quite interesting.

This paper describes our investigation of the soft magnetic properties—including the saturation magnetic flux density, coercivity, and permeability—of the FeSiBPCu nanocrystalline alloy system with Co content in the range of x = 0.35 to x = 0.65. Additionally, we describe the grain size of the nano-scale crystalline phases and the crystallization behavior of the varying Co content. Our results left us with the conclusion that the nanocrystalline alloy with Co content of x = 0.35 exhibited a high saturation magnetisation of 1.68 T, low coercivity of 5.4 A/m, and high permeability of 2.9 × 104 at 1 kHz.

2 Experimental procedure

We used arc melting mixtures consisting of Fe (99.99 % by mass), Co (99.99 % by mass), Si (99.99 % by mass), B (99.9 % by mass), Cu (99.99 % by mass), and premelted Fe3P (99.9 % by mass), in a highly purified Ar atmosphere to prepare FeCoSiBPCu alloy ingots. Via single-roller melt spinning, we produced amorphous (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) alloy ribbons [21]. The ribbons were approximately 1.5 mm wide and 20 μm thick. We obtained nanocrystalline alloys composed of a nanocrystalline phase embedded in the amorphous matrix as a result of the crystallization of the as-quenched amorphous under proper annealing conditions. The microstructures of as-quenched and annealed samples were identified by X-ray diffraction (XRD) with Cu-K α radiation and transmission electronic microscopy (TEM), respectively. We evaluated the mean grain size, D, of the α-Fe(Co) phase by using the Scherrer formula from the full width at half maximum bcc (110) X-ray diffraction peck. The thermal behavior of the as-quenched ribbons was evaluated via differential scanning calorimetry (DSC) in argon flow at heating rates of 10, 20, 30 and 40 K/min. We calculated the activation energies of the crystallizations by using the Kissinger equation. We applied a crystallization treatment by treating the as-quenched amorphous specimens at different temperatures for 10 min under a vacuum, and followed that with water quenching. A vibrating sample magnetometer (VSM) and a dc B–H loop tracer were used to measure the saturation magnetic flux density (B s) and coercive force (H c) under the applied fields of 800 and 1 kA/m. The effective permeability (µ e) at 1 kHz was measured with a vector impedance analyzer under a field of 1 A/m. All property measurements were performed at room temperature.

3 Results and discussion

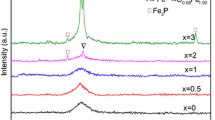

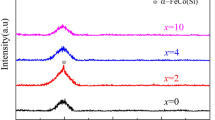

A structural analysis of the as-quenched and annealed (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) samples was done by the evolving x-ray diffraction patterns (XRD). Figure 1 shows the XRD patterns of the as-quenched ribbons, demonstrating the microstructural evolution of the alloy as a function of the Co composition. All XRD spectra show one broad peak, signifying an amorphous structure in the as-quenched state. Figure 2 shows the samples annealed at 763 K for 10 min. The crystallization step is characterized by the formation of α-FeCo phase in the residual amorphous matrix. Using Scherer’s equation, the average grain sizes of the α-FeCo precipitates were estimated from the full width at the half maximum of the reflection peak in the XRD patterns. The calculated crystallite size (D) ranged from 8 to 29 nm in various alloy compositions. The D showed a tendency to increase with increasing Co content.

We calculated the crystalline volume fraction V cry from the XRD spectra, with accordance to \(V_{cry} = \frac{{I_{cry} }}{{I_{cry} + I_{am} }}\), with I cry and I am as the integral intensities of diffraction peaks of crystalline and amorphous phase, respectively [22]. The thickness of the amorphous layer between adjacent grains (Λ), as a function of D and V cry, was estimated to be approximately \(\varLambda = D\left[ {\left( {\frac{1}{{V_{cry} }}} \right)^{1/3} - 1} \right]\) [23]. Table 1 summarizes the evolution of the microstructure as a function of the Co content for the annealed samples. We found that, with increasing Co content, the V cry decreases progressively whereas Λ becomes thicker, implying there is further crystallization and a much stronger exchange interaction between the adjacent nanograins when x = 0.35.

The DSC curves for the (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) as-quenched ribbons were measured at a heating rate of 0.67 K/s in a high-purity Ar flow, as shown in Fig. 3. Clearly, the replacement of Fe with Co brings about a change in the crystallization behavior. We observed two stages of the crystallisation process during the annealing of these ribbons. The initial crystallisation temperature (T x1) increased gradually as the Co content increased from x = 0.35 to 0.65, while T x2, which can be considered a parameter that reflects the thermal stability of the remaining amorphous state above T x1, showed the same trend. It may be noted that the (Fe0.65Co0.35)84Si4B8P3Cu1 has the lowest T x1 and the largest temperature interval (ΔT x = T x2 − T x1) at about 173 K. Thus, in this alloy system, it appears that Co addition improves the heat treatment temperature in this alloy.

Figure 4 shows the DSC curves of the as-quenched (Fe0.65Co0.35)84Si4B8P3Cu1 ribbon collected at different heating rates (10, 20, 30, 40 K/min) in the Ar atmosphere. Exothermic peaks shifted to higher temperatures with the increase of the heating rate, suggesting that the crystallization behavior of the alloy correlates to the heating rate, which has a dynamic effect. In order to further understand the effect of Co content on the alloy’s crystallization behavior, we measured the activation energies (E a ) of both exothermic peaks according to the Kissinger equation [24]

wherein β is the heating rate, T p is the peak temperature, and R is the gas constant. Thus, E a can be indirectly obtained from the slope of a straight line. Using the data from the DSC results, three Kissinger plots are shown in Fig. 5. The obtained activation energies E x , E p1 and E p2 are 265, 279 and 424 kJ/mol, respectively. The Co addition reduced the E p1 and increased the E p2 of FeSiBPCu alloy system effectively [25]. This result indicates that the proper addition of Co promotes the crystallization of α-FeCo and hinders precipitation of other compounds.

Figure 6 shows the TEM and selected area electron diffraction (SAED) patterns of the (Fe0.65Co0.35)84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) nanocrystalline alloys annealed at 763 K for 10 min. The bright-field image shows a homogeneous dispersion of nanocrystallites, with a uniform grain size distribution of about 9 nm, 11 nm and 28 nm. These nanocrystallites are embedded in the residual amorphous matrix, indicating the good thermal stability of the nanocrystalline alloy. Moreover, these results are mostly consistent with the measurements concerning the average grain size of about 8–29 nm by XRD, which supports the reliability of the XRD estimation. As we observed from select areas of electron diffraction patterns, the nanocrystals identified as part of the α-FeCo phase by the XRD measurement exhibits a typical continuous ring pattern, thus displaying the fine grains in the nanocrystalline alloy. These results indicate that the Co addition helps increasing the grain size in the studied alloy compositions.

Figure 7a–c shows the dependence of the effective permeability (µ e), saturation magnetic flux density (B s), and coercivity (H c), respectively, on the Co-content for the (Fe0.65Co0.35)84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) alloys annealed at 763 K for 10 min. It can clearly be observed in Fig. 6a that µ e decreased from 29,600 to 21,500 as the Co content increased from x = 0.35 to x = 0.65. Meanwhile, H c changed in the opposite manner, as shown in Fig. 6c; as the Co content increased from x = 0.35 to x = 0.65, H c increased from 5.4 to 11.8 A/m. According to the random anisotropy model [26], the soft magnetic properties of the nanocrystalline materials are ascribed to the averaging-out of the magneto crystalline anisotropy, as a result of the random distribution of the nanoscale grains. The coercivity and permeability are expected to vary roughly in the grain size as H c ∝ D 6 and µ ∝ 1/D 6, respectively. As Fig. 7c shows, in the (Fe0.35Co0.65)84Si4B8P3Cu1 alloy, D is >28 nm. Because of that rather large grain size, the H c for this alloy was as large as 11.8 A/m. As the Co content decreased, D decreased drastically and the alloys begin exhibiting a finer nanocrystalline structure, resulting in a drastic decrease in H c . The permeability was proportional to D −6, and the (Fe0.65Co0.35)84Si4B8P3Cu1 alloy had the smallest value of D, explaining why the (Fe0.65Co0.35)84Si4B8P3Cu1 alloy exhibited the maximum value of µ e . Furthermore, from Fig. 6b, it can be observed that B s decreased from 1.68 to 1.58 T as the Co content increased from x = 0.35 to x = 0.65, which occurred because of the microstructure change from an amorphous to a crystalline structure, caused by the precipitation of α-FeCo and the changing volume fraction of the nanocrystalline phase. As a result, we concluded that B s varies in proportion with the volume fraction of the nanocrystalline phase.

It is evident that Co addition has a noticeable effect on the crystallization behavior, microstructure and magnetic properties. According to recent studies, the existence of primary crystals in the as-quenched state is necessary for uniform nanocompound structure alloys, such as FeSiBCu and FeSiBPCu. In the FeSiBPCu nanocrystalline alloy, Cu clusters form prior to nanocrystallization, leading to an increase in the local concentration of Fe in the vicinity of these clusters, as well as the formation of bcc-Fe crystals. However, in this FeCoSiBPCu alloy system, especially in Co-rich alloys, Co addition results in crystallizations that differ from the FeSiBPCu nanocrystalline alloy. The formation of a nanocrystalline in the α-FeCo phase and the corresponding increase of average grain sizes in α-FeCo with increasing Co content shows that the Cu clusters do not act as nucleation sites for the primary crystal formation; hence, Cu is unnecessary for nanocrystallization in this Co-rich nanocrystalline alloy. From the perspective of molecular basis, when Co was substituted for Fe in this nanocrystalline, Co partly dissolved into α-Fe crystallization phase, which result in the α-FeCo crystallization phase formed. Because Co atomic radius is smaller than Fe, the substitution of Co for Fe could weakens the Cu clusters that act as nucleation sites for the formation of primary crystals during the melt-spinning process, which will result in the increase in grain size of the nanocrystals with increase in Co content. The addition of Co is effective at facilitating the formation of primary crystals during the melt-spinning process. During crystallization, large amounts of the clusters may act as nucleation sites for the α-FeCo grains, which presumably results in the increase in α-FeCo grain size and the improvement of the soft magnetic properties of the nanocrystalline alloys.

4 Conclusions

In the present work, we described our investigation into the microstructure, crystallisation behaviour, and soft magnetic properties of (Fe1−x Co x )84Si4B8P3Cu1 (x = 0.35, 0.5, 0.65) alloys. The results can be summarised as follows:

-

1.

By appropriately annealing the as-quenched ribbons at 763 K for 10 min, we obtained nanocrystalline alloys with a dispersed α-FeCo phase. We identified the phase produced by the primary crystallization as α-FeCo, with grains ranging in size from 9 to 28 nm.

-

2.

The (Fe0.65Co0.35)84Si4B8P3Cu1 nanocrystalline alloy exhibited a high saturation magnetisation (1.68 T), low coercivity (5.4 A/m), and high permeability (2.9 × 104).

-

3.

The substitution of Co for Fe in this alloy system improved the heat treatment temperature and contributed to the precipitation of the α-FeCo phase. The (Fe0.65Co0.35)84Si4B8P3Cu1 alloy had the largest interval temperature (ΔT x ) between the two crystallization temperatures and the largest crystalline volume fraction (V cry ). We conclude that the addition of Co weakens the Cu clusters that act as nucleation sites for the formation of primary crystals during the melt-spinning process.

These results indicate that this alloy system has promising applications in the soft-magnetics industry.

References

V. Cremaschi, G. Sánchez, H. Sirkin, Phys. Rev. B Condens. Matter 354, 213 (2004)

K. Suzuki, A. Makino, A. Inoue, T. Masumoto, J. Appl. Phys. 70, 6232 (1991)

A. Makino, T. Bitoh, A. Inoue, T. Masumoto, Scr. Mater. 48, 869 (2003)

M.E. McHenry, F. Johnson, H. Okumura, T. Ohkubo, V.R.V. Ramanan, D.E. Laughlin, Scr. Mater. 48, 881 (2003)

R. Xiang, S.X. Zhou, B.S. Dong, G.Q. Zhang, Z.Z. Li, Y.G. Wang, J. Mater. Sci. Mater. Electron. 25, 2979 (2014)

Y.M. Chen, T. Ohkubo, M. Ohta, Y. Yoshizawa, K. Hono, Acta Mater. 57, 4463 (2009)

A. Makino, H. Men, T. Kubota, K. Yubuta, A. Inoue, J. Appl. Phys. 105, 07A308 (2009)

Y. Yoshizawa, S. Oguma, K. Yamauchi, J. Appl. Phys. 64, 6044 (1988)

X. Xi, L. Li, B. Zhang, W. Wang, Y. Wu, Phys. Rev. Lett. 99, 095501 (2007)

Z.-P. Wen, Z. Wang, R.-M. Shi, J. Wang, H. Zhang, J. Appl. Phys. 113, 17A320 (2013)

S.X. Zhou, B.S. Dong, J.Y. Qin, D.R. Li, S.P. Pan, X.F. Bian, Z.B. Li, J. Appl. Phys. 112, 023514 (2012)

P. Pawlik, K. Pawlik, H.A. Davies, J.J. Wysłocki, W. Kaszuwara, M. Leonowicz, J. Magn. Magn. Mater. 304, e733 (2006)

B. Dong, S. Zhou, M. Hu, F. Kong, W. Chen, B. Shen, Sci. China Technol. Sci. 53, 1590 (2010)

V. Chunchu, G. Markandeyulu, J. Appl. Phys. 113, 17A321 (2013)

X. Mao, Z. Han, F. Xu, W. Gao, B. Gu, Y. Du, Appl. Phys. A 81, 839 (2005)

A. Gavrilovic, L.D. Rafailovic, D.M. Minic, J. Wosik, P. Angerer, D.M. Minic, J. Alloys Compd. 509s, s119 (2011)

C. Miguel, A.P. Zhukov, J. Gonzalez, J. Non-Cryst. Solids 287, 355 (2001)

A. Makino, Magn. Trans. IEEE 48, 1331 (2012)

A. Urata, M. Yamaki, M. Takahashi, K. Okamoto, H. Matsumoto, S. Yoshida, A. Makino, J. Appl. Phys. 111(1–3), 07A335 (2012)

S.H. Lim, W.K. Pi, T.H. Noh, H.J. Kim, I.K. Kang, J. Appl. Phys. 73, 6591 (1993)

M. Calvo-Dahlborg, U. Dahlborg, F. Haussler, E.D. Tabachnikova, V.Z. Bengus, Appl. Phys. A 74, s1131 (2002)

X.Y. Zhang, F.X. Zhang, J.W. Zhang, W. Yu, M. Zhang, J.H. Zhao, R.P. Liu, Y.F. Xu, W.K. Wang, J. Appl. Phys. 84, 1918 (1998)

A. Hernando, I. Navarro, P. Gorria, Phys. Rev. B 51, 3281 (1995)

H. Kissinger, Anal. Chem. 29, 1702 (1957)

F.L. Kong, H. Men, B.L. Shen, G.Q. Xie, Magn. Trans. IEEE 47, 3180 (2011)

G. Herzer, IEEE Trans. Magn. 26(5), 1397 (1990)

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant 51341002, by the Science and Technology Program of Beijing under Grant Z141100003814007, and by the National Scientific and Technological Support Projects under Grant 2013BAE08B01.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, R., Zhou, S.X., Dong, B.S. et al. Role of Co on microstructure, crystallization behavior and soft magnetic properties of (Fe1−xCox)84Si4B8P3Cu1 nanocrystalline alloys. J Mater Sci: Mater Electron 26, 2076–2081 (2015). https://doi.org/10.1007/s10854-014-2650-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2650-3