Abstract

Market demand for affordable frozen foods has grown due to changes in consumer lifestyle. The quality of frozen food must be maintained throughout production, storage, transport, and distribution. Recent developments in the science and technology of food freezing have led to improvements in the quality of frozen foods. Examples include the control of ice nucleation (by anti-freeze proteins and ice nucleation agents) and advances in freezing technologies (such as electric and magnetic freezing). Progress in the technology of frozen food distribution systems (such as use of time-temperature indicators) has enabled the delivery of high-quality, high-value, and safe frozen foods to consumers. However, unavoidable temperature fluctuations occur during the handling of frozen food. State and phase transitions in frozen food lead to ice recrystallization and quality changes, requiring optimized management strategies such as packaging-based and location-based approaches. Therefore, an understanding of ice recrystallization in frozen food, especially the physical and chemical properties of food matrices, is important. In this review, we evaluate the impact of temperature fluctuation and ice recrystallization on the quality of frozen food, based on characteristic thermal transitions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Meal planning, preparation, and eating habits have changed rapidly through the years. In today’s fast-paced life, consumers value quick and simple cooking methods [1]. They continue to demand convenient, ready-to-eat, or ready-to-cook foods.

Over the last 50 years, frozen foods have gained popularity. Due to increased effectiveness of the cold chain in the markets of developed countries, frozen foods have become a popular option for consumers. Frozen foods are prevalent in large outlet stores, retail supermarkets, and convenience stores, where they are purchased for direct consumption. They are also important in food service, as they are used as ingredients or undergo further processing prior to consumption.

High work force participation in the USA as well as long commutes make home food preparation a time challenge. The rise in single-person households and multi-income families [2] has created rising demand for frozen foods. Product categories and availability of a variety of frozen foods have also expanded. The introduction of a price premium for the convenience aspect of food is yet another factor fueling frozen food growth. In a study on food consumers of the convenience food market in Great Britain [3], “convenience seeking grazers” have been classified as the most frequent purchasers of frozen ready meals. This term refers to consumers who consider freshness to be least important and who are unlikely to plan meals involving the entire family. The global frozen food market size is expected to reach $360 billion by 2024 (https://www.grandviewresearch.com/press-release/global-frozen-food-market).

The sale of frozen foods in the USA was approximately $53 billion in 2018 (https://www.agweb.com/article/frozen-food-is-fired-up/), with a US frozen food market forecast of $73 billion by 2024. Some emerging trends in the frozen food industry include the reduction in or elimination of allergens (milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, and soybeans), expansion of organic, gourmet, and premium lines, eco-friendly packaging solutions, and convenient packaging design (https://www.marketresearch.com/Infiniti-Research-Limited-v2680/Global-Frozen-Food-Packaging-9746756/?progid=89294). The current challenge for the frozen food industry is to maintain their role in a market where consumer preference for fresh food remains dominant [4].

Consumers emphasize upon foods with functional attributes, such as increased bioactive components and development of allergen-free foods. Food manufacturers must meet consumer demands by developing foods with reduced calories, sodium, cholesterol, etc., which highlights the importance of food formulation. Although freezing involves conversion of water to ice, each ingredient undergoing freezing plays an important role in this conversion, which subsequently influences the final quality of the food. Besides supermarket aisles, frozen food is also a major component in food service, restaurants, vending machines, and convenience food stores. The debate about frozen food continues as consumers choose between fresh and frozen foods. The frozen food industry must aim to deliver foods with the best quality, balance consumer concerns, and develop frozen foods with improved properties.

With increased demand for frozen foods with a variety of attributes, it is important to understand the fundamentals of food freezing. More research is needed on ice crystal formation, thermal transition and rate of freezing, and their impact upon food quality. Recent findings in the science of crystal formation and technological advancements in the freezing process must be considered when developing frozen foods with desired physical (such as color, texture), chemical (such as oxidative stability, protein functionality), and microbial (such as food safety, food quality) attributes. With the improvements in nonthermal technologies such as ultrasound and pulsed electric field treatments, assisted freezing technologies have been developed. Here, the raw materials are subject to select nonthermal process, prior to freezing. As a result, there is better product quality and reduced freezing time [5]. In ice cream, high-intensity ultrasound-assisted freezing has been found to prevent incrustation on the freezing surface [6].

Despite progress in freezing science and technology, temperature fluctuations during handling, distribution, and storage are unavoidable, degrading the quality of frozen food. This review focuses on (a) the principles of food freezing, specifically ice recrystallization based on thermal transitions, and (b) understanding the impact of these factors on food quality parameters (physical, chemical, and biochemical), as a consequence of temperature fluctuations.

Science of Food Freezing

Principles of Food Freezing

Freezing Curve

Freezing Curve for Pure Water

As depicted in Fig. 1, freezing progresses through several stages, namely, precooling, phase transition, tempering, solute crystallization, eutectic solidification, cooling, ice crystal formation, growth, and recrystallization.

-

Stage 1:

Precooling (points A to S and S to B, Fig. 1a): Here, we observe the removal of sensible heat. At point S, the water is supercooled. The degree of supercooling is the difference between the actual temperature of the water and the temperature of the solid-liquid equilibrium. A high degree of supercooling encourages the formation of many small ice crystals. The point S, at − 48.3 °C, is below the point B, the initial freezing point, at 0 °C. However, the water remains unfrozen. Upon reaching S, the ice nucleation temperature, a sufficient degree of supercooling has been achieved. Hence, nucleation occurs (at point S). There is an increase in product temperature due to the release of latent heat of solidification from S to B.

Typical freezing curve a for pure water and b for food systems. Source: adapted from [8]

The transition from point S to point B is still considered cooling, despite the increase in product temperature. When heat is removed from liquid water, the water molecules slow down to the point at which hydrogen bonds will not permit further rotation of the liquid. This leads to ice crystal formation. The heat/energy of rotation has been transferred to the surrounding medium from the liquid water. At B, phase transition does not begin; however, cooling continues [7, 8].

-

Stage 2:

Phase transition (points B to C, Fig. 1a): The temperature remains constant at B. The removal of thermal energy is equal to the release of the latent heat of ice crystallization during the growth of ice crystals.

-

Stage 3:

Tempering (points C to D, Fig. 1a): The sensible heat of water is removed, and the ice cools to the temperature of the freezer.

Freezing Curve for Food

Pure water freezes at 0 °C, but there is depression of freezing point in the presence of dissolved solutes. The water in foods contains varying amounts of dissolved substances, so the freezing of food occurs at temperatures below 0 °C. The freezing point depression is determined by the following equation [9]:

Tf is the freezing point of pure water; Tfs is the freezing point of food; λA is the latent heat of fusion for pure water (6003 kJ/mol); MA is the molecular weight of water (18 g/mol); m is the molality of the solution representing the food system (number of moles of solute/1000 g of solvent; TKf is the freezing point of pure water (273 K) and R is the gas constant (8.31 J/mol/K).

The freezing point of foods is a useful reference in designing equipment for related processes. For example, understanding fluid flow at temperatures just above the freezing point of food is essential in designing freeze concentration equipment. This is applied in the production of soluble coffee, where low temperature processing is necessary for flavor preservation [10]. Also, during freeze-drying, the freezing process and in turn the ice crystal size, shape, morphology, and distribution determine the subsequent resistance to water vapor flow during drying. Thus, determination of freezing point is important in order to optimize the freeze-drying process [11].

-

Stage 1:

Precooling (points A to S and S to B, Fig. 1b): In food, supercooling occurs when cooling takes place without ice crystal nuclei formation. This occurs below the initial freezing point of the food [12]. In foods with very high solute concentration, supercooling is difficult to achieve [8].

Freezing point depression has been used to predict the molecular weight of aqueous solutions and liquid foods that are non-acidic [13]:

Δt is the freezing point depression,\( K=\frac{R{T}^2}{L} \), R is the ideal gas constant, T is the freezing point of water, L is the latent heat of fusion of water at 0 °C, Xs is the solids, b is a constant derived from the value of Xs and Δt, Ms is the molecular weight of solutes.

Equation (2) applies to solutions containing up to 40% concentration of sugar [13]. For higher concentration solutions, there is a derived logarithmic expression of Eq. (2) [13].

Freezing point depression is an important colligative property in the development of milk chocolate [14]. Edible fats are complex mixtures of tri acyl glycerol (TAG) (around 95%) and 5% of several other lipidic substances and fat soluble vitamins. Based on melting point and composition, edible fats may exist as solids or liquids at a particular temperature. In milk chocolate, when milk fat TAG interacts with cocoa butter TAG, there is a depression in the freezing point. Therefore, milk chocolate has a lower melting point and is softer than dark chocolate. Milk fat has a melting point of 37 °C (https://www.uoguelph.ca/foodscience/book-page/milk-lipids-physical-properties), cocoa butter melts at 31.2 °C, while cocoa butter with 10% milk fat melts at 23.9 °C [15].

When a food is subject to cooling, the food converts to a glassy state or a vitreous solid at a certain temperature range. Here, the material has low molecular mobility [16]. During formation of the glassy state, molecules in the food do not have the reaction time needed to attain a crystalline structure: there is a change in state but not in phase: this transition occurs over a temperature range. Most frozen foods are partly or fully amorphous. The molecular mobility of water and solutes continue even in the glassy state, leading to related changes in the food.

-

Stage 2:

Phase transition (point B to C, Fig. 1b): There is removal of water in the form of ice crystals, with increasing solute concentration through the phase transition. This reflects as a depression of freezing point from point B, the initial freezing point, to point C, where super saturation is achieved.

-

Stage 3:

Solute crystallization (point C to D, Fig. 1b): The latent heat of solute crystallization is liberated, causing an increase in temperature. The food attains the eutectic equilibrium composition. It behaves as one homogenous mixture, with a single freezing point, which is less than that of its individual components.

-

Stage 4:

Eutectic solidification (point D to E, Fig. 1b): The temperature and the composition of the solution reach an equilibrium.

-

Stage 5:

Cooling (point E to F, Fig. 1b): Below E, the solution undergoes complete solidification, and then cooling proceeds, followed by tempering to the target/freezer temperature. Table 1 shows the reported thermal transition parameters of select freeze-concentrated systems.

Ice Crystal Formation

Ice crystal formation in food consists of the following four steps [17]:

-

Step 1:

Driving force generation: The driving force for ice crystal formation is attained in the super saturation zone. The degree of super saturation is based on solute concentration and temperature.

-

Step 2:

Nucleation: Liquid water transforms into a crystal lattice structure [18]. In a food system, the solute provides the energy required for nucleation.

Nucleus formation occurs at the nanoscale level and is transient. Hence, there is no direct experimental evidence for this process [19]. The size of the solute/impurity has an impact on ice nucleation and is driven by the degree of supercooling.

-

Step 3:

Crystal growth: Molecules of water diffuse along the surface of an existing ice crystal until a lattice site is reached, and then they build up on the existing crystals. The major factors determining ice crystal growth are (i) diffusion of solute molecules away from the growing surface (mass transfer) of the ice crystal and (ii) heat removal from the growing surface (heat transfer).

The rate at which the radius of the nucleus grows, after nucleus formation, is the crystal growth rate. In typical high-moisture foods, there is adequate water and solutes. The mass transfer of these solutes away from the crystals seems to impact the crystal growth only at later stages of food freezing. Heat transfer controls ice crystal growth predominantly during freezing [20]. The nucleation temperature influences ice crystal growth [21]: lower nucleation temperature leads to large number of small ice crystals, while higher nucleation temperature leads to dendrite formation. This is depicted in Fig. 2.

-

Step 4:

Recrystallization: In a frozen food, ice crystals tend to be unstable and undergo repeated changes in number, size, and shape, which is called recrystallization [22]. Many mechanisms of recrystallization exist; however, the result of recrystallization is increase in average crystal size, leading to a coarser microstructure and food quality loss [23]. Further details are presented in the “Temperature Fluctuation and Related Challenges to Food Quality” section.

Ice crystal morphology of 10% mannitol solution. Source: [21]. a Upper position, nucleated at − 2.04 °C. b Lower position, nucleated at − 2.04 °C. c Upper position, nucleated at − 8.17 °C. d Lower position, nucleated at − 8.17 °C

Techniques to Quantify Ice Crystals

Observation of ice crystals may be direct or indirect. Direct observation methods include cryo-scanning electron microscopy (cryo-SEM), cold microscopy, and confocal laser scanning microscopy. Indirect methods include freeze substitution, freeze fixation, and freeze-drying, followed by sectioning.

Scanning Electron Microscopy

Scanning electron microscopy (SEM) can be used to reveal changes in the microstructure of frozen foods due to temperature fluctuation and accompanying crystal changes. For example, it has been used to study frozen squid mantle for fracture patterns and changes in inter-fiber spacing, induced by ice crystal formation [24]. Another example is a study on how freezing and ice crystal size affect the quality of lobster [25]. Zounis et al. [26] examined structural changes in dough during frozen storage due to temperature cycling. They used SEM to evaluate changes in ice crystal structure that indicate the extent of disruption.

Environmental SEM (ESEM) does not require the sample to be pretreated in order to be rendered electrically conductive and permits some moisture to be present. It can be used to elucidate ice crystal nucleation, growth, and morphology, along with freeze–thaw-induced phase transitions [27]. Syamaladevi et al. [28] examined mean ice crystal size, slope, percentage growth of ice crystal size, and pore equivalent diameter during frozen storage of salmon using ESEM (FEI Co., Hillsboro, OR): they have used SEM micrographs to interpret the median ice crystal size, X50 of frozen salmon.

Kumar et al. [29] determined the mean hydraulic radius, mean and median pore equivalent diameter, and mean number of pores/mm2 in frozen potatoes subjected to temperature fluctuation (Fig.6 ). Suitable imaging software tools are used to analyze the images.

X-ray Computerized Axial Tomography Scan

The X-ray computerized axial tomography (CAT) scan is a non-invasive technique to reveal the 3D microstructure of food products. It can be used to detect changes in X-ray attenuation arising from density differences. Usually, 2D images are recorded and a 3D map is reconstructed from the same [30]. Ice crystal parameters such as size, area, and width can be quantified by the technique. Syamaladevi et al. [28] examined selected pore parameters of salmon from images obtained with the X-ray CAT scan system (HYSIG Inc., Los Alamos, NM). They obtained percent object volume ranging from 49 to 65%, object surface/volume ratio ranging from 0.57 to 3.33 μm−1, degree of anisotropy ranging from 0.83 to 0.97%, and median ice crystal size ranging from 659 to 1645 μm.

Ullah et al. [31] have used the CAT scan (Model Micro XCT-400 Xradia, Pleasanton, CA) to study pore size as a function of fluctuation in freezing temperature in potatoes. They obtained the average pore area, ranging from 0.25 to 1.15 mm2, and the total number of pores, ranging from 302 to 1890 in the entire sample.

Other Methods for Quantifying Ice Crystals in Food

X-ray diffraction (XRD) is another method for determining ice crystal formation. It is sometimes used in combination with DSC. Exotherms that appear on the DSC curves can be correlated with the formation of ice crystals. The corresponding XRD patterns can help determine ice crystal size [32].

The atomic force microscope (AFM) is used to obtain molecular-level images of the structure and dynamics of ice crystals. Ice has the tendency to form monolayers, and their motion can be observed using AFM. By combining AFM with other methods, ice crystals and their dynamic behavior can be visualized directly at air–ice interfaces [33]. Numerical parameters can be obtained directly from AFM pictures, including pore size and pore size distribution, surface pore density (the number of pores per unit area), and porosity (the porous surface fraction). Figure 3 shows how X-ray microtomography is able to differentiate between the different parts of the carrot root with respect to ice crystal shape and size [34].

X-ray tomography image of freeze-dried carrot. Source: [34]

Crystal Formation and Freezing Rate

In a freezing process, two events occur [35]: (a) ice crystal formation (nucleation) and (b) crystal growth (subsequent increase in size). The rate of crystal growth is determined by three factors: (i) rate of reaction at the crystal surface, (ii) rate of diffusion of water to the growing crystal, and (iii) rate of heat removal. The crystal size has an inverse relationship with the number of nuclei, which is in turn determined by the rate of heat removal.

On a commercial scale, rapid freezing is preferred. Small crystals cause less cell wall rupture (since water expands when ice forms), and there is a lower possibility of internal cell desiccation. Freezing rate is more clearly defined by the rate of ice formation/rate of heat removal/rate of advancement of freezing interface (all these relate to rate of appearance of ice in the frozen system), rather than the rate of temperature change (since the latter depends upon a phase change) [36].

Crystal Formation in a Slow Cooling Process

Through the cooling process, there remains an unfrozen fraction containing cellular tissue and solutes. The concentration of solutes increases, while the volume of unfrozen water decreases. The increase in osmotic pressure causes an efflux of water from the cellular tissues, which can in turn result in water loss. Slow cooling is not recommended, since this allows an efflux of intracellular water, resulting in the formation of extracellular ice. Further, formation of new crystals is hampered due to the high viscosity of the unfrozen fraction, which now becomes an amorphous solid with no ice crystals. In this scenario, desiccation of cells can result, as temperature fluctuates and unfrozen water diffuses from inside the cell into the extracellular space.

In certain animal cells, solutes such as sucrose are added for cryoprotection of plant cells. Sucrose forms hydrogen bonds with the polar regions in the lipid membranes and stabilizes the membrane. Although this provides toughness to the membrane, the viscosity and glass transition of the unfrozen fraction is affected in this approach. Solute-assisted freezing may not be suitable for most food freezing approaches, regardless of the freezing rate, since at the concentrations required, food flavor can change significantly.

In some foods, such as oil in water emulsions, slow cooling could create more stable systems. If a fat-rich product is slowly cooled, the fat molecules have sufficient time to be incorporated into the crystalline system. These crystals have fewer dislocations and become more densely packed [37]. Fat droplets have more time to structurally reorganize themselves within the non-frozen aqueous phase. This reduces the risk of droplet coalescence. However, this phenomenon is specific to the particular emulsion structure and composition [38].

Some researchers argue that crystal formation in food is primarily intracellular, regardless of the cooling rate. Due to the presence of intracellular bulk water, extracellular crystal formation is not dominant, as little, or no extracellular water is available to drive the hypertonic removal of water from cells. In plant cells, although the cell membrane is semipermeable, the structure of the cell membrane breaks down upon ripening or post-harvest processes. Hence, exosmosis or passage of water to the surrounding media becomes unlikely [39].

Crystal Formation in a Cryogenic Freezing Process

In cryogenic foods, foods are exposed directly to a liquid with a low boiling point, such as liquid nitrogen (− 196 °C) or carbon dioxide (− 78.4 °C). The phase change from liquid to gas rapidly removes thermal energy from the products, resulting in uniform freezing throughout the product cells. This results in high product throughput, low floor space requirements, generally high product compatibility, and minimum surface dehydration (which is often high with air blast freezing).

Cryogenic freezing is often applied to high-value foods with a large surface area to volume ratio (usually fishery products such as shrimp and shellfish, meat slices). It can be used in applications where there is freezing of outer surface of food material, e.g., crust freezing, with a need to avoid surface dehydration during freezing. After crust freezing, the core material is frozen by more economic means [35]. However, due to the high cost of the cryogenic fluids, this freezing method is not cost efficient for large-scale processing for most foods. As cryogenic fluid contacts the product surface, thermal cracking may develop.

The major difference between the cryogenic and mechanical freezing systems lies in the heat transfer mechanism, shown in Fig. 4 [174]. Rapid freezing leads to formation of small crystals in cryogenic freezing. The sublimating cryogenic liquid on the surface of the product draws heat out of the product as vapor. During cryogenic freezing, radial and circumferential stress during freezing may occur, due to ice formation at the core of the product, and a frozen mantle can form on the outer surface.

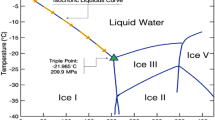

State Diagram

A state diagram is used to understand states of transition such as the glass transition in freezing of food, to estimate the storage stability, and to determine processing conditions for foods [40] (Fig. 5). A state diagram maps this information as a function of water content and temperature. For these purposes, a food is considered as a combination of solutes and water. The food may go through a change in state due to temperature fluctuation during storage and transport.

A state diagram consists of the following components [41]: a glass line (relationship between glass transition temperature and solids content); a melting/freezing curve (melting/freezing point depression and solids content); a solubility curve (solids concentration in a saturated aqueous solution at given temperatures); the eutectic temperature; the boiling temperature; maximum-freeze-concentration conditions corresponding to the onset of the ice melting temperature (Tm′), and that glass transition temperature at maximum ice formation conditions (Tg’).

Freezing Line

The freezing line describes the depression in the freezing point as the solids content increases. During freezing, a liquid is converted to a solid when its temperature is lowered below its freezing point. Pure water in the form of ice crystals is separated from a solution. In a binary solution, as in food, water molecules are present along with solute molecule(s). As the temperature of the product decreases from room temperature, it approaches the point at which the initial freezing of water in the food occurs, or the initial freezing point, Tf. The freezing point of food is lower than that of water that is depressed, in accordance with Raoult’s law [42]. As the temperature drops below Tf, ice forms in the extracellular region, followed by ice formation in the intracellular region. Cell membranes act as a barrier to ice growth, thereby leaving the intracellular region supercooled.

When determining the Tf using differential scanning calorimetry (DSC), the food is cooled to an adequately low temperature and Tf, the onset of ice crystallization, is seen as an abrupt increase in temperature due to the release of latent heat on a DSC thermogram [43]. The Chen model [13], an extension of the ideal Clausius–Clapeyron equation (which is applicable only to dilute aqueous solutions), is used in most cases to model Tf values for changes in the moisture content of food:

(Tw − Tf) is the freezing point depression, Tf is the freezing point of the food material (°C), Tw is the freezing point of water (°C), β is the molar freezing point constant of water (1860 kg K/kg mol), λw is the molecular mass of water, Xs is the solids mass fraction, E is the molecular mass ratio of water to solids (λw/λs), and B is the ratio of unfreezable water to the total solids content. E and B are determined by non-linear optimization analysis.

A cooling curve method is also used to determine Tf, especially for multicomponent systems, where DSC sample quantity is not representative. A metallic cylinder containing the food is frozen to very low temperatures, and the temperature at the geometric center of the food is determined from time to time [43]. The abrupt increase in temperature can be noted at Tf due to release of latent heat, along with a slow cooling. This is not suitable for materials with a low water content. Sablani et al. [44] have shown a diagrammatic representation of a typical cooling curve.

Glass Line

The glass line represents the relationship between the glass transition temperature (Tg) and the solids content at constant pressure, differentiating the glassy and the rubbery states. At Tg, there is a reversible transformation from the glassy to the rubbery state, usually determined by calorimetry, rheological approaches, or spectroscopy [45]. When a food is rapidly cooled, the molecules do not have time to rearrange into crystalline structures, resulting in the formation of a glass [46]. A food exists in the amorphous state until it attains the glass transition temperature. The glass transition temperature of a binary mixture can be predicted as a function of water content, by the Gordon–Taylor equation, as [47]:

Tgm is the glass transition temperature of the mixture, °C; Tgs is the glass transition temperature of the solids, °C; Tgw is the glass transition temperature of the water, °C; Xw is the water content, kg; Xs is the total solids content, kg; k is the Gordon–Taylor parameter, no unit. The Gordon–Taylor model can also be reorganized into a straight line, with Tgs−Xw data from experiments and Tg was − 135 °C [51].

Thermal Transition in Maximally Freeze-Concentrated Systems

With further lowering of temperature below Tf, more water crystallizes as ice and the binary solution attains the onset of melting temperature, Tm′. When the frozen food is heated, it is here that the melting of the first crystal occurs. Upon further lowering of temperature below Tm′, more water converts to ice and the product attains the glass transition temperature, Tg’ [48]. Here, the water tries to attain a glassy state from a viscous rubbery state. When cooled below the glass transition temperature, the water in the product cannot freeze further due to the high viscosity of the solute-containing medium (1012 to 1014 Pa.s) that is now freeze-concentrated [49]. At this stage, the food has the highest stability due to restricted molecular motion. Therefore, high viscosity makes it impossible for the remaining unfrozen water molecules to move and form ice crystals, creating what is called unfreezable water. This unfrozen water in frozen foods creates several chemical and biochemical reactions [50, 51], including oxidation of lipids and vitamins and enzyme activity. The maximal freeze concentration temperature corresponds to maximum ice formation in food systems, along with unfreezable water in the matrix, which can degrade food texture and other sensory attributes.

Role of Glass Transition in Frozen Food Stability

Glass transition is important for three reasons: (a) there is better food quality retention when the unfrozen phase is in the glassy state, (b) at temperatures close to the glass transition temperature, reaction rates are a function of the temperature difference between the storage temperature by the Williams–Landel–Ferry model, aiding shelf life prediction of stored frozen foods [52], and (c) knowing the effect of inherent and external factors upon the glass transition aids in formulation of frozen foods. Tables 2 and 3 show a list of select quality changes in frozen food as a result of thermal transitions/temperature fluctuations.

At the maximally freeze-concentrated state, diffusion of reactants and products are reduced. At conditions above Tg’, reaction rates are likely to increase exponentially, as per the Williams, Landel, and Ferry relationship. The WLF is an empirical equation describing the temperature dependence of viscoelastic properties of polymers. In the vitrified system, the glass transition is not always a limiting factor, due to the varying diffusional characteristics. In frozen sugar–protein systems, the Tg’ is lower than frozen sucrose systems, and the Tm′ is higher. This means that in ice cream, glass transition occurs over a broader range of temperature. Therefore, improperly stored ice cream may undergo lactose crystallization and ice recrystallization [53]. In frozen dough, salts decrease the Tg’ of starch from − 5 to − 30 °C. Yeast viability is affected at this temperature, while at slightly higher temperatures, viability and freeze concentration are better.

Reduction in molecular reorganization below Tg’, attained intrinsically, is desirable in the concentrated phase around food constituents [54]. Tm′ is normally several degrees greater than Tg’, due to differences in viscosity [55]. As the glass transition is approached during freezing, the timescale of molecular rearrangement continually changes. This minimizes the temperature difference between storage temperature and Tg’ and improves food stability. Molecular diffusion, reactivity, and shelf stability can be understood based on knowledge of glass transition.

During freezing, kinetic factors begin to dominate over the thermodynamic factors. Viscosity can have exponential effects on mass transfer properties, acting as the limiting factor for ice crystal growth. Hence, freezing becomes progressively slower as ice crystallization is hindered, and more time is required for crystal lattice growth.

At storage temperatures below the Tg’, frozen foods have better stability. If the Tg’ is very low, the formulation can be modified to increase it accordingly. However, this is not always feasible, and adding stabilizers may alter the sensory properties of the food. In addition, the actual Tg’ may be too low for commercial storage. The amount of low molecular weight solutes and hence the glass transition temperatures vary depending on the food matrix (e.g., meats and vegetables vs. ice cream). The Tg’ varies with the dilution of the freeze-concentrated phase since the chemical composition is not constant over the particular time and temperature.

Reported studies show that the Tm′ of frozen strawberries is at − 42 °C, and the Tg’ occurs at even lower temperatures. Therefore, ice melting occurs at temperatures well below regular storage temperatures (− 18 to − 20 °C). Thereby, frozen strawberries can be stored and transported according to the conditions the support the maximally freeze-concentrated state for stability [56].

Determination of Tm′ and Tg’ from DSC Thermograms

In order to design freezing processes and optimize frozen storage and transport conditions, it is important to determine thermal transition parameters. To determine Tm′ and Tg’ from DSC thermograms, an empty sealed aluminum pan is used as a reference in a pre-calibrated DSC instrument. A small amount (e.g., 10 mg) of the food sample is sealed in another pan and subjected to a thermal scan. The range is determined by the nature of the food and the moisture content, usually at 5 to 10 °C/min [40]. For most foods, the food is frozen to temperatures between − 30 and − 60 °C, followed by heating up to 30 °C. The scan rate influences glass transition. The glass transition is seen as a step transition in the resulting thermogram/heat flow curve.

The onset, mid, and end points of glass transitions can be observed, and the midpoint of glass transition is taken for reference. It is assumed that food stability is maintained in the glassy state. Various changes may occur above Tg’, with rates determined by the temperature difference T − Tg’ [57].

The Tg’ plays a role in the shelf life determination of foods. Annealing is performed for high-moisture foods (moisture more than 50%) to identify accurate glass transition temperature [58]. The glass transition is detected from the first derivative of the DSC heat flow curve. Calculation of the second derivative makes these data easier to interpret and is used to analyze melting and identify shoulders in the peak shape due to multiple events [59]. To determine the amount of unfreezable water, the enthalpy of fusion for the sample studied is compared to that of pure ice.

Depending on the moisture content of the sample, the amount of unfreezable water is calculated as:

X’w is the unfreezable water in sample, kg water/kg sample; Xow is the water content of the frozen food, kg water/kg sample; (ΔHm)frozenfood is the change in enthalpy during melting of ice in the frozen food, kJ/kg; (ΔHm)water is the change in latent heat of melting of ice, 334 kJ/kg.

The unfreezable water content is also determined by the relationship between the moisture content and the freezing enthalpy of a substance, using DSC. The sample is equilibrated to various moisture contents by reconstituting with water and is subjected to suitable heating and cooling ramps in the DSC. The change in enthalpy during melting of ice in the frozen food (ΔHm)frozenfood is plotted against the moisture content values of the sample. The unfreezable water content is extrapolated as that at which the enthalpy of freezing is zero.

Around the glass transition temperature, the rate of diffusion-controlled reactions is restricted in an amorphous material. This applies to ice crystal formation as well the maximum net rate of ice nucleation and crystal growth occurs at a temperature of T = 0.5*(Tm′ + Tg’) [60].

Usually, foods freeze over a range of temperatures, starting from the initial freezing point, Tf, to the onset of melting temperature, Tm′. Foods often behave as pseudo-binary solutions, where the Tf depends upon the solute concentration, and the molecular weight and is less than zero. With the onset of freezing, some of the water converts to ice, and the solute concentration increases. This leads to depression of the freezing point so that further conversion of water to ice occurs at lower temperatures. The concentration and size of solutes, along with the solute type present in the food, determine the depression of freezing point [61]. The solutes prevent the water molecules from coming together, thereby depressing the freezing point. The lower the solute molecular weight, the lower the freezing point. A more concentrated solution continues to form, and further conversion of water to ice then occurs at lower temperatures. Hence, the conversion of freezable water into ice occurs over a temperature range that varies for any particular food.

Advances in Frozen Food Research

Frozen food quality is driven by ice crystal morphology, the ice fraction, and the amount of unfrozen water in a food at any given storage temperature. Several approaches are employed to control ice crystal formation, with three main aspects as follows: (i) controlling ice shape and growth, (ii) controlling ice nucleation, and (iii) inhibition of ice recrystallization.

Controlling Ice Shape and Growth

The use of anti-freeze proteins (AFPs) to direct ice crystal shape and growth is a recent advance. AFPs influence ice nucleation since they can order the water molecules into an ice-like structure. AFPs work primarily by adsorbing onto interfacial water at specific ice binding sites in their structure. At these sites, there is no further ice growth. However, growth continues in between the adsorbed proteins until water molecule addition is no longer energetically favorable. At this point, ice growth halts and the freezing point decreases [62].

The addition of AFPs has been shown to reduce ice crystal size in ice cream and in bovine and ovine muscle tissue [63]. Li et al. [64] reported that adding AFPs reduced syneresis and hardness loss in corn and wheat starch suspensions, cycled between − 20 and 30 °C, through 9 temperature fluctuation cycles. AFPs adsorb to specific planes in the ice crystal, thereby directing crystal growth [65]. This ability to selectively adsorb onto sites, based on a physical orientation, gives the AFP the property to inhibit ice recrystallization.

Controlling Ice Nucleation

One approach to controlling ice crystal formation is to induce heterogeneous ice nucleation using ice nucleation agents (INAs) of biogenic origin. INAs favor ice nucleation at higher temperatures. Select structural moieties at the surface interact with hydrogen and oxygen atoms in water [66] and are efficient at larger sizes [67].

INAs influence morphological characteristics and ice formation pattern in frozen foods. They are usually present in animal tissues and microbes. If the molecular structure of the surface matches the lattice size of ice crystal, there is a greater probability for nucleation to occur at that site [68]. This is associated with a decrease in supercooling, resulting in shorter freezing times and more efficient ice production [69].

Inhibition of Ice Recrystallization

Slurry Ice Technique

Slurry ice, a pool of spherical ice crystals in fresh water or seawater, has been used to preserve fish [70]. Small spherical ice crystals prevent sharp ice flakes, reducing physical damage. The slurry provides a layer of physical protection on the skin of the fish, reducing tissue damage as well as damage by lipid oxidation. Agglomeration of small ice crystals must be addressed in order to prevent subsequent mechanical damage.

Gas Hydrate Formation Technique

Purwanto et al. [71] developed a gas hydrate formation technique in which inert gas is used to form ice-like crystals trapped in the water lattice. These hydrates restrict water diffusion and prevent the formation of large ice crystals. Small ice crystals help retain structural homogeneity, reduce mechanical damage in tissues, and minimize drip loss [8]. These novel technologies offer several approaches to improving the technology of freezing food by altering food properties, ice crystal growth, or heat transfer.

Freezing Technology Advances in Manufacturing and Distribution

Advances in Frozen Food Manufacturing

Novel technologies in freezing focus on improving food properties or optimizing production costs (Table 4, Fig. 9) [72]:

Techniques used in conjunction with freezing can improve the effectiveness of the freezing process. These include the use of pressure, ultrasound, magnetic fields, microwaves, and electrostatic fields that control ice crystal formation and reduce damage to cells. This is useful in the case of plant and animal tissues, where texture is a significant factor in product quality. Mahato et al. [73] have explored the impact of food composition, with reference to glass transition and to freezing technologies on frozen food stability. This concept has also been explored in subsequent sections.

Ultrasound-Assisted Freezing

When liquids are subject to high-intensity sound waves, there are alternating high- and low-pressure cycles. During the low-pressure cycle, small vacuum bubbles/voids are created. At a certain volume, these bubbles can no longer absorb energy. As a result, the bubbles collapse during one of the high-pressure cycles. This phenomenon is referred to as cavitation. The gas bubbles formed during cavitation serve as nuclei for ice nucleation/influence crystallization by their collapse and motion. One study found that when an ultrasound pulse was applied to a freezing sucrose solution (50%) every 30 s for 10 min, ice crystal size decreased. The number of ice crystals 50 μm or larger also decreased by about 60% [74]. Since ice is dense and incompressible, it fractures when subjected to sound waves, reducing the size of ice crystals [75]. Ultrasound energy enhances water removal in food, leading to decreased water removal and increased Tg’ [73]. Tian et al. [76] have developed a laboratory scale orthogonal ultrasound-assisted rapid freezing technique, studied for freezing of potatoes. Here, multiple ultrasound transducers were evenly distributed in a system. This approach was experimented to overcome the negative effects of conventional ultrasound-assisted freezing: high temperature and high pressure associated with the collapse of cavitation bubbles.

Pressure-Assisted Freezing

Ice exists in select polymorphs, based on external pressure and temperature. Around 10 ice polymorphs occur at external temperatures from − 100 to 50 °C and between 0 and 2.4 GPa pressure [77]. Of these forms, ice I has a greater specific volume (1.09 cm3/g) than liquid water (1.00 cm3/g) at the same pressure. Therefore, its volume expands during conventional freezing, leading to mechanical damage to tissues.

When liquid water freezes, it tends to form an open structure of low density and low packing efficiency as it attains the polymorph ice I, up to pressures of 209.9 MPa (from 0 to − 60 °C). Pressure plays a vital role in ice-water transitions; hence, pressure-assisted freezing can influence ice crystal morphology and freezing kinetics [77]. Further increases in pressure beyond 209.9 MPa shifts the water to other ice crystal forms. These forms beyond ice I do not increase in volume during freezing, as pressure opposes the volume increase. This reduces the mechanical damage to food tissues [78]. Hence, pressure-assisted freezing helps prevent the formation of the polymorph ice I.

The phase change temperature of water decreases with pressure (0 °C at 0.1 MPa to − 21 °C at 210 MPa). A reverse trend occurs above this pressure level. This enables exploring different approaches while using pressure-assisted freezing, to control crystal size [79].

The concept of free volume can help understand the relationship between pressure and changes in mechanical properties during vitrification of food [73]. During pressure-assisted freezing, the free volume decreases with increase in applied pressure, unlike temperature. Appropriate reconsiderations can be made to the coefficients involved in calculation of the free volume [80]. High pressure treated sea bass muscle was found to have higher Tg’, as a result of muscle protein aggregation [81].

Impingement Freezing

One newer method of freezing is impingement freezing, which employs a high-velocity fluid jet on the solid food surface. This disturbs the surrounding air and replaces it with a turbulent fluid. This also increases the heat transfer efficiency and subsequent freezing rate [72]. In impingement freezing, there is the advantage of having very high convective heat transfer coefficients. However, these coefficients are not uniform, as there are changes in flow patterns, and this requires optimization [82]. Immersion freezing provides similar high rates of heat transfer and involves placing the food into a refrigerant bath. The effectiveness of both impingement and immersion freezing depend upon the product size and surface heat transfer.

Magnetic Freezing

Magnetic freezing, which is used to delay nucleation, is termed commercially proton freezing (a combination of static magnetic field and electromagnetic waves) and the cells alive system (a combination of static and oscillating magnetic fields). When a magnetic field is applied to foods, the polar water molecules in the food undergo orientation. This delays nucleation and promotes supercooling, and resulting in smaller ice crystals and better texture [7]. The enhanced supercooling inhibits ice crystal formation and accelerates heat transfer. When the applied magnetic field is removed, we have uniform small ice crystals in a product.

Otero et al. [83] have evaluated the effect of electromagnetic freezing on the quality of crab sticks (storage, drip loss, water-holding capacity, toughness, and whiteness). They report that there is no significant effect of electromagnetic field in freezing, compared to air blast freezing. Evaluation of the effect of electromagnetic fields in food freezing from a commercial standpoint is challenging, due to the following reasons:

-

Technical aspects of the process, such as presence of static, oscillating, or both magnetic fields; strength and frequency values; combination with electric fields, electromagnetic waves, etc. are not usually known.

-

Variation in food products (size, shape, structure, and composition) will lead to challenges in having the complete effects of the applied field.

To be able to explore the potential of electromagnetic field for food freezing, it is important to study wide range of process parameters, such as field strength and frequency. It is challenging to arrive at conclusive information related to the implications of magnetic field on food freezing in many matrices, as experimental parameters are not strictly controlled in these cases [84].

Electro-freezing

A recent approach to controlling ice crystal size is electro-freezing [85]. In this process, a charge or an external electric field is imparted into water during freezing. In charged flow-assisted freezing, a high DC voltage (50 V, carbon electrodes) is applied between electrodes that are in direct contact with the sample. Here, nucleation occurs at a higher temperature than that used in supercooling. As current flows through the product, water crystallization is assisted by increasing the cation concentration on the electrode [86]. During freezing under an external electric field, the time required for nucleation is reduced, while the phase transition time is prolonged [87]. This, in turn, reduces the critical radius of the ice nucleus, hastening nucleation [88]. Electro-freezing in the presence of ionic additives like sodium chloride was found to be capable of controlling ice nucleation between − 4 and − 14 °C, which could assist in cell cryopreservation [89]. Water molecules are rearranged and join the growing ice lattice under the application of an external electric field [20].

Microwave-Assisted Freezing

Applying an electromagnetic field forces water molecules to reorient, as well as results in breaking of hydrogen bonds (http://www1.lsbu.ac.uk/water/). Microwave energy at 915 MHz is used to induce rapid nucleation, reducing the degree of supercooling required to achieve the formation of small ice crystals. When an electromagnetic field is applied, the intrinsic dipole moment of water molecules leads to efficient reorientation of the water molecule in the induced electric field (http://www1.lsbu.ac.uk/water/). The limited temperature oscillation during nucleation and crystal growth reduces the size of ice crystals during freezing, leading to a large number of small ice crystals [90]. One important parameter to be considered during microwave-assisted freezing is product dimension (height and width) to ensure thermal homogeneity. Optimum dimensions will help understand the impact of microwaves on ice crystal sizes during the freezing process [91]. Xanthakis et al. [90] also observed a 62% reduction in the equivalent diameter of ice crystal size during freezing of fresh pork tenderloin, from 1 to − 30 °C assisted with a domestic microwave oven (2450 MHz at a 60% power level) as the source of energy.

A lower frequency is expected to have significant impacts on the structure of liquid water (http://www1.lsbu.ac.uk/water/) due to the inverse relationship of microwave energy with its depth of penetration. However, the precise role of the magnetic field in delaying ice nucleation is still unclear [92].

Dehydro-freezing

Several reports on dehydro-freezing have suggested altering food properties during freezing. Dehydro-freezing is recommended for fruits and vegetables that are sensitive to textural changes such as cucumbers [93], the food undergoes partial dehydration prior to freezing. Partial dehydration is often performed by osmosis, and sometimes by vacuum impregnation, pulsed electric field, microwave drying or air drying, or a combined approach of these. The amount of dehydration is selected according to the freezing approach and the product [94]. The effects of dehydro-freezing include reduced specific heat capacity and increased glass transition temperature as well as reduced freezing time [95]. However, more research is needed to elucidate the interaction between the dehydration pre-treatment and the freezing process [94].

There are challenges in implementation of certain novel processing technologies at the commercial scale. However, process intensification (such as matching the processing times to the time scales of fundamental biochemical processes in the food) can play an important role in improving and maintaining the quality of frozen food [96].

Proper design of freezing equipment is important, regardless of the advances in food freezing technology. Biglia et al. [97] have developed a chart reporting the production rate, cooling capacity, and the freezing time considering food size, shape, and chemical composition. Considering the freezing process and type of freezer, optimum equipment design can be achieved using this chart.

Advancements in Frozen Food Distribution

The development of time-temperature-integrator (TTI) indicator systems has improved distribution management of frozen foods. Rodriguez and Zaritzky [98] developed an early TTI indicator for frozen beef to monitor deterioration based upon activation energy. This indicator is useful to predict the percentage loss during the practical storage life. TTI displays a measurable, time-temperature-dependent change, indicating the full or partial temperature history of a food product [99]. And and Taoukis [100] reported changes in color and vitamin C content of frozen green peas and white mushrooms from − 3 to − 20 °C using a TTI indicator system. They predicted the remaining shelf life at different temperature exposure regimes from production to consumption. Timestrips® are used as a leading TTI indicator system for frozen foods (Timestrips UK Ltd., Cambridge, UK). Timestrips® are single-use, consumer activated smart labels that indicate how long a product has been left open or in use. Consumers can record the time elapsed since label activation and label changes are tied to the remaining food shelf life. The label can be integrated by the manufacturer during packaging or added by the consumer at home during use [101].

TTI indicator systems can also be used to monitor quality changes and are a useful tool for determining whether temperature abuse has occurred. With some TTIs, the temperature to which the product was exposed during distribution can also be determined by a sharp spike in temperature, or by monitoring the temperature range in which the product has been held.

Recent Innovations in Food Freezing

While a number of aspects related to food freezing are being discussed in this paper, optimal food thawing is also an important step related to food freezing. Some assisted thawing technologies, such as pressure and ultrasound-assisted thawing, have been developed at the laboratory level; further studies are needed to focus on the commercialization aspect of these technologies. The freezing process involves 3 stages: actual freezing, frozen storage, and thawing [102]. Suboptimal thawing can lead to changes in food quality and encourage microbial growth [103]. To evaluate the efficiency of thawing process, the structural analysis of thawed food, such as microstructure and texture, is important. These studies will give a detailed understanding of food quality upon thawing. Some challenges related to food thawing that need to be addressed include [103]:

-

Alternatives to thermally assisted thawing for fruits and vegetables (due to water loss and softening)

-

Over-heating of small sized foods and lack of penetration in foods of large thickness in microwave-assisted thawing

Xu et al. [104] have evaluated the possibility of smart freezing technologies to improve the freezing process efficiency. For example, in-line freezing process data could be collected and monitored, helping achieve better process efficiency. This could be extended to cold chain distribution system and warehouse management systems as well. Individual steps in the freezing process could be controlled by automated sensing technologies like computer vision, electronic nose, electronic tongue, digital simulation, confocal laser, near infrared spectroscopy, nuclear magnetic resonance technology, and ultrasound. Approaches to implementing these techniques to commercial food production would enable better quality retention in food freezing.

Temperature Fluctuation and Related Challenges to Food Quality

Delivery of frozen foods of high quality at the consumer end is critical. This requires maintenance of a regulated cold chain from the manufacturing site through retail sale. If this is not properly managed, it can lead to loss in quality. The quality of refrigerated storage is also important, and temperature fluctuations can caused repeated freezing and thawing, impacting acts food quality. During temperature fluctuation, the state/phase of the food changes from one transition zone to another (e.g., between glassy and rubbery states). As the mobility of water in the food changes, more water loss can occur. It is important to understand the detrimental effects of these temperature fluctuations. Figure 8 shows how different food matrices are sensitive to changes in food quality, as a result of temperature fluctuations.

Tissue desiccation and loss of gel structure result from moisture migration in a frozen food, resulting in phase separation, oxidation, and textural changes. Moisture migration from the food into the surrounding environment decreases the freezing point of the liquid within the food. This makes it more difficult to maintain the food in a solid state under the initial set of frozen storage conditions.

Several researchers have examined the effects of temperature fluctuations on food quality. Boonsumrej et al. [105] studied the effect of freeze–thaw cycles caused by temperature fluctuations in tiger shrimp (Panaeus monodon). They found that an increase in the number of freeze–thaw cycles increased the cutting force, an indication of toughening, caused cell membrane damage and increased drip loss.

One solution may be adding suitable ingredients to counter the impacts from temperature fluctuations. Hagiwara and Hartel [106] reported a 50% reduction in the recrystallization rate in a sucrose-based ice cream formulation when 0.3% of commercial stabilizer (80% locust bean gum and 20% carrageenan) was added. Arocas et al. [107] found that adding hydrocolloids to frozen white sauce had a significant impact at the molecular level. The addition of hydrocolloid was found to counter changes in viscosity during storage, which is partly induced by water rearrangement during thawing. However, Adler-Nissen and Zammit [108] found that thawing frozen prepared meals to sub-zero temperatures during distribution lengthened shelf life and improved food quality. Therefore, chilled distribution of frozen meals may be more suitable than frozen distribution, in certain cases.

Temperature Fluctuation and Ice Recrystallization

Temperature fluctuations are unavoidable due to the following reasons: the cyclic nature of refrigeration systems, the manual defrost mode, and the handling of food during transport. Hagiwara and Hartel [106] proposed that ice recrystallization occurs through a non-convective diffusion process, given by the time-dependent equation:

r is the mean crystal radius, m; ro is the initial crystal radius, m; K is the crystallization rate, s−1; t is the reaction time, s.

According to Hartel [17], small crystals melt at lower temperatures than large crystals, due to the lower radius of curvature. They are also more soluble, and eventually disappear, while larger crystals remain. While the crystal volume remains constant, there are differences in crystal size. In the presence of temperature fluctuation, there is increased rate of crystal melting and decreased formation of large crystals.

Glass transition has a pronounced effect on the mechanical properties of food materials. Changes in viscosity and modulus take place well above the glass transition temperature range, affecting the crystallization of amorphous solids and recrystallization of ice in frozen systems [109]. Hagiwara et al. [110] have reported that the self-diffusion rates of water can directly influence the recrystallization rate in sugar solution–based frozen food. One approach to reduce recrystallization is to store foods at temperatures below their Tg’. In some foods, such as ice cream, suitable stabilizers are added to increase the resistance/strength of the unfrozen phase, reducing the degree of recrystallization. Such approaches are helpful in formulated foods, in which ice crystal size plays a defining role in the mouthfeel and texture of the product.

Ben-Yoseph and Hartel [111] performed computer simulation of ice recrystallization in ice cream during storage. They found that storage temperature fluctuations had a greater influence near the container’s surface, resulting in higher mean size closer to the surface at the end of the storage. Very low storage temperatures (≈ − 30 °C) during the initial steps of storage decreased the recrystallization rate significantly. High heat transfer coefficient of cooling medium-inhibited recrystallization at storage stages involved initial cooling and low-amplitude temperatures.

Ice crystallization and subsequent recrystallization may depend on thermal transition parameters. Crystal formation dynamics directly affect product texture and mouthfeel. The irregular shape of ice crystals poses a challenge to defining their shape in frozen food [112]. Recrystallization alters the distribution of unfrozen water in frozen food, altering the solute concentration. In some formulated foods, salt concentration increases, accelerating enzyme action [16]. If temperature decreases, free water freezes on the surface of the existing crystals. This increases the mean crystal size; however, the number of crystals decreases with each fluctuation cycle [22].

The rate of recrystallization is aggravated by temperature fluctuations [28]. Ice recrystallization is characterized by the instability of ice crystals and the change in their number, shape, and size during frozen storage and transport. If the temperature increases during frozen storage, the ice crystals melt, increasing the amount of unfrozen water and causing deterioration. Recrystallization is driven by minimization of internal energy that causes crystals to rearrange. Hence, it is important to study food texture with respect to recrystallization induced by temperature fluctuations. Figure 7 shows how ice crystal size range is impacted by state and phase transition/temperature fluctuations in different products.

Mechanisms of Ice Recrystallization

Recrystallization is a combination of several crystallization-related mechanisms, namely melting, regrowth, and ripening enhanced during temperature fluctuations. Due to temperature fluctuation–induced recrystallization, there is a phenomenon of ice crystal coarsening accompanied by isomass rounding. There are several mechanisms of recrystallization, including migratory, accretive, isomass, and irruptive recrystallization (the only mechanism in which mean ice content is altered) [113].

Migratory Recrystallization/Grain Growth/Ostwald Ripening

When a frozen food is stored at a constant temperature, water vapor moves from regions of high vapor pressure (small ice crystals) to that of low vapor pressure (large ice crystals). Recrystallization due to Ostwald ripening does not cause any deleterious effects in food. Large ice crystals grow at the expense of small ones. When an ice crystal is at equilibrium, it has minimum surface free energy. At a constant volume and temperature, the structure is said to be perfect. Stability differences lead to size differences at constant temperature. According to the Kelvin equation, the chemical potential of a curved surface differs from that of a plane, and vapor pressure over a spherical solid surface is related to the radius of curvature (r) [114]:

μ is the chemical potential of crystal; p is the vapor pressure; r is the mean radius; V is the molar volume of ice; σ is the interfacial tension.

The Clausius–Clapeyron equation is used to calculate the crystal melting points a function of its radius of curvature. The equilibrium crystal size depends upon the storage temperature. For pure water, the crystal melting point varies from − 0.004 to − 3.99 °C, when the crystal radius decreases from 10 to 0.01 μm [115].

Accretive Recrystallization/Sintering

Two or more crystals join into larger ones through a “neck” formation between adjacent crystals due to the difference in vapor pressure. The neck continues to grow, dependent upon temperature [114]. Eventually, the original crystals cannot be visualized. The vapor pressure of a spherical surface is greater than that of a concave surface. With reducing the surface concavity, this difference in vapor pressure can be overcome. Moisture migration is enabled easily with the help of the physical contact between ice crystals. The rate of accretion is dependent upon the ice volume [116].

Isomass Recrystallization

Even in the absence of temperature fluctuation, ice crystals tend to increase their sphericity during storage [117] due to pressure differences. These crystals tend to smooth out over time. Due to the close physical contact, water diffusion may not be easily observable. The rate of diffusion is less than the rate of actual crystal size increase by other mechanisms.

Melt-Refreeze Recrystallization

As temperature changes, ice crystals melt and refreeze. This is enabled by the high free energy and low melting point of the small ice crystals. With time, there is no further nucleation and these small ice crystals start to disappear. The water obtained by melting begins to refreeze on the surface of the remaining crystals. Therefore, a large number of small ice crystals are converted into a small number of larger ice crystals. This mechanism of ice recrystallization occurs in parallel with other mechanism, as temperature fluctuations in frozen storage are unavoidable.

Irruptive Recrystallization/Devitrification

Rewarming may lead to changes in the volume of ice crystals by inducing additional ice formation. Devitrification usually occurs in systems that are cooled with or without incomplete crystallization (ultra-rapid freezing), where the unfrozen medium has been vitrified for products with high viscosity or low water content. The product must attain a temperature below its Tg’. Irruptive recrystallization does not occur in most commercial food freezing processes since the viscosity is not high enough or the water content is not low enough. However, this process does occur during high pressure-assisted freezing, in which the product is supercooled and nucleation is instantaneous, resulting in very fast crystallization.

Recrystallization with Reference to State/Phase Transitions

During temperature fluctuation, the food undergoes change in phase/state, from one transition zone to another (e.g., between glassy and rubbery states), altering the mobility and amount of water present in the food. The transition back to the rubbery state leads to increased molecular mobility and triggers an increase in crystal size. The small ice crystals formed during freezing are relatively unstable during temperature fluctuations. However, these small crystals grow in size during storage, nullifying the advantage of quick freezing. In addition, fluctuation in storage temperature leads to state and phase transitions [31]. Depending on the characteristic thermal transition temperatures, each food undergoes change in phase and state, based on the storage temperature and the degree of temperature fluctuation. These phases and state include glassy state, rubbery state, partially freeze-concentrated state, and thawed state.

Syamaladevi et al. [28] reported an increase of mean ice crystal size in salmon subjected to a state/phase transitions over a 4-week storage. The mean ice crystal size increased when the salmon was stored in the glassy state without fluctuation (22.1%, from 121.4 to 148.3 μm), the glassy state with fluctuation (45.3%, from 121.4 to 176.4 μm), the glassy to partial freeze-concentrated state (52.3%, from 121.4 to 184.9 μm) and the glassy to rubbery state (82.4%, from 121.4 to 148.3 μm). They employed a kinetic model for ice recrystallization in frozen salmon:

D is the mean ice crystal size after time t, D0 is the initial mean ice crystal size, k is the recrystallization rate constant, A is a constant, and n is the power-law exponent.

In similar studies with mangoes, Zhang et al. [51] reported an increase in mean ice crystal size as the state changed. They found an 80.5% increase in mean ice crystal size in mangoes stored in the glassy state without temperature fluctuation (from 43.1 to 77.8 μm), a 162% increase in mean ice crystal size in the glassy to partial freeze-concentrated state (from 43.1 to 113 μm), and a 187% increase in mean ice crystal size in the glassy to the rubbery state (from 43.1 to 124 μm). These results show that mango and salmon are more susceptible than potatoes to the effects of temperature fluctuation in terms of ice recrystallization.

Kumar et al. [29] reported an increase in ice crystal size when potatoes, both unblanched and blanched, undergo state and phase transition–based temperature fluctuations in both air and aqueous ethylene glycol as the freezing media. The pore size increase in unblanched potatoes subject to temperature fluctuation in air was less discernible. Rounding of pores in some treatments was attributed to isomass rounding, a common mechanism of recrystallization [28]. They also reported the pore size frequency distribution. In ethylene glycol as the freezing media, pores in the range of 0–150 μm in unblanched potatoes in the glassy state with temperature fluctuation (from − 32 to − 12 °C) were found to disappear. This indicates the disappearance of small ice crystals and formation of large ice crystals in recrystallization. The authors attribute these findings to increased molecular mobility of water molecules at higher temperatures (T > Tg’), as well as accretion of ice crystals at lower temperatures.

Chemical and Physical Changes During Frozen Storage

The quality of a frozen food is influenced more by temperature than by storage time. The freezing rate can influence ice crystal location. When the product is subjected to freezing for a longer time, water is able to migrate from the inner region of the cell to the concentrated intercellular region, driven by osmosis. This causes cell desiccation, disruption, turgor loss, and crushing of cells due to the large intercellular ice mass [118]. The unfrozen water zone may fill with solute molecules that migrate from the freezing region due to the concentration gradient. This results in the formation of two types of crystals: ice crystals and solute crystals. The unfrozen water region attains super saturation before the product reaches its glass transition temperature, e.g., lactose crystallization in ice cream.

During frozen storage, the amount of ice in a system remains constant, while the number of ice crystals decreases and the average ice crystal size increases. Due to surface energy between ice and the unfrozen matrix, as well as the need for a nucleus to grow, there is a trend toward reduced surface area whether the temperature fluctuates or not. Ice crystal size growth can lead to damage and quality loss in frozen foods. Ice crystal growth can disrupt the structure of foods by physical fracture and by osmosis due to extracellular concentration of solutes. Excessively rapid growth of ice crystals can cause intracellular nucleation in meat and fish, which can crystallize with temperature fluctuation during storage. Some important and related quality aspects to be understood are (i) moisture migration, (ii) freeze cracking, and (iii) loss of protein and lipid functionality.

-

(a)

Moisture migration

State diagram showing different regions and state of foods. Adapted from [44]

Representative SEM images of potato subjected to temperature fluctuation, with increasing degree of temperature fluctuation, from a through d: Representative pores are outlined in red, in each image. Source: [29]. Degree of temperature fluctuation: a control sample, stored at − 32 °C. b Fluctuation from − 32 to − 12 °C. c Fluctuation from − 32 to − 6 °C. d Fluctuation from − 32 to 0 °C

Temperature gradients within a product during frozen storage leads to moisture migration and relocation, as water tends to move away from the denser regions of the product [119]. Specifically, this can occur as moisture loss by sublimation, moisture absorption and redistribution, ice recrystallization, and drip loss. Moisture migration affects the appearance, juiciness, texture, and weight of the food. Some amount of moisture loss is required to reduce a glossy appearance on the surfaces well as surface water activity. Moisture redistribution can alter the food texture, especially in multicomponent foods with varying water contents. For example, a frozen pizza may have a soggy crust due to water uptake from the filling. Recrystallization can alter food texture and appearance, as seen in ice cream and raspberries. Drip loss is driven by many factors apart from moisture loss, causing irreversible tissue damage. Once the proteins lose hydration, they crosslink among themselves. The proteins are then unable to rehydrate to the same extent upon thawing.

-

b

Freeze cracking

Freeze cracking is a consequence of build-up of internal stress, due to volume expansion upon freezing, which is suppressed by the frozen outer crust [120]. The crust acts as a shell, preventing further expansion. If the resulting stress is beyond the resistance of the food material, cracks form.

Harnkarnsujarit et al. [121] have examined the possible pre-freezing conditions on rehydration properties of freeze-dried soybean curd. Freezing using liquid nitrogen followed by freeze-drying resulted in substantial cracking after rehydration, as depicted in Fig. 10.

-

c

Loss of protein and lipid functionality

Rehydration of freeze-dried tofu pre-frozen at different conditions. Source: [121]

Ice crystal formation, dehydration, and solute concentration are responsible for freeze-induced protein denaturation. This affects food properties such as water-holding capacity, viscosity, and emulsification. Lipid oxidation is also possible during frozen storage due to presence of water/oxygen, causing loss of texture, flavor, color, and nutrition [122]. Some lipid oxidation products can induce oxidation of proteins, greatly altering food texture.

Mulot et al. [123] have studied dehydration in freezing, with respect to product surface states (smooth vs. streaked) and product porosities (full vs. perforated). They conclude that in order to limit the weight loss due to dehydration in frozen storage, the surface temperature of the product must be lowered as quickly as possible during freezing process. While the combination of a streaked surface and a perforated plate has a larger surface and a higher water vaporization, it also enables higher heat transfer and a shorter freezing time.

Constant Temperature Storage

Thawing a frozen product prior to consumption can markedly influence food quality, even if the food has been stored under constant temperature. In many cases, frozen food is thawed at the consumer end, and there is little control over thawing conditions compared to industrially thawed foods. Freezing of food involves conversion of water into ice crystals. The density of ice is less than that of water and hence greater in volume. Therefore, freezing causes food to expand. Thawing of food can lead to membrane rupture and subsequent textural damage. Ice crystal formation dynamics significantly influences product texture and mouthfeel.

-

(a)

Physical quality changes

Recrystallization has various effects based on the food matrix [124]. In meats, for example, recrystallization can lead to toughening and drying due to large ice crystals. In seafood, recrystallization can affect firmness, juiciness, and fibrousness and observable texture hardness. Texture change in muscle foods is evident in cell separation. Muscle foods are more rigid than plant foods. With semi-rigid cell walls, they sustain pronounced mechanical damage due to recrystallization, freezing, and handling. The pre-freezing stage renders the plant tissue more permeable, with loss of intracellular pressure. The direction, growth, and location of ice crystals coupled with size and number distribution can create irreversible changes in food texture.

A quick-freezing method involves better retention of texture, but could involve further damage such as cracking if the freezing rate is not optimized. Slow freezing creates large ice crystals and damages cell walls. The intercellular structure is disrupted, releasing enzymes that interfere with sensory properties.

Sun and Li [125] reported that the shape of cells in frozen potatoes change from polyhedral (in fresh potatoes) to irregular upon immersion freezing followed by thawing. The loss of the regular polyhedral structure, accompanied by intra- and extracellular crystallization, leads to possible changes in firmness of potato tissues. The authors also identified intercellular voids after freezing, at sizes appearing visually larger than those of the air spaces in intact potatoes. This indicates the formation of large extracellular ice crystals during immersion freezing. The presence of intercellular ice crystals would indicate a lower freezing rate.

In the case of starch-based foods, textural changes are accompanied by retrogradation or are indicative of it during low temperature handling and storage. Yu et al. [126] developed an optimized freezing rate (1.45 °C/min) and storage temperature (− 18 °C) for frozen cooked rice for a period of 7 months. This led to an acceptable increase in hardness (58.72 ± 1.97 N to 61.30 ± 2.19 N) and an acceptable decrease in adhesiveness (7.84 ± 0.59 Ns to 6.75 ± 0.43 Ns). There was also a minimum increase in amylopectin retrogradation enthalpy (0.5 to 1.25 J/g).

Freezing and thawing was found to significantly increase tenderness in terms of its Warner–Braztler shear force in cooked beef [127]. Fresh beef had a value of 7.4 kg after 3 days of aging. Beef stored at − 20 °C for 90 days showed a value of 5.27 kg. Large extracellular ice crystals disrupt the myofibrils and cause loss of physical structure.