Abstract

The food industry generates millions of tonnes of waste annually from citrus, apple, and other fruits. Commercial pectin extracted from citrus and apple pomace is commonly used in food industries, but there is limited research on extracting pectin from other fruit wastes. Passion and tamarillo fruits are excellent sources of dietary fiber, hydrocolloids, polyphenols, and micronutrients. This manuscript discusses the optimization and characterization of pectin extracted from two varieties of passion fruit peel (P. edulis (PE) & P. ligularis (PL)) and tamarillo (TT) fruit pomace using different extraction methods with different extractants and compared the pectin quality. The pectin yield was higher in TM (Tamarillo, microwave extraction method) and PeC (Passiflora edulis, conventional extraction method) with tartaric acid used as an extractant. Nitric acid extraction of TT and PE had significantly higher AUA values in conventional and microwave extraction methods respectively, with a relatively highest yield of pectin. In this study, pectin extracted from TT and PE by conventional methods showed higher DE values, indicating HMP (High Methoxyl Pectin). FTIR (Fourier-transform infrared spectroscopy) spectral analysis showed that the extracted pectin had a characteristic band similar to commercial pectin. The surface morphological characteristics of the peel were flaky, rough, and uneven in texture, whereas the pectin had a smoother surface with a slightly flaky texture. The flow behaviour index of extracted pectin was less than one, indicating shear thinning behaviour. The presence of protein in the extracted pectin may enhance the stability of the emulsions, used in various food applications.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Waste valorization of peel and pomace is generated from the fruit processing industry. During processing, by-products of passion fruit and tamarillo generates 49% and 50–60% of peel and pomace waste, respectively. Extracting pectin from these wastes will become advantageous in both environmental and economic aspects like reducing the cost as well as solid waste disposal problems. There is a demand of pectin in various industries like beverage and food industries (5–30%), pharmaceutical & nutraceutical (2–10%), biotechnological and biomedical (1–3%), personal care and cosmetics (1–5%).

Passion fruit or sweet granadilla (Passiflora edulis) is well spread in tropical regions worldwide. Two main edible species are cultivated for commercial purposes; purple passion fruit (P. edulis Sims), sweeter in taste, and yellow passion fruit (YPF) (P. edulis f. Flavicarpa Degener), slightly acidic in taste. The dietary fiber from passion fruit seed has been found to consist mainly of cellulose, pectic substances, and hemicellulose [59]. Sweet granadilla fruit has 40–55% edible parts, 72–80% moisture content, and 7.0–8.0°Brix [52]. It is known for its low-fat content and high contribution in fiber, vitamins A, C, and K. It also contains phosphorus, iron, and calcium [27]. Tamarillo or tree tomato (Cyphomandra betaceae) which belongs to the Solanaceae family, is low in fat and calories. It has high nutritional value providing significant amounts of micronutrients such as pro-vitamin A, vitamin C, B6, E, and Fe, and bioactive components like anthocyanins, carotenoids, and flavonoids [38]. Tamarillo is a potential source of food hydrocolloids. Hydrocolloid from tamarillo puree contains 21.8% protein, 66.48% dietary fiber, and 0.83% starch. The degree of esterification derived from tamarillo hydrocolloid was 49.47%, it can be utilized as an alternative to low methoxyl pectin [22]

The pectin extraction process involves various methods to improve the pectin quality and quantity. The functional, structural, and chemical properties of pectin depend on its source and extraction methods. The conventional one is the traditional method, which uses hot water (60-100ºC) acidified with mineral acids (Hydrochloric, sulphuric, or nitric acid) or organic acids (citric or tartaric acid) within a pH range of 1.5–3 to extract the pectin. However, this process is considered time-consuming and causes thermal degradation of the extracted fiber. Sometimes, pectin yield is limited by the process conditions [46].

In the novel methods, ultrasonication and microwave are one of the innovative methods of extraction techniques used for pectin. Microwave extraction involves electromagnetic radiation using microwave frequency range in the sample to produce thermal energy in the solvent. This energy induces polar molecule vibration and increases temperature rapidly while the efficiency of the extraction process [19]. Ultrasonication is a process that produces acoustic at higher frequency; this acoustic energy is used to extract target compounds from the pomace and peels of the fruits to enhance the mass transfer which is brought about by the acoustic cavitation induced in a liquid medium. Pectin in the cell wall of the tissues is extracted to disrupt the cell walls and may help to enhance the mass transfer from the solid matrix to the solvent [14].

Several process variables affect the pectin extractions like extraction techniques (microwave, conventional, ultrasonication methods), time and temperature of extraction, raw materials, and acid types used (mineral or organic acids), sample-to-extractant ratio, and pH. These are essential factors in the yield and properties of pectin and thus, earlier report says that the AUA and DE value of tamarillo and passion fruit pectin was not similar using different extraction methods [21, 22, 57, 59].

The pectin extraction from fruits in greater quantities is not only stated to be a good source of commercial pectin. Citrus and apple are the two known fruits used commercially for the extraction of pectin because apple pomace yields 10–15% and citrus peel yields 20–30%. Pectin is also extracted from other fruits and by-products like sunflower head, mango peel, soybean hull, passion fruit peel, sugar beet pulp, Akebia trifoliata peel, peach pomace, banana peel, and chickpea husk. It has shown variations in structures and modifications in side-chain sugars and also having different gelling properties [51].

This study discusses the optimization and characterization of pectin extracted from the peel of two varieties of passion fruits (P. edulis, PE & P. ligularis, PL) and tree tomato (TT) or tamarillo pomace. In the present study, the pectin was extracted by using conventional method and compared with other methods of extraction. The extracted pectin was evaluated for its structural and functional properties.

Material and Methods

Materials

Passion fruits of two varieties, Passiflora edulis (PE), Passiflora ligularis (PL), Tamarillo, or tree tomato (TT) were collected from growers in the Western Ghats region of India. Peel and pulp were separated and studied for their physicochemical characteristics, organic acids, sugars, and phytonutritional content. Further, the peel and pomace were dried and used for the pectin extraction. The pectin was evaluated for DE, AUA, MeO, equivalent weight, structural and functional properties.

The chemicals like HPLC grades of solvents (acetonitrile, methanol), commercial pectin (DE > 50%), malic, acetic, citric, oxalic acid, ascorbic acid, meta-phosphoric acid, and bovine serum albumin were purchased from Sigma Aldrich, Germany, and mineral standards (Merck). All the other chemicals used in this study were analytical grade.

Physicochemical Characteristics of Whole Fruits and Peel

The parameters like weight, length, shape, and diameter of PE, PL and TT were recorded for ten fruits and analyzed the titrable acidity [45], total soluble solids [3], and pH [5] in the pulp. The peel and pomace powders of passion and tamarillo fruits respectively were analyzed for moisture [2], crude fiber [48] ash [4], and mineral composition [4] using a microwave plasma-atomic emission spectrometer (Agilent 4210 MP-AES). Color value was determined by using a Konica Minolta, spectrophotometer CM-5 [25], protein [8, 37], and total carbohydrates [29]. The methanolic extracts of the peel powders were analyzed for total phenolic content, total flavonoid content [16], and total antioxidant activity [9].

Determination of Organic Acids

The individual organic acids like malic, acetic, citric, oxalic, and ascorbic acid were determined by using HPLC. The dried peel sample was extracted with meta-phosphoric acid (MPA) and stirred for 45 min. It was then filtered through a Whatman No.4 filter followed by 0.22 µm nylon filters before injecting the sample. HPLC (Shimadzu, 10AV UV–VIS detector) connected with a photodiode array detector was used for the quantification of organic acids. The separation was performed by supelcogel C-610Hchromatographic column (30 cm × 7.8 mm) using0.1% H2SO4 as mobile phase at the flow rate of 1.0 ml/min at 40ºC [50].

Determination of Sugars

Free sugars like glucose, fructose, and sucrose were quantified by the UPLC method. Dried peel powder (1 g) was extracted with ethanol for 15 min, centrifuged and the supernatant was collected and re-extracted the remaining solids by using the same solvent. The extracts were combined and then evaporated using a rotary evaporator and the concentrate was diluted with MilliQ water followed by filtration using 0.45 µm nylon filters. The following UPLC method was slightly modified by the method given by Lamani et al. [34]. The UPLC coupled with ELSD (Evaporative light scattering detector) was used, the conditions of ELSD were 200, gain,40 psi, gas pressure; 40 °C, the temperature of drift tube; cooling, nebulizer. The separation of free sugars was carried out by using UPLC BEH Amide column (100 × 2.1 mm × 1.7 micron) and the mobile phase used were A: 80:20ACN: water containing 0.2% TEA and B: 30:70ACN: water containing 0.2% TEA. The gradient elution was carried out by using 40% A for 10 min and 60% B for 10 min with column temperature at 35ºC at the flow rate of 0.1 ml/min.

Extraction and Characterization of Pectin

Pectin was extracted from passion fruit peel and tamarillo pomace. Various extraction methods like conventional, microwave, and ultrasound were used during the extraction process to optimize processing techniques with high quality and yield. Four different acids of citric acid, tartaric acid, HCl, and HNO3 were used. The extraction technique was slightly modified by the method given by Yapo (2005). The pectin was precipitated from slurry using alcohol precipitation. The precipitated pectin was dried at 40 °C, pulverized and stored in the desiccator for further analysis.

The extracted pectin from two varieties of PE, PL and TT were analysed for equivalent weight (Eq.W) and Methoxyl content (MeO) by the methods given by Ranganna [45]. The total Anhydrouronic Acid Content (AUA) was determined using the method by Khamsucharit et al. [32]. The Degree of Esterification (DE) was determined based on methoxyl and AUA content and it was calculated by using the formula given by Azad et al. [6]. Organic acids present in pectin were determined by using the HPLC method and the same protocol discussed in the above Sect. (2.3). Protein present in pectin was also quantified by using Lowry’s method [37].

Structural Characterization of Pectin

Scanning Electron Microscopy (SEM)

The microstructure of peel powders and pectin samples was observed by using scanning electron microscopy (S-3400N, Hitachi, Japan, Thermo Fisher Scientific). Before and after the extraction process, the images were taken. Samples were placed with the support of double b-sided conductive carbon tape and then metalized with gold coating to ensure electrical conductivity to the observed surface [36, 47].

Fourier Transform Infrared Spectroscopy (FTIR)

Fourier transform infrared spectroscopy (FTIR) of pectin samples was analyzed by using a Tensor II FTIR spectrometer (Bruker Optics, Wissembourg, France) and equipped with a single-reflectance horizontal ATR cell (Golden Gate equipped with a diamond crystal, Bruker Optics). The pectin sample was uniformly mixed with potassium bromide (KBr) and pressed into a 1 mm pellet. FTIR spectra were recorded in this range of 4000-400 cm-1 [55].

Functional Characterization of Pectin

Rheological Properties of Peel and Pectin

The rheology of extracted pectin was carried out by using a Modular compact Rheometer MCR52 model (Anton Paar) with a 75 mm parallel plate and plate combination. 1% pectin solution for rheological tests was stirred using a magnetic stirring for 15 min at 65ºC. The pectin solutions were subjected to steady- shearing at 25ºC and the shear rates tested in this study ranged from 1 to 500 s−1. Data were fitted to a Herschel-Bulkley (τ = τ0 + Kγ˙ n), where τ is the shear stress (Pa), K is the consistency index (Pa sn), γ˙ is the shear rate (s−1), n is the flow behaviour index (dimensionless) and τ0 is the yield stress (Pa) [1].

Preparation of Emulsion and Emulsifying Properties of Pectin

Emulsions were made using various pectins (PE, PL, and TT) at a concentration of 1%. Each pectin solution (10 ml) was homogenized with an equal amount of corn oil to make an emulsion. It was filled in glass tubes and calculated the percentage of the creaming index during storage for 20 days with the intervals of 10 days storage [12].

Hs: the serum layer height of emulsions; Ht: the total height of emulsions.

Statistical Analysis

The statistical analysis of the results was carried out using Minitab 21 software. The results are reported as Mean ± SD. Tukey’s test was done as a post hoc analysis to determine the variability of means.

Results and discussion

Physicochemical Characteristics of Whole Fruits and Peel Powder

Whole fruit, pulp, and peel were characterized by PE, PL, and TT (Table 1). PE showed higher acidity and lower pH, whereas TSS was found to be higher in PL pulp compared with PE and TT pulp. Crude fiber content was higher in PE peel powder (46.83%) followed by PL peel powder (34.06%). Protein was found to be higher in tamarillo pomace powder (4.72 g/100 g). Organic acids and free sugars in peel and pomace powders were also studied by using HPLC and UPLC methods (Fig. 1). Citric acid was the predominant acid present in all the samples. PL had the highest citric acid content compared with PE and TT. Fructose was the major sugar present in all the samples. TT had a higher sugar content than the other samples. The total phenolics, total flavonoids, and total antioxidant capacities of passion fruit peel and tamarillo pomace powders were studied. TT showed a higher total phenolic content with higher antioxidant capacities followed by PE than PL (Fig. 1).

A Fructose and glucose content (g/100g) (B) Organic acid content (g/100g), in peel and pomance powders of passion abd tamarillo fruits. Results followed by different small letters in the column indicate significant difference (p < 0.005) according to Turkey’s test. C UPLC chromatograms of simple sugars in peel and pomance powders of passion and tamarillo fruits: 1-Fructose,2-Glucose, 3-Sucrose (D) Total phenolic content, total flavonoid content and total antioxidant capacity in peel and pomance powders of passion and tamarillo fruits

Extraction and Characterization of Pectin

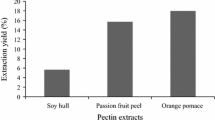

The quality and quantity of pectin from peel were influenced by various factors like the type of fruits, acids, and extraction methods for pectin. The yield of pectin ranged from 2.66 to 17.09% from tamarillo and passion fruit, respectively. Kliemann et al. [33] reported that pectin extracted from passion fruit using several acids and pectin yield ranged from 10 to 70 g/100 g of peel, which was remarkably high considering that pectic compounds account for roughly 25 g/100 g of cell wall material from passion fruits [59]. The acid type, source of fruit, and various extraction methods significantly influence the pectin yield. A high concentration of hydrogen ions in the solvents enhances protopectin hydrolysis [31]. The highest yield was observed with TT using the microwave extraction method and tartaric acid as an extractant. The lowest yield was observed with PL using the conventional method and citric acid as an extractant.

The yield of pectin is highly dependent on acids and methods used for extraction. Among the three fruits, PE showed a higher yield of pectin followed by TT and PL. Tartaric acid with microwave methods showed a higher yield of pectin in both TT and PE. Similarly, Seixas et al. [47] reported a higher yield of pectin in passion fruit with microwave and tartaric acid. In this present study, ultrasound extraction methods showed a very low yield of pectin from all acids used for extraction. However, other researchers found that a higher yield of pectin was obtained from grapefruit and passion fruit with ultrasound extraction [7, 14]. This might be due to the overexposure of the plant materials by ultrasound extraction methods, the extraction medium is destructed and disintegrated causing the yield to decrease drastically [42].

The equivalent weight of pectin indicates its gel-forming ability [54]. A higher Eq. W designates a higher gel-forming effect. The amount of free acids may influence the equivalent weight [13]. In this present study, the equivalent weight of the extracted pectin ranged from 227.27 to 5000. PL produced pectin with the highest equivalent weight using citric acid and also with the conventional method of extraction. Pectin extracted from tartaric acid in all the extraction methods showed a lower equivalent weight.

The methoxyl content reflects pectin dispersibility in water and pectin gel formation [10]. High methoxyl pectin (HMP) form gels (8–11%) with higher sugar content ((> 55%), used for jam and jelly preparations. The gelling process of pectin and its stabilization follows different mechanisms for different types of pectin. HM pectins form a gel at pH < 3.5 and high sugar concentrations (> 55%). During the gelation process of HMP, junction zones are formed due to the cross-linking of two or more pectin molecules. These junctions are stabilized by weak molecular interactions such as hydrogen and hydrophobic bonds between polar and nonpolar methyl-esterified groups and require high sugar concentration and low pH [51]. Variations in fruit varieties and acids used for extraction affected the methoxyl content of the pectin. In this present study, the highest MeO% was observed in the conventional method with nitric acid, which indicates that the extracted pectin was HMP. Nitric acid extraction of both PE and TT resulted in high MeO% whereas, HCl and tartaric acid extractions showed lower MeO% exhibited LMP (Low Methoxyl Pectin). When compared between the fruits, PL showed the lowest MeO% values.

Based on DE values, the extracted pectin can be classified as HMP (> 50%) and LMP (< 50%) [15, 24]. In this study, pectin extracted from TT and PE using the conventional method showed higher DE values indicating HMP. The values are consistent with the MeO% values. Total anhydrouronic acid content (AUA) in pectin is an essential parameter for determining purity and degree of esterification. It also aids in determining the physical properties of a given pectin sample [45]. According to the Food Chemical Codex, the AUA content of pectin should not be less than 65% and free of ash. Pectin purity reflects on the gel strength, if it gets contaminated with ash, neutral sugars, starch, and proteins which affect the gel formation [57, 58].

In this study, the AUA content ranged from 10.56 to 95.04%. The pectin extracted from tartaric acid, citric acid, nitric acid, and HCl showed very low AUA% in PL peel (13.2 to 63.36%), the highest AUA% showed in TT and PE ranged from 88 to 95.04% (Fig. 2) which implicates that the extracted pectin purity with the presence of protein. Similarly, the pectin extracted from citric acid with conventional methods showed the highest AUA (95.04%). Nitric acid extraction with conventional and microwave extraction methods showed significantly higher AUA values in both TT and PE with relatively higher yields of pectin (Table 2). Citric and oxalic acid were the predominant acids present in pectin samples. The highest amount of oxalic acid is present in PE pectin (0.84%), followed by TT pectin (0.67%). PL showed the least oxalic acid content (0.27%). The citric acid present in PE pectin was 0.29%. Malic acid was present in trace amounts in all the pectin samples ranging from 0.001 to 0.01%. The presence of citric acid in the pectin would be an added advantage for various food applications, as oxalic acid acts as a cheating agent [30]. The conventional method of extracted pectin showed higher amount of yield (10.36%), MeO (12.50%) and AUA (83.30%) in passion fruit peel. Even though, the highest yield of pectin was found in other extraction methods but there was an undesirable qualities of low molar mass, lower uronic acid content which influence the viscosity of pectin. Based on the results obtained, a higher amount of pectin yield, > 65% AUA, and < 2% ash were found in the PE and TT pectin by using conventional methods (PEC & TTC), which reflects the high quality of pectin and its gel strength. Therefore, the PEC and TTC pectin were analyzed for structural and functional properties.

Structural Characterization of Pectin

Surface Morphology of Peel and Pectin

Scanning electron microscopy of peel and pectin powder was studied by SEM to investigate the influence of the extraction method. The morphology is influenced by the penetration of the solvent, method, increasing temperature and internal pressure, cell wall being destroyed and ruptured [28]. The structure of passion fruit peel and tamarillo pomace powder was flakier, wrinkled, rough, and unevenly textured than the pectin samples. Pectin showed a smooth as well as flaky texture (Fig. 3b). TT pectin was smoother than PE pectin. Liew et al. [36] also reported a smooth nano texture of pectin with small mound-shaped pellets in pectin extracted from passion fruit peel.

Fourier-Transform Infrared Spectroscopy (FTIR)

FTIR spectroscopy is a powerful technique for characterizing organic molecules because it is sensitive to functional groups such as hydroxyl, carboxyl, esters, and amides found in these molecules. The pectin samples extracted from PE and TT methods were analyzed using FTIR. The extracted pectin spectra were found to have absorption patterns identical to those of commercial pectin (Fig. 3a). FTIR spectra in the wavelength range from 950-1200 cm−1 are considered fingerprint regions as carbohydrates show high absorbance in this region, allowing possible identification of major chemical groups of polysaccharides [18]. For commercial pectin, the characteristic absorption peak at 3435 cm−1, 2935 cm−1, and 1747 cm−1 corresponds to OH, O–H, and C = O esterification, respectively. The peaks at 1643 cm−1, 1444 cm−1 and 1369 cm−1 could be assigned to COO- asymmetric stretching COO- symmetric stretching, and C-H bending, respectively. The peak at 1267 cm−1, 1231 cm−1, 1150 cm−1, 1104 cm−1, 1078 cm−1, 1049 cm−1, 1017 cm−1 and 920 cm−1 indicated the presence of C-O stretching. The peak at 1231 cm−1 accounted for the presence of amide III. The peak at 890 cm−1 indicated the stretching of β-glycosidic bonds. Similar results of FTIR characterization of pectin have been reported by other authors [39, 49, 60]

Functional Characterization of Pectin

Rheological Properties of Pectin

Rheological properties of materials allow for the evaluation of how the stress or force applied to that material is related to the flow and deformation of the material, which is dependent on the interaction with the solvent and molecule size. The rheological curves of pectin from three extraction methods were fitted by using Herschel-Bulkley models, power-law equation and Ostwald –de waele models [23]. The flow behaviour of the pectin solution was compared with commercial pectin (Fig. 4a). They showed a convex curvature concerning the shear rate axis. The shear viscosity value becomes higher as the polymer concentration rises, and the viscosity decreases as the shear rate increases. When the flow behaviour index (n), n is greater than one, the fluid has shear-thickening properties; and when n = 1, the fluid has Newtonian properties. The viscoelastic behaviour of pectin solutions depends on the degree of methylation or esterification (DE) and gelling properties of pectin [17]. The flow behaviour of HM pectins extracted from the Tamarillo pulp [17] mango pulp [26] apple pomace [41] and cacao pod husks [53] showed the shear-thinning behaviour. The rheological curves for the pectin extracted from PE and TT exhibited a flow behaviour index (n) lower than one (n < 1), which indicates that the flow behaviour is pseudoplastic (Shear-thinning) due to the formation of weak pectin intermolecular forces with increasing shear rate [35]. The pectin’s extracted from Opuntia robusta exhibited shear-thinning behaviour with increasing shear rate and decreasing viscosity, using Newtonian and Ostwald-de Waele models [43]. The flow behaviour of pectin extracted from PE showed a higher flow index (0.88) than the pectin extracted from TT (0.58). Commercial pectin (HMP) showed a higher flow index (0.97) followed by PE (0.88). This might also depend on the higher equivalent weight of the pectin (1428.57). Pectin’s extracted from different methods exhibited a shear-thinning flow behaviour, as evidenced by a marked drop in viscosity with increasing temperature and confirmed by the Ostwald-de Waele model, which produced correlation coefficients of 0.998–0.999 [43]. According to Chan et al. [11], pectin solutions at 3% behave like Newtonian liquids, and subsequent increases in concentration result in shear thinning behaviour. It is also important to note that the concentration at which the pectin solutions turn from Newtonian to shear thinning depends on the molar mass of the pectin. Similar results were reported by [20] where 1% pectin solutions extracted from pomelo fruit showed shear thinning behaviour. Shear-thinning allows viscosity to decrease under shear rate, improving pourability and mouthfeel. This is desirable for developing products like fruit drinks, dressings, and sauces. [1] also reported the formation of shear-thinning gels using passion fruit pectin.

Emulsification Properties of Extracted Pectin

Pectin content and intrinsic factors like the degree of esterification may affect the emulsifying properties of pectin. The emulsifying activity (EA) of extracted pectin’s was compared with commercial pectin (CP). The prepared emulsions showed excellent emulsifying properties (Fig. 4b). After 2 h, the various degrees of phase separation and emulsification were evaluated. PE pectin showed an excellent creaming index (%) after 20 days of storage (Table 3). EA of PE and TT pectin were higher than the earlier reported values of citrus and potato pectin (44.87%—47.71%) [56]. In this study, other mechanisms like steric hindrance caused by protein content and the electrostatic contribution of charged non-esterified GalA units are also responsible for reducing the emulsion stability of PL [40]. The presence of hydrophobic methyl ester groups allows pectin to stabilize emulsions by reducing emulsion droplet size and improving long-term stability [43]. The protein content of the PE and TT (3.84 and 8.16 g/100 g) was higher than the PL (1.47 g/100 g). Pectin extracted from the fruit of the palmyra palm and watermelon rinds contained 3.9 to 8.2% protein as an effective emulsifier [44]. Therefore, the residual proteins present in the pectin enhance the emulsion stability. A high emulsion stability with DE above 50% facilitates biopolymer network formation via hydrogen bonding and hydrophobic interactions between the methyl esters, positioning the polysaccharide at the oil–water interface. This biopolymer network formation, enabled by the methyl ester groups when DE is high, is responsible for pectin's excellent emulsion stabilizing capability [43].

Food Applications

The passion and tamarillo fruits are potential sources of functional food ingredients and additives in various food applications. The by-products of fruits rich in dietary fiber (56–85%) and polyphenol content were incorporated and developed into functional food products (cookies and jam). There was a partial replacement of refined wheat flour in the preparation of cookies. The dietary fiber in the peel and pomace contains polyphenol compounds bound with polysaccharide complexes, significantly increasing the total antioxidant capacity of cookies compared with control cookies made with 100% refined wheat flour. The sensory evaluation of cookies made with peel showed highly acceptable organoleptic properties.

The extracted pectin from both fruit by-products was further purified and used for the jam preparation. The pectin showed excellent gelling and stabilizing properties as compared to commercial citrus pectin. Our findings revealed that extracted pectin contains protein, which enhances its functionality as an emulsifier and stabilizer. Jam prepared with peel showed a higher amount of total phenolics and total flavonoid content, significantly increasing the total antioxidant content. Therefore, the valorization of whole fruit into zero waste concepts aims to utilize the by-products into value-added products as multifunctional hydrocolloid ingredients like emulsifiers, thickeners, stabilizers, gelling agents, and glazing agents in the food industry.

Conclusions

This study concluded that the conventional and microwave methods showed higher yield, MeO, AUA, and DE. FTIR spectral analysis revealed that the extracted pectin from tamarillo pomace and passion fruit peel had the same pectin characteristic bands as compared to commercial pectin (HMP). The highest yield of pectin was observed with passion fruit peel and tamarillo pomace using nitric acid and tartaric acid as an extractants. Depending on its high solubility, emulsification properties, and viscosity of pectin from passion and tamarillo fruits can be used as a potential source of food additives (emulsifier, thickener, stabilizer, gelling, and glazing agents). The extracted pectin can be further purified and used as functional ingredients for various dietary food and nutritional applications.

Data Availability

The data sets generated and analysed in this study are available from the corresponding author on reasonable request.

References

Abboud, K.Y., Iacomini, M., Simas, F.F., Cordeiro, L.M.: High methoxyl pectin from the soluble dietary fiber of passion fruit peel forms weak gel without the requirement of sugar addition. Carbohydrate Polymers 246, 116616 (2020). https://doi.org/10.1016/j.carbpol.2020.116616

Acosta-Quezada, P.G., Raigón, M.D., Riofrío-Cuenca, T., García-Martínez, M.D., Plazas, M., Burneo, J.I., Prohens, J.: Diversity for chemical composition in a collection of different varietal types of tree tomato (Solanum betaceum Cav.), an Andean exotic fruit. Food Chem. 169, 327–335 (2015). https://doi.org/10.1016/j.foodchem.2014.07.152

AOAC: Official Methods of Analysis of the Association of Official Analytical Chemists(14th Eds). AOAC Washington, DC (1985)

AOAC: Official Methods of Analysis of the Association of Official Analytical Chemists (18th Eds). AOAC Gaithersburgs, MD (2006)

AOAC: Official Methods of Analysis of the Association of Official Analytical Chemists(13th Eds). AOAC Washington, DC.(1980)

Azad, A.K.M., Ali, M.A., Akter, M.S., Rahman, M.J., Ahmed, M.: Isolation and characterization of pectin extracted from lemon pomace during ripening. J. Food. Nutrition. Sci. 2(2):30–35 (2014). http://www.sciencepublishinggroup.com/j/jfns

Bagherian, H., Ashtiani, F.Z., Fouladitajar, A., Mohtashamy, M.: Comparisons between conventional, microwave-and ultrasound-assisted methods for extraction of pectin from grapefruit. Chem Eng Processing: Process Intensification. 50(11–12), 1237–1243 (2011). https://doi.org/10.1016/j.cep.2011.08.002

Bueno, A.S., Pereira, C.M., Menegassi, B., Arêas, J.A.G., Castro, I.A.: Effect of extrusion on the emulsifying properties of soybean proteins and pectin mixtures modelled by response surface methodology. J. Food Eng. 90(4), 504–510 (2009). https://doi.org/10.1016/j.jfoodeng.2008.07.028

Bystrom, L.M., Lewis, B.A., Brown, D.L., Rodriguez, E., Obendorf, R.L.: Characterisation of phenolics by LC–UV/Vis, LC–MS/MS and sugars by GC in Melicoccus bijugatus Jacq‘Montgomery’fruits. Food. Chem. 111(4), 1017–1024 (2008). https://doi.org/10.1016/j.foodchem.2008.04.058

Castillo-Israel, K.A.T., Amian, J.F.R., Garibay, Z.J.S., Leyeza, V.E.B., Sarte, A.J.T.: A comparative study on characteristics of pectins from various fruit peel wastes extracted using acid and microbial enzymes. J. Microbiol. Biotechnol. Food. Sci. 9(2), 216 (2019). https://doi.org/10.15414/jmbfs.2019.9.2.216-221

Chan, S.Y., Choo, W.S., Young, D.J., Loh, X.J.: Pectin as a rheology modifier: Origin, structure, commercial productionand rheology. Carbohydr. Polym. 161, 118–139 (2017). https://doi.org/10.1016/j.carbpol.2016.12.033

Chen, H., Liu, Y., Zhang, J., Jiang, Y., Li, D.: Pectin extracted from dragon fruit Peel: An exploration as a natural emulsifier. Int. J. Biol. Macromol. 221, 976–985 (2022). https://doi.org/10.1016/j.ijbiomac.2022.09.069

Daud, N.Z.A., Said, B.N.M., Ja’afar, F., Yasin, H.M., Kusrini, E., Usman, A.: pH - dependent yield and physicochemical properties of pectin isolated from Citrus maxima. Int. J. Technol. 10(6), 1131–1139 (2019). https://doi.org/10.14716/ijtech.v10i6.3595

de Oliveira, C.F., Giordani, D., Lutckemier, R., Gurak, P.D., Cladera-Olivera, F., Marczak, L.D.F.: Extraction of pectin from passion fruit peel assisted by ultrasound. LWT-Food Sci. Technol. 71, 110–115 (2016). https://doi.org/10.1016/j.lwt.2016.03.027

Devi, W. E., Kumar, R. S., Mishra, A. A.: Extraction of pectin from citrus fruit peel and its utilization in preparation of jelly.Int. J. Eng. Res. 3(5). 1925–1932. ISSN: 2278–0181 (2014)

Dewanto, V., Wu, X., Adom, K.K., Liu, R.H.: Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J. Agric. Food Chem. 50(10), 3010–3014 (2002). https://doi.org/10.1021/jf0115589

do Nascimento, G.E., Simas-Tosin, F.F., Iacomini, M., Gorin, P.A.J., Cordeiro, L.M.: Rheological behavior of high methoxyl pectin from the pulp of tamarillo fruit (Solanum betaceum). Carbohydrate Polymers. 139, 125–130 (2016). https://doi.org/10.1016/j.carbpol.2015.11.067

Filippov, M.P.: Practical infrared spectroscopy of pectic substances. Food Hydrocolloids 6(1), 115–142 (1992). https://doi.org/10.1016/S0268-005X(09)80060

Fishman, M.L., Chau, H.K., Hoagland, P.D., Hotchkiss, A.T.: Microwave assisted extraction of lime pectin. Food Hydrocolloids. 20(8), 1170–1177 (2006). https://doi.org/10.1016/j.foodhyd.2006.01.002

Gamonpilas, C., Buathongjan, C., Kirdsawasd, T., Rattanaprasert, M., Klomtun, M., Phonsatta, N., Methacanon, P.: Pomelo pectin and fiber: Some perspectives and applications in food industry. Food Hydrocolloids. 120:106981. (2021). https://doi.org/10.1016/j.foodhyd.2021.106981

Gannasin, S.P., Adzahan, N.M., Hamzah, M.Y., Mustafa, S., Muhammad, K.: Physicochemical properties of tamarillo (Solanum betaceum Cav.) hydrocolloid fractions. Food Chem. 182, 292–301 (2015). https://doi.org/10.1016/j.foodchem.2015.03.010

Gannasin, S.P., Ramakrishnan, Y., Adzahan, N.M., Muhammad, K.: Functional and preliminary characterisation of hydrocolloid from tamarillo (Solanum betaceum Cav) puree. Molecules. 17(6), 6869–6885 (2012). https://doi.org/10.3390/molecules17066869

Garakani, A.K., Mostoufi, N., Sadeghi, F., Fatourechi, H., Sarrafzadeh, M., Mehrnia, M.: Comparison between different models for rheological characterization of activated sludge. J. Environ. Health. Sci Eng. 8(3), 255–264 (2011). https://doi.org/10.3390/molecules17066869

Hosseini, S.S., Khodaiyan, F., Yarmand, M.S.: Aqueous extraction of pectin from sour orange peel and its preliminary physicochemical properties. Int. J. Biol. Macromol. 82, 920–926 (2016). https://doi.org/10.1016/j.ijbiomac.2015.11.007

Huyskens-keil, S.H., Prono-widayat, P., Schreiner, Ludders M.: Postharvest quality of pepino (Solanum muricatum Ait.) fruit in controlled atmosphere storage. J. Food. Eng. 77(3), 628–634 (2006). https://doi.org/10.1016/j.jfoodeng.2005.07.028

Iagher, F., Reicher, F., Ganter, J.L.M.S.: Structural and rheological properties of polysaccharides from mango (Mangifera indica L) pulp. Int. J. Biol. Macromol. 31(1–3), 9–17 (2002). https://doi.org/10.1016/S0141-8130(02)00044-2

Joint FAO/WHO Expert Committee on Food Additives. Meeting (64th: 2005: Rome, Italy), Food and Agriculture Organization of the United Nations, World Health Organization & International Programme on Chemical Safety. (2006). Safety evaluation of certain contaminants in food: prepared by the sixty-fourth meeting of the Joint FAO/WHO Expert Committee on Food Additives. World Health Organization. https://apps.who.int/iris/handle/10665/43406

Karbuz, P., Tugrul, N.: Microwave and ultrasound assisted extraction of pectin from various fruits peel. J. Food. Sci. Technol. 58(2), 641–650 (2021). https://doi.org/10.1007/s13197-020-04578-0

Kavya, P., Sujatha, M., Pandravada, S.R., Hymavathi, T.V.: Determination of Protein and Carbohydrate Content and Its Correlation with Grain Yield in Foxtail Millet Germplasm. Int. J. Curr. Microbiol. App. Sci. 7(6), 363–367 (2018). https://doi.org/10.1093/aob/mcu150

Kaya, M., Sousa, A.G., Crépeau, M.J., Sørensen, S.O., Ralet, M.C.: Characterization of citrus pectin samples extracted under different conditions: influence of acid type and pH of extraction. Ann. Bot. 114(6), 1319–1326 (2014). https://doi.org/10.1093/aob/mcu150

Kertesz, A. J.: The Pectin Substance. Inter science. New York, England. (1951). https://doi.org/10.1016/j.aaspro.2014.11.033

Khamsucharit, P., Laohaphatanalert, K., Gavinlertvatana, P., Sriroth, K., Sangseethong, K.: Characterization of pectin extracted from banana peels of different varieties. Food. Sci. Biotechnol. 27(3), 623–629 (2018). https://doi.org/10.1007/s10068-017-0302-0

Kliemann, E., De Simas, K.N., Amante, E.R., Prudêncio, E.S., Teófilo, R.F., Ferreira, M.M., Amboni, R.D.: Optimisation of pectin acid extraction from passion fruit peel (Passiflora edulis flavicarpa) using response surface methodology. Int. J. Food Sci. Technol. 44(3), 476–483 (2009). https://doi.org/10.1111/j.1365-2621.2008.01753

Lamani, S., Anu-Appaiah, K.A., Murthy, H.N., Dewir, Y.H., Rikisahedew, J.J.: Analysis of Free Sugars, Organic Acids, and Fatty Acids of Wood Apple (Limonia acidissima L) fruit Pulp. Horticulturae. 8, 67 (2022). https://doi.org/10.3390/horticulturae8010067

Lewandowska, K., Dąbrowska, A., Kaczmarek, H.: Rheological properties of pectin, poly (vinyl alcohol) and their blends in aqueous solutions. E-Polymers. 12(1) (2012). https://doi.org/10.1515/epoly.2012.12.1.160

Liew, S.Q., Chin, N.L., Yusof, Y.A.: Extraction and characterization of pectin from passion fruit peels. Agricul. Agricultural Sci. Procedia 2, 231–236 (2014). https://doi.org/10.1016/j.aaspro.2014.11.033

Lowry, O.H., Rosebrough, N.J., Farr, A.L., Randall, R.J.: Protein measurement with the folin phenol reagent. J. Biol. Chem. 193(1), 265–275 (1951). https://doi.org/10.1016/0003-2697(86)90191-0

Mandal, P., Ghosal, M.: Antioxidant activities of different parts of tree tomato fruit. Int. J. Pharm. Sci. Rev. Res, 13, 39–47. ISSN 0976 – 044X (2012).

McCann, M.C., Hammouri, M., Wilson, R., Belton, P., Roberts, K.: Fourier transform infrared microspectroscopy is a new way to look at plant cell walls. Plant Physiol. 100(4), 1940–1947 (1992). https://doi.org/10.1104/pp.100.4.1940

Mendez, D.A., Fabra, M.J., Martínez-Abad, A., Μartínez-Sanz, Μ, Gorria, M., López-Rubio, A.: Understanding the different emulsification mechanisms of pectin: Comparison between watermelon rind and two commercial pectin sources. Food Hydrocolloids 120, 106957 (2021). https://doi.org/10.1016/j.foodhyd.2021.106957

Min, B., Lim, J., Ko, S., Lee, K.G., Lee, S.H., Lee, S.: Environmentally friendly preparation of pectins from agricultural byproducts and their structural/rheological characterization. Biores. Technol. 102(4), 3855–3860 (2011). https://doi.org/10.1016/j.biortech.2010.12.019

Moorthy, I.G., Maran, J.P., Ilakya, S., Anitha, S.L., Sabarima, S.P., Priya, B.: Ultrasound assisted extraction of pectin from waste Artocarpus heterophyllus fruit peel. Ultrason. Sonochem. 34, 525–530 (2017)

Mota, J., Muro, C., Illescas, J., Hernández, O.A., Tecante, A., Rivera, E.: Extraction and Characterization of Pectin from the Fruit Peel of Opuntia robusta. Chemistry Select 5(37), 11446–11452 (2020). https://doi.org/10.1002/slct.202002181

Petkowicz, C.L.O., Vriesmann, L.C., Williams, P.A.: Pectins from food waste: Extraction, characterization and properties of watermelon rind pectin. Food Hydrocolloids 65, 57–67 (2017). https://doi.org/10.1016/j.foodhyd.2016.10.040

Ranganna, S.: Handbook of analysis and quality control for fruits and vegetable products. 7th Eds. Tata McGraw Hill Book Co., New Delhi. (2001)

Rodsamran, P., Sothornvit, R.: Microwave heating extraction of pectin from lime peel: Characterization and properties compared with the conventional heating method. Food Chem. 278, 364–372 (2019). https://doi.org/10.1016/j.foodchem.2018.11.067

Seixas, F.L., Fukuda, D.L., Turbiani, F.R., Garcia, P.S., Carmen, L.D.O., Jagadevan, S., Gimenes, M.L.: Extraction of pectin from passion fruit peel (Passiflora edulis f. flavicarpa) by microwave-induced heating. Food Hydrocolloids 38, 186–192 (2014)

Śmiechowska, M., Dmowski, P.: Crude fibre as a parameter in the quality evaluation of tea. Food Chem. 94(3), 366–368 (2006). https://doi.org/10.1016/j.foodchem.2004.11.026

Umoren, S.A., Obot, I.B., Madhankumar, A., Gasem, Z.M.: Performance evaluation of pectin as ecofriendly corrosion inhibitor for X60 pipeline steel in acid medium: Experimental and theoretical approaches. Carbohyd. Polym. 124, 280–291 (2015). https://doi.org/10.1016/j.carbpol.2015.02.036

Vanhanen, L., Savage, G.: Effect of simple processing methods on oxalate content of taro petioles and leaves grown in central Viet Nam. LWT-Food Sci. Technol. 50(1), 259–263 (2013). https://doi.org/10.1016/j.lwt.2012.05.015

Vanitha, T., Khan, M.: Role of Pectin in Food Processing and Food Packaging. Pectins - Extraction, Purification, Characterization and App. (2019). https://doi.org/10.5772/intechopen.83677

Vasco, C., Ruales, J., Kamal-Eldin, A.: Total phenolic compounds and antioxidant capacities of major fruits from Ecuador. Food Chem. 111, 816–823 (2008). https://doi.org/10.1016/j.foodchem.2008.04.054

Vriesmann, L.C., Petkowicz, C.L.: Highly acetylated pectin from cacao pod husks (Theobroma cacao L.) forms gel. Food Hydrocolloids. 33(1), 58–65 (2013). https://doi.org/10.1016/j.foodhyd.2013.02.010

Wongkaew, M., Sommano, S.R., Tangpao, T., Rachtanapun, P., Jantanasakulwong, K.: Mango peel pectin by microwave-assisted extraction and its use as fat replacement in dried Chinese sausage. Foods 9(4), 450 (2020). https://doi.org/10.3390/foods9040450

Xu, S.Y., Liu, J.P., Huang, X., Du, L.P., Shi, F.L., Dong, R., Cheong, K.L.: Ultrasonic-microwave assisted extraction, characterization and biological activity of pectin from jackfruit peel. LWT- Food Sci. Technol. 90, 577–582 (2018). https://doi.org/10.1016/j.lwt.2018.01.007

Yang, J.S., Mu, T.H., Ma, M.M.: Extraction, structure, and emulsifying properties of pectin from potato pulp. Food Chem. 244, 197–205 (2018). https://doi.org/10.1016/j.foodchem.2017.10.059

Yapo, B.M.: Biochemical characteristics and gelling capacity of pectin from yellow passion fruit rind as affected by acid extractant nature. J. Agric. Food Chem. 57(4), 1572–1578 (2009). https://doi.org/10.1021/jf802969m

Yapo, B.M.: Pectin quantity, composition and physicochemical behaviour as influenced by the purification process. Food Res. Int. 42(8), 1197–1202 (2009)

Yapo, B.M., Koffi, K.L.: The polysaccharide composition of yellow passion fruit rind cell wall: chemical and macromolecular features of extracted pectins and hemicellulosic polysaccharides. J. Sci. Food Agric. 88(12), 2125–2133 (2008). https://doi.org/10.1002/jsfa.3323

Zimniewska, M., Rozańska, W., Gryszczynska, A., Romanowska, B., Kicinska-Jakubowska, A.: Antioxidant potential of hemp and flax fibers depending on their chemical composition. Molecules. 23(8), 1993 (2018). https://doi.org/10.3390/molecules23081993

Acknowledgements

The authors wish to thank the Director, CSIR-CFTRI, Mysore for encouraging and providing research facilities.

Funding

This research work was funded by the Indian Council of Medical Research (ICMR Project No.3/1/2/108/2019-Nut), New Delhi.

Author A—Manjula N received the financial grant for fellowship, to carry out the research work.

Author B and (Author C, as research advisor for funding acquisition) declares they have no financial interest.

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Manjula N: Conceptualization, validation, investigation, formal analysis, writing. Kotha Hridhay Keerthana: Formal analysis, writing. Thiraviam Vanitha: Conceptualization, supervision, validation, funding acquisition.

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of Novelty

Fruit wastes (pomace, peel, rind, and seed) are rich in polyphenols, pigments, oils, enzymes, fibers, vitamins, and other bioactive compounds. The processing of fruits generates 25% waste and produces up to 8–10% of the world’s greenhouse gas emissions. In this study, we have discussed the novel use of peel and pomace waste from passion (PE) and tamarillo (TT) fruit into the soluble dietary fiber, pectin (3–10%). Our findings revealed that extracted pectin contains protein (3–8%) that acts as a surfactant and enhances its functionality as an emulsifier and stabilizer. Further, the purified pectin can be used as functional ingredients for various dietary food and nutritional applications.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manjula, N., Kotha, H.K. & Vanitha, T. Valorization of Passion and Tamarillo Fruit Waste for Extraction and Characterization of Pectin. Waste Biomass Valor 15, 5263–5274 (2024). https://doi.org/10.1007/s12649-024-02529-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-024-02529-w