Abstract

The addition of pectin to fluid systems alters its gelling, consistency, and texture characteristics. Thus, the use of this acid polysaccharide in product development can generate materials with different technological properties, capable of industrial use. For this, low-cost pectin sources are required. Among these is passion fruit, whose peel is an industrial byproduct that is rich in pectin. It is noteworthy that passion fruit peel is a byproduct generated in large quantities during fruit processing for the production of passion fruit pulp and juice, and that Brazil is the world’s largest fruit producer. In this context, this review presents the characteristics of several methods (conventional extraction, enzyme-assisted extraction, extraction with subcritical fluids, UAE, MAE, UAME, S-MAE, HHP, DESs, and NADESs) used for pectin extraction and explains the effect of the studied variables, with emphasis on the extraction from passion fruit peel. The application of pectins in different industrial systems is also addressed. Pectins are featured as functional food ingredients of high commercial value due to their technological properties. It also has applications in different areas, such as the pharmaceutical and biotechnology industries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pectin, a polysaccharide discovered in 1790, is native to the cell wall of many plants, mostly fruits and vegetables [1, 2]. It is known for its extensive use in the food industry because of its ability to gel and give viscosity and consistency to food products. It also has applications in different areas, such as the pharmaceutical and biotechnology industries [3, 4].

Pectin is cited as an attractive investment and has therefore been industrialized by companies such as CP Kelco, Calleva, FMC Biopolymers, and Herbstreith & Fox, contributing significantly to the global hydrocolloid market.

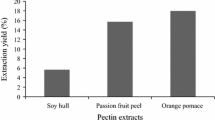

Most commercial pectins are extracted from citrus peels such as lemon and orange. However, with the growth of pectin applications, alternative sources have been presented, such as guava pulp [5], mango peel [6, 7], passion fruit peel [8, 9], and fig seed [10].

It is noteworthy that passion fruit peel is a byproduct generated in large quantities during fruit processing for the production of passion fruit pulp and juice, and that Brazil is one the world’s largest fruit producer. In 2018, 602,651 tons of passion fruit were harvested in Brazil (Fig. 1), which generated approximately 319,405 tons of peel in that year [11]. It is emphasized that the peel represents about 53% of the total mass [12].

Amount of passion fruit produced in recent years in Brazil. Source FAOSTAT [11]

The large quantity of passion fruit peel justifies the need to study the methodologies that can be used to extract pectin from the passion fruit peel, the influence of the extraction conditions, and the results obtained so that propositions of productive pectin arrangements are efficient.

Pectin Chemical Structure

Pectin naturally exhibits remarkable diversity in its molecular structure, in which there is a variety of functional groups that can assign different functionalities to this biomolecule, depending on the environmental conditions. Selective changes in the molecular structure of pectin and its characteristics can make such polysaccharide suitable for numerous applications. Properties, like size and solubility, associated with chemical and enzymatic reactions during the isolation process of pectin can affect its composition [13,14,15,16,17]. Thus, the functional properties of pectin are dependent on their structural characteristics.

Pectin is a vegetable macromolecule with one of the most complex and diverse molecular structure that varies according to the physiological state of the plant and between its tissues. The structure of the polysaccharide mainly includes the homogalacturonan (HG), xylogalacturonan (XGA), rhamnogalacturonan I (RGI), and rhamnogalacturonan II (RGII) [8, 15, 18, 19].

The ratio between HG, XGA, RGI, and RGII may vary. However, HG generally constitutes, on average, 65% of pectin, standing out as the most abundant polysaccharide, while RGI constitutes 20 to 35%. XGA and RGII are smaller components, making up less than 10% [20, 21]. It is worth mentioning that the different pectic polysaccharides are not separate molecules, but domains covalently linked [19].

Through enzymatic and non-enzymatic reactions, depolymerization and de-esterification can occur in HG. Due to depolymerization, there is a decrease in the molar mass of pectin [22]. By de-esterification, polymers are produced with non-esterified galacturonic acid residues [23, 24]. RGI is mainly exposed to enzyme-catalyzed depolymerization reactions. The main and side chains of RGI can be degraded with ease and affect the average molar mass of pectin [25,26,27].

Regarding the basic structure, pectin is formed by at least 17 different monosaccharides, of which galacturonic acid is the most abundant, followed by L-arabinose, D-galactose, L-rhamnose, and others, presenting as part of the chain, main, linked as a side chain or as isolated contaminants [28, 29]. According to the Food and Agriculture Organization (FAO), at least 65% of the structure of pectin corresponds to galacturonic acid (Fig. 2) [30].

The physicochemical properties of pectin are influenced by molecular characteristics, such as protein fraction, acetyl group content, and molecular mass. Generally, the chemical composition of pectin extracts reveals the presence of proteins (mainly bound to neutral sugar side chains), which are considered as contaminants or a non extracted component of the polymer. The presence of these proteins can be explained because due to its growth mechanism the primary cell wall of plants contains both polysaccharides and structural proteins [15]. Changes in the pectin structure, and thus in its molecular properties, have an impact on its quality and physicochemical properties such as size and solubility which are associated with chemical and enzymatic reactions during the pectin isolation process affecting the composition of the extracts [16].

The emulsifying properties of pectin are related to the presence of proteins and their molecular characteristics such as degree of acetylation and average molecular weight and extrinsic characteristics such as pectin concentration and pH of solution [15, 31, 32]. The emulsifying activity is greater for pectins with a high content of acetyl-esterified. The literature reported that acetyl groups, like ferulic groups, can promote the increase of the interfacial activity of pectin, which is also associated with the presence of methyl groups [32,33,34,35]. The influence of the methyl ester groups on the surface activity of the pectin molecule is because they are more hydrophobic than the carboxyl groups [36]. Regarding the molecular mass, this is a fundamental parameter that determines the ability to guarantee the stabilization of emulsions [15, 32, 37]. The reduction of the length of the pectin chain, through acid hydrolysis, decreases the interfacial tension and, consequently, decreases the size of the emulsion droplets [32, 33]. Siew et al. [38] and Funami et al. [39] studied the influence of neutral sugar chains on the emulsifying capacity of pectin and observed the preferential adsorption of pectin chains rich in neutral sugars in oil droplets.

Modifications in Pectin for Different Applications

Given the different demands for industrial applications of pectins, physical, chemical, and enzymatic changes are made in the pectin structure to improve its functionality. As a result, these modifications promote changes in the pectin physicochemical properties, such as molecular change, degree of esterification, molecular mass, and basic chemical structure [40]. These changes ultimately result in changes in the pectin biological activities like for example antioxidant [41], anticancer [42], prostate carcinoma, colon carcinoma, and breast carcinoma [43] activities. Modification of pectin can be achieved using techniques such as substitution (alkylation, amidation, thiolation, and sulfation, etc.), chain elongation (crosslinking and grafting), and depolymerization (acidic or enzymatic hydrolysis, elimination of β and mechanical degradation) [44].

Regarding the carboxylate alkylation technique, the alkylating carboxyl group of the COO-alkyl ester group is used to increase the hydrophobicity of the pectin. If the pectin is alkylated with the methyl group, it is called methoxylation. The esterification of pectin with methanol, in the presence of sulfuric acid or hydrochloric acid as a catalyst, is a usual method used for the methoxylation [45]. Opposite to pectin methoxylation, demethoxylation is a reaction that eliminates the methyl esters of the esterified galacturonic acid residues and converts the C-6 carbon into the carboxylic acid. A relevant issue is the methoxylation pattern, as it can largely affect the pectin properties, influencing depolymerization rates [44, 46].

Acetylation is one of the most relevant alkylations of hydroxyl groups in pectin, because pectin extracted from some plants, for example, potato and sunflower, can be naturally acetylated in O-2 and/or O-3 of galacturonic acid units, which makes gelation difficult. Complete gelation inhibition occurs when one in eight D-galacturonic acids is acetylated in O-2 or O-3 [44, 47]. Acetylated pectin can be utilized as a stabilizer and emulsifier. Besides, acetylating agent-modified pectin has shown promise in modifying the release pattern of ibuprofen, a weakly acidic drug, throughout the gastrointestinal tract, due to the reduced polarity and solubility of pectin. Generally, acetylation is performed in types of solvent catalyst systems with acetic anhydride [32, 48].

Amidated pectin can form stronger gels, mainly at low pH, due to the establishment of hydrogen bonds between the amide groups [49, 50]. However, the simplest amidated pectin most applied industrially contains the primary amino groups –CO–NH2 that is particularly useful for the food segment due to its excellent gelling properties. The amidated pectin gels are thermoreversible. Thermoreversibility indicates when the heating is transitioning to a liquid and a solid after cooling. In addition, it is allowed to be prepared in hydrogel spheres that can be used in the administration of specific drugs in the colon and also retain insulin in order to make it oral [44]. The common method of pectin amidation is ammonolysis of methyl ester groups with ammonia in anhydrous methanol. It can be classified as a type of alkaline demethoxylation by the action of ammonia in the ester groups, in which amino groups replace some of the methyl ester groups. Amidation can also be prepared by reacting pectin with amino acids [24, 44].

Quaternization is reported as an efficient method for assigning new functional properties to polysaccharides, which can transform ionic hydrocolloids into their cationic derivatives [44]. Fan et al. [51] prepared quaternized pectin by reacting pectin with 3-chloro-2-hydroxypropyltrimethylammonium chloride in the presence of sodium hydroxide obtaining pectin with exceptional absorption capability, moisture retention ability, and pronounced antimicrobial activity. This type of pectin derivative can also be used in pharmaceutical, packaging, preservatives, and cosmetics fields.

The thiolation technique also encloses the interest for the development of the “second generation” of mucoadhesives, since the mucoadhesive properties of natural polysaccharides, which belong to the “first generation,” can be improved by their thiolation [52]. Sharma, Ahuja, and Kaur [53] prepared nanoparticles of thiolated pectin using timolol maleate as a model medicine and magnesium chloride as an ionic crosslinker and verified that thiolated pectin is a promising mucoadhesive polymer for the ocular distribution of timolol maleate.

Sulfation is the method in which sulfate groups replace the hydroxyl groups of the polymeric structure. Through sulfation, significant effects are obtained on the physiological functions of polysaccharides, such as anticoagulant, antithrombotic, contraceptive, antioxidant, and anti-inflammatory infection [54, 55]. Sulfuric acid, chlorosulfonic acid, monomethyl sulfate, or sulfamic acid is generally utilized in the presence of formamide, trimethylamine, or pyridine [44]. However, the use of these agents can degrade the polysaccharide chain during the reaction; besides, it can promote pollution problems. Therefore, other sulfating agents were developed. For example, Fan et al. [56] synthesized apple pectin sulfates in aqueous solution with trisulfonated sodium amine [N(SO3Na)3] as a sulfating agent.

Oxidation of pectin has also received attention in recent years since oxidized pectin has more reactive groups and faster degradation than non-oxidized when used in supports for controlled drug delivery [57]. The reactions take place in the –OH groups at the C-2 and C-3 positions of the galacturonic acid units and can be carried out by the use of sodium periodate, with the formation of two aldehyde groups in each oxidized monomer, by breaking the carbon- linkage carbon [44].

Pectin is used in several industrial applications. Therefore, for a given application, different characteristics are required. Such characteristics can be obtained through modifications in the molecule structure to obtain knowledge of the physical and chemical properties and to assign adequate conditions to meet the necessary functions.

Degree of Pectin Esterification

Pectins have part of the esterified galacturonic acid main chain carboxyl groups, the most common substituent being the methyl group. Other substituents include ethyl and acetyl groups. Therefore, this substitution is expressed as the degree of methylation (DM) or degree of esterification (DE). DM corresponds to the total percentage of esterified galacturonic acids with methyl groups, while DE corresponds to the ratio of esterified galacturonic acid clusters to total galacturonic acid clusters [58].

The degree of esterification (DE) plays an essential role in the gelling capacity of pectin, being a parameter to indicate the physical, functional, and technological properties. Pectins are commercially classified into high esterification pectins (when they contain over 50% of their esterified carboxylic groups) and low esterification pectins (when 50% or less of these groups are esterified) [59].

Both pectin classifications have industrial applications. However, high DE pectins are employed in products with sugar presence, usually at pH below 3.6. Regarding the time required for gelation, as the DE increases, the time decreases [30, 60,61,62]. Low DE pectins are used in the presence of calcium, with a pH range of 2.6–6.0. They are chemically more stable to moisture and heat than high DE pectins. High DE pectins stored in powder lose their ability to form gels when stored in hot, humid conditions [63].

Pectin Extraction Sources

Pectin is one of the polysaccharides present in the plant’s cell wall along with cellulose, hemicellulose, and lignin and can be extracted from various natural sources. It is present in abundance in the walls surrounding the growing and dividing cells and in the junction zone between the cells with secondary walls. It is a component of all superior plant walls and the walls of gymnosperms, pteridophytes, bryophytes, and Chara, a carophyllous algae believed to be the closest relative of terrestrial plants [64].

Different plant species may have different pectin contents. Physicochemical properties vary according to the source, degree of fruit maturity, harvest time, storage time, the process used during extraction, and subsequent treatments [65].

Literature over the last few years has shown that there is a significant difference in pectin content according to fruit varieties. Considering the source from which pectin is extracted, pectin may vary in gel-forming capacity due to differences in the size of the polygalacturonic acid chain and the degree of esterification of its carboxylic groups [66].

Many sources are currently employed to obtain pectin; the main ones are listed in Table 1.

Factors Affecting Pectin Extraction

During the extraction of pectin from the passion fruit peel, some factors must be taken into account, as they can alter the process yield. These factors are discussed below:

-

pH: It is evaluated as one of the most critical parameters. As shown in the literature, extraction yield increases with decreasing pH, because the acid condition favors pectin extraction [3].

-

Time: It should be enough for the solvent to dissolve a sufficient amount of the product since the mass transfer occurs until equilibrium is reached. Thus, the longer the time, the higher the yield. However, once equilibrium is attained, time should not be extended, as very long times can cause pectin degradation [74].

-

Temperature: The higher the temperature, the higher the rate at which the solvent dissolves a solute, hence the higher the extraction yield. On the other hand, studies that evaluated the influence of temperature on the degree of esterification proved that high temperatures have a reducing effect on the degree of esterification [8].

-

Solvent: A low-viscosity solvent must be used to be able to easily enter the bed of dry substances [75]. Research on the type of solvent seeks to favor extraction, ease of purchase, and economic and environmental benefits, mainly due to problems with the use of strong acids, such as toxicity and difficulty in treating the effluents generated during the process, which causes impacts [3]. In this sense, studies have been carried out to replace mineral acids with organic acids [76]. With the increasing application of green chemistry, attention is focused on solvents called ecologically correct. With unique characteristics, biodegradable deep eutectic solvents (DES) are suitable for pectin extraction due to their low volatility at room temperature, non-flammability, and miscibility in water [77].

-

Agitation: Pectin yield tends to increase significantly with increasing agitation rate as agitation causes increased mass transfer rate and decreases diffusion layer thickness, which consequently improves extraction [3].

-

Surface area: It is proportional to the mass transfer rate, i.e., the smaller the granulometry of the raw material, the better the mass transfer in the extraction step [75].

-

Solid-Liquid Ratio: According to published studies [8, 9, 61, 74, 75, 78, 79], dry peel and solvent ratios are generally maintained at the ratio 1:10 and 1:50 m/v. Based on the results obtained, when using a proportion lower than 1:10 m/v, a low extraction was extracted, this can be justified by the fact that the amount of solvent is insufficient for the solubilization of pectin. An increase is found in the solid-liquid relation (up to 1:30 m/v) increments in the pectin yield due to the rise of dissolution capacity. However, an additional increase does not conduce to significant effects [8].

Conventional Pectin Extraction

Conventional pectin extraction can be performed by acidic or basic aqueous medium. Alkaline extraction results in pectins with a low degree of esterification due to the saponification of the ester group. The acid extraction generally results in pectins with a high esterification degree, close to the naturally occurring esterification degree. Another advantage of acid extraction is that as a result, pectin is commonly enriched with galacturonic acid units [10, 80].

On an industrial scale, acid extraction is generally performed in which strong acid solutions such as nitric, phosphoric, sulfuric, and hydrochloric acid are used, under heating. However, mineral acids have some disadvantages, such as equipment corrosion and difficulty in treating process waste. For these reasons, many studies are currently seeking to replace strong acids with organic acids such as citric, lactic, malic, acetic, or tartaric [81]. Organic acids cause less pectin depolymerization due to the low dissociation capacity [67] and, therefore, have been used by some researchers, such as Liew, Chin, and Yusof [74], Yapo [82] and Pinheiro et al. [61]. A study with citric, nitric, and sulfuric acids showed that the type of acid strongly influences the macromolecular and gelling properties of the extracted pectin [82].

In the specific case of passion fruit, the process begins with the preparation of the raw material, that is, the obtaining of the flour of the passion fruit peel through the drying and grinding operations, being used in the extraction step. The other steps employed to obtain pectin involve purification of liquid extract and isolation of pectin by precipitation and drying [83]. Extraction from the passion fruit peel flour in an acidified solution occurs for a set time and temperature. Purification of the liquid extract containing soluble pectins is generally accomplished by filtration and/or centrifugation. Subsequently, the filtrate is cooled to a temperature of ± 4 °C. The cooled solution proceeds to precipitation by the addition of two to four volumes of alcohol (ethanol, methanol, isopropanol), followed by washing with alcohol successively to remove alcohol-soluble compounds such as salts and free sugars. These solvents can be used due to their polarity [5, 61, 78]. If pectin should be addressed to the food industry, the use of toxic solvents should be avoided, and green solvents, such as ethanol, are indicated. For extractions of food products using toxic solvents for human beings, it is necessary the complete removal of the solvent to guarantee its absence in the final product. Evaporation is one unit operation that could be used to reach such purpose. Drying is performed at temperatures below 50 °C [81]. The general process for obtaining pectin from passion fruit peel flour is shown in Fig. 3.

Given the various methodologies used in the conventional extraction of passion fruit peel pectin, it is clear that there is a need to gather information on the studies performed in order to verify the influence of changes in the variables and methods used.

Based on this, information summarizing the studies found in the literature involving conventional extraction of passion fruit peel pectin is presented in Table 2.

Given the above, it is confirmed that pectin can be efficiently extracted from the passion fruit peel, with an average yield of 143.5 mg of pectin/1 g of the dry peel. Besides, the importance of performing statistical planning when conducting a survey is highlighted, since there is a strong influence of variables, both on yield and the quality of the extracted product.

Alternative Methods for Pectin Extraction

Due to the prolonged warming duration of conventional pectin extraction, the need to study faster alternatives for extraction has emerged. Some alternatives include enzyme-assisted extraction, use of subcritical fluids, ultrasound-assisted extraction, microwave-assisted extraction, the combination of these methods [84], high hydrostatic pressure, deep eutectic solvents, and natural deep eutectic solvents.

The extraction with enzymes is noteworthy due to the ability of enzymes to catalyze reactions, reduce the extraction time and the volume of alcohol used in the precipitation step, and increase the yield. One of the prominent enzymatic methods for pectin extraction is enhanced in protopectinases, which are microbial enzymes capable of solubilizing protopectin pectin. Although many advantages, the application of this technique on an industrial scale is linked to several factors, especially the cost of enzymes. As large volumes of raw materials are used in industry, enzyme extraction makes the route more expensive and less attractive. Also, scaling up this process may be hampered by changes in environmental conditions such as temperature and nutrient availability [85, 86].

Extraction with subcritical water occurs with the use of high-pressure liquid water as a solvent, being able to reach higher temperatures without phase change [87]. The process occurs with water temperature variation between the boiling point (100 °C) at 1 atm and the critical point (374 °C), under pressure necessary to keep the water in the liquid state [88]. Among the advantages presented by this process are the faster extraction process and the saving of acid solvents [87]. In this method, hydrolysis occurs without the use of acid, which eliminates the treatment of liquid waste generated and the need for corrosion-resistant equipment [87, 89, 90]. Therefore, extraction with subcritical water is known as a green method and can be successfully used to extract value-added products, such as pectin [76]. The supercritical CO2 extraction is frequently used for extracting bioactive compounds from fruit peels [91,92,93] and is being utilized for polysaccharide extraction [94, 95]. However, the high cost of implementation of the two processes, extraction with subcritical water pressurized and extraction with supercritical CO2, in the industry can be a hindrance, and the inadequate control of process conditions can lead to hydrolysis of the pectin chain [96].

Ultrasound-assisted extraction (UAE) is based on a process called cavitation, produced by sound waves (ultrasound is a special type of sound wave). These waves pass through a medium creating compression and expansion. This process leads to cavitation, that is, the production, growth and collapse of bubbles. The cavitation occurs at high temperatures and pressures. The kinetic energy of the movement is converted into heating of the medium. UAE has many advantages, such as reduced extraction time, energy consumption and equipment size, more effective mixture, and increased production, which is considered more environmentally friendly than the conventional method. In contrast, ultrasound-extracted polysaccharides have lower viscosity, molecular mass, and degree of esterification [97, 98].

Microwave-assisted extraction (MAE) is a green method in which a polar solvent absorbs microwave energy and consists of two oscillating perpendicular fields: electric and magnetic fields. Among the advantages of this form of extraction, it is worth mentioning that during heating, there is no temperature gradient, as is the case with conventional thermal processing [99]. The control inside the oven makes the system safer since inadequate closed system control can result in user and equipment risks and extraction time becomes reduced, as well as solvent requirements and equipment size can be considerably reduced. On the other hand, despite the reduced volume of acidified water used in the process, the fact that this acidic solvent is used and needs to be discarded creates the corrosion problem and subsequent wear of the equipment [84].

A new technology involving the combination of the UAE and MAE resulted in the method of ultrasound-assisted microwave extraction (UAME), for which ultrasound is used as a pre-treatment step, followed by microwave treatment [100]. According to Bagherian et al. [18], this method provides a better effect on the qualitative and quantitative characteristics of the extracted pectin when compared with the individual use of UAE and MAE. The authors extracted pectin from grapefruit and obtained results of 191.6, 278.1, 179.2, and 318.8 mg pectin/g of dry peel for conventional treatments, MAE, UAE, and UAME, respectively.

Surfactant-assisted microwave extraction (S-MAE) is also an alternative extraction method [101]. Surfactants are amphiphilic molecules with a hydrophilic head and a hydrophobic tail. The nonionic surfactant had better extraction efficiency than the ionic surfactant, as reported by Hosseinzadeh, Khorsandi, and Hemmaty [102]. Su et al. [103] evaluated the extraction of pectin from the orange peel using the MAE and S-MAE methods, as surfactants were tested with Tween-80, Tween-20, polyethylene glycol (PEG) 4000, PEG 8000, sucrose fatty acid esters (SE), and sodium dodecyl sulfate (SDS). S-MAE offers advantages such as greater efficiency of extraction, reduction of time, and better quality of pectin. The yields obtained by the conventional, MAE, and S-MAE methods were 275, 280, and 328 mg pectin/g dry peel, respectively [103].

High hydrostatic pressure (HHP) is an alternative non-thermal technology to traditional heat treatment reported as a green processing technique capable of providing a higher yield compared with conventional methods [75, 104, 105]. To obtain satisfactory results from the HHP treatment, the three process parameters such as pressure, temperature, and time must be adjusted appropriately. Generally, in most pectin extraction studies, the pressures used are in the range of 100 to 600 MPa, temperatures vary from 10 to 50 °C, and the processing time from 5 to 30 min [67, 104,105,106,107]. HHP has been used for the valorization of by-products, such as orange peel, lemon, potato, and beet as unconventional resources for pectin production [104,105,106,107]. An advantage of the method is less use of solvents. Oliveira et al. [67] evaluated the potential for high pressure to extract pectin from the passion fruit peel. The results showed values of extraction yield almost doubled, indicating HHP as an effective, time-saving, and ecological method for extracting pectin from the passion fruit peel.

Bearing in mind that mineral acids have been replaced by organic acids, it should be noted that deep eutectic solvents (DESs) are interesting for pectin extraction, as they are not volatile at room temperature, non-toxic, and of low cost [75, 77, 108]. For the formation of DES, at least two compounds are used, which consist of the eutectic mixture of bases and Bronsted-Lewis acids in a particular proportion. The system is represented by a cation and an anion from organic salt and hydrogen bond–donating species (for example, choline chloride) from a hydrogen bond donor (for example, citric acid). This mixture is formed in a certain molar ratio, and then it is stirred and heat until a transparent liquid form. DES provides greater interaction with plant material and therefore can result in a significant increase in pectin extraction [76, 109], acting as an appropriate medium for extracting polar and non-polar components showing themselves as an effective means for the extraction of pectin [76, 110, 111].

Even more environmentally friendly than DESs, natural deep eutectic solvents (NADESs) are composed of natural ingredients such as amino acids, sugars, and carboxylic acid. Some studies mention the preparation of NADESs based on the molar ratio of choline chloride and hydrogen bonding donor, through heating and mixing, until obtaining a homogeneous and stable mixture without visible precipitate. It is noteworthy that the preparation based on choline chloride and organic acid is a favorable option for extraction. According to the literature, the utilization of NADESs carried out to high extraction yields when compared with the use of their separated compounds [60, 112], due to the wide range of physical characteristics and extractive abilities of NADESs. The extraction differs from the conventional method only during precipitation, in which a larger amount of ethanol is used. Also, evaporation becomes easier, allowing the reuse of NADESs, which is essential to make the process economically viable [60, 112,113,114,115,116]. Elgharbawy et al. [60] extracted pectin from pomelo peel using NADESs and verified both high extraction yields and an average degree of esterification.

Several studies have demonstrated the application of alternative methods for pectin extraction from passion fruit peel, some of which are shown in Table 3.

In summary, the alternative methods studied for pectin extraction are well established and feature innovative techniques. However, there is a need for process improvement, not only to maximize pectin yield and quality but for industrial-scale application, which is still a hindrance due to the high cost. Besides, it is worth highlighting the importance of performing statistical planning when conducting a survey, since there is a strong influence of variables, both on yield and the quality of the extracted product.

Pectin Applications

The food applications of pectin are diverse, from drinks [119, 120], dairy products [121], meat processing [122], cosmetics, and polymers [123].

Pectins are featured as functional food ingredients of high commercial value due to their technological properties. For this reason, they are used as thickeners, gelling agents, and stabilizers in the production of many food products [4, 61, 78, 124].

Due to its hydrophilic character, due to the presence of polar groups, pectin has the property of involving a large amount of water, producing a viscous solution. Because of this capacity, it is employed in the preparation of jellies, fruit jams, fruit juices, and other branches of the food industry [125]. One of its main applications is as a thickening agent, being used in the formulation of some concentrated dairy products, such as yogurts. Pectin for home use is often sold as a complementary ingredient and is diluted with sugar and citric acid in the proper concentration to produce jelly. Its use as a food additive is usually between 0.5 and 1.0% [78].

Pectin’s ability to increase viscosity and stabilize emulsions enables its use in suspensions in liquid pharmaceutical preparations. They are appreciated as a natural textured agent in creams and oils and employed as a stabilizer and thickener in hair lotions, body lotions, and shampoos. Its use can be employed in wound healing preparations, special medical patches, deodorants, toothpaste, throat lozenges, and syrups [3].

Pectin also is known to have a positive influence on cholesterol, lipoprotein, and bile acid metabolism; plasma glucose levels after a high carbohydrate meal; atherosclerosis mechanisms; and weight reduction. It has properties to be used in the treatment of disorders related to overfeeding, due to its ability to interact with water, which results in a feeling of satiety, thus reducing food consumption [61, 126].

Pectin can be used as a biosorbent because of its strong affinity for metal ions and is considered in many studies [127]. Pectin-based hydrogels have been employed in the elimination of aqueous solution pollutants [128, 129].

It is known for its relationship to colon cancer prevention as it is a soluble dietary fiber. It is reported that soluble dietary fiber cannot be digested in the gastrointestinal tract but can be degraded and fermented by the colon microbiota, which is useful for reducing the risk of colon cancer [130, 131].

It can be used to produce biodegradable films, paper substitute adhesives, foams, and plasticizers. In the tobacco industry, it is used as a natural glue for cigar and cigar manufacture [20, 132].

Besides, pectins may be used alone or in combination with other biopolymers to prepare micro- and nano-capsules containing bioactive ingredients [133, 134].

Ways to Market Pectin

Since many factors influence the extraction process, pectin rarely presents a similar composition from one batch to another. For this reason, the commercial product is usually added with sugars in order to standardize the gelation process as to application and speed. Pectin is marketed as a powder with varying colors depending on the raw material from which it is extracted and the processing and/or storage conditions. They are obtained in commercial form, mainly light brown, and may have white, beige, yellow, pink, grayish, or darkened/caramelized samples [78, 82].

Final Considerations

As presented throughout this manuscript, in the literature, it is possible to find several methodologies and variables for the pectin extraction process from passion fruit. Still, it is noted that the industrial process is commonly performed by the conventional methodology because despite the alternative methodologies have advantages such as high yield and shorter extraction time, the disadvantages are still significant, especially when it comes to the high cost for the implementation of the process.

Thus, we realize the need for further research with advances in viable, efficient, and ecological processes, so that they can be implemented in the future in the industry.

References

Christiaens S, Buggenhout SV, Houben K, Kermani ZJ, Moelants KRN, Ngouémazong ED, Loey AV, Hendrickx MEG (2015) Process–structure–function relations of pectin in food. Crit Rev Food Sci Nutr 56:1021–1042. https://doi.org/10.1080/10408398.2012.753029

Muzzarelli RAA, Boudrant J, Meyer D, Manno N, Demarchis M, Paoletti MG (2012) Current views on fungal chitin/chitosan, human chitinases, food preservation, glucans, pectins and inulin: a tribute to Henri Braconnot, precursor of carbohydrate polymers science, on the bicentennial chitin. Carbohydr Polym 87:995–1012. https://doi.org/10.1016/j.carbpol.2011.09.063

Kanse NG, Chirag S, Swapnil S, Vishal S (2017) Extraction of pectin from orange peel’s and its applications: review. International Journal of Innovative Research in Science, Engineering and Technology. doi: https://doi.org/10.15680/ijirset.2017.0609142

Thakur BR, Singh RK, Handa AK, Rao MA (2009) Chemistry and uses of pectin: a review. Crit Rev Food Sci Nutr 37:47–73. https://doi.org/10.1080/10408399709527767

Munhoz CL, Sanjinez-Argandoña EJ, Soares-Junior MS (2010) Extraction of dehydrated guava pectin. Food Sci Technol 30:119–125. https://doi.org/10.1590/s0101-20612010005000013

Koubala BB, Kansci G, Mbome LI, Crépeau MJ, Thibault JF, Ralet MC (2008a) Effect of extraction conditions on some physicochemical characteristics of pectins from “Améliorée” and “Mango” mango peels. Food Hydrocoll 22:1345–1351. https://doi.org/10.1016/j.foodhyd.2007.07.005

Koubala BB, Mbome LI, Kansci G, Mbiapo FT, Crepeau MJ, Thibault JF, Ralet MC (2008b) Physicochemical properties of pectins from amberella peels (Spondias cytherea) obtained using different extraction conditions. Food Chem 106:1202–1207. https://doi.org/10.1016/j.foodchem.2007.07.065

Kulkarni SG, Vijayanand P (2010) Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. Flavicarpa L.). Food Science and Technology. doi: https://doi.org/10.1016/j.lwt.2009.11.006

Yapo BM (2009b) Pectin quantity, composition and physicochemical behavior as influenced by the purification process. Food Res Int 42:1197–1202. https://doi.org/10.1016/j.foodres.2009.06.002

Liang RH, Chen J, Liu W, Yu W, Yuan M, Zhou WQ (2012) Extraction, characterization and spontaneous gel-forming property of pectin from creeping fig (Ficus pumila Linn.) seeds. Carbohydrate Polymers. doi: https://doi.org/10.1016/j.carbpol.2011.07.013

FAOSTAT - Production Data 2019. Food and Agriculture Organization of the United Nations. http://www.fao.org/faostat/en/#data/QC. Acessed 09 Jun 2020

Oliveira LF, Nascimento MRF, Borges SV, Ribeiro PCN, Ruback VB (2002) Alternative use of yellow passion fruit (Passiflora edulis f. Var. Flavicarpa) peel for sweet production in syrup. Food Science and Technology. doi: https://doi.org/10.1590/s0101-20612002000300011

Houben K, Christiaens S, Ngouémazong DE, Buggenhout SV, Loey AMV, Hendricks ME (2014) The effect of endogenous pectinases on the consistency of tomato–carrot purée mixes. Food Bioprocess Technol 7:2570–2580. https://doi.org/10.1007/s11947-014-1284-z

Lopez-Sanchez P, Nijsse J, Blonk HCG, Bialek L, Schumm S, Langton M (2011) Effect of mechanical and thermal treatments on themicrostructure and rheological of carrot, broccoli and tomato dispersions. J Sci Food Agric 91:207–217. https://doi.org/10.1002/jfsa.4168

Ngouémazong ED, Christiaens S, Shpielman A, Loey AV, Hendrickx M (2015) The emulsifying and emulsion-stabilizing properties of pectin: a review. Compr Rev Food Sci Food Saf 14:705–718. https://doi.org/10.1111/1541-4337.12160

Novosel‘Skaya IL, Voropaeva NL, Semenova LN, Rashidova SS (2000) Trends in the science and applications of pectins. Chem Nat Compd 36:1–10. https://doi.org/10.1007/bf02234898

VanBuggenhout S, Sila D, Duvetter T, VanLoey A, Hendrickx M (2009) Pectins in processed fruits and vegetables: part III-texture engineering. Compr Rev Food Sci Food Saf 8:105–117. https://doi.org/10.1111/j.1541-4337-2009-00072-x

Bagherian H, Ashtiani FZ, Fouladitajar A, Moshtashamy M (2011) Comparisons between conventional, microwave- and ultrasound-assisted methods for extraction of pectin from grapefruit. Chem Eng Process Process Intensif 50:1237–1243. https://doi.org/10.1016/j.cep.2011.08.002

Harholt J, Suttangkakul A, Scheller HV (2010) Biosynthesis of pectin. Plant Physiol 153:384–395. https://doi.org/10.1104/pp.110.156588

Mohnen D (2008) Pectin structure and biosynthesis. Curr Opin Plant Biol 11:266–277. https://doi.org/10.1016/j.pbi.2008.03.006

Zandleven J, Sorensen SO, Harholt J, Beldman G, Schols HA, Scheller HV, Voragen AJ (2007) Xylogalacturonan exists in cell walls from various tissues of Arabidopsis thaliana. Phytochemistry. Doi: https://doi.org/10.1016/j.phytochem.2007.01.016

Shpigelman A, Kyomugasho C, Christiaens S, Loey AMV, Hendrickx ME (2015) The effect of high pressure homogenization on pectin: importance of pectin source and pH. Food Hydrocoll 43:189–198. https://doi.org/10.1016/j.foodhyd.2014.05.019

Racape E, Thibault JF, Reitsma JCE, Pilnik W (1989) Properties of amidated pectins. II Polyelectrolyte behavior and calcium binding of amidated pectins and amidated pectic acids. Biopolymers 28:1435–1448. https://doi.org/10.1002/bip.360280809

Sinitsya A, Copíkova J, Prutyanov V, Skoblya S, Machovic V (2000) Amidation of highly methoxylated citrus pectin with primary amines. Carbohydr Polym 42:359–368. https://doi.org/10.1016/s0144-8617(99)00184-8

Funami T, Zhang G, Hiroe M, Noda S, Nakauma M, Asai I, Cowman MK, Al-Assaf S, Phillips GO (2007) Effects of the proteinaceous moiety on the emulsifying properties of sugar beet pectin. Food Hydrocoll 21:1319–1329. https://doi.org/10.1016/j.foodhyd.2006.10.009

Morris GA, Rallet MA (2012a) The effect of neutral sugar distribution on the dilute solution conformation of sugar beet pectin. Carbohydr Polym 88:1488–1491. https://doi.org/10.1016/j.carbpol.2012.02.020

Morris GA, Rallet MA (2012b) A copolymer analysis approach to estimate the neutral sugar distribution of sugar beet pectin using size exclusion chromatography. Carbohydr Polym 87:1139–1143. https://doi.org/10.1016/j.carbpol.2011.08.077

Yapo BM, Koffi KL (2006) Yellow passion fruit rinds a potential source of low-methoxyl pectin. Journal of Agricultural and Food Chemistry. doi: https://doi.org/10.1021/j052605q

Yapo BM, Lerouge P, Thibaul TJF, Ralet MC (2007) Pectins from citrus peel cells contain homogalacturonans homogenous with respect to molar mass, rhamnogalacturonan I and rhamnogalacturonan II. Carbohydr Polym 69:426–435. https://doi.org/10.1016/j.carbpol.2006.12.024

Williats WGT, Knox JP, Mikkelsen JD (2006) Pectin: new insights into an old polymer are starting to gel. Trends Food Sci Technol 17:97–104. https://doi.org/10.1016/j.tifs.2005.10.008

Kpodo FM, Agbenorhevi JK, Alba K, Oduro IN, Morris GA, Kontogiorgos V (2018) Structure-function relationships in pectin emulsification. Food Biophysics 13:71–79. https://doi.org/10.1007/s11483-017-9513-4

Leroux J, Langendorff V, Schick G, Vaishnav V, Mazoyer J (2003) Emulsion stabilizing properties of pectin. Food Hydrocoll 17:455–462. https://doi.org/10.1016/s0268-005x(03)00027-4

Akhtar M, Dickinson E, Mazoyer J, Langendorff V (2002) Emulsion stabilizing properties of depolymerized pectin. Food Hydrocoll 16:249–256. https://doi.org/10.1016/s0268-005x(01)00095-9

Alba K, Kontogiorgos, V (2016) Pectin at the oil-water interface: Relationship of molecular composition and structure to functionality. Food Hydrocolloids. doi: https://doi.org/10.1016/j.foodhyd.2016.07.026

Siew CK, Williams PA (2008) Role of protein and ferulic acid in the emulsification properties of sugar beet pectin. J Agric Food Chem 56:4164–4171. https://doi.org/10.1021/jf073358o

Schmidt US, Koch L, Rentschler C, Kurz T, Endre HU, Schuchmann HP (2014) Effect of molecular weight reduction, acetylation and esterification on the emulsification properties of citrus pectin. Food Biophysics 10:217–227. https://doi.org/10.1007/s11483-014-9380-1

Dea ICM, Madden JK (1986) Acetylated pectin polysaccharides of sugar beet. Food Hydrocoll 1:71–88. https://doi.org/10.1016/s0268-005x(86)80009-1

Siew CK, Williams PA, Cui SW, Wang Q (2008) Characterization of the surface-active components of sugar beet pectin and the hydrodynamic thickness of the adsorbed pectin layer. J Agric Food Chem 56:8111–8120. https://doi.org/10.1021/jf801588a

Funami T, Nakauma M, Ishihara S, Tanaka R, Inoue T, Phillips GO (2011) Structural modifications of sugar beet pectin and the relationship of structure to functionality. Food Hydrocoll 25:221–229. https://doi.org/10.1016/j.foodhyd.2009.11.017

Zhang W, Xu P, Zhang H (2015) Pectin in cancer therapy: a review. Food Sci Technol 44:258–271. https://doi.org/10.1016/j.tifs.2015.04.001

Rubio-Senent F, Rodríguez-Gutiérrez G, Lama-Munõz A, García A, Fernández-Bolaños J (2015) Novel pectin present in new olive mill wastewater with similar emulsifying and better biological properties than citrus pectin. Food Hydrocoll 50:237–246. https://doi.org/10.1016/j.foodhyd.2015.03.030

Salehi F, Behboudi H, Kavoosi G, Ardestani SK (2018) Oxidative DNA damage induced by ROS-modulating agents with the ability to target DNA: a comparison of the biological characteristics of citrus pectin and apple pectin. Sci Rep 8:13902. https://doi.org/10.1038/s41598-018-32308-2

Zhang L, Ye X, Xue SJ, Zhang X, Liu D, Meng R, Chen S (2012) Effect of high-intensity ultrasound on the physicochecimal properties and nanostructure of citrus pectin. J Sci Food Agric 93:2028–2036. https://doi.org/10.1002/jsfa.6011

Chen J, Liu W, Liu CM, Li T, Liang RH, Luo SJ (2015) Pectin modifications: a review. Food Science and Nutrition 55:1684–1698. https://doi.org/10.1080/10408398.2012.718722

Ralet MC, Dronnet V, Buchholt HC, Thibault JF (2001) Enzymatically and chemically de-esterified lime pectins: characterisation, polyelectrolyte behaviour and calcium binding properties. Carbohydr Res 336:117–125. https://doi.org/10.1016/s0008-6215(01)00248-8

Fraeye I, Roeck A, Duvetter T, Verlent I, Hendrickx M, Van-Loey A (2007) Influence of pectin properties and processing conditions on thermal pectin degradation. Food Chem 105:555–563. https://doi.org/10.1016/j.foodchem.2007.04.009

Iglesias M, Lozano J (2004) Extraction and characterization of sunflower pectin. J Food Eng 62:215–223. https://doi.org/10.1016/s0260-8774(03)00234-6

Bhatia MS, Deshmukh R, Choudhari P, Bhatia NM (2010) Chemical modification of pectins, characterization and evaluation for drug delivery. Sci Pharm 76:775–784. https://doi.org/10.3797/scipharm.0805-23

Fraeye I, Duvetter T, Doungla E, Loey AV, Hendrickx M (2010) Fine-tuning the properties of pectin-calcium gels by control of pectin fine structure, gel composition and environmental conditions. Trends Food Sci Technol 21:219–228. https://doi.org/10.1016/j.tifs.2010.02.001

Lofgren C, Guillotin S, Hermansson AM (2006) Microstructure and kinetic rheological behavior of amidated and nonamidated LM pectin gels. Biomacromolecules. 7:114–121. https://doi.org/10.1021/bm050459r

Fan L, Cao M, Gao S, Wang W, Peng K, Tan C, Wen F, Tao S, Xie W (2012a) Preparation and characterization of a quaternary ammonium derivative of pectin. Carbohydr Polym 88:707–712. https://doi.org/10.1016/j.carbpol.2012.01.021

Smart JD (2005) The basics and underlying mechanisms of mucoadhesion. Adv Drug Deliv Rev 57:1556–1568. https://doi.org/10.1016/j.addr.2005.07.001

Sharma R, Ahuja M, Kaur H (2012) Thiolated pectin nanoparticles: preparation, characterization and ex vivo corneal permeation study. Carbohydr Polym 87:1606–1610. https://doi.org/10.1016/j.carbpol.2011.09.065

Maas NC, Gracher AHP, Sassaki GL, Gorin PAJ, Iacomini M, Cipriani TR (2012) Sulfation pattern of citrus pectin and its carboxy-reduced derivatives: influence on anticoagulant and antithrombotic effects. Carbohydr Polym 89:1081–1087. https://doi.org/10.1016/j.carbpol.2012.03.070

Martinichen-Herrero JC, Carbonero ER, Gorin PAJ, Iacomini M (2005) Anticoagulant and antithrombotic activity of a sulfate obtained from a glucan component of the lichen Parmotrema mantiqueirense Hale. Carbohydr Polym 60:7–13. https://doi.org/10.1016/j.carbpol.2004.11.014

Fan L, Gao S, Wang L, Wu P, Cao M, Zheng H, Xie W, Zhou J (2012b) Synthesis and anticoagulant activity of pectin sulfates. J Appl Polym Sci 124:2171–2178. https://doi.org/10.1002/app.35239

Takei T, Sato M, Ijima H, Kawakami K (2010) In situ gellable oxidized citrus pectin for localized delivery of anticancer drugs and prevention of homotypic cancer cell aggregation. Biomacromolecules. 11:3525–3530. https://doi.org/10.1021/bm1010068

Huismann MMH, Oosterveld A, Schols HA (2004) Fast determination of the degree of methyl esterification of pectins by head-space GC. Food Hydrocolloids. doi: https://doi.org/10.1016/j.foodhyd.2003.11.006

Turquois T, Rinaudo M, Taravel FR, Heyraud A (1999) Extraction of highly gelling pectic substances from sugar beet pulp and potato pulp: influence of extrinsic parameters on their gelling properties. Food Hydrocoll 13:255–262. https://doi.org/10.1016/s0268-005x(99)00007-7

Elgharbawy AAM, Hayyan A, Hayyan M, Mirghani MES, Salleh HM, Rashid SN, Ngoh GC, Liew SQ, Nor MRM, Zulkifli MZ, Alias Y (2019) Natural deep eutectic solvent-assisted pectin extraction from pomelo peel using sonorector: experimental optimization approach. Processes. 7. https://doi.org/10.3390/pr7070416

Pinheiro ER, Silva IMDA, Gonzaga LV, Lover ER, Teófilo RF, Ferreira MMC, Amboni RDMC (2008) Optimization of extraction of high-ester pectin from passion fruit peel (Passiflora edulis flavicarpa) with citric acid by using response surface methodology. Bioresour Technol 99:5561–5566. https://doi.org/10.1016/j.iortech.2007.10.058

Sundar A, Rubila S, Jayabalan R, Ranganathan TVA (2012) Review on pectin: chemistry due to general properties of pectin and its pharmaceutical uses. Sci Rep. https://doi.org/10.4172/scientificreports.550

Lara-Espinoza C, Carvajal-Millán E, Balandrán-Quintana R, López-Franco Y, Rascón-Chu A (2018) Pectin and pectin-based composite materials: beyond food texture. Molecules. doi: https://doi.org/10.3390/molecules23040942, 23

Matsunaga T, Ishii T, Matsumoto S, Higuchi M, Darvill A, Albersheim P, O’neill MA (2004) Occurrence of rhamnogalacturonan II primary cell wall polysaccharide in pteridophytes, lycophytes and bryophytes: implication for the evolution of vascular plants. Plant Physiol 134:339–351. https://doi.org/10.1104/pp.103.030072

Chan SY, Choo WS, Young DJ, Loh XJ (2017) Pectin as a rheology modifier: origin, structure, commercial production and rheology. Carbohydr Polym 161:118–139. https://doi.org/10.1016/j.carbpol.2016.12.033

Kumar A, Chauhan GS (2010) Extraction and characterization of pectin from apple pomace and its evaluation as lipase (steapsin) inhibitor. Carbohydr Polym 82:454–459. https://doi.org/10.1016/j.carbpol.2010.05.001

Oliveira C, Giordani D, Lutckemier R, Gurak PD, Clarera-Oliveira F, Marczak LDF (2016) Extraction of pectin from passion fruit peel assisted by ultrasound. LWT-Food Sci Technol 71:110–115. https://doi.org/10.1016/j.lwt.2016.03.027

Begum R, Aziz MG, Uddin MB, Yusof YA (2014) Characterization of jackfruit (Artocarpus heterophyllus) waste pectin as influenced by various extraction conditions. Agriculture and Agricultural Science Procedia 2:244–251. https://doi.org/10.1016/j.Aspro.2014.11.035

Kaya M, Sousa AG, Crépeau MJ, Sorensen SO, Ralet MC (2014) Characterization of citrus pectin samples extracted under different conditions: influence of acid type and pH of extraction. Ann Bot 114:1319–1326. https://doi.org/10.1093/aob/mcu150

Seixas F, Fukuda DL, Turbiani FRB, Garcia PS, Petkowicz CLO, Jagadevan S, Gimenes ML (2014) Extraction of pectin from passion fruit peel (Passiflora edulis f. Flavicarpa) by microwave-induced heating. Food Hydrocolloids. doi: https://doi.org/10.1016/j.foodhyd.2013.12.001

Chan SY, Choo WS (2013) Effect of extraction conditions on yield and chemical properties of pectin from cocoa husks. Food Chem 141:3752–3758. https://doi.org/10.1016/j.foodchem.2013.06.097

Gan CY, Latiff AA (2011) Extraction of pectic-polysaccharide antioxidant from mangosteen (Garcinia mangostana) rind: optimization using response surface methodology. Carbohydr Polym 83:600–607. https://doi.org/10.1016/j.carbpol.2010.08.025

Canteri-Schemin MH, Fertonani HCR, Waszczynskyj N, Wosiacki G (2005) Extraction of pectin from apple pomace. Brazilian Archives of Biology ang Technology 48:259–266. https://doi.org/10.1590/s1516-89132005000200013

Liew SQ, Chin NL, Yusof YA (2014) Extraction and characterization of pectin from passion fruit peels. Agriculture and Agricultural Science Procedia 2:231–236. https://doi.org/10.1016/j.aaspro.2014.11.033

Oliveira CF, Giordani D, Gurak PD, Clarera-Olivera F, Marczak LDF (2015) Extraction of pectin from passion fruit peel using moderate electric field and conventional heating extraction methods. Innov Food Sci Emerg Technol 29:201–208. https://doi.org/10.1016/j.ifset.2015.02.005

Liew SQ, Ngoh GC, Yusoff R, Teoh WH (2018) Acid and deep eutectic solvent (DES) extraction of pectin from pomelo (Citrus grandis (L.) Osbeck) peels. Biocatalysis and Agricultural Biotechnoly. doi: https://doi.org/10.1016/j.bcab.2017.11.001

García A, Rodríguez-Juan E, Rodrígues-Gutiérrez G, Rios JJ, Fernández-Bolaños J (2016) Extraction of phenolic compounds from virgin olive oil by deep eutectic solvents (DESs). Food Chem 197:554–561. https://doi.org/10.1016/j.foodchem.2015.10.131

Canteri MHG, Moreno L, Wosiacki G, Scheer AP (2010) Pectina: from raw material to final product. Polymers. https://doi.org/10.1590/s0104-1428201200500002

Freitas CMP, Costa AR, Rodrigues FA, Júnior MMJ, Dias MMS, Sousa RCS (2020) Optimization of pectin extraction from passion fruit (Passiflora edulis flavicarpa) using the response surface method. Brazilian Journal of Development. Doi: https://doi.org/10.34117/bjdv6n5-132

Fissore EN, Ponce NMA, Pla ME, Stortz CA, Rojas AM, Gerschenson LN (2010) Characterization of acid-extracted pectin-enriched products obtained from red beet (Beta vulgaris L. var. Conditiva) and butternut (Cucurbita moschata Shower x Poiret). Journal of Agricultural and Food Chemistry. Doi: https://doi.org/10.1021/jf903844b

Vriesmann LC, Teófilo RF, Petkowicz CLO (2012) Extraction and characterization of pectin from cacao pod husks (Theobroma cacao L.) with citric acid. Food Science and Technology. doi: https://doi.org/10.1016/j.lwt.2012.04.018

Yapo BM (2009a) Biochemical characteristics and gelling capacity of pectin from yellow passion fruit rind as affected by acid extractant nature. J Agric Food Chem 57:1572–1578. https://doi.org/10.1021/jf802969m

Yeoh S, Shi J, Langrish TAG (2008) Comparisons between different techniques for water-based extraction of pectin from orange peels. Desalination. 218:229–237. https://doi.org/10.1016/j.desal.2007.02.018

Adetunji LR, Adekunle A, Orsat V, Raghavan V (2017) Advances in the pectin production process using novel extraction techniques: a review. Food Hydrocoll 62:239–250. https://doi.org/10.1016/j.foodhyd.2016.08.015

Norton IT, Fryer P, Moore S (2006) Product/process integration in food manufacturing: engineering sustained health. AICHE J 52:1632–1640. https://doi.org/10.1002/aic.10815

Puri M, Sharma D, Barrow CJ (2012) Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol 30:37–44. https://doi.org/10.1016/j.tibtech.2011.06.014

Zakaria SM, Kamal SMM (2015) Subcritical water extraction of bioactive compounds from plants and algae: applications in pharmaceutical and food ingredients. Food Engineering Reviews. doi: https://doi.org/10.1007/s12393-015-9119-x

Koomyart I, Nagamizu H, Khuwijitjaru P, Kobayashi T, Shiga H, Yoshii H, Adachi S (2016) Using severity factor as a parameter to optimize krill treatment under subcritical water conditions. Biosci Biotechnol Biochem 80:2192–2197. https://doi.org/10.1080/09168451.2016.1204220

Maurya DP, Singla A, Negi S (2015) Na overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech. doi: https://doi.org/10.1007/s13205-015-0279-4

Rojas R, Contreras-Esquivel JC, Orozco-Esquivel MT, Munoz C, Aguirre-Joya JA, Aguilar CN (2015) Mango peel as source of antioxidants and pectin: microwave assisted extraction. Waste and Biomass Valorization 6:1095–1102. https://doi.org/10.1007/s12649-015-9401-4

Durante M, Lenucci MS, Mita G (2014) Supercritical carbon dioxide extraction of carotenoids from pumpkin (Cucurbita spp.): a review. International journal of molecular Siences. doi: https://doi.org/10.3390/ijms15046725

Garcia-Mendoza MP, Paula JT, Paviani LC, Cabral FA, Martinez-Correa HA (2015) Extracts from mango peel by-product obtained by supercritical CO2 and pressurized solvent processes. LWT Food Sci Technol 62:131–137. https://doi.org/10.1016/j.lwt.2015.01.026

Jaime L, Vázquez E, Fornari T, López-Hazas MC, García-Risco MR, Santoyo S, Reglero G (2014) Extraction of functional ingredients from spinach (Spinacia oleracea L.) using liquid solvent and supercritical CO2 extraction. Journal of the Science of Food and Agriculture. doi: https://doi.org/10.1002/jsfa.6788

Chen J, Li J, Sun A-D, Zhang B-O, Qin S-G, Zhang Y-Q (2014) Supercritical CO2 extraction and pre-column derivatization ofpolysaccharides from Artemisia sphaerocephala Krasch. seedsvia gas chromatography. Industrial Crops and Products. doi: https://doi.org/10.1016/j.indcrop.2014.06.013

Zou X, Liu Y, Tao C, Liu Y, Liu M, Wu J, Lv Z (2017) CO2 supercritical fluid extraction and characterization of polysaccharide from bamboo (Phyllostachys heterocycla) leaves. Journal of Food Measurement and Characterization 12:35–44. https://doi.org/10.1007/s11694-017-9614-2

Khajavi SH, Kimura Y, Oomori T, Matsuno R, Adachi S (2005) Degradation kinetics of monosaccharides in subcritical water. Journal of Food Engineering. doi: https://doi.org/10.1016/j.jfoodeng.2004.06.004

Azmir J, Zaidul ISM, Rahman MM, Sharif KM, Mohamed A, Sahena F, Jahurul MHA, Ghafoor K, Norulaine NAN, Omar AKM (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436. https://doi.org/10.1016/j.jfoodeng.2013.01.014

Luque-García JL, Castro MLD (2003) Ultrasound: a powerful tool for leaching. Trends Anal Chem 22:41–47. https://doi.org/10.1016/so165-9936(03)00102-x

Routray W, Orsat V (2012) Microwave-assisted extraction of flavonoids: a review. Food Bioprocess Technol 5:409–424. https://doi.org/10.1007/s11947-011-0573-z

Sengar AS, Rawson A, Muthiah M, Kalakandan SK (2019) Comparison of different ultrasound assisted extraction techniques for pectin prom tomato processing waste. Ultrason Sonochem 61:104812. https://doi.org/10.1016/j.ultsonch.2019.104812

Li F, Raza A, Wang YW, Xu XQ, Chen GH (2017) Optimization of surfactantmediated, ultrasonic-assisted extraction of antioxidant polyphenols from rattan tea (Ampelopsis grossedentata) using response surface methodology. Pharmacogn Mag doi: https://doi.org/10.4103/pm.pm_159_16, 13, 446

Hosseinzadeh R, Khorsandi K, Hemmaty S (2013) Study of the effect of surfactants on extraction and determination of polyphenolic compounds and antioxidant capacity of fruits extracts. PLoS One 8:e57353. https://doi.org/10.1371/journal.pone.0057353

Su DL, Li PJ, Quek SY, Huang ZQ, Yuan YJ, Li GY, Shan Y (2019) Efficient extraction and characterization of pectin from orange peel by a combined surfactant and microwave assisted process. Food Chem 286:1–7. https://doi.org/10.1016/j.foodchem.2019.01.200

Guo X, Han HD, Xi H, Rao L, Liao X, Hu X, Wu J (2012) Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: a comparasion. Carbohydr Polym 88:441–448. https://doi.org/10.1016/j.carbpol.2011.12.026

Xie F, Zhang W, Lan X, Gong S, Wu J, Wang Z (2018) Effects of high hydrostatic pressure and high pressure homogenization processing on characteristics of potato peel waste pectin. Carbohydr Polym 196:474–482. https://doi.org/10.1016/j.carbpol.2018.05.061

Naghshineh M, Olsen K, Georgiou CA (2013) Sustainable production of pectin from lime peel by high hydrostatic pressure treatment. Food Chem 136:472–478. https://doi.org/10.1016/j.foodchem.2012.08.036

Peng X, Mu T, Zhang M, Sun H, Chen J, Yu M (2016) Effects of pH and high hydrostatic pressure on the structural and rheological properties of sugar beet pectin. Food Hydrocoll 60:161–169. https://doi.org/10.1016/j.foodhyd.2016.03.025

Zainal-Abidin MH, Hayyan M, Hayyan A, Jayakumar NS (2017) New horizons in the extraction of bioactive compounds using deep eutectic solvents: a review. Anal Chim Acta 979:1–23. https://doi.org/10.1016/j.aca.2017.05.012

Shafie MH, Yusof R, Gan CY (2019) Deep eutectic solvents (DES) mediated extraction of pectin from Averrhoa bilimbi: optimization and characterization studies. Carbohydr Polym 216:303–311. https://doi.org/10.1016/j.carbpol.2019.04.007

Cunha SC, Fernandes JO (2018) Extraction techniques with deep eutectic solvents. TrAC Trends Anal Chem 105:225–239. https://doi.org/10.1016/j.trac.2018.05.001

Zdanowicz M, Wilpiszewska K, Spychaj T (2018) Deep eutectic solvents for polysaccharides processing: a review. Carbohydr Polym 200:361–380. https://doi.org/10.1016/j.carbpol.2018.07.078

Dai Y, Rozema E, Verpoorte R, Choi YH (2016) Application of natural deep eutectic solvents to the extraction of anthocyanins from Catharanthus roseus with high extractability and stability replacing conventional organic solvents. J Chromatogr A 1434:50–56. https://doi.org/10.1016/j.chroma.2016.01.037

Aroso IM, Paiva A, Reis RL, Duarte ARC (2017) Natural deep eutectic solventes from choline chloride and betaine: physicochemical properties. J Mol Liq 241:654–661. https://doi.org/10.1016/j.molliq.2017.06.051

Hayyan M, Mbous YP, Looi CY, Wong WF, Hayyan A, Salleh Z, Mohd-Ali O (2016) Natural deep eutectic solvents: cytotoxic profile. SpringerPlus. 5:913. https://doi.org/10.1186/s40064-016-2575-9

Jablonský M, Skulcová A, Kamenská L, Vrska M, Sima J (2015) Deep eutectic solvents: fractionation of wheat traw. Bioresources. Doi: https://doi.org/10.15376/biores.10.4.8039-8047

Tommasi E, Cravotto G, Galleti P, Grillo G, Mazzotti M, Sacchetti G, Samorì C, Tabasso S, Tacchini M, Tagliavini E (2017) Enhanced and selective lipid extraction from the Microalga P. tricornutum by dimethyl carbonate and supercritical CO2 using deep eutectic solvents and microwaves as pretreatment. ACS Sustainable Chemistry and Engineering. doi: https://doi.org/10.1021/acssuschemeng.7b02074

Vasco-Correa J, Zapata AD (2017) Enzymatic extraction of pectin from passion fruit peel (Passiflora edulis f. Flavicarpa) at laboratory and bench scale. LWT Food Science and Technology. doi: https://doi.org/10.1016/j.lwt.2017.02.024

Souza CG, Rodrigues THS, Silva LMA, Ribeiro PRV, Brito ES (2017) Sequential extraction of flavonoids and pectin from yellow passion fruit rind using pressurized solvent or ultrasound. J Sci Food Agric 98:1362–1368. https://doi.org/10.1002/jsfa.8601

Nakamura A, Yoshida R, Maeda H, Corredig M (2006) The stabilizing behavior of soybean soluble polysaccharide and pectin in acidified milk beverages. Int Dairy J 16:361–369. https://doi.org/10.1016/j.idairyj.2005.01.014

Zulueta A, Esteve MJ, Frasquet I, Frigola A (2007) Vitamin C, vitamin A, phenolic compounds and total antioxidant capacity of new fruit juice and skim milk mixture beverages marketed in Spain. Food Chem 103:1365–1374. https://doi.org/10.1016/j.foodchem.2006.10.052

Joudaki H, Mousavi M, Safari M, Razavi SH, Emam-Djomeh Z, Gharibzahedi SMT (2013) A practical optimization on salt/high-methoxyl pectin interaction to design a stable formulation for Doogh. Carbohydr Polym 97:376–383. https://doi.org/10.1016/j.carbpol.2013.05.056

Pereira CM, Marques MF, Hatano MK, Castro IA (2010) Effect of the partial substitution of soy proteins by highly methyl esterified pectin on chemical and sensory characteristics of sausages. Food Sci Technol Int 16:401–407. https://doi.org/10.1177/1082013210366888

Lupi FR, Gabriele D, Seta L, Baldino N, Cindio B, Marino R (2014) Rheological investigation of pectin-based emulsion gels for pharmaceutical and cosmetic uses. Rheol Acta 54:41–52. https://doi.org/10.1007/s00397-014-0809-8

Qiu L, Zhao G, Wu H, Jiang L, Li X, Liu J (2010) Investigation of combined effects of independent variables on extraction from banana peel using response surface methodology. Carbohydr Polym 80:326–331. https://doi.org/10.1016/j.carbpol.2010.01.018

Voragen AGJ, Coenen GJ, Verhoef RP, Schols HA (2009) Pectin, the versatile polysaccharide polysaccharide present in plant cell walls. Struct Chem 20:263–275. https://doi.org/10.1007/s11224-009-9442-z

Silva DC, Freitas ALP, Pessoa CDS, Paula RCM, Mosque JX, Leal LKAM, Brito GAC, Gonçalves DO, Viana GS (2011) Pectin from Passiflora edulis shows anti-inflammatory action as well as hypoglycemic and hypotriglyceridemic properties in diabetic rats. J Med Food 14:1118–1126. https://doi.org/10.1089/jmf.2010.0220

Annadurai G, Juang RS, Lee DJ (2003) Adsorption of heavy metals from water using banana and orange peels. Water Sci Technol 47:185–190. https://doi.org/10.2166/wst.2003.0049

Kumar R, Kumar A, Chauhan KR, Gupta R, Ahn JH, Chauhan GS (2009) Removal of as (V) from water by pectin based active hydrogels following geochemical approach. Bioresour Technol 100:1474–1477. https://doi.org/10.1016/j.biortech.2008.08.008

Singha NR, Karmakar M, Mahapatra M, Mondal H, Dutta A, Roy C, Chattopadhyay PK (2017) Systematic synthesis of pectin-g-(sodium acrylate-co-N-isopropylacrylamide) interpenetrating polymer network for superadsorption of dyes/M (ii): determination of physicochemical changes in loaded hydrogels. Polym Chem 8:3211–3237. https://doi.org/10.1039/c7py00316a

Jackson CL, Dreaden TM, Theobald LK, Tran NM, Beal TL, Eid M, Gao MY, Shirley RB, Stoffel MT, Kumar MV, Mohnen D (2007) Pectin induces apoptosis in human prostate cancer cells: correlation of apoptotic function with pectin structure. Glycobiology. 17:805–819. https://doi.org/10.1093/glycob/cwm054

Wicker L, Kim Y, Kim MJ, Thirkield B, Lin Z, Jung J (2014) Pectin as a bioactive polysaccharide-extracting tailored function from less. Food Hydrocolloids. doi: https://doi.org/10.1016/j.foodhyd.2014.01.002

Cuq B, Gontard N, Guilbert S (1995) Edible film and coating as active layers. In: Rooney ML (ed) Active food packaging. Blackie Academic & Professional, London

Ji F, Li J, Qin Z, Yang B, Zhang E, Dong D, Wang J, Wen Y, Tian L, Yao F (2017) Engineering pectin-based hollow nanocapsules for delivery of anticancer drug. Carbohydr Polym doi: https://doi.org/10.1016/j.carbpol.2017.08.107, 177, 86, 96

Krivorotova T, Cirkovas A, Maciulyte S, Staneviciene R, Budriene S, Serviene E, Sereikaite J (2016) Nisin-loaded pectin nanoparticles for food preservation. Food Hydrocoll 54:49–56. https://doi.org/10.1016/j.foodhyd.2015.09.015

Funding

The authors received financial support from the National Council for Scientific and Technological Development (CNPq), the Coordination for the Improvement of Higher Education Personnel (CAPES), and the Minas Gerais State Research Support Foundation (FAPEMIG).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

FREITAS, C.M.P., SOUSA, R.C.S., DIAS, M.M.S. et al. Extraction of Pectin from Passion Fruit Peel. Food Eng Rev 12, 460–472 (2020). https://doi.org/10.1007/s12393-020-09254-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09254-9