Abstract

Freezing is a widely used technology for food processing that not only lowers the temperature of food below its freezing point but also inhibits microbial activity and slows down biochemical reactions to enable long-term preservation. However, the freeze thawing cycle can cause various chemical and physical damages to food, which are the main influencing mechanisms of low-temperature preservation. The size of ice crystals determines the degree of physical damage to cells, which has a significant impact on the freezing quality. Magnetic field (MF) treatment is a physical method that has been found to be milder, more effective, and have no obvious side effects compared to chemical treatments. Numerous studies have reported that MF promotes the cold storage of food, prolongs shelf life, inhibits ice crystal nucleation, increases supercooling, accelerates freezing speed, and reduces ice crystal sizes significantly. However, the role of MF in ice nuclei formation is still unresolved, and there are inconsistencies in research results and a lack of clear understanding of its potential mechanism. This paper aims to introduce the influence of MF on the formation and growth of ice crystals, summarize freezing curves on water and salt solutions, and analyze MF applications from two aspects: the thermodynamic mechanism and molecular dynamics point of view for freezing processes. Additionally, it discusses the problems encountered in recent researches and presents future development trends. The conclusion can be drawn that MF demonstrates great application potential in the field of freezing processes and food quality attribute evaluation. However, many questions remain with little consensus in the literature regarding their roles, and the mechanism of action is not unified. The application of MF in food freezing processes is still challenging. This paper hopes to provide guidance for future work on food freezing and contribute to the advancement of this field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, China has seen a significant increase in the annual production of perishable food, reaching approximately 1.3 billion tons [1]. However, due to inadequate cold chain infrastructure and high rates of food spoilage, there is a substantial waste of social resources. This issue has gained attention from experts and scholars worldwide, with freezing being recognized as a crucial method in cold chain logistics. While heat treatment and chemical methods have their limitations, magnetic field (MF) technology offers a non-thermal processing approach that has minimal impact on food quality [2]. Studies have demonstrated the potential of MF technology in various areas, including seed germination [3, 4], plant growth [5, 6], fruit yield [7, 8], food cold storage [9, 10], shelf-life extension [4], beer making [11], biomedicine [12] and more. This paper aims to explore the potential applications of MF in freezing food preservation and discuss its advantages over other methods. Food freezing involves converting the water content of food into ice crystals [13]. By lowering the temperature below the freezing point, microorganisms are inhibited, and biochemical reactions are slowed down. The formation of ice crystals prevents liquid water from facilitating enzymatic and other biochemical reactions, thus extending the shelf life of food at low temperatures [14, 15]. Under cold storage temperature, perishable food can only be stored for a short time. However, when the temperature drops below the freezing point, the food will freeze and can be stored for an extended period. This principle applies to all types of food, where lower temperatures generally result in better quality and longer practical storage periods [16].

Conventional freezing methods often lead to harmful effects such as the formation of larger intracellular ice crystals, which can cause cell rupture and negatively impact the sensory quality of frozen foods. However, several studies have shown that the application of MF can influence the degree of supercooling and freezing rate [17,18,19]. For example, one study demonstrated that water droplets with a diameter of 6 mm experienced an increase in supercooling of up to 10 °C under the influence of a strong MF of 18 T [20]. Another study by Aleksandrov et al. [21] revealed that the critical supercooling degree of water droplets decreased as the strength of the static magnetic field (SMF) increased. When the SMF strength exceeded 0.5 T, the supercooling phenomenon no longer occurred, and the water droplets froze through homogeneous nucleation. Furthermore, Song et al. [22] observed that MF could significantly inhibit the growth of ice crystals, reduce their size, damage cells, and shorten the phase change time. Wang et al. [23] found that MF-assisted freezing could preserve the freshness of samples to a greater extent in the case of bananas. Zhao et al. [24] investigated the inhibition of chilling injury using an alternating magnetic field (AMF) and found significant reductions in respiratory intensity, polyphenol oxidase (PPO) activity, and chilling injury degree when exposed to AMF. In the context of strawberries and blueberries, Tang et al. [17, 25] demonstrated that both SMF and AMF led to a considerable decrease in the average ice crystal area, resulting in lower phase transition temperatures and shorter phase transition times. However, when subjected to AMF, the phase transition temperature increased along with the phase transition time.

Water in food can be classified into bound water and free water. Bound water remains unfrozen during the freezing process [26]. Free water, contains solutes that lower its freezing point compared to pure water [27]. When food is frozen, the concentration of solutes in the free water increases, resulting in a continuous decrease in the freezing point [28]. Consequently, regions with lower solute concentrations freeze first, followed by solute diffusion to unfrozen areas, increasing their solute concentration and lowering their freezing point [29, 30]. However, the application of MF can influence the behavior of water during freezing. MF causes the aggregation of free water molecules, known as water clusters, to break into smaller groups. As a result, a portion of the free water hydrates with proteins and sugars, forming bound water [31]. This reduction in the content of free water inhibits the formation of ice crystals. During the freezing process, a phenomenon called supercooling occurs, where the temperature inside the food drops below the supercooling point before stable ice crystal nuclei form [32, 33]. In general, smaller ice crystals are preferred as they cause less damage to cell membranes and improve the overall quality of frozen food. The degree of supercooling and freezing rate influence the size, position, and morphology of ice crystals during the phase transition stage [34]. MF is known to affect the freezing process by increasing supercooling [35], delaying nucleation [36], accelerating freezing rate [37] and promoting the formation of uniformly distributed small ice crystals [38].

Currently, there are two types of magnetic freezers available in the market: the "CAS (Cells Alive System) freezing" manufactured by ABI Corporation since 2000 and the "Proton freezers" manufactured by Ryoho Freeze Systems since 2003. According to the patent (US Patent 7237400B2) [38], ABI Corporation utilizes a combination of SMF and oscillating magnetic field(OMF) to assist food freezing, In an earlier patent (US Patent 6250087B1) [39], they used electromagnetic fields along with sound waves for the same purpose. On the other hand, Ryoho Freeze Systems combines SMF and electromagnetic waves, as stated in the US Patent (US Patent 8127559B2) [40]. The principle behind these magnetic freezers is based on their direct effect on water molecules by rotating, orienting, and/or vibrating them, preventing aggregation. This process promotes supercooling and reduces the size of ice crystals. This technology has been successfully applied to preserve cells, aquatic products, meat, fruits, and vegetables. From a thermodynamic standpoint, the application of MF affects the Gibbs free energy and alters the nucleation process. By lowering the energy barrier for phase transition, the MF allows water crystallization to initiate at lower supercooling temperatures. From a molecular dynamics point of view, when the MF acts upon food, it induces changes in the orbital motion of electrons, resulting in an opposing magnetic moment proportional to the applied MF.

This paper provides a comprehensive summary of previous research on the freezing process of water, solutions, and food with MF. It discusses the underlying principles of low-temperature preservation during sample freezing and explains strategies to control the formation and growth of ice crystals. The two mechanisms employed in MF applications for frozen food processing are also outlined. The article further emphasizes the effects of different MF on the freezing process of food, including freezing curves, sensory evaluation attributes, as well as physiological and biochemical aspects. However, recent studies have reported inconsistent results regarding the mechanism of MF, and there is still a lack of clear understanding regarding its potential mechanisms. In light of these gaps, the primary objective of this article is to offer novel insights into the low-temperature preservation of food. By summarizing existing research and exploring the current limitations, it aims to contribute to our understanding of the impact and potential mechanisms of MF in frozen food preservation.

Effects of Ice Crystal Formation

Supercooling refers to the state in which a substance's temperature is below its freezing point but has not yet solidified or crystallized [41]. This condition is essential for ice formation in liquid. The process of ice crystallization involves two main steps: ice crystal nucleation and crystal growth. Nucleation is the initial and critical step in forming a crystal nucleus from the parent phase [42]. It plays a crucial role in applications that require control over crystal formation. Crystal nuclei, also known as crystal buds, are the initial particles that precipitate from the supersaturated parent phase and reach a critical size before continuing to grow [43, 44]. Water can enter a supercooled state when it exists in a metastable state, enabling the occurrence of crystal nucleation. There are two types of nucleation: homogeneous and heterogeneous nucleation, based on the influencing factors [45]. Homogeneous nucleation occurs in a uniform, particle-free supercooled liquid and is relatively rare due to the significant degree of supercooling required. On the other hand, heterogeneous nucleation occurs in systems with solid surfaces, active bacteria, or debris, making it more common in food-related scenarios [46]. In summary, supercooling is a necessary condition for ice crystallization, and controlling the nucleation process is vital for applications requiring precise control over crystal formation. Water can exist in a supercooled state, and the type of nucleation that occurs depends on various factors such as the presence of solid surfaces, active bacteria, and debris.

The growth rate of ice crystals during freezing is influenced by the degree of supercooling in the solution. A higher degree of supercooling leads to a higher nucleation rate, resulting in slower crystal growth. The size of the ice crystals formed is determined by the interplay between crystallization kinetics and thermodynamics [47]. Rapid cooling rates promote high nucleation rates, leading to slower growth and the formation of fine, uniformly round ice crystals [26, 48]. The size, shape, and distribution of ice crystals significantly impact the quality of frozen food. Therefore, it is important to control these factors during the freezing process to ensure proper freezing and maintain the quality of the food.

Several studies have demonstrated that MF can affect the properties of water by altering the electron and nuclear spins of water molecules [13, 49,50,51]. In the absence of MF, water lacks a magnetic dipole moment and has a net magnetic moment of zero. However, when MF is applied, the hydrogen nucleus in the water molecule aligns with the external MF, resulting in an internal magnetic dipole moment for the water molecule [52,53,54]. Research has also indicated that MF can modify the electromagnetic properties of water, including its refractive index, permittivity, and conductivity[55,56,57,58]. Moreover, MF can impact the optical properties of water [53, 54], such as infrared, Raman, visible, ultraviolet, and X-ray spectra [43, 52,53,54, 59,60,61,62]. The application of MF can also influence the surface tension and viscosity of water [54, 61, 63,64,65,66], as well as its thermodynamic properties [58, 67,68,69,70,71], kinetic properties (e.g., self-diffusion coefficient) [60, 63, 72, 73], and molecular structure (e.g., hydrogen bond structure) [60, 63, 72, 73].

The freezing process of water and salt solutions is influenced by multiple factors, such as solution temperature, cooling medium temperature, cooling rate, volume, container type, and particle presence. Despite efforts to control these factors, heterogeneous nucleation can occur randomly, leading to inconsistent supercooling levels in repeated experiments. This variability is particularly evident in biological samples, where obtaining exact replicates can be challenging. Consequently, achieving completely consistent test conditions may not be feasible.

MF primarily affects the freezing of water and salt solutions by delaying nucleation, increasing supercooling, accelerating freezing, and promoting the formation of small, uniformly distributed ice crystals. Table 1 provides an overview of the effects of MF on different types of water and salt solutions during freezing. It is believed that MF directly acts on water molecules by orienting, vibrating, and/or rotating them, which prevents aggregation and promotes supercooling [35]. Various studies have produced conflicting results regarding the influence of MF on the freezing behavior of water and salt solutions. For instance, Jin et al. [74] reported that SMF increased the supercooling of deionized water(the test device is shown in Fig. 1(A)), reaching its maximum effect at 16mT. Furthermore, they found that the influence of SMF on the supercooling of a 0.9% NaCl solution was even greater than that on deionized water. This difference may be attributed to the presence of ions. Pulsed magnetic field (PMF) of 6mT and 25 Hz significantly reduced the temperature of initial nucleation, freezing point, and solidification of pure water [80]. Additionally, it notably decreased the phase transition time and subcooling time (the test device is shown in Fig. 1(B)). Mok et al. [29] combined pulsed electric field treatment with SMF treatment, resulting in uniformly round ice crystal patterns for a 0.9% NaCl solution, with the smallest average ice crystal size. They suggested that this mixed treatment enhanced particle vibration, heat transfer, suppressed the formation of water clusters and ice crystals, and reduced the initial nucleation temperature. However, the existing experimental data in the literature do not provide clear evidence of the influence of MF on the kinetics of supercooling or freezing of water. Zhou et al. [77] observed an increase in the supercooling degree of tap water with increasing MF intensity (0.74–5.95 mT). However, Aleksandrov et al. [21] reported the opposite conclusion, stating that the supercooling of distilled water decreased when subjected to MF intensities ranging from 0 to 0.5 T. Zhao et al. [76] found no significant relationship between the supercooling degree and nucleation temperature of deionized water and MF strength. Otero et al. [75] conducted experiments on pure water and a 0.9% NaCl solution, determining that there was no influence of SMF on nucleation time, supercooling degree, phase transition, and total freezing time when different magnetic poles (107–359 mT) faced each other, or when the same magnetic poles (0–241 mT) were adjacent to each other.

Schematic diagram of some MF-assisted freezing and refrigerating devices. A Schematic diagram of SMF freezing device for deionized water and 0.9% NaCl solution[74]. B Schematic diagram of dynamic device for freezing water and cucumber tissue fluid by PMF [80]. C Schematic diagram of water freezing device by OMF [79]. D Schematic diagram of SMF auxiliary freezing device for golden pompano [81]. E Schematic diagram of PMF auxiliary freezing device for blueberries [82]. F Schematic diagram of AMF freezing device for micromachining guava [83]. G Schematic diagram of SMF auxiliary freezing device for potato [84]. H Schematic diagram of cherry freezing device by SMF and AMF [25]. I Schematic diagram of SMF supercooling storage device for beef [85]

Divergent conclusions also exist concerning the impact of OMF on the freezing of water and salt solutions. Kang et al. [79] observed that under OMF intensities of 10 mT, no pendulum movement was detected, while at 50 mT, visible oscillating motion inhibited ice nucleation, with greater displacements corresponding to higher OMF intensities(the test device is shown in Fig. 1(C)). This method of maintaining the supercooled state has potential applications in prolonging the storage time of perishable food [86]. The application of MF during phase transition can disrupt hydrogen bonds in free water clusters, breaking down macromolecular clusters into smaller ones or even single molecular clusters, resulting in smaller ice crystals and shorter phase transition times [87]. Conversely, Otero et al. [42] found that weak OMF (0.8 mT, 20–2000 Hz) did not improve the conventional freezing process, nor did they affect the supercooling degree or freezing kinetics of pure water and 0.9% NaCl solutions. Zhan et al. [78] similarly confirmed that OMF of 10 mT at the frequency of 100-250 Hz had no significant effect on nucleation time and phase transition time.

Several Studies have explained that the effect of low-intensity OMF on freezing is attributed to the presence of submicron ferromagnetic particles within cells. These particles act as nucleation points and are influenced by the MF [26, 88, 89]. However, water and salt solutions do not contain submicron ferromagnetic particles, making it difficult for weak OMF to affect the freezing process of these substances.

The experimental data presented in these studies exhibit inconsistent results, and there are ongoing debates regarding the theoretical explanations of how MF influences the behavior of water. Nevertheless, it is suggested that MF may affects the hydrogen bond network within water and salt solutions. One possibility is that MF strengthen hydrogen bonds [57, 64, 73, 90], while another possibility is that they weaken them [67, 70]. Water molecules organize themselves through hydrogen bonds [91, 92], and according to Toledo et al. [63], these hydrogen bonds can be categorized into inter-cluster and intra-cluster types. The MF may disrupt the hydrogen bonds within clusters while enhancing the hydrogen bonds between clusters. This could result in smaller clusters of water molecules with stronger hydrogen bonds between them, as illustrated in Fig. 2.

Effect of MF on Freezing of Food

Factors such as food size, heat transfer efficiency, and freezing rate are important considerations in traditional freezing technology. However, these factors can also limit the effectiveness of the process, leading to issues such as large ice crystal size, low freezing rates, and poor freezing quality.

During freezing, the volume of food can increase by about 9% due to volume expansion, resulting in significant internal pressure [93]. This pressure can cause cracking in thick foods with high moisture content when there is a rapid decrease in surface temperature. MF have been found to enhance the aggregation of water molecules and increase their interaction with proteins. When MF is applied to frozen food, the free water present in the food is transferred to bonded water molecules that form hydrated structures through interactions with proteins and sugars. This reduction in free water reduces the probability of ice crystal formation, thereby inhibiting nucleation [94, 95]. The freeze concentration effect occurs during freezing, which can lead to protein denaturation. Food is a complex mixture comprising high water content, various nutrients, minerals, and trace ingredients. The application of MF affects the freezing characteristics of food by influencing physical, chemical, and biochemical processes. On one hand, MF provides supercooling during the freezing process, keeping the food at a low temperature for an extended period without ice crystal formation. On the other hand, MF-assisted freezing can achieve greater supercooling compared to traditional methods, resulting in smaller ice crystals that cause less damage to cells. Additionally, AMF generates extra heat through the vibrations of polar water molecules, which can have a negative effect on food freezing. Consequently, SMF offers better cooling effects than AMF in terms of heat transfer efficiency.

Freezing Curve

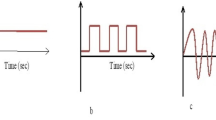

The freezing process of food can be characterized by three stages, as depicted in Fig. 3 [75, 96]. MF can influence the freezing curves of food in various ways, as summarized in Table 2. By applying MF during freezing, the degree of supercooling can be altered, resulting in a slower rate of temperature decrease during the intermediate cooling phase. Additionally, MF-assisted freezing can lead to the formation of smaller ice crystals during this phase. This reduction in crystal size can improve the quality of frozen samples when thawed, as it minimizes the damage caused by large ice crystals. Overall, the use of MF in freezing processes has the potential to modify the freezing curves of food. These effects can contribute to enhancing the quality of frozen food products upon thawing.

Temperature–time curve of supercooled freezing of water [97]. The freezing curve of water is generally divided into three stages, the first stage (precooling stage), the second stage (phase transition stage), and the third stage (subcooling stage). MF can significantly increase the degree of supercooling, shorten the phase transition time and accelerate the freezing speed

The first stage of the freezing process, known as the precooling stage, is characterized by a rapid decrease in temperature of the food. In this stage, the temperature curve is steep and the heat release is primarily due to sensible heat. The initial nucleation temperature, at which the first ice crystals begin to form, is reached during this stage. Kang et al. [98] observed that OMF of 10mT with 1 Hz kept the pineapple sample supercooled at-7 ℃ for 14 days, and successfully inhibited the formation of ice core. Lin et al. [99] also maintained the supercooled state of -4 ℃ for 14 days by using 8mT SMF for beef. Similarly, in the tests of SMF and OMF of asparagus, SMF maintained the undercooled of samples at-3 ℃ for 14 weeks, and the OMF of 50mT with 1 Hz also inhibited the formation of ice nuclei of fresh-cut pineapples, resulted in higher supercooling probability [100]. It shows that the treatment of MF is helpful to prolong the time of supercooled state. One possible point of view can explain this phenomenon. When the MF is applied to the sample freezing, the free water contained in the frozen sample will be transferred, and this part of the free water will hydrate with the proteins and sugars of the food to form the molecules of the hydrated advanced structure, which will eventually be converted into bound water. As a result, the free water is reduced and the probability of ice crystal formation is reduced, which can further inhibit the nucleation of ice crystals. This possible explanation is consistent with the MF-assisted freezing results of Jiang et al. [31] for gel model food, and the MF-assisted freezing of golden pompano by Zhou et al. [81] also confirms this view(the test device is shown in Fig. 1(D)). The supercooled state is important to maintaining product quality [101], supercooling storage was superior to conventional refrigeration [102]. In the supercooled state, even if the temperature drops until the freezing point, the water inside the sample remains liquid, but the process is metastable.

The second stage of freezing, known as the phase transition process, involves removing the latent heat from the system as ice crystals form. During this stage, the freezing curve appears flat, indicating that more than 80% of the water has already been frozen into ice. This zone of maximum crystallization is particularly concerning for food quality, and it is important to pass through this stage as quickly as possible [103].

MF have a multifaceted influence on this stage, primarily by affecting the nucleation temperature of the sample. Research on blueberries subjected to MF showed that SMF with strengths ranging from 0 to 10 mT reduced the nucleation temperature. However, AMF with strengths ranging from 0 to 1.74 mT initially decreased the nucleation temperature and then increased it [17]. Similar findings were reported in research on pork subjected to SMF of 0 to 16 mT [104]. Studies on cucumbers also demonstrated that PMF with a frequency of 25 Hz and an intensity of 0 to 6 mT significantly reduced the nucleation temperature [80]. The possible explanation for this effect is that water molecules are randomly arranged in their natural state, and ice nucleation is also a random process. However, under the influence of an external MF, the orbital motion of water molecule electrons opposes the external MF, making it more challenging for ice to crystallize and leading to a lower nucleation temperature. It is worth noting that ARTEAGA et al. [82] conducted research on blueberries and found that PMF with frequencies ranging from 30 to 120 Hz and an intensity of 44.7 mT increased the nucleation temperature(the test device is shown Fig. 1(E)). The authors believe that PMF further randomize the nucleation process, resulting in an elevated temperature. In summary, MF have a diverse impact on the phase transition process during freezing. SMF and certain AMF can lower the nucleation temperature by hindering ice crystallization through their influence on water molecule orbital motion. However, at higher intensities or different frequencies, PMF may have the opposite effect, increasing the nucleation temperature. The specific effects of MF can vary depending on the nature of the food product being frozen and the parameters of the applied MF.

The application of MF has been found to affect the phase transition time and freezing efficiency of food. Several studies have explored the effects of SMF, AMF, PMF, and OMF on the freezing process and quality of various food products. SMF with a strength of 2 mT was shown to accelerate the time it takes to pass through the maximum ice crystal formation zone while reducing the melting enthalpy of ice in bread dough after multiple freeze–thaw cycles [105]. Similarly, SMF with a strength of 3.5 mT significantly reduced the phase transition time of blueberries [17]. Studies on cauliflower, broccoli, and channel catfish also demonstrated that increasing SMF strength led to a decrease in phase transition time [25, 106, 107]. AMF with a frequency of 50 Hz and a strength ranging from 2.5 to 3.0 mT for tomatoes [101] and a frequency of 50 Hz and a strength ranging from 2.4 to 8.8 mT for guava [83] (the test device is shown Fig. 1(F)) supported the notion of reduced phase transition time. Furthermore, PMF with a frequency of 25 Hz and a strength ranging from 0 to 6.0 mT for cucumbers also showed a reduction in phase transition time [80]. OMF with a frequency of 50 Hz and a strength of 4 mT for avocado puree significantly decreased the temperature zone for maximum ice formation and phase transformation time [97].

The influence of MF on phase transition time can vary depending on factors such as intensity, frequency, and type of MF. In some cases, higher intensities or frequencies of SMF and PMF were found to prolong the phase change stage [17, 81]. Additionally, the fluctuation of MF in changing MF can induce additional Joule heat, resulting in extended phase transition time. It is worth noting that the effects of MF on freezing processes are not universal, and the specific range of MF intensity and type may differ for each food product. Some studies have shown no significant influence of certain SMF intensities on the freezing process or quality of frozen potatoes [87] (the test device is shown Fig. 1(G)). Similarly, the CAS system was found to have no major influence on freezing parameters for apples and potatoes [108]. The application of MF has been observed to reduce the size of ice crystals during freezing, thereby preserving the integrity of food cells. SMF ranging from 0 to 10 mT maintained the integrity of blueberry cells [17], while SMF ranging from 0 to 20 mT decreased the ice crystal area by 67% in cherries (the test device is shown Fig. 1(H)) [25]. The size of ice crystals and their reduction during freezing directly impact the quality of frozen food. In summary, the application of MF can affect the phase transition time, freezing efficiency, and ice crystal size in various food products. However, the specific effects can vary depending on factors such as the strength, frequency, and type of MF used, highlighting the need for further research to optimize the application of MF in different food preservation processes.

During the third stage of freezing, also known as the subcooling stage [80], the temperature of the food continues to decrease until it reaches the specified final temperature. Meanwhile, the unfrozen water within the food undergoes further freezing. However, this phase is susceptible to a phenomenon called recrystallization, where small ice crystals formed during this stage can regrow due to external temperature fluctuations. Recrystallization is highly undesirable for the preservation of food at low temperatures. The growth of these small ice crystals can puncture cell membranes and cause irreversible damage to the cells [109]. To address this issue, the addition of MF during the freezing process has been proposed. The presence of MF can improve the nucleation rate of water molecules, leading to enhanced supercooling and accelerated freezing speed. This results in the formation of numerous small ice crystals with uniform sizes and a homogeneous distribution throughout the food [110]. By maintaining the structure and function of cells, the inclusion of MF helps mitigate the detrimental effects associated with recrystallization.

In summary, the third stage of freezing involves further temperature reduction and continued freezing of unfrozen water inside the food. Recrystallization, which can be detrimental to food preservation, may occur during this stage. The application of MF in the freezing process improves nucleation, increases supercooling, accelerates freezing, and promotes the formation of small, uniformly sized ice crystals. This helps preserve the integrity and functionality of the food's cellular structure.

The Possible Mechanism of MF on Food Freezing Process

The application of SMF has been observed to have an impact on the size of ice crystals during the freezing process. Several experiments provide evidence of the effects of SMF on different types of food products. For instance, in the case of asparagus, it was found that under the influence of SMF, the degree of supercooling remained at -3 °C for a duration of two weeks [100]. Blueberry cells, when examined under a microscope, exhibited clear outlines [17]. The area occupied by cherry ice crystals decreased by 67% [25]. Cauliflower experienced significant reductions in nucleation time and phase transition time [106]. Beef stored at -4 °C with SMF for over 14 days showed inhibited ice nucleation [85] (the test device is shown Fig. 1(I)), while without SMF, ice nucleation occurred after 9 days, and 9 days without ice nucleation [99]. These experimental results can be explained using thermodynamic and molecular dynamics methods.

The Thermodynamic Point of View

Analysis of Gibbs free energy demonstrates that the application of MF can lower the energy barrier for phase transition, allowing water crystallization and nucleation to occur at lower supercooling levels, resulting in a decrease in the nucleation rate. The presence of a surface electric field can alter the free energy barrier for phase transition, thereby influencing the nucleation process. Specifically, the electrostatic field tends to reduce the critical radius, leading to a decrease in the system's Gibbs free energy and an increased nucleation rate [29, 32, 113,114,115,116]. Referring to the mechanisms attributed to electric fields outlined in the references, similar principles can be applied to understand the role of MF in the freezing process of water.

In the absence of MF [117], the formation free energy(\(\Delta G\)) of spherical microcrystals in parent phase is equal to the sum of surface free energy(\({\Delta G}_{\left(s\right)}\)) and volume free energy(\(\Delta G\left(V\right)\)):

where \(r\) is the equivalent radius of the ice crystal, m; \(\sigma\) is surface free energy of the crystal fluid interface without the MF, J/m2; \(\Delta {G}_{V}\) is free energy of freezing per unit volume, J/m3; \(\Delta {H}_{m,f}\), is molar enthalpy of fusion, J/mol; \({V}_{m}\) is molar volume, m3/mol; \({T}_{f}\) is melting temperature, K; \(T\) is temperature, K; \({T}_{f}-T\) is the degree of supercooling, K.

Under the MF, a new term is added to the volume energy [67], and the Gibbs free energy (\(\Delta {G}_{m}\)) can be rewritten as Eq. (3):

where \(H\) is MF intensity, A/m; \(M\) is magnetic polarization, A/m; \(B\) is magnetic flux density, T; \(\mu\) is magnetic permeability; \({\mu }_{0}\) is magnetic permeability of vacuum.

Figure 4 describes the changing trend of Gibbs free energy in the Eq. (3). With the increase of nucleation radius, a critical equivalent radius can be observed if the ice particle is larger than the critical size, which will continue to grow until it becomes microscopic ice crystals. In order to maximize Eq. (3), setting \(d\Delta G/dr=0\), and we can get the critical radius \({r}^{*}\) of the equation and the critical radius \({r}_{m}^{*}\) under the MF:

Critical free energy \(\Delta {G}_{m}^{*}\) under the influence of MF

Jha et al. [113, 117] summarized the theoretical method for calculating the nucleation rate related to supercooling degree under electric field. The relationship of nucleation rate under the utilization of MF is given by this paper. In a certain period of time, with the influence of MF, the concentration of nuclei (\({N}_{m}^{*}\)) formed in the parent phase relative to supercooling degree can be written as:

where \({N}_{1}\) is the monomer concentration; \(k\) is Boltzmann constant; ∆T = \({T}_{f}-T\) is supercooling degree, K.

Elimination of the second term (\(\frac{1}{2}BM\)) in Eq. (9) gives the concentration of nuclei in the absence of MF:

Thus, the relative nucleation rate, that is, the ratio of the concentration of nuclei with field to the concentration of nuclei without field (\({N}_{m}^{*}/{N}^{*}\)) and the induction time(\(\tau\))can be expressed as:

By comparison \({N}_{m}^{*}\) and \({N}^{*}\),it can be concluded that the utilization of MF influences the Gibbs free energy and thus change the nucleation process. The application of MF reduces the energy barrier of phase transition and permits water crystallization nucleation at a lower supercooling degree, which has been recognized by many studies [118, 119]. The formation process of ice is generally described as a parameter of the nucleation rate\(K\), which is a statistical physical quantity. Can be used for all kinds of nucleation.

where \(z\) is imbalance factor; \(f\) is frequency of monomer attachment to the nucleus, it is related to particle surface, molecular diffusion coefficient, temperature and concentration; \({C}_{0}\) is the concentration of nucleation sites.

From the expression of \(K\), we know that the nucleation rate is related to the Gibbs free energy, supercooling degree and other factors. With the presence of MF, the Gibbs free energy is less than the Gibbs free energy with the absence of MF, resulting in a lower nucleation rate.

The Molecular Dynamics Point of Ciew

Figure 5 provides a schematic representation of the distribution of water molecules under the influence of SMF. The magnetism observed in matter arises from the orbital motion and spin of electrons within atoms. Specifically, the orbital motion of electrons around the atomic nucleus creates a small ring of current, generating a magnetic moment along the axis of rotation. Similarly, the rotation of electrons also produces magnetic moments. The overall magnetic moment of an atom is the vector sum of the orbital and spin moments of all its electrons [35]. In the absence of an external MF, water does not possess a net magnetic moment. Consequently, the arrangement of water molecules is dispersed, as depicted in Fig. 5A(a).

Schematic diagram of water molecule distribution under the influence of SMF or PMF. A With SMF, there is no magnetic dipole moment inside the water molecules, and the water molecules are arranged in disorder. Under the influence of SMF, the water molecules generate torque in response to the applied SMF, and the orbital motion of electrons is consistent. B When the direction of the AMF changes, water molecules are constantly disturbed with the direction of AMF

However, when SMF is applied, such as in the food industry, the orbital motion of electrons is altered. This alteration induces an opposing torque, following the principles akin to Lenz's law, which stems from the conservation of energy. This can be observed in Fig. 5A(b).

In the case of AMF, the direction of the AMF changes with the current direction. As a result, water molecules constantly move in alignment with the changing direction of the AMF (as depicted in Fig. 5B). The oscillation of the AMF induces continuous motion in the water molecules, increasing the chances for these molecules to interact and combine with each other. This enhanced interaction promotes nucleation, leading to the formation of numerous ice crystals at higher nucleation temperatures. Studies have shown that the application of AMF results in fine and uniform ice crystals in blueberries [17]. Additionally, the phase transition time is significantly reduced when subjected to AMF intensities of 2.5 and 3.5 mT [101]. Moreover, experimental findings indicate that as the intensity of the AMF increases, the phase transition time decreases [83]. In the case of cherries, it was observed that as the intensity of the MF increased, the phase transition time increased, while the area of ice crystal formation decreased by 67% [25].

With the advancement of computer technology, an increasing number of researchers are employing computer simulations to study the effects of MF on water molecules [63, 67, 73]. Molecular dynamics simulations involving a water molecule system with N = 64 have shown that the internal energy and heat of water exhibit multimodal behavior in response to varying external MF strengths (Fig. 6) [67]. When the MF strength (B) is set at 0.1 or 0.2 T, the internal energy (E) increases by approximately 0.5% or 1.5%, respectively, compared to the case without MF. In contrast, the heat capacity (Cv) decreases by around 0.8% or 1.7% under the same conditions. Conversely, when B ranges from 0.12 to 0.16 T or exceeds 0.23 T, the internal energy decreases and the heat capacity increases compared to the absence of MF. These findings suggest that exposure to MF leads to an increase in the average distance between water molecules. The values of internal energy are primarily determined by the interaction between magnetic moments and the structure of water. When two water molecules approach each other, the interaction energy between their magnetic moments increases, resulting in higher internal energy. This, in turn, reduces the average number of hydrogen bonds formed between water molecules and contributes to a decrease in heat capacity in the presence of MF.

Overall, computer simulations reveal the complex interplay between MF and water molecules, demonstrating how magnetic moment interactions and changes in water structure can affect internal energy, hydrogen bonding, and heat capacity. These insights contribute to a deeper understanding of the influence of MF on water systems.

In order to ensure the uniformity of the MF, particularly in SMF used in food freezing processes, different techniques can be employed. Two common methods involve the use of permanent magnets and Helmholtz coils to generate the desired MF. Permanent magnets are arranged in a specific configuration to create a roughly equal SMF with good uniformity. Multiple permanent magnets of the same size are aligned in the same direction with equal spacing between them. The space between the magnets forms the desired MF. Various types of permanent magnets such as ferrite magnets, alnico magnets, or neodymium magnets can be used for this purpose. One advantage of using permanent magnets is that they do not generate additional heat during operation. Helmholtz coils consist of a pair of circular parallel coils with the same size and a fixed distance between them. The currents flowing through the two coils are in the same direction, which generates a uniform MF between the coils. The main component of the MF produced by Helmholtz coils is parallel to the axes of the two coils. However, it is important to note that the use of Helmholtz coils can generate joule heat due to the current flowing through the coils. When designing MF system for freezing applications, it is crucial to find a balance between achieving the desired freezing effect and minimizing unnecessary heat generation. This requires careful consideration of the type and configuration of magnets or coils used, ensuring that the MF remains uniform while minimizing any heat production from the system. By optimizing the design and configuration of the MF apparatus, the freezing process can be efficiently carried out while maintaining the desired uniformity of the MF and minimizing any unwanted heat generation.

Effect of MF on Physical Property

Table 3 presents the different physical properties of the food, such as its appearance, texture, smell, and overall quality [120]. The objective of this paper is to assess the efficacy of the MF-assisted freezing process in preserving these properties. This will be achieved by examining alterations in pigmentation, color, weight loss, dripping loss, texture, and conducting sensory evaluations to evaluate the changes.

Color Change

Chlorophyll is essential for plant photosynthesis and is predominantly found in chloroplasts. A study by You et al. [100] on asparagus demonstrated that supercooling and freezing storage have an impact on chlorophyll levels. Supercooling was found to significantly reduce the loss of chlorophyll and slow down its decomposition caused by oxidation. The content of chlorophyll a was closely related to the color change of asparagus, with supercooled samples showing higher green values compared to refrigerated and frozen ones [124] (Fig. 7(A)). Total anthocyanins, water-soluble flavonoid pigments responsible for the colorful hues of fruits and vegetables, can be affected by traditional freezing methods due to cell damage. However, Arteaga et al. [82] demonstrated that PMF at certain frequencies and intensities (30 and 90 Hz, 44.7 mT) could help maintain the total anthocyanin content in blueberries, similar to that of fresh blueberries. In contrast, traditional freezing may cause the release of anthocyanins from vacuoles due to cell damage [125]. Furthermore, fruits and vegetables contain various phenolics and polyphenol oxidase (PPO) [126, 127], which contribute to enzymatic browning when cells are damaged.

Effect of MF on food sensory quality. A Color changes between fresh, refrigerated, and supercooled asparagus samples after two weeks of storage [100]. B Appearance differences of beef between samples after 14 days of different treatment. Photos of (A) fresh, (B) SM-ES treated, (C) refrigerated, (D) frozen, and (E) slow frozen samples [85]. C Effects of different freezing and cold storage methods on the color of beef stored for 7 days [122]. D Change in hardness and thawing loss of tomatoes after freezing with the application of MF at 0mT(D1), 2.5mT(AMF) (D2) and 3mT(AMF) (D3) [101]. E Color variation between pineapple samples after 14 days treatment under different conditions: (A) fresh, (B) refrigeration, (C) freeze thawing, and (D) supercooling [98]

Furthermore, fruits and vegetables contain various phenolics and polyphenol oxidase (PPO), which contribute to enzymatic browning when cells are damaged. MF can reduce cell damage by decreasing ice crystal size. For example, PMF treatment of avocado puree resulted in a gradual decrease in color variation (ΔE) with increasing PMF dimensions, indicating that the color quality of PMF-treated samples resembled that of fresh samples [97]. PMF treatments also preserved cell integrity, preventing contact between pigments and PPO after release, thus inhibiting enzymatic browning. Additionally, PMF has the ability to regulate the activities of endogenous enzymes such as PPO and chlorophyllase, which aids in avocado preservation [123]. The effectiveness of MF treatment may vary depending on the type of MF. SMF treatment was found to have a better effect on controlling the color change of cherry tomatoes compared to AMF treatment. It is important to note that the intensity of the MF should be controlled at a weak level for AMF treatment in cherry tomatoes [121]. The theory behind the increase in chlorophyll content under the influence of MF suggests that paramagnetic substance Mn2+ present in chloroplasts may be absorbed by plants. This absorption can affect the mobility and uptake of ions, which play crucial roles in photosynthesis [128].

The application of MF not only helps reduce the color change of fruits and vegetables but also maintains the original color of meat more effectively. In a study by Lin et al. [85], beef was treated with a combination of low temperature supercooling and static magnetic field (SM-ES) at -4 ℃ for 14 days(Fig. 7(B)). The results showed that compared to cold storage (4 ℃), slow freezing (-4 ℃), and freezing (-18 ℃), the color of SM-ES treated beef closely resembled that of fresh beef. Similarly, the application of OMF at 10 mT during the freezing process of beef demonstrated positive effects. Compared to conventional cold storage and frozen storage, beef stored in a supercooled state with OMF treatment exhibited color and tenderness closer to that of fresh samples [122] (Fig. 7(C)). One reason for the maintenance of color in meat under the influence of MF is the significant reduction in methemoglobin content [129]. The color of meat is closely associated with the level of methemoglobin. When the methemoglobin content is low, the meat appears bright red, while higher levels of methemoglobin result in a darker red color.

Color change is an important factor in sensory evaluation, and the closer the color of the experimental product is to that of the fresh sample, the higher its quality.

Weight Loss Rate and Drip Loss

Weight loss is a crucial factor in assessing the quality and nutritional value of fruit and vegetable. as it reflects changes in moisture content. The rate of weight loss depends on factors such as respiration intensity and transpiration, which can affect the food's freshness and shelf life. A slower rate of weight loss indicates better moisture retention, generally resulting in higher quality and a longer shelf life. Conversely, a faster rate of weight loss suggests evaporation of moisture, which can impact flavor, texture, and nutrient content. Therefore, monitoring weight loss during freezing is essential to ensure food quality and safety. Studies have shown that both SMF and AMF can reduce the weight loss rate of cherry tomatoes [121]. the application of OMF can maintain supercooling at -5 ℃ for an extended period, resulting in significantly lower weight loss in mango slices [79]. In the absence of ice crystal formation, cell damage is minimized in the supercooled state. The use of 3D AMF (4mT and 50 Hz) has been found to significantly reduce weight loss in avocado puree, with a more prominent effect observed over longer durations [123]. Low-field nuclear magnetic resonance analysis revealed that AMF treatment reduced the area of the T21 peak, indicating inhibition of biopolymer dehydration, delayed water transformation and distribution, and maintenance of texture and quality in avocado puree.

During freezing, water inside cells condenses into ice, which later melts upon thawing. If the melted water cannot be absorbed by tissue cells and returned to its original state, it becomes separated out as lost liquid, leading to weight loss and degradation in food quality [130]. Therefore, minimizing transpiration, water loss, and ice crystal recrystallization is crucial during the freezing and storage of food. Dripping loss is an important parameter for assessing cell damage and quality deterioration in frozen food [131]. Jiang et al. [106] conducted freezing experiments on cauliflower using both electric fields and SMF and found that both treatments significantly reduced dripping loss in cauliflower. Samples in a supercooled state experience less dripping loss compared to those in a frozen state, affecting the texture and taste of vegetables like asparagus [100]. Similar results were observed with potatoes, where after a freeze–thaw cycle, the average dripping loss of the control group was 19.3%, while under SMF intensity of 40 mT, it decreased to 18.9%, and under SMF intensity of 150 mT, it further decreased to 16.8%. These findings indicate that SMF can reduce dripping loss during freeze–thaw cycles to some extent [84]. The dripping loss is strongly influenced by the sample size and the strength of the MF. For instance, guava samples with MF strength of 5.6 mT and a size of 4 cm exhibited the lowest dripping loss [83]. In the case of tomato freezing assisted by AMF, research showed that the drip loss of tomatoes frozen with AMF decreased from 1.73% to 0.02% compared to traditional freezing methods. This indicates that the quality of tomatoes frozen with AMF closely resembled that of fresh tomatoes [101] (Fig. 7(D)). Dripping loss is associated with the number, size, and location of ice crystals formed during freezing. The application of MF promotes the formation of numerous small ice crystals during the freezing process, which helps maintain the integrity of cells and reduces dripping loss.

Texture Characteristics

Texture is a crucial aspect in assessing the quality and freshness of food. It provides objective information about changes in the physical properties of food, which can be influenced by various factors like processing, storage, and packaging. Key texture characteristics include hardness, spread-ability, viscosity, and microstructure, all of which contribute to the overall assessment of food quality.

Hardness refers to the resistance of a food item to deformation, while spread-ability measures how easily it can be spread on a surface. Viscosity describes the thickness or thinness of a food product, and microstructure refers to the internal arrangement of particles or fibers within a food item. Analyzing these texture characteristics enables us to determine if there have been significant changes that could impact the quality and freshness of the food product. Research conducted by Otero et al. [84] demonstrated that the hardness of frozen potato samples treated with SMF (40mT) remained the highest compared to other treatments. SMF reduce membrane fluidity, enhance cell membrane stability, minimize mechanical stress during freezing, and slow down dehydration damage caused by slow freezing [132,133,134]. In experiments involving avocado puree treated with PMF, an increase in PMF dimension resulted in increased hardness. However, spread-ability had little effect, and the viscosity of the avocado puree was higher than that of the control group [97]. Moreover, the water content of PMF-treated avocado puree was noticeably higher, and the soluble solid content was lower compared to the control group. This was attributed to the formation of small ice crystals induced by PMF. Similar effects were observed in cucumber tissue fluid treated with PMF, where viscosity was significantly affected by the intensity and duration of the MF treatment [80]. Studies on apple preservation showed that AMF could effectively maintain the hardness of apples [9]. Additionally, research by Panayampadan et al. [83] revealed that the hardness of guava was significantly influenced by the linear and product terms of AMF and sample size, with smaller-sized samples experiencing greater hardness loss due to increased drip loss during thawing [135]. In studies on supercooling mango slices, it was found that the application of OMF did not significantly affect the hardness of the slices [79]. Similarly, in the case of supercooling pineapple samples, the cell structure closely resembled that of fresh pineapple samples( Fig. 8(A)) [98]. This indicates that supercooling can effectively prevent long-term moisture loss, maintain hardness, and prolong the shelf life of the fruit. When it comes to SMF-assisted freezing of tilapia, it was observed that the microstructure of the fish was positively influenced by MF with intensities ranging from 0.5 to 5 mT. Among these intensities, 1.5 mT SMF had the most significant effect (Fig. 8(B)) [136]. Similarly, SMF had a remarkable impact on the microstructure of frozen cells in Litopenaeus vannamei (a type of shrimp). As the intensity of the SMF increased, the holes in the scanning electron microscope image first decreased and then increased. The group exposed to SMF of 60 mT showed the most complete structure, with the smallest and most uniform holes(Fig. 8(C)) [137]. Likewise, AMF significantly improved the quality of frozen tilapia, reducing cell damage. An intensity of 5 mT was found to be the most effective for abdominal and tail samples (Fig. 8(D)) [138]. These results collectively demonstrate that MF can effectively maintain the texture of food and enhance the quality of frozen samples. The main mechanism behind this improvement is the considerable reduction in ice crystal size due to the influence of the MF. Upon thawing, the ice crystals transform into water, leaving behind tiny holes in the product.

Microstructure of some samples with or without MF. A Microstructure images of fresh-cut pineapple samples stored under different conditions: (A) fresh, (B) freeze thawing, and (C) supercooling for 14 days(OMF, 10mT和1 Hz) [98]. B Microscope image of tilapia under different MF strengths [136]. C Scanning electron microscope results of litopenaeus vannamei samples [137]. D Scanning electron microscope results of tilapia under MF of different strengths [138]

Sensory Evaluation and Economic Analysis

Wang et al. [123] demonstrated that AMF has a significant impact on maintaining the flavor of avocado puree, particularly the 3D AMF method. The supercooled state achieved through AMF maximizes the sensory hardness of pineapple [98] (Fig. 7(E)). By considering the sensory quality of various foods, it is observed that MF help retain the original color of food by maintaining the supercooled state and reducing the size of ice crystals, thereby minimizing damage to cell membranes. They can also reduce discoloration, drip loss, weight loss, and preserve the original texture and odor. Based on evaluations of these factors, it can be concluded that MF improve the sensory quality of frozen food. However, Owada et al. [139] found that the color and smell of oranges did not significantly change under freezing conditions, regardless of whether MF (0.1 mT) was applied or not. Similarly, low-intensity PMF had no significant effect on the pH value, titratable acidity, and color of orange juice [140] or the hardness of bananas [141].

Kaur et al. [101] demonstrated that AMF reduced the mechanical damage to tomato cells by promoting the formation of smaller ice crystals during freezing, thus preserving the hardness of tomatoes and leading to higher scores in sensory evaluations. Additionally, Kaur performed an economic analysis comparing ordinary freezing with AMF-assisted freezing of 4 kg tomato samples over an 18-day period. The results showed that the equipment cost for ordinary freezing was Rs. 28,000, variable cost was Rs. 1,400, electricity cost was Rs. 200, resulting in a total cost of Rs. 29,600. For MF-assisted freezing, the equipment cost was Rs. 39,500, variable cost was Rs. 1,515, power cost was Rs. 91.28, with a total cost of Rs. 41,106.28. Despite the higher cost associated with MF-assisted freezing, it significantly improved the freezing quality and extended the shelf life of tomatoes, making it beneficial for tomato storage. In summary, AMF has been shown to maintain flavor, preserve color, reduce damage to cell membranes, and improve sensory quality in various foods. However, the effects may vary depending on the specific food item and the type and intensity of the applied MF.

Effect of MF on Physiological and Biochemical Index

Table 4 illustrates the impact of MF on the physiological and biochemical reactions of food. Table 4 emphasizes the impact of MF on various aspects, including plasma membrane permeability, ion transport in ion channels, and membrane permeability, Furthermore, demonstrates that MF can decrease the electrical conductivity of plant leachate, influence the functions of both endogenous enzymes and exogenous enzymes in food [142,143,144,145]. These alterations have the potential to bring about changes in the overall quality and safety of food products.

Relative Conductivity

During food preservation, cell senescence can lead to increased cell activity and membrane permeability. This can cause the infiltration of intracellular electrolytes into the extracellular phase of the food sample. When exposed to MF, these fields can significantly impact the biological current and charged ions within the sample. MF has the ability to alter membrane permeability and ion transport properties, which in turn affect the intracellular electrolyte balance and overall quality of preserved food. A study conducted by Zhao et al. [121] investigated the effect of AMF on the freezing of virgin fruit. Their results demonstrated that the intensity of AMF had a significant impact on the electrical conductivity of the fruit. The control group exhibited the highest electrical conductivity during storage, while the experimental group exposed to AMF (8mT) showed only 81% conductivity compared to the control group. Similar observations were made in studies on cauliflower [106], asparagus [100], chickpea seed [147], sunflower seed [148] and maize seed [149] where MF exposure effectively reduced the electrical conductivity of seed leachate and reduced relative conductivity and cell rupture in cauliflower and asparagus samples. The study on SMF-assisted freezing of tilapia [136] also indicated that MF-assisted freezing effectively reduced the electrical conductivity of tilapia. Zareei et al. [150] illustrated that MF increased the concentration and motion intensity of free ions. In the freezing process, when food is damaged by ice crystals, the cell membrane becomes prone to breakage, resulting in intracellular electrolyte leakage and increased relative electrical conductivity. Therefore, relative conductivity can be used as an indicator of cell membrane permeability in food. Higher conductivity indicates greater permeability and poorer physiological condition of the food. These findings highlight the role of MF in altering membrane permeability, reducing electrical conductivity, and influencing the physiological state of preserved food. Further research is needed to fully understand the underlying mechanisms and optimize the application of MF in food preservation.

Enzyme Activity and Antioxidation

Phenols are abundant in fruits and vegetables, with polyphenols being natural antioxidants. Studies have shown that anthocyanins make up approximately 90% of the polyphenols in blueberries [151]. Arteaga et al. [82] investigated the effects of PMF on blueberries and found that PMF treatment (44.7mT/90 Hz) maintained similar levels of total phenols compared to fresh blueberries. Furthermore, PMF was found to preserve the antioxidant activity of blueberries effectively. On the other hand, AMF can inhibit the affinity of polyphenol oxidase PPO to substrates, thereby reducing its maximum reaction rate [152]. Additionally, PMF can inactivate or even completely inhibit PPO activity [153]. Fruits and vegetables contain various enzymes that work together to ensure their normal growth and metabolism. The traditional freezing process significantly affects the tissue cells of food [154]. Fruits and vegetables have large vacuoles, high water content, and experience significant freezing loss. They also possess thick and inelastic cell membranes that are prone to bursting. When damaged, these fruits and vegetables can undergo enzymatic browning due to the presence of various oxidases reacting with corresponding substrates [155]. To prevent this, fruits and vegetables often undergo blanching or sugar treatments before freezing [156]. However, MF-assisted freezing can slow down the occurrence of browning.

Freezing has a considerable impact on the inhibition or inactivation of PPO, primarily due to the formation of ice crystals that pierce the cells, enabling contact between phenolic substrates and PPO. AMF application has been shown to inhibit PPO activity. After 42 days of storage, the group exposed to 3D AMF (4mT and 50 Hz) demonstrated the most significant decrease in PPO activity compared to the control group [123]. This reduction in PPO activity benefits the preservation of polyphenols. Furthermore, AMF effectively reduces the decrease in free radical scavenging rate and better maintains antioxidant activity. Similarly, Ma et al. [157] concluded that PMF can inactivate peroxidase (POD) without compromising sensory and nutritional qualities. Tan et al. [97] explained that this occurs because MF reduces the size of ice crystals, which helps maintain cell structure integrity and isolates the role of PPO. The freezing of cherry tomatoes using SMF and AMF showed improvements in catalase (CAT) activity, with higher CAT activity observed under AMF compared to SMF [121]. MF treatments also reduced malondialdehyde (MDA) content and electrical conductivity of the sample tissues while enhancing antioxidant capacity. These enzymes belong to the same enzyme class [158, 159], and their active centers contain metal ions. MF exerts force on these metal ions, changing their positions in the enzyme's active center and thus affecting enzyme activity.

Superoxide dismutase (SOD) and peroxidase (POD) are essential enzymes in the antioxidant defense system of plants. They play a crucial role in mitigating the harmful effects of reactive oxygen species (ROS) generated during various stress conditions [160]. MDA is commonly used as an indicator to assess the extent of lipid peroxidation, reflecting the severity of diseases, chilling injury, and other types of damage. Research conducted by You et al. [100] on asparagus investigated the effects of OMF. After 14 days of preservation, the supercooled samples exhibited significantly higher SOD activity compared to refrigerated samples. This increase in SOD activity led to a reduced accumulation rate of MDA and inhibited the rise in relative conductivity. Similarly, electromagnetic treatment of cucumber [161] demonstrated that under the influence of AMF, the activities of catalase (CAT) and SOD were higher than those in the control group, resulting in decreased MDA content. In a study on bananas [162] AMF was shown to inhibit banana chilling injury, with MDA content being only 81.9% compared to the control group. Furthermore, research on the SMF treatment of corn [160] revealed a reduction in superoxide radicals and a 43% and 23% decrease in the antioxidant enzymes SOD and POD, respectively.

These findings demonstrate that MF helps maintain polyphenol content in fruits and vegetables while sustaining their antioxidant activity. MF also regulates enzyme activity by interacting with metal ions in the enzyme's active center, thereby slowing down or preventing the browning reaction in fruits and vegetables. However, it is worth noting that Qian et al. [163] reported that PMF had minimal effect on the scavenging activity of total phenols and DPPH radicals in apple juice.

Microorganism

During the storage of food, microorganisms can grow and reproduce, leading to food spoilage. Freezing is known to slow down the growth and reproduction of microorganisms [164]. Studies have shown that using a CAS system in freezing can further inhibit the growth and reproduction of microorganisms compared to conventional freezing methods [146]. After 180 days of storage, the CAS system was found to have fewer microorganisms compared to conventional freezing. Another study focused on the use of AMF in fresh-cut apple refrigeration. The AMF was found to inhibit the growth and reproduction of microorganisms, thereby extending the shelf-life of apples [165]. This effect is attributed to the high-temperature inactivation of microorganisms caused by magnetic induction heating of the AMF. The inhibitory effects of MF on microorganisms can be explained by several mechanisms. MF may alter the membrane permeability of biological cells, leading to the destruction of microorganism cell membranes and the outflow of substances from their cells, affecting their activity. Additionally, the fluctuation of the MF during freezing causes changes in magnetic flux, leading to electromagnetic induction in the object being frozen. This induction generates free electrons within the object, which can then transfer electrons to water molecules, generating free radicals such as hydroxyl radicals. These hydroxyl radicals can destroy the cell membranes of microorganisms like bacteria. As a result, the number of live bacteria can be limited. Overall, the application of MF in freezing processes has shown promise in inhibiting the growth and reproduction of microorganisms, leading to improved frozen food preservation and extended shelf-life. Further research is needed to fully understand the underlying mechanisms and optimize the use of MF in food storage and preservation.

Discuss and Prospects

This paper aims to discuss scientific research concerning the effects of MF on the freezing process of water, salt solutions, and food. The findings exhibit a range of perspectives among scholars regarding how MF influences freezing processes. Some argue that MF primarily delays nucleation, increases supercooling, accelerates freezing, and promotes the formation of small ice crystals with a uniform distribution. Conversely, others suggest an opposite effect, resulting in inconsistencies in experimental results. However, there is consensus among most scholars that MF can influence the hydrogen bond network of water and solutions. In the freezing of food, MF primarily inhibits ice nuclei formation, increases supercooling, reduces phase transition time, and decreases the size of ice crystals. Certain experiments show few effects of MF on food freezing, potentially due to its failure to achieve the biological "window effect". Nonetheless, thermodynamic analysis reveals that MF lowers the energy barrier of phase transition, allowing water crystallization and nucleation at lower supercooling levels. In the presence of MF, the Gibbs free energy is reduced compared to its absence, resulting in a decreased nucleation rate. Molecular dynamics simulations demonstrate that the oscillation of AMF improves the movement of water molecules, enhances their ability to combine with each other, and increases nucleation possibilities, leading to the formation of numerous ice crystals at higher nucleation temperatures.

The positive effects of MF are not limited to the freezing process but extend to the sensory quality, physiology, and biochemistry of food. Exposure to MF leads to significantly lower color changes in food, resembling that of fresh samples. Moreover, the MF-treated samples display lower thawing weight loss rate and dripping loss compared to the control group. The MF treatment also increases the hardness of food tissue, indicating improved texture, while the microstructure becomes closer to that of fresh samples, demonstrating better organization. The relative conductivity of the MF-treated samples is also lower than that of the control group. Additionally, the presence of microorganisms such as bacteria, yeast, and mold are found to be lower in the MF-treated samples compared to the control group. Enzyme activities, including SOD and CAT, are suggested to be higher in the MF-treated samples, whereas PPO activity is lower. Furthermore, the content of MDA during storage is lower in the MF-treated samples. Overall, it can be concluded that MF has a beneficial effect on frozen food preservation by maintaining the quality and freshness of fruits and vegetables while preserving their oxidation resistance. MF-assisted is an efficient, safe, and environmentally friendly method for food freezing. Furthermore, the inconsistency in findings suggests that the effects of MF on food are species-specific and depend on exposure field strength and exposure time. This has good research potential in the coming years.

The prospect of research on MF-assisted freezing of food can be explored in several aspects:

-

1.

Standardizing Test Parameters: It is important to provide detailed information about MF intensity, frequency, cooling medium state, cooling rate, and other relevant parameters while conducting MF-assisted freezing tests. These parameters significantly influence the test results and should be explicitly stated in the literature.

-

2.

Independent Testing of MF: When comparing MF-assisted freezing with traditional methods, it is crucial to test MF as an independent factor. Other influencing factors should be kept constant, such as MF intensity, frequency, processing time, cold fluid temperature, cold fluid speed, heat transfer temperature difference, and cooling rate.

-

3.

Consideration of Electromagnetic Thermal Effect: Many studies have examined the influence of AMF on the freezing process but overlook the 'electromagnetic thermal effect.' This effect can lead to changes in physiological and biochemical indexes inside the food. Researchers should consider how to eliminate or mitigate the impact of this effect during experiments.

-

4.

Thawing by MF: While there are numerous studies on the influence of MF on freezing food, few have focused on thawing. Future research could investigate the effects and potential advantages of MF-assisted thawing techniques.

-

5.

Comprehensive Evaluation of MF Effects: Current studies mainly provide recommended MF parameters for specific types of food, without considering variations in kind, size, geometry, water content, and other parameters. Future research can explore characteristic parameters or criteria to evaluate the effect of MF on food freezing. Additionally, investigating whether the magnetic effect persists in the food after MF treatment and its duration would be valuable.

-

6.

Economic Analysis: The economic analysis of MF-assisted freezing in the food industry is relatively limited. Future studies should aim to analyze the economic aspects of MF-assisted freezing comprehensively. This analysis can contribute to the advancement and wider adoption of cryopreservation techniques in the field of food.

Data Availability

Data availability is not applicable to this article as no new data were created or analyzed in this study.

Abbreviations

- MF:

-

Magnetic field

- SMF:

-

Static magnetic field

- AMF:

-

Alternating magnetic field

- OMF:

-

Oscillating magnetic field

- PMF:

-

Pulsed magnetic field

- 1D:

-

One-dimensional

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- PPO:

-

Polyphenol oxidase

- CAT:

-

Catalase

- SOD:

-

Superoxide dismutase

- POD:

-

Peroxidase

- MDA:

-

Malondialdehyde

- \(\Delta G\) :

-

Gibbs free energy, J

- \({\Delta G}_{\left(s\right)}\) :

-

Surface free energy, J

- \(\Delta G\left(V\right)\) :

-

Volume free energy, J

- \(\Delta {G}_{V}\) :

-

Free energy of freezing per unit volume, J/m3

- \(r\) :

-

The equivalent radius of the ice crystal, m

- \({r}^{*}\) :

-

The critical equivalent radius of the ice crystal without the magnetic field, m

- \({r}_{m}^{*}\) :

-

The critical equivalent radius of the ice crystal with the magnetic field, m

- \(\sigma\) :

-

Surface free energy of the crystal fluid interface without the magnetic field, J/m2

- \({\sigma }_{m}\) :

-

Surface free energy of the crystal fluid interface with the magnetic field, J/m2

- \(\Delta {H}_{m,f}\) :

-

Molar enthalpy of fusion, J/mol

- \(\Delta {G}_{V,m}\) :

-

Free energy change of the transformation per unit volume,J/m3

- \({T}_{f}\) :

-

Melting temperature, K

- \(T\) :

-

Temperature, K

- \({V}_{m}\) :

-

Molar volume, m3/mol

- \(H\) :

-

Magnetic field intensity, A/m

- \(M\) :

-

Magnetic polarization, A/m

- \(B\) :

-

Magnetic flux density, T

- \(\mu\) :

-

Magnetic permeability

- \({\mu }_{0}\) :

-

Magnetic permeability of vacuum

- \(K\) :

-

Parameter of nucleation rate

- \(C\) :

-

Pre-exponential term

- \(k\) :

-

Boltzmann constant

- \(f\) :

-

Frequency of monomer attachment to the nucleus

- \({C}_{0}\) :

-

The concentration of nucleation sites

- \(z\) :

-

Zeldovich or imbalance factor

- \({N}_{1}\) :

-

The monomer concentration

- \({N}^{*}\) :

-

Concentration of nuclei

References

Shi H, Xu H, Gao W, et al. (2022) The impact of energy poverty on agricultural productivity: The case of China[J]. Energy Policy 167:113020. https://doi.org/10.1016/j.enpol.2022.113020

Haq ZU, Iqbal M, Jamil Y et al (2016) Magnetically treated water irrigation effect on turnip seed germination, seedling growth and enzymatic activities. Inform Proc Agric 3(2):99–106

Florez M, Carbonell M, Martinez E (2007) Exposure of maize seeds to stationary magnetic fields: Effects on germination and early growth. Environ Exp Bot 59(1):68–75

Saletnik B, Zaguła G, Saletnik A et al (2022) Effect of Magnetic and Electrical Fields on Yield, Shelf Life and Quality of Fruits. Appl Sci 12(6):3183

Sokolov AA, Vinogradov DV, Kryuchkov MM (2022) Influence of seed treatment with a magnetic field on sowing qualities and performance of spring barley. IOP Conf Ser Earth Environ Sci 954(1):012075

Saletnik B, Saletnik A, Slysz E et al (2022) The Static Magnetic Field Regulates the Structure, Biochemical Activity, and Gene Expression of Plants. Molecules 27(18):5823

de Souza A, Garci D, Sueiro L et al (2006) Pre-sowing magnetic treatments of tomato seeds increase the growth and yield of plants. Bioelectromagnetics 27(4):247–257

Hafeez MB, Zahra N, Ahmad N et al (2022) Growth, physiological, biochemical and molecular changes in plants induced by magnetic fields: A review. Plant Biol (Stuttg)

Saletnik B, Zaguła G, Saletnik A et al (2022) Method for Prolonging the Shelf Life of Apples after Storage. Appl Sci 12(8):3975

Lu N, Ma J, Sun DW (2022) Enhancing physical and chemical quality attributes of frozen meat and meat products: Mechanisms, techniques and applications. Trends Food Sci Technol 124:63–85

Shokribousjein Z, Galan DR, Michiels C et al (2015) Effect of a magnetic field on dispersion of a hop extract and the influence on gushing of beer. J Food Eng 145:10–18

Song YS, Moon S, Hulli L et al (2009) Microfluidics for cryopreservation. Lab Chip 9(13):1874–1881

Toner M, Cravalho EG, Karel M (1990) Thermodynamics and kinetics of intracellular ice formation during freezing of biological cells. J Appl Phys 67(3):1582–1593

Mainvil LA, Horwath CC, McKenzie JE et al (2011) Validation of brief instruments to measure adult fruit and vegetable consumption. Appetite 56(1):111–117

Chen B-K, Chang C-K, Cheng K-C et al (2022) Using the response surface methodology to establish the optimal conditions for preserving bananas (Musa acuminata) in a pulsed electric field and to decrease browning induced by storage at a low temperature. Food Packaging Shelf Life 31:100804

Rodríguez AC, James C, James SJ (2017) Effects of Weak Oscillating Magnetic Fields on the Freezing of Pork Loin. Food Bioprocess Technol 10(9):1615–21

Tang J, Shao S, Tian C (2020) Effects of the magnetic field on the freezing process of blueberry. Int J Refrig 113:288–295

Liu B, Song JF, Yao ZD et al (2017) Effects of Magnetic Field on the Phase Change Cells and the Formation of Ice Crystals in Biomaterials: Carrot Case. J Ther Sci Eng Appl 9(3)

Chen A, Liu Y, El Achkar G et al (2021) Effects of magnetic field on freezing characters of carrot, potato and broccoli. Eur Phys J Appl Phys 93(1):10201

Tagami M, Hamai M, Mogi I et al (1999) Solidifcation of levitating water in a gradient strong magnetic field. J Cryst Growth 203:594–598

Aleksandrov VD, Barannikov AA, Dobritsa NV (2000) Effect of Magnetic Field on the Supercooling of Water Drops. Inorg Mater 36:1072–5

Jianfei S, Bin L, Wenqiang G et al (2016) Effect of DC Magnetic Field on Freezing Process of Onion Cells. J Refrig 37(02):107–112

Xiaoyang W, Bin L, Jianfei S et al (2020) Effect of Magnetic Field Assist Freezing on the Storage Quality of Beans. J Refrig Technol 43(03):10–14