Abstract

The improvement of soft magnetic properties at elevated temperature was realized by doping Co into the Nb-free Fe80.5Cu1.5Si4B14 alloy. The Curie temperature of amorphous alloy TC increases to 400 °C when 10 at.% Fe is substituted by Co. For the nanocrystalline Fe70.5Co10Cu1.5Si4B14 alloy, a considerable initial permeability μi can be maintained above 450 °C, which is much higher than the TC of amorphous alloy. It is found that the cyclic annealing is effective to improve the saturation flux density BS, which is attributed to the enhanced crystallization volume fraction. Especially for the nanocrystalline Fe78.5Co2Cu1.5Si4B14 alloy, the BS is increased to 1.83 T. Furthermore, the cyclic annealing reduces the grain size, giving rise to the decrease of coercivity HC and the increase of μi.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

FeCuSiB nanocrystalline alloys have been extensively studied for their ability to realize both high magnetic flux density BS and low iron loss P simultaneously [1,2,3,4,5]. Their BS is more than 20% larger than that of conventional Fe-based nanocrystalline alloys [6], and P is about the half of Si steels [7]. The excellent soft magnetic properties of the FeCuSiB nanocrystalline alloy are attributed to the high-density α-Fe nanocrystals as well as the high Fe content.

There has been an increasing need for the identification of new materials with superior soft magnetic properties for high-temperature applications, while the high-temperature magnetic softness of Nb-free FeCuSiB alloys was seldom dealt with in the past literatures because of the difficulty to realize for this alloy family. Generally, Fe-based nanocrystalline alloy cannot be used at elevated temperature due to the relatively low Curie temperature of the residual amorphous matrix [8]. The partial substitution of Fe by Co in Nb-containing FeCuSiB alloy has confirmed the improvement of magnetic response at high temperatures with respect to the Co-free alloys [9], which is ascribed to the reinforced magnetic exchange coupling between the crystals [10]. However, superfluous Co doping into Nb-containing FeCuSiB would damage the magnetic softness because of larger magnetostriction [11]. It has been confirmed that the substitution of 10 at.% Co for Fe in Fe74.5Nb2Si17.5B5Cu1 alloy can lower the onset primary crystallization temperature and enhance crystallized interval temperature [12]. Thus, the substitution of Fe with appropriate amount of Co in Nb-free FeCuSiB alloy should be a possible approach to realize the improvement of high-temperature magnetic softness. Additionally, the uniform and fine nanostructure is the key to obtain excellent soft magnetic properties for nanocrystalline alloys. The high Fe content in FeCuSiB alloy usually leads to the formation of pre-existing α-Fe nuclei in amorphous precursors [13] and these nuclei will grow in size rapidly during the annealing process, which results in a non-uniform precipitation of α-Fe grains [14]. It has been reported that the cyclic annealing is effective to refine and uniform α-Fe grains, the BS of FeBCu nanocrystalline alloy was increased and the HC was decreased simultaneously when the alloy was subjected to cyclic annealing [15].

In this work, Fe80.5−xCoxCu1.5Si4B14 (x = 0, 2, 4, 10) amorphous alloys were fabricated on the purpose of improvement of magnetic softness at elevated temperature. The alloys were subjected to cyclic annealing to achieve the refined nanostructure and thus the excellent soft magnetic properties.

2 Experimental procedure

Multicomponent alloy ingots with nominal compositions of Fe80.5−xCoxCu1.5Si4B14 (x = 0, 2, 4, 10) were synthesized by melting the mixtures of raw materials Fe (99.9 mass%), Si (99.99 mass%), Fe-18 mass% B, Cu (99.9%) and Co (99.9%) at an argon atmosphere using high frequency induction melting technology. Amorphous ribbons with about 1 mm width and 30 μm thickness were fabricated by single-roller melt spinning method under argon atmosphere onto a copper wheel with circumferential speed of 4000 r/min. These ribbons were wound into toroidal core samples of 16 mm inner diameter and 18 mm outer diameter. To obtain a two-phase composite structure, the melt-spun ribbons and cores were annealed at 410 °C for 10 min with different thermal cyclic numbers (N = 1 and 5) under an Ar flow, where N = 1 represents an isothermal annealing treatment without cycle. N = 5 represents the cyclic annealing, per heat preservation stage at 410 °C was kept for 2 min and subsequently cooled to room temperature, such a process was repeated 5 times continuously. The total holding time at 410 °C of the alloy ribbon and cores is 10 min. The heating and cooling rates in the program of cyclic annealing are 40 °C/min and 10 °C/min, respectively. The thermal characteristics of the melt-spun ribbons were evaluated by differential scanning calorimetry (DSC) at a constant heating rate of 40 °C/min. The microstructure of amorphous and annealed samples was identified by X-ray diffractometry (XRD) with Cu-Kα radiation. The BS and HC of the annealed samples were measured by a DC B-H loop tracer under a maximum applied field of 1000 A/m. The permeability was in situ measured in a furnace with Ar atmosphere protection by using an HP4294A impedance analyzer at H = 0.4A/m and f = 10 kHz, and the heating rate was 10 °C/min.

3 Results and discussion

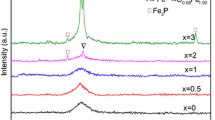

Figure 1 shows the XRD patterns of melt-spun Fe80.5−xCoxCu1.5Si4B14 (x = 0, 2, 4, 10) ribbons. The sample with x = 2 shows a small crystallization peak at 2θ = 44.5°, which corresponds to the (110)-refection of α-FeCo(Si) crystalline phase. For the other samples, only a typical broad scattering peak is observed, indicating the fully amorphous structure of alloys. It has been reported that the primary crystals in the as-quenched state are necessary for the excellent soft magnetic properties in the present alloy system [1]. Therefore, the superior magnetic softness could be expected in the 2at.% Co-containing FeCuSiB alloy.

The temperature dependence of initial permeability (μi ~ T curve) was measured for the Curie temperatures of as-quenched Fe80.5−xCoxCu1.5Si4B14 (x = 0, 2, 4, 10) alloys, as shown in Fig. 2. A characteristic sharp Hopkinson peak is observable on all μi ~ T curves at the Curie temperature of amorphous alloys, TC, which is due to a faster decrease of magnetic anisotropy than that of saturation magnetization. The TC of alloys was extracted and displayed in the inset of Fig. 2. TC increases from 365 °C for the Co-free alloy (x = 0) up to 400 °C for the Co-containing alloy (x = 10), indicating that the partial substitution Co for Fe is in favor of enhancing the TC. The effect of Co on the Curie temperature for Nb-free FeCuSiB alloy is similar to that for Nb-containing FeCuSiB alloy [10].

The thermal performance of the as-quenched ribbons was investigated by DSC, as shown in Fig. 3. Two exothermic peaks for each alloy could be observed, suggesting the crystallization of all these ribbons occurs in two stages. The onset temperature of primary crystallization TX1 and the second crystallization TX2 marked with arrows are originated from the precipitation of α-Fe(Co)Si soft magnetic phase and Fe(Co)B compounds, respectively [16]. With the increasing of Co content, TX1 increases from 370 to 405 °C corresponding to the samples with x = 0 and 10, respectively. The evolution of TX2 with Co content is similar to that of TX1, increasing from 520 to 535 °C. The amorphous precursor would transform into a single nanocrystalline structure without any precipitation of other compounds in the temperature interval between TX1 and TX2, the heat treatment temperature was chosen from the DSC results.

Figure 4a and b shows the XRD patterns of Fe80.5−xCoxCu1.5Si4B14 ribbons annealed at 410 °C with and without cycle, respectively. As presented patterns of all the annealed samples show the characteristic diffraction peaks corresponded to α-Fe(Co)Si crystalline precipitates. It is indicated that all the annealed samples partially crystallize after annealing and their microstructure consists of the residual amorphous phase and the nanocrystalline phase. The volume fraction of crystalline phase Vcry can be estimated from the XRD spectra according to the following equation [17]

where Icry and Iam are the integral intensities of diffraction peaks of crystalline phase and amorphous phase, respectively. These integral intensities are determined from peak areas.

The evolution of Vcry with Co content for the samples annealed at 410 °C with and without cycle are shown in Fig. 5a. With the increasing of Co content, the Vcry decreases from 60 to 40% for the samples with N = 1 and 67% to 49% for the samples with N = 5, respectively. In the condition of the same annealing temperature and time, the lower the crystallization temperature of alloy is, the stronger extent of crystallization of alloy becomes. Accordingly, the decreasing of Vcry is due to the raising of TX1 with Co content (reflected in Fig. 3). The saturation flux density BS of dual-phase nanocrystalline alloy is closely dependent on the Vcry, their relationship can be expressed as [18]

where \(B_{S}^{{cry}}\) and \(B_{S}^{{am}}\) is the saturation magnetic flux densities of the crystalline phase and the residual amorphous phase, respectively. The Co content dependence of BS for the nanocrystalline Fe80.5−xCoxCu1.5Si4B14 alloys (x = 0, 2, 4, 10) is observed in Fig. 5b. The Co content dependence of BS shows a similar variation tendency for the samples annealed at 410 °C with and without cycle. For the samples with N = 1, the BS increases from 1.51 to 1.80 T when 2at.% Co replaces Fe, which decreases subsequently with Co increasing. It is noteworthy that the \(B_{S}^{{cry}}\) is larger than \(B_{S}^{{am}}\) [19] and thus the higher Vcry obtained in the samples with N = 5 results in the increase of BS. Especially for the 2 at.% Co-containing sample annealed with cycle, the BS is about 1.83 T, which is the largest compared with that of the other samples studied here. However, the Vcry of 2 at.% Co-containing sample is smaller than that of Co-free sample, although the BS of which is larger as shown in Fig. 5b. Except for the Vcry, the BS of dual-phase nanocrystalline alloy is closely related to the \(B_{S}^{{cry}}\) and/or the \(B_{S}^{{am}}\). \(B_{S}^{{cry}}\) of α-FeCo(Si) phase (~ 2.45 T) is higher than that of α-Fe(Si) phase (~ 2.18 T) [20]. Therefore, compared with the BS of Co-free alloy, the relatively larger BS of Co-containing alloy originated from the addition of Co content can be affected by the synergetic influence of Vcry and \(B_{S}^{{cry}}\) for the Co-containing alloys.

From the full width at half maximum (FWHM) of the (110) peak, the average grain size, D, can be estimated by means of the Scherrer formula from the XRD pattern. As shown in Fig. 6a, the D shows a slight increase with Co content for the N = 1 sample, which is about 21 ~ 23 nm. However, the D of N = 5 samples increases from 12 to 17 nm and then decrease to 12 nm with Co increasing. The D of the samples annealed with cycle is smaller than that of the ones annealed without cycle, indicating that the cyclic annealing effectively suppresses the coarsening of crystalline grain. From Fig. 6b, the coercivity, HC, increases from 17.1 to 32.5 A/m corresponding to Co-free and 10 at.% Co-containing samples annealed without cycle. Similarly, the variation tendency of HC is in accordance with that of D for the samples annealed with cycle, which increases from 11.2 to 18.9 A/m and then decreases to 13.4 A/m. HC is directly related to the grain size D [9]

where PC is dimensionless pre-factor of the order of unity, K1 denotes the local magnetocrystalline anisotropy, JS is the average saturation polarization and A is the exchange stiffness. It can be seen that HC is proportional to D6, and thus the reduction of HC for the samples annealed with cycle is attributed to the decrease of D.

Figure 7 presents the evolution of initial permeability with temperature (μi ~ T curve) for the nanocrystalline Fe80.5−xCoxCu1.5Si4B14 alloys (x = 0, 2, 4, 10). The common feature of μi ~ T curves for the alloys is that μi maintains relatively higher value from room temperature to a certain temperature (depends on the composition of alloys) and then decreases with T increasing. It should be recognized that the μi value of studied alloys is significantly lower than that of Nb-containing FeCuSiB alloys [12]. It remains an open issue to enhance the initial permeability in Nb-free FeCuSiB alloys. It is an attention-worth feature that the temperature at which μi drops to zero increases with the Co content. The μi drops to zero at about 370 °C for the Co-free alloy, but the μi still keeps a relatively higher value above 450 °C for the 10 at.% Co-containing alloy. The soft magnetic behavior at elevated temperature is dependent on the magnetic exchange coupling between the crystalline grains through the intergranular phase. The grains will begin to decouple as the temperature exceeds TC, which results from the thermal activation of exchange coupled moments in the ferromagnetic grains that are separated by significant amounts of paramagnetic intergranular amorphous phase [21]. The increase of TC due to the doping of Co content is responsible for the improvement of magnetic softness at elevated temperature for the alloys described here.

Simultaneously, the magnitude of μi at room temperature is nearly doubled by the cyclic annealing for the samples (except for the sample with x = 2). As is reported, the grain size plays a dominant role in the evolution of the magnetic properties for the dual-phase nanocrystalline alloy, μi can be expressed as [10]

where μ0 denotes the vacuum magnetic permeability, \(M_{S}^{{cry}}\) and \(M_{S}^{{am}}\) is the saturation magnetization of crystalline phase and residual amorphous phase, respectively. It is clear that μi is strongly related to the grain size D. From Fig. 6a, the D of samples annealed with cycle is significantly smaller than that of ones annealed without cycle, which is the reason for the increase of μi.

4 Conclusions

In this work, the effect of Co doping on the microstructure and soft magnetic properties was investigated for the Nb-free FeCuSiB alloys. The Curie temperature TC increases with the Co content, which is enhanced to 400 °C for the amorphous Fe70.5Co10Cu1.5Si4B14 alloy. The μi of Fe70.5Co10Cu1.5Si4B14 alloy annealed at 410 °C exhibits relatively higher value above 450 °C, which is higher than the TC of amorphous alloy. The effect of cyclic annealing was focused on the evolution of saturation flux density BS and coercivity HC together with room-temperature μi. The BS of samples annealed with cycle is enhanced with respect to that of the ones annealed without cycle due to the increase of crystallization volume fraction. Especially for the Fe78.5Co2Cu1.5Si4B14 alloy annealed at 410 °C with cycle, BS is improved to 1.83 T. HC of the samples is decreased significantly by cyclic annealing, which is due to the reduced D. For the same reason, the room-temperature μi of samples annealed with cycle is nearly twice as much as that of ones annealed without cycle.

References

M. Ohta, Y. Yoshizawa, New high-BS Fe-based nanocrystalline soft magnetic alloys. Jpn. J. Appl. Phys. 46, L477–L479 (2007)

M. Ohta, Y. Yoshizawa, Magnetic properties of high-BS Fe-Cu-Si-B nanocrystalline soft magnetic alloys. J. Magn. Magn. Mater. 320, e750–e753 (2008)

M. Ohta, Y. Yoshizawa, Effect of heating rate on soft magnetic properties in nanocrystalline Fe80.5Cu1.5Si4B14 and Fe82Cu1Nb1Si4B12 Alloys. Appl. Phys. Express 2, 023005 (2009)

M. Ohta, Y. Yoshizawa, Cu addition effect on soft magnetic properties in Fe-Si-B alloy system. J. Appl. Phys. 103, 07E722 (2008)

M. Ohta, Y. Yoshizawa, Magnetic properties of nanocrystalline Fe82.65Cu1.35SixB16-x alloys (x=0–7). Appl. Phys. Lett. 91, 062517 (2007)

Y. Yoshizawa, S. Oguma, K. Yamauchi, New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 64, 6044–6046 (1988)

M. Abe, Y. Takada, T. Murakami et al., Magnetic properties of commercially produced Fe-65.wt% Si sheet. J. Mater. Eng. 11, 109–116 (1989)

Z. Wang, K.Y. He, J. Jin et al., Temperature dependence of permeability for Fe-Cu-M-Si-B alloys. Mater. Sci. Eng. 204–306, 1046–1049 (2001)

C. Gómez-Polo, P. Marín, L. Pascual et al., Structural and magnetic properties of nanocrystalline Fe73.5-xCoxSi13.5B9Cu1Nb3 alloys. Phys. Rev. B 65, 024433 (2001)

Y.M. Han, Z. Wang, X.H. Che et al., Influence of Co content on the structure and magnetic permeability of nanocrystalline (Fe1-xCox)73.5Cu1Nb3Si13.5B9 alloys. Mater. Sci. Eng. B 156, 57–61 (2009)

Z. Wang, J. Yang et al., Magnetostriction and effective magnetic anisotropy of Co-contained Finemet nanocrystalline alloys. J. Appl. Phys. 107, 09A308 (2010)

L. Wen, Z. Wang et al., High temperature magnetic permeability of Si-rich Finemet-type nanocrystalline (Fe1-xCox)74.5Nb2Si17.5B5Cu1 alloys. J. Magn. Magn. Mater. 379, 265–269 (2015)

A. Makino, H. Men, T. Kubota et al., New Fe-metalloids based nanocrystalline alloys with high BS of 1.9T and excellent magnetic softness. J. Appl. Phys. 105, 07A308 (2009)

P. Sharma, X. Zhang, Y. Zhang et al., Competition driven nanocrystallization in high BS and low coreloss Fe-Si-B-P-Cu soft magnetic alloys. Scripta Mater. 95, 3–6 (2015)

X.B. Zhai, L. Zhu, H. Zheng et al., Optimization of crystallization, microstructure and soft magnetic properties of Fe-B-Cu alloys by rapid cyclic annealing. J. Alloys Compd. 768, 591–597 (2018)

H.J. Duan, Z. Wang, Y.R. Jia, Al addition effect on structure and magnetic properties in high BS Fe-Cu-Si-B alloys. Mater. Res. Bull. 111, 289–293 (2019)

X.Y. Zhang, F.X. Zhang, J.W. Zhang et al., Influence of pressures on the crystallization process of an amorphous Fe73.5Cu1Nb3Si13.5B9 alloy. J. Appl. Phys. 84, 1918 (1998)

M. Ohta, Y. Yoshizawa, High BS nanocrystalline Fe84-x-yCuxNbySi4B12 alloys (x=0.0–1.4, y=0.0–2.5). J. Magn. Magn. Mater. 321, 2220–2224 (2009)

F.L. Kong, A.D. Wang, X.D. Fan et al., High BS Fe84-xSi4B8P4Cux (x=0–1.5) nanocrystalline alloys with excellent magnetic softness. J. Appl. Phys. 109, 07A303 (2011)

T. Liu, F.Y. Kong, L. Xie et al., Fe(Co)SiBPCCu nanocrystalline alloys with high BS above 1.83T. J. Magn. Magn. Mater. 441, 174–179 (2017)

M.A. Willard, M. Daniil, K.E. Kniping, Nanocrystalline soft magnetic materials at high temperatures: a perspective. Scripta Mater. 67, 554–559 (2012)

Acknowledgements

This work was supported by National Natural Science Foundation of China (under Grant No. 51271130), Scientific and Technological Research Project of Colleges and Universities in Hebei Province of China (under Grant No. QN2019314) and Key Research Project of Handan University (under Grant No.2017103).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, Rm., Wang, Z. & Duan, Hj. Effect of heat treatment on the microstructure and soft magnetic properties of nanocrystalline Fe80.5−xCoxCu1.5Si4B14 alloys (x = 0, 2, 4, 10). J Mater Sci: Mater Electron 32, 19110–19116 (2021). https://doi.org/10.1007/s10854-021-06429-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06429-w